Attached files

| file | filename |

|---|---|

| 8-K - VSM 8-K - Versum Materials, Inc. | vsm8-k121216.htm |

VERSUM MATERIALS

INVESTOR MEETINGS

December 2016

FORWARD-LOOKING STATEMENTS

This presentation contains certain statements regarding future actions, results and other matters which are “forward-looking statements” within the

meaning of the safe harbor provisions of the U.S. Private Securities Litigation Reform Act of 1995. The words “believe,” “expect,” “anticipate,” “project,”

“estimate,” “budget,” “continue,” “could,” “intend,” “may,” “plan,” “potential,” “predict,” “seek,” “should,” “will,” “would,” “objective,” “forecast,” “goal,”

“guidance,” “outlook,” “effort,” “target” and similar expressions identify these forward-looking statements, which speak only as of the date the statements

were made. Forward-looking statements include, without limitation, statements about business strategies, operating plans, and outlook for Versum

Materials, our growth prospects, expectations as to future sales, operating income or Adjusted EBITDA, estimates regarding capital requirements and needs

for additional financing, estimates of expenses and cost reduction efforts, future revenues and profitability, our future operating results on a segment basis,

anticipated cash flows, estimates of the size of the market for our products, estimates of the success of other competing technologies that may become

available, and our future success as an independent public company. These forward-looking statements are based on management’s reasonable

expectations and assumptions as of the date of this presentation. Actual results and the outcomes of future events may differ materially from the those

expressed or implied in the forward-looking statements because of a number of risks and uncertainties, including, without limitation, weakening of global or

regional general economic conditions and product supply versus demand imbalances in the semiconductor industry could decrease the demand for our

goods and services; our concentrated customer base; our ability to continue technological innovation to meet the evolving needs of our customers; our

inability to protect and enforce intellectual property rights; our available cash and access to additional capital is limited by our substantial debt; uncertainty

regarding the availability of financing to us in the future and the terms of such financing; restrictions in the agreements governing our indebtedness;

operational, political and legal risks of our international operations; hazards associated with specialty chemical manufacturing could disrupt our operations

or the operations of our suppliers or customers; changes in government regulations in the countries we operate; raw material shortages and price increases;

sole source and limited source suppliers; costs of complying with global environmental health and safety regulations; the impact of changes in

environmental, tax or other legislation and regulations in jurisdictions in which Versum Materials and its affiliates operate; the security of our information

technology networks and systems could be compromised and disrupted; fluctuation of currency exchange rates; increased competition; costs and outcomes

of litigation or regulatory investigations; the timing, impact, and other uncertainties of future acquisitions; the successful relocation of our headquarters and

organizational changes; our ability to realize the anticipated benefits as a result of our Separation from Air Products; our ability to successfully complete the

transition to an independent public company; our historical financial data as part of Air Products may not reflect what our financial results would have been

had we been an independent company; the loss of certain benefits enjoyed as part of Air Products; increased costs as a separate public company; our ability

to assure customers of our financial stability as a separate company; tax and other potential liabilities to Air Products assumed in connection with the

separation and spin-off; restrictions against engaging in certain corporate transactions; potential conflicts of interest between us and Air Products by our

directors and officers; potential state and federal law liabilities arising out of the separation and spin-off from Air Products; fluctuations in our stock price; no

guarantee regarding the timing, amount or payment of dividends; dilution of your percentage of stock ownership; restrictions in our governing documents

and of Delaware law may prevent or delay an acquisition of us. These and other important factors that could cause actual results or events to differ

materially from those expressed in our forward-looking statements are described in our filings with the U.S. Securities and Exchange Commission, including

our Form 10 Registration Statement, as amended, and our periodic filings. Versum Materials disclaims any obligation or undertaking to disseminate any

updates or revisions to the outlook and any forward-looking statements contained in this document to reflect any change in assumptions, beliefs or

expectations, or any change in circumstances occurring after the date of this presentation.

Non-GAAP Financial Measures

This presentation contains certain “Non-GAAP financial measures.” Please refer to the Appendix for definitions of the non-GAAP financial measures used

herein and for a reconciliation of those non-GAAP financial measures to their most comparable GAAP measures.

CONTENTS

Semiconductor Industry Overview

Versum Materials’ Business

Financial Profile

2017 Industry Trends and Versum Priorities

Appendices and Reconciliations

3

VERSUM MATERIALS

INVESTMENT HIGHLIGHTS

Solid growth

High margins

Low capital intensity

Strong cash flow

4

BEST IN CLASS ELECTRONIC MATERIALS COMPANY

Leadership positions in a profitable and

complex semiconductor materials industry

Strong technology, commercial and

operations capabilities

Compelling growth platforms with

sustainable competitive advantage

Strong financial performance and cash flow

generation

Experienced management team with

proven track record

Global infrastructure

Refer to Appendix for reconciliations between GAAP and non-GAAP measures.

SEMICONDUCTOR OVERVIEW

SEMICONDUCTOR INDUSTRY FUNDAMENTALS

DEMAND, COMPLEXITY AND PERFORMANCE FOR NEW GENERATION NODES DRIVES MATERIALS GROWTH

• Growing technology driven industry that enables human advancement

- Computation / Mobility / Big Data / Internet of Things (IoT)

• Complexity of Growing technology driven industry that enables human advancement

- Computation / Mobility chip architectures driving materials innovation and growth

- New Materials required to enable next generation nodes

- Increased processing steps changing the number of products and volume requirements

- Managing complexity and collaboration is critical to success in Materials

• Substantial industry capital spending across the cycles

• Significant industry concentration and growth in Asia

6

Source: ASM ISS 2016 and Versum estimates

GROWTH SUPPORTED BY NEED FOR NEW MATERIALS KEY GROWTH METRICS

2013 2014 2015 2016

Wafer Equipment

(Gartner, CY) -8% 16% 0% -1%

MSI Growth (Hilltop

Economics, FY) 2% 8% 7% 0%

SOURCE: Linx/Hilltop Economics, Gartner, Versum estimates

7

SCOPE OF SEMICONDUCTOR SPACE

MATERIALS MARKET OF OVERALL SEMICONDUCTOR REVENUES

• Critical competencies in molecular design,

formulation expertise and ultra high purity

• Changing semiconductor industry dynamics

reducing cyclicality and lowering volatility

• More than 80% of VSM materials sales to

semiconductor industry in both the memory

and logic segments

• Increased importance of materials in next

generation nodes driving growth

• Strong customer intimacy with strong product

development partnerships with customers

and OEMs

• Strategically located assets in Asia

• Advanced Materials revenue growth driven

by new product and new applications

Our Business

$0 $100 $200 $300 $400 $500

Semiconductor Market

OEM

$450 B Semiconductor Value Chain

IC

Materials

Wafers

34%

Polysilicon

13%

Photomasks

9%

Photoresists

4% CMP slurries

4%

Specialty gases

4%

Specialty

Chemicals

1%

Bulk Gases

4%

Specialty

substrates

4%

Wet Process

Chemicals

3%

Sputtering

Targets

2%

Other

18%

$50 Billion IC Materials Market Our Focus ~ $5B

Versum Participates

in Only ~1% of

the Overall

Semiconductor

Market(a)

(a) Excludes Delivery

Systems SBU.

Source: SEMI , 2016 McClean Report by IC Insights, Versum estimates

SEMICONDUCTOR INDUSTRY IS CHANGING

SHIFTING GROWTH DRIVERS (MOBILITY & IOT) & INDUSTRY CONCENTRATION

8

IC MARKET SHARE BY SYSTEM TYPE (%)

Scale and concentration in leading edge semiconductor manufacturers

Move towards consumer products driven demand

Source: 2015 McClean Report by IC Insights.

55.6% 51.3%

45.0%

37.2% 32.7%

18.5% 22.0%

29.3%

36.7% 41.8%

13.0% 12.9% 12.2% 11.6% 10.3%

4.7% 6.3% 6.5% 7.4% 8.4%

8.2% 7.5% 7.0% 7.1% 6.8%

0%

20%

40%

60%

80%

100%

1998 2003 2008 2013 2018F

P

e

rc

e

n

t

S

h

a

re

(

%

)

Computer Communications Consumer Auto Industrial/Other

Source: SEMI

* Projected

*

CONCENTRATION OF IC SUPPLIERS

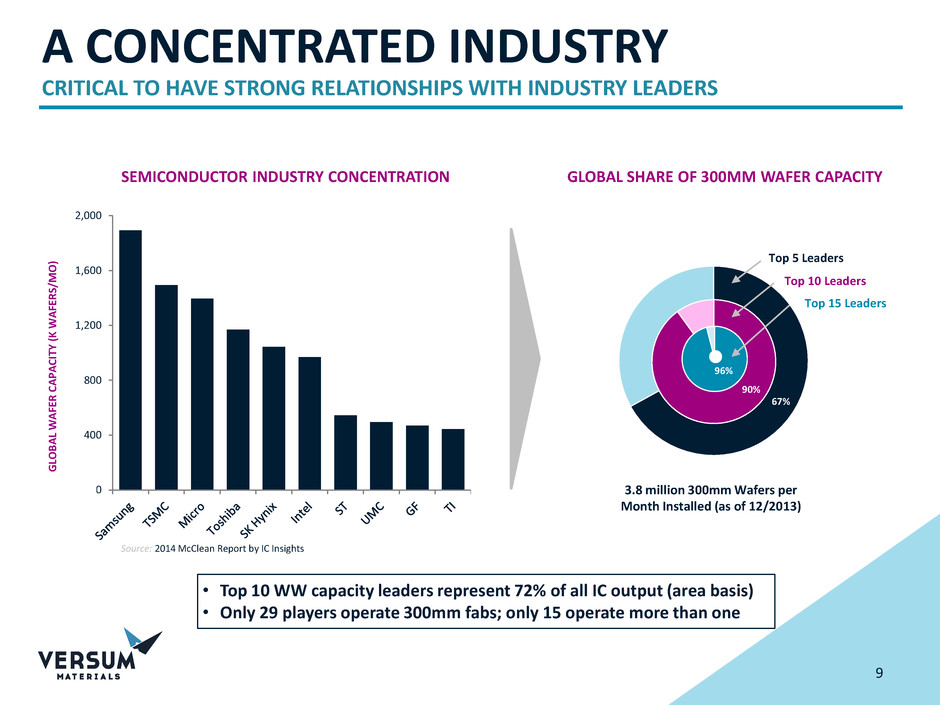

A CONCENTRATED INDUSTRY

CRITICAL TO HAVE STRONG RELATIONSHIPS WITH INDUSTRY LEADERS

67%

• Top 10 WW capacity leaders represent 72% of all IC output (area basis)

• Only 29 players operate 300mm fabs; only 15 operate more than one

SEMICONDUCTOR INDUSTRY CONCENTRATION

$0

$400

$800

$1,200

$1,600

$2,000

G

LO

B

A

L

W

A

FE

R

C

A

P

A

C

ITY

(K

W

A

FE

R

S/

M

O

)

Source: 2014 McClean Report by IC Insights

GLOBAL SHARE OF 300MM WAFER CAPACITY

3.8 million 300mm Wafers per

Month Installed (as of 12/2013)

90%

96%

Top 5 Leaders

Top 10 Leaders

Top 15 Leaders

9

MULTIPLE GROWTH DRIVERS

MATERIALS ARE CRITICAL TO BOTH LEGACY AND ADVANCED NODES

10

• Stripping and cleaning products

• Selective release etching chemistries

• Dielectrics and cleans for advanced

packaging and through silicon vias

• New memory fabs for VNAND and

DRAM

• Foundry fabs for advanced logic devices

• Vertical NAND requires new dielectrics,

metals and polishes

• DRAM scaling via multiple patterning

materials

• New etch hardmasks

• Higher k capacitor dielectrics

• New dielectrics and low defectivity CMP slurries

• Metals for work function tuning and barriers

• Lower k interconnect dielectrics

• Metal and barrier CMP slurries

• Scaling via multiple patterning materials

• Selective etching chemistries

N10 & BELOW

ADVANCED

LOGIC

MEMORY

INTERNET

OF

THINGS

NEW CHINA FABS

& EXPANSIONS

• Overall silicon demand more correlated with global GDP

• Advanced Nodes growing faster, about 2x GDP

• Materials growing faster, about 1.5x - 3x GDP, driven primarily by innovation

required to enable advanced nodes

• Substantial semiconductor capex across the cycles

MATERIALS & EQUIPMENT GROWTH

DRIVERS FOR INNOVATION AND USE

11

• Industry volume growth

- MSI of Silicon for Materials

- CAPEX Investment for Equipment and Services

• Technology changes from new chip architectures

- Next generation nodes (new materials)

- 3 dimensional structures (more processing steps)

• Competitive position as a materials supplier

- Innovation/Differentiation capabilities

- Supply infrastructure/Cost/Quality

- Customer Partnership/Access

LOGIC TRANSISTOR ROADMAP

VERTICAL NAND 3D XPOINT

3D MEMORY

12

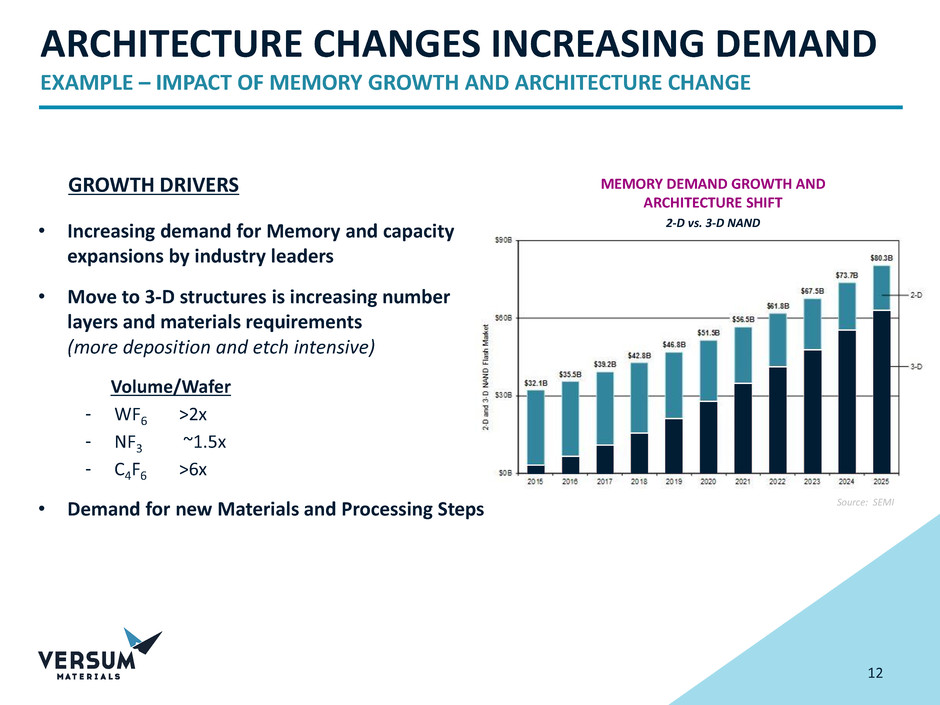

ARCHITECTURE CHANGES INCREASING DEMAND

EXAMPLE – IMPACT OF MEMORY GROWTH AND ARCHITECTURE CHANGE

GROWTH DRIVERS

• Increasing demand for Memory and capacity

expansions by industry leaders

• Move to 3-D structures is increasing number of

layers and materials requirements

(more deposition and etch intensive)

Volume/Wafer

- WF6 >2x

- NF3 ~1.5x

- C4F6 >6x

• Demand for new Materials and Processing Steps

MEMORY DEMAND GROWTH AND

ARCHITECTURE SHIFT

2-D vs. 3-D NAND

Source: SEMI

VERSUM’S BUSINESS

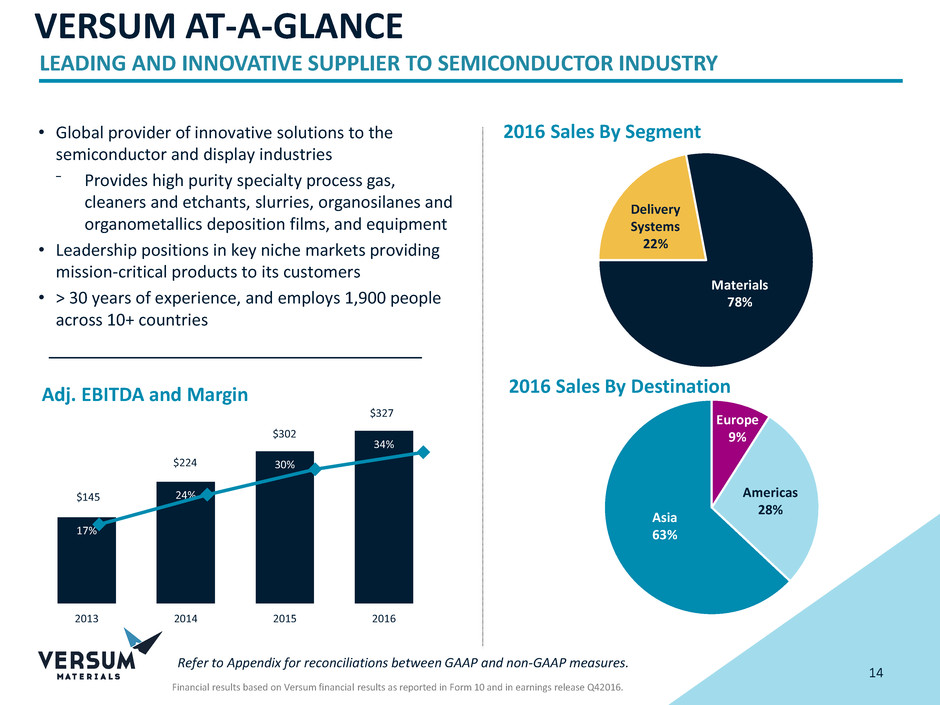

14

• Global provider of innovative solutions to the

semiconductor and display industries

⁻ Provides high purity specialty process gas,

cleaners and etchants, slurries, organosilanes and

organometallics deposition films, and equipment

• Leadership positions in key niche markets providing

mission-critical products to its customers

• > 30 years of experience, and employs 1,900 people

across 10+ countries

Adj. EBITDA and Margin

Financial results based on Versum financial results as reported in Form 10 and in earnings release Q42016.

2016 Sales By Segment

Delivery

Systems

22%

Materials

78%

Europe

9%

Asia

63%

Americas

28%

17%

24%

30%

34%

2013 2014 2015 2016

$224

$145

$302

$327

2016 Sales By Destination

VERSUM AT-A-GLANCE

LEADING AND INNOVATIVE SUPPLIER TO SEMICONDUCTOR INDUSTRY

Refer to Appendix for reconciliations between GAAP and non-GAAP measures.

GLOBAL INTRASTRUCTURE

SCALE AND BREADTH TO SUPPORT CUSTOMERS GLOBALLY

15

• Well-invested global infrastructure

• In-region flexible manufacturing capabilities

• Local technical support

• Collaborative product development with customers

• 1,900 employees

• 14 production facilities

• 6 R&D + technical centers

16

The Materials Partner Of Choice Of The

Semiconductor Industry

• Focus on the semiconductor (IC) materials space where

materials provide low cost in use/high value in use

• Leverage technology leadership, global scale, quality

and reliability capabilities

• Partnership with customers and OEMs to develop and

commercialize the next generation technologies which

will advance the industry

Versum Materials Participates In Six Of Seven

Key Semiconductor Process Steps

PROFITABLE GROWTH PLATFORM

FOCUSED PURE PLAY WITH STRONG PORTFOLIO AND CAPABILITIES

POSITIONED WITH THE KEY PLAYERS

HIGH QUALITY GLOBAL CUSTOMER BASE

17

Top 20

Customers

80%

• Serve semiconductor industry leaders with broad and diverse products portfolio

• Growth driven by partnerships requiring innovation capabilities, collaboration, and trust

• Many products are Process of Record (POR) in customer manufacturing process

VERSUM MATERIALS

Asia

63%

Europe

9%

Americas

28%

Other

20%

Customers

11 – 20

11%

Top 10

Customers

69%

CREATING VALUE BY MANAGING COMPLEXITY

VERSUM RECOGNIZED AS A VALUED SUPPLIER

18

SUPPLY CHAIN TECHNOLOGY

QUALITY &

RELIABILITY

DELIVERY &

SERVICE

SAFETY

MATERIALS SEGMENT

DIVERSIFIED PORTFOLIO FOCUSED ON TECHNOLOGY DRIVEN SEMICONDUCTORS

• Integrated provider of leading edge specialty materials, more than

80% to the semiconductor market

• Advanced Materials - ~85% of portfolio is based on proprietary or

patent-protect positions

• Process Materials - High-purity gases & chemicals for cleaning,

etching, doping & film deposition

• 980 employees, 11 production and 6 R&D facilities serving more

than 250 customers

19

Solid growth

High margins

Low capital intensity

Strong free cash flow

Sales: $757

Op Income: $252

Op Inc Margin: 33%

Adj EBITDA: $297

Adj EBITDA Margin: 39%

Process

Materials

51%

Advanced

Materials

49%

Asia

67%

Europe

7%

Americas

26%

2016 Sales By Business Unit 2016 Sales By Destination

Refer to Appendix for reconciliations between GAAP and non-GAAP measures.

ADVANCED MATERIALS

DIFFERENTIATED AND INNOVATIVE MATERIALS TO MEET NEXT-GENERATION REQUIREMENTS

20

CMP SLURRY

ADVANCED

DEPOSITION

SURFACE PREP

AND CLEAN

- $500 $1,000 $1,500 $2,000 $2,500

Share

Estimate

#3 #1 #2/#3

Product

Market

Size ($m)

Solvent & semi-aqueous formulations

of acids, bases, corrosion inhibitors,

complexing agents

Designed to remove debris and

contamination left behind from wafer

processing (etching, CMP, others)

High purity specialty gases and

specialty chemicals; molecules

designed for low temperature, clean

decomposition

Used to create the conductor,

insulator, and semiconductor layers

of IC transistors

High purity, functionalized abrasive

particles suspended in an aqueous

chemical formulation

Formulated to planarize deposited

films to provide a flat surface for

fabricating the next device layer

Applications

CMP Slurry Surface Prep and Clean Advanced Deposition

Advanced Materials

Growth

HIGH-VALUE DIFFERENTIATED MATERIALS

DEMONSTRATED TRACK RECORD OF PROVIDING INTEGRATED TECHNOLOGY SOLUTIONS

COLLABORATION WITH BOTH SEMICONDUCTOR AND EQUIPMENT MANUFACTURERS

Source: Linx and Versum estimates

PARTNERSHIPS CRITICAL TO SUCCESS

COMMITMENT, PARTNERSHIP AND TECHNOLOGY CRITICAL TO ADDING VALUE

21

COMPLEX, HIGH BARRIERS TO ENTRY

ADVANCED DEPOSITION

Applied Materials, TEL,

Lam Research, ASMi, HIKE

PLANARIZATION

Ebara, Applied Materials

SURFACE PREP & CLEAN

Screen, TEL, Lam

Research

LE

A

D

IN

G

A

D

V

A

N

C

ED

M

A

T

ER

IA

LS

OE

M

S

OEMs

CUSTOMERS

Cost-of-ownership is driven

by process efficiency

(throughput and yield)

Equipment facilitates the

scaling and efficient use

of new materials

Materials are emerging

as the enablers for

advanced device

performance

STRATEGIC

ELEMENT

BENEFIT

TO EMD

• Align with

innovation

leaders

• Collaborate with

the best

partners and

industry trend

setters

• Win Best Known

Method status

• Facilitate

information flow

• Win Process

of Record

• Understand the

cost-of-

ownership

• Partner to

optimize High

Volume use of

new offerings

• Improve

forecasting

• Understand

impact of

localized OEMs

• Align with the

right regional

partners

TIMELINE FOR NEW PRODUCTS FOR IC MANUFACTURING

> 10% OF ITS ADVANCED MATERIALS SALES INTO RESEARCH AND DEVELOPMENT

22

VO

LUM

E

[W

A

FER

S/

M

O

N

TH

]

MONTHS

-60 -24 -12 0 12 24

PROCESS DEVELOPMENT HIGH VOLUME MANUFACTURING

Source: ITRS Roadmap, Versum Estimates

Alpha Tool HVM Tool Beta Tool

ADM ADM / PLA / SP&C

Material Selection Material Integration

OEM BKMs IDM PORs

PROCESS MATERIALS

GLOBAL DISTRIBUTION CAPABILITIES, COMPETIVE COST, PURITY, QUALITY AND RELIABILITY

23

- $250 $500 $750 $1,000 $1,250 $1,500 $1,750 $2,000 $2,250

Market Dynamics

2014-2020

Share

Estimate

FLUORINATED GASES DOPANTS

INORGANIC HYDRIDES,

OXIDES, AND HALIDES

Fluorinated Gases

Inorganic Hydrides,

Oxides, and Halides

Process Materials

Growth

#3 #2

Market

Size ($M)

Competitors rebalanced supply/demand

given PV over capacity overinvestment

and low profitability

Growth in memory, especially 3D

VNAND, driving significant increase in

demand of key products

Industry debottlenecking to support

increased demand

Regional players source crude

commodities and purify or

distribute purified electronic

grade products

Few competitors due to high

barriers to entry into specialty

gases (sensitive and difficult to

handle products)

Forecast new demand drivers

for hydrides to improve IC

speed

IMPROVED OUR COST COMPETITIVENESS AND IN-REGION SUPPLY INFRASTRUCTURE

LEVERAGE OUR GLOBAL SUPPLY CHAIN AND SAFETY, QUALITY AND RELIABILITY CAPABILITIES

GROW WITH OUR CUSTOMERS

SILICON

PRECURSORS

Dopants

#1

Source: Linx and Versum estimates

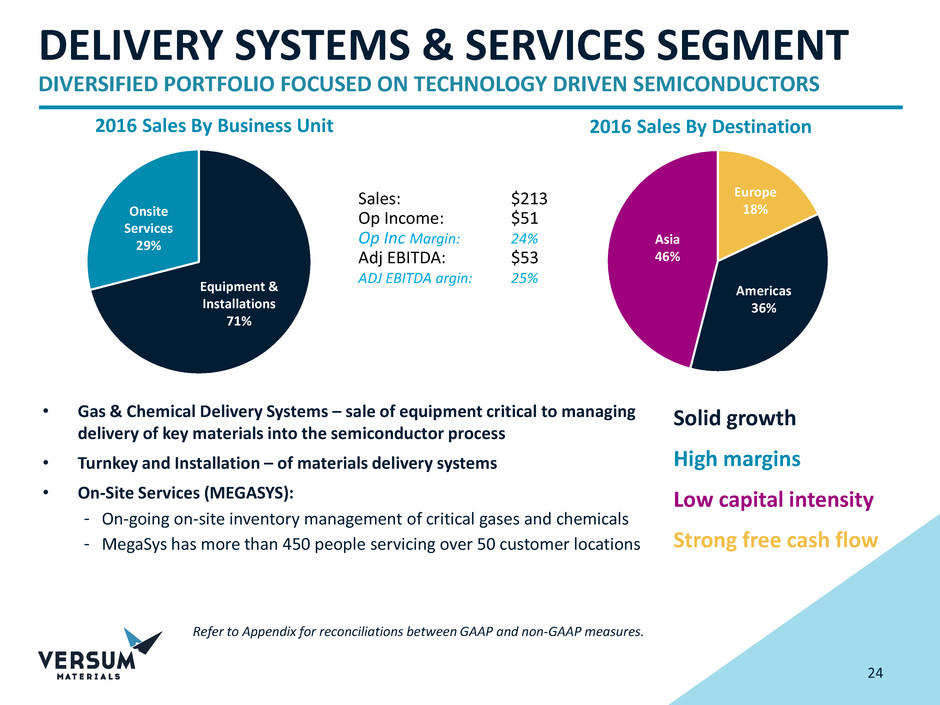

DELIVERY SYSTEMS & SERVICES SEGMENT

DIVERSIFIED PORTFOLIO FOCUSED ON TECHNOLOGY DRIVEN SEMICONDUCTORS

24

Solid growth

High margins

Low capital intensity

Strong free cash flow

• Gas & Chemical Delivery Systems – sale of equipment critical to managing

delivery of key materials into the semiconductor process

• Turnkey and Installation – of materials delivery systems

• On-Site Services (MEGASYS):

- On-going on-site inventory management of critical gases and chemicals

- MegaSys has more than 450 people servicing over 50 customer locations

Sales: $213

Op Income: $51

Op Inc Margin: 24%

Adj EBITDA: $53

ADJ EBITDA argin: 25%

Onsite

Services

29%

Equipment &

Installations

71%

Asia

46%

Europe

18%

Americas

36%

2016 Sales By Business Unit 2016 Sales By Destination

Refer to Appendix for reconciliations between GAAP and non-GAAP measures.

FINANCIAL PROFILE

ESTIMATED CASH FLOW NET DEBT TO ADJ EBITDA

(In millions, except debt multiple) FY2016

Debt

Term Loan 575

Senior Notes 425

Total Debt 1,000

Less Cash 106

Net Debt 894

2016 ADJ EBITDA 327

Net Debt/Adjusted EBITDA (x) 2.7x

(In millions) FY2016

Total Adjusted EBITDA $327

Working Capital (7)

Estimated Cash Taxes (54)

Cash Interest & Principal Repayment (49)

Less Working Capital, Cash Taxes and Interest $217

Capital Expenditures (36)

Cash Flow $181

CASH GENERATION AND LEVERAGE

FISCAL YEAR 2016 BASIS

26

NOTES: FY16 EBITDA and capital spending based on carve-out unaudited financials. Working capital is estimated change in accounts receivable,

inventory and accounts payables for FY16. Interest and principal repayment reflect forward estimates on $1B debt financing closed September 30,

2016. Estimated cash taxes based on 23% cash tax rate, which management believes will be consistent with current tax position on a stand-alone

basis.

Refer to Appendix for reconciliations between GAAP and non-GAAP measures.

CALENDAR YEAR % CHANGE

GLOBAL GDP 2.7% – 3.0%

GLOBAL MSI 2% – 6%

WAFER FAB EQUIPMENT 5% – 9%

SOURCE: Linx/Hilltop Economics, Gartner, Versum estimates

FINANCIAL OUTLOOK

NOTES: 2016 Actual reflects carveout financials and includes $3 million of Adjusted EBITDA for businesses remaining with APD. 2017 guidance includes

approximately $10 million of transition costs; Adj EBITDA excludes estimated one time restructuring costs of $20 - $25mm. 2017 D&A estimate of $50MM; cash

and book tax rate in range of 20 – 25%, capital spending includes $35-40 of stand-up capital

2017 FISCAL YEAR FINANCIAL OUTLOOK

FISCAL YEAR 2016 ACTUAL VERSUS 2017 OUTLOOK AND DRIVERS

27

MARKET DRIVERS:

Continued strong VNAND demand

Acceleration of advanced

logic devices

Logic and memory drive continued

new fab expansions

BUSINESS DRIVERS:

Volume growth from new products,

capacity expansions and increased

equipment sales

Continued cost optimization

Maintain margins

ASSUMPTIONS FOR GROWTH OUTLOOK

Reconciliation of net income to our 2017 outlook for adjusted EBITDA is not

provided. See Appendix for more information.

(In millions) FISCAL 2016 ACTUAL 2017 OUTLOOK

SALES $970 $990 – $1,050

ADJ EBITDA $327 $330 – $350

Capital Expenditures $36 $75 – $85

2017 TRENDS & PRIORITIES

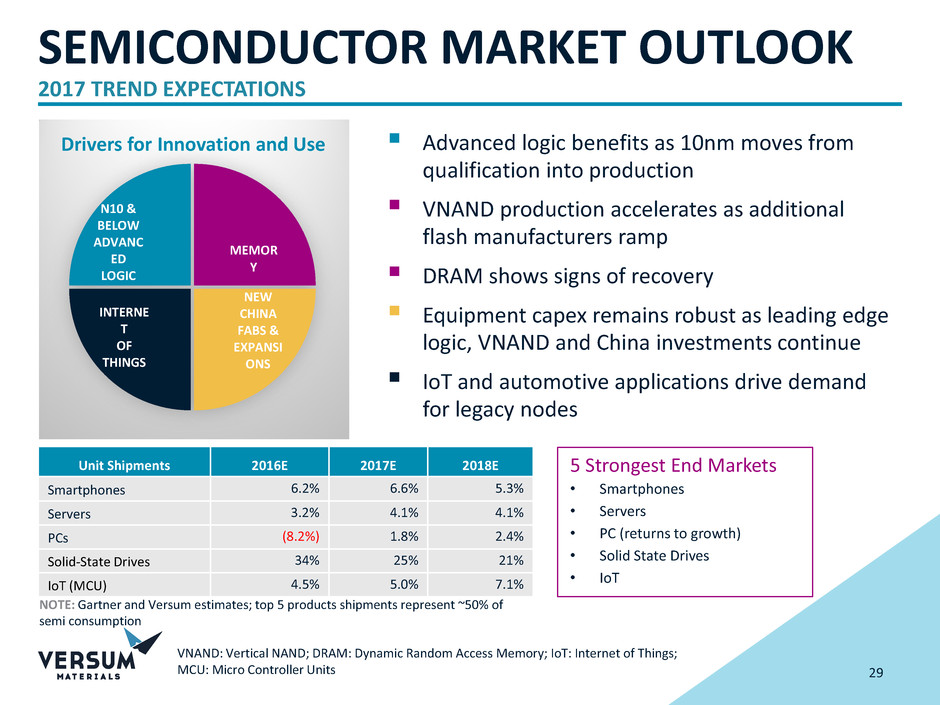

29

SEMICONDUCTOR MARKET OUTLOOK

2017 TREND EXPECTATIONS

Advanced logic benefits as 10nm moves from

qualification into production

VNAND production accelerates as additional

flash manufacturers ramp

DRAM shows signs of recovery

Equipment capex remains robust as leading edge

logic, VNAND and China investments continue

IoT and automotive applications drive demand

for legacy nodes

5 Strongest End Markets

• Smartphones

• Servers

• PC (returns to growth)

• Solid State Drives

• IoT

VNAND: Vertical NAND; DRAM: Dynamic Random Access Memory; IoT: Internet of Things;

MCU: Micro Controller Units

Unit Shipments 2016E 2017E 2018E

Smartphones 6.2% 6.6% 5.3%

Servers 3.2% 4.1% 4.1%

PCs (8.2%) 1.8% 2.4%

Solid-State Drives 34% 25% 21%

IoT (MCU) 4.5% 5.0% 7.1%

NOTE: Gartner and Versum estimates; top 5 products shipments represent ~50% of

semi consumption

NEW

CHINA

FABS &

EXPANSI

ONS

INTERNE

T

OF

THINGS

N10 &

BELOW

ADVANC

ED

LOGIC

MEMOR

Y

Drivers for Innovation and Use

30

2017 PRIORITIES

DRIVING OPERATIONAL EXCELLENCE AND FINANCIAL EXECUTION AS A STAND-ALONE COMPANY

APD TSA: Air Products and Chemicals Transition Service Agreements; VSM: Versum

Stand-Alone Activities

Transition Fully to Stand-Alone

• Move from APD TSA to VSM

stand-alone managed cost

structure

• Robust Reporting and

Governance processes

• Investor Engagement

• Implement enterprise

resource planning (ERP)

system

Deliver on 2017 Fiscal Year

Financial Targets

Drive Innovation to capture

market share on next

generation nodes

Strengthen front line

commercial and technical

capabilities

Optimize Cash Flow generation

to fund value enhancing

organic and inorganic

investments

Complete debottlenecking

and capacity expansions in

Materials segment

Continue to optimize our

global supply network

Increase operating

productivity and yield

Expand our Quality and

Reliability capabilities

Productivity Growth

Customer Focus – Strengthened capabilities to collaborate and create value for customers

Accountability – Increased alignment of compensation to direct business level performance

Culture

VERSUM MATERIALS

INVESTMENT HIGHLIGHTS

Solid growth

High margins

Low capital intensity

Strong cash flow

31

BEST IN CLASS ELECTRONIC MATERIALS COMPANY

Leadership positions in a profitable and

complex semiconductor materials industry

Strong technology, commercial and

operations capabilities

Compelling growth platforms with

sustainable competitive advantage

Strong financial performance and cash flow

generation

Experienced management team with

proven track record

Global infrastructure

APPENDICES

33

2016 MARKET FUNDAMENTALS

SEMICONDUCTOR TRENDS

Advanced logic focused on start-up of

next generation node (i.e., 10nm)

Robust demand for solid state drives

accelerating VNAND production

Equipment capex from new fabs and

expansion pulled forward for both logic

and VNAND devices

IoT and Automotive applications driving

sustainability of legacy nodes

NEW

CHINA

FABS &

EXPANSI

ONS

INTERNET

OF

THINGS

N10 &

BELOW

ADVANCE

D

LOGIC

MEMORY

Subject FYQ416 FYQ415 % change

FY16 FY15 % change

GDP (CY) n/a n/a n/a n/a n/a 2.5%

MSI (FY) 2730 2591 5.4% 10478 10480 -

Wafer Fab Equip Spend (FY) $9.3 B $8.3 B 11.4% $31.9 B $32.1 B (0.5%)

IoT: Internet of Things; VNAND: Vertical NAND ; MSI: Millions of Square Inches

SOURCE: Semi, Gartner (Q4FY16E), IMF (April 2016) and Versum estimates

Drivers for Innovation and Use

34

REVENUES BY BUSINESS & REGION

FISCAL YEARS 2014 - 2016

Year Ended September 30,

2016 2015 2014

Sales to External Customers (by Origin) (In millions)

United States $ 349.4

$ 361.3

$ 330.3

Taiwan 230.8

236.3

228.0

South Korea 217.2

220.3

184.3

China 53.8

70.9

76.9

Europe 57.8

69.2

70.3

Asia, excluding China, Taiwan, and South Korea 61.1

51.3

52.7

Total $ 970.1

$ 1,009.3

$ 942.5

Geographic Information

Year Ended September 30,

2016 2015 2014

(In millions)

Materials

Process Materials $ 387.4

$ 387.3

$ 321.8

Advanced Materials 369.3

356.1

318.2

DS&S

Equipment and Installations 150.8

208.3

244.1

Site Services 62.6

57.6

58.4

Total $ 970.1

$ 1,009.3

$ 942.5

Sales by Product Group

RECONCILIATIONS

Non-GAAP Financial Measures

This presentation includes “non-GAAP financial measures,” including Adjusted EBITDA, Segment Adjusted EBITDA, Adjusted EBITDA

margin, Segment Adjusted EBITDA margin, net debt and estimated cash flow. We define Adjusted EBITDA as net income excluding

certain disclosed items which we do not believe to be indicative of underlying business trends, including interest expense, income tax

provision, depreciation and amortization expense, non-controlling interests, and business separation, restructuring and cost reduction

actions. Versum Materials defines Segment Adjusted EBITDA as segment operating income excluding segment depreciation and

amortization expense, and equity affiliates’ income. Adjusted EBITDA margin and Segment Adjusted EBITDA margin are calculated by

dividing Adjusted EBITDA and Segment Adjusted EBITDA, respectively, by sales. In the Appendix to this presentation, Versum Materials

has provided reconciliations of net income to Adjusted EBITDA and of segment operating income (loss) to Segment Adjusted EBITDA,

in each case the most directly comparable GAAP financial measure. We encourage investors to read these reconciliations.

Our presentation of estimated cash flow is defined as Adjusted EBITDA, less capital expenditures, working capital, cash taxes and cash

Interest and principal repayment. Management believes that estimated cash flow is meaningful to investors because it is an indication

of the strength of the company and its ability to generate cash. However, a limitation of estimated cash flow is that it does not

represent the total increase or decrease in cash during the period. Estimated cash flow is not intended to be an alternative to cash

flows from operating activities as a measure of liquidity. In addition, the term “cash flow” does not have a standardized meaning.

Therefore, other companies may use the same or a similarly named measure but exclude different items or use different

computations, which may provide investors a comparable view of our performance in relation to other companies.

RECONCILIATIONS

Non-GAAP Financial Measures (continued)

The presentation of these non-GAAP financial measures is intended to enhance the usefulness of financial information by providing measures which

management uses internally to evaluate operating performance. We use these non-GAAP measures to assess our operating performance by excluding

certain disclosed items that we believe are not representative of our underlying business. We use Adjusted EBITDA to calculate performance-based cash

bonuses and determine whether certain performance-based options and restricted stock units vest (as such bonuses, options and restricted stock units

are tied to Adjusted EBITDA). We use Segment Adjusted EBITDA as the primary measure used by our chief operating decision maker to evaluate the

ongoing performance of our business segments. We believe non-GAAP financial measures provide investors with meaningful information to understand

our underlying operating results and to analyze financial and business trends. These non-GAAP financial measures should not be viewed in isolation, are

not a substitute for GAAP measures, and have limitations which include but are not limited to the following: (a) Adjusted EBITDA excludes expenses

related to business separation, restructuring and cost reduction actions which we do not consider to be representative of our underlying business

operations, however, these disclosed items represent costs to Versum; (b) Adjusted EBITDA is not intended to be a measure for management’s

discretionary use, as it does not consider certain cash requirements such as interest payments, tax payments and debt service requirements; (c) though

not business operating costs, interest expense and income tax provision represent ongoing costs of Versum; (d) depreciation, amortization, and

impairment charges represent the wear and tear or reduction in value of the plant, equipment, and intangible assets which permit us to manufacture

and market our products; and (e) other companies may define non-GAAP measures differently than we do, limiting their usefulness as comparative

measures. A reader may find any one or all of these items important in evaluating our performance. Management compensates for the limitations of

using non-GAAP financial measures by using them only to supplement our GAAP results and to provide a more complete understanding of the factors

and trends affecting our business. In evaluating these non-GAAP financial measures, the reader should be aware that we may incur expenses similar to

those eliminated in this presentation in the future.

A reconciliation of net income to Adjusted EBITDA as forecasted for 2017 is not provided. Versum Materials does not forecast net income as it cannot,

without unreasonable effort, estimate or predict with certainty various components of net income. These components include additional costs

associated with the separation from Air Products, further restructuring and other income or charges incurred in 2017 as well as the related tax impacts

of these items. Additionally, discrete tax items could drive variability in our forecasted effective tax rate. All of these components could significantly

impact net income. Further, in the future, other items with similar characteristics to those currently included in Adjusted EBITDA that have a similar

impact on comparability of periods, and which are not known at this time, may exist and impact Adjusted EBITDA.

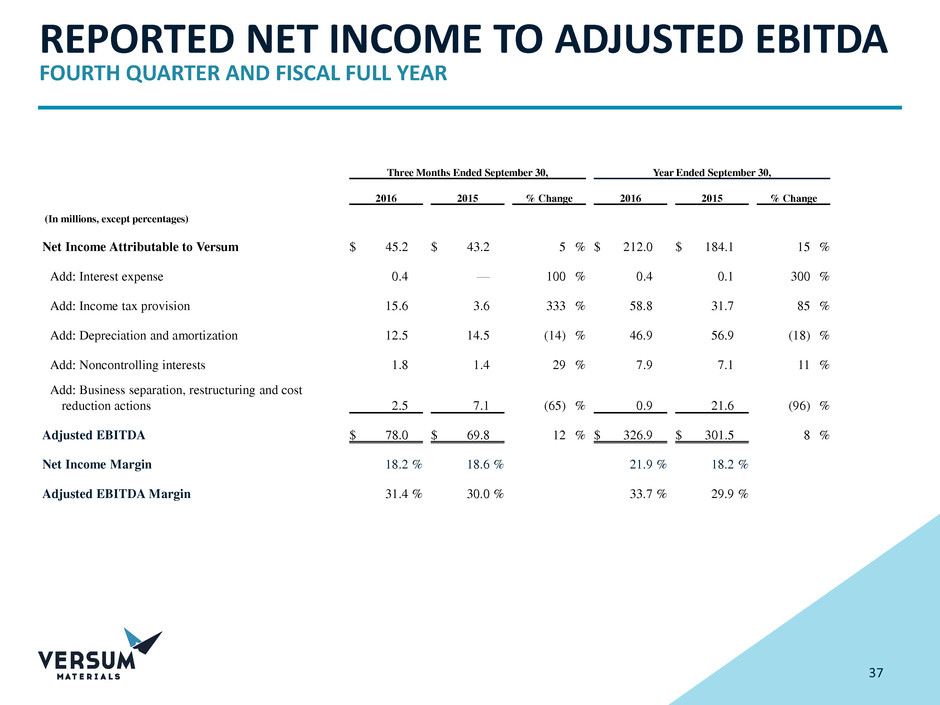

REPORTED NET INCOME TO ADJUSTED EBITDA

FOURTH QUARTER AND FISCAL FULL YEAR

37

Three Months Ended September 30, Year Ended September 30,

2016 2015 % Change 2016 2015 % Change

(In millions, except percentages)

Net Income Attributable to Versum $ 45.2 $ 43.2 5 % $ 212.0 $ 184.1 15 %

Add: Interest expense 0.4 — 100 % 0.4 0.1 300 %

Add: Income tax provision 15.6 3.6 333 % 58.8 31.7 85 %

Add: Depreciation and amortization 12.5 14.5 (14) % 46.9 56.9 (18) %

Add: Noncontrolling interests 1.8 1.4 29 % 7.9 7.1 11 %

Add: Business separation, restructuring and cost

reduction actions 2.5 7.1 (65) % 0.9 21.6 (96) %

Adjusted EBITDA $ 78.0 $ 69.8 12 % $ 326.9 $ 301.5 8 %

Net Income Margin 18.2 % 18.6 % 21.9 % 18.2 %

Adjusted EBITDA Margin 31.4 % 30.0 % 33.7 % 29.9 %

SEGMENT OPERATING INCOME TO ADJUSTED EBITDA

QUARTER AND FISCAL FULL YEAR

38

(A) Adjusted EBITDA margin is calculated by dividing Adjusted EBITDA by sales.

For the Quarter Ended For the Quarter Ended

December

31, 2015

March 31,

2016

June 30,

2016

September

30, 2016 Total

December

31, 2014

March 31,

2015

June 30,

2015

September

30, 2015 Total

(In millions, except percentages) (In millions, except percentages)

Materials

Operating income $ 68.5 $ 60.1 $ 66.4 $ 57.3 $ 252.3 $ 42.7 $ 53.0 $ 62.9 $ 55.1 $ 213.7

Add: Depreciation and amortization 10.9 10.5 11.2 11.8 44.4 13.4 11.3 11.2 12.2 48.1

Add: Equity affiliates’ income 0.2 — — — 0.2 0.4 0.3 — 0.3 1.0

Segment Adjusted EBITDA $ 79.6 $ 70.6 $ 77.6 $ 69.1 $ 296.9 $ 56.5 $ 64.6 $ 74.1 $ 67.6 $ 262.8

Segment Adjusted EBITDA margin(A) 42.2 % 38.9 % 40.1 % 35.8 % 39.2 % 32.2 % 36.1 % 37.7 % 35.1 % 35.4 %

Delivery Systems and Services

Operating income $ 15.9 $ 9.7 $ 11.9 $ 13.3 $ 50.8 $ 15.4 $ 14.7 $ 14.1 $ 4.9 $ 49.1

Add: Depreciation and amortization 0.5 0.5 0.5 0.6 2.1 1.8 2.1 2.2 2.2 8.3

Add: Equity affiliates’ income — — — — — — — — — —

Segment Adjusted EBITDA $ 16.4 $ 10.2 $ 12.4 $ 13.9 $ 52.9 $ 17.2 $ 16.8 $ 16.3 $ 7.1 $ 57.4

Segment Adjusted EBITDA margin(A) 28.9 % 19.6 % 25.2 % 25.0 % 24.8 % 21.6 % 21.0 % 24.4 % 17.9 % 21.6 %

Corporate

Operating loss $ (4.7 ) $ (3.7 ) $ (9.8 ) $ (5.1 ) $ (23.3 ) $ (4.4 ) $ (4.5 ) $ (5.3 ) $ (5.0 ) $ (19.2 )

Add: Depreciation and amortization 0.1 0.1 0.1 0.1 0.4 0.1 0.1 0.2 0.1 0.5

Add: Equity affiliates’ income — — — — — — — — — —

Segment Adjusted EBITDA $ (4.6 ) $ (3.6 ) $ (9.7 ) $ (5.0 ) $ (22.9 ) $ (4.3 ) $ (4.4 ) $ (5.1 ) $ (4.9 ) $ (18.7 )

Total Versum Adjusted EBITDA $ 91.4 $ 77.2 $ 80.3 $ 78.0 $ 326.9 $ 69.4 $ 77.0 $ 85.3 $ 69.8 $ 301.5