Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K DATED DECEMBER 30, 2009 - MTS SYSTEMS CORP | mts095898_8k.htm |

positioned

for opportunity

M T S S Y S T E M S C O R P O R A T I O N

ORDERS

BACKLOG

$500M

400

300

200

100

0

$250M

200

150

100

0

REVENUE

NET INCOME

$500M

400

300

200

100

0

$50M

40

30

20

10

0

DILUTED EPS

RETURN ON INVESTED

CAPITAL

$3.00

2.25

1.50

.75

0

25%

20

15

10

5

0

DEBT

CASH(1)

$40M

30

20

10

0

$200M

150

100

50

0

(1)Cash, cash equivalents and short-term investments.

financial highlights

2008

2009

(Expressed in thousands, except per share and percent data)

Revenue

$ 460,515

$ 408,881

Net income

$ 49,191

$ 17,394(2)

Earnings per share, diluted

$ 2.80

$ 1.03(2)

Cash provided by operating activities

$ 30,174

$ 43,838

Return on sales

10.7%

4.3%

Return on invested capital

22.3%

7.9%

Dividends per share

$ 0.60

$ 0.60

Weighted average shares outstanding, diluted

17,544

16,831

Orders

$ 485,274

$ 340,839

Backlog of orders at year-end

$ 234,710

$ 167,726

(2)Includes severance impact of $8.0M in net income & $0.48 earnings per share.

geographic revenue

2008

2009

SENSORS

Americas

27%

29%

Europe

50%

49%

Asia

23%

22%

TEST

Americas

39%

36%

Europe

29%

28%

Asia

32%

36%

positioned

MTS: 43 years strong. Where we’ve been and where we are

makes us feel more confident about where we’re going.

Our expertise, commitment to customers, and favorable

geographic and market presence position us well to

capture the opportunities ahead.

for opportunity

MTS technology and services help researchers, engineers and manufacturers design and develop higher-quality products faster and at a lower cost.

Our solutions are integral to industries ranging from aerospace engineering and clean energy to industrial manufacturing, mobile hydraulics, biomedical device development, and civil engineering.

3

A global focus on energy-efficiency and the

environment has created

new opportunity in

rail, wind and geothermal technology.

to our shareholders

Before we

gladly bid farewell to 2009, I want to write a brief chapter on this period of

MTS’ history because its

importance will be felt for years to come.

It was a difficult year, one of our most challenging.

Our purpose, People Committed to Building Confidence in Product Performance, has not changed. Our intent, to secure the next 40 years, has not changed. Our pursuit to be a great company has not changed.

As we move forward, our goal is not to return to the past. Rather, we must chart the next 10 years, delivering exceptional performance in the eyes of our customers, employees and shareholders. Strong strategy execution got us here and is the key to our future success.

We start this next era in a better position for having experienced and successfully managed through the worst economic decline in decades. Our stated goal was to exit the year stronger than we went in. We feel this is exactly what we did by aggressively realigning our business, appropriately resizing our company, and quickly making difficult choices, all while keeping a strong focus on our customers.

In Sensors, we continued our work to improve product performance, maintain competitive pricing and, working with our customers, develop new applications that improve the performance of their products. In Test, we quickly responded to the drop in the automotive industry, established flexible market development teams and reduced our cost base while making MTS easier to work with in the future. Across MTS, we are leveraging our expertise in legacy markets to drive growth in emerging areas such as renewable energy and China, where we see the greatest near-term growth potential.

Visit www.MTS.com/AR09/CEO.HTML

to watch brief videos of CEO

Laura B. Hamilton discussing MTS.

We experienced a 29.8% drop in orders, but with our strong backlog entering the year, our revenue decline was limited to 11.2%. Together with tough decisions to reduce our workforce, dramatically curtail spending, and more tightly manage our assets, we remained profitable with positive cash flow while confidently maintaining our dividend. We worked to make good choices that appropriately balanced short-term and long-term needs.

Despite the difficulties we faced, our customers, shareholders and employees stuck with us throughout 2009, which we take as a very positive sign. This was especially true for our people. The uncertainty, change and layoffs were stressful. MTS employees pulled together and focused on what could be done at a time when it would have been easy to do otherwise. They deserve the credit for our accomplishments in 2009.

5

China continues to be a bright

spot in the

world economy, and we have made the

necessary investments in both

Sensors and

Test to participate in their rapid expansion.

a new reality for our customers

It is a new day. Our customers are adjusting to the new economic reality while also addressing the macro-trends of energy, the environment and globalization. They are under extreme pressure to perform, which creates both new challenges and opportunities for us all.

Our markets have reset well below historical levels. Our customers are making less money, and in response they are driving cost reduction, eliminating non-value-added work and being more selective in their investments. They are also experiencing increased competition. Everyone is going after a bigger piece of a smaller pie.

While this creates challenges for MTS, it also creates opportunity. In response to increased competition, our customers are pushing their organizations to develop fresher products, faster. They are increasingly turning to technology to differentiate — creating higher-performing, more energy-efficient, and “greener” offerings.

positioned for opportunity

So what does the future look like for MTS? The economic picture is mixed and has yet to fully play out. It will take time for the U.S., Europe, Japan, Korea and other regions to work through the many structural issues that still exist. At the same time, successful companies are moving forward to address the challenges and capture the opportunities. While the timing for meaningful economic growth remains unclear, we are confident that MTS is positioned to capitalize on the opportunities ahead.

In Sensors, we will not let up on our pursuit for increased performance while reducing cost. Together with our applications support, we have enabled machine builders around the world in steel, plastics, and

energy production to improve the efficiency of their machines and reduce the total cost of ownership for their customers. In Test, our applications expertise and real-life simulation capabilities are helping build confidence for our customers as they change materials to make greener engines that burn at higher temperatures, and as they change designs to make safer structures while removing weight.

We are excited about the opportunities to work with our customers on new applications in Sensors’ industrial and mobile hydraulics markets, and to address challenges like cost, energy and the environment. In Test, we continue to see opportunity to partner with our customers in product leadership and lifecycle management, where we can build confidence in product performance faster and more effectively. And, in both businesses, we see broad opportunity in China – whether in infrastructure investment like steel and rail, or in capability-building like automotive and plastic machine manufacturing. Across MTS, we are well positioned to help our customers successfully move forward.

We are

proud of what we accomplished in 2009.

We are pleased with our strong position

today.

We are

prepared to make the most of 2010 and beyond.

Chair and Chief Executive Officer

7

MTS solutions enable more

precise and repeatable

testing in extreme operating

environments, equipping our

customers to meet the demand

for energy-efficient products.

INDUSTRIES

» Aerospace

» Biomedical

» Clean energy

» Ground vehicles

» Geomechanical, civil and seismic engineering

» Rail

MTS ADVANTAGES

» Application knowledge

» Technology leadership

» Comprehensive offerings

» Worldwide service and consultation

» Standard and custom solutions

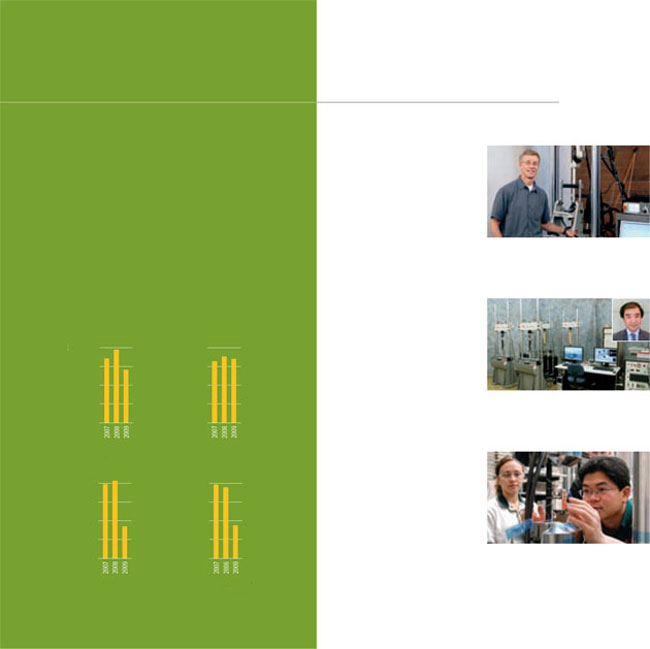

test

Test professionals rely on MTS expertise and technology to optimize their designs, improve productivity and enhance time-to-market performance. Our integrated solutions are globally recognized for enabling the efficient characterization of materials, components, subsystems and full-scale prototypes.

The comprehensive MTS offering of testing hardware, software and global support includes both standard tools and custom solutions, which are used worldwide by customers ranging from suppliers and researchers to large manufacturers.

$400M

$400M

300

300

200

200

100

100

0

0

ORDERS

REVENUE

$ millions

$ millions

$40M

30

20

10

0

12%

9

6

3

0

INCOME FROM

INCOME FROM

OPERATIONS

OPERATIONS

$ millions

$ millions

what our customers are saying

“We are now able to evaluate prototypes much earlier and launch better products sooner. Our partnership with MTS was instrumental in making this possible.”

Eric Rubie

President

Stealth Companies

“MTS technology allows us to uncover and resolve unknown items of quality function development (QFD) during the preparation stage, reducing our vehicle testing time by at least one month.”

Yoichi Sakai

Head Representative for

System

Experimental Development

Nissan Motor Co., Ltd.

“MTS has been a dependable partner from the very beginning, always going the extra mile to ensure we receive the equipment and support required.”

Lamia Salah (pictured on

left)

Manager

Wichita State University

National Institute

for Aviation Research

(NIAR)

9

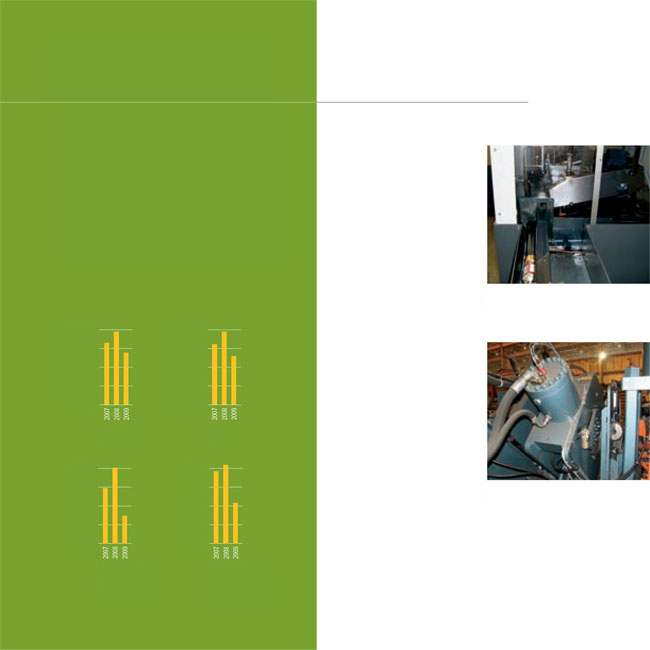

New MTS triple-redundant

sensor technology simplifies

programming and virtually

eliminates recalibration for our

customers in applications such

as hydroturbine manufacturing,

automated welding and more.

INDUSTRIES

» Fluid power

» Fuel storage

» Medical products

» Metals

» Mobile equipment

» Plastics

» Wind and clean energy

» Wood processing

MTS ADVANTAGES

» Exclusive technologies in magnetostriction sensing

» Unrivaled application expertise

» Worldwide service and consultation

sensors

Highly precise and durable MTS position

and velocity sensors help fixed and mobile

equipment manufacturers automate their

machine functions. Leveraging exclusive

magnetostrictive technology, our sensors

allow customers to achieve high levels of

manufacturing speed, safety and efficiency.

$100M

75

50

25

0

ORDERS

$ millions

$100M

75

50

25

0

REVENUE

$ millions

$20M

15

10

5

0

INCOME FROM

OPERATIONS

$ millions

20%

15

10

5

0

INCOME FROM

OPERATIONS

as percent of revenue

what our customers are saying

“After having integrated sensors from

MTS, the profitability of our machines

has grown by 30 percent on average.

The sensor is actually the most

economic component of the machine.”

Oliver Hoffman

Managing Director

Hoffmann Sondermaschinenbau

“Our customers are demanding

machines with repeatability,

accuracy and

minimum downtime.

Since we switched to MTS EtherCAT

transducers, our FMI

machines have

improved in each of these three

areas. FMI has full confidence in

the

MTS product and will continue to

use it on future machines.”

Ken Carson

Franklin Manufacturing

11

corporate information

|

|

|

|

|

|

Board of Directors |

Executive Management |

Investor Relations |

Corporate Headquarters |