Attached files

| file | filename |

|---|---|

| EX-32 - CERTIFICATIONS UNDER SECTION 906 OF THE SARBANES-OXLEY ACT OF 2002 - FASTENAL CO | fast1231201710-kexhibit32.htm |

| EX-31 - CERTIFICATIONS UNDER SECTION 302 OF THE SARBANES-OXLEY ACT OF 2002 - FASTENAL CO | fast1231201710-kexhibit31.htm |

| EX-23 - CONSENT OF INDEPENDENT REGISTERED PUBLIC ACCOUNTING FIRM - FASTENAL CO | fast1231201710-kexhibit23.htm |

| EX-21 - SUBSIDIARIES OF FASTENAL COMPANY - FASTENAL CO | fast1231201710-kexhibit21.htm |

| EX-13 - PORTIONS OF 2017 ANNUAL REPORT TO SHAREHOLDERS NOT INCLUDED IN THIS FORM 10-K - FASTENAL CO | final2017annualreportweb.htm |

| EX-10.1 - BONUS PROGRAM FOR EXECUTIVE OFFICERS - FASTENAL CO | fast1231201710-kexhibit101.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

____________________________________________________________

FORM 10-K

(Mark One)

x | Annual report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

For the fiscal year ended December 31, 2017 | |

or

o | Transition report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

For the transition period from to | |

Commission file number 0-16125

FASTENAL COMPANY

(Exact name of registrant as specified in its charter)

Minnesota | 41-0948415 |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

2001 Theurer Boulevard Winona, Minnesota | 55987-0978 |

(Address of principal executive offices) | (Zip Code) |

(Registrant's telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

Title of Each Class | Name of Each Exchange on Which Registered |

Common Stock, par value $.01 per share | The Nasdaq Stock Market |

None

____________________________________________________________

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act Yes x No o

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act Yes o No x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or an emerging growth company. See definition of "large accelerated filer", "accelerated filer", "smaller reporting company", and "emerging growth company" in Rule 12b-2 of the Exchange Act.

Large Accelerated Filer | x | Accelerated Filer | o |

Non-accelerated Filer | o (Do not check if a smaller reporting company) | Smaller Reporting Company | o |

Emerging Growth Company | o | ||

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. o

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes o No x

The aggregate market value of the Common Stock held by non-affiliates of the registrant as of June 30, 2017, the last business day of the registrant's most recently completed second fiscal quarter, was $12,488,792,738, based on the closing sale price of the Common Stock on that date. For purposes of determining this number, all executive officers and directors of the registrant as of June 30, 2017 are considered to be affiliates of the registrant. This number is provided only for the purposes of this report on Form 10-K and does not represent an admission by either the registrant or any such person as to the status of such person.

As of January 19, 2018, the registrant had 287,603,912 shares of Common Stock issued and outstanding.

FASTENAL COMPANY

ANNUAL REPORT ON FORM 10-K

TABLE OF CONTENTS

Page | |||

Item 1. | |||

Item 1A. | |||

Item 1B. | |||

Item 2. | |||

Item 3. | |||

Item 4. | |||

Item 5. | |||

Item 6. | |||

Item 7. | |||

Item 7A. | |||

Item 8. | |||

Item 9. | |||

Item 9A. | |||

Item 9B. | |||

Item 10. | |||

Item 11. | |||

Item 12. | |||

Item 13. | |||

Item 14. | |||

Item 15. | |||

Item 16. | |||

DOCUMENTS INCORPORATED BY REFERENCE

Portions of our Proxy Statement for the annual meeting of shareholders to be held Tuesday, April 24, 2018 ('Proxy Statement') are incorporated by reference in Part III. Portions of our 2017 Annual Report to Shareholders are incorporated by reference in Part II.

FORWARD-LOOKING STATEMENTS

Certain statements contained in this Form 10-K, or in other reports of the company and other written and oral statements made from time to time by the company, do not relate strictly to historical or current facts. As such, they are considered 'forward-looking statements' that provide current expectations or forecasts of future events. These forward-looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. Such statements can be identified by the use of terminology such as anticipate, believe, should, estimate, expect, intend, may, will, plan, goal, project, hope, trend, target, opportunity, and similar words or expressions, or by references to typical outcomes. Any statement that is not a purely historical fact, including estimates, projections, trends, and the outcome of events that have not yet occurred, is a forward-looking statement. Our forward-looking statements generally relate to our expectations regarding the business environment in which we operate, our projections of future performance, our perceived marketplace opportunities, our strategies, goals, mission and vision, and our expectations related to the impact of tax reform. You should understand that forward-looking statements involve a variety of risks and uncertainties, known and unknown, and may be affected by inaccurate assumptions. Consequently, no forward-looking statement can be guaranteed and actual results may vary materially. Factors that could cause our actual results to differ from those discussed in the forward-looking statements include, but are not limited to, economic downturns, weakness in the manufacturing or commercial construction industries, competitive pressure on selling prices, changes in our current mix of products, customers, or geographic locations, changes in our average branch size, changes in our purchasing patterns, changes in customer needs, changes in fuel or commodity prices, inclement weather, changes in foreign currency exchange rates, difficulty in adapting our business model to different foreign business environments, failure to accurately predict the market potential of our business strategies, the introduction or expansion of new business strategies, weak acceptance or adoption of our vending or Onsite business models, increased competition in industrial vending or Onsite, difficulty in maintaining installation quality as our industrial vending business expands, the leasing to customers of a significant number of additional industrial vending devices, the failure to meet our goals and expectations regarding branch openings, branch closings, or expansion of our industrial vending or Onsite operations, changes in the implementation objectives of our business strategies, difficulty in hiring, relocating, training, or retaining qualified personnel, difficulty in controlling operating expenses, difficulty in collecting receivables or accurately predicting future inventory needs, dramatic changes in sales trends, changes in supplier production lead times, changes in our cash position or our need to make capital expenditures, credit market volatility, changes in tax law or the impact of any such changes on future tax rates, changes in the availability or price of commercial real estate, changes in the nature, price, or availability of distribution, supply chain, or other technology (including software licensed from third parties) and services related to that technology, cyber-security incidents, potential liability and reputational damage that can arise if our products are defective, and other risks and uncertainties detailed in this Form 10-K under the heading 'Item 1A. Risk Factors'. Each forward-looking statement speaks only as of the date on which such statement is made, and we undertake no obligation to update any such statement to reflect events or circumstances arising after such date.

1

PRESENTATION OF DOLLAR AMOUNTS

All dollar amounts in this Form 10-K are presented in millions, except for share and per share amounts or where otherwise noted. Throughout this document, percentage and dollar change calculations, which are based on non-rounded dollar values, may not be able to be recalculated using the dollar values in this document due to the rounding of those dollar values.

STOCK SPLIT

All information contained in this Form 10-K reflects the two-for-one stock split in 2011.

2

PART I

ITEM 1. | BUSINESS |

Note – Information in this section is as of year end unless otherwise noted. The year end is December 31, 2017 unless additional years are included or noted.

Overview

Fastenal Company (together with our subsidiaries, hereinafter referred to as 'Fastenal' or the company or by terms such as we, our, or us) began as a partnership in 1967, and was incorporated under the laws of Minnesota in 1968. We opened our first branch in 1967 in Winona, Minnesota, a city with a population today of approximately 27,000. We began with a marketing strategy of supplying threaded fasteners to customers in small, medium-sized, and, in subsequent years, large cities. Over time, that mandate has expanded to a broader range of industrial and construction supplies that we break into twelve product lines (described later in this document). The large majority of our transactions are business-to-business, though we also have some walk-in retail business. At the end of 2017, we had 2,988 in-market locations (defined in the table below) in 24 countries supported by 14 distribution centers in North America (11 in the United States, two in Canada, and one in Mexico), and we employed 20,565 people. We believe our success can be attributed to the high quality of our employees and their convenient proximity to our customers, and our ability to offer customers a full range of products and services to reduce their total cost of procurement.

The following table shows our consolidated net sales for each fiscal year as well as the number of public branches, Onsite locations, and total in-market locations at the end of each of the last ten years:

2017 | 2016 | 2015 | 2014 | 2013 | 2012 | 2011 | 2010 | 2009 | 2008 | ||||||||||||

Net sales | $ | 4,390.5 | 3,962.0 | 3,869.2 | 3,733.5 | 3,326.1 | 3,133.6 | 2,766.9 | 2,269.5 | 1,930.3 | 2,340.4 | ||||||||||

Public branches | 2,383 | 2,503 | 2,622 | 2,637 | 2,687 | 2,652 | 2,585 | 2,490 | 2,369 | 2,311 | |||||||||||

Onsite locations(1) | 605 | 401 | 264 | 214 | |||||||||||||||||

Total in-market locations(2) | 2,988 | 2,904 | 2,886 | 2,851 | 2,687 | 2,652 | 2,585 | 2,490 | 2,369 | 2,311 | |||||||||||

(1) Onsite location information prior to 2014 is intentionally omitted. While such locations have existed since 1992, we did not specifically track their number until we identified our Onsite program as a growth driver in 2014.

(2) 'In-market locations' is defined as the sum of the total number of public branches and the total number of Onsite locations.

One of Fastenal's guiding principles since inception is that we can improve our service by getting closer to the customer. Through much of our history, this was achieved by opening branches, and today we believe there are few companies that offer our North American branch coverage. In our view, this has proved to be an efficient means of providing customers with a broad range of products and services on a timely basis. These branches have represented, and continue to represent, the foundation of our service approach. However, we are constantly evaluating the efficacy of our branch network, and in recent years, we have developed additional models that get us still closer to the customer, including vending, bin stocks, and Onsite locations.

We currently have several versions of selling locations: (1) a 'traditional (or public) branch' services a wide variety of customers and stocks a wide selection of products we offer, (2) an 'overseas branch' focuses on manufacturing customers and our fastener product line and is the format we typically deploy outside the United States and Canada, (3) a 'strategic account branch' is a unique location that sells to multiple large accounts in a market, (4) a 'strategic account site' is similar to a strategic account branch, but typically operates out of an existing branch rather than from a unique location, and (5) an 'Onsite location' (defined as dedicated sales and service provided from within, or in close proximity to the customer's facility).

Traditional, overseas, and strategic account branches sell to multiple customers, and together comprise our total branch count. Our strategic account sites are considered an extension of the branch from which it operates, and are not included separately in our total branch counts. Onsite locations, which serve a single customer, are similarly not included in our total branch counts. However, outside of the fact that they serve a single customer, we believe the function and operation of an Onsite location is similar to that of a branch. This model is also beginning to represent a meaningful portion of the company's total revenue, and we expect that share to grow materially over time. As a result, we have begun to refer to our network in terms of in-market locations, which includes our total branches and Onsite locations, and we began to refer to strategic account sites as non-in-market locations.

Branch locations are selected primarily based on their proximity to our distribution network, population statistics, and employment data for manufacturing and non-residential construction companies. We stock all new branches with inventory drawn from all of our product lines, and over time, where appropriate, our district and branch personnel may tailor the inventory offering to the needs of the local customer base. Since Fastenal's founding and through 2013, branch openings were a primary growth driver for the company, and we experienced net openings each year over that time span. We have long

3

maintained that marketplace demographics could support a North American network of 3,500 traditional branches. However, since establishing this figure, new growth drivers and business models (Onsite, vending, e-commerce) have emerged and diminished the direct role of traditional branch openings in our growth. It is now unlikely that we will operate the total traditional branch locations we previously believed would be the potential of North America. We will continue to open traditional branches as the company sees fit. However, in each year since 2013, the company has experienced a net decline in its total branch count including net declines of 15 branches in 2015, 119 branches in 2016, and 120 branches in 2017.

There is one branch subset, overseas, that we anticipate expanding in the future. Selling locations outside of the United States and Canada contributed approximately 7% of our consolidated net sales in 2017, with approximately 4% and 3% of this amount attributable to our Mexican and 'rest-of-world' operations, respectively.

The following table provides a summary of the traditional, overseas, and strategic account branch locations we operated at the end of each year, as well as the openings, closings, and conversions during each year:

North America | Outside North America | ||||||||||||||||||||||

United States | Canada | Mexico | Puerto Rico and Dominican Republic | Subtotal | Central & South America (1) | Asia (2) | Southeast Asia (3) | Europe (4) | Africa (5) | Total | |||||||||||||

Total as of December 31, 2015 | 2,320 | 200 | 47 | 8 | 2,575 | 9 | 10 | 7 | 20 | 1 | 2,622 | ||||||||||||

Opened branches | 27 | 3 | 5 | — | 35 | — | — | — | 4 | 1 | 40 | ||||||||||||

Closed branches | (140 | ) | (3 | ) | — | — | (143 | ) | (1 | ) | — | — | — | — | (144 | ) | |||||||

Converted branches(6) | (13 | ) | (2 | ) | — | — | (15 | ) | — | — | — | — | — | (15 | ) | ||||||||

Total as of December 31, 2016 | 2,194 | 198 | 52 | 8 | 2,452 | 8 | 10 | 7 | 24 | 2 | 2,503 | ||||||||||||

Opened branches | 5 | 3 | 2 | — | 10 | 1 | — | — | 7 | — | 18 | ||||||||||||

Closed branches | (118 | ) | (6 | ) | (1 | ) | — | (125 | ) | (2 | ) | (2 | ) | — | (1 | ) | — | (130 | ) | ||||

Converted branches(6) | (5 | ) | — | — | — | (5 | ) | (1 | ) | (1 | ) | — | (1 | ) | — | (8 | ) | ||||||

Total as of December 31, 2017 | 2,076 | 195 | 53 | 8 | 2,332 | 6 | 7 | 7 | 29 | 2 | 2,383 | ||||||||||||

(1) Panama, Brazil, Colombia, and Chile

(2) China

(3) Singapore, Malaysia, and Thailand

(4) The Netherlands, Hungary, United Kingdom, Germany, Czech Republic, Italy, Romania, Poland, Sweden, Ireland, and Switzerland

(5) South Africa

(6) Converted locations are sites converted from traditional branches to Onsite locations or non-in-market locations, net of sites converted from non-in-market locations or Onsite locations to traditional branches.

Onsite locations may influence the trend in total branch count over time. In this model, the company services a customer from a location that is physically within the customer's facility (or, in some cases, at a strategically placed off-site location), with inventory that is specific to the customer's needs. The model is best suited to larger companies, though we believe we can provide a higher degree of service at a lower level of revenue than most of our competitors. In most cases, we are shifting revenue with the customer from an existing branch. It has been our experience, however, that while gross profit margins at Onsite locations tend to be lower than at branches, we gain significant revenue with the customer and our cost to serve is materially lower. The Onsite concept is not new, in that we entered into the first such arrangement in 1992. However, the company identified it as a growth driver in 2014 and made substantial investments toward accelerating its traction in the marketplace beginning in 2015. As a result, we have identified over 15,000 customer locations with potential to implement the Onsite service model. These customers include those where we have a national account relationship today, as well as new customers we know of due to our local market presence. We expect revenues from Onsite arrangements to increase meaningfully over time. We experienced net increases of 50, 137, and 204 Onsite locations in 2015, 2016, and 2017, respectively. We currently have over 600 Onsite locations and we believe we will have 1,000 Onsite locations in the next 12 to 18 months.

4

The following table provides a summary of the new Onsite customer locations signed and the total Onsite locations we operated at the end of each year, as well as the Onsite openings and closings during each year:

New Onsite Customer Locations Signed | Total Active Onsite Locations | |||

Total as of December 31, 2015 | 80 | 264 | ||

Opened Onsite locations | 161 | |||

Closed Onsite locations | (24 | ) | ||

Total as of December 31, 2016 | 176 | 401 | ||

Opened Onsite locations | 218 | |||

Closed Onsite locations | (14 | ) | ||

Total as of December 31, 2017 | 270 | 605 | ||

In 1997, we developed a national accounts program aimed at making our products and services more competitive with customers that operate multiple facilities. These customers tend to have more complex supply chains and structures for managing the MRO and OEM products we provide while at the same time, by virtue of their size and opportunity, have more negotiating power. We believe our local presence as part of a national, and increasingly international, footprint, our ability to provide a consistent level of high-touch service and broad product availability, and our ancillary capabilities around manufacturing, quality control, and product knowledge, are attractive to these larger customers. We believe our advantage with these customers has only been strengthened as we have added other channels, such as industrial vending, Onsite, and Fastenal Managed Inventory ('FMI®'), and resources to serve these customers' unique demands. As a result, in 2017, national accounts represented 48.7% of our net sales, compared to 47.4% and 46.4% in 2016 and 2015, respectively. We believe we will continue to perform well with these customers.

We introduced industrial vending in 2008. Vending provides our customers the benefits of reduced consumption, reduced purchase orders, reduced product handling, and 24-hour product availability, and we believe our company has a market advantage by virtue of our extensive in-market network. For these reasons, the initiative began to gain significant traction in 2011 and we finished 2017 with over 86,000 devices in the field (71,000 generating product revenue and 15,000 in a locker lease program). Our discussion generally focuses on the 71,000 product revenue devices. We believe vending has proven its effectiveness in strengthening our relationships with customers and helped to streamline the supply chain where it has been utilized. We also believe there remains considerable room to grow our current installed base before it begins to approach the number of units we believe the market can support. We estimate the market could support as many as 1.7 million industrial vending devices, and as a result we anticipate continued growth in installed devices over time. We believe we will have 100,000 total devices deployed in the next 12 to 18 months.

Our expanded industrial vending portfolio consists of 23 different vending devices, with the FAST 5000 device, our helix-based machine, representing approximately 40% of the installed product revenue devices. We have learned much about these devices over the last several years and currently the target monthly revenue ranges from under $1,000 per device to in excess of $3,000 per device. The following two tables provide two views of our data: (1) actual device count regardless of the type of device and (2) 'machine equivalent' count based on the weighted target monthly revenue of each device (compared to the FAST 5000 device, which has a $2,000 monthly revenue target). For example, the 12-door locker, with target monthly revenue of $750, would be counted as '0.375 machine equivalent' (0.375 = $750/$2,000).

The industrial vending (product revenue devices) information related to contracts signed during each period was as follows:

Q1 | Q2 | Q3 | Q4 | Annual | ||||||||||||

Device count signed during the period | 2017 | 5,437 | 4,881 | 4,771 | 4,266 | 19,355 | ||||||||||

2016 | 4,647 | 4,869 | 4,783 | 3,760 | 18,059 | |||||||||||

2015 | 3,962 | 5,144 | 4,689 | 4,016 | 17,811 | |||||||||||

'Machine equivalent' count signed during the period | 2017 | 4,476 | 4,032 | 4,010 | 3,640 | 16,158 | ||||||||||

2016 | 3,696 | 3,941 | 3,520 | 2,951 | 14,108 | |||||||||||

2015 | 2,916 | 3,931 | 3,769 | 3,319 | 13,935 | |||||||||||

5

The industrial vending (product revenue devices) information related to installed devices at the end of each period was as follows:

Q1 | Q2 | Q3 | Q4 | ||||||||||||

Device count installed at the end of the period | 2017 | 64,430 | 66,577 | 69,058 | 71,421 | ||||||||||

2016 | 56,889 | 58,346 | 60,400 | 62,822 | |||||||||||

2015 | 48,545 | 50,620 | 53,547 | 55,510 | |||||||||||

'Machine equivalent' count installed at the end of the | 2017 | 49,921 | 51,950 | 54,215 | 56,436 | ||||||||||

period | 2016 | 43,329 | 44,707 | 46,399 | 48,399 | ||||||||||

2015 | 35,997 | 37,714 | 40,067 | 41,905 | |||||||||||

In addition to industrial vending noted above, which primarily relates to our non-fastener business, we also provide Fastenal Managed Inventory ('FMI') programs, (also known as 'keep fill' or bin stock programs in the industry) to numerous customers. This business relates to both our maintenance customers (MRO fasteners and non-fasteners) and original equipment manufacturers (OEM fasteners). FMI is like our industrial vending business in that it involves moving product closer to the point of customer use within their facilities. However, the device is typically an open bin which is clustered with other bins in a racking system, each of which holds OEM fasteners, MRO fasteners, and/or non-fastener products that are consumed in the customers' operations. These bins utilize a variety of technologies. For instance, some bins are set up with the latest scanning technologies to determine when product is at a minimum desired level and requires refill, while others utilize scales to measure the volume of a bin's content by its weight, and our fully integrated distribution network allows us to manage the supply chain for all sizes of customers. FMI programs foster a strong relationship with customers, as we are often their preferred supplier, and a higher frequency of business transactions.

We believe our current growth drivers – Onsite locations, national accounts, industrial vending, and FMI – represent alternative means to address the requirements of certain customer groups. They get us closer to the customer and to where the product is actually consumed. This is consistent with our strategy and offers significant value by providing differentiated and 'sticky' service. Combined with ongoing strategic investments in end market initiatives (such as our Customer Service Project ('CSP') initiatives which expand inventory placement at our branches to enhance same-day capabilities) as well as selling (in-market and otherwise) and non-selling (engineering, product specialists, manufacturing, etc.) employees, we offer a range of capabilities that is difficult for large and small competitors to replicate.

We remain committed to a large, robust service network, including traditional branches; it remains the indispensable foundation of our business. In any given year, it is difficult to predict whether our total branch count will rise or fall. However, with the growth we anticipate in Onsite locations, we believe our total in-market locations will increase over time.

It has been our experience that our profitability is affected by the average revenue produced by each branch. While certain costs related to growth at a branch are at least partly variable, such as employee-related expenses, others, like rent and utility expenses, tend to be fixed. As a result, it has been shown that as a branch increases its sales base over time it typically will achieve a higher operating profit margin. This ability to increase our average revenue per branch is influenced by: (1) general growth based on end market expansion and/or market share gains, (2) the age of the branch base (new branches tend to be less profitable due to start-up costs and the time necessary to generate a customer base; however, when these new branches mature and increase their sales base, their profitability similarly increases), and (3) rationalization actions – in the past several years the company has seen a net decline in its branch base. There are many reasons why local or regional management might decide to close a branch. Key customers may have migrated to a different part of the market or transitioned to our Onsite model, plants may have closed, or our own supply chain capabilities in a market may have evolved to allow us to service some areas with fewer traditional branches. In the short term, the Onsite program can hurt the profitability of our existing branch network as it can pull established revenue away from an existing branch.

We operate 11 regional distribution centers in the United States – Minnesota, Indiana, Ohio, Pennsylvania, Texas, Georgia, Washington, California, Utah, North Carolina, and Kansas – and three outside the United States – Ontario, Canada; Alberta, Canada; and Nuevo Leon, Mexico. These 14 distribution centers give us approximately 3.5 million square feet of distribution capacity. These distribution centers are located so as to permit deliveries of two to five times per week to our in-market locations using our trucks and overnight delivery by surface common carrier, with approximately 83% of our North American in-market locations receiving service four to five times per week. We would expect to add new distribution centers over time as our scale and the number of our in-market locations increases. The distribution center in Indiana also serves as a 'master' hub, with those in California, North Carolina, and Kansas serving as 'secondary' hubs to support the needs of the in-market locations in their geographic regions as well as provide a broader selection of products for the in-market locations serviced by the other distribution centers.

6

We currently operate our Minnesota, Indiana, Ohio, Pennsylvania, Texas, Georgia, California, North Carolina, and Ontario, Canada distribution centers with automated storage and retrieval systems (ASRS). These nine distribution centers operate with greater speed and efficiency, and currently handle approximately 85% of our picking activity. The Indiana facility also contains our centralized replenishment facility for a portion of our industrial vending business. This operation is also highly automated. Construction of an ASRS began in 2017 at our Kansas distribution center, and we expect this project to be completed in the first quarter of 2018. Construction of a new distribution center in Washington, which will include ASRS technology, is scheduled to begin in 2018.

Our information systems department develops, implements, and maintains the computer based technology used to support business functions within Fastenal. Corporate, e-business, distribution center, and vending systems are primarily supported from central locations, while each selling location uses a locally installed Point-Of-Sale (POS) system. The systems consist of both customized, purchased, and licensed software. A dedicated Wide Area Network (WAN) is used to provide connectivity between systems and authorized users.

Trademarks and Service Marks

We conduct business under various trademarks and service marks, and we utilize a variety of designs and tag lines in connection with each of these marks, including Growth Through Customer Service®. Although we do not believe our operations are substantially dependent upon any of our trademarks or service marks, we consider the 'Fastenal' name and our other trademarks and service marks to be valuable to our business.

Products

Fastenal was founded as a distributor of fasteners and related industrial and construction supplies. This includes threaded fasteners, which represent approximately 85% of total fastener sales and includes bolts, nuts, screws, studs, and related washers, as well as miscellaneous supplies and hardware, such as pins, machinery keys, concrete anchors, metal framing systems, wire rope, strut, rivets, and related accessories. Our fastener product line, which is primarily sold under the Fastenal product name, represented 35.6%, 36.6%, and 38.3% of our consolidated net sales in 2017, 2016, and 2015, respectively. Of this, threaded fasteners represented approximately 30%, 33%, and 34% of our consolidated net sales in 2017, 2016, and 2015, respectively.

Fastener distribution is complex. In most cases the product has low per unit value but high per unit weight. This presents challenges in moving product from suppliers, most of whom are outside of North America, to our distribution centers, as well as from our distribution centers to our branch, Onsite, and customer locations. At the same time, fasteners are ubiquitous in manufactured products, construction projects, and maintenance and repair while at the same time exhibiting great geometric variability based on use and application. In many cases, a fastener is a critical part in machine uptime and/or effective use. These features have greatly influenced our logistical development, training and educational programs, support capabilities, and inventory decisions, which we believe would be difficult for competitors to replicate.

In 1993, we began to aggressively add additional product lines, and these represented 64.4%, 63.4%, and 61.7% of our consolidated sales in 2017, 2016, and 2015, respectively. These products, which we refer to as non-fastener product lines, tend to move through the same distribution channel, get used by the same customers, and utilize the same logistical capabilities as the original fastener product line. This logic is as true today as it was when we first began to diversify our product offering. However, over time, the supply chain for these product lines has evolved in ways independent of the fastener line. For instance, non-fastener product lines benefit from our development of industrial vending.

The most significant category of non-fastener products is our safety supplies product line, which accounted for 15.2%, 14.9%, and 13.9% of our consolidated sales in 2017, 2016, and 2015, respectively. This product line has enjoyed dramatic sales growth in the last ten years (roughly doubling as a percentage of sales over that ten year time frame). This is directly related to our success in industrial vending. Our tools product line now accounts for more than 10% of consolidated net sales, representing 10.1%, 9.9%, and 9.5% in 2017, 2016, and 2015, respectively. Also, in the last several years we added 'private label' brands (often referred to as 'Fastenal brands') to our offering, and these represented approximately 12% of our consolidated net sales in 2017, 2016, and 2015.

We plan to continue to add other product lines in the future.

Detailed information about our sales by product line is provided in Note 12 of the Notes to Consolidated Financial Statements included later in this Form 10-K. Each product line may contain multiple product categories.

Inventory Control

Our inventory stocking levels are determined using our computer systems, by our sales personnel at in-market locations, by our district and regional leadership, and by our product managers. The data used for this determination is derived from sales activity from all of our selling locations, from individual selling locations, and from different geographic areas. It is also derived from supplier information and from customer demographic information. The computer system monitors the inventory

7

level for all stock items and triggers replenishment, or prompts a buyer to purchase, as necessary, based on an established minimum-maximum level. All branches stock a base inventory and may expand beyond preset inventory levels as deemed appropriate by the district and branch personnel. Non-branch selling locations (primarily Onsites) stock inventory based on customer-specific arrangements. Inventories in distribution centers are established from computerized data for the selling locations served by the respective distribution center. Inventory quantities are continuously re-balanced utilizing an automated transfer mechanism we call 'inventory re-distribution'.

Inventory held at our selling locations, close to customers and available on a same-day basis, accounted for approximately 65%, 64%, and 61% of our total inventory at the end of 2017, 2016, and 2015, respectively. Inventory held at our distribution centers and manufacturing locations accounted for approximately 35%, 36%, and 39% of our total inventory at the end of 2017, 2016, and 2015, respectively. The distribution center and manufacturing location inventory, when combined with our trucking network, allows for incredibly fast, next-day service at a very competitive cost.

Manufacturing and Support Services Operations

In 2017, approximately 96% of our consolidated net sales were attributable to products manufactured by other companies to industry standards or to customer specific requirements. The remaining 4% related to products manufactured, modified or repaired by our manufacturing businesses or our support services. The manufactured products consist primarily of non-standard sizes of threaded fasteners made to customers' specifications or standard sizes manufactured under our Holo-Krome® and Cardinal Fasteners® product lines. The services provided by the support services group include, but are not limited to, the repair of tools and hoists, the fabrication of chain sling and hose, band saw blade welding, and other light manufacturing and fabrication. We may add additional services in the future. However, we engage in these activities primarily as a service to our customers and expect them to continue to contribute in the range of 4% to 6% of our consolidated net sales in the future.

Sources of Supply

We use a large number of suppliers for the standard stock items we distribute. Most items distributed by our network can be purchased from several sources, although preferred sourcing is used for some stock items to facilitate quality control. No single supplier accounted for more than 5% of our inventory purchases in 2017.

Beyond inventory, we have some concentration of purchasing activity. For example, we utilize a limited number of suppliers for distribution equipment, two main suppliers for our vehicle fleet, and primarily one supplier for our industrial vending equipment. However, we believe there are viable alternatives to each of these, if necessary.

Geographic Information

Information regarding our revenues and long-lived assets by geographic location is set forth in Note 8 of the Notes to Consolidated Financial Statements included later in this Form 10-K. Our ability to procure products overseas at competitive prices, as well as net sales at our foreign locations, could be impacted by foreign currency fluctuations, changes in trade relations, or fluctuations in the relative strength of foreign economies.

Customers and Marketing

We believe our success can be attributed to our ability to offer customers a full line of quality products, our convenient locations and diverse methods of providing those products, and the superior service orientation and expertise of our employees. Most of our customers are in the manufacturing and non-residential construction markets. The manufacturing market includes both original equipment manufacturers (OEM) and maintenance, repair, and operations (MRO). The non-residential construction market includes general, electrical, plumbing, sheet metal, and road contractors. Other users of our products include farmers, truckers, railroads, oil exploration, production, and refinement companies, mining companies, federal, state, and local governmental entities, schools, and certain retail trades. During the fourth quarter of 2017, our total number of active customer accounts (defined as accounts having purchase activity within the last 90 days) was approximately 400,000, while our total 'core accounts' (defined as the average number of accounts each month with purchase activity of at least $250 per month) was approximately 111,000. In 2017, no one customer accounted for more than 5% of our sales.

Based on our customer profile being oriented toward manufacturing and non-residential construction, our business has historically been cyclical. However, we believe our model has certain protections that moderate the volatility of our results around cyclical changes. First, we have a large number of customers that serve a wide range of segments within the broader manufacturing and non-residential construction market, although slumps in one industry served by us can rapidly spread to other, interrelated industries, locally or globally. However, we still believe this customer and market segment diversity provides some insulation from economic changes that are not across multiple industries and geographic regions. In addition, a meaningful part of our revenue is derived from products that are incorporated into final products. However, we also have a significant portion of revenue that is derived from products used to maintain sites, and while this revenue tends to be directly influenced by cyclical changes, its rate of change tends to be less dramatic.

8

Direct marketing continues to be the backbone of our business through our local in-market selling personnel, as well as our non-branch selling personnel. We support our branches with multi-channel marketing including email and online marketing, print and radio advertising, catalogs, promotional flyers, events, and branch signage. In recent years, our national advertising has been focused on a NASCAR® sponsorship through our partnership with Roush Fenway Racing® as the primary sponsor of Ricky Stenhouse Jr.'s No. 17 car in the Monster Energy® NASCAR® Cup Series.

Seasonality

Seasonality has some impact on our sales. The first and fourth quarters are typically our lowest volume periods, given their overlap with winter months in North America during which our sales to customers in the non-residential construction market typically slow due to inclement weather. The fourth quarter also tends to be more greatly affected by the Thanksgiving (October in Canada and November in the United States), Christmas, and New Year holiday periods, due to plant shut downs. In contrast, the second and third quarters typically have higher revenues due to stronger non-residential construction activity and relatively fewer holidays (although Good Friday will sometimes fall in the second quarter and the 4th of July will always fall in the second quarter).

Competition

Our business is highly competitive, and includes large competitors located primarily in large cities and smaller distributors located in many of the same smaller markets in which we have branches. We believe the principal competitive factors affecting the markets for our products, in no particular order, are customer service, price, convenience, product availability, and cost saving solutions.

Market strategies in industrial distribution are varied. Where products are concerned, while many larger distributors have trended toward a broad-line offering over time, they are often still closely associated with a specific product that can influence their ability to capture market share. This association with a specific product line is often even more pronounced among smaller competitors, though many smaller competitors do deploy a broad-line model. Means of serving the customer are even more diverse. For instance, many competitors maintain a local, branch-based presence in their markets, while others use vans to sell products in markets away from their main warehouses, while still others rely on catalogs or telemarketing sales. Recent years have seen the emergence of digital solutions, such as websites, and while this channel has been embraced by many traditional distributors it also has introduced non-traditional, e-commerce-based competitors into the marketplace. The diversity of product and service models supported in the marketplace is a reflection of the equally diverse product and service needs of the customer base. The large majority of our customers utilize multiple channels, from a single distributor where they are offered or from a range of distributors, to procure the products they need in their operations.

We believe that better service, and a competitive selling advantage, can be provided by maintaining a physical presence closer to the customer's location(s). As a result, we maintain branches in small, medium, and large markets, each offering a wide variety of products. The convenience of a large number of branches in a given area, combined with our ability to provide frequent deliveries to such branches from centrally located distribution centers, facilitates the prompt and efficient distribution of products. We also believe our industrial vending and bin stock solutions, supported from an in-market (branch or Onsite) location, provides a unique way to provide our customers convenient access to products and cost saving solutions using a business model not easily replicated by our competitors. Having trained personnel at each in-market location also enhances our ability to compete (see 'Employees' below).

Our Onsite service model provides us with a strategic advantage with our larger customers. Building on our core business strategy of the local branch, the Onsite model provides value to our customers through customized service while giving us a competitive advantage through stronger relationships with those customers, all with a relatively low investment given the existing branch and distribution structure.

9

Employees

At the end of 2017, we employed 20,565 full and part-time employees. Of these, approximately 74% held an in-market or non-branch selling role. We characterize these personnel as follows:

2017 | 2016 | |||

In-market locations | 13,424 | 12,966 | ||

Non-branch selling | 1,711 | 1,575 | ||

Selling subtotal | 15,135 | 14,541 | ||

Distribution | 3,575 | 3,403 | ||

Manufacturing | 652 | 594 | ||

Administrative | 1,203 | 1,086 | ||

Non-selling subtotal | 5,430 | 5,083 | ||

Total | 20,565 | 19,624 | ||

We believe the quality of our employees is critical to our ability to compete successfully in the markets we currently serve and to our ability to develop new markets and customer relationships. We foster the growth and education of skilled employees throughout the organization by operating training programs and by decentralizing decision-making. Wherever possible, our goal is to 'promote from within'. For example, most new branch and Onsite managers are promoted from an outside sales position and district managers (who supervise a number of in-market locations) are usually former branch managers.

The Fastenal School of Business (our internal corporate university program, known as FSB) develops and delivers a comprehensive array of industry and company-specific education and training programs that are offered to our employees. FSB provides core curricula focused on key competencies determined to be critical to the success of our employees' performance. In addition, we provide specialized educational tracks within various institutes of learning. These institutes of learning are advanced levels that provide specific concentrations of education and development and have been designed to focus on critical aspects of our business, such as leadership, effective branch best practices, sales and marketing, product education, and distribution.

Our selling personnel are compensated with a base salary and an incentive bonus arrangement that places emphasis on achieving increased sales on a branch, Onsite, district, regional, and national account basis, while still attaining targeted levels of, among other things, gross profit and trade accounts receivable collections. As a result, a significant portion of our total employment cost varies with sales volume. We also pay incentive bonuses to our leadership personnel based on one or more of the following factors: sales growth, earnings growth (before and after taxes), profitability, and return on assets, and to our other personnel for achieving predetermined departmental, project, and cost containment goals.

Our employees are not subject to any collective bargaining agreements and we have experienced no work stoppages. We believe our employee relations are good.

Available Information

Our Internet address for corporate and investor information is www.fastenal.com. The information contained on our website or connected to our website is not incorporated by reference into this annual report on Form 10-K and should not be considered part of this report.

Our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act are available free of charge on or through our website at www.fastenal.com as soon as reasonably practicable after such reports have been filed with or furnished to the SEC.

10

ITEM 1A. | RISK FACTORS |

In addition to the other information in this Form 10-K, the following factors should be considered in evaluating our business. Our operating results depend upon many factors and are subject to various risks and uncertainties. The most significant risks and uncertainties known to us which may cause our operating results to vary from anticipated results or which may negatively affect our operating results and profitability are as follows:

Company Risks

Products that we sell may expose us to potential material liability for property damage, environmental damage, personal injury, or death linked to the use of those products by our customers. Some of our customers operate in challenging industries where there is a material risk of catastrophic events. We are actively seeking to expand our sales to certain categories of customers, some of whose businesses may entail heightened levels of such risk. If any of these events are linked to the use by our customers of any of our products, claims could be brought against us by those customers, by governmental authorities, and by third parties who are injured or damaged as a result of such events. In addition, our reputation could be adversely affected by negative publicity surrounding such events regardless of whether or not claims against us are successful. While we maintain insurance coverage to mitigate a portion of this risk and may have recourse against our suppliers for losses arising out of defects in products procured from them, we could experience significant losses as a result of claims made against us to the extent adequate insurance is not in place, the products are manufactured by us or legal recourse against our suppliers is otherwise not available, or our insurers or suppliers are unwilling or unable to satisfy their obligations to us.

We may be unable to meet our goals regarding the growth drivers of our business. Our sales growth is dependent primarily on our ability to attract new customers and increase our activity with existing customers. Historically, the most effective way to attract new customers has been opening new branches. In recent years, however, we have devoted increased resources to other growth drivers, including our industrial vending business, our Onsite business, and our national accounts team. While we have taken steps to build momentum in the growth drivers of our business, we cannot assure you those steps will lead to additional sales growth. Failure to achieve any of our goals regarding industrial vending, Onsite locations, national accounts signings, or other growth drivers could negatively impact our long-term sales growth. Further, failure to identify appropriate customer sites for our Onsite businesses or failure to find suitable locations for our Onsite businesses once appropriate customer sites are identified may adversely impact our goals regarding the number of new Onsite locations we are able to open.

Changes in customer or product mix, downward pressure on sales prices, and changes in volume of orders could cause our gross profit percentage to fluctuate or decline in the future. Changes in our customer or product mix could cause our gross profit percentage to fluctuate or decline. For example, the portion of our sales attributable to fasteners has been decreasing in recent years. That has adversely affected our gross profit percentage as our non-fastener products generally carry lower gross profit margins than our fastener products. Similarly, in recent years, revenues from national accounts customers, which typically have lower gross profit margins by virtue of their scale and available business, have tended to grow faster than revenues from smaller customers. This factor has become more significant as revenues from Onsite locations has grown in the mix. If our customer or product mix continues to change, our gross profit percentage may decline further. Downward pressure on sales prices and changes in the volume of our orders could also cause our gross profit percentage to fluctuate or decline. We can experience downward pressure on sales prices as a result of deflation, pressure from customers to reduce costs, or increased competition. Reductions in our volume of purchases can adversely impact gross profit by reducing supplier volume allowances. Customer and product mix have contributed to the decline in our gross profit percentage over time, including in 2017 and 2016, and will likely continue to affect our gross profit percentage in 2018 and beyond. However, whether this adverse mix impact will result in a decline of our gross profit percentage in any given year will depend on the extent to which they are, or are not, offset by positive impacts to gross profit margin during such year.

Our operating and administrative expenses could grow more rapidly than net sales which could result in failure to achieve our goals related to leveraging revenue growth into higher net earnings. Over time, we have generally experienced an increase in our operating and administrative expenses, including costs related to payroll, occupancy, freight, and information technology, among others, as our net sales have grown. However, historically, a portion of these expenses has not increased at the same rates as net sales, allowing us to leverage our growth and sustain or expand our operating profit margins. There are various scenarios where we may not be able to continue to achieve this leverage as we have been able to do in the past. For instance, it is typical that when demand declines, most commonly from cyclical factors (though it could be due to customer losses or some other company-specific event), our operating and administrative expenses do not fall as quickly as net sales. It is also possible that in the future we will elect to make investments in operating and administrative expenses that would result in costs growing faster than net sales. In addition, market variables, such as labor rates, energy costs, and legal costs, could move in such a way as to cause us to not be able to manage our operating and administrative expenses in a way that would enable us to leverage our revenue growth into higher net earnings. Should any of these scenarios, or a combination of them, occur in the future, it is possible that our operating and pre-tax profit margins could decline even if we are able to grow revenue.

11

Our competitive advantage in our industrial vending business could be eliminated and the loss of key suppliers of equipment and services for that business could be disruptive and could result in failure to deploy devices. We believe we have a competitive advantage in industrial vending due to our vending hardware and software, our local branch presence (allowing us to service devices more rapidly), our 'vendible' product depth, and in North America, our distribution strength. These advantages have developed over time; however, other competitors could respond to our expanding industrial vending business with highly competitive platforms of their own. Such competition could negatively impact our ability to expand our industrial vending business or negatively impact the economics of that business. In addition, we currently rely on a limited number of suppliers for the vending devices used in, and certain software and services needed to operate, our industrial vending business. While these devices, software, and services can be obtained from other sources, loss of our current suppliers could be disruptive and could result in us failing to meet our goals related to the number of devices we are able to deploy in the next twelve to eighteen months.

The ability to identify new products and product lines, and integrate them into our selling locations and distribution network, may impact our ability to compete and our sales and profit margins. Our success depends in part on our ability to develop product expertise at the selling location level and identify future products and product lines that complement existing products and product lines and that respond to our customers' needs. We may not be able to compete effectively unless our product selection keeps up with trends in the markets in which we compete or trends in new products. In addition, our ability to integrate new products and product lines into our branches and distribution network could impact sales and profit margins.

Our ability to successfully attract and retain qualified personnel to staff our selling locations could impact labor costs, sales at existing selling locations, and the successful execution of our growth drivers. Our success depends in part on our ability to attract, motivate, and retain a sufficient number of qualified employees, including inside and outside branch associates, Onsite managers, and national account sales representatives, who understand and appreciate our culture and are able to adequately represent this culture to our customers. Qualified individuals of the requisite caliber and number needed to fill these positions may be in short supply in some areas, and the turnover rate in the industry is high. If we are unable to hire and retain personnel capable of consistently providing a high level of customer service, as demonstrated by their enthusiasm for our culture and product knowledge, our sales could be materially adversely affected. Additionally, competition for qualified employees could require us to pay higher wages to attract a sufficient number of employees. An inability to recruit and retain a sufficient number of qualified individuals in the future may also delay the planned openings of new branches and planned expansion of our other selling channels.

Our inability to attract or transition key executive officers may divert the attention of other members of our senior leadership and adversely impact our existing operations. Our success depends on the efforts and abilities of our key executive officers and senior leadership. In the event of voluntary or involuntary vacancies in our executive team in the future, the extent to which there is disruption in the oversight and/or leadership of our business will depend on our ability to either transition internal, talented individuals or recruit suitable replacements to serve in these roles. In addition, difficulties in smoothly implementing any transition to new members of our executive team, or recruiting suitable replacements, could divert the attention of other members of our senior leadership team from our existing operations.

We may not be able to compete effectively against traditional or non-traditional competitors, which could cause us to lose market share or erode our operating income. The industrial, construction, and maintenance supply industry, although slowly consolidating, still remains a large, fragmented, and highly competitive industry. Our current or future competitors may include companies with similar or greater market presence, name recognition, and financial, marketing, technological, and other resources, and we believe they will continue to challenge us with their product selection, financial resources, technological advancements, and services. Increased competition from brick and mortar retailers in markets in which we have in-market locations or from on-line retailers (particularly those major internet providers who can offer a wide range of products and rapid delivery), and the adoption by competitors of aggressive pricing strategies and sales methods, could cause us to lose market share or reduce our prices or increase our spending, thus eroding our operating income.

Interruptions in the proper functioning of information systems could disrupt operations and cause unanticipated increases in costs and/or decreases in revenues. The proper functioning of our information systems is critical to the successful operation of our business. Although our information systems are protected with robust backup systems, including physical and software safeguards and remote processing capabilities, information systems are still vulnerable to natural disasters, power losses, unauthorized access, telecommunication failures, and other problems. In addition, certain software used by us is licensed from, and certain services related to our information systems are provided by, third parties who could choose to discontinue their relationship with us. If critical information systems fail or these systems or related software or services are otherwise unavailable, our ability to process orders, maintain proper levels of inventories, collect accounts receivable, pay expenses, and maintain the security of company and customer data could be adversely affected.

In the event of a cyber security incident, we could experience certain operational interruptions, incur substantial additional costs, become subject to legal or regulatory proceedings, or suffer damage to our reputation in the marketplace. The nature of our business requires us to receive, retain, and transmit certain personally identifying information that our customers provide

12

to purchase products or services, register on our websites, or otherwise communicate and interact with us. While we have taken and continue to undertake significant steps to protect our customer and confidential information, a compromise of our data security systems or those of businesses we interact with could result in information related to our customers or business being obtained by unauthorized persons. We develop and update processes and maintain systems in an effort to try to prevent this from occurring, but the development and maintenance of these processes and systems are costly and require ongoing monitoring and updating as technologies change and efforts to overcome security measures become more sophisticated. Consequently, despite our efforts, the possibility of cyber security incidents cannot be eliminated entirely. While we also seek to obtain assurances that third parties we interact with will protect confidential information, there is a risk the confidentiality of data held or accessed by third parties may be compromised. If a compromise of our data security were to occur, it could interrupt our operations, subject us to additional legal, regulatory, and operating costs, and damage our reputation in the marketplace.

If we experience a loss related to our information systems or are unable to maintain or upgrade our information systems, or convert to alternate systems, in a timely and efficient manner, our operations may be disrupted or become less efficient. We depend on information systems for many aspects of our business and we could be adversely affected if we experience a disruption or data loss relating to our information systems and are unable to recover in a timely manner. We could also be adversely impacted if we are unable to improve, upgrade, maintain, and expand our information systems. Difficulties resulting from the transition of our industrial vending hosting services could also be disruptive to the success of our efforts to grow our industrial vending presence. The success of our growth drivers is dependent in varying degrees on the timely delivery and the functionality of information technology systems to support them. Extended delays or unexpected expenses in securing, developing, and otherwise implementing technology solutions to support our growth drivers could delay the achievement of our goals regarding these growth drivers.

Our business is subject to a wide array of laws and regulations in every jurisdiction where we operate. Compliance with these laws and regulations increases the cost of doing business and failure to comply could result in the imposition of fines or penalties and the termination of contracts. We are subject to a variety of laws and regulations including without limitation; import and export requirements, anti-bribery and corruption laws, tax laws (including U.S. taxes on foreign subsidiaries), product compliance laws, environmental laws, foreign exchange controls and cash repatriation restrictions, advertising regulations, data privacy and cyber security requirements, regulations on suppliers regarding the sources of supplies or products, labor and employment laws, and anti-competition regulations. In particular, our future effective tax rates could be affected by legislative tax reform, changes in statutory rates, or changes in tax laws or the interpretation thereof. In addition, notwithstanding the reduction in the corporate income tax rate included in the recently enacted comprehensive tax legislation commonly referred to as the Tax Cuts and Jobs Act (the 'Tax Act'), the overall impact of the Tax Act on our future financial results is subject to uncertainties and our financial results could be adversely impacted by certain other aspects of the Tax Act, including one-time taxes on accumulated offshore earnings, requiring a current inclusion in U.S. federal income of certain earnings of controlled foreign corporations, allowing a domestic corporation an immediate deduction in U.S. taxable income for a portion of its foreign-derived intangible income, and the base erosion anti-abuse tax. These factors could result in our 2018 provisional income tax expense booking rate to differ from our expectations. In addition, as a supplier to federal, state, and local government agencies, we must comply with certain laws and regulations relating specifically to the formation, administration, and performance of our governmental contracts. We are also subject to governmental audits and inquiries in the normal course of business. Ongoing audit activity and changes to the legal and regulatory environments could increase the cost of doing business, and such costs may increase in the future as a result of changes in these laws and regulations or in their interpretation. While we have implemented policies and procedures designed to facilitate compliance with these laws and regulations, there can be no assurance that our employees, contractors, or agents will not violate such laws and regulations, or our policies. Any such violations could result in the imposition of fines and penalties, damage to our reputation, and, in the case of laws and regulations relating specifically to governmental contracts, the loss of those contracts.

We may not be successful in integrating acquisitions and achieving intended benefits and synergies. We have completed several acquisitions of businesses in recent years. We expect to continue to pursue strategic acquisitions that we believe will either expand or complement our business in new or existing markets or further enhance the value and offerings we are able to provide to our existing or future potential customers. Acquisitions involve numerous risks and challenges, including, among others, a risk of potential loss of key employees of an acquired business, inability to achieve identified operating and financial synergies anticipated to result from an acquisition, diversion of our capital and our management's attention from other business issues, and risks related to the integration of the acquired business including unanticipated changes in our business, our industry, or general economic conditions that affect the assumptions underlying the acquisition. Any one or more of these factors could cause us to not realize the benefits anticipated to result from the acquisitions.

13

Industry and General Economic Risks

A downturn in the economy or in the principal markets served by us and other factors may affect customer spending, which could harm our operating results. In general, our sales represent spending on discretionary items or consumption needs by our customers. This spending is affected by many factors, including, among others:

• | general business conditions, |

• | business conditions in our principal markets, |

• | interest rates, |

• | inflation, |

• | liquidity in credit markets, |

• | taxation, |

• | government regulations, |

• | energy and fuel prices and electrical power rates, |

• | unemployment trends, |

• | terrorist attacks and acts of war, |

• | weather conditions, and |

• | other matters that influence customer confidence and spending. |

A downturn in either the national or local economy where we operate, or in the principal markets served by us, or changes in any of the other factors described above, could negatively impact sales at our in-market locations, sales through our other selling channels, and the level of profitability of those in-market locations and other selling channels.

This risk was demonstrated in 2015 and 2016. We have significant exposure to companies involved in the manufacture of capital goods and heavy equipment. In 2015, our business was impacted by lower commodity prices, including oil, lower corporate capital spending, and a strong U.S. dollar. These variables resulted in some of our customers exhibiting a reduced level of business activity and confidence. When this happens, these customers tend to cut back on spending which yields a slowdown in our business with these customers. These same dynamics carried into 2016. In 2017, these conditions mostly reversed. Certain commodity prices recovered and corporate investment improved, leading to better capital spending trends among our customers. This improvement in customer spending helped to improve our net sales and sales growth.

Products manufactured in foreign countries may cease to be available, which could adversely affect our inventory levels and operating results. We obtain certain of our products, and our suppliers obtain certain of their products, from China, Taiwan, South Korea, Mexico, and other foreign countries. Our suppliers could discontinue selling products manufactured in foreign countries at any time for reasons that may or may not be in our control or our suppliers' control, including foreign government regulations, domestic government regulations, political unrest, war, disruption or delays in shipments, changes in local economic conditions, or trade issues. Additionally, the shipment of goods from foreign countries could be delayed by container shipping companies encountering financial or other difficulties. Our operating results and inventory levels could suffer if we are unable to promptly replace a supplier or shipper who is unwilling or unable to satisfy our requirements with another supplier or shipper providing equally appealing products and services.

New trade policies could make sourcing product from overseas more difficult and/or more costly. We source a significant amount of the products we sell from outside of the United States, primarily Asia. This sourcing is both direct (through our wholly-owned, Asia-based subsidiary, FASTCO Trading Co., Ltd.) and indirect (from suppliers that themselves procure product from international sources). Considerable political uncertainty in the United States may result in changes to trade policies that may affect our sourcing operations. Should this occur, it may be difficult in light of the significant structural investments made over time and the absence of significant domestic fastener production for us to adjust our capabilities to any new policies in the short term, which could increase the difficulty and/or cost of sourcing products. Such changes could adversely affect our ability to secure sufficient product to service our customers and/or adversely affect our cost of operating in a way that hurts our financial results.

Changes in energy costs and the cost of raw materials used in our products could impact our net sales, cost of sales, gross profit percentage, distribution expenses, and occupancy expenses, which may result in lower operating income. Costs of raw materials used in our products (e.g., steel) and energy costs have fluctuated during the last several years. Increases in these costs result in increased production costs for our suppliers. These suppliers typically look to pass their increased costs along to us through price increases. The fuel costs of our distribution and branch operations have fluctuated as well. While we typically try to pass increased supplier prices and fuel costs through to our customers or to modify our activities to mitigate the impact, we may not be successful, particularly if supplier prices or fuel costs rise rapidly. Failure to fully pass any such increased prices and costs through to our customers or to modify our activities to mitigate the impact would have an adverse effect on our operating income. While increases in the cost of fuel or raw materials could be damaging to us, decreases in those costs, particularly if severe, could also adversely impact us by creating deflation in selling prices, which could cause our gross profit

14

to deteriorate, or by negatively impacting customers in certain industries, which could cause our sales to those customers to decline.

New trade policies could have an adverse impact on industries we sell into, negatively affecting our net sales and profits. Considerable political uncertainty in the United States may result in changes to trade policies that could create disruption in geographic demand trends. To the extent that the United States government enacts tariffs or taxes that penalize imports to benefit domestic manufacturing, we may improve our domestic sales which may have an overall positive impact on us given that 88% of our total revenue is derived from the United States. However, any such action may adversely impact our foreign sales, which may, in turn, adversely impact our ability to expand our overseas branches in the future. In addition, should a foreign government engage in its own trade protection, independent of or in response to another nation's action, it could have a negative direct or, more likely, indirect effect on our net sales and profits by reducing demand for exports by United States companies. It is difficult to know in advance what the net effect of such actions will be on companies such as ours, but it is possible that such changes could adversely affect our financial results.

The industrial, construction, and maintenance supply industry is consolidating, which could cause it to become more competitive and could negatively impact our market share, gross profit, and operating income. The industrial, construction, and maintenance supply industry in North America is consolidating. This consolidation is being driven by customer needs and supplier capabilities, which could cause the industry to become more competitive as greater economies of scale are achieved by suppliers, or as competitors with new business models are willing and able to operate with lower gross profit on select products. Customers are increasingly aware of the total costs of fulfillment and of the need to have consistent sources of supply at multiple locations. We believe these customer needs could result in fewer suppliers as the remaining suppliers become larger and capable of being a consistent source of supply.

There can be no assurance we will be able in the future to take advantage effectively of the trend toward consolidation. The trend in our industry toward consolidation could make it more difficult for us to maintain our current gross profit and operating income. Furthermore, as our industrial customers face increased foreign competition, and potentially lose business to foreign competitors or shift their operations overseas in an effort to reduce expenses, we may face increased difficulty in growing and maintaining our market share.

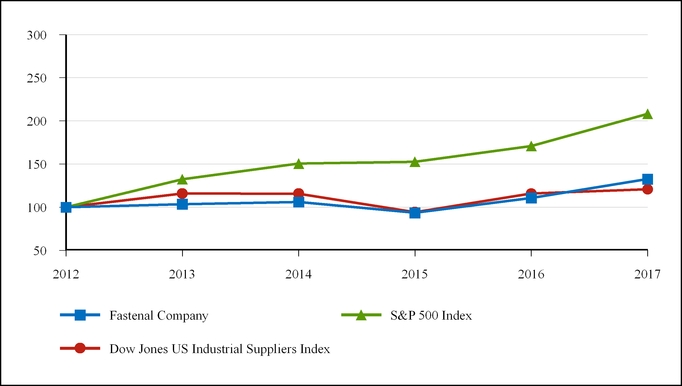

Inclement weather and other disruptions to the transportation network could adversely impact our distribution system and demand for our products. Our ability to provide efficient distribution of core business products to our branch network is an integral component of our overall business strategy. Disruptions at distribution centers or shipping ports may affect our ability to both maintain core products in inventory and deliver products to our customers on a timely basis, which may in turn adversely affect our results of operations. In addition, severe weather conditions could adversely affect demand for our products in particularly hard hit regions. In August and September 2017, we experienced temporary disruptions in our distribution network in our Gulf Coast, Florida, Georgia, and Puerto Rico regions due to hurricanes Harvey, Irma, and Maria. These storms adversely impacted our product demand and revenues, as well as our gross and operating profit percentages, due to an increase in demand for storm-related products which have a lower gross profit margin, and inefficiencies in delivery services in the immediate aftermath of the storms.