Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - Bison Merger Sub I, LLC | d251845d8k.htm |

Investor Presentation September 2016 Exhibit 99.1

Forward-Looking Statements This presentation contains forward-looking statements. These statements can be identified by the use of forward-looking terminology including “will,” “may,” “believe,” “expect,” “anticipate,” “estimate,” “continue,” or other similar words. These statements discuss future expectations including company growth expectations, demand for our products, capacity expansion plans, market trends, liquidity, transportation services, commercial product launches and research and development plans and may contain projections of financial condition or of results of operations, or state other “forward-looking” information. These forward-looking statements involve risks and uncertainties. Many of these risks are beyond management’s control. When considering these forward-looking statements, you should keep in mind the risk factors, Management’s Discussion and Analysis of Financial Condition and Results of Operations, and other cautionary statements in the company’s SEC filings. Forward-looking statements are not guarantees of future performance or an assurance that our current assumptions or projections are valid. Our actual results and plans could differ materially from those expressed in any forward-looking statements. We undertake no obligation to publicly update any forward-looking statements, whether as a result of new information or future events, except as required by law.

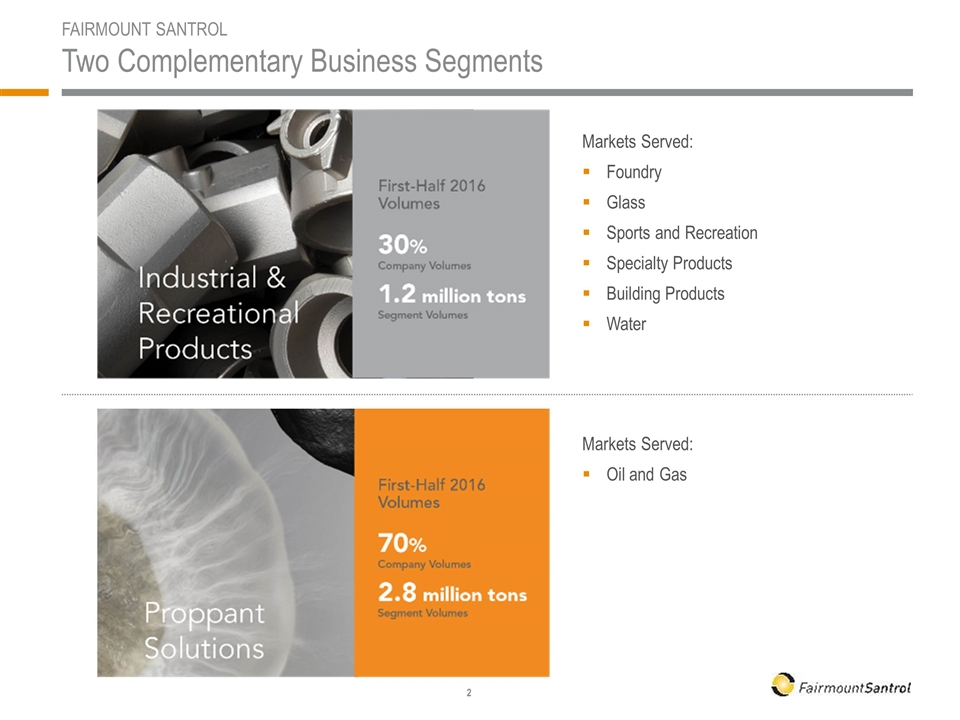

FAIRMOUNT SANTROL Two Complementary Business Segments Markets Served: Foundry Glass Sports and Recreation Specialty Products Building Products Water Markets Served: Oil and Gas

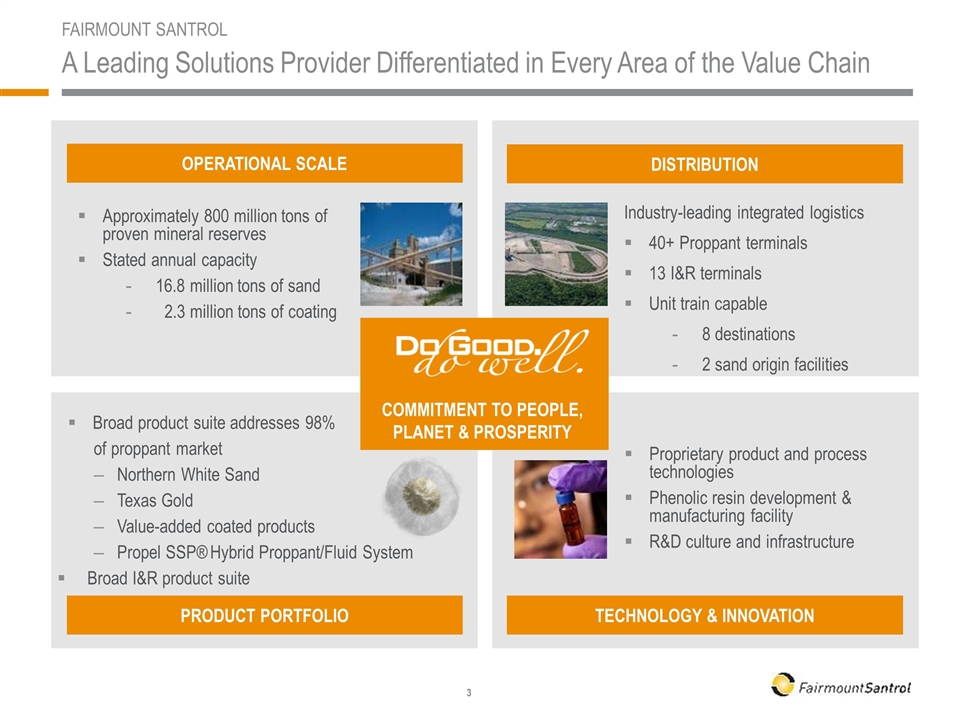

FAIRMOUNT SANTROL A Leading Solutions Provider Differentiated in Every Area of the Value Chain Operational Scale Approximately 800 million tons of proven mineral reserves Stated annual capacity 16.8 million tons of sand 2.3 million tons of coating Distribution Product Portfolio Technology & Innovation Broad product suite addresses 98% of proppant market Northern White Sand Texas Gold Value-added coated products Propel SSP® Hybrid Proppant/Fluid System Broad I&R product suite Proprietary product and process technologies Phenolic resin development & manufacturing facility R&D culture and infrastructure Commitment to People, Planet & Prosperity Industry-leading integrated logistics 40+ Proppant terminals 13 I&R terminals Unit train capable 8 destinations 2 sand origin facilities

“ FAIRMOUNT SANTROL “ALL IN” Commitment to Sustainable Development _____________________ Source: Company website and corporate filings >3,700 learning opportunities offered through 17 Empower U courses since 2012 18.8 avg. paid volunteer hours per Family Member in 2015; >5,500 hours donated YTD in 2016 >1.5M safe working hours in 2015 = a record high 30 Zero Waste Facilities Reduced 90% of waste sent to landfills since 2009 Implemented an energy saving process for a dryer at our highest consumption facility that resulted in a 5% reduction in gas usage in 2015 Planted >132,000 trees to offset greenhouse gases in 2015 alone; >500,000 total planted since 2007 Net SD Pays between $5M and $9M since 2012 ~$2.3M invested into communities during 2015 80% of Family Members participated in Financial Wellness Course in 2015 Filed three patent applications in 2015

HIGH-PURITY SANDS ENGINEERED RESIN-COATED SANDS TechniSand® Resin-Coated Sands Signature Gold TruCoat™ New, safer shell and core casting system Dramatically lowers in-plant smoke, odor and emissions while delivering superior performance HIGH-PERFORMANCE RESIN SYSTEMS Full Portfolio of Resin Solutions Offering high-quality traditional foundry resin systems Meeting industry demands by offering environmentally progressive resin systems with lower VOCs and HAPs Wedron Silica, Wedron Illinois Round grain 99.9% pure silica sand Best Sand, Chardon, Ohio Sub-angular round grain Foundry sand – ideal for helping reduce expansion defects in cores and molds Engineered bunker sands Colored sand Custom blended products I&R SEGMENT The Market’s Only Integrated Sand & Resin Solutions Provider product/ Characteristics

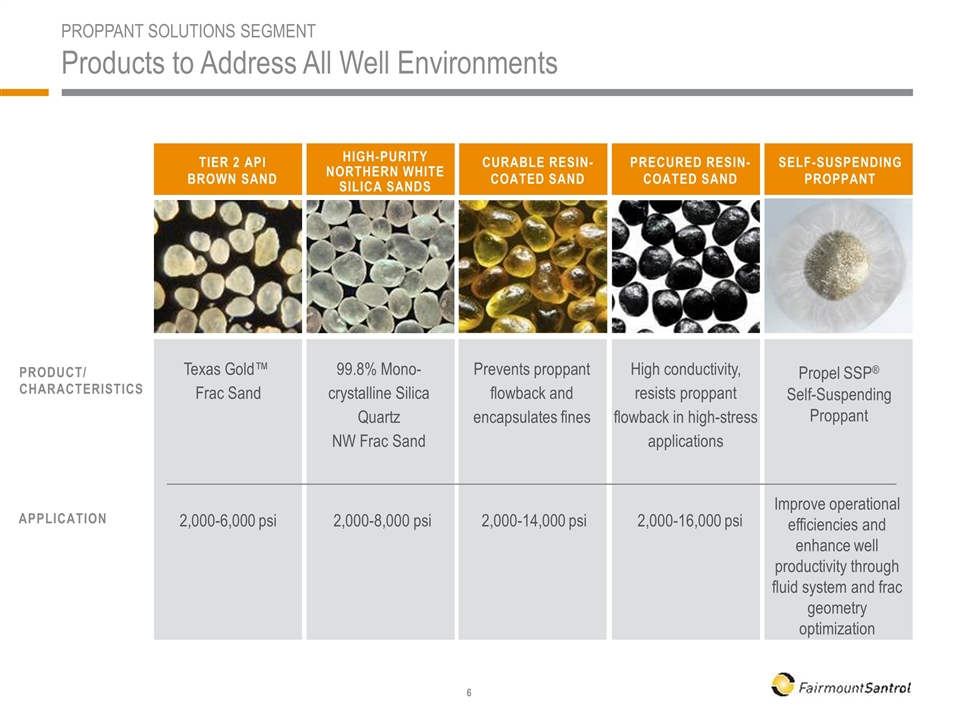

High-Purity Northern White Silica Sands Texas Gold™ Frac Sand Precured Resin-Coated Sand High conductivity, resists proppant flowback in high-stress applications Curable Resin-Coated Sand Prevents proppant flowback and encapsulates fines Self-Suspending Proppant Propel SSP® Self-Suspending Proppant Tier 2 API Brown Sand 99.8% Mono-crystalline Silica Quartz NW Frac Sand Application PROPPANT SOLUTIONS SEGMENT Products to Address All Well Environments 2,000-6,000 psi 2,000-8,000 psi 2,000-14,000 psi 2,000-16,000 psi Improve operational efficiencies and enhance well productivity through fluid system and frac geometry optimization Product/ Characteristics

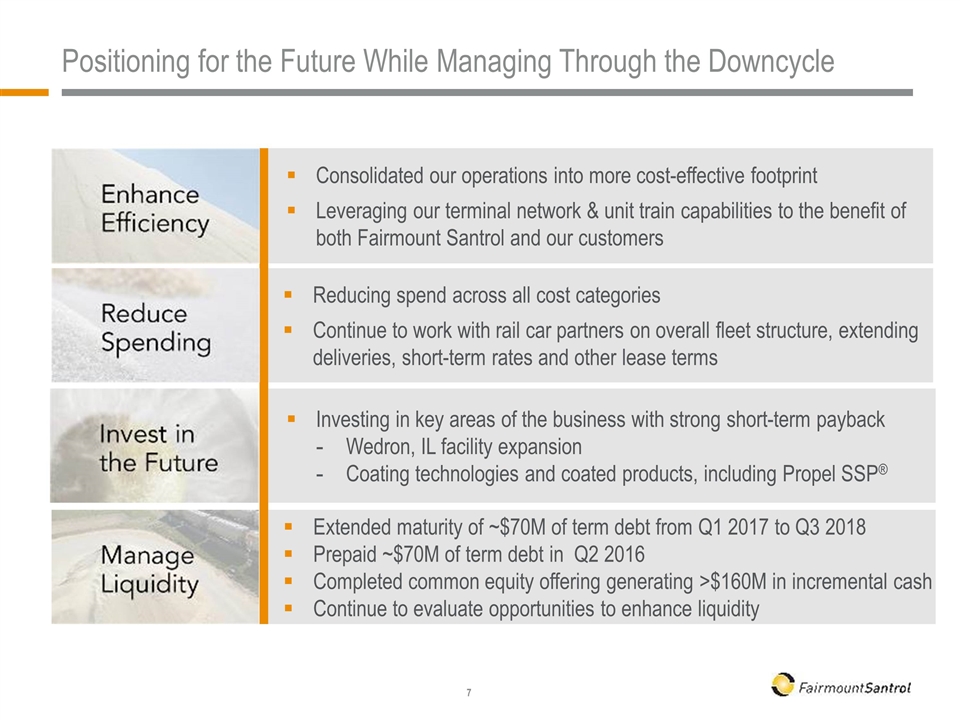

Positioning for the Future While Managing Through the Downcycle Consolidated our operations into more cost-effective footprint Leveraging our terminal network & unit train capabilities to the benefit of both Fairmount Santrol and our customers Reducing spend across all cost categories Continue to work with rail car partners on overall fleet structure, extending deliveries, short-term rates and other lease terms Investing in key areas of the business with strong short-term payback Wedron, IL facility expansion Coating technologies and coated products, including Propel SSP® Extended maturity of ~$70M of term debt from Q1 2017 to Q3 2018 Prepaid ~$70M of term debt in Q2 2016 Completed common equity offering generating >$160M in incremental cash Continue to evaluate opportunities to enhance liquidity

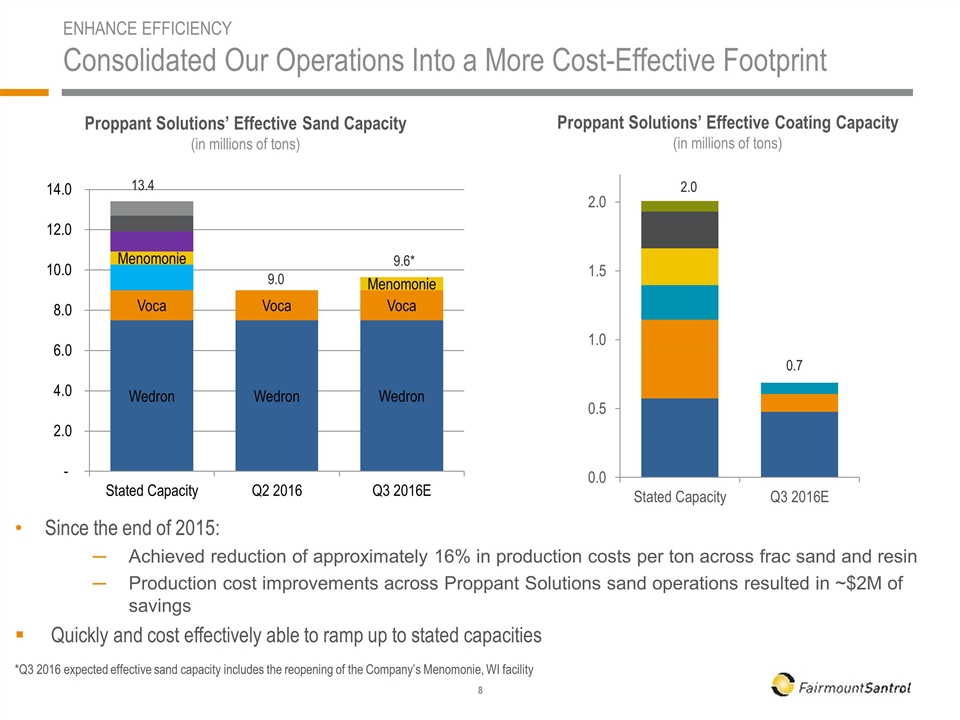

ENHANCE EFFICIENCY Consolidated Our Operations Into a More Cost-Effective Footprint Since the end of 2015: Achieved reduction of approximately 16% in production costs per ton across frac sand and resin Production cost improvements across Proppant Solutions sand operations resulted in ~$2M of savings Quickly and cost effectively able to ramp up to stated capacities *Q3 2016 expected effective sand capacity includes the reopening of the Company’s Menomonie, WI facility Proppant Solutions’ Effective Sand Capacity (in millions of tons) Proppant Solutions’ Effective Coating Capacity (in millions of tons) 13.4 9.0 9.6*

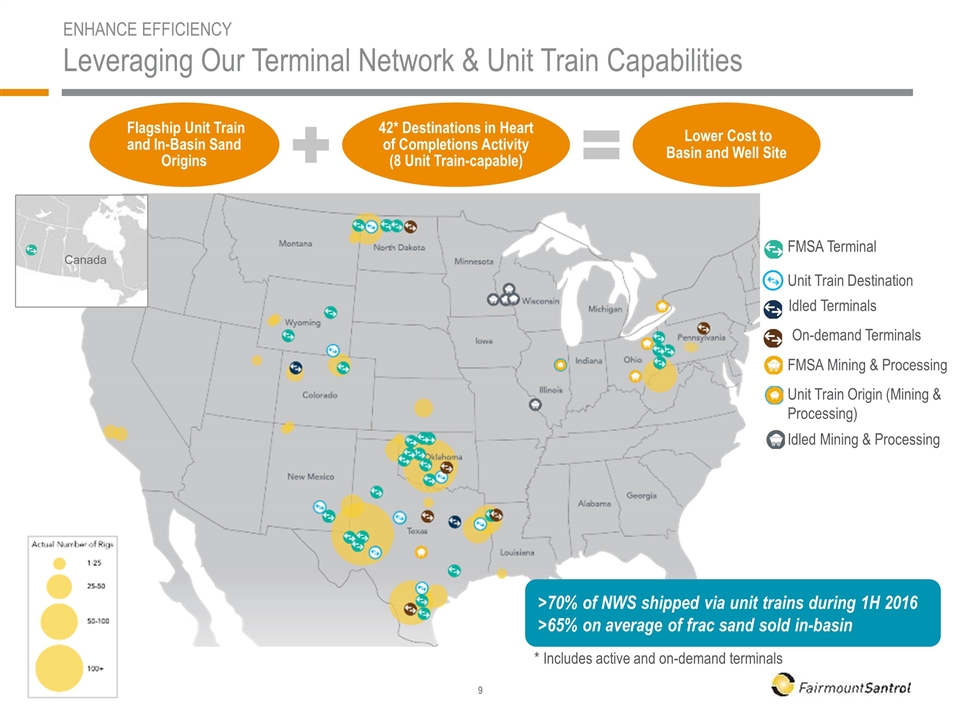

FMSA Terminal FMSA Mining & Processing Unit Train Destination Unit Train Origin (Mining & Processing) ENHANCE EFFICIENCY Leveraging Our Terminal Network & Unit Train Capabilities >70% of NWS shipped via unit trains during 1H 2016 >65% on average of frac sand sold in-basin Idled Terminals Idled Mining & Processing On-demand Terminals Canada * Includes active and on-demand terminals Flagship Unit Train and In-Basin Sand Origins Lower Cost to Basin and Well Site 42* Destinations in Heart of Completions Activity (8 Unit Train-capable)

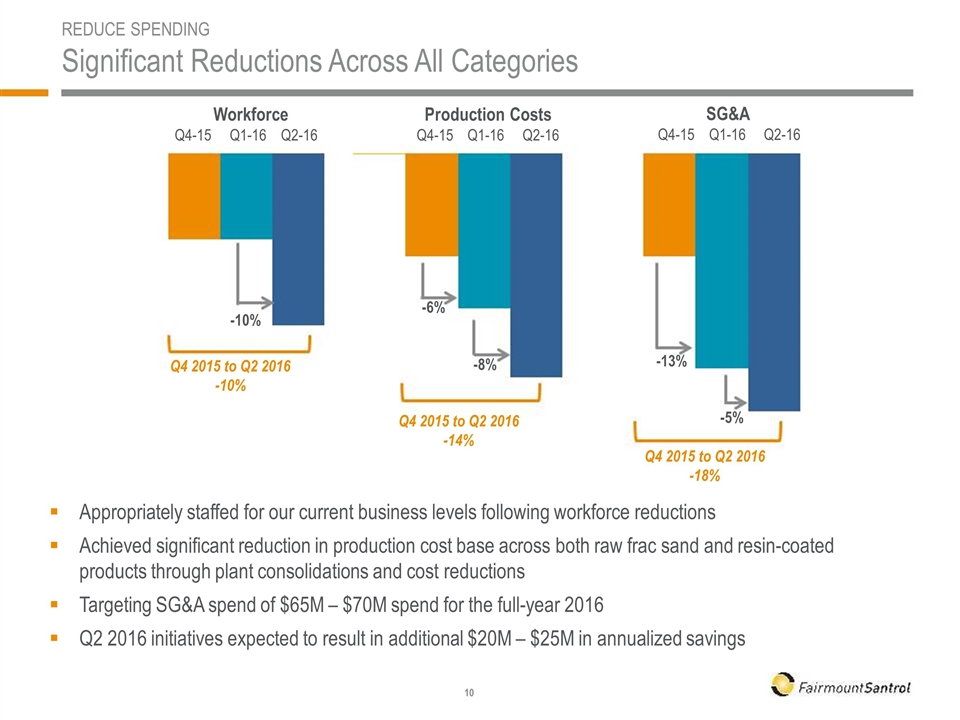

REDUCE SPENDING Significant Reductions Across All Categories Appropriately staffed for our current business levels following workforce reductions Achieved significant reduction in production cost base across both raw frac sand and resin-coated products through plant consolidations and cost reductions Targeting SG&A spend of $65M – $70M spend for the full-year 2016 Q2 2016 initiatives expected to result in additional $20M – $25M in annualized savings -10% -6% -8% -13% -5% Q4 2015 to Q2 2016 -14% Q4 2015 to Q2 2016 -10% Q4 2015 to Q2 2016 -18% Production Costs Q4-15 Q1-16 Q2-16 SG&A Q4-15 Q1-16 Q2-16 Workforce Q4-15 Q1-16 Q2-16

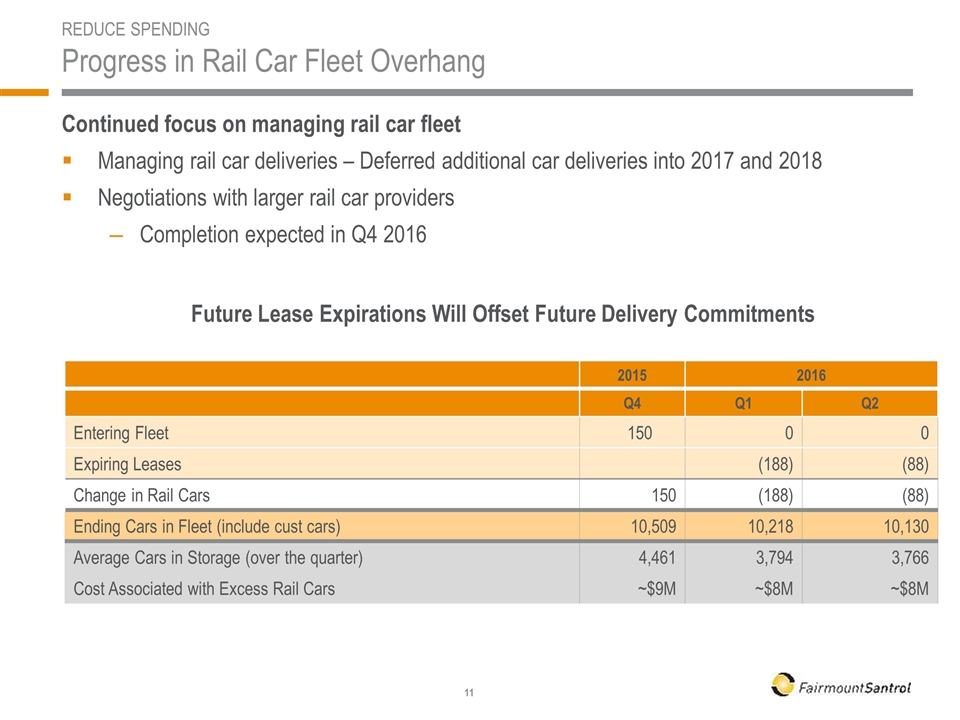

REDUCE SPENDING Progress in Rail Car Fleet Overhang Continued focus on managing rail car fleet Managing rail car deliveries – Deferred additional car deliveries into 2017 and 2018 Negotiations with larger rail car providers Completion expected in Q4 2016 Future Lease Expirations Will Offset Future Delivery Commitments 2015 2016 Q4 Q1 Q2 Entering Fleet 150 0 0 Expiring Leases (188) (88) Change in Rail Cars 150 (188) (88) Ending Cars in Fleet (include cust cars) 10,509 10,218 10,130 Average Cars in Storage (over the quarter) 4,461 3,794 3,766 Cost Associated with Excess Rail Cars ~$9M ~$8M ~$8M

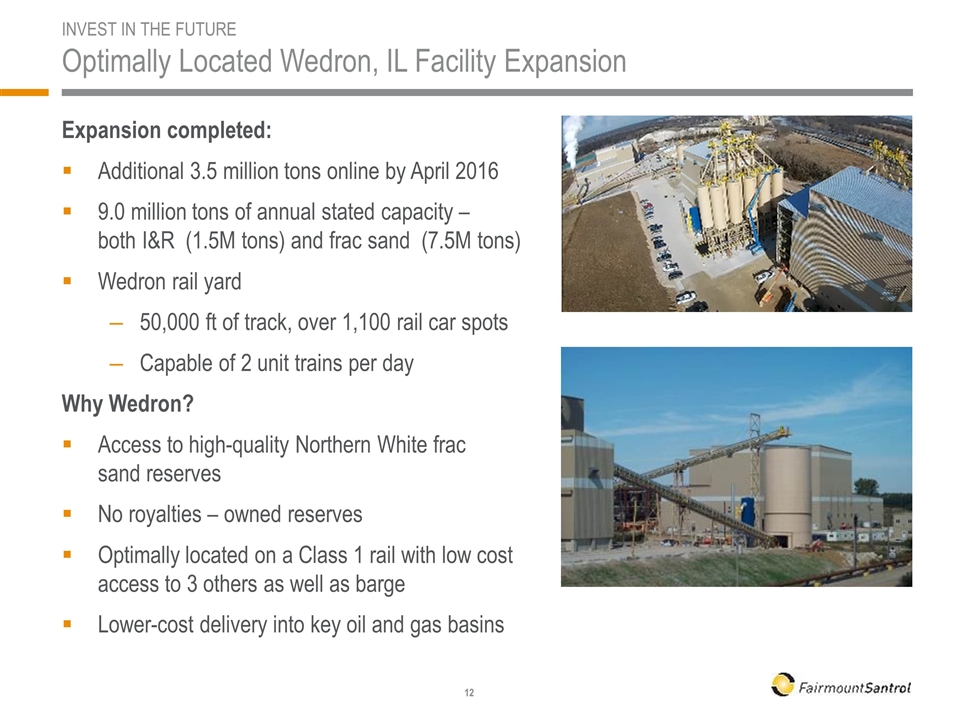

INVEST IN THE FUTURE Optimally Located Wedron, IL Facility Expansion Expansion completed: Additional 3.5 million tons online by April 2016 9.0 million tons of annual stated capacity – both I&R (1.5M tons) and frac sand (7.5M tons) Wedron rail yard 50,000 ft of track, over 1,100 rail car spots Capable of 2 unit trains per day Why Wedron? Access to high-quality Northern White frac sand reserves No royalties – owned reserves Optimally located on a Class 1 rail with low cost access to 3 others as well as barge Lower-cost delivery into key oil and gas basins

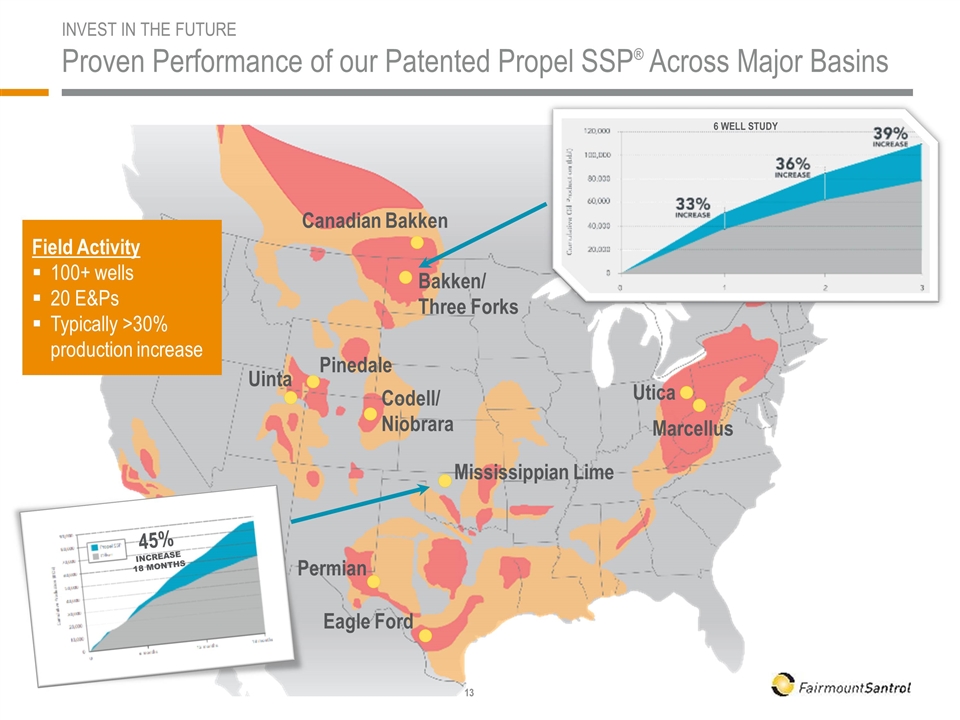

INVEST IN THE FUTURE Proven Performance of our Patented Propel SSP® Across Major Basins Bakken/ Three Forks Canadian Bakken Codell/ Niobrara Mississippian Lime Utica Marcellus Eagle Ford Uinta Permian 45% INCREASE 18 MONTHS 6 WELL STUDY Pinedale Field Activity 100+ wells 20 E&Ps Typically >30% production increase

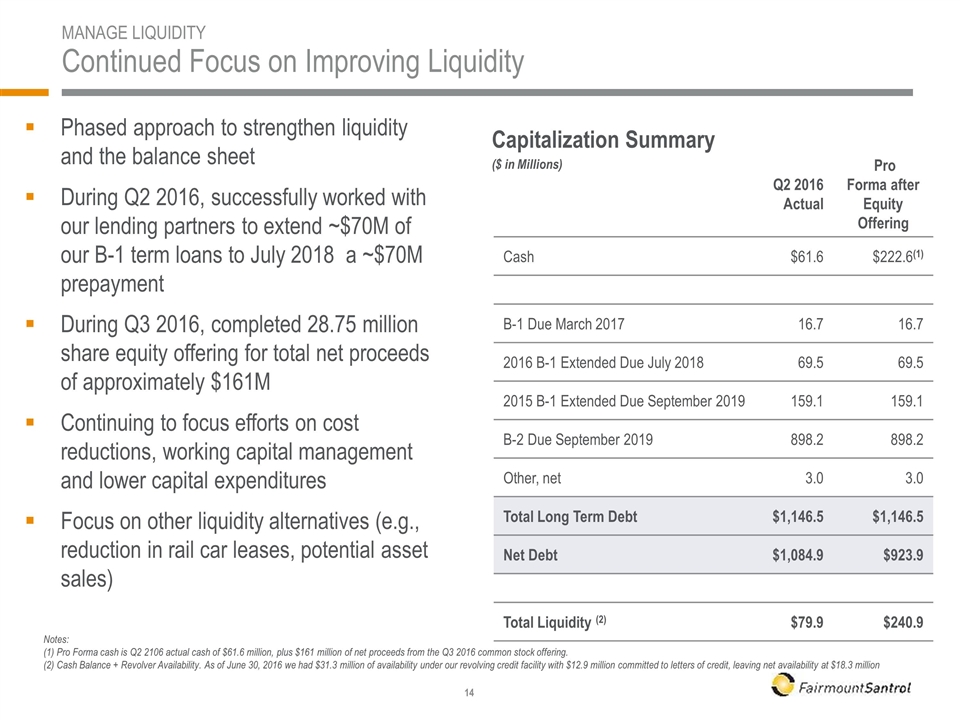

MANAGE LIQUIDITY Continued Focus on Improving Liquidity Q2 2016 Actual Pro Forma after Equity Offering Cash $61.6 $222.6(1) B-1 Due March 2017 16.7 16.7 2016 B-1 Extended Due July 2018 69.5 69.5 2015 B-1 Extended Due September 2019 159.1 159.1 B-2 Due September 2019 898.2 898.2 Other, net 3.0 3.0 Total Long Term Debt $1,146.5 $1,146.5 Net Debt $1,084.9 $923.9 Total Liquidity (2) $79.9 $240.9 Capitalization Summary ($ in Millions) Phased approach to strengthen liquidity and the balance sheet During Q2 2016, successfully worked with our lending partners to extend ~$70M of our B-1 term loans to July 2018 a ~$70M prepayment During Q3 2016, completed 28.75 million share equity offering for total net proceeds of approximately $161M Continuing to focus efforts on cost reductions, working capital management and lower capital expenditures Focus on other liquidity alternatives (e.g., reduction in rail car leases, potential asset sales) Notes: (1) Pro Forma cash is Q2 2106 actual cash of $61.6 million, plus $161 million of net proceeds from the Q3 2016 common stock offering. (2) Cash Balance + Revolver Availability. As of June 30, 2016 we had $31.3 million of availability under our revolving credit facility with $12.9 million committed to letters of credit, leaving net availability at $18.3 million

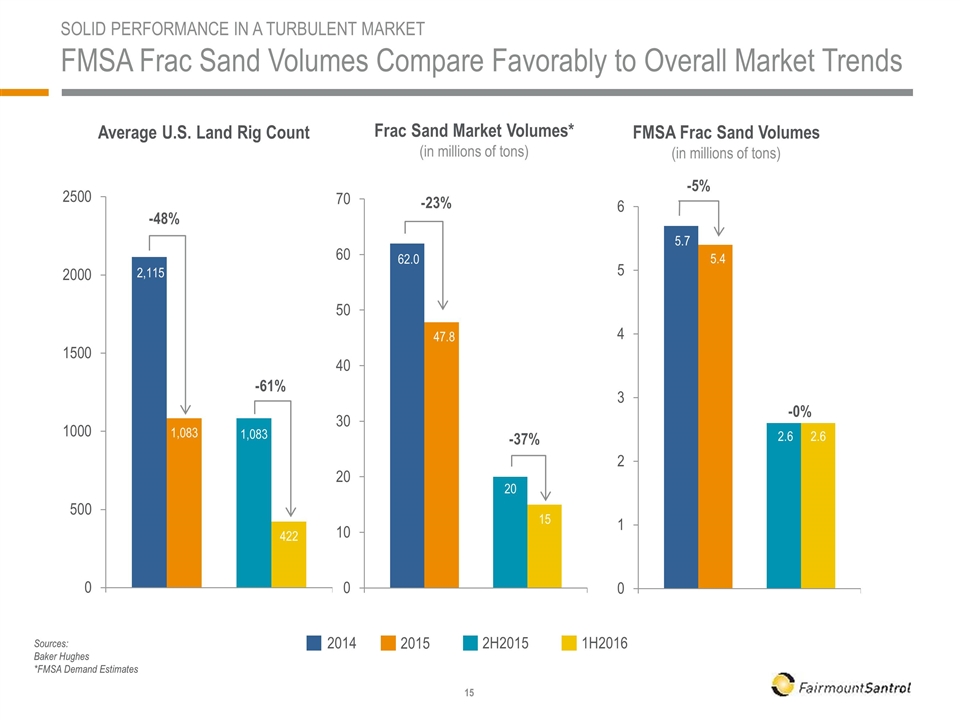

SOLID PERFORMANCE IN A TURBULENT MARKET FMSA Frac Sand Volumes Compare Favorably to Overall Market Trends -48% Sources: Baker Hughes *FMSA Demand Estimates FMSA Frac Sand Volumes (in millions of tons) Average U.S. Land Rig Count Frac Sand Market Volumes* (in millions of tons) -23% -5% -61% -37% 1H2016 2014 2015 2H2015 -0%

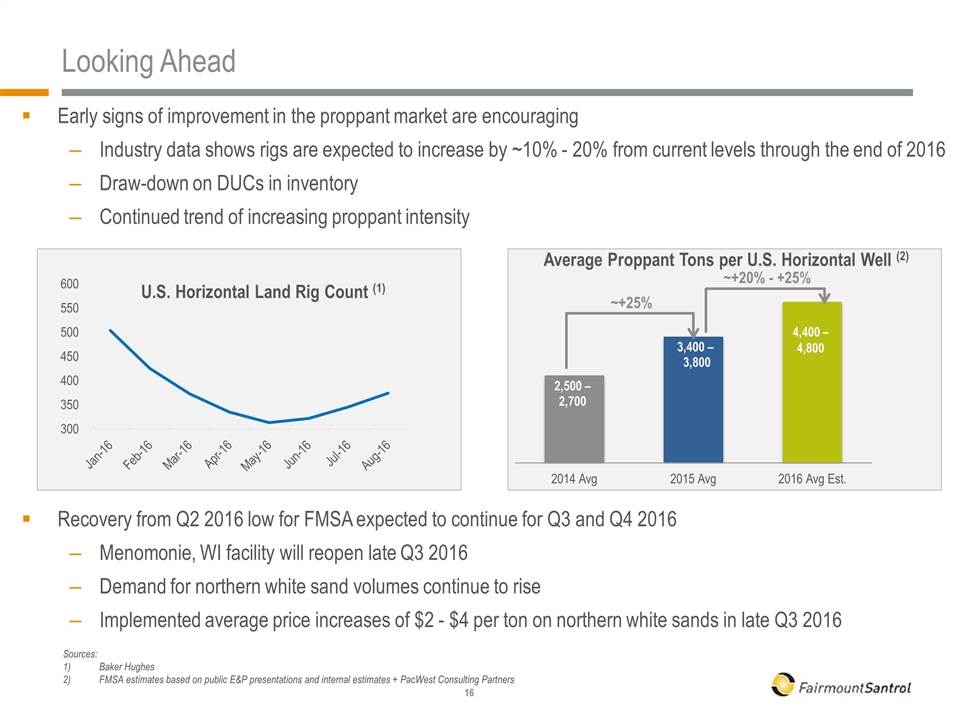

Early signs of improvement in the proppant market are encouraging Industry data shows rigs are expected to increase by ~10% - 20% from current levels through the end of 2016 Draw-down on DUCs in inventory Continued trend of increasing proppant intensity Recovery from Q2 2016 low for FMSA expected to continue for Q3 and Q4 2016 Menomonie, WI facility will reopen late Q3 2016 Demand for northern white sand volumes continue to rise Implemented average price increases of $2 - $4 per ton on northern white sands in late Q3 2016 Average Proppant Tons per U.S. Horizontal Well (2) Looking Ahead ~+25% Sources: 1)Baker Hughes 2)FMSA estimates based on public E&P presentations and internal estimates + PacWest Consulting Partners U.S. Horizontal Land Rig Count (1) ~+20% - +25% 4,400 – 4,800

WHY INVEST IN FMSA? Leading Solutions Provider Differentiated in Every Area of the Value Chain Operational Scale & Optimized Cost Structure Leading Distribution & Unit Train Capabilities Broad Product Portfolio Technology & Innovation

Questions?