Attached files

| file | filename |

|---|---|

| EX-32.2 - EX-32.2 - GLAUKOS Corp | gkos-20151231ex3221eda92.htm |

| EX-23.1 - EX-23.1 - GLAUKOS Corp | gkos-20151231ex231ef7d64.htm |

| EX-21 - EX-21 - GLAUKOS Corp | gkos-20151231ex214360b12.htm |

| EX-10.23 - EX-10.23 - GLAUKOS Corp | gkos-20151231ex1023f5a8b.htm |

| EX-31.1 - EX-31.1 - GLAUKOS Corp | gkos-20151231ex311b69378.htm |

| EX-32.1 - EX-32.1 - GLAUKOS Corp | gkos-20151231ex32164dd90.htm |

| XML - IDEA: XBRL DOCUMENT - GLAUKOS Corp | R9999.htm |

| EX-31.2 - EX-31.2 - GLAUKOS Corp | gkos-20151231ex312493dc9.htm |

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark one)

☒ ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2015

OR

☐ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from: to

Commission File No. 001-37463

GLAUKOS CORPORATION

(Exact name of registrant as specified in its charter)

|

Delaware |

|

33-0945406 |

|

(State or other jurisdiction of incorporation or organization) |

|

(I.R.S. Employer Identification No.) |

|

|

|

|

|

26051 Merit Circle, Suite 103 |

|

92653 |

|

(Address of principal executive office) |

|

(Zip Code) |

(949) 367-9600

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Common Stock, $0.001 par value per share |

|

New York Stock Exchange |

|

(Title of each class) |

|

(Name of each exchange on which registered) |

Securities registered pursuant to Section 12(g) of the Act: None.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☒

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a smaller reporting company. (See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act).

|

Large accelerated filer ☐ |

|

Accelerated filer ☐ |

|

Non-accelerated filer ☒ |

|

Smaller reporting company ☐ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☒

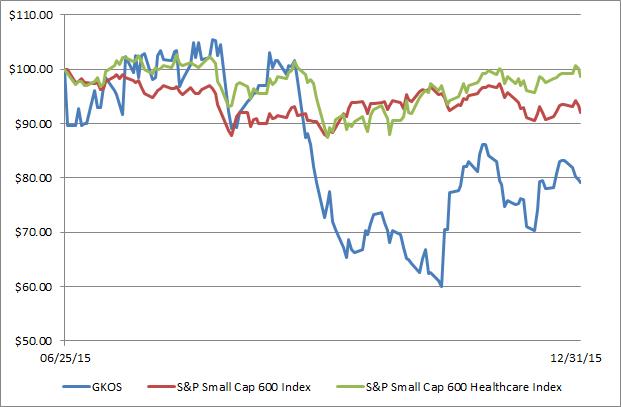

As of June 30, 2015, the last business day of the registrant’s most recently completed second quarter, the aggregate market value of common stock held by non-affiliates of the registrant, based on the closing sales price for the registrant’s common stock as reported on The New York Stock Exchange, was $523.2 million. Shares of common stock held by each executive officer, director and by each person who owns 10% or more of the outstanding common stock have been excluded in that such persons may be deemed to be affiliates. The determination of affiliate status is not necessarily a conclusive determination for other purposes.

The number of shares of the Registrant’s common stock outstanding as of March 7, 2016 (latest practicable date) was 32,340,033 shares.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Registrant's Proxy Statement for the 2016 Annual Meeting of Stockholders are incorporated herein by reference in Part III of this Annual Report on Form 10-K to the extent stated herein. Such Proxy Statement will be filed with the Securities and Exchange Commission within 120 days of the registrant's fiscal year ended December 31, 2015.

We use Glaukos, our logo, iStent, iStent Inject, iStent Supra, iDose, MIGS and other marks as trademarks. This report contains references to our trademarks and service marks and to those belonging to other entities. Solely for convenience, trademarks and trade names referred to in this report, including logos, artwork and other visual displays, may appear without the ® or ™ symbols, but such references are not intended to indicate in any way that we will not assert, to the fullest extent under applicable law, our rights or the rights of the applicable licensor to these trademarks and trade names. We do not intend our use or display of other entities’ trade names, trademarks or service marks to imply a relationship with, or endorsement or sponsorship of us by, any other entity.

References throughout this document to “we,” “us,” “our,” or “Glaukos” refer to Glaukos Corporation and its consolidated subsidiaries.

i

SPECIAL NOTE REGARDING FORWARD-LOOKING STATEMENTS AND INDUSTRY DATA

This Annual Report on Form 10-K contains forward‑looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended (Exchange Act). These statements are based on management’s beliefs and assumptions and on information currently available to management. Some of the statements under Item 1 - “Business,” Item 1A - “Risk Factors,” Item 7 - “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and elsewhere in this Annual Report on Form 10-K contain forward‑looking statements. In some cases, you can identify forward‑ looking statements by the following words: “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing” or the negative of these terms or other comparable terminology, although not all forward‑looking statements contain these words.

These statements involve risks, uncertainties and other factors that may cause actual results, levels of activity, performance or achievements to be materially different from the information expressed or implied by these forward‑ looking statements. Although we believe that we have a reasonable basis for each forward‑looking statement contained in this report, we caution you that these statements are based on a combination of facts and factors currently known by us and our projections of the future, about which we cannot be certain.

In addition, you should refer to the “Risk Factors” section of this report for a discussion of other important factors that may cause actual results to differ materially from those expressed or implied by the forward‑ looking statements. As a result of these factors, we cannot assure you that the forward‑looking statements in this report will prove to be accurate. Furthermore, if the forward‑looking statements prove to be inaccurate, the inaccuracy may be material. In light of the significant uncertainties in these forward‑looking statements, you should not regard these statements as a representation or warranty by us or any other person that we will achieve our objectives and plans in any specified time frame, or at all. We undertake no obligation to publicly update any forward‑looking statements, whether as a result of new information, future events or otherwise, except as required by law.

This Annual Report on Form 10-K contains market data and industry forecasts that were obtained from industry publications. These data involve a number of assumptions and limitations, and you are cautioned not to give undue weight to such information. Although we believe that the industry publications on which the market and industry statements are based are reliable and we are not aware of any misstatements regarding any market data or industry forecasts presented herein, we have not independently verified any of the third party information. Statements in this Annual Report on Form 10-K regarding our market position, market opportunity, market size and our general expectations involve risks and uncertainties and are subject to change based on various factors, including those discussed under Item 1A - “Risk Factors” and Item 7 - “Management’s Discussion and Analysis of Financial Condition and Results of Operations” included elsewhere in this Annual Report on Form 10-K.

ii

Overview

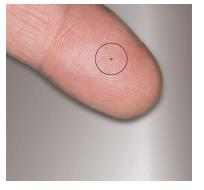

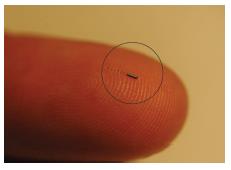

We are an ophthalmic medical technology company focused on the development and commercialization of breakthrough products and procedures designed to transform the treatment of glaucoma, one of the world’s leading causes of blindness. We have pioneered Micro‑Invasive Glaucoma Surgery (MIGS) to revolutionize the traditional glaucoma treatment and management paradigm. We launched the iStent, our first MIGS device, in the United States in July 2012 and we are leveraging our platform technology to build a comprehensive and proprietary portfolio of micro‑scale injectable therapies designed to address the complete range of glaucoma disease states and progression. We believe the iStent is the smallest medical device ever approved by the Food and Drug Administration (FDA), measuring 1.0 mm long and 0.33 mm wide.

Glaucoma is a group of eye diseases characterized by progressive, irreversible and largely asymptomatic vision loss caused by optic nerve damage, which is most commonly associated with elevated levels of pressure within the eye, or intraocular pressure. Elevated intraocular pressure often occurs when aqueous humor, the thin watery fluid that fills the front part of the eye, is not circulating normally and draining properly. According to Market Scope, more than 80 million people worldwide have glaucoma, a number it expects to grow to more than 90 million by 2020. This estimate includes approximately 4.3 million people with glaucoma in the United States, growing to approximately 4.8 million by 2020. Glaucoma is a chronic condition that progresses slowly over long periods of time and can have a devastating impact on a patient’s vision and quality of life.

Reducing intraocular pressure is the only proven treatment for glaucoma. Glaucoma has traditionally been treated through a range of approaches that often require patients to use multiple types of prescription eye drops for the rest of their lives, and sometimes undergo complex and invasive eye surgery. Prescription eye drops, which are estimated to account for approximately $4.7 billion in global sales in 2015, according to Market Scope, are often used to control intraocular pressure throughout glaucoma progression. Unfortunately, these medications can be ineffective over time due to patient noncompliance and other factors. Complex and invasive glaucoma surgical options are typically reserved for more advanced disease and have remained largely unchanged since the 1970’s.

We developed MIGS to address the shortcomings of current glaucoma treatment options. MIGS procedures involve the insertion of a micro‑scale device from within the eye’s anterior chamber through a small corneal incision. MIGS devices reduce intraocular pressure by restoring the natural outflow pathways for aqueous humor. Based on clinical studies and published reports, we believe MIGS procedures are safer, preserve more eye tissue and result in faster recovery times and fewer complications than invasive glaucoma surgical options.

The iStent is the first commercially available MIGS treatment solution. FDA‑approved for insertion in combination with cataract surgery, the iStent has been shown to lower intraocular pressure in adult patients with mild‑to‑moderate open‑angle glaucoma, which represents the majority of glaucoma cases. The iStent procedure is currently reimbursed by Medicare and a majority of commercial payors and we have sold more than 140,000 iStent devices worldwide.

We are building a broad portfolio of micro‑scale injectable therapies designed to address the complete range of glaucoma disease states and progression, including three innovative pipeline products: the iStent Inject, the iStent Supra and iDose. The iStent Inject includes two stents pre‑loaded in an auto‑injection inserter. We are developing two versions of this product: the first is currently being studied for lowering intraocular pressure in conjunction with cataract surgery in a U.S. investigational device exemption (IDE) pivotal trial; the second is currently being studied in an initial U.S. IDE study as a standalone treatment for lowering intraocular pressure. This second version is also capable of making its own self‑sealing corneal penetration, potentially offering patient treatment in a minor surgical suite or an in‑office setting. The iStent Supra is designed to access an alternative drainage space within the eye where we estimate 20% of aqueous humor outflow occurs, and is now in a U.S. pivotal IDE trial. iDose is an implant that is designed to continuously deliver therapeutic levels of medication from within the eye for extended periods of time to lower intraocular pressure in glaucoma patients. To validate the safety and efficacy of our iStent products, we are currently conducting 17 prospective clinical trials.

1

Our corporate headquarters and production facilities are located in Laguna Hills, California, and as of December 31, 2015, we had 182 employees. We have built and are continuing to grow our commercial organization, which includes a direct sales force in the United States, Germany, Australia and Canada, and distribution partners in Europe, Asia Pacific and other targeted international geographies. Information about geographic revenue is set forth in Note 13 of our notes to consolidated financial statements included in Part II, Item 8 of this Annual Report on Form 10-K.

Our net sales increased to $71.7 million in 2015 from $45.6 million in 2014 and $20.9 million in 2013, and our net losses were $38.3 million, $14.1 million and $14.2 million for the years ended December 31, 2015, 2014 and 2013, respectively.

Our Market Opportunity

According to Market Scope, more than 80 million people worldwide have glaucoma, a number it expects to grow to more than 90 million by 2020. This estimate includes approximately 4.3 million people with glaucoma in the United States, growing to approximately 4.8 million by 2020. Market Scope estimates 2015 global sales of products used to treat glaucoma patients to be approximately $5.1 billion, growing to approximately $7.1 billion in 2020. Open‑angle glaucoma is the most common form of the disease. Approximately 3.5 million people in the United States have open‑angle glaucoma, growing to approximately 3.8 million by 2020 according to Market Scope. Despite therapeutic options that attempt to manage disease progression, researchers estimate that 8.4 million people were bilaterally blind from glaucoma in 2010, with this figure forecasted to rise to 11.1 million by 2020.

Many factors are driving significant growth in the glaucoma market. Populations worldwide in both mature and emerging markets are growing and aging, while life expectancies continue to rise. Treatment of glaucoma is expected to increase due to better healthcare access globally and advances in glaucoma technology designed to provide earlier diagnosis and more cost‑effective treatment to a larger portion of the glaucoma population.

Care for glaucoma patients in the United States is administered by many of the approximately 18,900 ophthalmologists who diagnose the disease and provide medical management according to Market Scope. There are more than 8,000 ophthalmic surgeons in the United States focused on performing cataract or glaucoma procedures. These ophthalmic surgeons perform approximately 3.8 million cataract surgeries annually in the United States according to Market Scope. We believe that approximately 20% of cataract surgeries are performed on patients also diagnosed with open‑angle glaucoma and/or ocular hypertension. Appropriate treatment options are determined based on the progression and severity of the disease and include medical management with prescription pharmaceuticals, laser therapy, surgical therapy and now MIGS.

Glaucoma Treatment Overview and Limitations

Glaucoma and the eye’s drainage system

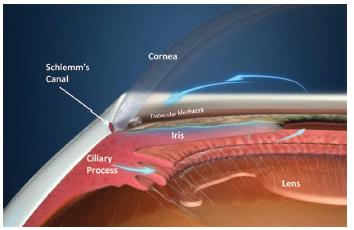

Glaucoma is a group of eye diseases characterized by progressive, irreversible and largely asymptomatic vision loss in which elevated levels of intraocular pressure are often associated with optic nerve damage. While some glaucoma patients do not experience an increase in intraocular pressure, it is widely considered a major risk factor in glaucoma’s progression and reduction in intraocular pressure is the only clinically proven treatment. Elevated intraocular pressure occurs when aqueous humor is not circulating normally and properly drained from the front part of the eye. Normally, this fluid flows through the trabecular meshwork, an area of spongy mesh‑like tissue in the eye located around the base of the cornea, and into Schlemm’s canal, a circular channel in the eye that collects the aqueous humor and delivers it back into the bloodstream. This trabecular meshwork pathway is also known as the conventional outflow pathway.

A second outflow pathway is located in the suprachoroidal space, which lies between the sclera and the choroid, where we estimate 20% of the eye’s total aqueous humor outflow occurs. This pathway is also known as the unconventional or uveoscleral pathway. The suprachoroidal space is characterized as an area of less venous resistance to aqueous humor outflow than Schlemm’s canal.

2

The following image depicts the blockage of aqueous humor outflow in an eye with open‑angle glaucoma.

Open‑angle glaucoma is the most common type of glaucoma. In open‑angle glaucoma, structures of the eye may appear normal, but aqueous humor outflow through the trabecular meshwork and into Schlemm’s canal is reduced due to gradual degeneration and obstruction. Direct causes of this blockage are unknown, but the disease is linked to age, ethnicity and hereditary factors. Loss of aqueous humor absorption leads to increased resistance and thus a chronic, painless buildup of pressure in the eye.

Glaucoma is a progressive disease that can be categorized based by severity levels ranging from ocular hypertension (or pre‑glaucoma) to severe glaucoma, as shown in the chart below. According to industry experts, mild‑to‑moderate glaucoma patients account for a majority of the population. An eye doctor usually diagnoses glaucoma as part of a comprehensive exam that includes measuring intraocular pressure and corneal thickness, evaluating optic nerve damage and testing visual fields. Intraocular pressure is measured in millimeters of mercury (mm Hg), with normal eye pressures ranging from 10 to 21 mm Hg. Glaucoma is typically characterized by an intraocular pressure greater than 21 mm Hg.

An eye doctor will monitor optic nerve damage by tracking the cup to disc (C:D), ratio. This exam measures the diameter of the optic disc (the round area in back of the eye where retinal nerve fiber layers collect to form the optic nerve) relative to the diameter of the optic cup (the center of the optic disc). Expansion and deepening of this optic cup indicates damage. Visual field, or perimetry, tests are used to check for peripheral vision impairment in one or more

3

quadrants. Once diagnosed, the treatment goal in all cases is to control intraocular pressure. Glaucoma progression stages are described in the following chart.

|

Stage |

|

Intraocular pressure |

|

Optic nerve damage |

|

Visual field |

|

Intraocular pressure |

|

|

Ocular Hypertension |

|

20 ‑ 30 mm Hg |

|

No measurable or observable change |

|

Visual function intact |

|

20% reduction in baseline: ≤ 18 mm Hg |

|

|

Mild Glaucoma |

|

20 ‑ 35 mm Hg |

|

Minor; C:D ≤ 0.8 with documented expansion and deepening of cup |

|

Some visual field loss |

|

25% reduction in baseline; ≤ 18 mm Hg |

|

|

Moderate Glaucoma |

|

> 30 mm Hg |

|

Significant; C:D ≤ 0.8 with documented expansion and deepening of cup |

|

Expanded visual field loss in up to two quadrants; peripheral progressing to central loss |

|

30% reduction in baseline; ≤ 15 mm Hg |

|

|

Severe Glaucoma |

|

Intraocular pressure uncontrolled |

|

Severe; C:D > 0.8 with severe expansion and deepening of cup |

|

Significant visual field loss in up to three quadrants; central loss |

|

< 15 mm Hg |

|

4

Glaucoma treatment overview

The traditional treatment of glaucoma encompasses a variety of medication regimens, laser and surgical methods to lower intraocular pressure.

|

Therapy |

|

Medications |

|

Laser |

|

Surgery |

|

|

Product or procedure |

|

Prescription eye drops |

|

Selective argon and micropulse lasers |

|

Invasive trabeculectomy with or without aqueous shunt device |

|

|

Treatment |

|

First‑line |

|

First or second‑line |

|

Last resort |

|

|

Description |

|

Eye drops taken one or more times a day in single or multiple medication regimens |

|

Laser trabeculoplasty performed at outpatient centers |

|

Filtration surgery or aqueous shunt, a flexible plastic tube with an attached silicone drainage pouch |

|

|

Mechanism of action |

|

Increasing aqueous humor outflow and/or decreasing production of aqueous humor |

|

SLT laser energy targets melanin‑containing cells in the trabecular meshwork, creating changes in the tissue and improving the aqueous humor outflow |

|

Creating a drainage channel from the anterior chamber and through the sclera to allow aqueous humor outflow to area beneath the conjunctiva |

|

|

Considerations |

|

Poor patient compliance; complex, frequent and lifelong dosing regimens; loss of effect over time; cost; side effects; contraindications and adverse interactions with other medications |

|

Effects of surgery dissipate after several years necessitating additional procedures; medication therapy may be necessary post‑treatment |

|

Little innovation; high failure rates; complication risks; lack of long‑term efficacy; medication therapy may be necessary post‑treatment |

|

Multiple clinical trials have shown that medications can reduce intraocular pressures to baseline targets that can minimize vision loss. However, poor adherence to and lack of persistence with glaucoma medication regimens have been documented in numerous independent studies, which often place the incidence of patient noncompliance up to or above 50%, particularly in patients on two or more prescription eye drops. Even daily glaucoma single medication use has been associated with noncompliance rates as high as 75%.

According to Market Scope, more than 47% of patients use two or more prescription eye drops. Furthermore, because glaucoma progresses slowly and with few symptoms, patients often do not adhere to their medication regimens as prescribed until the disease has progressed to the point of significant vision loss. As a result, despite the availability of medication therapies to combat glaucoma, progressive visual loss and blindness still occur. According to a study published in 2014, 15% of glaucoma patients progress to blindness within 20 years of diagnosis.

Laser treatments have been developed to provide an alternative to lifelong medication treatments. Laser procedures are typically performed at an outpatient surgical center and involve the use of lasers to create changes in eye tissue and improve aqueous humor outflow. Ophthalmic surgeons may perform laser procedures as initial treatment, or for patients who are noncompliant with prescription eye drops or whose intraocular pressure is not well controlled by medications. According to Market Scope, selective laser trabeculoplasty (SLT) is the most frequently performed glaucoma laser procedure in the United States. Although SLT can help to lower intraocular pressure, the procedure’s effectiveness often wears off within one to five years, according to the Glaucoma Research Foundation. While a second procedure can be performed, the results of repeated laser surgeries are less predictable and less effective than those of the first surgery. Additionally, medication therapy may still be required post‑treatment.

Where medication therapy and laser treatment are unsuccessful in managing glaucoma, invasive surgical procedures such as trabeculectomies or implantation of tube shunts are performed, usually as outpatient procedures. In a

5

trabeculectomy, the surgeon cuts open the conjunctiva and sclera to create flaps, and removes a plug of scleral tissue and sometimes a portion of the trabecular meshwork to create an opening into the anterior chamber. The conjunctiva and sclera flaps are sutured back down and a small blister, or bleb, is created between the conjunctiva and sclera. The surgery results in a new drainage channel that allows increased outflow of aqueous humor into the bleb. While some patients experience significant reductions in intraocular pressure, trabeculectomy failure rates can approach 50% according to published research. A common complication is scarring, which can prevent fluid drainage from the eye and interfere with the proper function of the bleb. If the bleb doesn’t work properly, more surgery may be needed. Among the other complications associated with trabeculectomies are blurred vision, bleeding in the eye, bleb leaks, low intraocular pressure, or hypotony, infection, persistent corneal edema, choroidal detachment and cataract development. Implantations of tube shunts, devices that divert the aqueous humor from the anterior chamber, are generally reserved for eyes in which a trabeculectomy has failed or has a poor likelihood of success. A tube shunt surgery is similar to a trabeculectomy, except that the device’s tube is inserted through the scleral channel to maintain the channel, and the device’s reservoir end is placed deep under the conjunctiva to maintain the drainage space. While invasive glaucoma surgery often leads to significant reductions in intraocular pressure, it is associated with high long‑term failure rates, long recovery times and significant complication risks. Additionally, as with laser treatment, the effects may dissipate over time, requiring additional procedures, and medication therapy may still be required post‑treatment.

We believe that because of the limitations of medications and laser and the morbidity associated with invasive surgical therapies, a clear unmet medical need exists in the management of open‑angle glaucoma patients.

Our Solution

We pioneered the development of MIGS in order to address the shortcomings of current pharmaceutical and surgical options, and in doing so have established an entirely new market segment within the global glaucoma marketplace. We believe that by using our core competencies to develop, manufacture and obtain regulatory approval for products incorporating our proprietary technologies, we have created a platform capable of disrupting and revolutionizing the traditional glaucoma treatment and management paradigm.

In contrast to invasive surgical approaches, MIGS procedures access the anterior chamber of the eye through small corneal incisions or penetrations. MIGS procedures reduce intraocular pressure by restoring the natural physiologic pathways for aqueous humor outflow. Based on clinical studies and published reports, we believe MIGS procedures are safer, preserve more eye tissue and result in faster recovery times and fewer complications than invasive glaucoma surgical options.

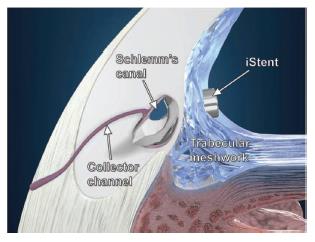

We launched our first micro‑scale MIGS treatment solution, the iStent, in the United States following FDA approval in June 2012. We believe the iStent represents the next generation in glaucoma surgical innovation and it is the first FDA‑approved surgical device available for insertion in conjunction with cataract surgery for the reduction of intraocular pressure in adult patients with mild‑to‑moderate open‑angle glaucoma. The iStent is a micro‑bypass stent made of surgical‑grade non‑ferromagnetic titanium that is coated with heparin. An extensive history of development efforts preceded the current form of the iStent, with contribution by our Caltech‑associated founder, during which more than 80 prototype iterations were produced. Packaged in a sterile, pre‑loaded configuration, the iStent is inserted through the small corneal incision made during cataract surgery and placed into Schlemm’s canal, a circular channel in the eye that collects aqueous humor and delivers it back into the bloodstream. Once inserted, the iStent improves aqueous humor outflow while fitting naturally within Schlemm’s canal. The ergonomic rail design protects and accesses underlying collector channels while the iStent’s three retention arches ensure secure placement. The iStent is currently approved only for insertion in conjunction with cataract surgery because this was the product usage in the U.S. IDE clinical trial information that was included in the premarket approval (PMA).

The iStent is rated “MRI Conditional” by the American Society for Testing and Materials. This means that a patient implanted with the iStent can be scanned safely via magnetic resonance imaging (MRI) under the following conditions specified on the product label: static magnetic field of 3‑Tesla or less, and maximum spatial magnetic field gradient of 4,000‑Gauss/cm or less. Therefore, it may not be safe for iStent recipients to undergo MRIs in environments that do not match these specified conditions; however, the vast majority of MRI systems in use in the United States today are rated 3‑Tesla or less. Following implantation of an iStent, the surgeon is instructed to provide to the patient a wallet‑sized patient identification card citing the model and serial number of the device, implant date, and surgeon’s

6

name along with the aforementioned MRI conditions. The surgeon is also instructed to advise the patient that the patient identification card contains important information related to the iStent and that the card should be shown to their current and future health care providers.

The image below left shows a gloved hand holding the pre‑loaded iStent inserter; the image below center is a magnified view of the insertion tip and iStent device; the image below right shows an iStent on the tip of a finger (inside circle).

|

|

|

|

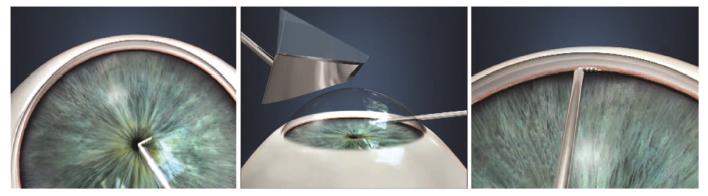

The following series of graphics illustrates the insertion of an iStent into the eye: (left) the pre‑loaded iStent inserter enters the anterior chamber through a small corneal incision made during cataract surgery; (center) a gonioscope is used to visualize Schlemm’s canal; (right) the iStent is inserted into Schlemm’s canal.

7

The following series of graphics illustrates the effect of iStent in the eye: (left) after placement of the iStent, aqueous humor outflow is restored; (right) close‑up illustration of iStent placement in Schlemm’s canal.

|

|

|

In combination with cataract surgery, the iStent has been clinically proven to decrease intraocular pressure. We believe the iStent provides numerous benefits that address the significant unmet need for a durable and effective glaucoma treatment earlier in the treatment paradigm. These benefits include:

Reduces intraocular pressure. In the pivotal U.S. clinical trial, after one year, 68% of mild‑to‑moderate open‑angle glaucoma patients who received the iStent in combination with cataract surgery remained medication free while sustaining target intraocular pressures of ≤ 21 mm Hg, a level consistent with normal, non‑glaucomatous eyes. In the same trial, 64% of patients who received the iStent remained medication free while sustaining a mean intraocular pressure reduction of 20% compared to baseline.

Facilitates compliance, convenience. The iStent is designed to establish continuous outflow of aqueous fluid for sustained reduction in intraocular pressure. This mechanism is intended to assure uninterrupted therapy, thus overcoming the primary limitation of patient noncompliance to prescribed eye drop regimens. By reducing intraocular pressure on a sustained basis, iStent efficacy does not depend on patients remembering to use their prescription eye drops. Re‑establishing normal, steady‑state physiologic outflow of aqueous humor may reduce the large fluctuations in intraocular pressure that occur throughout the day in glaucoma patients. These large fluctuations in intraocular pressure have been shown in independent studies to be a significant risk factor in glaucoma progression.

Safe procedure and rapid recovery. Clinical studies have demonstrated that inserting the iStent in combination with cataract surgery yields an overall safety profile and recovery rate similar to cataract surgery alone, a surgery that has minimal complications and is the most commonly performed ophthalmic procedure today. The iStent procedure is not associated with the complication risks of invasive glaucoma surgery, and it also spares conjunctival tissue, or the clear skin that covers the sclera, enabling rapid recovery and preserving the potential for future glaucoma treatment options.

Broad segment of ophthalmic practitioners can perform procedure. Because the iStent procedure is straightforward, a broad segment of ophthalmic surgeons can effectively perform the MIGS procedure to insert an iStent. We believe this characteristic increases the procedure’s appeal and utilization as an early and effective treatment option for ophthalmic surgeons.

Our Pipeline

Our research and development goal is to leverage our core capabilities in MIGS‑based design and development to create a full portfolio of micro‑scale injectable therapies for glaucoma management. We have developed a series of innovative products, in varying stages of development, that are designed to expand market penetration and adoption,

8

further enhance ease of use for surgeons, reach a wider glaucoma patient population and broaden our offering for glaucoma management in order to address the complete range of glaucoma disease states and progression:

iStent Inject trabecular micro‑bypass stent. The iStent Inject is approximately one‑third the size of the iStent and relies on a similar method of action to improve aqueous humor outflow into Schlemm’s canal and reduce intraocular pressure. Packaged in a two‑stent, preloaded, auto‑inject mechanism, the iStent Inject allows the surgeon to inject these stents into multiple trabecular meshwork locations through a single corneal entry with the goal of achieving greater intraocular pressure reduction. We are developing two versions of this product. One version of the iStent Inject is currently being evaluated in a pivotal U.S. IDE clinical trial for the reduction of intraocular pressure in mild‑to‑moderate open‑angle glaucoma in combination with cataract surgery. A second version of the iStent Inject is designed to make its own self‑sealing corneal needle penetration to achieve insertion without an incision. An initial U.S. IDE study is currently underway to evaluate this second version of the device as a stand‑alone procedure in glaucoma patients who are not undergoing concurrent cataract surgery. Both versions of the iStent Inject have been approved for marketing in the European Union and Canada and are currently in a commercial launch in Germany and Canada. The version of the iStent Inject that may be used for the reduction of intraocular pressure in mild‑to‑moderate open angle glaucoma in combination with cataract surgery is approved for marketing and currently in a commercial launch in Australia.

The image below left is the iStent Inject injection system, pre‑loaded with two iStent Inject devices; the image below center is a magnified view of two iStent Inject devices; the image below right shows two iStent Inject devices on a penny (inside circle).

|

|

|

|

iStent Supra suprachoroidal micro‑bypass stent. The iStent Supra is designed to reduce intraocular pressure by accessing the suprachoroidal space in the eye, an area that we estimate is responsible for 20% of its total aqueous outflow. We believe that the iStent Supra device could be used alone to lower intraocular pressure or in combination with the iStent or the iStent Inject to achieve even lower intraocular pressure in patients with progressive or more advanced open‑angle glaucoma. An international study showed the iStent Supra achieved a 30% pressure reduction in comparison to the unmedicated baseline at 12 months. A U.S. pivotal IDE trial for the iStent Supra used in conjunction with cataract surgery to lower intraocular pressure is underway. The iStent Supra device has already been approved for marketing in the European Union.

9

The image below left is a magnified view of the iStent Supra; the image below center illustrates the iStent Supra device implanted into the suprachoroidal space of the eye; the image below right shows the iStent Supra device on the tip of a finger (inside circle).

|

|

|

|

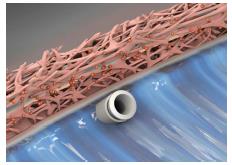

iDose. The iDose is a targeted injectable drug delivery implant that uses our micro‑scale platform. The iDose implant is designed to be pre‑loaded into a small gauge needle and injected into the eye via a self‑sealing corneal needle penetration, where it is secured within the eye. Once secured in the eye, the iDose is designed to continuously deliver therapeutic levels of medication from within the eye for extended periods of time. The titanium implant is comparable in size to the Company’s other proprietary MIGS devices. It is filled with a special formulation of travoprost, a prostaglandin analog used to reduce elevated intraocular pressure. The implant is capped with a membrane that is designed for continuous controlled drug elution into the anterior chamber. When depleted, the implant can be removed and replaced in a similar, subsequent procedure. Glaukos has designed the product to be an alternative to chronic, daily prescription eye drop treatments, which may have high rates of patient noncompliance and cause long‑term ocular surface damage to glaucomatous eyes. In November 2015, the Company submitted an Investigational New Drug (IND) application to the FDA seeking authorization to study the iDose delivery system for investigational use in the reduction of elevated intraocular pressure in patients with glaucoma. In the IND application, we proposed to conduct a randomized and 12-week masked Phase II clinical trial to assess the safety and preliminary efficacy of two models of the iDose delivery system with different travoprost elution rates compared to topical timolol maleate ophthalmic solution, 0.5%. In addition, the IND application included information on travoprost’s history of safety and efficacy, as well as Glaukos’ preclinical program and early data from an initial international clinical trial on the iDose implant involving 69 patients. In this initial international study, subjects were randomized to receive either one of two models of the implant, each with different elution rates, or topical travoprost. Through 12 months, mean intraocular pressure was lower in the implant groups than in the topical medication group. The results from this initial trial demonstrated that both implant models had a potent intraocular pressure‑lowering effect and that the implants were generally well‑tolerated. In December 2015, the FDA allowed the Phase II clinical trial of iDose to proceed. We plan to initiate the Phase II clinical trial for iDose in early 2016.

Our injectable therapies could further transform the glaucoma patient value proposition. We believe newly diagnosed glaucoma patients, and mild‑to‑moderate open‑angle glaucoma patients who have failed on medication therapy, or those who are noncompliant with their prescribed eye drop regimens, could have iStent or iDose injectable therapy as a meaningful alternative to lifelong treatment with prescription eye drops. Our simple, straightforward injectable solutions may reduce the daily need, side effects and cost of prescription eye drops.

Research & Development

We are leveraging our micro‑scale technology platform to address the full range of glaucoma disease states and progression and to fundamentally change the way glaucoma patients are treated. Our research and development efforts are focused primarily on continuous improvement of our iStent designs and injector systems and improvements to our proprietary MIGS platform. Our research and development objectives are:

|

· |

To advance glaucoma patient care through continuous improvement of the MIGS platform, to provide a viable MIGS alternative to lifelong medication regimens and invasive surgical procedures for intraocular pressure management; and |

10

|

· |

To further transform glaucoma treatment and care by introducing micro‑scale injectable therapies—including our iStent Inject, iStent Supra and iDose pipeline products—that can be performed in minor surgical suites or in‑office settings with topical anesthetic. |

As of December 31, 2015, our research and development team consisted of 66 employees. Our research and development process is supported by multiple clinical research programs and regulatory affairs activities. We currently have 17 prospective clinical trials underway. In addition, our technologies have been discussed in 40 articles published in peer‑reviewed journals to date. Our research and development expenses were approximately $25.0 million, $19.2 million and $15.5 million in the years ended December 31, 2015, 2014 and 2013, respectively. We expect our research and development expenditures to increase as we continue to devote significant resources to clinical trials and regulatory approvals of our new products.

iStent clinical validation

The iStent pivotal U.S. clinical trial that served as the basis for the FDA approval of our PMA application by the FDA was the first prospective, randomized, open‑label, multi‑center, controlled U.S. IDE clinical trial ever to be conducted in support of a glaucoma device. A total of 29 U.S. investigational sites participated in the trial, which demonstrated that insertion of the iStent in patients undergoing cataract surgery provided clinically and statistically significant improvements in intraocular pressure and an overall safety profile similar to cataract surgery alone.

To be enrolled in the trial, subjects were required to have mild or moderate open‑angle glaucoma with visual field or nerve pathology characteristic of glaucoma, a C:D ratio of 0.8 or less, and intraocular pressure ≤ 24 mm Hg while taking one to three prescription eye drops. After discontinuation of glaucoma medications, intraocular pressure was required to be between 22 mm Hg and 36 mm Hg. Excluded from the trial were individuals with severe glaucomatous field defects, severely uncontrolled intraocular pressure, angle closure glaucoma, neovascular, uveitic or angle recession glaucoma, prior glaucoma surgery other than iridectomy, prior refractive procedures, known corticosteroid responders, ocular disease that would affect safety, monocular subjects or those with fellow eye best corrected visual acuity, or BCVA, worse than 20/200. In this study, the “p” values were statistical calculations to determine whether the effects of receiving the iStent in conjunction with cataract surgery were significant in comparison to cataract surgery alone based on pre‑specified statistical targets. We specified that any result where p ≤ .05 would be significant.

A total of 240 eyes (239 subjects) were randomized, of which 117 were randomized to receive the iStent in conjunction with cataract surgery (treatment group) and 123 to cataract surgery only (control group). Of the 117 eyes randomized to the treatment group, 111 underwent insertion of the iStent in conjunction with cataract surgery. Of the 123 eyes randomized to receive cataract surgery only, 117 eyes underwent cataract surgery. At the 12‑month visit, subject accountability was 97% in the treatment group and 99% in the control group. After the randomized phase of the trial, an additional 50 subjects were enrolled for the safety purposes in the non‑randomized phase.

Pivotal trial efficacy data

Of subjects in the treatment group, 68% achieved the primary efficacy endpoint of an intraocular pressure ≤ 21 mm Hg without prescription eye drops at 12 months, compared to 50% for the control group (p = 0.004). Of subjects in the treatment group, 64% achieved the secondary efficacy endpoint of intraocular pressure reduction ≥ 20% without prescription eye drops at 12 months, compared to 47% in the control group (p = 0.010). Throughout the postoperative period, prescription eye drops were prescribed in a lower proportion of patients, and initiated later, in the treatment group than in the control group. At 12 months, 85% of treatment group subjects were medication free compared to 65% of control group subjects at 12 months.

11

Pivotal trial safety data

The following table provides information on the most common adverse events reported in the pivotal trial.

|

|

|

Cataract surgery |

|

Cataract surgery |

|

|

|

|

with iStent |

|

only |

|

|

|

|

N=116 |

|

N=117 |

|

|

Adverse events |

|

n (%) |

|

n (%) |

|

|

Early postop corneal edema |

|

9 (8) |

% |

11 (9) |

% |

|

Any BCVA loss of at least one line at or after the three-month visit |

|

8 (7) |

% |

12 (10) |

% |

|

Posterior capsular opacification |

|

7 (6) |

% |

12 (10) |

% |

|

Stent obstruction |

|

5 (4) |

% |

0 (0) |

% |

|

Blurry vision or visual disturbance |

|

4 (3) |

% |

8 (7) |

% |

|

Elevated intraocular pressure |

|

4 (3) |

% |

5 (4) |

% |

The overall rate of adverse events was similar between the treatment and control groups and no unanticipated adverse device complications were reported. The trial showed that when inserted in conjunction with cataract surgery for subjects with mild‑moderate open‑angle glaucoma, the benefits of the iStent procedure exceeded its risks.

Additional iStent studies

Two‑year results from the pivotal trial showed relatively similar outcomes, although it was not designed nor statistically powered for two‑year efficacy endpoints. Numerous other studies performed in Western Europe and the United States evaluating the iStent in combination with cataract surgery have found statistically significant reductions in mean intraocular pressure and medication use. For example, in a prospective, double‑masked, randomized controlled trial on 36 patients with cataract and primary open‑angle glaucoma, patients who received a single iStent in conjunction with cataract surgery showed an intraocular pressure decline to 14.8 mm Hg from 17.9 mm Hg at 15 months. This compared to an intraocular pressure decline to 15.7 mm Hg from 17.3 mm Hg in patients who underwent cataract surgery only. This trial included a washout of medications at 15 months in order to remove the confounding effect of glaucoma medications and, at 16 months, intraocular pressure was 16.6 mm Hg in the combined group, compared to 19.2 mm Hg in the cataract surgery‑only group.

Two other Western European studies have demonstrated the sustained efficacy and safety of a single iStent inserted in combination with cataract surgery after three or more years of postoperative follow up. In one international prospective, non‑comparative, uncontrolled, non‑randomized, interventional case series study, 19 subjects with mild‑to‑moderate open‑angle glaucoma underwent iStent implantation in conjunction with cataract surgery. At a mean follow‑up of 53 months, patients’ mean intraocular pressure was 16.3 mm Hg, compared to preoperative medicated intraocular pressure of 19.4 mm Hg. In 42% of patients, no glaucoma medications were used at the end of follow‑up and the mean number of prescription eye drops used by the patients declined to 0.8 from 1.3 medications preoperatively.

The other Western European study, a prospective, open‑label, non‑randomized study, assessed the long‑term postoperative outcomes of one iStent implanted during cataract surgery in subjects with primary open‑angle glaucoma, pseudoexfoliation glaucoma, secondary or post‑traumatic glaucoma or ocular hypertension. There was no preoperative medication washout period and 40% of eyes had undergone previous glaucoma surgeries, primarily laser procedures. In the study, a single iStent was implanted through the same incision used for cataract surgery in a consecutive series of 62 eyes of 43 subjects. In 39 eyes followed through three years, the mean intraocular pressure at three years was 14.9 mm Hg, compared to a mean preoperative intraocular pressure of 23.4 mm Hg, representing a 36% decline. In the same 39 eyes, the mean number of glaucoma medications used three years following surgery declined to 0.3, compared to a mean of 1.9 medications at subjects’ preoperative visits, representing an 86% reduction. No operative complications occurred during the cataract surgical procedure or during the stent implantation procedure. Over the three‑year follow‑up period, five secondary surgeries, two postoperative ocular sequelae and two non‑ocular adverse events were reported.

12

Additional iStent studies with multiple stents in standalone procedures

In a prospective, pilot study in Eastern Europe, 39 phakic and pseudophakic subjects with open‑angle glaucoma and preoperative unmedicated intraocular pressure between 22 mm Hg and 38 mm Hg received two iStents in a standalone procedure. At 36 months, subjects not taking medication achieved mean intraocular pressure of 15.2 mm Hg, representing a 37% reduction from unmedicated baseline intraocular pressure. In four subjects who required medication, intraocular pressure ranged from 13 mm Hg to 15.7 mm Hg at 36 months. There were no postoperative adverse events related to stent implantation, except for one incidence of early postoperative hyphema that resolved at one week. The study is designed for follow‑up through five years.

In another international prospective, randomized study, 119 subjects with open‑angle glaucoma and preoperative unmedicated intraocular pressure between 22 mm Hg and 38 mm Hg received one, two or three iStents in a standalone procedure. In this study, the number of stents was based on randomization and not on each glaucoma patient’s specific needs. The study design included a primary efficacy endpoint of ≥ 20% intraocular pressure reduction at 12 months from baseline unmedicated intraocular pressure without use of prescription eye drops or secondary glaucoma procedures. The secondary efficacy endpoint was intraocular pressure ≤ 18 mm Hg at 12 months without use of prescription eye drops or secondary glaucoma procedures. Approximately 89%, 90% and 92% of the one‑, two‑ and three‑stent groups met the primary and secondary endpoints, respectively. In addition, at 18 months, mean unmedicated intraocular pressure was 15.9 mm Hg, 14.1 mm Hg and 12.2 mm Hg in the one‑, two‑ and three‑stent groups, respectively. No intraoperative ocular adverse events occurred and safety data were similar across all stent groups. By month 18, four eyes had undergone cataract surgery due to progression of cataract. Under the study design, follow‑up will continue through five years.

To show the benefits of combining trabecular meshwork stents and suprachoroidal stents to achieve dual physiologic outflow in patients with severe glaucoma, 80 failed trabeculectomy patients received two iStents, one iStent Supra and one prescription eye drop in an international study. In 49 patients followed through 12 months, mean intraocular pressure declined 49% to 13.4 mm Hg, compared to a baseline intraocular pressure of 26.4 mm Hg. In addition, 100% of patients met the primary endpoint of ≥ 20% reduction in intraocular pressure at 12 months.

Sales and Marketing

In the United States, we sell our products through a direct sales organization that, as of December 31, 2015, consisted of 65 sales professionals, including regional business managers, sales directors, clinical relations personnel and reimbursement specialists. Our sales organization is primarily responsible for training ophthalmic surgeons on the iStent procedure, helping these physicians integrate the technology into their practices and providing resources to support reimbursement, while also identifying and supporting investigational sites for clinical trials of our pipeline technologies. We continue to recruit experienced sales professionals with extensive sales and/or clinical experience in ophthalmic medical technologies. Our weighted average number of domestic sales representatives increased to 45 for the year ended December 31, 2015 from 35 for the year ended December 31, 2014. The higher number of sales representatives in each period helped increase our customer base, leading to growth in unit sales. Increased unit volume was responsible for the majority of the increase in net sales for the three months and year ended December 31, 2015.

We invest significant time and expense to provide comprehensive training to our sales professionals so that they are proficient in all aspects of our iStent technologies, including features and benefits, procedure techniques and reimbursement. In addition, we provide technical education regarding the eye’s anatomy, glaucoma diagnosis, disease states and treatment, and cataract surgery.

Outside the United States, we sell our products primarily through a network of distribution partners located in markets where we see the greatest potential for iStent adoption. In late 2013, we formed a wholly‑owned subsidiary in Germany that employs five direct sales representatives. In early 2015, we formed a wholly‑owned subsidiary in Japan that employs five direct sales representatives. We intend for this subsidiary to commence a commercial launch in the event we receive regulatory approval to market the iStent in Japan. Following our initial public offering (IPO), we formed wholly‑owned subsidiaries in Australia and Canada. In Australia, we have hired a general manager and five direct sales representatives who commenced a commercial launch in January 2016. In Canada, we have hired a general manager and five direct sales representatives who commenced a commercial launch in January 2016. We continually

13

monitor our international sales progress and will consider conversion to a direct sales approach on a country‑by‑country basis, depending on our assessment of market conditions, net sales and profitability trends, reimbursement coding and coverage potential, and other factors. As of December 31, 2015, we had agreements with approximately 17 distributor organizations. No single distributor accounted for more than 10% of our total net sales for the years ended December 31, 2015, 2014 or 2013.

Our global sales efforts and promotional activities are currently aimed at ophthalmic surgeons and other eye care professionals. Our primary customers include ophthalmic surgeons, hospitals and ambulatory surgery centers (ASCs). We require physicians to complete a mandatory training program before commencing iStent procedures. To facilitate this, we have developed a multi‑faceted education program that includes interactive webinars, wet‑lab training, in‑office didactic sessions, observation of surgical cases and off‑site information seminars. We also offer physician‑to‑physician training that involves preoperative diagnostics, procedure assistance and postoperative consultations. We believe our education and training programs enable ophthalmic surgeons and other eye care professionals to improve patient outcomes and satisfaction with the iStent and procedure.

We support our sales organization with marketing programs and initiatives designed to build awareness and appreciation for our iStent technologies. These include advertisements and editorial coverage in professional publications, exhibits at major ophthalmic congresses and meetings, MIGS and iStent user meetings, and targeted direct‑to‑consumer marketing efforts.

Reimbursement

United States reimbursement

Reimbursement for iStent procedure

There are three key aspects of reimbursement in the United States:

|

· |

Coding refers to distinct numeric and alphanumeric billing codes that are used by healthcare providers to report the provision of medical procedures and the use of supplies for specific patients to payors. There are different categories of Current Procedural Terminology (CPT) codes (Category I, II and III) based on the procedure or supply. |

|

· |

Coverage refers to decisions made by individual payors as to whether or not to pay for a specific procedure and related supplies and if so, under what conditions (i.e., for which specific diagnoses and clinical indications). Payors typically base coverage decisions on reviews of the published medical literature. |

|

· |

Payment refers to the amount paid to providers for specific procedures and supplies. Payment is generally determined for the specific billing code and, in addition, there may be separate numeric codes, under which the billing code is classified, to establish a payment amount. |

In 2008, in consultation with and with the approval of the American Academy of Ophthalmology, we applied for and received a temporary Category III CPT code to describe insertion of devices such as the iStent using MIGS procedures.

Category III codes expire five years after the date they become effective. Prior to expiration, there are two options: submit an application to convert to a Category I code; or submit an application for a five year extension of Category III status. CPT code 0191T, which describes the insertion of the iStent and iStent Inject devices, first became effective in 2008. Prior to expiration, an application for a five-year extension was approved in 2012 and expires on December 31, 2018. We will need to either submit an application to convert CPT code 0191T to a Category I code or apply for another five-year extension by June 2017 in order for the new code to be effective by January 1, 2019.

We also successfully applied for, and the American Medical Association created, a new CPT code 0253T, which describes the insertion of the iStent Supra device, in 2011. An application for a five-year extension was approved at the same time as the application for the extension of CPT code 0191T. We will need to either submit an application for a Category I code or apply for another five‑year extension by June 2017.

14

The iStent is approved by the FDA for reduction of intraocular pressure in adult patients with mild‑to‑moderate open‑angle glaucoma undergoing cataract surgery who are currently treated with prescription eye drops. Based on data released by Centers for Medicare & Medicaid Services (CMS) regarding total cataract surgery volume in the Medicare Fee for Service program and data published by Market Scope, we estimate that Medicare pays for 70% of all cataract surgeries performed in the United States. Due primarily to strong published clinical data, including the FDA pivotal trial, all MACs had begun covering the iStent procedure by February 2013, approximately seven months after FDA approval.

We estimate that 20% of patients who meet the FDA indication for iStent insertion are covered by private health insurance companies, and we have secured positive coverage policies for iStent insertion with many of these private payors. As of December 31, 2015, we had secured reimbursement for the iStent insertion for approximately 80% of individuals covered by private insurance. These include United HealthCare, CIGNA, Aetna and all Blue Cross and Blue Shield (BCBS) plans except Anthem BCBS, Humana and Tricare. The positive coverage by most of the BCBS plans is a result of medical policy issued by the BCBS Association (national) in October 2013 stating that iStent insertion is considered medically necessary for mild‑to‑moderate open‑angle glaucoma patients undergoing cataract surgery. While BCBS plans, which are independent licensees, are not required to follow BCBS national guidelines, the majority of the plans do so. We continue to work with private insurance providers in an effort to broaden coverage for the iStent procedure.

iStent insertion in the United States is almost always performed in an outpatient setting and virtually all U.S. iStent sales are to ASCs and hospital outpatient departments (HOPDs). At the average facility, 70% of claims reporting iStent insertion with cataract surgery will be processed and paid for by Medicare. National payment rates by Medicare to ASCs and HOPDs are determined each year through a complex formula, which takes into account reported costs for each claim submitted. When two procedures are performed in an ASC on the same patient on the same day (e.g., iStent insertion and cataract surgery), Medicare reduces the payment of the lower‑paying procedure by 50%. The ASC facility payment for cataract surgery is generally lower than the payment for iStent insertion. Therefore, when these two procedures are performed together in an ASC, the payment for cataract surgery is reduced by 50%. We believe that the incremental payment the ASC facility receives for performing iStent insertion in conjunction with cataract surgery over and above what the facility would receive for performing cataract surgery alone covers the cost of the iStent device and the profit for the facility. The incremental ASC facility payment has remained relatively stable over the past few years, however there is no assurance that this payment will remain stable in the future. If the incremental facility payment were to decrease such that it did not cover the cost of the iStent device, it could reduce the profit margin of the ASC where the cataract surgery is performed, make it difficult for existing customers to continue using, or new customers to adopt, our products and create additional pricing pressure for us.

Reimbursement for iStent insertion and cataract procedures performed in HOPDs was similar to ASCs until CMS implemented a rule change, effective January 1, 2016, reflecting a trend by CMS of bundling payment for procedures that are clinically similar and performed at the same time in HOPDs. Procedures covered by these combined reimbursement codes are grouped into levels and reimbursed with a single, all‑inclusive payment. As a result of this recent rule change, CMS combined the cataract and MIGS/iStent procedure within a single comprehensive reimbursement code, which eliminated the separate 50% facility reimbursement for the cataract portion of the procedure when performed in the HOPD. While this change will result in lower Medicare fee‑for‑service reimbursement when iStent and cataract procedures are performed at the same time in HOPDs, we do not expect it to have a material impact on our 2016 iStent utilization rates. We intend to preserve our current HOPD pricing on the iStent device. We estimate that approximately 25% of US iStent procedures are currently performed in HOPDs but only a portion of these procedures are reimbursed through traditional Medicare fee‑for‑service. This change will likely reduce the profit margin of the iStent and cataract procedure for some HOPD customers and could potentially make it more difficult for some existing HOPD customers to continue using, or new HOPD customers to adopt, our products and could create additional pricing pressure on the iStent implant.

Physicians are paid separately from the facility for surgical procedures. Unlike the facility payment, for the CPT code that describes iStent insertion, there is no published Medicare payment schedule at the national level, and the physician payment rate is left to the discretion of the individual Medicare contractor. In order to adopt a new procedure, one of the factors that the surgeon evaluates is whether or not payment for the procedure adequately covers the surgeon’s time. As with the facility payment, the incremental payment the physician receives for inserting the iStent device in conjunction with cataract surgery over and above what he or she would receive for performing cataract surgery alone

15

plays a role in a surgeon’s decision to adopt the technology. We estimate that the national average incremental payment is approximately $500.

Unlike Medicare, commercial payors do not publish fee schedules. In general, based on selected feedback from facilities and surgeons, payments for iStent insertion from the commercial payors who cover the procedure generally run somewhat higher than the comparable local Medicare payment.

Reimbursement for future products

We have also filed and received approval of applications for CPT codes that describe our pipeline iStent devices. Our application for a CPT code to describe insertion of the iStent Supra was approved by the American Medical Association, or AMA, in 2011 resulting in the creation of Category III CPT code 0253T. Our application for a CPT code to describe the insertion of additional trabecular meshwork stents (as with the iStent Inject procedure) was approved by the AMA in early 2014 resulting in the creation of Category III CPT code 0376T. While this code was available beginning on January 1, 2015, for the reporting of procedures in which more than one iStent is inserted in the same eye, it currently does not result in any incremental facility or professional fee payment from Medicare. In addition, it is unclear whether any other third‑party payor will cover the insertion of a second stent or that payment for a second stent will be adequate.

Reimbursement outside the United States

Reimbursement in Europe

In most of the developed European countries, healthcare is funded by the central government. In general, obtaining broad‑based reimbursement and adequate payment for new technologies is more difficult in these markets than in the United States. As with the United States, high‑quality published clinical data (i.e., randomized, controlled trials) is required to obtain coverage. However, most of the developed European countries require new medical technologies to not only be safe and effective, but also to be able to demonstrate clinical benefits that outweigh the costs when compared to the standard of care. Conversely, while some U.S. private insurers take cost into consideration, Medicare by law does not consider cost in its coverage decisions.

Our primary focus has been on the U.S. market and we are in the early stages of commercialization in Europe. With regard to reimbursement in the larger developed countries, we have made the most progress in Germany. Prior to 2013, surgeons in Germany who implanted the iStent used a code for a general glaucoma operation. This code was only payable in the hospital inpatient setting and, although the payment was sufficient to cover the cost of the iStent and payment to the surgeon, the requirement of an overnight stay in the hospital was a significant barrier to adoption. Effective January 1, 2013, there is a specific code (5‑133.9) describing implantation of a trabecular stent (e.g., the iStent and iStent Inject). This code was added to the Einheitlicher Bewertungsmaßstab (EBM) or Unified Rating Scale of procedures that are payable in the outpatient setting. The 5‑133.9 code can be reported in conjunction with cataract surgery or as a stand‑alone procedure. In addition, the payment to the surgeon for 5‑133.9 is considered adequate to cover the surgeon’s costs (i.e., time) for inserting the iStent. Also, under the EBM, the cost of the implant can be passed through to the payor.

Although under German law healthcare is a universal right, and approximately 90% of the population is covered under the Statutory Health Insurance (SHI) or public plan, coverage decisions and payment are decentralized. Physicians who treat SHI patients must belong to a Kassenärztliche Vereinigung (KV) or Physician’s Association. There are 17 KVs in Germany, and the KVs are responsible for negotiating the budget with the State Sickness Fund for physician and facility payments for outpatient procedures in their region. Generally, procedures that are added to the EBM are covered and paid for by the KVs; however, this is not automatic and the process of achieving routine payment for a new procedure listed on the EBM can take several months. With several KVs, an application must be made to the KV by a surgeon in that area who wishes to perform the procedure. In some cases, the addition of a new outpatient procedure can create budget issues and there can be a delay while the KV negotiates additional funds with the State Sickness Fund to cover payment for the new procedure.

16

Surgeons in each of the states continue to work to gain KV approval so that claims are processed smoothly. While the majority of claims submitted to KVs in 2015 were processed and paid, some were denied. We are working with reimbursement consultants in Germany who have a successful track record of securing adequate payment for new medical technologies. In light of the strong favorable clinical data for iStent, we anticipate that reimbursement will continue to improve in Germany.

Under German law, if a person has an income above a certain level, that person can opt out of the SHI and obtain private insurance. Approximately 10% of Germans have opted out and are covered by private insurance companies. Each of these private insurance companies makes its own decisions on individual claims. In general, the private insurance companies cover and pay for outpatient procedures listed on the EBM and that has been our experience to date with iStent insertion.

We have also made significant progress in reimbursement in Switzerland where the procedure that describes iStent insertion is on the list of approved outpatient procedures. This also means that the costs of any implants or supplies used during these procedures can be passed through for payment. Like Germany, coverage and payment decisions are decentralized, with 26 cantons and numerous private insurers determining coverage. To date, the vast majority of claims for iStent procedures have been processed and paid with no issues.

In France, our application for a code to describe iStent insertion and our application to add the iStent to the list of devices approved for pass through payment were denied in 2013. Following the publication of data on iStent Inject, we submitted new applications for both devices in 2014. In November 2015, the French government approved the iStent application for reimbursement. Unless there is a code and listing on the pass through list, the only opportunity for payment for the iStent in France would result from successful negotiations at the individual hospital level. There can be no assurance that the French government will approve pass through payment for iStent even though iStent has been approved for reimbursement.

In the United Kingdom, Spain and Italy, there are no codes that specifically describe the insertion of a trabecular stent. We do not anticipate this changing in Spain and Italy in the near future. In addition, there is no mechanism to provide incremental payment for the iStent when insertion is in conjunction with cataract surgery. Our success to date relies on our distributors in these countries negotiating with individual hospitals to cover the cost of inserting the iStent.

Reimbursement in other regions

We currently market the iStent in Australia, New Zealand and Canada. In Australia, we have been successful at including the iStent and iStent Inject on the pass through list so that the cost of the device is paid separately. In New Zealand, the vast majority of the population is covered under a publicly‑funded, universal‑coverage health system, with services provided by public, private and non‑governmental sectors. We have yet to achieve significant success with any of the public and major private payors in New Zealand. In Canada, the iStent and iStent Inject is paid through individual hospital budgets for glaucoma implants. We have yet to achieve a special funding pathway for iStent and iStent Inject in Canada and we will be subject to the limitations of individual hospital budgets until Canadian Provinces provide a special funding pathway for our products.

Although we are not yet commercial in Japan, we believe that the current reimbursement structure that would apply to iStent insertion in conjunction with cataract surgery may support adequate reimbursement to both the facility and physician.

Competition

We are positioning our products and MIGS procedures for use instead of, or in combination with, prescription eye drop therapies that currently dominate the glaucoma treatment marketplace. To a lesser extent, we also compete with manufacturers of medical devices used in other surgical therapy procedures for treating glaucoma, including laser as well as more complex and invasive surgeries.

17

Many of our current and future competitors are large public companies or divisions of publicly‑traded companies and have several competitive advantages, including:

|

· |

greater financial and human resources for product development, sales and marketing and patent litigation; |

|

· |

significantly greater name recognition; |

|

· |

longer operating histories; |

|

· |

established relationships with healthcare professionals, customers and third‑party payors; |

|

· |

additional lines of products, and the ability to offer rebates or bundle products to offer higher discounts or incentives; |

|

· |

more established sales and marketing programs and distribution networks; and |

|

· |

greater experience in conducting research and development, manufacturing, clinical trials, preparing regulatory submissions and obtaining regulatory clearance or approval for drug and device products and marketing approved products. |

Companies with competing products include Alcon, Inc., a division of Novartis International AG (which has entered into a definitive agreement to acquire Transcend Medical, Inc. (Transcend), a MIGS competitor), Abbott Medical Optics Inc., Allergan plc (which has entered into a definitive merger agreement with Pfizer, Inc., pursuant to which the two companies intend to combine), STAAR Surgical Company, Lumenis Ltd., NeoMedix,Inc. and Ellex Medical Lasers Limited. Alcon, Inc. and Abbott Medical Optics Inc. are the leading manufacturers of aqueous shunts, and Alcon, Inc. also markets the EX‑PRESS Glaucoma Filtration Device and, upon its completion of the Transcend acquisition, will be a manufacturer of a MIGS device. Lumenis Ltd. is a leading manufacturer of SLT equipment. NeoMedix, Inc. markets an electrosurgical device and Ellex Medical Lasers Limited markets a canaloplasty device that some physicians employ to lower intraocular pressure in glaucoma.

In addition to these current competitors, we may also in the future compete with manufacturers of alternative technologies to treat glaucoma. We are aware of several companies, including Transcend (which has entered into a definitive agreement to be acquired by Alcon, Inc.), AqueSys, Inc. (which was recently acquired by Allergan plc, a publicly traded company, which has entered into a definitive merger agreement with Pfizer, Inc., pursuant to which the two companies intend to combine), InnFocus Inc. and Ivantis Inc., that are conducting FDA‑approved IDE clinical trials or have filed for regulatory approval of MIGS devices. These products or other products that may be developed could demonstrate better safety or effectiveness, clinical results, ease of use or lower costs than our iStent or other products under development. If approved for marketing, these devices may compete directly with the iStent and our products under development. If any of these alternative technologies gain market acceptance, this may reduce demand for our primary product, the iStent, as well as for our products in development.

In addition to competing for market share for our products, we also compete against these companies for personnel, including qualified sales representatives that are necessary to grow our business, as well as scientific and clinical personnel from universities and research institutions that are important to our research and development efforts.

We believe the principal competitive factors in our market include:

|

· |

improved outcomes for glaucoma; |

|

· |

acceptance by ophthalmic surgeons; |

|

· |

ease of use and reliability; |

|

· |

product price and availability of reimbursement; |

|

· |

technical leadership; |

|

· |

effective marketing and distribution; and |

18

|

· |

speed to market. |

Facilities, Manufacturing and Distribution