Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - IRELAND INC. | form8k.htm |

DISCLOSURE/DISCLAIMER

The author of this report, Dr. Charles A. Ager, PhD, PEng, PGeo, is a shareholder, directly and indirectly, of Ireland, Inc. (IRLD). The scientific research and development of the mineralogy and metallurgy for the Columbus Project has been under the direction of Dr. Ager for the period 2006-2015. All reported gold assays have been by independent assayers (AuRIC Metallurgical Labs, LLC, Salt Lake City, Utah and Arrakis Inc., Denver, Colorado) except where noted that IRLD personnel assisted. The TPAC process, partially disclosed herein, is proprietary technology owned by Ager/Arrakis for which IRLD has been given the right to use only on the Columbus Project.

The author believes that all data presented is factual, that all interpretations are of the highest scientific quality and that all conclusions/recommendations are justified based on the data presented herein and from the technical records of IRLD. However, because the author is not independent of IRLD, readers of this report should seek independent metallurgical guidance and advice before making any financial decisions about the economic potential of the Columbus Project as summarized herein.

2

EXECUTIVE SUMMARY

This report summarizes the gold extraction results at the Columbus Project as at February 17, 2015. Collectively, these results have identified the mineralogy and metallurgy of the gold found in the sands at the Columbus Project. It is expected that these results will provide Ireland Inc. (IRLD) and its metallurgical team with the necessary knowledge to improve gold extractions at the Columbus Project. Recent laboratory work (2014-2015), completed on material from drill site location 10S7A, has resulted in an increase of gold extraction from ± 0.057 opt Au using caustic fusion (5g) to an average of ±0.26 opt Au using newly developed extraction protocols (TPAC) on 100g – 500g samples. Further work to confirm the extraction rates, to re-assay drill samples and to optimize the extraction process are underway.

|

1. |

Gold Mineralogy | |

|

|

||

|

Gold at Columbus occurs as clusters (<1000 nm) of coated nanoGold particles (<30nm) entombed in silicate minerals. | ||

|

|

||

|

2. |

Gold Assay: Caustic Fusion Assay | |

|

|

||

|

AuRIC Metallurgical Labs, LLC (“AuRIC Labs”) used caustic fusion (CF2011) to extract gold as metal in hand from ~500 tests (drill/bench/bulk samples; 2007-2013) from the sand zones at the Columbus Project. On average this work resulted in 0.034 opt Au and 0.179 opt Ag extracted from 37 sand zone drill holes (0-200 foot depth). | ||

|

|

||

|

3. |

Gold Bars: Bulk Sample Leaches | |

|

|

||

|

Gold bars have been produced at AuRIC Labs from leaching ITC concentrates produced at Columbus. Four separate runs (10S3A: 5 to 7 tons each) produced concentrates (≈ 1 ton each) for an extracted head grade of 0.046 opt Au and 0.145 opt Ag from 24 tons. | ||

|

|

||

|

Bulk leach tests (~80) completed at the Columbus pilot plant, on gravity (ITC) concentrates produced at Columbus, consistently gave low gold extractions (<0.01 opt Au) from these concentrates. Further tests identified an onsite leach circuit problem. | ||

|

|

||

|

4. |

Gold in Leach | |

|

|

||

|

Transmission electron microscope (TEM) micrographs and zeta potential (ZP) tests showed that gold is leached into solution as “negative charged colloids” and not as “ionic complexes” as evidenced by various leach methods, including sodium thiosulphate (STS). |

3

| 5. |

Ground Potential: Pilot Plant | |

|

The voltage on ground (ground potential) at the Pilot Plant was measured to be “+9VDC”. This indicated that the Columbus Basin acts as a “+9VDC battery”. The pilot plant, including all stainless steel leach tanks and other equipment, is grounded and therefore carries this +9VDC charge. When identical leach tanks were tested at AuRIC Lab’s facilities in Salt Lake City, Utah, the ground potential was found to be electrically neutral (0 VDC). | ||

| 6. |

Columbus Leach Analysis | |

|

The leaches extracted negative charged gold colloids at both AuRIC and Columbus. However, at Columbus, these colloids appeared to have precipitated to the positive charged leach tank walls during leaching. Agitation would have then carried these gold colloids to the filter tails and left the filtered pregnant leach solution (“PLS”) mostly devoid of gold. This is the apparent cause of low gold to be extracted from the PLS by the resins at the Pilot Plant. | ||

| 7. |

TPAC Process | |

|

A new process (TPAC), based on the mineralogical/metallurgical data collected since 2007, was successfully developed in the past year (2014- 2015). The TPAC process is proprietary technology owned by Ager/Arrakis for which IRLD has the right to use this process only on the Columbus Project. Sand samples (North Sand Zone) were first processed through a thermal pre-treatment process (TP) and then autoclave leached (AC). The TPAC products then became fire assayable for the first time and resulted in extractions of ±0.26 opt Au from 100g to 500g 10S7A head ore samples. Testing of this process on Columbus sands and concentrates, as well as re- assaying of drill holes, continues. |

Respectfully Submitted

Nanominerals Corp.

“Charles A. Ager”

Dr Charles A. Ager, PhD, PEng,

PGeo

Founder and Chairman

February 17, 2015

4

COLUMBUS METALLURGY

HISTORY

During 2007-2010 Ireland, Inc. (IRLD) discovered a gold deposit in the “tuff sands” area of the Columbus Basin, Nevada (Columbus Project) (See Figure 1). Drill programs were conducted by IRLD from 2007 to 2010. All drill-hole sampling and assaying was completed in 2007-2010 by independent geologists/engineers on chain-of-custody samples. Assays/leaches on material from the North and South Sand Zones were conducted on approximately 500 samples from drill hole, bench and bulk samples (5g to 7 tons) by AuRIC Metallurgical Labs, LLC (“AuRIC Labs”) of Salt Lake City, Utah. Assays were by caustic fusion (CF2011), a well known whole rock assay method, followed by gravimetric and ICP/AA finish of extracted dore. Leaches were by AuRIC Labs using sodium thiosulphate (STS) followed by resin ashing to produce extracted dore.

GEOLOGICAL MODEL

The North Sand Zone has been the main focus for sampling and drilling operations (34 holes) and covers a surface area of approximately 0.67 mi2. The South Sand Zone (3 drill holes) covers a surface area of approximately 0.48 mi2. The North and South Sand Zones are located in the tuff sands area, on the western margin of the Columbus Basin (see Figures 1-3).

These Sand Zones are alluvial material occurring as “fans.” Drilling has shown that these sands plunge, at shallow angle, under the clays to the east. The average dry bulk density of the sands is 1.165 ton/yd³ (1.383 tonnes/m³). The sand zone averages 91.4% -1/4 inch as determined from 258 screen analyses of sonic drill samples from 0-200 ft. depth.

The lakebed “clay” to the east varies in color, moisture content, texture, and organic content. Because of the wide drill hole spacing in the clays, it is not possible to correlate between individual clay units. At present, the clay is not sub classified and is referred to as a single unit. Average dry bulk density of the clay, taken from the 200+ samples, is 1.198 tons/yd3 (1.423 tonnes/m3). Caustic fusion assays of the overlying clays indicate low gold grades whereas the underlying sands are of similar grade as the outcropping sands to the west.

5

The North Sand Zone and South Sand Zone are mostly comprised of tuff sands, but also contain some silt and clays. Even though the South Sand Zone has only one line of drill holes, assays indicate that these zones are similarly mineralized and are of exploration significance. Caustic fusion assays of drill samples by AuRIC Labs under chain-of-custody mostly range between 0.020 -0.055 opt t Au with an average of all assays completed in the Sand Zones of 0.034 opt Au and 0.179 opt Ag from the surface to 200 feet as shown on Figure 3.

6

7

8

PILOT PLANT TESTING

Further successful testing by AuRIC Labs (±100 bench tests, ±10 bulk tests; 2010-2012; 7 sites North Sand Zone, 1 site South Sand Zone; see Figure 3) led to the development of a gravity concentrate and thiosulphate leach circuit. These results then led IRLD to build an onsite pilot plant and lab in order to prove the commercial viability of this process for extracting gold from this deposit. AuRIC installed the leach circuit at Columbus, using identical leach tanks, as successfully tested at Salt Lake City, Utah. The gravity concentration circuit (ITC circuit), the lab and other infrastructure were also installed to complete the onsite facilities. The pilot plant started operations in 2012.

Approximately 80 bulk leach tests completed through the pilot plant resulted in low leach extraction of gold (<0.01 opt Au). The ITC circuit was checked by shipping bulk ITC concentrates, produced at the Columbus pilot plant, to AuRIC Labs for thiosulphate leaching and resin extraction. These tests (10S3A: Run 2, 10, 27, 30) produced four gold/silver bars as shown below. They totaled 1.1134 oz Au and 3.4914 oz Ag from 24 tons of 10S3A head ore for a calculated extractable head grade of 0.046 opt Au and 0.145 opt Ag. These results indicated that the gold extraction problem at the Columbus site was in the leach circuit.

9

4 Bulk Tests (10S3A: 24 tons) = 0.046 opt Au and 0.145 opt Ag

The low Pilot Plant gold extractions resulted in IRLD and its consultants engaging in an extensive research program over two years (2012-2014) to isolate the problem in the leach circuit. The exhaustive testing by the metallurgical team included scanning electron microscope (SEM), energy dispersive spectroscopy (EDS), transmission electron microscope (TEM), UV-VIS-NIR spectroscopy, atomic absorption (AA), graphite furnace AA (GFAA), inductive coupled plasma (ICP), ICP mass spectrometry (ICP-MS), zeta potential (ZP), electrophoresis (EP), electro-winning (EW), precipitation, resin analysis, X-ray diffraction (XRD), thermal pre-treatment (TP) and autoclave leaching (AC). Various leach chemicals, water supplies, head ore samples (North Sand Zone), ITC concentrates, leach-PLS and caustic fusion-PLS were all examined in detail. The results of these tests not only identified the leach problems, as mentioned above, but also uncovered the mineralogy of the gold in the sand and the metallurgy of the gold in the leach PLS at Columbus.

Electron microscope work (SEM/EDS, TEM) identified that the gold in the sand occurs as clusters, generally <1000 nm, of refractory coated nanogold particles (<30nm) further entombed in silicate minerals. Occasionally grains of aggregated clusters (<200µ) were also found in the ITC concentrates. The SEM micrograph and EDS spectrum below clearly show the gold and its coatings in the sands. Analysis of the PLS in 2014, using TEM (+300,000x magnification) and zeta potential, identified that the gold in both the caustic fusion and leach PLS occurred as negative charged colloids and not as ionic complexes.

10

It was also found that the pilot plant ground potential was +9 volt DC as delivered by the Columbus Basin itself. In other words, the grounded stainless steel leach tanks were positively charged instead of neutral (0 volts). During leaching, the negative charged gold colloids were apparently plated out of solution to the tank walls, swept into the solids by agitation and deposited into the tails during filtration. As a consequence, only minor gold was left in the pregnant leach solution (PLS) for capture by the resins as depicted in the Flow Diagrams below.

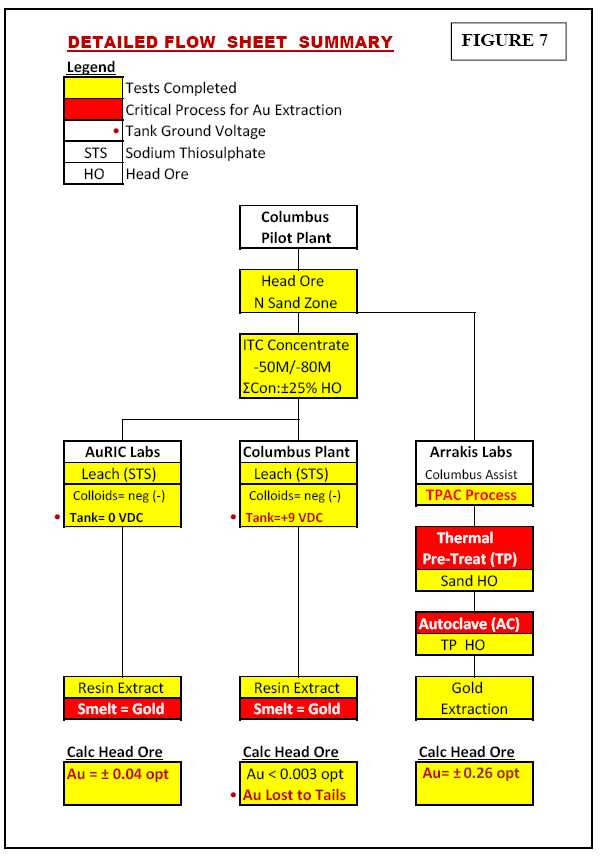

This work led to the development of a new process (TPAC) which increased 10S7A sand gold extraction from 0.057 opt Au, under laboratory conditions using a caustic fusion assay, to ±0.26 opt Au, under laboratory conditions, using TPAC as summarized below, Figure 7.

11

12

TPAC Process

A new process (TPAC), based on the mineralogical and metallurgical data collected since 2007, was developed by Ager/Arrakis during the past year (2014-2015) in response to the problems experienced during pilot plant testing at the Columbus Project. Original scientific research and development of the TPAC process was conducted by Dr. Ager. All subsequent development, testing and assaying was by Arrakis at their facility in Denver, Colorado. The TPAC process is proprietary to Ager/Arrakis for which IRLD has the right to use this process only on the Columbus Project.

The TPAC process requires that sand samples be first processed through a thermal pre-treatment method (TP) and then autoclave leached (AC). The TPAC products then became fire assayable as well as leachable. Initial results on North Sand material have resulted in extractions of ±0.26 opt Au from 100g to 500g head ore samples (10S7A) under laboratory conditions:

Test 1: 500g head sand – 0.314 opt Au

(TP and AC at Arrakis)

Test 2: 100g

head sand – 0.203 opt Au (TP at Columbus, AC at Arrakis)

Weight Mean Average=0.296 opt Au; Average=0.259 opt

Au

The samples were splits from a bulk sample taken at the 10S7A drill hole location in the North Sand Zone by Columbus and then shipped to Arrakis for final TPAC processing and assaying. Third party chain of custody protocols were not observed during these tests as IRLD personnel assisted in sample collection and preparation.

Testing and optimization of the TPAC process on Columbus sands, ITC concentrates and PLS precipitates under laboratory conditions is ongoing. As well, due to the increase in gold extraction using the TPAC process, it is recommended that all the North and South Zone drill samples be re-assayed to establish an updated gold grade for these sands using the TPAC method. This work should be done under third party chain-of-custody protocols.

Flow sheets detailing the AuRIC STS leach circuit (Salt Lake City, UT), the Columbus STS leach circuit (Columbus site) and Arrakis TPAC tests (Denver, CO) are shown in Figure 7 below.

13

14

CONCLUSIONS & RECOMMENDATIONS

Work conducted between 2012-2015 has led to the development of a new extraction method (TPAC) that addresses the refractory nature of the gold in the sands at Columbus. Recent tests, completed by Arrakis (Jan 2015), have increased extracted gold from 0.057 opt Au to ±0.26 opt Au using the TPAC process under laboratory conditions on 100g-500g splits from a bulk sample taken from the Columbus North Sands (10S7A).

It is recommended that the TPAC method, under chain-of-custody, be used to re-assay all the North and South Sand drill samples in order to determine an updated mineralization grade. Concurrently, optimization of the TPAC extraction process under laboratory conditions should continue in order to re-assess the economics of gold extraction, using the pilot plant, from the sand zones at the Columbus Project.

Respectfully Submitted

Nanominerals Corp

“Charles A. Ager”

Dr Charles A. Ager

PhD PEng PGeo

February 17, 2015

15