Attached files

| file | filename |

|---|---|

| S-1/A - S-1/A - XG SCIENCES INC | s102925_s1a.htm |

| EX-23.1 - EXHIBIT 23-1 - XG SCIENCES INC | s102925_ex23-1.htm |

| EX-10.37 - EXHIBIT 10-37 - XG SCIENCES INC | s102925_ex10-37.htm |

Exhibit 99.1

Company

XG Sciences, Inc. (“XGS”), formed in May 2006, is a first mover and market leader in the design and manufacture of graphene nanoplatelets. Graphene nanoplatelets are particles consisting of multiple layers of graphene and are considered a game changer for numerous industries. XGS’ graphene nanoplatelets, trademarked under the name xGnP®, have demonstrated performance impacting multi-billion dollar markets and have unique capabilities for energy storage, thermal conductivity, electrical conductivity, barrier properties and the ability to impart strength when incorporated into plastics or other matrices. XGS has sold products to over 1,000 customers in 47 countries who are in various stages of trialing its products for numerous applications. XGS has also licensed elements of its technology to leading supply chain and distribution partners, such as Cabot Corp and POSCO. Headquartered in Lansing, Michigan, the Company has raised $32 million to date and has 23 full-time employees.

Lux Research says:

XG Sciences – Positive – Advanced Materials. Top Ten Innovative Companies.

“Despite increasing competition from a handful of new entrants to the graphene space, XG remains the low cost leader and also boasts the most impressive business execution to date.”

XG Sciences Well Positioned for Success

| - | Significant Customer Traction: 1,000+ in 40+ countries since inception. Strong portfolio of customer engagements in end-use markets ranging from polymer composites, energy storage, electrically conductive films and thermal management. |

| - | Revenue Traction: Commercial sales started in multiple applications and gaining momentum. $5-10 million in estimated 2016 revenue. |

| - | Proven Technology: Significant IP in the form of patents, trade secrets and know-how. XG SiG™ Composite with 3-5x the energy storage capacity versus today’s LiB anode technology. XG Leaf® with one-third the density of copper films, 50% more thermally conductive than copper and more than 2x that of aluminum. Formulated water- and solvent-based inks with conductivity approaching 1 W/o at 1 mil thickness. Industry-leading performance available in bulk powders and dispersions. |

| - | Positioned To Grow: Technology, partners and management positions XG for substantial growth. Proven manufacturing technology and strong customer channel to deliver on success. Moved beyond proof of concept into commercialization phase. |

| - | Strategic Partners: Well positioned with world class strategic partners, Investors and licensees. Investors: Aspen Advanced Opportunity Fund, Hanwha, POSCO and Samsung Ventures. Licensees: Cabot and POSCO. |

Graphene: The “Miracle Material”

First discovered in 2004, graphene is the thinnest material known - a single layer of carbon atoms configured in an atomic-scale honeycomb lattice, and is noted for its strength, density, impermeability, light weight, and both electrical and thermal conductivity. Among many noted properties, graphene is harder than diamonds, lighter than steel but significantly stronger, conducts electricity better than copper and one of the most thermally conductive materials available today.

| 1 |

Markets

XGS is a “platform play” in advanced materials where the Company’s proprietary processes produce varying grades of graphene nanoplatelets which can be mapped to a variety of applications in many market segments. The Company’s primary focus markets are Energy Storage and Thermal Management where they currently have a portfolio of products undergoing design-in with a range of marquee customers. They also target the Inks & Coatings market with products in development and are engaged in commercial and development activities for the Composites market.

XGS Market/Application Focus Areas & 2018 Market Size

XG SiG™ in Lithium-ion Battery Markets

The global LiB market is large and growing rapidly. According to Avicenne Energy[1], the 2014 LiB market is $13.6B and growing to $21.5B in 2016, driven by the rapid proliferation of tablets, smart phones, electric vehicles, and grid storage applications. The portion of the market that XGS addresses is the anode materials segment, which Avicenne values at about $850 million in 2014 and expects to grow to $1.3-1.4B by 2018.

| 1 | Avicenne Energy, "The Worldwide Rechargeable Battery Market 2014 - 2025", 24th Edition - V3, July 2015. |

| 2 | Avicenne Energy, "The Worldwide Rechargeable Battery Market 2014 - 2025", 24th Edition - V3, July 2015 & Internal Estimates. |

| 3 | ArcActive via Nanalyze, April 3, 2015. |

| 4 | ArcActive via Nanalyze, April 3, 2015 & Internal Estimates. |

| 5 | Future Markets Insights, "Consumer Electronics Market: Global Industry Analysis and opportunity Assessment 2015 - 2020", May 8, 2015. |

| 6 | Prismark, "Market Assessment: Thin Carbon-Based Heat Spreaders", August 2014. |

| 7 | Reporterlink.com, "Semiconductor & IC Packaging Materials Market…", May 2014. |

| 8 | Prismark, 2015. |

| 9 | Grand View Research, "Global Plastics Market Analysis…", August 2014. |

| 10 | From (9) and internal estimates: 2018 = 305 million tons of plastic, if 10% of the market adopted xGnP to enhance their properties, and at only 1% by weight as an additive, then in 2018 305,000 tons or 305,000,000 kilos of xGnP would be required. At $30 a Kg - the value is $9.1 Bn per year. |

| 2 |

XG Leaf® in Portable Electronics

XG Leaf® can be used for a variety of applications such as heat dissipation in electronics, electromagnetic interference (EMI) shielding, and resistive heating. Among these, thermal application has the biggest apparent market potential especially in consumer electronics. According to a private client study by Prismark Partners, LLC, a leading electronics industry consulting firm specializing in advanced materials, the 2014 market for finished graphitic heat spreaders as sold to the OEM and EMS companies with adhesive, PET, and/or copper backing for selected portable applications, is $600 million, and is expected to reach $900 million in 2018. The market is currently in a significant expansion period driven by the demand for portable devices.

Other Markets

| - | Energy Storage: lead acid batteries, supercapacitor electrodes, lithium-ion battery cathodes, lithium-ion anodes; |

| - | Thermal Management: circuit boards, portable electronic devices, such as cell phones and tablets, thermal management systems for battery packs used in electric vehicles; inks, coatings, polymer composites and greases; cooling liquids / fluids; |

| - | Electrical Conductivity: aqueous and solvent-based formulations to print conductive circuits using flexo, gravure, off-set and screen-printing processes on flexible and rigid substrates; |

| - | Composites: polymers (urethanes, polycarbonate, Teflon, rubber, polypropylene, thermoplastic polyolefin and nylon), polymer processes (e.g., thermoset, solvent cast and thermoplastic) and cement; and |

| - | Lubricity: oil and grease additives. |

XGS Products

xGnP® Graphene Nanoplatelets

xGnP® graphene nanoplatelets consist of ultrathin particles of graphite that are short stacks of graphene. They are produced in various grades, which vary by average particle thickness, and average particle diameters. xGnP® graphene nanoplatelets are especially applicable for use as additives in polymeric or metallic composites, or in coatings or other formulations where particular electrical, thermal or barrier applications are desired by our customers.

XG Leaf®

XG Leaf® is a family of sheet products suited for use in industrial, electronics, and automotive markets. These sheets are made using special formulations of xGnP® graphene nanoplatelets as precursors, along with other materials for specific applications. There are several different types of XG Leaf™ available in various thicknesses (20 to 120 microns), depending on the end-use requirements for thermal conductivity, electrical conductivity, or resistive heating.

| 3 |

XG SiG™ Li-ion Battery Anode Materials

XG SiG™ is a composite of silicon and graphene nanoplatelets designed to deliver 3-5 times the energy storage capacity of today’s graphite-based LiB anodes. Anode capacity is a key driver for extended battery runtime in applications such as portable electronics, power tools and electric vehicles (“EV”). Silicon has 10x the storage capacity of graphite and has been targeted as the next-generation material to replace graphite. However, silicon suffers from poor cyclability limiting its adoption in LiB anodes. XGS’ breakthrough is the creation of a SiG composite that allows the use of silicon as an active component in anodes, delivering on the industry need for long battery cycle life, high efficiency and at a cost and scale that meets industry targets. Product design-in is underway with battery manufacturers targeting early commercialization performance requirements. The combination of performance, cost and manufacturability positions XG SiG™ and XGS as a leader in high energy density LiB materials.

Strategic Investors and License Agreements

The Company has partnered with leading global companies as manufacturing, technology and distribution partners as a way to accelerate XGS’ customer and manufacturing reach. Each of these partners has spent significant time with XGS to validate the technology and market need.

| Mar 2014 | POSCO | $1.2M investment exercising certain pre-emptive rights |

| Jan 2014 | Samsung Ventures | $3M investment + Joint Development Program ongoing with Samsung SDI for next gen Li-Ion batteries |

| Nov 2011 | Cabot Corp | $4M licensing agreement + royalties |

| Jun 2011 | POSCO | $4M investment with licensing agreement + royalties |

| Dec 2010 | Hanwha Chemical | $3M investment |

Customer Traction

| - | Year-on-year addition of new customers in a range of end-use applications. |

| - | Track record of annual order growth as well as repeat customers underlying commercial traction with multiple customers and markets. |

| 4 |

Management Team

Dr. Philip Rose, CEO

| - | President, Hitech, Sigma Aldrich (2010 to 2013) |

| - | General Management, M&A, Business Development and Marketing, Rohm and Haas (1989-2010) |

Dr. Liya Wang, VP R&D

| - | Renowned expert in the field of batteries and advanced materials |

| - | Former Principal Scientific Director for Spain’s CIC Energigune and Director for emerging technologies at A123 |

Rob Privette, VP Energy Markets

| - | 25 years of experience in technology development and commercialization of fuel cells, batteries, and other energy related devices |

| - | Former Director for Product Development at Energy Conversion Devices and Director of US Fuel Cell Development at Umicore with experience at the US DOE, DARPA, the US Army and US Navy. |

Dr. Hiroyuki Fukushima, Technical Director

| - | Founding shareholder and inventor of xGnP® production processes |

Scott Murray, VP Operations

| - | Seasoned professional with 30 years as a senior operations executive |

| - | Formerly Founder and CEO of Uretech International Inc., Director of Development for McKechnie Automotive and various positions with Motor Wheel Corporation |

Board of Directors

Dr. Philip Rose, CEO, President, Treasurer and Director

Arnold A. Allemang, Director, Chairman and Audit Committee member. Retired Board member, Dow Chemical, former Operating Officer of Dow

Ravi Shanker, General Manager, Lightweighting Platform, Dow Chemical

Steven C. Jones, Director and Audit Committee Chairman. Chairman, Aspen Capital Group LLC. President, Aspen Capital Advisors, LLC

Michael Pachos, Director and Audit Committee member. Principal, Samsung Ventures

Dave Pendell, Director, owns and operates AdvancedStage Capital LLC, ASC Lease Income, and general partner in Veterans Capital Fund

| 5 |

Company Overview Presentation 1

Forward - looking Statements This presentation contains statements which constitute forward - looking statements within the meaning of Section 27A of the Securities Act, as amended; Section 21E of the Securities Exchange Act of 1934; and the Private Securities Litigation Reform Act of 1995. The words “may”, “would”, “could”, “will”, “expect”, “estimate”, “anticipate”, “believe”, “intend”, “plan”, “goal”, and similar expressions and variations thereof are intended to specifically identify forward - looking statements. All statements that are not statements of historical fact are forward - looking statements. Investors and prospective investors are cautioned that any such forward - looking statements are not guarantees of future performance and involve risks and uncertainties, and that actual results may differ materially from those projected in the forward - looking statements as a result of various factors. The risks that might cause such differences are identified in our private placement memorandum. We undertake no obligation to publicly update or revise the forward looking statements made in this presentation to reflect events or circumstances after the date of this presentation or to reflect the occurrence of unanticipated events. 2

The Carbon Revolution – A New Materials World 3 DATE 100,000 BC 10,000 BC 1,000 BC 0 BC/AD 500 AD 1000 AD 1500 AD 1800 AD 1850 AD 1900 AD 1920 AD 1940 AD 1960 AD 1980 AD 2000 AD Stone Age Copper Age Bronze Age Iron Age Age of Steel Age of Polymers Age of Silicon The Nano Age Carbon Black Carbon Fiber Fullerene Carbon Nano - Tube Graphite • Tightly bonded carbon atoms arranged in a hexagonal lattice • 2 00x stronger than steel, yet… • Like rubber that can stretch up to 25% of its original length • More electrically conductive than Copper • Better at conducting heat than any material • Optically Transparent • Atomic - level barrier properties Graphene If the 20 th century was the age of plastics, then the 21 st century seems set to become the age of Graphene! Graphene

Potential Future is Endless? 4 It is currently only limited based on your imagination! • Flexible, wearable electronics • Stronger and lighter airplanes • More efficient solar panels • Energy Savings power systems • Longer battery life time • More storage memory in portable electronics • Supercapacitors charged in seconds • Desalination

Investment Highlights XG Sciences has significant market momentum taking shape Revenue Traction : Significant customer engagements, 1,000+ in 40+ countries since inception • C ommercial revenue started and gaining momentum • $5 - 10 million of revenue expected in 2016 • Actively engaged with multiple customers and across a range of end - use markets • S trong and robust customer pipeline to sustain growth into the future Proven Technology : Significant IP in the form of patents, trade secrets and know - how • Demonstrated value proposition in commercial and development relationships • Technology validated by licensees ( Cabot and POSCO) and strategic investors • Deep know - how from 10 years of technology development Positioned To Grow : Technology, partners and management positions XG for substantial growth • Management Team with over 100 years combined experience commercializing new products into new markets • Seasoned Board , governance processes and procedures in place • Investors: Aspen Advanced Opportunity Fund , Hanwha, POSCO and Samsung Ventures . $32 million of funded capital since inception. • Targeting $24 million in this raise for full - scale commercialization Manufacturing : Low - cost, world - scale manufacturing capabilities • > 100 Tons of capacity across commercial product families 5

6 Source: Lux Research, July, 2015 1.0 – 1.9 2.0 – 2.9 3.0 – 3.9 4.0 – 3.9 5.0 Maturity Lux Take Strong Positive Positive Wait and See Caution Strong Caution Dominant Undistinguished Long - shot Technical Value 1 1 5 XG Sciences Vorbeck Materials Sixth Element Angstron Materials Incubation Alliance Grafoid Graphenix Development Ningbo Morsh Xolve Avanzare Grafen Graphene Platform Haydale R.S. Group Knano Graphenea Times N ano NUS Bluestone AGM DCT Rushford Cambridge Nanosystems Graphene Frontiers NanoIntegris Directa Plus Graphene Labs G T LeaderNano Ugent Tech NanoCarbon CNM Anderlab Grafentek Gelanfong Absolute Nano National Nano Materials Graphene 3D Lab Innophene Business Execution 3 3 5 High - Potential XG Science Market Leadership

Significant Accomplishments 7 2006 2010 2011 2012 2013 • Hanwha Chemical – Investment • Shipping sample materials since early 2010 • Cabot Corp - L icensing agreement + royalties • POSCO - I nvestment with licensing agreement + royalties • Demonstrated 4x energy storage capacity vs. traditional Li - ion anode materials • Samsung - I nvestment + Joint Development Program with Samsung SDI for next gen Li - Ion batteries • POSCO - I nvestment exercising certain pre - emptive right 2014 • Company Founded • Aspen Advanced Opportunity Fund investment • Launch of XG Leaf® pilot production line • Rapid progress towards commercialization of XG SiG ™ products • $1M DOE grant to further develop XG SiG ™ • Completed large - scale xGnP ® production facility 2015 • Commercial penetration into multiple markets • Large Scale commercialization planning • Additional capital raise

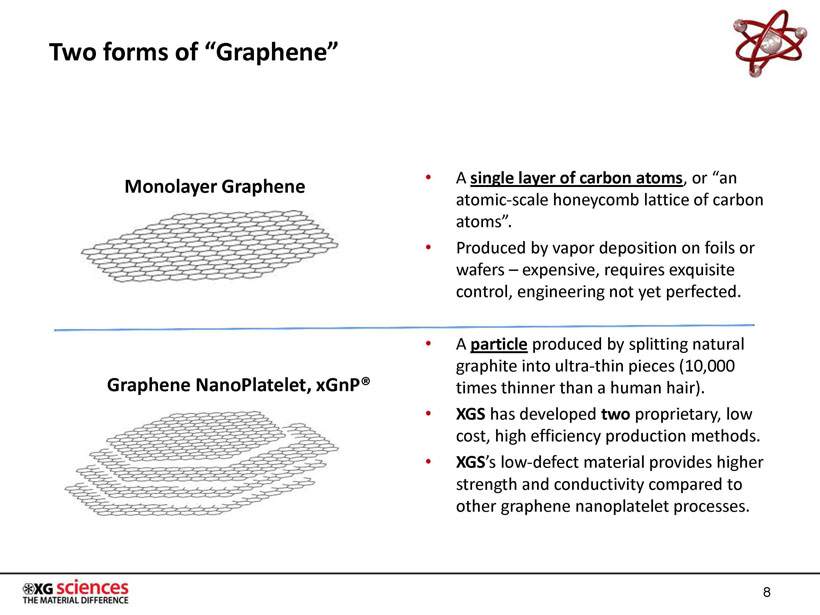

Two forms of “ Graphene ” • A single layer of carbon atoms , or “an atomic - scale honeycomb lattice of carbon atoms”. • Produced by vapor deposition on foils or wafers – expensive, requires exquisite control, engineering not yet perfected. • A particle produced by splitting natural graphite into ultra - thin pieces (10,000 times thinner than a human hair). • XGS has developed two proprietary, low cost, high efficiency production methods. • XGS ’s low - defect material provides higher strength and conductivity compared to other graphene nanoplatelet processes. 8 Monolayer Graphene Graphene NanoPlatelet , xGnP ®

Properties are Enabling for Many Applications 9 M - Grade C - Grade H - Grade XGS Control Material Attribute Property Function Application Customer Performance

Key Customer Portfolio (1) • Energy Storage – Lithium Ion Battery ( LiB ) • Anode Replacement • Cathode Conductive Additive – Lead - Carbon Anode Additive • Thermal – XG Leaf • Portable Electronics • LiB Pack Thermal Management – Adhesives – Thermal Interface Materials – Consumer Products – Clothing • Composites – Sporting Goods – Automotive – Office Automation – Packaging – Construction Materials – Wear Parts 10 Energy Storage Thermal Management Composites Lubrication Electrical Conductivity (1) Total Customer pipeline includes opportunities with over 75 customers.

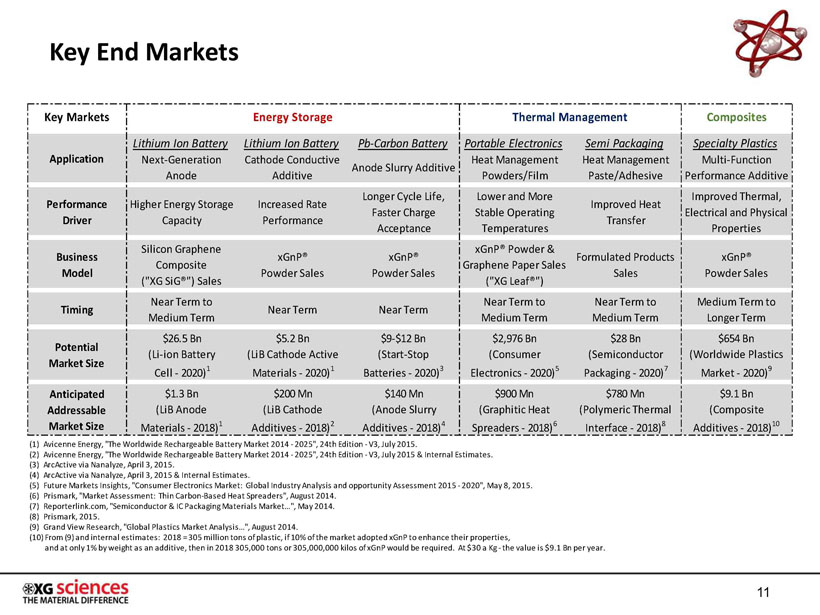

Key End Markets 11 Key Markets Composites Lithium Ion Battery Lithium Ion Battery Pb-Carbon Battery Portable Electronics Semi Packaging Specialty Plastics Next-Generation Anode Cathode Conductive Additive Anode Slurry Additive Heat Management Powders/Film Heat Management Paste/Adhesive Multi-Function Performance Additive Performance Driver Higher Energy Storage Capacity Increased Rate Performance Longer Cycle Life, Faster Charge Acceptance Lower and More Stable Operating Temperatures Improved Heat Transfer Improved Thermal, Electrical and Physical Properties Business Model Silicon Graphene Composite ("XG SiG®") Sales xGnP® Powder Sales xGnP® Powder Sales xGnP® Powder & Graphene Paper Sales ("XG Leaf®") Formulated Products Sales xGnP® Powder Sales Timing Near Term to Medium Term Near Term Near Term Near Term to Medium Term Near Term to Medium Term Medium Term to Longer Term Potential Market Size $26.5 Bn (Li-ion Battery Cell - 2020) 1 $5.2 Bn (LiB Cathode Active Materials - 2020) 1 $9-$12 Bn (Start-Stop Batteries - 2020) 3 $2,976 Bn (Consumer Electronics - 2020) 5 $28 Bn (Semiconductor Packaging - 2020) 7 $654 Bn (Worldwide Plastics Market - 2020) 9 Anticipated Addressable Market Size $1.3 Bn (LiB Anode Materials - 2018) 1 $200 Mn (LiB Cathode Additives - 2018) 2 $140 Mn (Anode Slurry Additives - 2018) 4 $900 Mn (Graphitic Heat Spreaders - 2018) 6 $780 Mn (Polymeric Thermal Interface - 2018) 8 $9.1 Bn (Composite Additives - 2018) 10 (1) Avicenne Energy, "The Worldwide Rechargeable Battery Market 2014 - 2025", 24th Edition - V3, July 2015. (2) Avicenne Energy, "The Worldwide Rechargeable Battery Market 2014 - 2025", 24th Edition - V3, July 2015 & Internal Estimates. (3) ArcActive via Nanalyze, April 3, 2015. (4) ArcActive via Nanalyze, April 3, 2015 & Internal Estimates. (5) Future Markets Insights, "Consumer Electronics Market: Global Industry Analysis and opportunity Assessment 2015 - 2020", May 8, 2015. (6) Prismark, "Market Assessment: Thin Carbon-Based Heat Spreaders", August 2014. (7) Reporterlink.com, "Semiconductor & IC Packaging Materials Market…", May 2014. (8) Prismark, 2015. (9) Grand View Research, "Global Plastics Market Analysis…", August 2014. (10) From (9) and internal estimates: 2018 = 305 million tons of plastic, if 10% of the market adopted xGnP to enhance their properties, and at only 1% by weight as an additive, then in 2018 305,000 tons or 305,000,000 kilos of xGnP would be required. At $30 a Kg - the value is $9.1 Bn per year. Application Energy Storage Thermal Management

Value Creation Business Model xGnP ® Graphene Nanoplatelets Designing and manufacturing graphene nanoplatelets for specific applications and customers xGnP ® + Binder System Formulating functional inks and coatings to enable performance in customer coating processes xGnP ® Enabled Products High - value products enabled by graphene nanoplatelets Manufacturing Services Leveraging unique manufacturing processes to tailor other 2 - D materials XG Ink XG TIM XG SiG ® XG Leaf® Grades H, M & R Grade C 12

Customer Growth and Repeat Order Traction 13 Cumulative Customers, by Year Total Orders, by Year and Customer Type 81 111 233 381 400 456 476 536 New Customer Repeat Customer 2008 2009 2010 2011 2012 2013 2014 2015 2008 2009 2010 2011 2012 2013 2014 2015

Sample Customer Commercialization Pipeline (1) 14 (1) Total Customer pipeline includes opportunities with over 75 customers. (2) $5 - 10 million in forecasted 2016 revenue. Estimate of sales based on customer commitments, customer forecasts and management es timates. 1H 2016 2H 2016 2017 Fiberglass Rebar Composite C-750 x Construction Materials C-300 x Chemical Additive, Oil and Gas M-5 x Sporting Equipment M-15 x Scratch Resistant Coating C-300 x Resistive Heating M-15 x Pb-Acid Battery, Anode Additive C-300 x Composite, Elastomer C-300 x Heat Spreading, Seating xGnP® x Composite, Office Automation R-10 x Wear Part C-500 x Engine Oil Additive C-500 x LED Packaging XG TIM™ x LiB Anode XG SiG™ x LiB Cathode Conductive Additive R-10 x Polymer Composite, Thermal R-100 x Sporting Equipment xGnP® x Thermal Transfer Fluid R-25 x Sensor Calibration XG Leaf® x Consumer Products, Thermal R-10 x LiB Cathode Conductive Additives C-150/300 x Thermal Adhesive xGnP® x High-Voltage Cable Coating xGnP® x Sporting Equipment xGnP® x Thermal Transfer Fluid xGnP® x Auto Composites, Interior & Under Hood xGnP® x Auto Transmission, Thermal Mgmt xGnP® x TIM, Electrical Inks xGnP® x Electrical Inks, LiB Anode xGnP®, XG SiG™ x Customer Validation Commercial Launch Anticipated Revenue (2)Application Product R&D Technical Validation Pilot Production

Management Team Board of Directors Dr. Philip Rose, CEO: More than 20 years managing and growing businesses based on advanced materials in technical applications and markets – lived in Japan/Korea for ~8 years . Dr. Liya Wang, VP R&D: Renowned expert in the field of batteries and advanced materials. Former Principal Scientific Director for Spain’s CIC Energigune and Director for emerging technologies at A123 . Rob Privette, VP Energy Markets: 25 years of experience in technology development and commercialization of fuel cells, batteries, and other energy related devices . Dr. Hiroyuki Fukushima, Technical Director : Founding shareholder and inventor of xGnP ® production processes . Scott Murray, VP Operations: Seasoned professional with 30 years as a senior operations executive . 15 Dr. Philip Rose , CEO, President, Treasurer & Director Arnold A. Allemang , Director, Chairman and Audit Committee Member: Former member , Board of Directors, Dow Chemical Company (NYSE: DOW); former Chief Operating Officer of Dow. Dr. Ravi Shanker , Director: General Manager, Lightweighting Platform, Dow Chemical Company. Steven C. Jones , Director and Audit Committee Member : Chairman of Aspen Capital Group, Member Board of Directors, NeoGenomics (NASDAQ: NEO) and various other private companies. Michael Pachos , Director and Audit Committee Member : Principal, Samsung Ventures focused on Consumer, Display and Energy related investments. Dave Pendell , Director: Owns and operates AdvancedStage Capital LLC, ASC Lease Income, and is a general partner in Veterans Capital Fund.

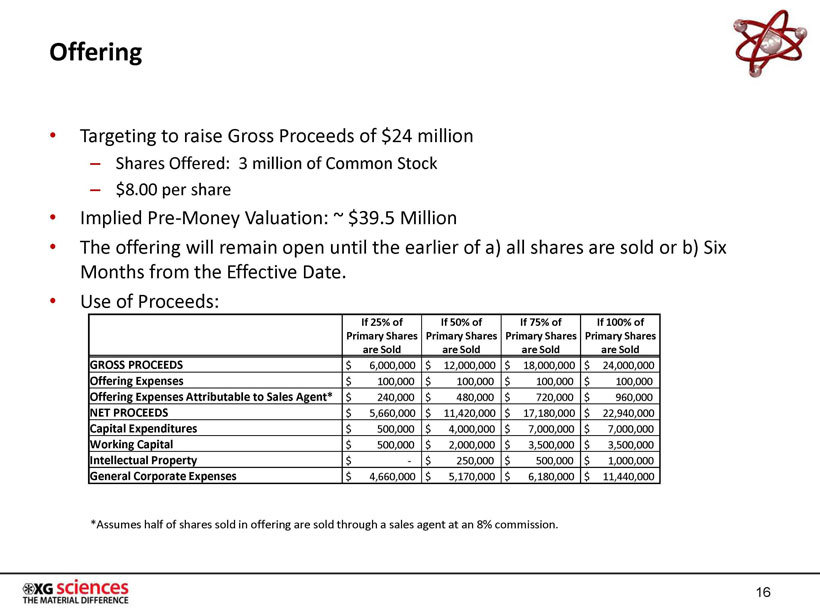

Offering • Targeting to raise Gross Proceeds of $24 million – Shares Offered: 3 million of Common Stock – $8.00 per share • Implied Pre - Money Valuation: ~ $39.5 Million • The offering will remain open until the earlier of a) all shares are sold or b) Six Months from the Effective Date. • Use of Proceeds: 16 *Assumes half of shares sold in offering are sold through a sales agent at an 8% commission. If 25% of Primary Shares are Sold If 50% of Primary Shares are Sold If 75% of Primary Shares are Sold If 100% of Primary Shares are Sold GROSS PROCEEDS $ 6,000,000 $ 12,000,000 $ 18,000,000 $ 24,000,000 Offering Expenses $ 100,000 $ 100,000 $ 100,000 $ 100,000 Offering Expenses Attributable to Sales Agent* $ 240,000 $ 480,000 $ 720,000 $ 960,000 NET PROCEEDS $ 5,660,000 $ 11,420,000 $ 17,180,000 $ 22,940,000 Capital Expenditures $ 500,000 $ 4,000,000 $ 7,000,000 $ 7,000,000 Working Capital $ 500,000 $ 2,000,000 $ 3,500,000 $ 3,500,000 Intellectual Property $ - $ 250,000 $ 500,000 $ 1,000,000 General Corporate Expenses $ 4,660,000 $ 5,170,000 $ 6,180,000 $ 11,440,000

Summary • Recognized leader in disruptive, emerging advanced materials • Robust competitive advantages with diverse applications • Broad customer base with multiple design - in relationships • Revenue ramp starting • World class investors and licensees • Significant IP position • Low cost, scalable manufacturing capabilities • Strong Management Team with outstanding industry experience 17

Thank You Philip Rose, Ph.D. Chief Executive Officer +1 517 999 5453 p.rose@xgsciences.com 18

Sample Customer Pipeline Summaries

On the Ramp

The following customers represent a sub-set of our portfolio where XG Sciences value proposition as it relates to price and performance is clear, our customer has developed a product concept in response to their customer’s need, our customer has confirmed they can manufacture such a product, there are no technical barriers to the commercial launch of their product and they have started to market their product to one or more customers.

| 1. | Sporting goods equipment manufacturer with an emphasis in netball, cricket, rugby and field hockey. Introduced XGS’ product in late 2015 in composite for field hockey sticks. Top of the line models are priced at £400 and are described as: “Graphene fibre matrix construction formulae with fully integrated carbon, aramid & graphene resin system”, “Improved control performance provided by energy absorbing basalt” and “Excellent energy transfer when hitting”. Initial production order of 30Kg filled and waiting on customer response before providing further 2016 estimates. Informed customer intends to extend to two additional product families within their portfolio. |

| 2. | Custom-tailored formulations and oilfield chemicals company. Stock item for oilfield chemicals incorporating XGS’ graphene nanoplatelets. Introduced in late 2014. Ordered in 2015 to refill inventory as needed. Expect to see increased demand in 2016. Estimate 100-200 Kgs in 2016. |

| 3. | European construction materials company specializing in composites for rebar, road signs, pipes and seawalls. Introduced XGS’ C-series product into their fiberglass rebar product in late 2014. Improved flexural strength. Ordered regular quantities throughout 2015. Introduced XGS’ C-series product into a second application in late 2015. Estimate 5 to 10 Tons in 2016. First order received. Looking for additional opportunities to extend into other parts of their product portfolio. |

| 4. | European technology company based in Spain. Developed a novel scratch-resistant coating incorporating C-300 and targeted to protect the screens of portable electronics, watches, sunglasses and in automotive applications. Demonstrated the technology in late 2014, filed IP and finalized the formulation(s) in 2015. Actively marketing beginning in January, 2016. Waiting to see response before providing “volume” estimate. |

| 5. | Korean specialty chemical company specializing in unique metal composites and metal forming processing. Licensed formulation and use IP from the Korean Electronics Technology Institute for resistive heating where XGS’ graphene nanoplatelets are an enabling component of the composition. Marketing activities starting in late 2014. Target markets include office automation, automotive (seat heating, steering wheel heating), in-floor heating and other consumer and industrial heating applications. The office automation opportunity has demonstrated shorter startup time, 30% energy savings and improved lifetime for laser printers. The company has quoted multiple customers in multiple markets. Expects adoption in the first half of 2016 and ramping into the second half and into 2017. Estimate 500Kg to 1T in 2016. |

| 6. | US-based, international specialty material company with broad product offering for specialty carbon-based materials with a strategic interest in graphene nanoplatelets and XGS licensee. Have been working with XGS materials for over 5 years. Focus on energy storage (lead acid anode additive and lithium ion cathode conductive additive) and elastomers. Demonstrated performance for lead-acid batteries in auto and telecommunications applications and delivering improved cycle life and dynamic charge acceptance. Multiple customers in major scale testing. Demonstrated performance for both LiB cathode conductive additives and elastomeric composites meeting customer needs to win the business. Estimate is 10-50T in 2016 across the applications. Timing and actual amounts will vary by customer pace of adoption. |

| 1 |

| 7. | UK-based, international supplier of engineered materials for applications ranging from medical instruments, aerospace, power generation and satellite communications, to body armor, trains and fire protection systems. Demonstrated efficacy for improved wear resistance of carbon-based wear components when incorporating XGS graphene nanoplatelets. Intent to commercialize in the second half of 2016. No estimate at this time. |

Product Confirmation Pending

The following customers represent a sub-set of our portfolio where XG Sciences value proposition as it relates to price and performance is clear, our customer has developed a product concept in response to their customer’s need and our customer has confirmed they can manufacture such a product. However, they have not finalized the product formulation and are completing engineering work and expect to launch commercially in 2016.

| 8. | Korean specialty chemical company specializing in oil additives. Demonstrated improvement in wear properties for lubrication application when incorporating XGS’ graphene nanoplatelets. Targeting improved dispersion and 2016 product launch. |

| 9. | Sporting goods equipment manufacturer with emphasis in lacrosse, ice hockey and field hockey. Desire to incorporate graphene nanoplatelets in lacrosse stick heads to improve strength at lower weight. Samples under testing within customers manufacturing infrastructure. First target application at 400,000 pieces. Market reputation for innovation leader and stated desire to move quickly. Lab testing expected to be complete in Q1, followed by 4-6 month field trial and then commercial launch. |

| 10. | US-based manufacturer of refrigeration equipment. Actively working towards validation of the value of XGS’ products in heat transfer fluids in their equipment. Independent verification of the efficacy of XGS’ technology from Argonne National Labs. Further validation within XGS laboratories. Customer reporting over 25% performance improvement through use of XGS’ product in their formulation. Active engagement with this customer and extending to two other customers. Expecting target insertion within 2016 but no firm timeline established until after product validation. |

| 11. | World leader in the development, design, manufacture and distribution of manual and powered wheelchairs, mobility scooters and both standard and customized seating and positioning systems. Use of XGS’ product in gel packs in seat cushions achieved 30% improvement in distribution of heat, although some developmental work will likely be required to optimize the chemistry of customer’s gel packs. Tentative implementation timing. Targeting second half of 2016. |

| 12. | US-based leader in the development of wet friction technology used in powertrain components and system solutions. Seeking improved thermal performance for a friction component of a transmission part. Have manufactured prototype composite films including XGS’ graphene nanoplatelets. Developed coated solutions currently in testing at the customer. Will down-select to the best option. Revenue likely to begin in 2017. |

| 2 |

| 13. | The global leader in lighting technology solutions. The company develops, manufactures and distributes groundbreaking LEDs and automotive lighting products. Sampled thermal interface grease in China for use in LED packaging. Feedback indicates initial samples are close to the best they are using in production and have recommended our product to their suppliers. Comparison tests underway. No timing yet established for commercial adoption. |

| 14. | Japanese company involved in the manufacture of composite plastic parts for multiple industries (among other initiatives). Interested in improved thermal stability for PEEK plastics for office automation parts. Demonstrated efficacy using XGS’ products. Will begin in late 2016 at 100Kg per quarter and ramp to 2 Tons per year. Very performance driven, not highly price sensitive. |

| 15. | Family-owned business of high-end professional styling equipment. Use of XGS’ coating provides more uniform temperature than the standard material. Customer is motivated to move quickly and has involved their supply chain in the evaluation. Getting volume estimates and confirming manufacturing parameters in Korean plant. Expect to ramp in mid 2016. |

Development Engagements

The following customers represent a sub-set of our portfolio where XG Sciences value proposition as it relates to price and performance is defined, our customer has identified a product concept in response to their customer’s need and are highly motivated to work with XG Sciences to define a solution.

| 16. | Specialty materials company operating worldwide with leading brands and technologies in three business areas: Laundry & Home Care, Beauty Care and Adhesive Technologies. Engaged with 2 groups in their Electronic Materials unit interested in conductive inks, thermal interface materials and heat spreaders. XGS has demonstrated value propositions in each area and the customer is eager to reproduce the results in their labs. No commercial timing established at this phase. |

| 17. | One of the world's leading suppliers in the additives and instruments for the quality control of color, appearance and physical properties. Have identified numerous areas of synergy (dispersion of nanomaterials, coatings, rheology modification, composites and lithium ion battery conductive additives). The customer’s key coating accounts have graphene projects that they are interested in pursuing and are encouraging the customer to get involved in graphene. Defined two areas to begin collaboration: coatings and composites. Targets identified and testing started. Expect data to be generated throughout Q2. |

| 18. | Boston Power: Formal joint development agreement signed in December targeting customizing XG Sciences’ silicon-graphene anode materials for use in Boston-Power’s lithium-ion battery products. Work statement details plans to optimize electrochemical and microstructural electrode performance, as well as developing electrode and battery manufacturing techniques using the two companies’ proprietary materials. The companies see a real synergy between Boston-Power’s battery engineering and design capabilities and the new XG-SiG anode materials. Boston-Power has the ability to design and manufacture the battery, while XG Sciences has the ability to customize the anode materials to best fit the Boston-Power system. |

| 19. | Large Korean LiB manufacturer. Formerly working under joint development agreement targeting next-generation lithium ion batteries for consumer electronics and other devices. Currently engaged on meeting their needs for lithium ion battery cathode and anode conductive additives. Not expected to commercialize in 2016. |

| 3 |

| 20. | China-based lithium ion battery manufacturer. Eager to adopt graphene nanoplatelets for use as conductive additives in cathode formulations. Currently using carbon nanotubes (CNT). XGS internal data demonstrates that a significant portion of the CNT can be replaced with xGnP and retain the high rate discharge capacity from 100% CNT and with the benefits of low cost, reduced spring back and high pressed density. Current CNT costs of $125/Kg on a dry powder basis. Customer has agreed to fast-track 25Ah battery tests using our materials. Potential demand in the multiple tons per month. Customer reported their data match what we have indicated. They will continue more intermediate durability and cycling testing. |

| 21. | Korean specialty chemical company focusing on electronic materials and with a commercial presence in other industrial markets and applications. Business model to sell resin loaded XGS’ graphene nanoplatelets. Demonstrated good dispersion and performance acceptable for market entry. CEO is positioning the company as leading manufacturer of graphene-based composites. Targeting initially camera housing and CD-Disc covers with eventual target of automotive parts. Estimate 10-30 Kg per month through first 3 quarters of 2016 as they progress toward late 2016 commercial launch. |

| 22. | Large consumer electronics company not wishing to be identified. Working closely to develop thermal heat spreading solution using XGS’ proprietary XG Leaf technology. Estimate low 1,000’s of sheets in 2016. |

| 23. | Carbon nanotube company based in the US with production and R&D in China. Demonstrated efficacy for use of XGS’ products in combination with customer’s carbon nanotubes for use as a cathode conductive additive in lithium ion batteries. Improved energy density and process yield using XGS products. Marketing formulations to customers in China. Estimating the potential for up to 5T in 2016 but do not currently have orders. Successful adoption up to 5T per month. |

| 24. | Korean-based lead acid battery manufacturer. Engaged in a program to use our materials to improve performance for high temperature geographies. Active sampling with initial positive feedback. Continuing with in-house trials and pricing discussions. Customer would like to scale up in 2016 pending completion of development efforts. Volume estimates pending decisions on breadth of product adoption within their porfolio. |

| 25. | Korean-based specialty tape and adhesive supplier. Their customer in need of improved thermal adhesive for high-brightness LED TV. Wishes to work with mid-tier, Korean-based supplier. XGS working with our customer to supply XGS precursors for use in a thermal adhesive tape and for supply to their customer. Targeting late Q1/early Q2 for qualification and initial production in late 2016. Initial coating results validating value proposition. No volume estimates at this time. |

| 26. | Large Korean-based supplier of PET films and specialty chemicals. Working to define product and technical solutions using XGS’ product portfolio. Initially target thermally conductive adhesives and coatings. Also pursuing options for XG Leaf integration. |

| 27. | Korean-based specialty materials provider. Working closely with cable companies in Korea to develop semi-conductive coating materials for ultra-high voltage cables. Incorporation of XGS’ product improves the coating mechanical performance and the mechanical stability during heat shock and shrinkage in the ultra-high voltage cable application. Commercial timing is mid to late 2017. Potential volume is given to XGS as 1 to 20T per year. |

| 4 |

| 28. | World leader in rolled aluminum products, delivering unique solutions for the most demanding global applications, such as beverage cans, automobiles, architecture and consumer electronics. Applying XGS technology to aluminum processing and expecting results in Q1. No timing yet defined for commercial launch. Unlikely to be in 2016. |

| 29. | Recognized as the world's leading provider of lubricant solutions offering a range of advanced automotive motor oil, including synthetic, synthetic blend, high mileage, conventional and diesel oils. Engaged for well over a year on use of XGS products as an oil additive to improve friction and wear, particularly for gear box applications. Demonstrated benefits for high gear load applications (i.e., drivetrains). Also interested in nanofluid with thermal transfer properties for cooling of cutting tools. Exploring options to better move these projects forward. |

| 30. | Technology and innovation leader specializing in defense, civil and cybersecurity markets throughout the world. Specified use of XGS product for sensor calibration in multi-layered system. Have validated efficacy for thermal heat transfer and are completing integration design efforts. Small volume application. |

Sampling Examples

An additional >30 customers represent a sub-set of our portfolio where XG Sciences value proposition as it relates to price and performance is theorized but not yet demonstrated and where we are sampling products and formulations against a defined market need but have not yet entered into a collaborative development effort.

Transformational Customers

The following customers represent a sub-set of our portfolio where success can drive significant commercial volume and subsequent value for XGS shareholders. These customers are specifically managed at the account level while we actively engage in development and commercialization efforts.

| 31. | International auto manufacturer. Actively engaged with the group having a mandate to explore opportunities for graphene. Currently focusing on three applications that we are not at liberty to disclose. They have demonstrated a compelling value proposition in the lab and we have started working with their supply chain partners, upon the request of our customer, in multiple applications. Target is to have graphene in a car on the road in 2017. They have alignment up to the VP of R&D and out into the relevant business groups. They have indicated that they believe XGS is the only commercially viable supplier of graphene nanoplatelets. Specific feedback on the value proposition includes “substantial property enhancements at much lower loadings” compared to other types of additives for composite applications and “increased both tensile and flexural moduli and strength” and “enhanced thermal stability”. Only estimated data thus far is for a target application requiring 25T of XGS’ product starting in 2018. |

| 32. | US-based coatings company. Engaged with multiple businesses to exploit the properties of graphene nanoplatelets for barrier, thermal transfer and structural components in paint. Initial samples weren’t compelling but customer admits were cursory and not likely definitive with regard to the potential for performance. Held a technical face-to-face to define next steps in collaboration. Initial dispersions were prepared without knowledge of the customer’s chemistry. Knowledge of the chemistry will allow for tailored formulations. Engagement supported at program director level. Strong desire on the part of the customer to see graphene nanoplatelets adopted and have represented their view of XGS as a leading supplier in the industry. |

| 5 |

| 33. | Global sporting goods manufacturer. Engaged in multiple projects being sponsored by the golf division. One such project is an injection molded composite for a club head, targeting improved strength and modulus. Working directly with customer’s supplier. A second project is for club shafts and we are working directly with the customer’s supplier. We are expecting an on-going engagement to validate efficacy. Success would support brand recognition efforts and provide additional validation of our broad value proposition. |

| 34. | International chemical company. Engaged in multiple R&D efforts. XGS technology has broad appeal within the customer’s business units. Two projects are progressing through their stage gage process: thermal transfer fluids and composites. Customer estimates the potential for up to 2,000 Tons of annual demand for XGS’ product by 2020, assuming successful product development and market launch efforts. Broader success would drive significant demand for XGS’ products and commensurate shareholder value. |

Lithium Ion Battery Anode Replacement

XG Sciences has developed an advanced Silicon-based anode that, as a critical battery component, can potentially enable high energy cells for future generation batteries, enabling longer battery life and/or more functional performance for portable electronics. Silicon (Si) is considered the most promising anode material due to its high capacity and proper working voltage. Theoretically, Si can provide up to 4,200 mAh/g of Lithium storage capacity, which is more than 10 times that of graphite. It can be lithiated in the potential range of 0.0 ~ 0.4 V, which enables a high energy density battery when paired with an appropriate cathode. The global market for lithium ion anode materials is estimated to be $1.3 Billion in 2018.

Two major barriers have hindered the development of Si-based anodes for commercial applications, especially for use in EV batteries: poor cycle life and high synthesis costs. XGS’ Si/graphene (SiG) composite anode is based on a unique nano-structure design and an innovative compositing process that utilizes graphene to mitigate cycling stability issues of Si particles during cycling. Graphene creation and SiG compositing is achieved in a single unit process using an existing manufacturing process and low cost industrial precursors. Unlike other Si/graphene based materials where graphene is often produced separately and Si is deposited onto the graphene using exotic methods, XGS’ one-pot process allows to produce the SiG material at high volume and low cost.

XG Sciences technology is widely considered as a leading candidate for next generation anode materials. XGS received a $1.2MM grant from the DOE to further develop this technology. Samsung Ventures invested in XGS and we entered into a joint development program with Samsung SDI, the world’s leading lithium ion battery manufacturer. The company developed its technology to a level that allows it to aggressively pursue commercial efforts in applications requiring high energy storage and with cycle life up to 250 cycles. The company is pursuing commercialization in those applications. In parallel, the company has formed, and are seeking additional development relationships that will advance its technology, making it more amenable to a broad industry adoption. The company announced in December a joint development relationship with Boston Power. The company was recently awarded a funded development contract under which it will work with a cell manufacturer and a cathode material supplier to pair its silicon graphene composite and demonstrate performance against a commercial need. The customer funding the work wishes to not be named. The company is currently in active discussions with other parties to form additional joint development arrangements targeting both technology development and specific commercial implementation.

| 6 |

Frequently Asked Questions

1. How would you best characterize XG Sciences?

XG Sciences (XGS, Company, we, or us) is a platform play in advanced materials. We were formed in May 2006 and are a first mover and market leader in the design and manufacture of graphene nanoplatelets (the advanced materials). First isolated and characterized in 2004, graphene is a single layer of carbon atoms configured in an atomic-scale honeycomb lattice. Graphene nanoplatelets are particles consisting of multiple layers of graphene and are considered a game changer for numerous industries. Our graphene nanoplatelets, trademarked under the name xGnP®, have demonstrated performance impacting multi-billion dollar markets and have unique capabilities for energy storage, thermal conductivity, electrical conductivity, barrier properties and the ability to impart strength when incorporated into plastics or other matrices (the platform play). We have sold products to over 1,000 customers in 47 countries who are in various stages of trialing our products for numerous applications. We also license elements of our technology to leading supply chain and distribution partners, such as Cabot Corp and POSCO. Based on the status of current discussions with customers, we believe that we will begin to scale up revenue significantly this year and that we will be able to book approximately $5-10 million of revenue in 2016. Thus, we believe that we are well positioned for success. We have raised $32 million to date, have 23 full-time employees, and are headquartered in Lansing, Michigan.

2. Does the company have third-party validation of XG Sciences leadership position?

Yes. Lux Research has consistently ranked us as the leading company in the graphene market. Lux evaluates the technical value and business execution of market participants. According to Lux, XG Sciences has been the leading firm in the graphene space for the past two years. We also have a very strong investor base with Samsung Ventures, POSCO, Hanwha Chemical and Aspen Advanced Opportunity Fund, each having done extensive due diligence on the company before making an investment. As mentioned above, we have also licensed elements of our manufacturing technology to both POSCO and Cabot, further validating the value of our capabilities and product offerings.

3. What are XG Sciences competitive strengths?

We believe that we are a world leader in the emerging global market for graphene nanoplatelets. The following competitive strengths distinguish us in our industry:

| • | The strength of our intellectual property. Because of our focus on the development of manufacturing processes, we believe we have one of the world’s strongest internal knowledge bases in graphene nanoplatelet manufacturing, with most of our proprietary knowledge maintained as trade secrets to avoid the disclosures required by patenting. Through the end of 2015, we were managing 16 domestic patents/applications (with additional foreign filings), which we believe add value by protecting specific equipment or high-value end-user product applications. |

| • | The breadth of our product offering. As far as we are aware, we have the broadest product offering in our industry. In addition to offering three standard particle sizes in three different grades of bulk materials, we offer four different grades of XG Leaf® in multiple thicknesses, two different grades of silicon-graphene composite materials, three standard ink formulations, and optional custom dispersions and formulations of our bulk materials. We have other products, and formulated products, in development. We are the only company we are aware of that has successfully scaled a chemical intercalation process. We are also the only company we are aware of that has developed and scaled a graphene nanoplatelet mechanical exfoliation production process, which allows us to produce nanoplatelets with up to 800 square meters of surface area per gram of product. These two production processes enable us to have the widest product portfolio among all emerging entrants. |

| • | The low-cost nature of our manufacturing processes. As far as we are aware, our manufacturing processes have the potential to be among the lowest-cost approaches to the manufacture of graphene nanoplatelets (subject to economies of scale) based on our internal modelling of competitive processes as well as our analysis of alternative technologies. |

| • | Our corporate and strategic partners. Three global corporations have made investments in XGS, giving us a significant global reach as well as the ability to leverage the assets of our partners. |

| • | The number of development partners that are working with our materials. As of December 31, 2015, we have supplied materials to over 1,000 customers, including industrial, universities or government laboratories, in 40 different countries around the world. We shipped over 500 orders in 2015. We have more than 75 ongoing commercial and/or customer design-in relationships in a range of other application areas. |

| • | Our know-how and ability to tailor our products for use in multiple applications. Many of our products and product-development activities target use of our xGnP® graphene nanoplatelets in various matrices to form composite products that are then used by our customers. We have extensive knowledge of how to tailor our products to deliver performance as composite products in various applications and we also have knowledge of how to tailor other components of a composite to adjust the performance of the composite for use in various applications. |

4.

What is XG Sciences’ Go To Market Strategy?

We expect to use our intellectual property, business model, manufacturing techniques, management team, scientific credibility, and customer relationships to be the first graphene industry participant to successfully achieve commercial scale revenue with multiple clients. We intend to compete vigorously on a worldwide basis by:

| • | Implementing strategic partnerships with customers and other partners in many different geographic localities as well as specialized markets. |

| • | Focusing our resources on remaining a low-cost supplier of high-quality materials with sufficient production capacity to meet the needs of large, global customers. |

| • | Developing “value-added” products like XG Leaf®, XG SiG™ battery anode materials, inks and coatings, and similar specialized products for specific markets. |

| • | Investing in intellectual property, especially in areas covering novel formulations of our products and use of our products in end-use applications. |

5. Who are XG Sciences competitors?

Graphene suppliers are first segmented on whether they are a producer of graphene monolayer or of graphene nanoplatelets. XG Sciences does not manufacture graphene monolayer, because we believe it will be years before a commercial process exists to manufacture a 1 atom think monolayer of anything at a commercially viable price point. We focus exclusively on graphene nanoplatelets. The applications for each form of graphene do not compete, for the vast majority of projected applications, with one another. Therefore, XGS does not compete with graphene monolayer developers or manufacturers. Graphene nanoplatelet manufacturers may then be further segmented by the process(es) used to manufacture graphene nanoplatelets. In the US, there are at least two other companies producing graphene nanoplatelets. One leverages their nanoplatelet know-how to make conductive inks and sensors and is considered by many to be a sensor company. XGS is not actively targeting the sensor market. A second follows a technology license model and will typically work under development and license agreements for specific applications. XGS is a solutions provider and produces graphene nanoplatelets and products containing graphene nanoplatelets, principally for end-market needs in Energy Storage, Thermal Management, Composites, Lubrication and Electrically Conductive Coatings. There are also emerging producers in the Asia and Europe that may become more active as time progresses.

6. What is the average sales cycle? Can you explain a typical customer interaction?

There probably isn’t any “average” cycle. However, it is safe to generalize in that all commercialization efforts are a process. They almost always start with our own internal R&D to validate performance for an identified market or customer-specific need. We say, almost always, because we have examples where customers have ordered our materials, done their own work and then commercialized their product, all without further consultation with XG Sciences. In the more typical route, however, we will engage with customers to validate efficacy for their application following our internal work. This can be an iterative process of data exchange and sampling to further improve performance for a specific application. Once the performance has been validated, our customers may then determine that our products fit with their manufacturing. This is initially done at the pilot scale. Sometimes this is done in parallel with their product development activities or assessed prior to investing resources in product development. Our customers will then introduce their product to their customer(s) to validate performance. After their customer’s validation, our customers will move to commercial scale production. Every customer goes through the same basic process, but will do so at varying speed, depending on the customer, the product and the end-use market. From first engagement, a commercialization effort can be a short as 6 months and as long as 2 years, and even longer. The automotive industry, for example, is well known to have a 5-year commercialization time line.

7. XG Sciences is ten years old. Why hasn’t it generated more revenue historically?

The simple answer is that any new material takes time to develop and get industry traction. There are many examples where new materials took many years to get any meaningful commercial traction: nylon, Teflon, polycarbonate and carbon fibers, for example. Graphene nanoplatelets are new materials and similar to the introduction of other new materials, it takes time before the industrial complex has the confidence and knowledge to exploit them. Thus far, XG Sciences has gone through three distinct phases and is now in its fourth phase in which it is finally ready to commercialize its products in scale. The first phase of two to three years focused on moving from the lab scale to pilot scale. During this stage we validated the ability to make materials and developed a better understanding of their physical properties and how to manipulate their performance for specific applications. We started sampling materials from our pilot facility in the latter stages of this period. The second phase of another two to three years focused on moving from the pilot scale to what we refer to as a commercially relevant scale. We use this term as it represents a capacity and capability demonstrating our ability to make sufficient quantity, at an attractive price, and reproducibly, giving customers the confidence to incorporate our products into their products. Without a commercially relevant scale, we would not have been able to extend beyond academic curiosity. It was during this stage that we began to scale our two processes and further improve process quality and consistency. We increased the number of customer engagements and in a broader range of applications. The third phase of another two to three years focused on developing more specific application knowledge and developing key end-market value propositions in areas such as energy storage and composites. We invested in more internal application engineering and began to more fully support technical development within our growing customer base. It was during this time that XG Leaf and XG SiG were developed and we extended our base powder xGnP® nanoplatelet product portfolio. In the latter part of phase 2 and into the early part of phase 3, we got the attention of POSCO, Cabot and Hanwha, each taking an equity position in the company, a license or both. As the company demonstrated unique technology in energy storage, Samsung Ventures also became an investor. The company is now in a fourth phase, the commercialization phase. We believe we are well positioned with the reputation, products, technology, capacity, quality and customer pipeline. We understand the value proposition for graphene nanoplatelets in a range of end-use markets and we have focused our customer pipeline in the areas of energy storage, thermal management, composites, lubrication and electrical conductivity. We further believe that we have demonstrated to our customers that we are capable of producing consistent products in commercially relevant quantities, which is a key aspect of convincing customers to order larger quantities of products. Thus, we expect to begin to scale revenue rapidly in this phase and have forecast $5-10 million of revenue in 2016.

8. What is XG Sciences manufacturing footprint strategy?

It probably makes the most sense to answer this question in the context of the broader strategic plan. While we may entertain other material sets over time, for the foreseeable future, we are only focused on developing and producing graphene nanoplatelets and value-added products containing graphene nanoplatelets. It is our intent to maintain a presence in Lansing, Michigan for the foreseeable future. We currently have just over 100 T of annual capacity in Lansing. In the next 6 to 12 months we intend to debottleneck existing capacity and add other incremental capacity in Lansing, which we believe will allow us to meet our business plan over the next 1-2 years. Our Lansing facilities will serve as a base for production as well as a center of excellence for R&D, applications engineering and new manufacturing process development. Given that many of our potential customers are talking about the need for 100s or even 1000s of tons of our products per year once they commercialize their own products that use our products, we believe will need to locate large scale manufacturing capabilities overseas in order to optimize our production cost structure. Thus, additional capacity expansions needed beyond those in Lansing, Michigan will likely be done in partnership in order to move production to Asia or we will install customer-specific capacity wherever it may be needed. We believe this strategy will reduce the risk to our shareholders and customers.

9. What is XG Sciences IP strategy?

We believe that our intellectual property (“IP”) is an important asset. Our strategy is to keep some aspect of our production processes as legally defined and protected trade secrets rather than to patent them. We believe that by patenting our processes, we would simply be teaching others how to produce materials like ours. In addition, it would be difficult or impossible to detect infringement. Therefore, our basic intercalation and exfoliation processes are not patented. We have, however, patented some of the equipment used in these processes. Other processes we have chosen to patent and have been granted a patent for our mechanical process for producing graphene nanoplatelets.

Our intellectual property consists of four main types of assets:

| • | Employee knowledge and skills |

| • | Corporate “trade-secrets” and processing know-how |

| • | Exclusive licenses from Michigan State University (“MSU”) on certain inventions |

| • | Patents and trademarks owned by the Company |

10. What patents and applications does XG Sciences hold?

See Exhibit A.

11. Does XG Sciences seek foreign patent coverage?

Yes. For each patent application filed in the US, we make a determination on the nature and value of the patent. For many of the applications filed in the US, additional filings are made in other countries such as the European Union, Japan, South Korea, China, Taiwan or other applicable countries. These filings and analyses are made on a case-by-case basis. Typically, patents that are defensive in nature are not filed abroad, while those that are protective of active XGS products or application areas are filed in relevant countries abroad.

12. Does XG Sciences have any Trademarks?

Yes. We have filed for or been granted registered trademarks as follows:

| • | “xGnP®,” which is the brand name by which we designate our graphene nanoplatelets. |

| • | The corporate logo “XG Sciences” (design logo plus words) |

| • | The tag line “The Material Difference” which is used in conjunction with the corporate logo |

| • | The product designation “XG Leaf®”, which is the brand name for our family of sheet products. |

| • | The product designation “XG SiG™”, which is the brand name for our battery anode materials. | |

Our application is pending for the following trademark:

| • | The product designation “XG TIM™”, which is the brand name for our thermal interface materials. |

13. Why does Lux Research consider XG Sciences to be a world leader in the graphene space?

There is no way to definitively answer this question, other than to put it directly to Lux Research. However, we can speculate on the reasons. Lux’s July 2015 data, for which we remain the highest ranked company, contain both graphene monolayer and graphene nanoplatelet suppliers. These data also include Universities. It is our belief that Lux is biased toward organizations demonstrating the potential for commercial success and rates them more highly as a result. XG Sciences is fairly unique in our ability to attract a range of strategic investors such as POSCO, Hanwha and Samsung Ventures. We have licensed some aspect of our know-how to both POSCO and Cabot. We speculate that Lux sees this as early validation of our value proposition and as a differentiating factor in building a sound business model. We further speculate that we are differentiated having demonstrated scale in our manufacturing process. We also believe that we are differentiated by having two distinct graphene nanoplatelet production processes that provide a broad capability to meet a range of end-use market requirements. We don’t provide customer-specific information to Lux but we believe that through our press releases, Lux’s own patent citation searches and customer interviews, Lux concluded that we were among the best positioned in the industry for success.

14. Are there any filed or known pending law suits against XG Sciences?

No.

15. What keeps Philip Rose up at night?

I get this question fairly often so I offer it here for your consideration. Other than the usual on-going balance of shareholders, customers and employees, the primary issues that keep me up at night are the probability of revenue generation on a customer-specific basis and their adoption timing. I suppose the two are intimately related, but I do see them slightly differently. Probability relates to the robustness of our customer pipeline. We have a great customer pipeline. However, the finite probability of turning each engagement into a sale is the test of the true value of any pipeline. The priority of our product within each customer is not always transparent to XGS. A lack of real transparency is a source of frustration. With more transparency from our customers, we would be able to communicate with more certainty to shareholders about the timing and magnitude of our expected revenue ramp. I’ve culled out adoption timing as a separate cause for frustration. Even in those instances where it is clear we are strategically aligned with our customer(s), and we have a clear signal for technical and commercial success, there is still less clarity on the timing for commercial ramp. This relates mainly to the fact that graphene nanoplatelets are new materials and we find that our customers often deviate from “standard commercialization processes” given the non-standard nature of new-to-the-world materials.

16. What is the current burn rate and when does the company expect to hit cash-flow positive?

The current burn rate, with no offset from product or license revenue, is approximately $400K per month, or approximately $5 million per year. We expect to see that offset by increased revenue, but we will need to increase headcount in operations to deliver the higher output requirements. We expect to reach the breakeven point towards the second half of 2017.

17. What are the use of proceeds from this $18-24MM capital raise?

The use of proceeds will depend somewhat on how much capital we ultimately raise, but we expect that most of it will be used for General Corporate Purposes to increase our headcount, specifically in sales and marketing, R&D and production. By more fully developing our commercial organization and applications engineering capability, we believe we can improve and accelerate our customers’ rates of conversion from their own development activities to commercialization of their products incorporating our products. An additional $5-7 million of the Offering proceeds will be used to debottleneck our current production facilities and add incremental capacity in Lansing, which we believe will allow us to increase our annual production capacity enough to support $20-$25 million in annual revenue. Some of the proceeds will also be used to support increases in working capital as we scale revenue and to expand our intellectual property portfolio. The chart below depicts our current expected use of proceeds at various levels of capital raised.

If 50% of Primary Shares are Sold | If 75% of Primary Shares are Sold | If 100% of Primary Shares are Sold | ||||||||||

| GROSS PROCEEDS | $ | 12,000,000 | $ | 18,000,000 | $ | 24,000,000 | ||||||

| Offering Expenses | $ | 100,000 | $ | 100,000 | $ | 100,000 | ||||||

| Offering Expenses Attributable to Sales Agent* | $ | 480,000 | $ | 720,000 | $ | 960,000 | ||||||

| NET PROCEEDS | $ | 11,420,000 | $ | 17,180,000 | $ | 22,940,000 | ||||||

| Capital Expenditures | $ | 4,000,000 | $ | 7,000,000 | $ | 7,000,000 | ||||||

| Working Capital | $ | 2,000,000 | $ | 3,500,000 | $ | 3,500,000 | ||||||

| Intellectual Property | $ | 250,000 | $ | 500,000 | $ | 1,000,000 | ||||||

| General Corporate Expenses | $ | 5,170,000 | $ | 6,180,000 | $ | 11,440,000 | ||||||

The above estimates assume that we engage the services of non-exclusive sales agents and that such sales agent sell half of all shares sold in the Offering. Each sales agent will be paid a commission of 8%.

EXHIBIT A

Patents and Applications

As of December 31, 2015 the following technologies were included in the MSU License Agreements with XGS and were being actively prosecuted at the U.S. Patent Office:

| • | U.S. Patent Application No. 12/587,645. “Electrically Conductive, Optically Transparent Films of Exfoliated Graphite NanoParticles & Methods of Making the Same” |

| • | U.S. Patent Application No. 13/200,764. “Method of Preparing Metal Nanoparticles” |

In addition, one licensed MSU invention has recently been granted a US Patent:

| • | U.S. Patent 8,834,959. “Method for the Preparation of Doped Single Graphene Sheets.” |

As of December 31, 2015 the following patents and patent applications were being managed by XGS and its patent attorneys:

| • | U.S. Patent Application No. 13/435,260. “Mechanical Exfoliation Apparatus”, allowed but not yet granted |

| • | U.S. Patent Application No. 13/474,860. “Process of Dry Milling Particulate Materials” |

| • | U.S. Patent Application No. 13/686,961. “Single Mode Microwave Device for Producing Exfoliated Graphite” |

| • | U.S. Patent Application No. 61/786,735. “Graphene Carbon Compositions” |

| • | U.S. Patent Application No. 61/786,745. “Electrodes for Capacitors from Mixed Carbon Compositions” |

| • | U.S. Patent Application No. 13/858,149. “xGnP as conductive filler for resistor materials” |

| • | U.S. Patent Application No. 61/879,225. “Flexible Resin-Free Composites Containing Graphite & Fillers” |

| • | U.S. Patent Application No. 14/079,057. “Silicon-Graphene Nanocomposites for Electrochemical Applications” |

| • | U.S. Patent Application No. 62/060,319. “LiF-Embedded SiG Powder for Lithium-Ion Battery” |

| • | U.S. Patent Application No. 62/284,797. “Thermal Interface Materials using Graphene Coated Fillers” |

| • | U. S. Patent Application No. 62/244,927. “Heat Exchanger Elements and Devices” |

| • | U.S. Patent 9,206,051. “Mechanical Exfoliation Apparatus” |

| • | U.S. Patent 8,715,720. “A Cloud Mixer and Method of Minimizing Agglomeration of Particles” |

In addition, some of our early patent filings have been granted:

| • | US Patent 8,715,720: “A Cloud Mixer and Method of Minimizing Agglomeration of Particles.” |

| • | US Patent 9,061,259 B2 “Cloud Mixer and Method of Minimizing Agglomeration of Particles.” |