Attached files

| file | filename |

|---|---|

| 8-K - 8-K - FLOTEK INDUSTRIES INC/CN/ | a102720fd8k.htm |

Chemistries for Improved Asset Performance & Economics 2020 SPE Annual Technology Conference & Exhibition October 2020

Forward Looking Statements

The FlotekWay PROVEN CHEMISTRY We Provide Chemistry Solutions that Improve TECHNOLOGY Asset Performance & Economics 10,000+ Wells around theworld Reservoir-centric Chemistries and Services that Provide More Efficient Acreage Development, Driving Lower Capital Intensity Reservoir-First Approach Data Drives Seemless Delivery System-Optimized Focused on Results Our Partnership From Lab-to-Field A holistic approach to fluid Applying deep knowledge of the Underlying every chemistry Providing best-in-class field operations, systems at optimized dosages reservoir to develop & deliver recommendation is rigorous lab, world-class chemistries and fluid for improved economics and chemistry technologies that optimize field and economic performance systems applications for the reservoir, performance capital efficiency, maximize asset data – acquiring real-time analysis of relentlessly focused on quality performance & increase ROI hydrocarbon quality through in-line, sensor technology 3

Custom Chemistry Through all Phases of the Lifecycle Flotek chemistry systems have created value by enhancing production in unconventional basins across the United States and Canada Applications Initial Well Parent Well Well Remediation EOR Stimulation Frac Protection Drilling Frac’ing Production Remediation Enhanced Waterflooding 4

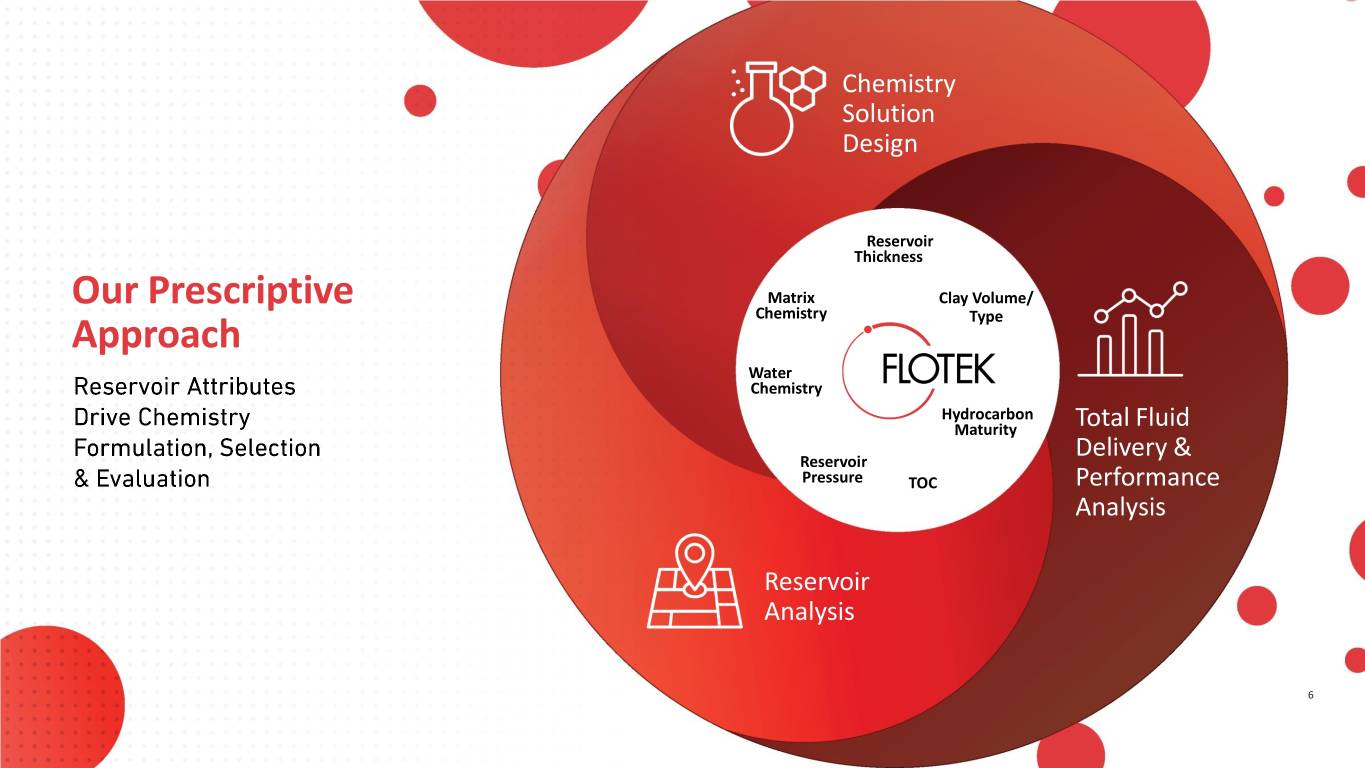

Chemistry Solution Design Our Prescriptive Approach Total Fluid Delivery & Performance Analysis Reservoir Analysis 5

Chemistry Solution Design Reservoir Thickness Our Prescriptive Matrix Clay Volume/ Chemistry Approach Type Water Chemistry Hydrocarbon Maturity Total Fluid Delivery & Reservoir Pressure TOC Performance Analysis Reservoir Analysis 6

Flotek Chemistries across North America and Basins around the World. Relentless Focus on Performance through Data We hold ourselves to the highest standards to evaluate the performance of our chemistries Polygon-level performance analysis driven by reservoir attributes Performance data validated through proprietary E&P data and high-quality public data. 7

Case Studies 8

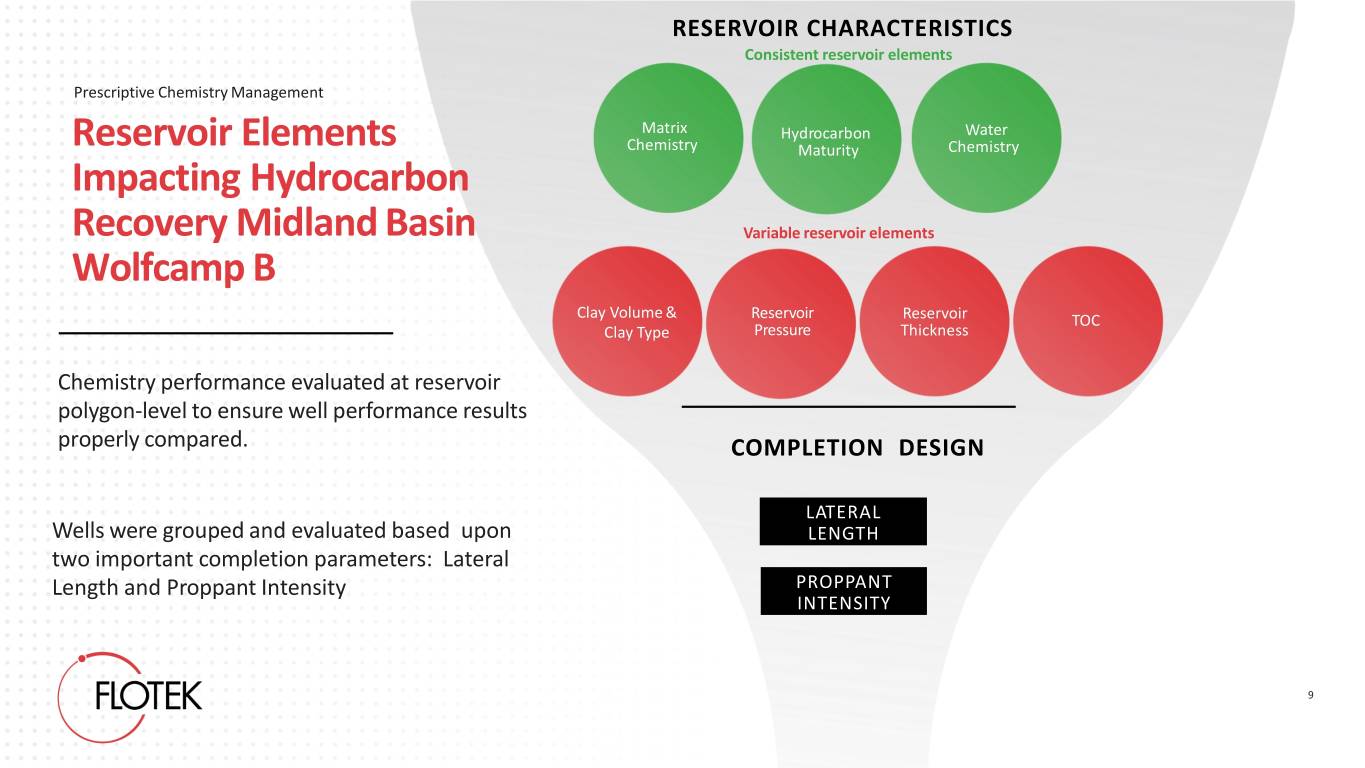

RESERVOIR CHARACTERISTICS Consistent reservoir elements Prescriptive Chemistry Management Matrix Hydrocarbon Water Reservoir Elements Chemistry Maturity Chemistry Impacting Hydrocarbon Recovery Midland Basin Variable reservoir elements Wolfcamp B Clay Volume & Reservoir Reservoir TOC Clay Type Pressure Thickness Chemistry performance evaluated at reservoir polygon-level to ensure well performance results properly compared. COMPLETION DESIGN LATERAL Wells were grouped and evaluated based upon LENGTH two important completion parameters: Lateral Length and Proppant Intensity PROPPANT INTENSITY 9

Prescriptive Chemistry Management Stimulation Case Study Midland Basin Wolfcamp B Improved Hydrocarbon Recovery More Predictable Recovery P = Probability 10 6,500 TO 8,500 FT WELLS | 2,000 TO 3,000 (lbs./ft) PROPPANT INTENSITY

Prescriptive Chemistry Management Stimulation Case Study Midland Basin Wolfcamp B Improved Hydrocarbon Recovery More Predictable Recovery P = Probability 11 9,000 TO 11,000 FT WELLS – 2,000 TO 3,000 (lbs./ft) PROPPANT INTENSITY

Prescriptive Chemistry Management Stimulation Case Study Midland Basin Wolfcamp B Improved Hydrocarbon Recovery More Predictable Recovery P = Probability 12 6,500 TO 8,500 FT WELLS | 2,500 TO 3,500 (lbs./ft) PROPPANT INTENSITY

The Pursuit of Transformative Chemistry Introducing StimOil® Q801 Performance chemistry built to mobilize hydrocarbons in quartz- dominant reservoirs Proven performance in Wolfcamp B in the Midland Basin Combining the power of solvents and surfactants to mobilize hydrocarbons 13 6,500 TO 8,500 FT WELLS | 2,500 TO 3,500 (lbs./ft) PROPPANT INTENSITY

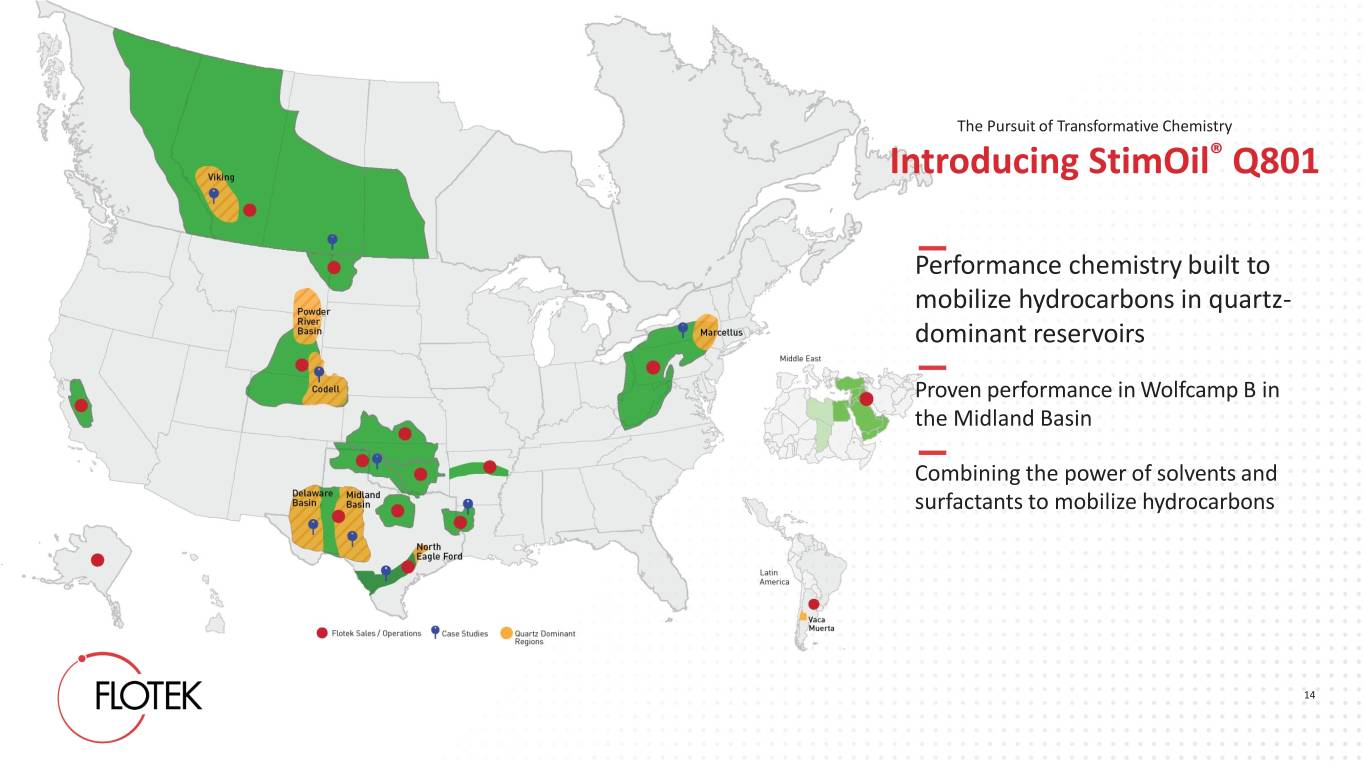

The Pursuit of Transformative Chemistry Introducing StimOil® Q801 Performance chemistry built to mobilize hydrocarbons in quartz- dominant reservoirs Proven performance in Wolfcamp B in the Midland Basin Combining the power of solvents and surfactants to mobilize hydrocarbons 14

The Pursuit of Transformative Chemistry Parent Well Case Study Prevention and Remediation FDI (Fracture Driven Interaction) can Hydraulic fractures and interconnected frac FDI can have positive or negative physically damage well integrity in extreme networks (whether complex or not) can effects on production, temporary or cases, and cause sand/proppant production provide conductive fluid pathways for FDI to long-term into the wellbore occur. Complexity can facilitate or hinder a FDI, depending if conductive interconnection occurs. Primary wells in formations that are Primary wells with more depletion tend to Total production from the primary/infill over-pressurized tend to experience experience negative FDIs combo can be lower than expected if positive FDIs, and vice-versa FDIs do occur 15

The Pursuit of Transformative Chemistry Parent Well Case Study - Southern Eagle Ford Shale Eagle Ford Reservoir-Centric Prescribed Pre-Soak Karnes County The Pre-Load Technique Is Simple • Large Volume • Pre-load two wells, • Put primary wells on-line And Follows The Basic Recipe Of: regardless of distance immediately after infill frac • Low Rate • Pre-load infill wells • Pre-load as close to start of on frac plane frac as possible Data Source: SPE 191712-MS | BHP 16

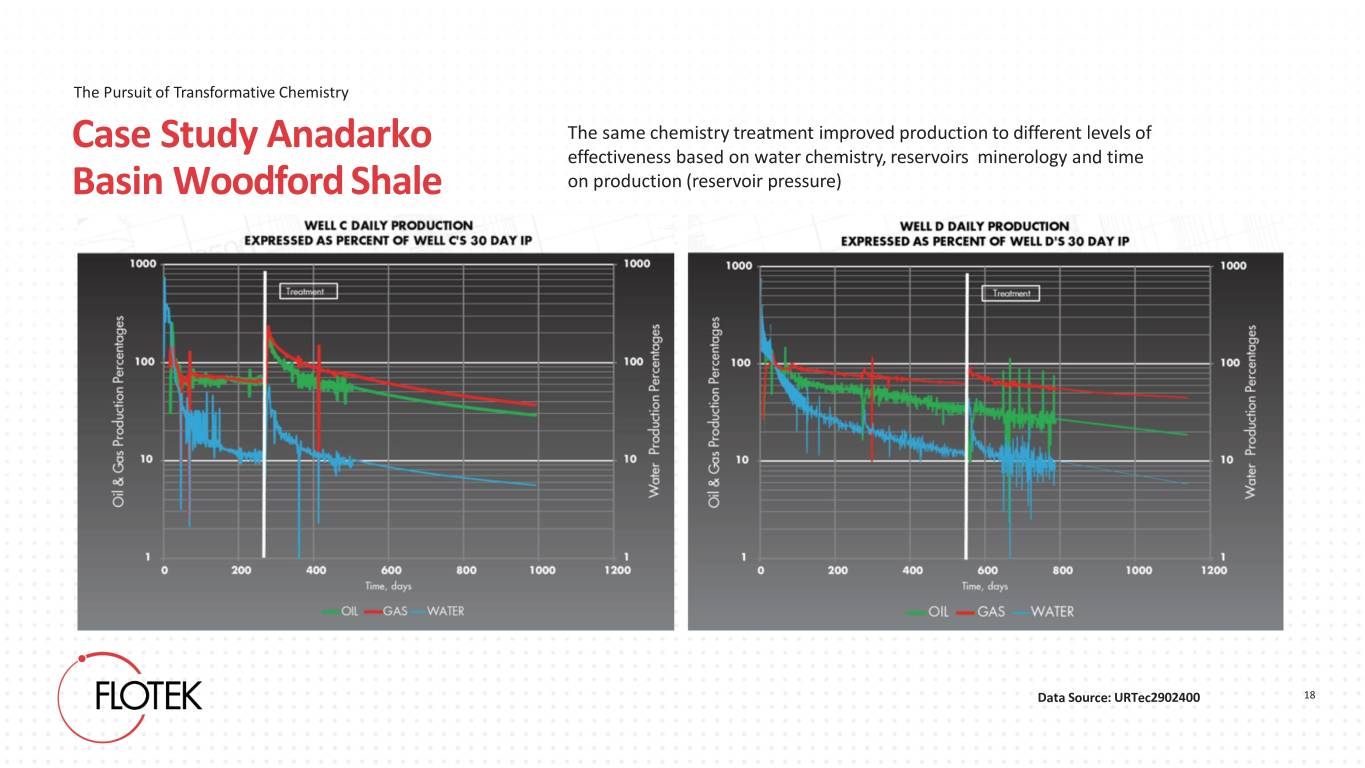

The Pursuit of Transformative Chemistry Parent Well - Remediation Case Study Anadarko Basin WoodfordShale Well remediation should consider the formation the following: • Reservoir Mineralogy • Bottom Hole Temperature and Pressure • Reservoir Fluid Chemistry • Corrosion Concerns • Suspected Damage Mechanisms UNDERPERF ORMING WELLS Properties Well C Well D Calcite 5.1 5.3 Chlorite 0.3 0.1 Illite 28.6 42.2 Illite & Illite-Smectite - - Fe-Illite & Illite-Smectite - - Quartz 48.1 32.7 Mineralogy and water chemistry Data Source: URTec2902400 17 varied between remediated wells

The Pursuit of Transformative Chemistry Case Study Anadarko The same chemistry treatment improved production to different levels of effectiveness based on water chemistry, reservoirs minerology and time Basin Woodford Shale on production (reservoir pressure) Data Source: URTec2902400 18

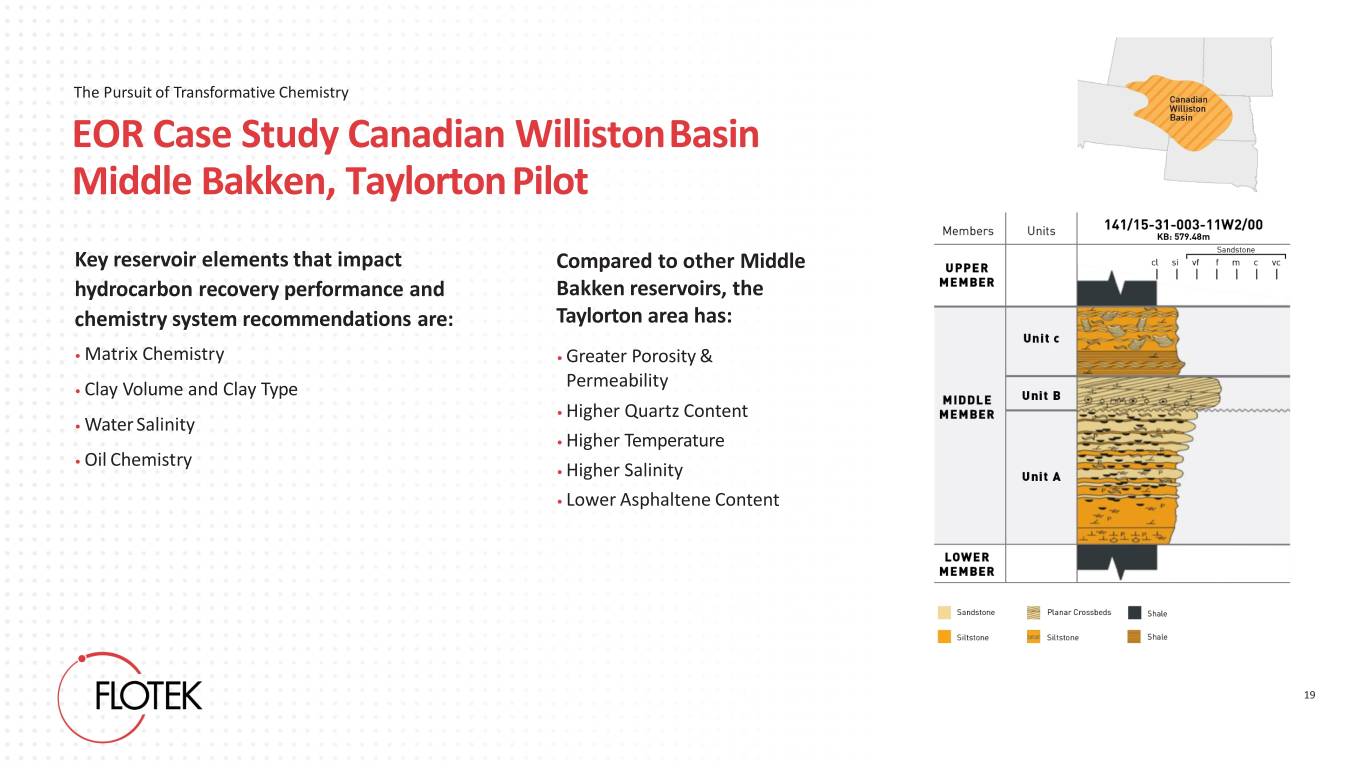

The Pursuit of Transformative Chemistry EOR Case Study Canadian WillistonBasin Middle Bakken, TaylortonPilot Key reservoir elements that impact Compared to other Middle hydrocarbon recovery performance and Bakken reservoirs, the chemistry system recommendations are: Taylorton area has: • Matrix Chemistry • Greater Porosity & Permeability • Clay Volume and Clay Type • Higher Quartz Content • Water Salinity • Higher Temperature • Oil Chemistry • Higher Salinity • Lower Asphaltene Content 19

The Pursuit of Transformative Chemistry EOR Case Study Canadian Williston Basin Middle Bakken, TaylortonPilot RESULTS & OBSERVATIONS Oil Rate ↑ >70% Water Rate ↓ 15% Oil Cut ↑ from 21.1% up to 35.1% 20

Questions?? Contact us at: sales@flotekind.com www. flotekind.com 713-849-9911