Attached files

| file | filename |

|---|---|

| EX-31.1 - CEO CERTIFICATION - FLOTEK INDUSTRIES INC/CN/ | exhibit311-10q09302015.htm |

| EX-32.1 - CEO 906 CERTIFICATION - FLOTEK INDUSTRIES INC/CN/ | exhibit321-10q09302015.htm |

| EX-32.2 - CFO 906 CERTIFICATION - FLOTEK INDUSTRIES INC/CN/ | exhibit322-10q09302015.htm |

| EX-31.2 - CFO CERTIFICATION - FLOTEK INDUSTRIES INC/CN/ | exhibit312-10q09302015.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-Q |

x | QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the quarterly period ended September 30, 2015

or

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 1-13270

FLOTEK INDUSTRIES, INC. (Exact name of registrant as specified in its charter) |

Delaware | 90-0023731 | |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) | |

10603 W. Sam Houston Parkway N., Suite 300 Houston, TX | 77064 | |

(Address of principal executive offices) | (Zip Code) | |

(713) 849-9911

(Registrant’s telephone number, including area code)

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer | x | Accelerated filer | ¨ | |||

Non-accelerated filer | ¨ (Do not check if a smaller reporting company) | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

As of October 15, 2015, there were 53,627,361 outstanding shares of Flotek Industries, Inc. common stock, $0.0001 par value.

TABLE OF CONTENTS

2

PART I — FINANCIAL INFORMATION

Item 1. Financial Statements

FLOTEK INDUSTRIES, INC.

UNAUDITED CONSOLIDATED BALANCE SHEETS

(in thousands, except share data)

September 30, 2015 | December 31, 2014 | ||||||

ASSETS | |||||||

Current assets: | |||||||

Cash and cash equivalents | $ | 2,998 | $ | 1,266 | |||

Accounts receivable, net of allowance for doubtful accounts of $910 and $847 at September 30, 2015 and December 31, 2014, respectively | 52,069 | 78,624 | |||||

Inventories | 84,421 | 85,958 | |||||

Income taxes receivable | 1,704 | — | |||||

Deferred tax assets, net | 1,835 | 2,696 | |||||

Other current assets | 9,417 | 11,055 | |||||

Total current assets | 152,444 | 179,599 | |||||

Property and equipment, net | 85,835 | 86,111 | |||||

Goodwill | 72,820 | 71,131 | |||||

Deferred tax assets, net | 19,392 | 12,907 | |||||

Other intangible assets, net | 70,454 | 73,528 | |||||

TOTAL ASSETS | $ | 400,945 | $ | 423,276 | |||

LIABILITIES AND EQUITY | |||||||

Current liabilities: | |||||||

Accounts payable | $ | 22,046 | $ | 33,185 | |||

Accrued liabilities | 12,611 | 12,314 | |||||

Income taxes payable | — | 1,307 | |||||

Interest payable | 93 | 93 | |||||

Current portion of long-term debt | 27,727 | 18,643 | |||||

Total current liabilities | 62,477 | 65,542 | |||||

Long-term debt, less current portion | 20,041 | 25,398 | |||||

Deferred tax liabilities, net | 22,910 | 25,982 | |||||

Total liabilities | 105,428 | 116,922 | |||||

Commitments and contingencies | |||||||

Equity: | |||||||

Cumulative convertible preferred stock, $0.0001 par value, 100,000 shares authorized; no shares issued and outstanding | — | — | |||||

Common stock, $0.0001 par value, 80,000,000 shares authorized; 56,126,314 shares issued and 53,624,592 shares outstanding at September 30, 2015; 54,633,726 shares issued and 53,357,811 shares outstanding at December 31, 2014 | 6 | 5 | |||||

Additional paid-in capital | 269,807 | 254,233 | |||||

Accumulated other comprehensive income (loss) | (1,033 | ) | (502 | ) | |||

Retained earnings | 40,675 | 52,762 | |||||

Treasury stock, at cost; 1,452,434 and 449,397 shares at September 30, 2015 and December 31, 2014, respectively | (14,296 | ) | (495 | ) | |||

Flotek Industries, Inc. stockholders’ equity | 295,159 | 306,003 | |||||

Noncontrolling interests | 358 | 351 | |||||

Total equity | 295,517 | 306,354 | |||||

TOTAL LIABILITIES AND EQUITY | $ | 400,945 | $ | 423,276 | |||

See accompanying Notes to Unaudited Consolidated Financial Statements.

3

FLOTEK INDUSTRIES, INC.

UNAUDITED CONSOLIDATED STATEMENTS OF OPERATIONS

(in thousands, except per share data)

Three months ended September 30, | Nine months ended September 30, | ||||||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||||||

Revenue | $ | 87,942 | $ | 116,761 | $ | 257,346 | $ | 324,653 | |||||||

Cost of revenue | 56,715 | 70,683 | 170,340 | 192,585 | |||||||||||

Gross profit | 31,227 | 46,078 | 87,006 | 132,068 | |||||||||||

Expenses: | |||||||||||||||

Selling, general and administrative | 23,634 | 21,499 | 70,223 | 63,924 | |||||||||||

Depreciation and amortization | 2,785 | 2,439 | 8,258 | 7,225 | |||||||||||

Research and development | 2,031 | 1,293 | 5,273 | 3,599 | |||||||||||

Impairment of inventory and rental equipment | — | — | 20,372 | — | |||||||||||

Total expenses | 28,450 | 25,231 | 104,126 | 74,748 | |||||||||||

Income (loss) from operations | 2,777 | 20,847 | (17,120 | ) | 57,320 | ||||||||||

Other income (expense): | |||||||||||||||

Interest expense | (476 | ) | (424 | ) | (1,303 | ) | (1,259 | ) | |||||||

Other income (expense), net | 74 | (87 | ) | (154 | ) | (306 | ) | ||||||||

Total other income (expense) | (402 | ) | (511 | ) | (1,457 | ) | (1,565 | ) | |||||||

Income (loss) before income taxes | 2,375 | 20,336 | (18,577 | ) | 55,755 | ||||||||||

Income tax (expense) benefit | (400 | ) | (6,064 | ) | 6,490 | (18,425 | ) | ||||||||

Net income (loss) | $ | 1,975 | $ | 14,272 | $ | (12,087 | ) | $ | 37,330 | ||||||

Earnings (loss) per common share: | |||||||||||||||

Basic earnings (loss) per common share | $ | 0.04 | $ | 0.26 | $ | (0.22 | ) | $ | 0.69 | ||||||

Diluted earnings (loss) per common share | $ | 0.04 | $ | 0.26 | $ | (0.22 | ) | $ | 0.67 | ||||||

Weighted average common shares: | |||||||||||||||

Weighted average common shares used in computing basic earnings (loss) per common share | 54,578 | 54,789 | 54,430 | 54,464 | |||||||||||

Weighted average common shares used in computing diluted earnings (loss) per common share | 54,947 | 55,690 | 54,430 | 55,536 | |||||||||||

See accompanying Notes to Unaudited Consolidated Financial Statements.

4

FLOTEK INDUSTRIES, INC.

UNAUDITED CONSOLIDATED STATEMENTS OF COMPREHENSIVE INCOME

(in thousands)

Three months ended September 30, | Nine months ended September 30, | ||||||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||||||

Net income (loss) | $ | 1,975 | $ | 14,272 | $ | (12,087 | ) | $ | 37,330 | ||||||

Other comprehensive income (loss): | |||||||||||||||

Foreign currency translation adjustment | (366 | ) | (67 | ) | (531 | ) | (38 | ) | |||||||

Comprehensive income (loss) | $ | 1,609 | $ | 14,205 | $ | (12,618 | ) | $ | 37,292 | ||||||

See accompanying Notes to Unaudited Consolidated Financial Statements.

5

FLOTEK INDUSTRIES, INC.

UNAUDITED CONSOLIDATED STATEMENTS OF CASH FLOWS

(in thousands)

Nine months ended September 30, | |||||||

2015 | 2014 | ||||||

Cash flows from operating activities: | |||||||

Net income (loss) | $ | (12,087 | ) | $ | 37,330 | ||

Adjustments to reconcile net income (loss) to net cash provided by operating activities: | |||||||

Impairment of inventory and rental equipment | 20,372 | — | |||||

Depreciation and amortization | 13,613 | 13,276 | |||||

Amortization of deferred financing costs | 260 | 257 | |||||

Gain on sale of assets | (3,010 | ) | (2,552 | ) | |||

Stock compensation expense | 10,479 | 7,429 | |||||

Deferred income tax (benefit) expense | (8,696 | ) | 237 | ||||

Excess tax benefit related to share-based awards | (2,154 | ) | (3,425 | ) | |||

Changes in current assets and liabilities: | |||||||

Restricted cash | — | (450 | ) | ||||

Accounts receivable, net | 26,555 | (3,896 | ) | ||||

Inventories | (16,294 | ) | (18,035 | ) | |||

Income taxes receivable | (1,704 | ) | — | ||||

Other current assets | 1,799 | (4,957 | ) | ||||

Accounts payable | (11,139 | ) | 12,617 | ||||

Accrued liabilities | (1,045 | ) | 1,019 | ||||

Income taxes payable | 847 | 1,082 | |||||

Interest payable | — | (35 | ) | ||||

Net cash provided by operating activities | 17,796 | 39,897 | |||||

Cash flows from investing activities: | |||||||

Capital expenditures | (11,078 | ) | (13,494 | ) | |||

Proceeds from sale of assets | 3,225 | 3,322 | |||||

Payments for acquisitions, net of cash acquired | (1,250 | ) | (5,704 | ) | |||

Purchase of patents and other intangible assets | (434 | ) | (780 | ) | |||

Net cash used in investing activities | (9,537 | ) | (16,656 | ) | |||

Cash flows from financing activities: | |||||||

Repayments of indebtedness | (8,357 | ) | (8,506 | ) | |||

Borrowings on revolving credit facility | 291,916 | 305,750 | |||||

Repayments on revolving credit facility | (279,832 | ) | (317,798 | ) | |||

Debt issuance costs | (10 | ) | (256 | ) | |||

Excess tax benefit related to share-based awards | 2,154 | 3,425 | |||||

Purchase of treasury stock related to share-based awards | (5,376 | ) | (6,060 | ) | |||

Proceeds from sale of common stock | 779 | 763 | |||||

Repurchase of common stock | (7,299 | ) | — | ||||

Proceeds from exercise of stock options | 22 | 461 | |||||

Proceeds from exercise of stock warrants | — | 1,545 | |||||

Proceeds from noncontrolling interest | 7 | — | |||||

Net cash used in financing activities | (5,996 | ) | (20,676 | ) | |||

Effect of changes in exchange rates on cash and cash equivalents | (531 | ) | (38 | ) | |||

Net increase in cash and cash equivalents | 1,732 | 2,527 | |||||

Cash and cash equivalents at the beginning of period | 1,266 | 2,730 | |||||

Cash and cash equivalents at the end of period | $ | 2,998 | $ | 5,257 | |||

See accompanying Notes to Unaudited Consolidated Financial Statements.

6

FLOTEK INDUSTRIES, INC.

UNAUDITED CONSOLIDATED STATEMENT OF EQUITY

(in thousands)

Common Stock | Treasury Stock | Additional Paid-in Capital | Accumulated Other Comprehensive Income (Loss) | Retained Earnings | Non-controlling Interests | Total Equity | |||||||||||||||||||||||||||

Shares Issued | Par Value | Shares | Cost | ||||||||||||||||||||||||||||||

Balance, December 31, 2014 | 54,634 | $ | 5 | 449 | $ | (495 | ) | $ | 254,233 | $ | (502 | ) | $ | 52,762 | $ | 351 | $ | 306,354 | |||||||||||||||

Net income (loss) | — | — | — | — | — | — | (12,087 | ) | — | (12,087 | ) | ||||||||||||||||||||||

Foreign currency translation adjustment | — | — | — | — | — | (531 | ) | — | — | (531 | ) | ||||||||||||||||||||||

Stock issued under employee stock purchase plan | — | — | (55 | ) | — | 779 | — | — | — | 779 | |||||||||||||||||||||||

Stock options exercised | 736 | 1 | — | — | 1,148 | — | — | — | 1,149 | ||||||||||||||||||||||||

Stock surrendered for exercise of stock options | — | — | 88 | (1,126 | ) | — | — | — | — | (1,126 | ) | ||||||||||||||||||||||

Restricted stock granted | 696 | — | — | — | — | — | — | — | — | ||||||||||||||||||||||||

Restricted stock forfeited | — | — | 24 | — | — | — | — | — | — | ||||||||||||||||||||||||

Treasury stock purchased | — | — | 396 | (5,376 | ) | — | — | — | — | (5,376 | ) | ||||||||||||||||||||||

Stock compensation expense | — | — | — | — | 10,479 | — | — | — | 10,479 | ||||||||||||||||||||||||

Excess tax benefit related to share-based awards | — | — | — | — | 2,154 | — | — | — | 2,154 | ||||||||||||||||||||||||

Investment in Flotek Gulf, LLC and Flotek Gulf Research, LLC | — | — | — | — | — | — | — | 7 | 7 | ||||||||||||||||||||||||

Stock issued in IAL acquisition | 60 | — | — | — | 1,014 | — | — | — | 1,014 | ||||||||||||||||||||||||

Repurchase of common stock | — | — | 550 | (7,299 | ) | — | — | — | — | (7,299 | ) | ||||||||||||||||||||||

Balance, September 30, 2015 | 56,126 | $ | 6 | 1,452 | $ | (14,296 | ) | $ | 269,807 | $ | (1,033 | ) | $ | 40,675 | $ | 358 | $ | 295,517 | |||||||||||||||

See accompanying Notes to Unaudited Consolidated Financial Statements.

7

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 1 — Organization and Significant Accounting Policies

Organization and Nature of Operations

Flotek Industries, Inc. (“Flotek” or the “Company”) is a global, diversified, technology-driven supplier of energy chemistries and consumer and industrial chemistries and is a global developer and supplier of drilling, completion, and production technologies and related services.

The Company’s strategic focus includes energy related chemistry technologies, drilling and production technologies, and consumer and industrial chemistry technologies. Within its energy related technologies, the Company provides oilfield specialty chemistries and logistics, downhole drilling tools, and production related tools used in the energy and mining industries. Flotek’s products and services enable customers to drill wells more efficiently, to realize increased production from both new and existing wells, and to decrease future well operating costs. Major customers include leading oilfield service providers, pressure-pumping service companies, onshore and offshore drilling contractors, major and independent oil and gas exploration and production companies, national and state-owned oil companies, and international supply chain management companies. Within consumer and industrial chemistry technologies, the Company provides products for the flavor and fragrance industry and the industrial chemical industry. Major customers include food and beverage companies, fragrance companies, and companies providing household and industrial cleaning products.

The Company is headquartered in Houston, Texas, with operating locations in Florida, Louisiana, New Mexico, North Dakota, Oklahoma, Colorado, Pennsylvania, Texas, Utah, Wyoming, Canada, the Netherlands, and the Middle East. Flotek’s products are marketed both domestically and internationally, with international presence and/or representation in over 20 countries.

Flotek was initially incorporated under the laws of the Province of British Columbia on May 17, 1985. On October 23, 2001, Flotek changed its corporate domicile to the state of Delaware.

Basis of Presentation

The accompanying Unaudited Consolidated Financial Statements and accompanying footnotes (collectively the “Financial Statements”) reflect all adjustments, in the opinion of management, necessary for fair presentation of the financial condition and results of operations for the periods presented. All such adjustments are normal and recurring in nature. The Financial Statements, including selected notes, have been prepared in accordance with applicable rules and regulations of the Securities and Exchange Commission (“SEC”) regarding interim financial reporting and do not include all information and disclosures required by accounting principles generally accepted in the United States of America (“U.S. GAAP”) for comprehensive financial statement reporting. These interim Financial Statements should be read in conjunction with the audited consolidated financial statements and notes included in the Company’s Annual Report on Form 10-K for the fiscal year ended December 31, 2014 (“Annual Report”). A copy of the Annual Report is available on the SEC’s website, www.sec.gov, under the Company’s ticker symbol (“FTK”) or on Flotek’s website, www.flotekind.com. The results of operations for the three and nine months ended September 30, 2015, are not necessarily indicative of the results to be expected for the year ending December 31, 2015.

Use of Estimates

The preparation of financial statements in conformity with U.S. GAAP requires management to make estimates and assumptions that affect reported amounts of assets and liabilities, disclosure of contingent assets and liabilities, and reported amounts of revenue and expenses. Actual results could differ from these estimates.

Reclassifications

Certain prior period amounts have been reclassified to conform to the current period presentation. The reclassifications did not impact net income (loss).

8

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 2 — Recent Accounting Pronouncements

(a) Application of New Accounting Standards

Effective January 1, 2015, the Company adopted the accounting guidance in Accounting Standards Update (“ASU”) No. 2014-08, “Presentation of Financial Statements and Property, Plant, and Equipment - Reporting Discontinued Operations and Disclosures of Disposals of Components of an Entity,” which amends the definition of a discontinued operation by raising the threshold for a disposal to qualify as discontinued operations. The ASU will also require entities to provide additional disclosures about discontinued operations as well as disposal transactions that do not meet the discontinued operations criteria. Implementation of this standard did not have a material effect on the consolidated financial statements.

Effective January 1, 2015, the Company adopted the accounting guidance in ASU No. 2014-12, “Accounting for Share-Based Payments When the Terms of an Award Provide That a Performance Target Could Be Achieved after the Requisite Service Period.” The ASU requires that a performance target that affects vesting and that could be achieved after the requisite service period be treated as a performance condition. As such, the performance target should not be reflected in estimating the grant-date fair value of the award. Implementation of this standard did not have a material effect on the consolidated financial statements or the Company’s current awards under its existing stock-based compensation plans.

(b) New Accounting Requirements and Disclosures

In May 2014, the Financial Accounting Standards Board (“FASB”) issued ASU No. 2014-09, “Revenue from Contracts with Customers.” The ASU will supersede most of the existing revenue recognition requirements in U.S. GAAP and will require entities to recognize revenue at an amount that reflects the consideration to which the Company expects to be entitled in exchange for transferring goods or services to a customer. The new standard also requires significantly expanded disclosures regarding the qualitative and quantitative information of an entity’s nature, amount, timing, and uncertainty of revenue and cash flows arising from contracts with customers. In August 2015, the FASB issued ASU No. 2015-14, which deferred the effective date by one year to annual reporting periods beginning after December 15, 2017, including interim periods within that reporting period. Early adoption is permitted, but not before the original effective date of reporting periods beginning after December 15, 2016. The Company is currently evaluating the impact the pronouncement will have on the consolidated financial statements and related disclosures.

In January 2015, the FASB issued ASU No. 2015-01, “Simplifying Income Statement Presentation by Eliminating the Concept of Extraordinary Items.” This ASU eliminates from U.S. GAAP the concept of extraordinary items and the need for an entity to separately classify, present, and disclose extraordinary events and transactions, while retaining certain presentation and disclosure guidance for items that are unusual in nature or occur infrequently. The pronouncement is effective for annual reporting periods beginning after December 15, 2015, including interim periods within that reporting period and may be applied retrospectively, with early application permitted. The Company is currently evaluating the impact the pronouncement will have on the consolidated financial statements and related disclosures.

In February 2015, the FASB issued ASU No. 2015-02, “Amendments to the Consolidation Analysis.” The amendment eliminates the deferral of certain consolidation standards for entities considered to be investment companies and modifies the consolidation analysis performed on certain types of legal entities. The pronouncement is effective for annual reporting periods beginning after December 15, 2015, including interim periods within that reporting period and may be applied retrospectively, with early application permitted. The Company is currently evaluating the impact the pronouncement will have on the consolidated financial statements and related disclosures.

In April 2015, the FASB issued ASU No. 2015-03, “Simplifying the Presentation of Debt Issuance Costs.” The accounting guidance requires that debt issuance costs related to a recognized debt liability be reported on the Consolidated Statements of Financial Condition as a direct deduction from the carrying amount of that debt liability. The pronouncement is effective for annual reporting periods beginning after December 15, 2015, including interim periods within that reporting period with early application permitted for financial statements that have not been previously issued. In August 2015, the FASB issued ASU No. 2015-15, which provides additional guidance related to the presentation or subsequent measurement of debt issuance costs related to line-of-credit arrangements. An entity may present debt issuance costs as an asset and subsequently amortize the deferred debt issuance costs ratably over the term of the line-of-credit arrangement, regardless of whether there are any outstanding borrowings. The Company is currently evaluating the impact these pronouncements will have on the consolidated financial statements and related disclosures.

9

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

In July 2015, the FASB issued ASU No. 2015-11, “Simplifying the Measurement of Inventory.” This standard requires management to measure inventory at the lower of cost or net realizable value. Net realizable value is the estimated selling prices in the ordinary course of business, less reasonably predictable costs of completion, disposal, and transportation. The pronouncement is effective for annual reporting periods beginning after December 15, 2016, including interim periods within that reporting period and should be applied retrospectively, with early application permitted. The Company is currently evaluating the impact the pronouncement will have on the consolidated financial statements and related disclosures.

In September 2015, the FASB issued ASU 2015-16, “Simplifying the Accounting for Measurement-Period Adjustments.” This standard replaces the requirement that an acquirer in a business combination account for measurement period adjustments retrospectively with a requirement that an acquirer recognize adjustments to the provisional amounts that are identified during the measurement period in the reporting period in which the adjustment amounts are determined. The acquirer is required to record, in the same period’s financial statements, the effect on earnings of changes in depreciation, amortization, or other income effects, if any, as a result of the change to the provisional amounts, calculated as if the accounting had been completed at the acquisition date. The pronouncement is effective for annual reporting periods beginning after December 15, 2015, including interim periods within that reporting period. The guidance is to be applied prospectively to adjustments to provisional amounts that occur after the effective date of the guidance. The Company is currently evaluating the impact the pronouncement will have on the consolidated financial statements and related disclosures.

Note 3 — Impairment of Inventory and Rental Equipment

During the three months ended June 30, 2015, as a result of decreased rig activity and its impact on management’s expectations for future market activity, the Company refocused the Drilling Technologies segment to businesses and markets that have the best opportunity for profitable growth in the future. In addition, the Company has shifted the focus of the Production Technologies segment to oil production markets and away from coal bed methane markets. As a result of these changes in focus and projected declines in asset utilization, the Company recorded a pre-tax impairment charge during the three months ended June 30, 2015, as follows (in thousands):

Drilling Technologies: | |||

Inventories | $ | 17,241 | |

Rental equipment | 2,327 | ||

Production Technologies: | |||

Inventories | 804 | ||

Total impairment | $ | 20,372 | |

Note 4 — Acquisitions

On January 27, 2015, the Company acquired 100% of the assets of International Artificial Lift, LLC (“IAL”) for $1.3 million in cash consideration and 60,024 shares of the Company’s common stock. IAL is a development-stage company that specializes in the design, manufacturing and service of next-generation hydraulic pumping units that serve to increase and maximize production for oil and natural gas wells.

On April 1, 2014, the Company acquired 100% of the membership interests in SiteLark, LLC (“SiteLark”) for $0.4 million in cash consideration and 5,327 shares of the Company’s common stock. SiteLark provides reservoir engineering and modeling services for a variety of hydrocarbon applications. Its services include proprietary software which assists engineers with reservoir simulation, reservoir engineering and waterflood optimization.

On January 1, 2014, the Company acquired 100% of the membership interests in Eclipse IOR Services, LLC (“EOGA”), a leading Enhanced Oil Recovery (“EOR”) design and injection firm, for $5.3 million in cash consideration, net of cash received, and 94,354 shares of the Company’s Common Stock. EOGA’s enhanced oil recovery processes and its use of polymers to improve the performance of EOR projects has been combined with the Company’s existing EOR products and services.

10

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 5 — Supplemental Cash Flow Information

Supplemental cash flow information is as follows (in thousands):

Nine months ended September 30, | |||||||

2015 | 2014 | ||||||

Supplemental non-cash investing and financing activities: | |||||||

Value of common stock issued in acquisitions | $ | 1,014 | $ | 2,043 | |||

Final Florida Chemical acquisition adjustment | — | 1,162 | |||||

Value of common stock issued in payment of accrued liability | — | 600 | |||||

Exercise of stock options by common stock surrender | 1,126 | 1,183 | |||||

Supplemental cash payment information: | |||||||

Interest paid | $ | 1,043 | $ | 1,038 | |||

Income taxes paid | 3,044 | 18,393 | |||||

Note 6 — Revenue

The Company differentiates revenue and cost of revenue based on whether the source of revenue is attributable to products, rentals or services. Revenue and cost of revenue by source are as follows (in thousands):

Three months ended September 30, | Nine months ended September 30, | ||||||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||||||

Revenue: | |||||||||||||||

Products | $ | 76,555 | $ | 92,708 | $ | 217,237 | $ | 257,415 | |||||||

Rentals | 7,574 | 16,966 | 28,146 | 45,954 | |||||||||||

Services | 3,813 | 7,087 | 11,963 | 21,284 | |||||||||||

$ | 87,942 | $ | 116,761 | $ | 257,346 | $ | 324,653 | ||||||||

Cost of revenue: | |||||||||||||||

Products | $ | 49,520 | $ | 57,315 | $ | 145,387 | $ | 155,048 | |||||||

Rentals | 3,387 | 8,272 | 13,315 | 22,444 | |||||||||||

Services | 2,160 | 3,074 | 6,283 | 9,042 | |||||||||||

Depreciation | 1,648 | 2,022 | 5,355 | 6,051 | |||||||||||

$ | 56,715 | $ | 70,683 | $ | 170,340 | $ | 192,585 | ||||||||

Note 7 — Inventories

Inventories are as follows (in thousands):

September 30, 2015 | December 31, 2014 | ||||||

Raw materials | $ | 45,734 | $ | 50,195 | |||

Work-in-process | 2,666 | 3,129 | |||||

Finished goods | 36,021 | 32,634 | |||||

Inventories | $ | 84,421 | $ | 85,958 | |||

11

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 8 — Property and Equipment

Property and equipment are as follows (in thousands):

September 30, 2015 | December 31, 2014 | |||||||

Land | $ | 7,145 | $ | 6,780 | ||||

Buildings and leasehold improvements | 34,349 | 33,765 | ||||||

Machinery, equipment and rental tools | 83,864 | 80,731 | ||||||

Equipment in progress | 6,447 | 7,299 | ||||||

Furniture and fixtures | 2,658 | 2,528 | ||||||

Transportation equipment | 7,426 | 6,566 | ||||||

Computer equipment and software | 10,519 | 7,605 | ||||||

Property and equipment | 152,408 | 145,274 | ||||||

Less accumulated depreciation | (66,573 | ) | (59,163 | ) | ||||

Property and equipment, net | $ | 85,835 | $ | 86,111 | ||||

Depreciation expense, including expense recorded in cost of revenue, totaled $3.2 million and $3.3 million for the three months ended September 30, 2015 and 2014, respectively, and $10.0 million and $9.7 million for the nine months ended September 30, 2015 and 2014, respectively.

Note 9 — Goodwill and Other Intangible Assets

During the nine months ended September 30, 2015, the Company recognized $1.7 million of goodwill within the Production Technologies reporting unit in connection with the acquisition of IAL. There were no impairments of goodwill recognized during the three and nine months ended September 30, 2015 and 2014.

Changes in the carrying value of goodwill for each reporting unit are as follows (in thousands):

Energy Chemistry Technologies | Consumer and Industrial Chemistry Technologies | Teledrift® | Production Technologies | Total | |||||||||||||||

Balance at December 31, 2014 | $ | 36,318 | $ | 19,480 | $ | 15,333 | $ | — | $ | 71,131 | |||||||||

Addition upon acquisition of IAL | — | — | — | 1,689 | 1,689 | ||||||||||||||

Balance at September 30, 2015 | $ | 36,318 | $ | 19,480 | $ | 15,333 | $ | 1,689 | $ | 72,820 | |||||||||

Finite lived intangible assets acquired are amortized on a straight-line basis over two to 20 years. Amortization of finite lived intangible assets acquired totaled $1.2 million and $1.2 million for the three months ended September 30, 2015 and 2014, respectively, and $3.6 million and $3.6 million for the nine months ended September 30, 2015 and 2014, respectively.

Amortization of deferred financing costs was $0.1 million and $0.1 million for the three months ended September 30, 2015 and 2014, respectively, and $0.3 million and $0.3 million for the nine months ended September 30, 2015 and 2014, respectively.

Note 10 — Long-Term Debt and Credit Facility

Long-term debt is as follows (in thousands):

September 30, 2015 | December 31, 2014 | ||||||

Long-term debt: | |||||||

Borrowings under revolving credit facility | $ | 20,584 | $ | 8,500 | |||

Term loan | 27,184 | 35,541 | |||||

Total long-term debt | 47,768 | 44,041 | |||||

Less current portion of long-term debt | (27,727 | ) | (18,643 | ) | |||

Long-term debt, less current portion | $ | 20,041 | $ | 25,398 | |||

12

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Credit Facility

On May 10, 2013, the Company and certain of its subsidiaries (the “Borrowers”) entered into an Amended and Restated Revolving Credit, Term Loan and Security Agreement (the “Credit Facility”) with PNC Bank, National Association (“PNC Bank”). The Company may borrow under the Credit Facility for working capital, permitted acquisitions, capital expenditures and other corporate purposes. Under terms of the Credit Facility, as amended, the Company (a) may borrow up to $75 million under a revolving credit facility and (b) has borrowed $50 million under a term loan.

The Credit Facility is secured by substantially all of the Company’s domestic real and personal property, including accounts receivable, inventory, land, buildings, equipment and other intangible assets. The Credit Facility contains customary representations, warranties, and both affirmative and negative covenants. The Credit Facility includes a financial covenant to maintain a fixed charge coverage ratio of 1.10 to 1.00. The numerator of the ratio includes (a) Adjusted EBITDA (consolidated earnings before interest, taxes, depreciation and amortization adjusted to exclude stock compensation expense and impairment expense of up to $23 million in 2015) minus (b) unfunded capital expenditures (excluding up to $7.5 million in 2015 and $5.0 million in 2016 associated with the construction of the Company’s Global Research and Innovation facility) and (c) cash taxes paid. The Credit Facility also includes a financial covenant to maintain a ratio of funded debt to Adjusted EBITDA of not greater than 4.0 to 1.0, and an annual limit on capital expenditures of approximately $35 million. The Credit Facility restricts the payment of cash dividends on common stock. In the event of default, PNC Bank may accelerate the maturity date of any outstanding amounts borrowed under the Credit Facility.

The Credit Facility includes a provision that 25% of EBITDA minus cash paid for taxes, dividends, debt payments and unfunded capital expenditures, not to exceed $3.0 million for any year, be paid within 60 days of the fiscal year end. For the year ended December 31, 2014, the excess cash flow exceeded $3.0 million. Consequently, the Company paid $3.0 million on its term loan balance to PNC Bank on March 2, 2015. This amount was classified as current debt at December 31, 2014.

Each of the Company’s domestic subsidiaries is fully obligated for Credit Facility indebtedness as a Borrower or as a guarantor.

(a) Revolving Credit Facility

Under the revolving credit facility, the Company may borrow up to $75 million through May 10, 2018. This includes a sublimit of $10 million that may be used for letters of credit. The revolving credit facility is secured by substantially all the Company’s domestic accounts receivable and inventory.

At September 30, 2015, eligible accounts receivable and inventory securing the revolving credit facility provided availability of $67.6 million under the revolving credit facility. Available borrowing capacity, net of outstanding borrowings, was $47.0 million at September 30, 2015.

The interest rate on advances under the revolving credit facility varies based on the level of borrowing under the Credit Facility. Rates range (a) between PNC Bank’s base lending rate plus 0.5% to 1.0% or (b) between the London Interbank Offered Rate (LIBOR) plus 1.5% to 2.0%. PNC Bank’s base lending rate was 3.25% at September 30, 2015. The Company is required to pay a monthly facility fee of 0.25% per annum, on any unused amount under the commitment based on daily averages. At September 30, 2015, $20.6 million was outstanding under the revolving credit facility, with $1.6 million borrowed as base rate loans at an interest rate of 3.75% and $19.0 million borrowed as LIBOR loans at an interest rate of 1.70%.

Borrowing under the revolving credit agreement is classified as current debt as a result of the required lockbox arrangement and the subjective acceleration clause.

(b) Term Loan

The Company increased borrowing to $50 million under the term loan on May 10, 2013. Monthly principal payments of $0.6 million are required. The unpaid balance of the term loan is due May 10, 2018. Prepayments are permitted, and may be required in certain circumstances. Amounts repaid under the term loan may not be reborrowed. The term loan is secured by substantially all of the Company’s domestic land, buildings, equipment and other intangible assets.

The interest rate on the term loan varies based on the level of borrowing under the Credit Facility. Rates range (a) between PNC Bank’s base lending rate plus 1.25% to 1.75% or (b) between LIBOR plus 2.25% to 2.75%. At September 30, 2015, $27.2 million was outstanding under the term loan, with $0.2 million borrowed as base rate loans at an interest rate of 4.50% and $27.0 million borrowed as LIBOR loans at an interest rate of 2.45%.

13

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 11 — Earnings (Loss) Per Share

Basic earnings (loss) per common share is calculated by dividing net income (loss) by the weighted average number of common shares outstanding for the period. Diluted earnings (loss) per common share is calculated by dividing net income (loss) by the weighted average number of common shares outstanding combined with dilutive common share equivalents outstanding, if the effect is dilutive.

Potentially dilutive securities were excluded from the calculation of diluted earnings (loss) per share for the nine months ended September 30, 2015, since including them would have an anti-dilutive effect on earnings (loss) per share due to the net loss incurred during the period. Securities convertible into shares of common stock that were not considered in the diluted earnings (loss) per share calculation were 0.8 million stock options and 0.4 million restricted stock units for the nine months ended September 30, 2015.

Basic and diluted earnings (loss) per common share are as follows (in thousands, except per share data):

Three months ended September 30, | Nine months ended September 30, | ||||||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||||||

Net income (loss) - Basic and Diluted | $ | 1,975 | $ | 14,272 | $ | (12,087 | ) | $ | 37,330 | ||||||

Weighted average common shares outstanding - Basic | 54,578 | 54,789 | 54,430 | 54,464 | |||||||||||

Assumed conversions: | |||||||||||||||

Incremental common shares from warrants | — | — | — | 162 | |||||||||||

Incremental common shares from stock options | 345 | 867 | — | 901 | |||||||||||

Incremental common shares from restricted stock units | 24 | 34 | — | 9 | |||||||||||

Weighted average common shares outstanding - Diluted | 54,947 | 55,690 | 54,430 | 55,536 | |||||||||||

Basic earnings (loss) per common share | $ | 0.04 | $ | 0.26 | $ | (0.22 | ) | $ | 0.69 | ||||||

Diluted earnings (loss) per common share | $ | 0.04 | $ | 0.26 | $ | (0.22 | ) | $ | 0.67 | ||||||

Note 12 — Fair Value Measurements

Fair value is defined as the amount that would be received for selling an asset or paid to transfer a liability in an orderly transaction between market participants at the measurement date. The Company categorizes financial assets and liabilities into the three levels of the fair value hierarchy. The hierarchy prioritizes the inputs to valuation techniques used to measure fair value and bases categorization within the hierarchy on the lowest level of input that is available and significant to the fair value measurement.

• | Level 1 — Quoted prices in active markets for identical assets or liabilities; |

• | Level 2 — Observable inputs other than Level 1, such as quoted prices for similar assets or liabilities, quoted prices in markets that are not active, or other inputs that are observable or can be corroborated by observable market data for substantially the full term of the assets or liabilities; and |

• | Level 3 — Significant unobservable inputs that are supported by little or no market activity or that are based on the reporting entity’s assumptions about the inputs. |

Fair Value of Other Financial Instruments

The carrying amounts of certain financial instruments, including cash and cash equivalents, accounts receivable, accounts payable and accrued expenses, approximate fair value due to the short-term nature of these accounts. The Company had no cash equivalents at September 30, 2015, or December 31, 2014.

14

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

The carrying value and estimated fair value of the Company’s long-term debt are as follows (in thousands):

September 30, 2015 | December 31, 2014 | ||||||||||||||

Carrying Value | Fair Value | Carrying Value | Fair Value | ||||||||||||

Term loan | $ | 27,184 | $ | 27,184 | $ | 35,541 | $ | 35,541 | |||||||

Borrowings under revolving credit facility | 20,584 | 20,584 | 8,500 | 8,500 | |||||||||||

The carrying value of the term loan and borrowings under the revolving credit facility approximate their fair value because the interest rates are variable.

Assets Measured at Fair Value on a Nonrecurring Basis

The Company’s non-financial assets, including property and equipment, goodwill and other intangible assets are measured at fair value on a non-recurring basis and are subject to fair value adjustment in certain circumstances. During the three months ended June 30, 2015, the Company recorded an impairment of $2.3 million relating to rental equipment held and used. Loss on impairment is reported in operating expenses. No impairments of goodwill or other intangible assets were recognized during the three and nine months ended September 30, 2015 and 2014.

Note 13 — Income Taxes

The Company’s corporate organizational structure requires the filing of two separate consolidated U.S. Federal income tax returns. Taxable income of one group cannot be offset by tax attributes, including net operating losses, of the other group.

A reconciliation of the U.S. federal statutory tax rate to the Company’s effective income tax rate is as follows:

Three months ended September 30, | Nine months ended September 30, | ||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||

U.S. federal statutory tax rate | 35.0 | % | 35.0 | % | 35.0 | % | 35.0 | % | |||

State income taxes, net of federal benefit | 5.7 | 1.8 | (1.8 | ) | 2.1 | ||||||

Non-U.S. income taxed at different rates | (29.1 | ) | — | 4.2 | — | ||||||

Non-deductible expenses | 0.2 | (0.2 | ) | (2.4 | ) | 0.1 | |||||

Domestic production activities deduction | 3.6 | (1.9 | ) | — | (2.4 | ) | |||||

Return to accrual adjustments | — | (4.9 | ) | — | (1.8 | ) | |||||

Other | 1.4 | — | (0.1 | ) | — | ||||||

Effective income tax rate | 16.8 | % | 29.8 | % | 34.9 | % | 33.0 | % | |||

The change in the effective income tax rate for the three and nine months ended September 30, 2015, compared to the three and nine months ended September 30, 2014, was primarily due to the mix of pre-tax profit and loss between domestic and international taxing jurisdictions in 2015 and the effect of a decrease in deferred tax liabilities related to a change in state tax apportionment in 2014. The Company plans to permanently reinvest profits from international operations into opportunities to expand the Company’s international presence.

Deferred taxes are presented in the balance sheets as follows (in thousands):

September 30, 2015 | December 31, 2014 | |||||||

Current deferred tax assets | $ | 1,835 | $ | 2,696 | ||||

Non-current deferred tax assets | 19,392 | 12,907 | ||||||

Non-current deferred tax liabilities | (22,910 | ) | (25,982 | ) | ||||

Net deferred tax assets (liabilities) | $ | (1,683 | ) | $ | (10,379 | ) | ||

15

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Note 14 — Convertible Preferred Stock and Stock Warrants

In August 2009, the Company sold convertible preferred stock with detachable warrants to purchase shares of the Company’s common stock. In February 2011, the Company exercised its contractual right to mandatorily convert all outstanding shares of convertible preferred stock into shares of common stock. Currently, the Company has no issued or outstanding shares of preferred stock.

On February 7, 2014, warrants were exercised to purchase 1,277,250 shares of the Company’s common stock at $1.21 per share. The Company received cash proceeds of $1.5 million in connection with the warrants exercised. Following the exercise, the Company no longer has any outstanding warrants.

Note 15 — Stock Repurchase Program

In November 2012, the Company’s Board of Directors authorized the repurchase of up to $25 million of the Company’s common stock. Repurchases may be made in the open market or through privately negotiated transactions. During the three months ended September 30, 2015, the Company repurchased 2,404 shares of its outstanding common stock on the open market at an average price of $16.44 per share, inclusive of transaction costs. During the nine months ended September 30, 2015, the Company repurchased a total of 549,723 shares of its outstanding common stock on the open market at a cost of $7.3 million, inclusive of transaction costs, or an average price of $13.28 per share.

In June 2015, the Company’s Board of Directors authorized the repurchase of up to an additional $50 million of the Company’s common stock. Repurchases may be made in open market or through privately negotiated transactions. Through September 30, 2015, the Company has not repurchased any of its common stock under this authorization.

As of September 30, 2015, the Company has $57.3 million remaining and available to repurchase shares under its share repurchase programs.

Note 16 — Business Segment, Geographic and Major Customer Information

Segment Information

Operating segments are defined as components of an enterprise for which separate financial information is available that is regularly evaluated by chief operating decision-makers in deciding how to allocate resources and assess performance. The operations of the Company are categorized into four reportable segments: Energy Chemistry Technologies (previously referred to as Energy Chemical Technologies), Consumer and Industrial Chemistry Technologies (previously referred to as Consumer and Industrial Chemical Technologies), Drilling Technologies, and Production Technologies.

• | Energy Chemistry Technologies designs, develops, manufactures, packages, and markets specialty chemistries used in oil and natural gas well drilling, cementing, completion, stimulation, and production. In addition, the Company’s chemistries are used in specialized enhanced and improved oil recovery markets. Activities in this segment also include construction and management of automated material handling facilities and management of loading facilities and blending operations for oilfield services companies. |

• | Consumer and Industrial Chemistry Technologies designs, develops, and manufactures products that are sold to companies in the flavor and fragrance industries and the specialty chemical industry. These technologies are used by beverage and food companies, fragrance companies, and companies providing household and industrial cleaning products. |

• | Drilling Technologies rents, sells, inspects, manufactures, and markets downhole drilling equipment used in energy, mining, and industrial drilling activities. |

• | Production Technologies assembles and markets production-related equipment, including the Petrovalve® product line of rod pump components, hydraulic pumping units, electric submersible pumps, gas separators, valves, and services that support natural gas and oil production activities. |

The Company evaluates performance based upon a variety of criteria. The primary financial measure is segment operating income. Various functions, including certain sales and marketing activities and general and administrative activities, are provided centrally by the corporate office. Costs associated with corporate office functions, other corporate income and expense items, and income taxes are not allocated to reportable segments.

16

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Summarized financial information of the reportable segments is as follows (in thousands):

As of and for the three months ended September 30, | Energy Chemistry Technologies | Consumer and Industrial Chemistry Technologies | Drilling Technologies | Production Technologies | Corporate and Other | Total | |||||||||||||||||

2015 | |||||||||||||||||||||||

Net revenue from external customers | $ | 60,181 | $ | 13,867 | $ | 10,812 | $ | 3,082 | $ | — | $ | 87,942 | |||||||||||

Gross profit | 24,257 | 3,082 | 3,302 | 586 | — | 31,227 | |||||||||||||||||

Income (loss) from operations | 14,283 | 1,728 | (2,614 | ) | (823 | ) | (9,797 | ) | 2,777 | ||||||||||||||

Depreciation and amortization | 1,200 | 548 | 2,038 | 212 | 435 | 4,433 | |||||||||||||||||

Total assets | 152,430 | 90,948 | 110,872 | 26,564 | 20,131 | 400,945 | |||||||||||||||||

Capital expenditures | 1,467 | 18 | — | 107 | 523 | 2,115 | |||||||||||||||||

2014 | |||||||||||||||||||||||

Net revenue from external customers | $ | 68,181 | $ | 13,713 | $ | 29,920 | $ | 4,947 | $ | — | $ | 116,761 | |||||||||||

Gross profit | 28,424 | 3,310 | 11,928 | 2,416 | — | 46,078 | |||||||||||||||||

Income (loss) from operations | 19,903 | 1,758 | 5,557 | 1,583 | (7,954 | ) | 20,847 | ||||||||||||||||

Depreciation and amortization | 1,103 | 547 | 2,433 | 81 | 298 | 4,462 | |||||||||||||||||

Total assets | 144,738 | 89,574 | 142,774 | 18,252 | 17,080 | 412,418 | |||||||||||||||||

Capital expenditures | 2,580 | 7 | 818 | 141 | 703 | 4,249 | |||||||||||||||||

As of and for the nine months ended September 30, | Energy Chemistry Technologies | Consumer and Industrial Chemistry Technologies | Drilling Technologies | Production Technologies | Corporate and Other | Total | |||||||||||||||||

2015 | |||||||||||||||||||||||

Net revenue from external customers | $ | 163,296 | $ | 42,808 | $ | 41,840 | $ | 9,402 | $ | — | $ | 257,346 | |||||||||||

Gross profit | 60,784 | 10,914 | 13,396 | 1,912 | — | 87,006 | |||||||||||||||||

Income (loss) from operations | 32,995 | 6,792 | (24,551 | ) | (2,958 | ) | (29,398 | ) | (17,120 | ) | |||||||||||||

Depreciation and amortization | 3,578 | 1,649 | 6,575 | 535 | 1,276 | 13,613 | |||||||||||||||||

Total assets | 152,430 | 90,948 | 110,872 | 26,564 | 20,131 | 400,945 | |||||||||||||||||

Capital expenditures | 5,910 | 46 | 2,744 | 883 | 1,495 | 11,078 | |||||||||||||||||

2014 | |||||||||||||||||||||||

Net revenue from external customers | $ | 193,148 | $ | 39,351 | $ | 82,061 | $ | 10,093 | $ | — | $ | 324,653 | |||||||||||

Gross profit | 85,074 | 10,237 | 32,477 | 4,280 | — | 132,068 | |||||||||||||||||

Income (loss) from operations | 60,690 | 5,064 | 13,073 | 1,925 | (23,432 | ) | 57,320 | ||||||||||||||||

Depreciation and amortization | 3,264 | 1,529 | 7,363 | 244 | 876 | 13,276 | |||||||||||||||||

Total assets | 144,738 | 89,574 | 142,774 | 18,252 | 17,080 | 412,418 | |||||||||||||||||

Capital expenditures | 5,383 | 37 | 6,139 | 252 | 1,683 | 13,494 | |||||||||||||||||

Geographic Information

Revenue by country is based on the location where services are provided and products are used. No individual country other than the United States (“U.S.”) accounted for more than 10% of revenue. Revenue by geographic location is as follows (in thousands):

Three months ended September 30, | Nine months ended September 30, | ||||||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||||||

U.S. | $ | 73,796 | $ | 92,643 | $ | 211,242 | $ | 271,663 | |||||||

Other countries | 14,146 | 24,118 | 46,104 | 52,990 | |||||||||||

Total | $ | 87,942 | $ | 116,761 | $ | 257,346 | $ | 324,653 | |||||||

Long-lived assets held in countries other than the U.S. are not considered material to the consolidated financial statements.

17

FLOTEK INDUSTRIES, INC.

NOTES TO UNAUDITED CONSOLIDATED FINANCIAL STATEMENTS

Major Customers

Revenue from major customers, as a percentage of consolidated revenue, is as follows:

Three months ended September 30, | Nine months ended September 30, | ||||||||||

2015 | 2014 | 2015 | 2014 | ||||||||

Customer A | 12.8 | % | 12.7 | % | 11.7 | % | 17.0 | % | |||

Customer B | 11.6 | % | * | * | * | ||||||

Customer C | 11.3 | % | * | 14.3 | % | * | |||||

* This customer did not account for more than 10% of revenue during the period.

Over 97% of the revenue from these customers was for sales in the Energy Chemistry Technologies segment.

Note 17 — Commitments and Contingencies

Litigation

The Company is subject to routine litigation and other claims that arise in the normal course of business. Management is not aware of any pending or threatened lawsuits or proceedings that are expected to have a material effect on the Company’s financial position, results of operations or liquidity.

Concentrations and Credit Risk

The majority of the Company’s revenue is derived from the oil and gas industry. Customers include major oilfield services companies, major integrated oil and natural gas companies, independent oil and natural gas companies, pressure pumping service companies and state-owned national oil companies. This concentration of customers in one industry increases credit and business risks.

The Company is subject to concentrations of credit risk within trade accounts receivable, as the Company does not generally require collateral as support for trade receivables. In addition, the majority of the Company’s cash is maintained at a major financial institution and balances often exceed insurable amounts.

18

Item 2. Management’s Discussion and Analysis of Financial Condition and Results of Operations

Forward-Looking Statements

This Quarterly Report on Form 10-Q (“Quarterly Report”), and in particular, Part I, Item 2 - “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” contains “forward-looking statements” within the meaning of the safe harbor provisions, 15 U.S.C. § 78u-5, of the Private Securities Litigation Reform Act of 1995 (“Reform Act”). Forward-looking statements are not historical facts, but instead represent the Company’s current assumptions and beliefs regarding future events, many of which, by their nature, are inherently uncertain and outside the Company’s control. Such statements include estimates, projections, and statements related to Flotek Industries, Inc.’s (“Flotek” or “Company”) business plan, objectives, expected operating results, and assumptions upon which those statements are based. The forward-looking statements contained in this Quarterly Report are based on information available as of the date of this Quarterly Report.

The forward-looking statements relate to future industry trends and economic conditions, forecast performance or results of current and future initiatives and the outcome of contingencies and other uncertainties that may have a significant impact on the Company’s business, future operating results and liquidity. These forward-looking statements generally are identified by words including, but not limited to, “anticipate,” “believe,” “estimate,” “continue,” “intend,” “expect,” “plan,” “forecast,” “project,” and similar expressions, or future-tense or conditional constructions such as “will,” “may,” “should,” “could,” etc. The Company cautions that these statements are merely predictions and are not to be considered guarantees of future performance. Forward-looking statements are based upon current expectations and assumptions that are subject to risks and uncertainties that can cause actual results to differ materially from those projected, anticipated, or implied.

A detailed discussion of potential risks and uncertainties that could cause actual results and events to differ materially from forward-looking statements is included in Part I, Item 1A - “Risk Factors” of the Annual Report on Form 10-K for the year ended December 31, 2014 (“Annual Report”) and periodically in subsequent reports filed with the Securities and Exchange Commission (“SEC”). The Company has no obligation to publicly update or revise any forward-looking statements, whether as a result of new information or future events, except as required by law.

Management’s Discussion and Analysis of Financial Condition and Results of Operations (“MD&A”) should be read in conjunction with the unaudited consolidated financial statements and the related notes thereto, as well as the Annual Report. Phrases such as “Company,” “we,” “our,” and “us” refer to Flotek Industries, Inc. and its subsidiaries.

Executive Summary

Flotek is a global diversified, technology-driven company that develops and supplies oilfield products, services, and equipment to the oil, gas, and mining industries, and high value compounds to companies that make cleaning products, cosmetics, food and beverages, and other products that are sold in the consumer and industrial markets.

The Company’s oilfield businesses include specialty chemistries and logistics, down-hole drilling tools, and production-related tools. Flotek’s technologies enable customers to drill wells more efficiently, increase well production, and decrease well operating costs. The Company also provides automated bulk material handling, loading facilities, and blending capabilities. The Company sources citrus oil domestically and internationally and is one of the largest processors of citrus oil in the world. Products produced from processed citrus oil include (1) high value compounds used as additives by companies in the flavors and fragrances markets and (2) environmentally friendly chemistries for use in numerous industries around the world, specifically the oil and gas (“O&G”) industry.

Flotek operates in over 20 domestic and international markets, including the Gulf Coast, Southwest, West Coast, Rocky Mountains, Northeastern and Mid-Continental regions of the United States (“U.S.”), Canada, Mexico, Central America, South America, Europe, Africa, Middle East, Australia, and Asia-Pacific. Customers include major integrated O&G companies, oilfield services companies, independent O&G companies, pressure-pumping service companies, national and state-owned oil companies, and international supply chain management companies. The Company also serves customers who purchase non-energy-related citrus oil and related products, including household and commercial cleaning product companies, fragrance and cosmetic companies, and food manufacturing companies.

19

The operations of the Company are categorized into four reportable segments: Energy Chemistry Technologies (previously referred to as Energy Chemical Technologies), Consumer and Industrial Chemistry Technologies (previously referred to as Consumer and Industrial Chemical Technologies), Drilling Technologies, and Production Technologies.

• | Energy Chemistry Technologies designs, develops, manufactures, packages, and markets specialty chemistries used in O&G well drilling, cementing, completion, stimulation, and production. In addition, the Company’s chemistries are used in specialized enhanced and improved oil recovery markets (“EOR” or “IOR”). Activities in this segment also include construction and management of automated material handling facilities and management of loading facilities and blending operations for oilfield services companies. |

• | Consumer and Industrial Chemistry Technologies designs, develops, and manufactures products that are sold to companies in the flavor and fragrance industries and the specialty chemistry industry. These technologies are used by beverage and food companies, fragrance companies, and companies providing household and industrial cleaning products. |

• | Drilling Technologies rents, sells, inspects, manufactures, and markets downhole drilling equipment used in energy, mining, and industrial drilling activities. |

• | Production Technologies assembles and markets production-related equipment, including the Petrovalve® product line of rod pump components, hydraulic pumping units (“HPU”), electric submersible pumps (“ESP”), gas separators, valves, and services that support natural gas and oil production activities. |

Market Conditions

The Company’s success is sensitive to a number of factors, which include, but are not limited to, drilling activity, customer demand for its advanced technology products, market prices for raw materials, and governmental actions.

Drilling activity levels are influenced by a number of factors, including the number of rigs in operation, the geographical areas of rig activity, and drill rig efficiency (rig days required per well). Additional factors that influence the level of drilling activity include:

• | Historical, current, and anticipated future O&G prices, |

• | Federal, State, and local governmental actions that may encourage or discourage drilling activity, |

• | Customers’ strategies relative to capital funds allocations, |

• | Weather conditions, and |

• | Technological changes to drilling methods and economics. |

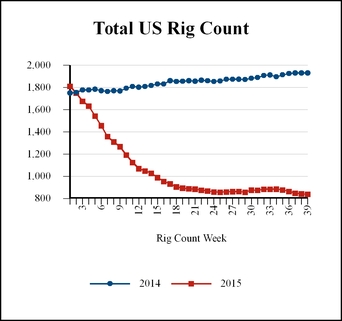

Historical North American drilling activity is reflected in “TABLE A” on the following page.

Customers’ demand for advanced technology products and services provided by the Company are dependent on their recognition of the value of:

• | Chemistries that improve the economics of their O&G operations, |

• | Drilling products that improve drilling operations and efficiencies, |

• | Chemistries that are economically viable, socially responsible, and ecologically sound, and |

• | Production technologies that improve production and production efficiencies in maturing wells. |

Market prices for citrus oils can be influenced by:

• | Historical, current, and anticipated future production levels of the global citrus (primarily orange) crop, |

• | Weather related risks, |

• | Health and condition of citrus trees (e.g., disease and pests), and |

• | International competition and pricing pressures resulting from natural and artificial pricing influences. |

Governmental actions may restrict the future use of hazardous chemicals, including but not limited to, the following industrial applications:

• | O&G drilling and completion operations, |

• | O&G production operations, and |

• | Non-O&G industrial solvents. |

20

TABLE A | Three months ended September 30, | Nine months ended September 30, | |||||||||||||||

2015 | 2014 | % Change | 2015 | 2014 | % Change | ||||||||||||

North American Average Active Drilling Rigs | |||||||||||||||||

U.S. | 866 | 1,903 | (54.5 | )% | 1,059 | 1,845 | (42.6 | )% | |||||||||

Canada | 190 | 386 | (50.8 | )% | 200 | 370 | (45.9 | )% | |||||||||

Total Average North American Drilling Rigs | 1,056 | 2,289 | (53.9 | )% | 1,259 | 2,215 | (43.2 | )% | |||||||||

U.S. Average Active Drilling Rigs by Type | |||||||||||||||||

Vertical | 123 | 372 | (66.9 | )% | 152 | 385 | (60.5 | )% | |||||||||

Horizontal | 659 | 1,314 | (49.8 | )% | 805 | 1,246 | (35.4 | )% | |||||||||

Directional | 84 | 217 | (61.3 | )% | 102 | 214 | (52.3 | )% | |||||||||

Total Average U.S. Drilling Rigs by Type | 866 | 1,903 | (54.5 | )% | 1,059 | 1,845 | (42.6 | )% | |||||||||

Oil vs. Natural Gas Average North American Drilling Rigs | |||||||||||||||||

Oil | 745 | 1,797 | (58.5 | )% | 906 | 1,731 | (47.7 | )% | |||||||||

Natural Gas | 311 | 492 | (36.8 | )% | 353 | 484 | (27.1 | )% | |||||||||

Total North America | 1,056 | 2,289 | (53.9 | )% | 1,259 | 2,215 | (43.2 | )% | |||||||||

Source: Rig counts are per Baker Hughes, Inc. (www.bakerhughes.com). Rig counts are the averages of the weekly rig count activity.

As crude oil prices peaked at approximately $106/barrel in June 2014 and began the descent to the current levels ranging between $40 to $50 per barrel, total U.S. rig count decreased from 1,929 rigs on November 21, 2014, to 838 rigs as of September 25, 2015, representing a 56.6% drop. As the total U.S. rig count dropped, the horizontal rig count declined 54.2%, the directional rig count decreased by 58.0%, and the vertical rig count fell by 65.1%. Horizontal rigs now represent 75.1% of the total working U.S. rig count, versus 71.1% at the peak U.S. drilling activity level in November 2014.

The Canadian rig count had a similar response. The Canadian rig count peaked on January 16, 2015, at 440 rigs, fell to 72 rigs for the week ending May 22, 2015, and has improved to 176 rigs on September 25, 2015. However, Canadian rig activity remains depressed, lagging normal levels by almost 200 rigs.

During the three and nine months ended September 30, 2015, total North American active drilling rig count significantly decreased when compared to the comparable periods of 2014, primarily in oil drilling rigs. Average North American oil drilling rig activity decreased by 58.5% and 47.7% for the three and nine months ended September 30, 2015, respectively, when compared to the same periods of 2014. North American natural gas drilling rig count decreased by 36.8% and 27.1% for the three and nine months ended September 30, 2015, respectively, compared to the same periods of 2014.

21

Company Outlook

Beginning in the second half of 2014 and continuing through the first quarter of 2015, the price of crude oil declined dramatically and, after a slight improvement in the second quarter, the price continued to fall to levels not seen since February 2009. As a result, most North American exploration and production companies - many of which are Flotek clients - have significantly reduced their exploration and drilling activity in 2015. The reduction in activity has created a more challenging environment in which to market the Company’s broad range of energy technologies, from chemistry to drilling and production technologies. Although the Company has seen demand for its oil and gas related products and services in North America impacted by these industry conditions, the Company continues to aggressively market its oil and gas based products and services including its Complex nano-Fluid® (“CnF®”) chemistries, Teledrift® product line, Stemulator® product line, and the growing line of production technologies. While international markets may react differently than North American markets to the decline in crude prices, the Company expects similar market challenges around the globe.

The Company’s continued emphasis on the promotion of the efficacy of its CnF® chemistries resulted in significant CnF® sales growth in the third quarter despite continued declines in oilfield activity. CnF® volumes increased 34%, compared to the second quarter of 2015, and 59%, compared to the third quarter of 2014. The Company expects CnF® sales to continue to outpace general oilfield activity as a result of the distinct benefits of CnF® in unconventional completions as demonstrated by the FracMax® analytical platform, which provides quantitative validation of the improved well economics achieved when CnF® is used in the well completion process. The Company has also initiated a direct-to-operator sales and marketing program, known as the Flotek Store™. By purchasing from Flotek through the Flotek Store™, exploration and production companies can benefit from a more direct relationship with Flotek’s technical expertise and supply chain.

In anticipation of CnF® demand growth, the Company has expanded its manufacturing capacity at its Marlow, Oklahoma chemistry facility over the past several years and believes it is well positioned to more than double production in its current facility. Additionally, the Company has added ample storage capacity and has excess production capacity at its Waller, Texas and Winter Haven, Florida facilities to meet future needs.

In response to the current market environment, the Company has been proactive in reducing costs to reflect current market conditions while, at the same time, remaining focused on preserving appropriate functions and capacity, which allows the Company to be opportunistic as market conditions improve. Cost reductions to date include headcount reductions and hiring restrictions that have not impacted customer service or production output; vendor price reductions that have partially mitigated gross margin erosion; the consolidation of certain operating bases which reduced lease and other expenses; and other cost controls that have reduced overall operating costs of our business. The Company regularly evaluates its cost structure based on market conditions with a focus on continuous efficiency improvements.

Capital expenditures, exclusive of acquisitions, totaled $11.1 million and $13.5 million for the nine months ended September 30, 2015 and 2014, respectively. Of the $11.1 million spent to date in 2015, 65% has been for the completion of projects started in 2014. The Company expects capital spending to be between $20 million and $23 million in 2015, inclusive of approximately $7 million for construction of laboratory facilities, including the Company’s Global Research & Innovation Headquarters in Houston. The Company will remain nimble in its core capital expenditure plans, adjusting as market conditions warrant.

The Company’s new Global Research & Innovation Headquarters in Houston will allow for the development of next-generation, innovative energy chemistries, as well as expand collaboration between clients, leaders from academia, and Company scientists. These collaborative opportunities will become an important and distinguishing capability within the industry and should generate substantial value in 2016 and beyond.

The Company also plans to continue to expand the capabilities and use of its FracMax® analytical platform, an innovative software technology that allows the Company to quantitatively demonstrate the benefits associated with the use of the Company’s patented and proprietary Complex nano-Fluid® chemistries. The FracMax® application has been integrated into the Company’s sales and marketing process leading to new sales opportunities. In October 2014, the Company announced the formation of FracMax Analytics, LLC, a wholly owned subsidiary that will use the FracMax® analytical platform to provide customized data analysis to oil and gas operators, investors, and other companies. The Company believes the FracMax® platform, driven by DREAM™ technology, has applications beyond the energy sector and is exploring options to expand the reach of this innovative software platform.

During the second quarter of 2015, as a result of decreased rig activity and its impact on management’s expectations for future market activity, the Company refocused the Drilling Technologies segment to businesses and markets that have the best opportunity for profitable growth in the future. Additionally, the Company has shifted the focus of the Production Technologies segment towards oil production markets and away from the less opportunistic coal bed methane (“CBM”) markets.

22

The Company continues to pursue selected strategic relationships, both domestically and internationally, to expand its business.

In October 2015, the Company announced a partnership with Ely and Associates (“Ely”), a leading international stimulation and completion consulting firm, under which the Company and Ely will provide the Company’s CnF® completion chemistry clients a suite of stimulation and completion consulting services to further extend the Company’s reach as the leading North American completion chemistry and consulting services firm. Through the partnership, the Company will package Ely’s world-class reservoir stimulation and completion consulting services with the Company’s CnF® customized completion chemistries for those clients that purchase CnF® chemistries directly through the Flotek Store™.

In March 2015, the Company entered into agreements with Solazyme, Inc. (“Solazyme”) to globally commercialize Flocapso™, an innovative, advanced drilling fluid additive that combines the Company’s patented Complex nano-Fluid® chemistries with Solazyme’s proprietary Encapso™ technology. Flocapso™ will allow the use of water-based fluids in wells that previously required more expensive and invasive oil-based products, providing an environmentally superior, more efficient solution to drilling challenges. In addition, the Company will market Solazyme’s Encapso™ lubricant - the first commercially available, biodegradable encapsulated lubricant for drilling fluids - in certain Middle Eastern markets.

In January 2015, the Company acquired 100% of the assets from International Artificial Lift, LLC (“IAL”), a development-stage company that specializes in the design, manufacturing, and service of next-generation hydraulic pumping units that serve to increase and maximize production for oil and natural gas wells.

The outlook for the Company’s consumer and industrial chemistries will be driven by the availability and demand for citrus oils and other bio-based raw materials. Current inventory and crop expectations are sufficient to meet the Company’s needs to supply its flavor and fragrance business, as well as the industrial markets. However, market price volatility may result in revenue and margin fluctuations from quarter-to-quarter.

Changes to geopolitical, global economic, and industry trends could have an impact, either positive or negative, on the Company’s business. In the event of significant adverse changes to the demand for oil and gas production and/or the market price for oil and gas, the market conditions affecting the Company could change rapidly and materially. Should such adverse changes to market conditions occur, management believes the Company has adequate liquidity to withstand the impact of such changes while continuing to make strategic capital investments and acquisitions if and when opportunities arise. In addition, management believes the Company is well-positioned to take advantage of significant increases in demand for its products should market conditions improve dramatically in the near term.

The Company expects that competition for contracts and margins will remain intense but that product innovation, service improvements, and data from its FracMax® analytical platform should enable the Company to realize relative market share gains during the remainder of 2015 and into 2016.

23

Consolidated Results of Operations (in thousands):

Three months ended September 30, | Nine months ended September 30, | |||||||||||||||

2015 | 2014 | 2015 | 2014 | |||||||||||||

Revenue | $ | 87,942 | $ | 116,761 | $ | 257,346 | $ | 324,653 | ||||||||

Cost of revenue | 56,715 | 70,683 | 170,340 | 192,585 | ||||||||||||

Gross profit | 31,227 | 46,078 | 87,006 | 132,068 | ||||||||||||

Gross margin % | 35.5 | % | 39.5 | % | 33.8 | % | 40.7 | % | ||||||||

Selling, general and administrative costs | 23,634 | 21,499 | 70,223 | 63,924 | ||||||||||||

Selling, general and administrative costs % | 26.9 | % | 18.4 | % | 27.3 | % | 19.7 | % | ||||||||

Depreciation and amortization | 2,785 | 2,439 | 8,258 | 7,225 | ||||||||||||

Research and innovation costs | 2,031 | 1,293 | 5,273 | 3,599 | ||||||||||||

Impairment of inventory and rental equipment | — | — | 20,372 | — | ||||||||||||

Income (loss) from operations | 2,777 | 20,847 | (17,120 | ) | 57,320 | |||||||||||

Income (loss) from operations % | 3.2 | % | 17.9 | % | (6.7 | )% | 17.7 | % | ||||||||

Interest and other expense, net | (402 | ) | (511 | ) | (1,457 | ) | (1,565 | ) | ||||||||

Income (loss) before income taxes | 2,375 | 20,336 | (18,577 | ) | 55,755 | |||||||||||

Income tax benefit (expense) | (400 | ) | (6,064 | ) | 6,490 | (18,425 | ) | |||||||||

Net income (loss) | $ | 1,975 | $ | 14,272 | $ | (12,087 | ) | $ | 37,330 | |||||||

Net income (loss) % | 2.2 | % | 12.2 | % | (4.7 | )% | 11.5 | % | ||||||||

Consolidated Results of Operations: Three and Nine Months Ended September 30, 2015, Compared to the Three and Nine Months Ended September 30, 2014

Consolidated revenue for the three and nine months ended September 30, 2015, decreased $28.8 million, or 24.7%, and $67.3 million, or 20.7%, respectively, relative to the comparable periods of 2014. The decrease in revenue was driven by the continued decline in drilling activity throughout 2015 as indicated by the 53.9% and 43.2% reduction in average North American rig count for the three and nine months ended September 30, 2015, respectively, versus the same periods of 2014, which affected Drilling Technologies revenues and, to a lesser extent, Energy Chemistry Technologies revenues.