Attached files

| file | filename |

|---|---|

| 8-K - MIDWAY GOLD CORP. - 8-K - Midway Gold Corp | midway8k09092014.htm |

NI 43-101 TECHNICAL REPORT ON RESOURCES

sPRING VALLEY Project

Pershing County, Nevada

PREPARED FOR

Report Date: September 9, 2014

Effective Date: August 1, 2014

Prepared by

William J. Crowl, R.G., MMSA QP

Zachary J. Black, SME-RM

Deepak Malhotra, PhD, SME-RM

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

William J. Crowl

Vice President, Mining

Gustavson Associates, LLC

274 Union Boulevard, Suite 450

Lakewood, Colorado 80228

Telephone: 720-407-4062 Facsimile: 720-407-4067

Email: wcrowl@gustavson.com

CERTIFICATE of AUTHOR

I, William J. Crowl do hereby certify that:

| 1. | I am currently employed as Vice President, Mining by Gustavson Associates, LLC at: |

274 Union Boulevard

Suite 450

Lakewood, Colorado 80228

- I am a graduate of the University of Southern California with a Bachelor of Arts in Earth Science (1968), and an MSc in Economic Geology from the University of Arizona in 1979, and have practiced my profession continuously since 1973.

- I am a registered Professional Geologist in the State of Oregon (G573) and am a registered member of the Mining and Metallurgical Society of America (01412QP)..

- I have worked as a geologist for a total of 40 years since my graduation from university; as a graduate student, as an employee of a major mining company, a major engineering company, and as a consulting geologist.

- I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101.

- I am responsible for the preparation of the technical report titled “NI 43-101 Technical Report on Resources, Spring Valley Project” dated September 9, 2014 with an effective date of August 1, 2014 (the “Technical Report”), with specific responsibility for Sections 1-8, and 15-19 and overall corporate responsibility for the general content and organization of the report. Mr. Crowl visited the site on October 24, 2013 for one day

- I have had prior involvement with the property that is the subject of this Technical Report. I was responsible for the preparation of the report titled “NI 43-101 Technical Report on the Spring Valley Project, Pershing County, Nevada,” dated May 24, 2011, with specific responsibility for Sections 9, 10 and 11 and overall corporate responsibility for the general content and organization of the report.

September 9, 2014 | i |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

In addition, I was responsible for the preparation of the technical report titled “Updated NI 43-101 Technical Report on the Spring Valley Project” dated November 29, 2012, with specific responsibility for Sections 9, 10 and 11 and overall corporate responsibility for the general content and organization of the report.

- I am independent of the issuer applying all of the tests in Section 1.5 of National Instrument 43-101.

- I have read National Instrument 43-101 and Form 43-101, and the Technical Report has been prepared in compliance with that instrument and form.

| 10. | I consent to the filing of the Technical Report with any stock exchange and other regulatory authority and any publication by them for regulatory purposes, including electronic publication in the public company files on their websites accessible by the public, of the Technical Report. |

| 11. | As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated this 9th day of September, 2014.

| /s/ William J. Crowl | ||

| Signature of Qualified Person | ||

William J. Crowl |

||

| Signature of Qualified Person | ||

September 9, 2014 | ii |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Zachary J. Black

Associate Resource Geologist

Gustavson Associates, LLC

274 Union Boulevard, Suite 450

Lakewood, Colorado 80228

Telephone: 720-407-4062 Facsimile: 720-407-4067

Email: zblack@gustavson.com

CERTIFICATE of AUTHOR

I, Zachary J. Black do hereby certify that:

- I am currently employed as Associate Resource Geologist with Gustavson Associates, LLC at:

274 Union Boulevard

Suite 450

Lakewood, Colorado 80228

- I am a graduate of the University of Nevada Reno with a Bachelor of Science in Geological Engineering, and have practiced my profession continuously since 2005.

- I am a registered member of the Society of Mining Metallurgy and Exploration (No. 4156858RM).

| 4. | I have worked as a Geological Engineer/Resource Estimation Geologist for a total of seven years since my graduation from university; as an employee of a major mining company, a major engineering company, and as a consulting engineer. I have estimated numerous mineral resources containing gold and have seven years of precious and base metals experience. |

- I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101.

- I am responsible for the preparation of the technical report titled “NI 43-101 Technical Report on Resources, Spring Valley Project” dated September 9, 2014 with an effective date of August 1, 2014 (the “Technical Report”), with specific responsibility for Sections 9-12 and 14. Mr. Black visited the site on October 21 and 22, 2010 and October 24, 2013 for one day.

- I have had prior involvement with the property that is the subject of this Technical Report. I prepared the resource estimate in the report titled “NI 43-101 Technical Report on the Spring Valley Project, Pershing County, Nevada,” dated May 24, 2011. In addition, I prepared the resource estimate in the report titled “Updated NI 43-101 Technical Report on the Spring Valley Project” dated November 29, 2012.

- I am independent of the issuer applying all of the tests in Section 1.5 of National Instrument 43-101.

September 9, 2014 | iii |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 9. | I have read National Instrument 43-101 and Form 43-101, and the Technical Report has been prepared in compliance with that instrument and form. |

| 10. | I consent to the filing of the Technical Report with any stock exchange and other regulatory authority and any publication by them for regulatory purposes, including electronic publication in the public company files on their websites accessible by the public, of the Technical Report. |

| 11. | As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated this 9th day of September, 2014.

/s/ Zachary J. Black |

||

| Signature of Qualified Person | ||

Zachary J. Black |

||

| Signature of Qualified Person | ||

September 9, 2014 | iv |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Deepak Malhotra, PhD,

Member SME-RM, CIMM

Resource Development, Inc.

11475 West I-70 Frontage Road North

Wheat Ridge, Colorado 80033

Telephone: (303) 422-1176 Facsimile: (303) 424-8580

Email: dmalhotra@aol.com

CERTIFICATE of AUTHOR

I, Deepak Malhotra do hereby certify that:

- I am currently employed as President by Resource Development, Inc. at:

11475 West I-70 Frontage Road North

Wheat Ridge, Colorado 80033

| 2. | I am a graduate of Colorado School of Mines with a M.Sc. degree in Metallurgical Engineering (1974), and PhD in Mineral Economics (1978). |

| 3. | I am a registered member of the Society of Mining, Metallurgy and Exploration, Inc. (SME), member No. 2006420RM. |

| 4. | I have worked as a Metallurgist/Mineral Economist for a total of 40 years since my graduation from university; as an employee of several mining companies, an engineering company, a mine development and mine construction company, an exploration company, and as a consulting engineer.. |

| 5. | I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101. |

| 6. | I am responsible for the preparation of the technical report titled “NI 43-101 Technical Report on Resources, Spring Valley Project” dated September 9, 2014 with an effective date of August 1, 2014 (the “Technical Report”), with specific responsibility for Section 13. I have not visited the Spring Valley Mine Site. |

| 7. | I have had prior involvement with the property that is the subject of this Technical Report. I was responsible for the preparation of the report titled “NI 43-101 Technical |

September 9, 2014 | v |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Report on the Spring Valley Project, Pershing County, Nevada,” dated May 24, 2011, with specific responsibility for Section 18.

| 8. | In addition, I was responsible for the preparation of the technical report titled “Updated NI 43-101 Technical Report on the Spring Valley Project” dated November 29, 2012, with specific responsibility for Section 18. |

| 9. | I am independent of the issuer applying all of the tests in Section 1.5 of National Instrument 43-101. |

| 10. | I have read National Instrument 43-101 and Form 43-101, and the Technical Report has been prepared in compliance with that instrument and form. |

| 11. | I consent to the filing of the Technical Report with any stock exchange and other regulatory authority and any publication by them for regulatory purposes, including electronic publication in the public company files on their websites accessible by the public, of the Technical Report. |

| 12. | As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading. |

Dated this 9th day of September, 2014.

/s/ Deepak Malhotra |

||

| Signature of Qualified Person | ||

Deepak Malhotra

Signature

of Qualified Person

September 9, 2014 | vi |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

TABLE OF CONTENTS

Section Title Page No.

| 1. SUMMARY | 1 |

| 1.1 Introduction | 1 |

| 1.2 Geology and Mineralization | 1 |

| 1.3 Drilling and Exploration Status | 2 |

| 1.4 Environmental and Permitting | 2 |

| 1.4.1 Environmental Liabilities | 2 |

| 1.4.2 Permits | 3 |

| 1.5 Operational Permits and Jurisdictions | 3 |

| 1.6 Infrastructure | 3 |

| 1.7 Mineral Processing and Metallurgical Testing | 4 |

| 1.8 Mineral Resources | 4 |

| 1.9 Interpretations and Conclusions | 6 |

| 1.9.1 Environmental | 6 |

| 1.9.2 Geology and Deposit Type | 6 |

| 1.9.3 Exploration, Drilling, and Analytical | 6 |

| 1.9.4 Quality Assurance/Quality Control | 6 |

| 1.9.5 Mineral Processing and Metallurgical Testing | 6 |

| 1.9.6 Data Verification | 7 |

| 1.9.7 Resource | 7 |

| 1.10 Recommendations | 7 |

| 1.10.1 Scoping Study | 7 |

| 1.10.2 Geologic Model | 7 |

| 1.10.3 Metallurgical Study | 8 |

| 1.10.4 Geotechnical and Hydrogeological Study | 8 |

| 1.10.5 Environmental Permitting | 8 |

| 1.10.6 Exploration Program | 8 |

| 1.10.7 Budget | 9 |

| 2. INTRODUCTION AND TERMS OF REFERENCE | 10 |

| 2.1.1 Details of Inspection | 10 |

| 2.1.2 Sources of Information | 11 |

| 2.2 Effective Date | 11 |

| 2.3 Units of Measure | 11 |

| 3. RELIANCE ON OTHER EXPERTS | 14 |

| 4. PROPERTY DESCRIPTION AND LOCATION | 14 |

| 4.1 Property Location | 14 |

| 4.2 Agreements and Royalties | 15 |

| 4.2.1 Barrick Agreement | 15 |

| 4.2.2 Agreements | 15 |

| 4.3 Environmental Liabilities | 16 |

September 9, 2014 | i |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 4.4 Permits | 17 |

| 5. ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 19 |

| 5.1 Accessibility | 19 |

| 5.2 Climate | 20 |

| 5.3 Local Resources and Infrastructure | 20 |

| 5.4 Physiography | 20 |

| 5.5 Water Rights | 21 |

| 6. HISTORY | 21 |

| 7. GEOLOGICAL SETTING AND MINERALIZATION | 22 |

| 7.1 Regional Geologic Setting | 22 |

| 7.2 Local Geologic Setting | 24 |

| 7.3 Lithologic Units | 26 |

| 7.3.1 Quaternary Alluvium (Qal) | 26 |

| 7.3.2 Limerick Greenstone: | 26 |

| 7.3.3 Rochester Rhyolite | 26 |

| 7.3.4 Upper Rhyolite | 27 |

| 7.3.5 Siltstone | 27 |

| 7.3.6 WT Rhyolite | 27 |

| 7.3.7 Breccia/Conglomerate | 28 |

| 7.3.8 Intrusive rocks | 28 |

| 7.4 Mineralization Style | 32 |

| 7.5 Alteration | 32 |

| 7.6 Geometry of Mineralization | 34 |

| 8. DEPOSIT TYPES | 35 |

| 9. EXPLORATION | 35 |

| 9.1 Pre-MGC Exploration | 36 |

| 9.2 MGC Exploration | 36 |

| 9.2.1 Surface Geochemistry | 36 |

| 9.2.2 Rock Samples | 36 |

| 9.2.3 Geological Mapping | 36 |

| 9.2.4 Geophysical Surveys | 36 |

| 9.3 Barrick Exploration | 37 |

| 9.4 Exploration Targets | 37 |

| 10. DRILLING | 37 |

| 10.1 Type and Extent | 37 |

| 10.2 Drilling Procedures and Conditions | 40 |

| 10.2.1 Reverse Circulation Drilling | 40 |

| 10.2.1 Diamond Core Drilling | 40 |

| 10.2.2 Drill Collar and Downhole Surveys | 41 |

| 10.3 Drilling Interpretations and Results | 41 |

September 9, 2014 | ii |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 11. SAMPLE PREPARATION, ANALYSES, AND SECURITY | 42 |

| 11.1 Sampling Method and Approach | 42 |

| 11.2 Midway Sampling Preparation, Analyses, and Security | 42 |

| 11.2.1 Sample Chain of Custody | 42 |

| 11.2.2 Diamond Drilling Core Sampling | 43 |

| 11.2.3 Sampling of Reverse Circulation Cuttings | 43 |

| 11.2.4 Sample Preparation and Assay Procedures | 44 |

| 11.2.5 Standards, Duplicates, and Blanks | 46 |

| 11.3 Barrick Sampling Preparation, Analyses, and Security | 52 |

| 11.3.1 Sample Chain of Custody | 52 |

| 11.3.2 Diamond Drilling Core Sampling | 52 |

| 11.3.3 Sampling of Reverse Circulation Cuttings | 53 |

| 11.3.4 Sample Preparation and Assay Procedures | 53 |

| 11.3.5 Standards, Duplicates and Blanks | 54 |

| 11.3.6 Check Assay Programs | 59 |

| 11.3.7 Twin Hole Comparisons | 59 |

| 11.3.8 Exploration drilling 2014 | 60 |

| 11.4 Data Entry Validation Controls | 60 |

| 11.5 Opinion on Adequacy | 61 |

| 12. DATA VERIFICATION | 61 |

| 12.1 Validation of Database | 63 |

| 12.1.1 Received Data | 63 |

| 12.1.2 Mechanical Audit | 63 |

| 12.1.3 Overlaps | 64 |

| 12.1.4 Gaps, Non-numeric Assay Values, and Negative numbers | 65 |

| 12.1.5 Survey Data | 66 |

| 12.1.6 Table Depth Consistency | 66 |

| 12.1.7 Assay Certificates | 66 |

| 13. MINERAL PROCESSING AND METALLURGICAL TESTING | 66 |

| 13.1 Mineral Processing and Metallurgical Testing | 66 |

| 13.2 Column Leach Tests | 67 |

| 13.3 Bottle Roll Tests | 67 |

| 13.4 Gravity Tests | 67 |

| 13.5 Bond Mill Work Index | 68 |

| 13.6 Historical Test Work | 68 |

| 13.7 Summary & Recommendations | 69 |

| 14. MINERAL RESOURCE ESTIMATE | 69 |

| 14.1 Block Model Physical Limits | 69 |

| 14.2 Data Used for the Grade Estimation | 70 |

| 14.3 Data | 70 |

| 14.4 Geologic Model | 70 |

| 14.5 Exploratory Data Analysis | 73 |

September 9, 2014 | iii |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 14.6 Compositing | 80 |

| 14.7 Capping | 81 |

| 14.8 Grade Shell Generation | 83 |

| 14.9 Variography | 84 |

| 14.10 Estimation Methodology | 90 |

| 14.11 Mineral Resource Classification | 90 |

| 14.12 Density | 91 |

| 14.13 Model Validation | 91 |

| 14.13.1 Statistical Model Comparison | 91 |

| 14.14 Swath Plots | 94 |

| 14.15 Mineral Resources | 96 |

| 14.16 Pit-constrained Mineral Resource | 97 |

| 15. ADJACENT PROPERTIES | 98 |

| 15.1 Coeur Rochester | 98 |

| 15.2 Lincoln Hill Property | 98 |

| 15.3 Moonlight Project | 98 |

| 16. OTHER RELEVANT DATA AND INFORMATION | 99 |

| 17. INTERPRETATION AND CONCLUSIONS | 99 |

| 17.1 Environmental | 99 |

| 17.2 Geology and Deposit Type | 99 |

| 17.3 Exploration, Drilling, and Analytical | 99 |

| 17.4 Quality Assurance/Quality Control | 99 |

| 17.5 Mineral Processing and Metallurgical Testing | 100 |

| 17.6 Data Verification | 100 |

| 17.7 Resource | 100 |

| 18. RECOMMENDATIONS | 100 |

| 18.1 Geologic Model | 101 |

| 18.2 Metallurgical Study | 101 |

| 18.3 Geotechnical and Hydrogeological Study | 101 |

| 18.4 Exploration Program | 101 |

| 18.5 Budget | 102 |

| 19. REFERENCES | 104 |

September 9, 2014 | iv |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

LIST OF FIGURES

Figure Page

| Figure 7-1 Geology of the Humboldt Range | 23 |

| Figure 7-2 Bedrock Geology Map of the Spring Valley Project | 25 |

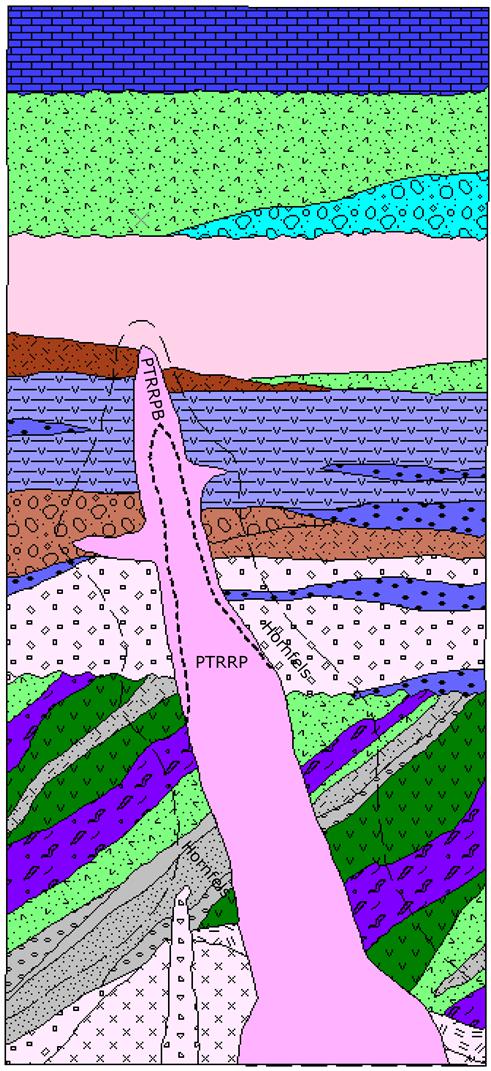

| Figure 7-3 Conceptual Cross Section of Lithologies (Modified from Chadwick, 2012) | 30 |

| Figure 7-4 Coarse Gold from SV08-435 Drilled in the Big Leap Zone | 33 |

| Figure 7-5 Coarse Gold from SV08-410 at 310’ | 34 |

| Figure 7-6 Coarse Gold from SV08-436 Drilled at the South End of the Big Leap | 34 |

| Figure 10-1 Spring Valley Project Area Drill Hole Location Map | 39 |

| Figure 11-1 2006 – 2007 Blank Results | 47 |

| Figure 11-2 2006 – 2007 Standard MEG055 Results | 48 |

| Figure 11-3 2006 – 2007 Standard MEG160 Results | 48 |

| Figure 11-4 2006 – 2007 Standard MEG200 Results | 49 |

| Figure 11-5 2007 Standard MEG067 Results | 49 |

| Figure 11-6 2007 Standard MEG045 Results | 50 |

| Figure 11-7 2007 – 2008 Standard OREAS102 Results | 51 |

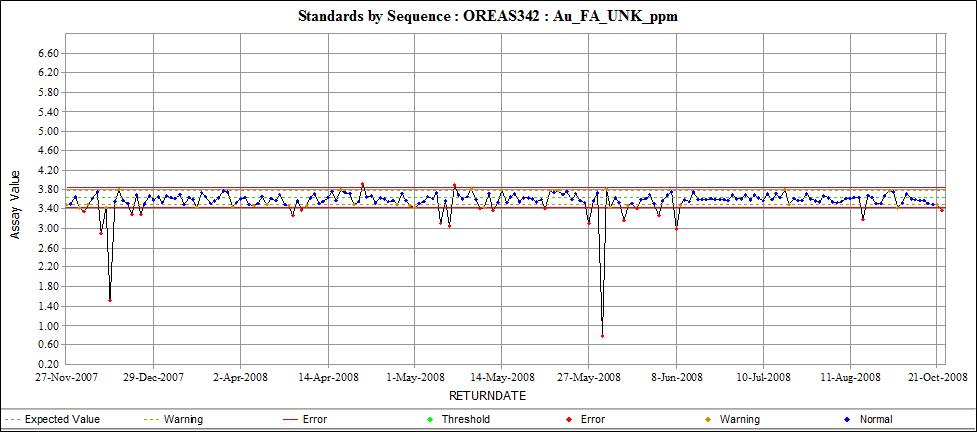

| Figure 11-8 2007 – 2008 Standard OREAS342 Results | 51 |

| Figure 11-9 Barrick 2011 Blank Results | 55 |

| Figure 11-10 Barrick 2011 Standard OxC72 Results | 56 |

| Figure 11-11 Barrick 2011 Standard OxG83 Results | 56 |

| Figure 11-12 Barrick 2011 Standard OxJ68 Results | 57 |

| Figure 11-13 Barrick 2011 Standard SE29 Results | 57 |

| Figure 11-14 Barrick 2011 Standard SE44 Results | 58 |

| Figure 11-15 Barrick 2011 Standard SG40 Results | 58 |

| Figure 11-16 Barrick 2011 Standard Si42 Results | 59 |

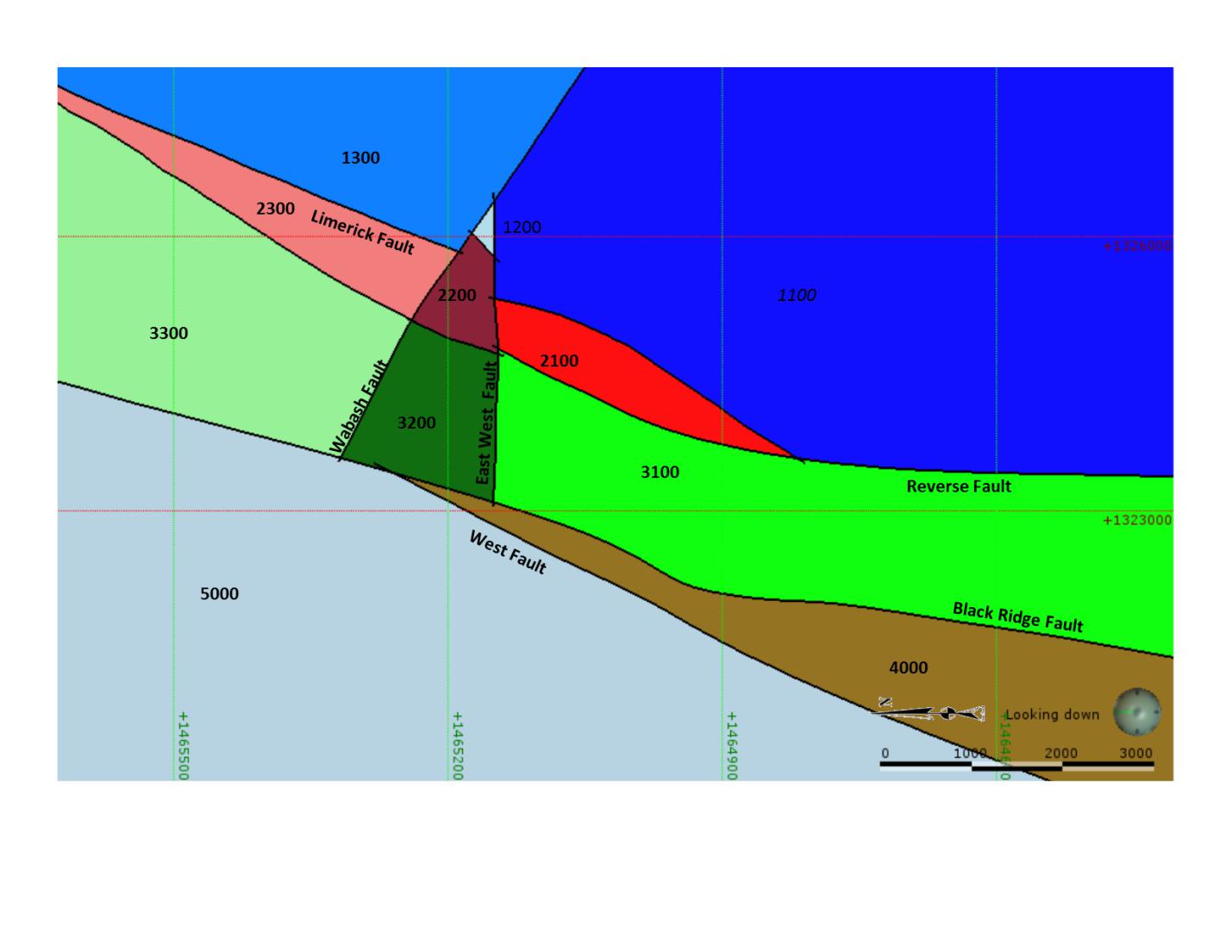

| Figure 14-1 Fault and Estimation Domain Plan View | 72 |

| Figure 14-2 Oblique View of Filtered Gold Values (Au≥0.002 oz/t) Limerick Trend Encircled | 74 |

| Figure 14-3 Gold (oz/t) Cumulative Frequency Plots by Lithology | 76 |

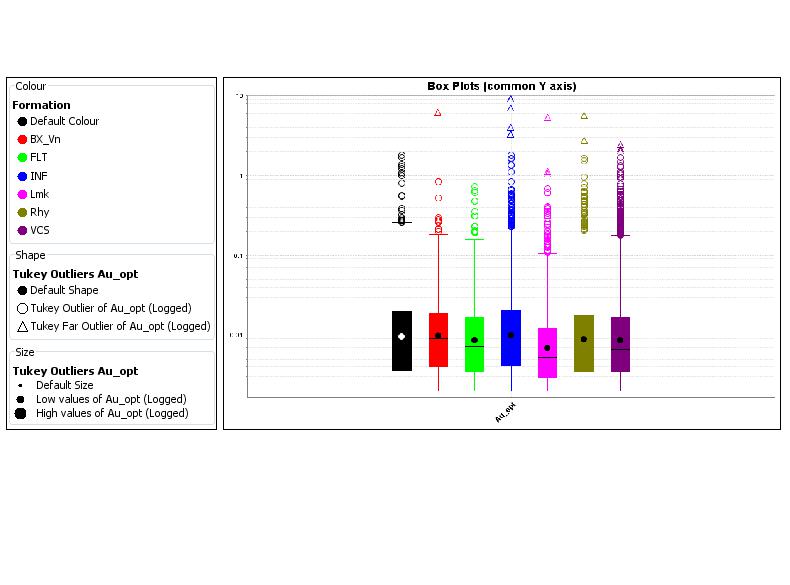

| Figure 14-4 Gold (oz/t) Box Plots by Lithology | 77 |

| Figure 14-5 Histogram of Samples within 5 Intervals (~25 ft) of a ≥ 0.022 oz/t Assay Interval | 79 |

| Figure 14-6 Samples above Cutoff within Range of Vein (>0.022 oz/t) Assay Interval | 80 |

| Figure 14-7 Composite Study | 81 |

| Figure 14-8 CFP Analysis by Domain | 82 |

| Figure 14-9 Grade Boundary | 83 |

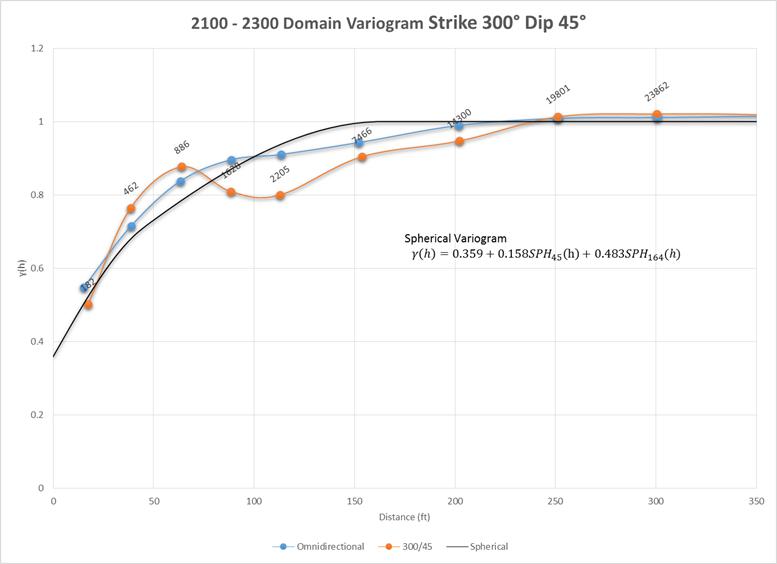

| Figure 14-10 Example Variograms, 2100-2300 domain | 85 |

| Figure 14-11 Example Variograms, 3100-3300 domain | 86 |

| Figure 14-12 Example Variograms, 3100-3300 domains | 87 |

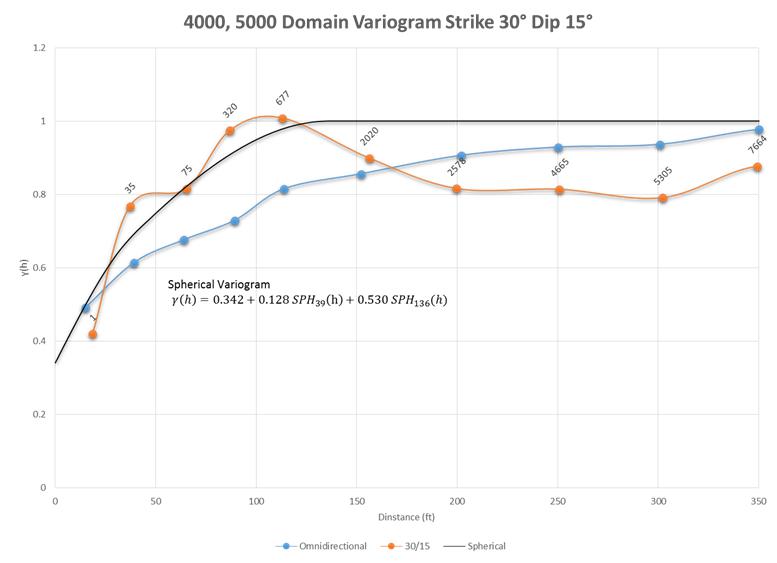

| Figure 14-13 Example Variograms, 4000-5000 domains | 88 |

| Figure 14-14 Example Variograms, 4000-5000 domains | 89 |

| Figure 14-15 Model Comparison Cumulative Frequency Plot (OK red, ID blue, NN Black) | 94 |

| Figure 14-16 Elevation Swath Model | 95 |

September 9, 2014 | v |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

LIST OF TABLES

Table Page

| Table 1-1 Mineral Resource Statement for the Spring Valley Project | 5 |

| Table 1-2 Proposed Budget | 9 |

| Table 4-1 Summary of Spring Valley Property Agreements | 16 |

| Table 4-2 Agency Permits and Authorizations* | 18 |

| Table 10-1 Summary of Drilling Campaigns in the Spring Valley Resource Area | 38 |

| Table 12-1 Mechanical Audit Errors | 64 |

| Table 12-2 Database Overlap Summary | 65 |

| Table 12-3 Interval Import Summary | 65 |

| Table 12-4 Certificate Validation Errors | 66 |

| Table 13-1 Composites | 67 |

| Table 14-1 Lithologic Groups | 75 |

| Table 14-2 Spring Valley Project Sample Assay Gold Descriptive Statistics (oz/t) | 75 |

| Table 14-3 Descriptive Statistics ≥0.002 oz/t Au by Lithology | 76 |

| Table 14-4 Capped Value by Domain | 81 |

| Table 14-5 Capped 10-foot Composite Statistics ≥0.001 oz/t | 83 |

| Table 14-6 Domain Variogram Parameters | 89 |

| Table 14-7 Estimation Parameters | 90 |

| Table 14-8 Rock Type Density Summary | 91 |

| Table 14-9 Descriptive Statistics for Domains 2100-2300 (Limb) | 91 |

| Table 14-10 Descriptive Statistics for Domains 3100-3300 (Main) | 93 |

| Table 14-11 Descriptive Statistics for Domains 4000 and 5000 (West 1 and West 2) | 93 |

| Table 14-12 Mineral Resource Statement for the Spring Valley Project, | 97 |

| Table 14-13 Pit-Constrained Resource for selected Whittle Shells. | 97 |

| Table 18-1 Proposed Budget | 103 |

LIST OF Appendices

| Claims List Exhibit | 106 |

September 9, 2014 | vi |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1. | SUMMARY |

| 1.1 | Introduction |

Gustavson Associates, LLC (“Gustavson”) was retained by Midway Gold Corp. (“Midway”) to update the National Instrument 43-101 (“NI 43-101”) Technical Report on Resources, Spring Valley Project (the “Project” or the “Spring Valley Project”) in Pershing County, Nevada, dated May 24, 2011 prepared by Gustavson. This report presents the results of the mineral resource estimate based on all available technical data and information as of August 1, 2014.

This report is prepared to fulfill Midway’s disclosure requirements to the Toronto Stock Exchange. It should be noted that this report is independent of and distict from any parallel resource estimates or scoping studies being carried out by the Spring Valley Venture, or by Barrick as operator.

This report has been prepared in accordance with the Canadian Securities Administrators (“CSA”) NI 43-101 and in compliance with the disclosure and reporting requirements set forth in Companion Policy 43-101CP and Form 43-101F1 (June 2011). Resources have been classified in accordance with standards as defined by the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) “CIM Definition Standards - For Mineral Resources and Mineral Reserves”, prepared by the CIM Standing Committee on Reserve Definitions and adopted by CIM Council on December 17, 2010.

| 1.2 | Geology and Mineralization |

The Spring Valley property is located in the Humboldt Range, a north-south oriented, up-thrown fault block (horst) bounded on the west by the Humboldt River valley and on the east by Buena Vista Valley. Quaternary alluvial deposits fill the intermontane basins and alluvial valleys.

The bedrock geology of the Humboldt range within 20 miles of the Spring Valley property consists of Triassic shales and carbonate rocks, a thick sequence of Permo-Triassic intermediate to felsic volcanic rocks, and a north-south trending belt of Tertiary volcanic rocks. Triassic leucogranite and Cretaceous granodiorite locally intrude the Permo-Triassic volcanic package.

The known Spring Valley mineral system is beneath an intermontane basin filled with post-mineral Quaternary alluvial deposits, thereby masking the bedrock geology immediately overlying or containing the mineralization. At the scale of the Spring Valley property position, the bedrock units are distributed in blocks aligned approximately north-south. The bedrock geology is dominated by the Limerick Formation in the western one-third of the property, the Rochester Formation in the central and eastern half of the property, and the Natchez Pass Limestone in the extreme northeast corner of the property. At this scale, the geology is segmented by a number of faults: a relatively older north to northeast trending set including the West Spring Valley, Limerick and Black Ridge Faults; and, northwest trending, steeply dipping cross faults with oblique or lateral offsets that displace the older north to northeast trending faults. The West Spring Valley fault is interpreted as a steeply east dipping normal fault, whereas the Black Ridge and Limerick faults are interpreted as moderate to high angle normal faults with westerly dips. The Limerick fault may be listric in character, with flattening dip at depth. East-west and northeasterly faults are also mapped, but are not part of the predominant fabric on the property.

September 9, 2014 | 1 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.3 | Drilling and Exploration Status |

Exploration work carried out by Midway and Barrick Gold Exploration Inc., a wholly owned subsidiary of Barrick Gold Corporation (“Barrick”) on the Spring Valley property has been and continues to be dominated by drilling. Midway and Barrick have also conducted extensive geological mapping and surface geochemical sampling campaigns in the surrounding hills and have conducted limited geophysical surveys in the basin to guide drilling. Early exploration work by previous operators included small-scale surface geochemical and geophysical surveys and drilling.

The Spring Valley resource area has been drilled with a total of 672 holes totaling 603,731 feet, including 531 Reverse Circulation (RC) drill holes totaling 428,500 feet and 141 diamond core holes totaling 173,011 feet.

| 1.4 | Environmental and Permitting |

| 1.4.1 | Environmental Liabilities |

Environmental liabilities at the property are limited to the construction of drill pads and roads, drilling, closure and reclamation of the currently permitted drilling program. This program is bonded with NDEP and the BLM. As work plans detailing the work, and reclamation cost estimates utilizing the states Standardized Reclamation Cost Estimator (SRCE), or equivalent, are required, the bond is considered adequate for the liability. Other potential environmental liabilities include the inadvertent impact of an unidentified cultural site or the allowance of invasion by a weedy species. The potential for impacting a cultural site or allowing the invasion of weedy species is considered low given the requirements for cultural surveys and the BLM’s Standard Operating Procedures (SOPs), which include general protection procedures to preclude weedy invasion. The potential for impacts to rangeland, impacts due to a hazardous or solid waste release, impact to water resources or impacts to a wetland is considered extremely low given the permitting requirements, SOPs, and Barrick’s operating practices.

September 9, 2014 | 2 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.4.2 | Permits |

According to the NDOM, all mining operations in Nevada are required to have:

| · | Legitimate mining claims registered with the BLM, or ownership or control of mineral rights on private land; |

| · | An approved Plan of Operation from the BLM, the U.S. Forest Service or the Nevada Division of Environmental Protection, (NDEP); and |

| · | Necessary state permits. |

| 1.5 | Operational Permits and Jurisdictions |

Midway and Barrick exploration activities are permitted under a Plan of Operations (PoO) approved by the BLM in July 2007, and Reclamation Permit No. 0258 approved by the NDEP in December 2006. All of the permits and approvals, and the bonds, were transferred to Barrick in 2009. A new or amended PoO will be required if disturbances beyond the currently approved 75 acres are necessary.

| 1.6 | Infrastructure |

The Spring Valley property is accessed by Nevada State Route (SR) 50 (also known as Lovelock-Unionville Road), which extends eastward from US Interstate 80 at exit 119. SR 50 also serves as the main access to the Rochester Mine until a turnoff at Spring Valley Pass. Once in Spring Valley, access to the various parts of the Property is by dirt road. Alternatively, access is possible from the Buena Vista Valley to the east through Spring Valley Canyon on SR 50.

The nearest town to the Property is Lovelock, Nevada, which is situated along US Interstate 80 and hosts a population of 1,895 (Census 2012 data). The nearest city is Reno, Nevada, approximately 120 miles to the southwest, which hosts a population of 231,027 (Census 2012 data).

Power lines cross the property and ground water is abundant as evidenced by artesian wells in the main area of drilling. There is an adequate workforce in the surrounding region and the town of Lovelock. Northern Nevada is home to many gold mining operations with all associated support and supplies.

September 9, 2014 | 3 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.7 | Mineral Processing and Metallurgical Testing |

Barrick contracted with McClelland labs in Sparks, Nevada to complete a detailed metallurgical testing program on thirteen drill core composites from Spring Valley. The composite samples representing four rock types and three oxidation states were tested by column leaching, bottle roll and gravity methods. The composites were from a total of 355 split diamond drill core intervals, each interval representing approximately five feet. Grades of the composite samples ranged from 0.21 grams per tonne (gpt) to 5.07 gpt (0.006 oz/t to 0.148 oz/t); nine of the samples had grades less than 1.03 gpt (0.030 oz/t). The reported gold grades were determined by metallic screen fire assays. Column leach tests simulating heap leach conditions were conducted over 260 days, and yielded gold recoveries from 46% to 98% for all materials tested.

In December 2005, samples from eight drill holes were submitted for metallurgical testing at McClelland Laboratories Inc. in Sparks, Nevada by Midway. Select samples were combined to produce 19 composites for Gravity Recoverable Gold (GRG) testing. The composite samples were sequentially milled to progressively finer sizes, the resulting material (or gravity tailings after the first grind size) was processed using a laboratory Nelson Concentrator. The resulting concentrate and tailings were then assayed to determine gravity recovery of gold versus grind size. Testing in this way provides an estimate of the maximum recoverable gold values by gravity concentration. Recoveries for nine composites with head grades greater than 0.030 oz/st gold were between 67.5% and 96.5%.

The test samples described above are considered representative of the mineralization of the deposit as a whole. As of the date of this report, there are no processing factors that could have a significant effect on potential extraction.

| 1.8 | Mineral Resources |

Zachary J. Black, SME-RM, an associate Resource Geologist with Gustavson is responsible for the estimation of the mineral resource herein. Mr. Black is a qualified person as defined by NI 43-101 and is independent of Midway and of Barrick. Gustavson estimated the mineral resource for the Spring Valley Project from drill-hole data, using controls from the main rock types and implicit grade shells with an Ordinary Kriging (“OK”) algorithm.

Gustavson received the exploration drill hole database on September 20, 2013. Drill hole data, including collar coordinates, down hole surveys, sample assay intervals, and geologic logs, were provided in a secure Microsoft Access database and as CSV files. The database is managed by Barrick under the Exploration, Development, and Joint Operating Agreement. A small number of additional drillholes have been completed by Barrick since the database was closed, but the results have not yet been received by Midway or by Gustavson. Gustavson does not expect that a few additional infill drillholes will materially impact the resource estimation.

September 9, 2014 | 4 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

The present database has been updated to include the remaining 2010, 2011, 2012, and the available 2013 drill holes, which were completed since the previous mineral resource estimate. The drill hole database contains gold assay analytical information for 112,858 sample intervals from core, RC, and mud rotary drilling methods.

A visual evaluation of the assay and geologic data in cross-section and plan view, in conjunction with the proximity analysis, reveals that while it is difficult to substantiate lithologic or alteration based domaining, there exists a significant spatial correlation between the higher grade samples and disseminated mineralization. It is Gustavson’s opinion that the statistical analyses justify the use of a grade boundary at +0.003 oz/t, as a proxy for the mineralized alteration selvages and vein zones, and domaining the resource within this grade boundary is both reasonable and appropriate.

The mineral resource estimate for the Spring Valley Project is summarized in Table 1-1. This mineral resource estimate includes all drill data available to Midway and Gustavson as of the effective date of this report, and has been independently estimated by Gustavson. Mineral resources are not mineral reserves and may be materially affected by economic, environmental, permitting, legal, socio-economic, marketing, political, or other factors. In Table 1-1, mineral resources are reported above a +0.006 oz/t Au cut-off, assuming the three year trailing average gold price of US$1,537 per ounce. This cut-off reflects the potential economic, marketing, and other issues relevant to an open pit mining scenario based on a carbon recovery process following cyanide heap leaching. Gustavson cautions that economic viability can only be demonstrated through prefeasibility or feasibility studies.

Table 1-1 Mineral Resource Statement for the Spring Valley Project

Pershing County, Nevada, Gustavson Associates, LLC, August 1, 2014

| Measured | Indicated | Measured + Indicated | Inferred | |||||||||

| Cutoff | Tons | Gold | Tons | Gold | Tons | Gold | Tons | Gold | ||||

| oz/t | (x1000) | oz/t | t. oz. (x1000) | (x1000) | oz/t | t. oz. (x1000) | (x1000) | oz/t | t. oz. (x1000) | (x1000) | oz/t | t. oz. (x1000) |

| 0.008 | 60,100 | 0.023 | 1,410 | 116,400 | 0.021 | 2,400 | 176,600 | 0.022 | 3,810 | 46,400 | 0.019 | 880 |

| 0.006 | 75,300 | 0.020 | 1,510 | 147,300 | 0.018 | 2,610 | 222,600 | 0.019 | 4,120 | 62,100 | 0.016 | 990 |

| *0.004 | 91,500 | 0.017 | 1,590 | 179,100 | 0.016 | 2,780 | 270,600 | 0.016 | 4,370 | 78,400 | 0.014 | 1,070 |

Note * based on discussion of cutoff presented above, material below 0.006 oz/t is not considered resource for the purposes of this report. 0.004 oz/t cutoff is presented for informational purposes and for consistency with prior reports. Note: Values may not sum due to rounding.

September 9, 2014 | 5 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.9 | Interpretations and Conclusions |

| 1.9.1 | Environmental |

There are no known environmental liabilities on the Spring Valley project.

| 1.9.2 | Geology and Deposit Type |

The Spring Valley deposit is hosted within structurally prepared zones within a porphyry intrusion and overlying felsic volcanic rocks. Overall deposit geometry suggests that primary mineralizing fluid flow is related to steeply dipping, N20E to N30E- trending, deep-seated faults. Mineral emplacement is localized within structural preparation along these faults, as well as on contact horizons, deformation structures, and within permissive host rocks within a local graben /basin. The mineralization is associated with relatively thin, crystalline quartz veins that have large alteration selvages. In areas of dense quartz veining, the alteration selvages coalesce into regions of pervasively altered and veined rock.

| 1.9.3 | Exploration, Drilling, and Analytical |

The property has been explored using a variety of techniques including mapping, geophysical surveys, and geochemical sampling. The Spring Valley resource area has been drilled with a total of 672 holes totaling 603,731 feet, including 531 Reverse Circulation (RC) drill holes totaling 428,500 feet and 141 diamond core holes totaling 173,011 feet.

All drill intervals were first assayed by a 30 gram fire assay and mineralized intervals have been systematically re-assayed using MSFA. Where available, the MSFA numbers were utilized in the resource estimate. The project data is stored in a secure database. Assay and geology data have been checked for accuracy for all programs prior to 2009, and spot checked in the Barrick programs from 2009 through 2013.

Gustavson is of the opinion that exploration activities, drilling, and analytical procedures are being conducted in manner that meets or exceeds industry best practice.

| 1.9.4 | Quality Assurance/Quality Control |

Gustavson has reviewed the QA/QC assay programs and believes the programs provide adequate confidence in the data. Sample standard failures and the samples associated with erroneous blank samples have been reanalyzed prior to the completion of this Report and the results are comparable to the original assay.

| 1.9.5 | Mineral Processing and Metallurgical Testing |

The Spring Valley project mineralized material is potentially amenable to both gravity and heap leach recovery methods.

September 9, 2014 | 6 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

The test samples described in the Mineral Processing and Metallurgical testing item of this Technical Report are representative of the mineralization of the deposit as a whole. As of the date of this report, there are no processing factors that could have a significant effect on potential extraction.

| 1.9.6 | Data Verification |

Gustavson received original assay certificates in pdf and comma delimited format for all samples included in the current drill hole database. A random manual check of 1,210 samples within the database against the original certificate revealed 3 total errors. The results of the analysis indicate that the data imported into the database matches the certificates 99.7% of the time with a confidence interval of ± 0.56% at a 95% confidence level. Gustavson considers the database adequate for estimation of mineral resource estimation purposes.

| 1.9.7 | Resource |

Within the main portion of the deposit, drill density is within 150 foot spacing, which is adequate to describe measured and indicated resources, given the variogram and the relative continuity of the resource estimate. However, some areas of the deposit are still in need of infill holes. Closer spaced drilling in these areas will be required to further upgrade the resource classification. Additionally there are areas of the project which are open to expansion of extents of mineralization.

| 1.10 | Recommendations |

Gustavson recommends the following program to advance the Spring Valley Project towards eventual development.

| 1.10.1 | Scoping Study |

Gustavson recommends that Midway complete a scoping study (PEA) on the project to evaluate proposed mining and processing methodologies, and economics associated with the implementation of various crushing, grinding, heap leach, and gravity recovery circuit combinations. The PEA should be completed to 43-101 standards and designed to support Midway’s reporting requirements as an independent issuer.

| 1.10.2 | Geologic Model |

Gustavson understands that Barrick is undertaking systematic relogging of the drilling including trace element analysis in an effort to refine the geologic and alteration model for the deposit. Gustavson recommends that Midway maintain a level of engagement in the relogging parameters and process in order to facilitate information transfer and share interpretive insights. The results of this logging should be considered in any resource updates moving forward.

September 9, 2014 | 7 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.10.3 | Metallurgical Study |

Existing metallurgical studies have established that gold at Spring Valley is amenable to cyanidation and to gravity separation. Gustavson recommends that additional metallurgical studies be completed to evaluate the mix of mineral processing methods best suited for the mineralization at Spring Valley. The evaluation should include the study of conventional cyanidation at different crush sizes, as well as the impact of gravity concentration at different steps in the process stream. Testwork should include samples of mineralization of various alteration and oxidation types.

| 1.10.4 | Geotechnical and Hydrogeological Study |

Gustavson recommends that the existing Golder pit slope analysis and geotechnical studies be reviewed to identify critical geotechnical areas and to define a geotechnical exploration program to support final design parameters. The Golder geotechnical studies should form the basis for mine design for the proposed PEA. Additionally, Gustavson recommends that the preliminary hydrogeological studies be reviewed to determine critical path to support project water needs, secure remaining required water rights, and address potential pit dewatering concerns. This information should be included in the support of a proposed PEA.

| 1.10.5 | Environmental Permitting |

Gustavson recommends that continued work towards meeting the requirements of the State of Nevada to permit a mine on public land should include in the short term:

- Finalize Class III Cultural Survey report;

- Endangered Species Act (ESA) and other biological requirements; and

- Ongoing collection and evaluation of environmental baseline data.

- Installation and monitoring of groundwater monitoring as recommended for hydrologic models and baseline studies.

| 1.10.6 | Exploration Program |

Continued exploration diamond core drilling should be targeted in three areas within and adjacent to the immediate mineral resource area:

- Infill and step out drilling at the furthest south extent of drilling near the flanks of Gold Mountain.

- Exploration drilling along the Wabash fault that bisects the main Spring Valley resource. Extensions of this fault to both the east and west of the main resource have the potential to host mineralization that has not yet been tested. Placer gold is common along the trace of the fault to the SE.

- Infill and step out drilling targeting the lower Felsic Porphyry unit at depth in the main resource area, to the northern extents of the project and along the eastern Limerick fault.

- Limited infill drilling, primarily in those areas where substantial in-pit inferred mineralization has been identified, or in areas of high potential for pit expansion.

September 9, 2014 | 8 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 1.10.7 | Budget |

Under the terms of the Joint Venture Agreement, Barrick has assumed the responsibility for the exploration and development activities. The Spring Valley Joint Venture has a project development budget which includes most of the recommendations listed above. The SVV project is operated by Barrick, with 75% of the costs borne by Barrick, and the remainder by Midway Gold.

Table 1-2 presents the 2014-2015 development and exploration budgets for the Spring Valley Venture, as well as budget line items for Midway based on the recommendations described above.

Table 1-2 Proposed Budget

| Midway Studies & Reports | Costs (US$) |

| Metallurgical Studies | 120,000 |

| Geotechnical Review | 30,000 |

| Hydrogeologic Review | 30,000 |

| Scoping Study (PEA) | 150,000 |

| Midway Reporting Subtotal | $330,000 |

| Spring Valley Venture PreFeasibility Study | |

| Hydrology Studies & Test Wells | 2,125,000 |

| Geochemistry, including ARD | 982,000 |

| Geotechnical | 500,000 |

| Metallurgy | 1,070,000 |

| Mine Planning and Site Design | 700,000 |

| Permit Development | 150,000 |

| Archaeological, Community & Related | 285,000 |

| Environmental Studies | 875,000 |

| Land & Water Rights | 3,100,000 |

| Condemnation Drilling | 500,000 |

| Subtotal | $ 10,287,000 |

| Midway Share at 25% | $ 2,571,750 |

| Spring Valley Venture Exploration | |

| Exploration Program 2014 - 2015 | 12,000,000 |

| Subtotal | $ 12,000,000 |

| Midway Share at 25% | $ 3,000,000 |

| Total Budget (Midway Share) | |

| Total Budget | $5,901,750 |

September 9, 2014 | 9 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 2. | INTRODUCTION AND TERMS OF REFERENCE |

Gustavson Associates, LLC (Gustavson) was commissioned by Midway Gold Corp. (Midway) to prepare an update to the Mineral Resources and resulting Technical Report on Resources for the Spring Valley Project (or the Project) site in Pershing County, Nevada. The purpose of this report is to present the findings of the resource estimation in accordance with Canadian National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101), NI 43-101 Form F1, and Canadian Institute of Mining, Metallurgy and Petroleum (CIM) “Best Practices and Reporting Guidelines.” This Technical Report is part of an ongoing effort by Midway to develop the Spring Valley Project.

This report is prepared to fulfill Midway’s disclosure requirements to the Toronto Stock Exchange. It should be noted that this report is independent of and distict from any parallel resource estimates or scoping studies being carried out by the Spring Valley Venture, or by Barrick as operator.

Items 15 through 22 of Form 43-101F1 (Mineral Reserve Estimates, Mining Methods, Recovery Methods, Project Infrastructure, Market Studies and Contracts, Environmental Studies, Permitting and Social or Community Impact, Capital and Operating Costs, and Economic Analysis, respectively) are not required for a Technical Report on Resources and are not included in this report.

| 2.1 | Qualifications of Consultants |

The Qualified Persons (QP’s) responsible for this report are:

- William J. Crowl, R.G., QP MMSA, Vice President, Mining, Gustavson is a QP as defined by NI 43-101 and is responsible for Sections 1-8, and 15-19.

| · | Zachary J. Black, SME-RM, Associate Resource Geologist, Gustavson is a QP as defined by NI 43-101 and is responsible for Sections 9-12 and 14. |

- Deepak Malhotra, PhD., SME-RM, President, RDi is a QP as defined by NI 43-101 and is responsible for Section 13.

| 2.1.1 | Details of Inspection |

Gustavson Associates representatives William J. Crowl and Zachary J. Black visited the Spring Valley Project on October 24, 2013. While on site, Mr. Crowl and Mr. Black conducted general geologic field reconnaissance and discussed in detail core drilling operations, sampling, and transportation with Barrick and Midway personnel. Mr. Crowl visited the Spring Valley project again on June 18th, 2014 and directly observed drilling and sampling practices at the project site. For the 2014 drill program, core splitting and sampling are being carried out at Barrick’s Turquoise Ridge Facility. Accordingly, Mr. Crowl visited Turquoise Ridge on June 17th 2014 to directly observe the splitting and sampling procedures being employed for the 2014 Spring Valley drill program.

September 9, 2014 | 10 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 2.1.2 | Sources of Information |

The information, opinions, conclusions, and estimates presented in this report are based on the following:

- Information and technical data provided by Midway;

- Observations made by Qualified Persons on site;

- Review and assessment of previous investigations;

- Assumptions, conditions, and qualifications as set forth in the report; and

- Review and assessment of data, reports, and conclusions from other consulting organizations and previous property owners.

Gustavson sourced information from referenced documents as cited in the text and those summarized in Section 19, References, of this report.

| 2.2 | Effective Date |

This report was completed based upon information available at the effective date of this report, August 1, 2014.

| 2.3 | Units of Measure |

Unless stated otherwise, all measurements reported here are in imperial units, tons are short tons, and currencies are expressed in constant US dollars. Precious metal content is reported in troy ounces per short ton (oz/t).

September 9, 2014 | 11 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Common Units

| Above mean sea level | amsl |

| Cubic foot | feet3 |

| Cubic inch | in3 |

| Cubic yard | yd3 |

| Day | d |

| Degree | ° |

| Degrees Fahrenheit | °F |

| Foot | feet |

| Gallon | gal |

| Gallons per minute (US) | gpm |

| Grams per tonne | g/t |

| Greater than | > |

| Hectare | ha |

| Hour | h |

| Inch | " |

| Kilo (thousand) | k |

| Less than | < |

| Micrometre (micron) | µm |

| Milligram | mg |

| Ounces per ton | oz/t |

| Parts per billion | ppb |

| Parts per million | ppm |

| Percent | % |

| Pound(s) | lb |

| Short ton (2,000 lb) | st |

| Short ton (US) | t |

| Specific gravity | SG |

| Square foot | feet2 |

| Square inch | in2 |

| Yard | yd |

September 9, 2014 | 12 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Metric Conversion Factors (divided by)

| Short tons to tonnes | 1.10231 |

| Pounds to tonnes | 2204.62 |

| Ounces (Troy) to tonnes | 32,150 |

| Ounces (Troy) to kilograms | 32.150 |

| Ounces (Troy) to grams | 0.03215 |

| Ounces (Troy)/short ton to grams/tonne | 0.02917 |

| Acres to hectares | 2.47105 |

| Miles to kilometres | 0.62137 |

| Feet to metres | 3.28084 |

|

| |

Abbreviations

| American Society for Testing and Materials | ASTM |

| Absolute Relative Difference | ARD |

| Atomic Absorption Spectrometry | AAS |

| Bureau of Land Management | BLM |

| Canadian Institute of Mining and Metallurgy | CIM |

| Diamond Drill | DD |

| Global Positioning System | GPS |

| Internal Rate of Return | IRR |

| Metallic Screen Fire Assay | MSFA |

| National Instrument 43-101 | NI 43-101 |

| Nearest Neighbour | NN |

| Net Smelter Royalty | NSR |

| Net Present Value | NPV |

| Probability Assigned Constrained Krigging | PACK |

| Reverse Circulation | RC/RCV |

| Rock Quality Designation | RQD |

| Selective Mining Unit | SMU |

| Universal Transverse Mercator | UTM |

| |

September 9, 2014 | 13 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 3. | RELIANCE ON OTHER EXPERTS |

During preparation of this report, Gustavson fully relied upon information provided by Midway regarding property ownership, mineral tenure, permitting, and environmental liabilities as described in Items 4 and 5 of this report.

Midway relies upon the accuracy and completeness of data provided by Barrick pursuant to the Exploration, Development, and Joint Operating Agreement dated March 9, 2009.

Based on the review conducted in 2011 and the further efforts documented in this report, Gustavson considers that the data provided by Barrick is sufficient for the purposes of a resource estimate.

| 4. | PROPERTY DESCRIPTION AND LOCATION |

| 4.1 | Property Location |

The Spring Valley property is located in Pershing County, Nevada 20 miles northeast of Lovelock within the Spring Valley Mining District. It is situated three miles north of the Rochester silver-gold mine in the Humboldt Range. The Spring Valley deposit lays 100% within the Spring Valley area of interest and is within the control of Midway and Barrick’s joint venture (the “Spring Valley Venture”). The Participants directly control approximately 10,140 gross acres on 642 contiguous unpatented lode and placer mining claims plus 1,550 gross acres of fee land.

The Property is located on the USGS Lovelock 1:100,000 scale topographic map and the USGS Rochester and Fitting 1:24,000 scale, 7.5 minute series quadrangle maps. It is centered at latitude 40° 20’ North and longitude 118° 08’ West. The principal area of known mineralization on the Spring Valley property is located within the southern half of Sections 34 and 35, Township 29 North, Range 34 East (T29N, R34E) Mount Diablo Base and Meridian (MDBM). Mineralization also occurs at the Limerick target in Section 4, Township 28 North, Range 34 East (T28N, R34E) MDBM; at the Golden Gate target in Section 8, T28N, R34E; and at the American Canyon target in Section 14, T28N, R34E.

Unpatented mining claims are kept active through payment of a maintenance fee due on 31 August of each year. A complete list of claims is presented in Appendix A.

September 9, 2014 | 14 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 4.2 | Agreements and Royalties |

| 4.2.1 | Barrick Agreement |

On March 9, 2009, Midway and Barrick Gold Exploration Inc., a wholly owned subsidiary of Barrick Gold Corporation (“Barrick”), signed an agreement for the exploration, development, and eventual joint operating activities at the project. On Nov 15, 2013, Barrick completed the $38 million expenditure required to earn a 70% interest at Spring Valley. As of Feb 24, 2014, the companies completed formation of the joint venture (the “Spring Valley Venture”) with Barrick holding a 70% interest and Midway holding a 30% interest.

On July 9, 2014, Midway elected to have Barrick carry Midway to a production decision and arrange financing for Midway’s share of mine construction expenses. The carrying and financing costs plus interest are to be recouped by Barrick from 90% of Midway’s share of production once production has been established. Accordingly, upon completion of construction of the mine, Barrick will earn an additional 5% (75% total interest.)

| 4.2.2 | Agreements |

The property agreements for the Spring Valley project are summarized in the table below. The table documents the nature of title, obligations to retain the property, royalties, payments, and expiration dates of the agreements. Claims are unpatented mining claims on land administered by the Bureau of Land Management.

September 9, 2014 | 15 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Table 4-1 Summary of Spring Valley Property Agreements

| Ownership | Agreement Date | Expiry | Owner (source) | Claims | Gold Royalty | Approximate Acreage* | Payments |

| Optioned | 10/30/2006 | 10/30/2016 (may be extended ) | Chabino | 2 | 3% NSR | 42 | $6,000/yr |

| Optioned | 6/10/2007 | 6/10/2017 purchase complete | G. Duffy | 2 | - | 42 | $12,000/yr plus periodic option payments |

| Optioned | 4/25/2006 | 4/25/2016 (may be extended) | L. Duffy | 12 | 3% NSR | 248 | $36,000/yr |

| Optioned | 7/17/2006 | 7/17/2016 (may be extended) | Rowe and Stoeberl | 46 | 3% NSR | 951 | $20,000/yr |

| Owned | 9/10/2003 | - | Midway Gold (Echo Bay) | 28 | 2% NSR | 579 | - |

| Owned | 1/25/2006 | - | Midway Gold (Coeur) | 98 | 3% NSR | 2087 | - |

| Owned | 7/3/2003, amended 8/15/2003 | - | Midway Gold (Schmidt) | 44 | 2-7% NSR | 909 | - |

| Owned | - | - | Midway Gold | 410 | - | 8452 | - |

| Owned | 5/5/2006 | - | Midway Gold (Seymork) | Fee | 3% NSR | 320/770 | - |

| Owned | 9/7/2005 | - | Midway Gold (NLRC) | Fee | - | 544/0 | - |

| Owned | 8/29/2006 | - | Midway Gold (Sentman) | Fee | - | 40/10 | - |

| Leased | 12/2/2010 | 12/2/2016 (may be extended) | Barrick Agreement with Third Party | Fee | 3% NSR | 0/544 | $300,000/yr |

|

0/76

0/120 | |||||||

| Owned | 10/01/2010 | Barrick Agreement with Third Party | Fee | - | 76/0 | - | |

| *Surface/Mineral |

| 4.3 | Environmental Liabilities |

Environmental liabilities at the property are limited to the construction of drill pads and roads, drilling, closure and reclamation of the currently permitted drilling program. This program is bonded with NDEP and the BLM. As work plans detailing the work, and reclamation cost estimates utilizing the states Standardized Reclamation Cost Estimator (SRCE), or equivalent, are required, the bond is considered adequate for the liability. Other potential environmental liabilities include the inadvertent impact of an unidentified cultural site or the allowance of invasion by a weedy species. The potential for impacting a cultural site or allowing the invasion of weedy species is considered low given the requirements for cultural surveys and the BLM’s Standard Operating Procedures (SOPs), which include general protection procedures to preclude weedy invasion. The potential for impacts to rangeland, impacts due to a hazardous or solid waste release, impact to water resources or impacts to a wetland is considered extremely low given the permitting requirements, SOPs, and Barrick’s operating practices.

September 9, 2014 | 16 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 4.4 | Permits |

According to the NDOM, all mining operations in Nevada are required to have:

| · | Legitimate mining claims registered with the BLM, or ownership or control of mineral rights on private land; |

| · | An approved Plan of Operation from the BLM, the U.S. Forest Service or the Nevada Division of Environmental Protection, (NDEP); and |

| · | Necessary state permits. |

Spring Valley Venture exploration activities are permitted under a Plan of Operations (POO) approved by the BLM in July 2007, and Reclamation Permit No. 0258 approved by the NDEP in December 2006. All of permits and approvals, and the bonds, were transferred to Barrick in 2009. A new or amended POO will be required if disturbances beyond the currently approved 75 acres are necessary.

The latest NDEP/BLM Annual site inspection was conducted July 8th, 2014. No issues were reported by the agencies.

Water for exploration drilling is supplied by two water wells drilled under a temporary grant of water rights from the Nevada Division of Water Resources. The current 180 Day permit is in effect as of April 17th, 2014.

Table

4-2 provides a general summary of permits required by Federal State and Local government entities for mining or milling operations

in the state of Nevada.

September 9, 2014 | 17 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Table 4-2 Agency Permits and Authorizations*

| Permit/Authorization | Agency |

| Federal | |

| Activities in Wetlands and/or Waters of the U.S. | U.S. Army Corps of Engineers |

| Amended Exploration Plan of Operations | BLM |

| Endangered Species Act Compliance | U.S. Fish and Wildlife Service |

| Mine Plan of Operations | BLM |

| Notice of Commencement of Operation | Northern Nevada Mine Safety & Health Administration |

| Purchase, Transport, or Storage of Explosives | Bureau of Alcohol, Tobacco and Firearms, for Northern Nevada |

| Right of Way for Electrical Transmission on BLM-Administered Land | BLM |

| Road Access (R/W) on BLM Administered Land | BLM |

| Use of BLM-Administered Land | BLM |

| State | |

| Air Quality Operating Permit | Nevada Division of Environmental Protection, Bureau of Air Quality |

| Annual Status and Production Report | Nevada Division of Minerals |

| Approval to Operate a Solid Waste System | Nevada Division of Environmental Protection, Bureau of Waste Management |

| Department of Transportation | Nevada Department of Transportation |

| Fire and Line Safety | Nevada State Fire Marshall |

| Ground Water Permit | Nevada Division of Environmental Protection, Bureau of Water Pollution Control |

| Hazardous Materials Permit | Nevada State Fire Marshal Division, Hazardous Materials Section |

| Historic Preservation | Nevada Historic Preservation Office |

| Mine Registry Forms | Nevada Division of Minerals |

| Industrial Artificial Pond Permit | Nevada Division of Wildlife |

| Mineral Exploration Hole Plugging | Nevada Division of Water Resources |

| Mining Reclamation Permit | Nevada Division of Environmental Protection – Bureau of Mining Regulation and Reclamation, Reclamation Branch |

| Notification of Opening & Closing Mines | Nevada State Mine Inspector |

| Permit to Appropriate the Public Waters | Nevada Division of Water Resources |

| Permit for Occupancy (Encroachment Permit) | Nevada Department of Transportation |

| Permit for Sanitation Facilities | Nevada State Health Division Bureau of Health Protection Services |

| Protection of Wildlife | Nevada Division of Wildlife |

| Stormwater General Permit | Nevada Division of Environmental Protection, Bureau of Water Pollution Control |

| Surface Disturbance Permit | Nevada Division of Environmental Protection – Bureau of Air Pollution Control |

| Water Pollution Control Permit | Nevada Division of Environmental Protection – Bureau of Mining, Regulation and Reclamation, Regulation Branch |

| Local** | |

| Building Permit | |

| General Plan | |

| Special Use Permit |

* Permits listed are general in nature; all items listed are not necessarily specific to Midway or Barrick.

** Local permits presented are general in nature.

September 9, 2014 | 18 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Barrick continues to move forward with conducting environmental studies on the project property. Gustavson knows of no other significant factors or risks that may affect access, title, or the ability to perform work on the Spring Valley property.

| 5. | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

| 5.1 | Accessibility |

The Spring Valley property is accessed by Nevada State Route (SR) 50 (also known as Lovelock-Unionville Road), which extends eastward from US Interstate 80 at exit 119. SR 50 also serves as the main access to the Rochester Mine until a turnoff at Spring Valley Pass. Once in Spring Valley, access to the various parts of the Property is by dirt road. Alternatively, access is possible from the Buena Vista Valley to the east through Spring Valley Canyon on SR 50.

The nearest town to the Property is Lovelock, Nevada, which is situated along US Interstate 80 and hosts a population of 1,895 (Census 2012 data). The nearest city is Reno, Nevada, approximately 120 miles to the southwest, which hosts a population of 231,027 (Census 2012 data).

September 9, 2014 | 19 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 5.2 | Climate |

The climate in the Spring Valley area is typical for northwestern Nevada. Average monthly high temperatures range from 82 to 94° F in the summer and 42° to 55° F in the winter. Yearly rainfall averages approximately 6 inches with nearly uniform distribution from October through June. July, August, and September are typically hot and dry months; December, January, and February receive the bulk of the snowfall (Desert Research Institute, 2010).

Exploration and operations are possible year round, although snow levels in winter and wet conditions in late autumn and in spring can make travel on dirt and gravel roads difficult.

| 5.3 | Local Resources and Infrastructure |

Power lines cross the property and ground water is abundant as evidenced by artesian wells in the main area of drilling. There is year-round road access directly to the project via Nevada state highway 50. The interstate (I80) runs approximately 10 miles west of the property. There is an adequate workforce in the surrounding region and the town of Lovelock. Northern Nevada is home to many gold mining operations with all associated support and supplies.

Coeur Mining’s Rochester operation is situated on adjacent claims to the south of the Spring Valley Project and has the necessary infrastructure to support their operation on site. Electrical power is supplied to the site by a public utility company (NV Energy) via a 69KV overhead transmission line.

Emergency services, including law enforcement, are located approximately 25 miles from the site in Lovelock. Regulatory and other off-site services are located throughout the county and region and are typical of standard United States agencies.The Spring Valley Venture controls sufficient surface rights within Spring Valley and the lower Buena Vista basin to support an open pit operation and the associated waste rock disposal and heap leach facility.

| 5.4 | Physiography |

Spring Valley is a large (approximately two square miles) intermontane basin in the central part of the Humboldt Range. The valley floor slopes gently to the east and ephemeral streams on its surface drain into Spring Valley Canyon at its eastern margin. Elevation at the Property ranges from 5,120 to 6,040 feet above mean sea level and the topographic relief can be characterized as gentle to moderate.

Vegetation is typical of the Basin and Range physiographic province. The Property is covered by sagebrush, grass, and various other desert shrubs.

September 9, 2014 | 20 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 5.5 | Water Rights |

Proposed mining operations at Spring Valley will require significant water rights for dust reduction, exploration drilling, process water, as well as potable water for domestic use and site facilities. The Spring Valley Venture has identified properties within the Buena Vista Valley with sufficient water rights to support mine operations and is in the process of securing such rights. Regulatory approval will be required to modify the water rights for use by the mine.

| 6. | HISTORY |

Gold, silver, lead, mercury, copper, antimony, and sericite-pyrophyllite have been produced from the Spring Valley Mining District since its discovery in 1868 (Tingley, 1992). Placer gold was discovered in 1875 and was worked extensively during the period 1880-1890 (Johnson, 1977). The placers are said to have been the most productive in Nevada: placer production from Spring Valley and American Canyons were estimated at $10 million (Ransome, 1909). The gravel deposits were up to 100 feet in depth or more and the gold recovered from them was generally coarse, though fine-grained gold was present and likely more abundant (Johnson, 1977).

The Wabash lead-silver mine, located on the eastern margin of the Property, was worked during the period of 1935 to 1938. Production recorded for 1938 was 170 tons of ore containing 1 oz gold, 6,774 oz silver, 651 lb copper, and 9,514 lb lead (Johnson, 1977). Mineralization at the Wabash mine consists of argentiferous galena and sphalerite in the matrix of intensely brecciated rocks in a fault zone.

Modern exploration at Spring Valley began in 1996 by Kennecott. Four reverse circulation (RC) holes, totaling 2,220 feet, were drilled across the basin in an effort to discover the source of the placer gold in Spring Valley Canyon. Hole KSV-2 intersected 40 feet grading 0.023 oz/t gold at the southeast edge of what is now known as the Pond Zone.

Echo Bay acquired the property in 2000 and drilled ESV-2, intersecting 145 feet grading 0.075 oz/t gold. Subsequent drilling by Echo Bay focused on step-out drilling from ESV-2, coring the mineralized zone and drilling exploration targets to the northwest. During the 2001-2002 drill campaign, Echo Bay completed 19 RC holes totaling 10,940 feet and 2 diamond drill (DDH) holes totaling 1,653 feet.

There were no historic mineral resources estimated for the Spring Valley project prior to Midway’s acquisition of the property.

September 9, 2014 | 21 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 7. | GEOLOGICAL SETTING AND MINERALIZATION |

| 7.1 | Regional Geologic Setting |

The Spring Valley property is located in the Humboldt Range, a north-south oriented, up-thrown fault block (horst) bounded on the west by the Humboldt River valley and on the east by Buena Vista Valley. Quaternary alluvial deposits fill the intermontane basins and alluvial valleys.

The bedrock geology of the Humboldt range within 20 miles of the Spring Valley property consists of Triassic shales and carbonate rocks, a thick sequence of Permo-Triassic intermediate to felsic volcanic rocks, and a north-south trending belt of Tertiary volcanic rocks (Figure 7-1). Triassic leucogranite and Cretaceous granodiorite locally intrude the Permo-Triassic volcanic package.

The oldest rocks exposed in the central Humboldt Range are a series of Permo-Triassic volcanic and metavolcanic rocks, named the Koipato Group, that include, from oldest to youngest, the Limerick Greenstone, the Rochester Rhyolite, the Weaver Rhyolite, and their intrusive equivalents (rhyolite porphyry and leucogranite). The Koipato Group is interpreted as representing bimodal volcanism in a back-arc setting that was subsequently accreted onto the continental margin (LeLacheur et al., 2009). Contacts of the Koipato Group with the Triassic Natchez Pass and Prida Limestones to the north, west and on the eastern flank of the range are all fault contacts. Cretaceous granodiorite locally intruded the Permo-Triassic units. Quaternary alluvial and colluvial deposits unconformably overlie the older bedrock units. North-south, north-northwest, and north-northeast normal faults are the dominant structural features in the region.

The Humboldt Range in the region surrounding the Spring Valley project is well-mineralized. Styles of mineralization in the central Humboldt Range include base and precious metal vein and vein-stockwork mineralization and Tertiary sediment-hosted gold deposits. Examples of vein/vein stockwork systems include Spring Valley, Rochester, Nevada Packard, the Unionville district and the Dun Glen district. Examples of Tertiary sediment-hosted gold mineralization in the region include Florida Canyon, Relief Canyon, Standard, and Willard.

September 9, 2014 | 22 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Figure 7-1 Geology of the Humboldt Range

September 9, 2014 | 23 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 7.2 | Local Geologic Setting |

The known Spring Valley mineral system is beneath an intermontane basin filled with post-mineral Quaternary alluvial deposits, thereby masking the bedrock geology immediately overlying or containing the mineralization. At the scale of the Spring Valley property position, the bedrock units are distributed in blocks aligned approximately north-south. The bedrock geology is dominated by the Limerick Formation in the western one-third of the property, the Rochester Formation in the central and eastern half of the property, and the Natchez Pass Limestone in the extreme northeast corner of the property (Figure 7-2). At this scale, the geology is segmented by a number of faults: a relatively older north to northeast trending set including the West Spring Valley, Limerick and Black Ridge Faults; and, northwest trending, steeply dipping cross faults with oblique or lateral offsets that displace the older north to northeast trending faults. The West Spring Valley fault is interpreted as a steeply east dipping normal fault, whereas the Black Ridge and Limerick faults are interpreted as moderate to high angle normal faults with westerly dips. The Limerick fault may be listric in character, with flattening dip at depth. East-west and northeasterly faults are also mapped, but are not part of the predominant fabric on the property.

The bedrock geology beneath the Quaternary alluvial cover has been interpreted and compiled by Midway and other workers based on drill hole information. The surficial and subsurface bedrock geology within the Spring Valley intermontane basin is described below as modified from Stiles (2008), LeLacheur et al. (2009), Neal (2004), and Neal & LeLacheur (2010).

The Spring Valley basin is completely covered by between 50 and 375 feet of Quaternary alluvium, consisting mainly of valley fill gravels and mud flow deposits (Figure 7-2). Bedrock geology beneath the alluvium features northeast trending felsic volcanic and volcaniclastic rocks intruded by a feldspar porphyry intrusion at depth (Figure 7-2). The rhyolitic vent complex is interpreted as coeval with development of the Rochester and/or Weaver Rhyolites, and is thereby believed to be Triassic in age.

Structures in the alluvium covered area are interpreted primarily from logging of drill core and chips and, to a lesser degree, from geophysical surveys, mapping and projection of faults observed in the hills surrounding the basin. Faults within the area covered by alluvium are difficult to document, and are inferred from offsets in geologic units and/or trends of mineralized/altered zones and gold grade distributions. Many faults appear to have complex, long-lived histories, and may have developed prior to or at the time of emplacement of the Spring Valley rhyolitic vent complex, with reactivations during accretion of the Koipato Group, and Basin and Range development. Many structures thereby appear syn- to late-mineral relative to alteration, mineralization and intrusion. The lack of detail regarding the timing and location of significant structures impacts the modeling of the associated gold mineralization, making determination of modeling domains difficult. Gustavson recommends a better understanding of the structural geology and its impact on the distribution of mineralization, alteration and rock types be developed.

September 9, 2014 | 24 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

Figure 7-2 Bedrock Geology Map of the Spring Valley Project

September 9, 2014 | 25 |

|

Midway Gold Corp. Spring Valley Project | Certificate of Authors NI 43-101 Technical Report on Resources |

| 7.3 | Lithologic Units |

Lithologies recognized under the alluvium covered area at the Spring Valley prospect are shown in conceptual cross section in Figure 7-3, and are listed below.

| 7.3.1 | Quaternary Alluvium (Qal) |

Alluvial gravels with coarse angular clasts of local lithologies cover much of the intermontane basin. Gold mineralization, possibly placer deposits, has been identified in places at the base of this unit but this mineralization is not included in the mineral resource estimate.

| 7.3.2 | Limerick Greenstone: |

The Limerick Greenstone is comprised of a thick pile of intermediate to mafic flows and interbedded volcaniclastic sediments. The base of the sequence is not exposed on the project. Felsic sills and dikes intrude the greenstone. Small felsic flow domes of the Rochester Rhyolite are present in the upper part of the Limerick sequence.