Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - KLONDEX MINES LTD | form8k.htm |

| Page 2 | Summary | Klondex Mines Ltd. |

This page intentionally left blank.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 3 |

| Lander County, Nevada |

Date and Signature Page

The undersigned prepared this Technical Report (Technical Report) report, titled: Technical Report for the Fire Creek Project, Lander County, Nevada, dated the 5th day of February 2018, with an effective date of November 30, 2017, in support of the public disclosure of Mineral Resource and Mineral Reserve estimates for the Fire Creek Project. The format and content of the Technical Report have been prepared in accordance with Form 43-101F1 of National Instrument 43-101 – Standards of Disclosure for Mineral Projects of the Canadian Securities Administrators.

Dated this 5th day of February 2018

| Signed “Mark Odell” | No. 13708, Nevada |

| Mark Odell, P.E | SME No. 2402150 |

| Practical Mining LLC | (Sealed) |

| 495 Idaho Street, Suite 205 | |

| Elko, Nevada 89815, USA | |

| (775) 345-3718 ext. 101 | |

| Email: markodell@practicalmining.com | |

| Signed “Laura Symmes” | SME No. 4196936 |

| Laura Symmes | (Sealed) |

| Practical Mining LLC | |

| 495 Idaho Street, Suite 205 | |

| Elko, Nevada 89815, USA | |

| (775) 345-3718 ext. 102 | |

| Email: laurasymmes@practicalmining.com | |

| Signed “Sarah Bull” | No. 22797, Nevada |

| Sarah Bull, P.E | (Sealed) |

| Practical Mining LLC | |

| 495 Idaho Street, Suite 205 | |

| Elko, Nevada 89815, USA | |

| 775-345-3718 ext. 502 | |

| Email: sarahbull@practicalmining.com | |

| Signed “Adam Knight” | No. 15796, Nevada |

| Adam Knight, P.E | (Sealed) |

| Practical Mining LLC | |

| 495 Idaho Street, Suite 205 | |

| Elko, Nevada 89815, USA | |

| 775-345-3718 ext. 503 | |

| Email: adamknight@practicalmining.com |

| Practical Mining LLC | February 5, 2018 |

| Page 4 | Summary | Klondex Mines Ltd. |

Table of Contents

| Date and Signature Page | 3 | ||

| List of Tables | 10 | ||

| List of Figures | 12 | ||

| List of Abbreviations | 16 | ||

| 1. | Summary | 17 | |

| 1.1. | Property Description | 17 | |

| 1.2. | Geology | 17 | |

| 1.3. | History | 18 | |

| 1.4. | Mineral Resource Estimate | 18 | |

| 1.5. | Mineral Reserve Estimate | 26 | |

| 1.6. | Cash Flow Analysis and Economics | 27 | |

| 1.7. | Conclusions | 28 | |

| 1.8. | Recommendations | 29 | |

| 2. | Introduction | 30 | |

| 2.1. | Terms of Reference and Purpose of this Technical Report | 30 | |

| 2.2. | Qualification of the Authors | 30 | |

| 2.3. | Sources of Information | 31 | |

| 2.4. | Units of Measure | 31 | |

| 2.5. | Coordinate Datum | 32 | |

| 3. | Reliance on Other Experts | 33 | |

| 4. | Property Description and Location | 34 | |

| 4.1. | Property Description | 34 | |

| 4.2. | Property Location | 34 | |

| 4.3. | Status of Mineral Titles | 36 | |

| 4.4. | Location of Mineralization | 44 | |

| 5. | Accessibility, Climate, Vegetation, Physiography, Local Resources and Infrastructure | 47 | |

| 5.1. | Access to Project | 47 | |

| 5.2. | Climate | 47 | |

| 5.3. | Vegetation | 47 | |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 5 |

| Lander County, Nevada |

| 5.4. | Physiography | 47 | ||

| 5.5. | Local Resources and Infrastructure | 48 | ||

| 6. | History | 49 | ||

| 6.1. | Exploration History | 49 | ||

| 6.2. | Historical Mining | 50 | ||

| 7. | Geological Setting and Mineralization | 51 | ||

| 7.1. | Regional Geology | 51 | ||

| 7.2. | Local Geology | 58 | ||

| 7.2.1. | Rock Units | 58 | ||

| 7.2.2. | Structure | 63 | ||

| 7.2.3. | Veins | 66 | ||

| 7.2.4. | Alteration | 68 | ||

| 7.2.5. | Mineralization | 70 | ||

| 8. | Deposit Types | 73 | ||

| 9. | Exploration | 75 | ||

| 9.1. | Historical Exploration | 75 | ||

| 9.2. | 2011 Drilling | 75 | ||

| 9.3. | 2012 Drilling | 77 | ||

| 9.4. | 2013 Drilling | 77 | ||

| 9.5. | 2014 Drilling | 77 | ||

| 9.6. | 2015 Drilling | 82 | ||

| 9.7. | 2016 Drilling | 82 | ||

| 9.8. | 2017 Drilling | 85 | ||

| 10. | Drilling and Sampling Methodology | 87 | ||

| 10.1. | Drilling Procedures | 89 | ||

| 10.1.1. | Drilling Procedures from 2004 through 2010 | 89 | ||

| 10.1.2. | Current Drilling Procedures | 90 | ||

| 10.2. | Collar Surveying | 91 | ||

| 10.2.1. | Surveying Surface Drill Collar Locations | 92 | ||

| Practical Mining LLC | February 5, 2018 |

| Page 6 | Summary | Klondex Mines Ltd. |

| 10.2.2. | Surveying Underground Drill Collar Locations | 93 | ||

| 10.3. | Downhole Surveying | 94 | ||

| 10.4. | Core Recovery | 94 | ||

| 10.5. | Logging Drilled Core Observations | 95 | ||

| 10.5.1. | Current Logging Protocol | 95 | ||

| 10.5.2. | Historic Logging Protocol | 95 | ||

| 10.5.3. | Re-logging Protocol for 2012-2013 | 96 | ||

| 10.6. | Core Sampling Methodology | 98 | ||

| 10.7. | RC Sampling Methodology | 99 | ||

| 10.8. | Channel Sampling Procedures | 99 | ||

| 10.8.1. | Channel Sampling | 100 | ||

| 10.8.2. | Procedures for Accurately Locating Channel Samples | 101 | ||

| 10.9. | Security Procedures | 103 | ||

| 11. | Sample Preparation, Analysis, and Security | 105 | ||

| 11.1. | Historic Sample Preparation | 105 | ||

| 11.2. | Current Sample Preparation | 106 | ||

| 11.2.1. | Core Sample Preparation | 106 | ||

| 11.2.2. | Channel Sample Preparation | 106 | ||

| 11.3. | Sample Analysis Protocol | 107 | ||

| 11.3.1. | Historic Drill Sample Analysis | 107 | ||

| 11.3.2. | Drill Sample Analysis from 2012 through April 30, 2014 | 108 | ||

| 11.3.3. | Current Drill Sample Analysis | 108 | ||

| 11.3.4. | Channel Sample Analysis | 109 | ||

| 11.3.5. | Handling Analyses Results | 111 | ||

| 11.4. | Sample Security Measures | 112 | ||

| 11.5. | Quality Control Measures | 112 | ||

| 11.5.1. | QAQC Prior to 2012 | 113 | ||

| 11.5.2. | Current QAQC Procedures | 116 | ||

| 11.6. | QAQC Analysis | 118 | ||

| 11.6.1. | Duplicate Performance- Accuracy | 118 | ||

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 7 |

| Lander County, Nevada |

| 11.6.2. | Duplicate Performance - Precision | 118 | ||

| 11.6.3. | Blank Assay Performance | 120 | ||

| 11.6.4. | Standards Performance | 122 | ||

| 11.7. | Opinion on the Adequacy of the Sampling Methodologies | 125 | ||

| 11.7.1. | Sampling Protocol Issues | 125 | ||

| 11.7.2. | Standards and Blanks Performance Issues | 126 | ||

| 12. | Data Verification | 127 | ||

| 12.1. | Results of Drill Data Review | 127 | ||

| 12.1.1. | Downhole Survey Checks | 128 | ||

| 12.1.2. | Geology Checks | 129 | ||

| 12.1.3. | Assay Checks | 129 | ||

| 12.2. | Results of Channel Sample Data Review | 129 | ||

| 12.2.1. | Location Measurement Check | 129 | ||

| 12.2.2. | Geology Check | 130 | ||

| 12.2.3. | Assay Check | 130 | ||

| 12.3. | Summary of Database Verification | 130 | ||

| 13. | Mineral Processing and Metallurgical Testing | 132 | ||

| 13.1. | Early Test Work | 132 | ||

| 13.2. | 2013 Test Work | 132 | ||

| 13.3. | 2014 Test Work | 133 | ||

| 13.4. | 2017 Test Work | 136 | ||

| 14. | Mineral Resource Estimates | 138 | ||

| 14.1. | Introduction | 138 | ||

| 14.2. | Database and Compositing | 138 | ||

| 14.2.1. | Assays | 139 | ||

| 14.2.2. | Lithology | 142 | ||

| 14.2.3. | Compositing | 143 | ||

| 14.3. | Geology and Modelling | 143 | ||

| 14.4. | Density | 153 | ||

| Practical Mining LLC | February 5, 2018 |

| Page 8 | Summary | Klondex Mines Ltd. |

| 14.5. | Statistics | 154 | ||

| 14.6. | Grade Capping | 162 | ||

| 14.7. | Variography | 169 | ||

| 14.8. | Block Model | 174 | ||

| 14.9. | Grade Estimation | 178 | ||

| 14.9.1. | Void Percentage | 180 | ||

| 14.9.2. | Minability Index | 181 | ||

| 14.10. | Mined Depletion and Sterilization | 185 | ||

| 14.11. | Model Validation | 187 | ||

| 14.11.1. | Model Smoothing Checks – Grade Tonnage Curves | 207 | ||

| 14.12. | Mineral Resource Statement | 210 | ||

| 14.12.1. | Underground Mineral Resources | 210 | ||

| 14.12.2. | Open Pit Mineral Resources | 215 | ||

| 15. | Mineral Reserve Estimates | 217 | ||

| 16. | Mining Methods | 221 | ||

| 16.1. | Mine Development | 221 | ||

| 16.1.1. | Access Development | 221 | ||

| 16.1.2. | Ground Support | 221 | ||

| 16.1.3. | Ventilation and Secondary Egress | 222 | ||

| 16.2. | Mining Methods | 222 | ||

| 16.2.1. | End Slice Stoping | 222 | ||

| 16.2.2. | Drift and Fill Stoping | 224 | ||

| 16.2.3. | Cut-and-Fill Stoping | 225 | ||

| 16.2.4. | Backstoping | 225 | ||

| 16.3. | Underground Labor | 226 | ||

| 16.4. | Mobile Equipment Fleet | 226 | ||

| 16.5. | Mine Plan | 227 | ||

| 17. | Recovery Methods | 231 | ||

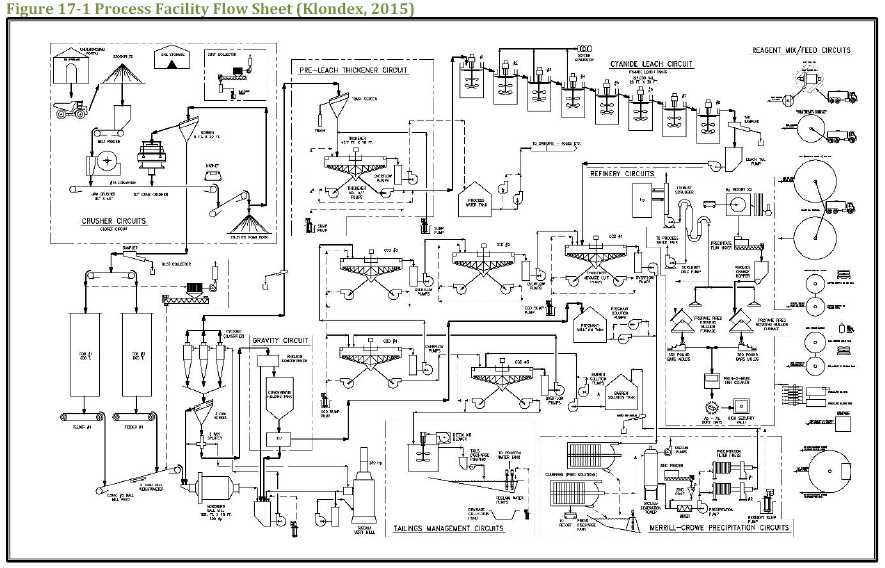

| 17.1. | Mill Capacity and Process Facility Flow Diagram | 231 | ||

| 17.2. | Physical Mill Equipment | 235 | ||

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 9 |

| Lander County, Nevada |

| 17.3. | Operation and Recoveries | 238 | |

| 17.4. | Tailings Storage Capacity | 238 | |

| 17.5. | Processing Costs | 239 | |

| 17.6. | Production | 239 | |

| 17.7. | Midas Mill Operating Permits | 240 | |

| 18. | Project Infrastructure | 241 | |

| 18.1. | Road Access | 241 | |

| 18.2. | Power and Electrical Infrastructure | 241 | |

| 18.3. | Water Management and Water Treatment | 241 | |

| 18.4. | Communication Infrastructure | 242 | |

| 18.5. | Site Infrastructure | 242 | |

| 19. | Market Studies and Contracts | 244 | |

| 19.1. | Precious Metal Markets | 244 | |

| 19.2. | Contracts | 244 | |

| 19.3. | Project Financing | 245 | |

| 20. | Environmental Studies, Permitting and Social or Community Impact | 246 | |

| 20.1. | Environmental Compliance and Monitoring | 246 | |

| 20.2. | Reclamation Bond Estimate | 246 | |

| 20.3. | Major Permitting and Approvals | 247 | |

| 21. | Capital and Operating Costs | 248 | |

| 21.1. | Capital Costs | 248 | |

| 21.2. | Operating Costs and Cutoff Grade | 248 | |

| 22. | Economic Analysis | 251 | |

| 22.1. | Life of Mine Plan and Economics | 251 | |

| 22.2. | Sensitivity Analysis | 253 | |

| 23. | Other Relevant Data and Information | 255 | |

| 24. | Interpretation and Conclusions | 256 | |

| 24.1. | Conclusions | 256 | |

| 24.2. | Project Risks | 256 | |

| Practical Mining LLC | February 5, 2018 |

| Page 10 | Summary | Klondex Mines Ltd. |

| 25. | Recommendations | 258 |

| 26. | Bibliography | 259 |

| 27. | Glossary | 263 |

| 28. | Appendix A: Certification of Authors and Consent Forms | 270 |

List of Tables

| Table 1-1 Chronology of Ownership of the Fire Creek Project | 18 |

| Table 1-2 Underground Mineral Resources as of November 30, 2017 | 21 |

| Table 1-3 Open Pit Mineral Resources as of November 30, 2017 | 25 |

| Table 1-4 Mineral Reserves as of November 30. 2017 | 26 |

| Table 1-5 Key Operating and After Tax Financial Statistics | 28 |

| Table 2-1 Qualified Professionals | 30 |

| Table 2-2 Klondex Contributors | 31 |

| Table 2-3 Units of Measure | 31 |

| Table 4-1 Summary of Klondex Owned Unpatented Mining Claims (US Department of the Interior 2018) | 38 |

| Table 4-2 Summary of Owned Fee Land Holdings T30N R47E (Lander County 2018) | 39 |

| Table 4-3 Summary of Leased Fee Land Holdings | 41 |

| Table 4-4 Summary of Fire Creek Project Holding Costs | 43 |

| Table 6-1 Exploration History | 49 |

| Table 11-1 ALS In-house QAQC Datasets Reviewed | 113 |

| Table 11-2 Blanks | 117 |

| Table 11-3 Standards | 117 |

| Table 11-4 Pulp Checks | 118 |

| Table 11-5 Channel Blank Assay Set Performance | 120 |

| Table 11-6 Drill Hole Standard Assay Performance | 122 |

| Table 11-7 Channel Standard Assay Performance | 124 |

| Table 12-1 Data Review Summary Drilled Material | 128 |

| Table 12-2 Data Review Summary Channel Sampled Material | 130 |

| Table 13-1 Summary of Cyanidation Test Results from 2011 Technical Report | 132 |

| Table 13-2 Combined Metallurgical Results, Gravity/Cyanidation Tests, 80% -212 um Feed (Grav.), Reground to 80% -75 um (CN) | 133 |

| Table 13-3 Summary Metallurgical Results, Bottle Roll Tests, Fire Creek West Zone Drill Core Composites | 134 |

| Table 13-4 Gold Metallurgical Results, Whole Mineralized Material Gravity Concentration with Cyanidation of the Gravity Cleaner and Rougher Tailings | 135 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 11 |

| Lander County, Nevada |

| Table 13-5 Silver Metallurgical Results, Whole Mineralized Material Gravity Concentration with Cyanidation of the Gravity Cleaner and Rougher Tailings | 135 |

| Table 13-6 Summary Metallurgical Results, Bottle Roll Tests, Fire Creek Mars Pit Drill Oxide Core Composites | 136 |

| Table 13-7 Summary Metallurgical Results, Bottle Roll Tests, Fire Creek Mars Pit Drill Mixed Oxide/Sulfide Core Composites | 136 |

| Table 13-8 Summary Metallurgical Results, Bottle Roll Tests, Fire Creek Mars Pit Drill Sulfide Core Composites | 137 |

| Table 14-1 Summary of Drill Hole and Channel Samples | 139 |

| Table 14-2 Lithology Codes | 142 |

| Table 14-3 Vein Orientation and Clipping Priorities | 148 |

| Table 14-4 Low-grade Open Pit Domains | 152 |

| Table 14-5 Lithologic Unit Densities | 153 |

| Table 14-6 Vein Gold Drill Hole Composite Statistics | 154 |

| Table 14-7 Vein Gold Channel Composite Statistics | 157 |

| Table 14-8 Vein Silver Drill Hole Composite Statistics | 157 |

| Table 14-9 Vein Silver Channel Composite Statistics | 160 |

| Table 14-10 Capping Methods | 163 |

| Table 14-11 Grade Capping Values for Ore shoots | 165 |

| Table 14-12 Top Cutting – Low-grade - Gold | 168 |

| Table 14-13 Top Cutting – Low-grade - Silver | 169 |

| Table 14-14 Variograms by Lithological Domain | 174 |

| Table 14-15 Block Model Variables | 177 |

| Table 14-16 Estimation Search Parameters by Resource Category | 179 |

| Table 14-17 Estimate Comparison for Gold versus a Nearest Neighbor at 0 Cutoff | 188 |

| Table 14-18 Estimate Comparison for Silver Versus a Nearest Neighbor at 0 Cutoff | 190 |

| Table 14-19 Grade Estimation comparison OK vs NN at 0 Cutoff – Gold | 205 |

| Table 14-20 Grade Estimation comparison OK vs NN at 0 Cutoff – Silver | 205 |

| Table 14-21 Underground Mineral Resource Cutoff Grade Parameters | 210 |

| Table 14-22 Underground Mineral Resources as of November 30, 2017 | 211 |

| Table 14-23 Open Pit Optimization Parameters | 215 |

| Table 14-24 Open Pit Mineral Resources as of November 30, 2017 | 216 |

| Table 15-1 Mineral Reserves Cut Off Grade Calculation | 217 |

| Table 15-2 Mineral Reserves as of November 30, 2017 | 218 |

| Table 16-1 Underground Workforce 2018 | 226 |

| Table 16-2 Underground Mobile Equipment | 226 |

| Table 16-3 Heading Productivity | 227 |

| Table 16-4 Annual Production and Development Plan | 230 |

| Practical Mining LLC | February 5, 2018 |

| Page 12 | Summary | Klondex Mines Ltd. |

| Table 17-1 Process Equipment Itemization by Area | 235 |

| Table 17-2 Midas Mill Operating Costs | 239 |

| Table 17-3 Fire Creek Mineralized Material Processed at the Midas Mill | 239 |

| Table 19-1 FNC Gold Delivery Schedule | 245 |

| Table 20-1 Fire Creek Project Significant Permits | 247 |

| Table 21-1 Capital Costs | 248 |

| Table 21-2 Underground Development Unit Costs | 248 |

| Table 21-3 Operating Costs | 248 |

| Table 21-4 Cut-off Grade Calculation | 249 |

| Table 22-1 Income Statement 2017 – 2020 ($000’s) | 252 |

| Table 22-2 Cash Flow Statement 2017 – 2021 ($000’s) | 252 |

| Table 22-3 Key Operating and After Tax Financial Statistics | 253 |

| Table 24-1 Potential Project Risks | 257 |

List of Figures

| Figure 1-1 Fire Creek Project Overview Showing Underground Workings and Resource Zones | 20 |

| Figure 4-1 Project Location Map | 35 |

| Figure 4-2 Klondex Land Holdings | 37 |

| Figure 4-3 Location of Fire Creek Project Relative to the Northern Nevada Rift System | 45 |

| Figure 7-1 Northern Nevada Rift in North-Central Nevada | 53 |

| Figure 7-2 Regional Geologic Map of the Northern Shoshone Range | 54 |

| Figure 7-3 Stratigraphic Sections for the Project and the Mule Canyon Mine with Tie Lines for Volcanic Packages | 55 |

| Figure 7-4 Geologic Map of the Fire Creek District | 56 |

| Figure 7-5 Schematic Structural Model for the Fire Creek Deposit | 57 |

| Figure 7-6 Example of Tbeq Basalt | 60 |

| Figure 7-7 Examples of different Tlat textures | 61 |

| Figure 7-8 Example of Tim Lithology | 63 |

| Figure 7-9 Fault Locations | 65 |

| Figure 7-10 Fault Block Model | 66 |

| Figure 7-11 Alteration Progression | 69 |

| Figure 7-12 Typical Argillic to Propylitic Alteration Progression Adjacent to the Karen Vein | 70 |

| Figure 7-13 Banded Vein Sample from the Vonnie Vein that Contains Large Clots of Electrum Gold | 71 |

| Figure 7-14 Picture of Split Core Sample Containing Dendritic Electrum | 72 |

| Figure 8-1 Schematic Diagram of Low-Sulfidation Au, Ag Solutions in Relationship with Magma at Depth | 74 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 13 |

| Lander County, Nevada |

| Figure 9-1 Surface and Underground Holes Completed in 2011 | 76 |

| Figure 9-2 Surface and Underground Holes Completed in 2012 | 78 |

| Figure 9-3 Surface and Underground Holes Completed in 2013 | 79 |

| Figure 9-4 Locations for Surface Holes Completed in 2014. | 80 |

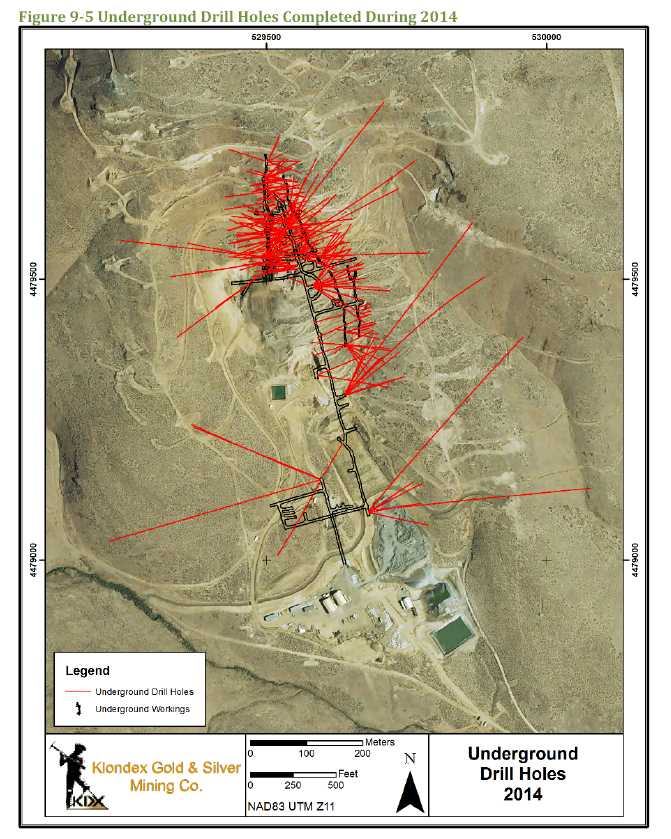

| Figure 9-5 Underground Drill Holes Completed During 2014 | 81 |

| Figure 9-6 Drill Holes Completed in 2015 | 83 |

| Figure 9-7 Drill Holes Completed in 2016 | 84 |

| Figure 9-8 Drill Holes Completed in 2017 | 86 |

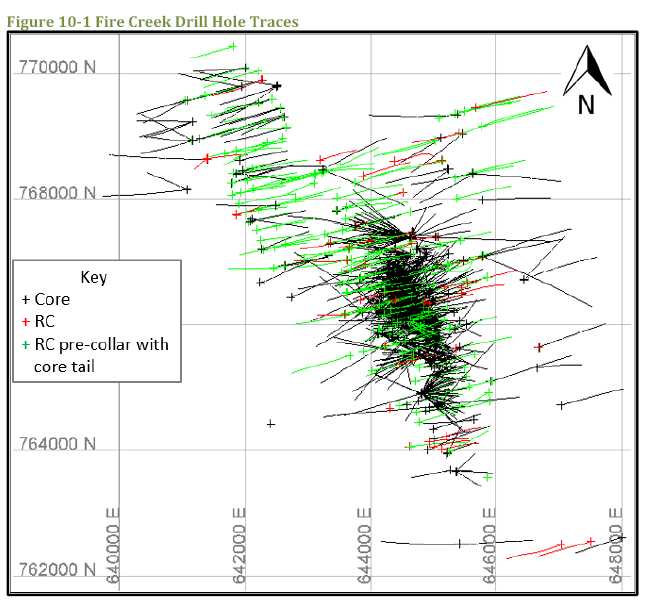

| Figure 10-1 Fire Creek Drill Hole Traces | 88 |

| Figure 10-2 Underground Core Hole Traces | 89 |

| Figure 10-3 Placing Core (January 2013) | 91 |

| Figure 10-4 Channel Sample Locations | 100 |

| Figure 10-5 Typical Cross Section with Drill Holes and Channel Samples | 102 |

| Figure 11-1 Drill Hole Pulp Au Duplicates | 119 |

| Figure 11-2 Channel Pulp Au Duplicates Klondex and ALS | 119 |

| Figure 11-3 ALS FCBLANK16 Au | 121 |

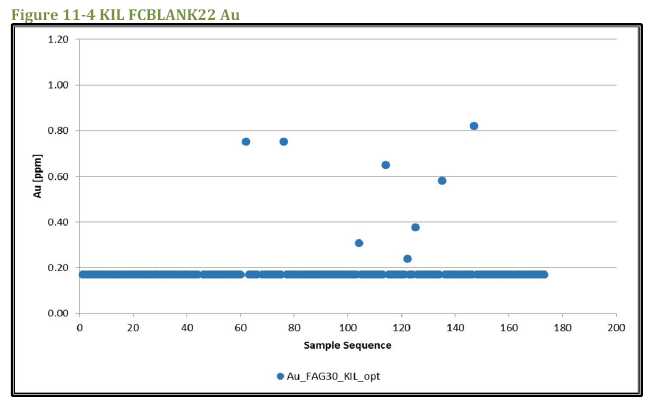

| Figure 11-4 KIL FCBLANK22 Au | 121 |

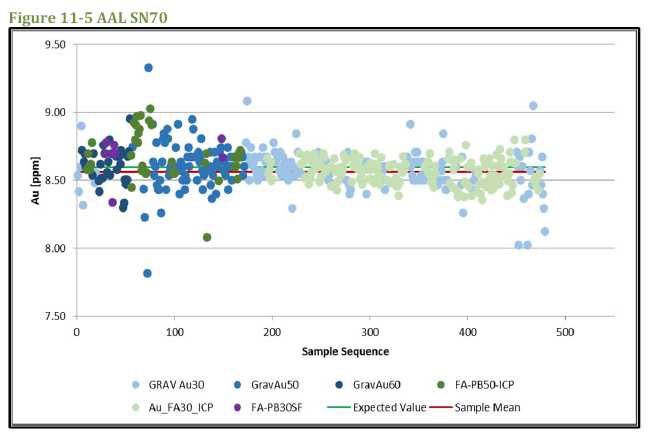

| Figure 11-5 AAL SN70 | 123 |

| Figure 11-6 ALS SN60 | 123 |

| Figure 11-7 KIL SN75 | 125 |

| Figure 14-1 Drill Hole and Vein Locations | 140 |

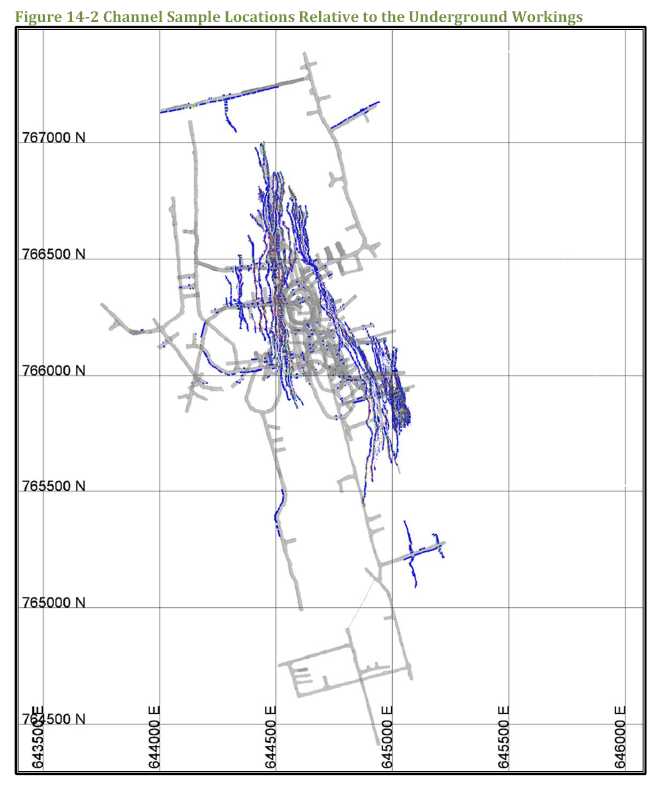

| Figure 14-2 Channel Sample Locations Relative to the Underground Workings | 141 |

| Figure 14-3 Long Section with Lithology | 143 |

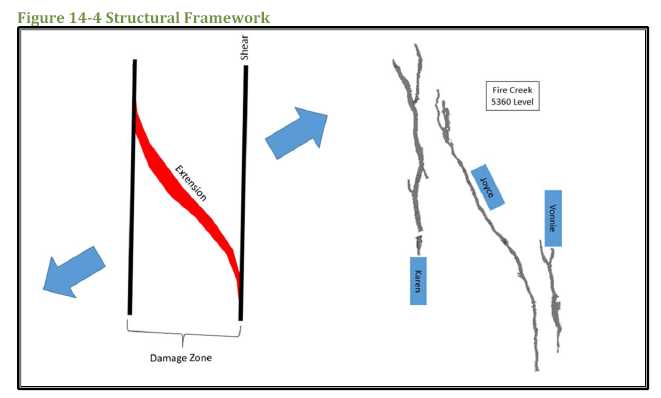

| Figure 14-4 Structural Framework | 144 |

| Figure 14-5 Vein Modelling Workflow | 145 |

| Figure 14-6 HW (Red) and FW (Yellow) Data Points Extracted from Sample and Survey Data Sets | 146 |

| Figure 14-7 Triangulated HW and FW Surfaces | 147 |

| Figure 14-8 HW and FW Surfaces are Combined to Generate a Valid Solid Triangulation | 148 |

| Figure 14-9 low-grade mineralization indicator model (z=5550) | 151 |

| Figure 14-10 Low-grade Disseminated Domains | 152 |

| Figure 14-11 Section A-A’ through Low-grade Disseminated Domains | 153 |

| Figure 14-12 Gold Boxplot for Low-grade Dissemination Sample Composites | 161 |

| Figure 14-13 Silver Boxplot for Low-grade Dissemination Sample Composites | 162 |

| Figure 14-14 Example Ore shoot Indicator Model on the Joyce Vein | 164 |

| Figure 14-15 Vonnie Vein Gold Grade Distribution Curve | 166 |

| Figure 14-16 Vonnie Vein Gold Grade Distribution Curve | 166 |

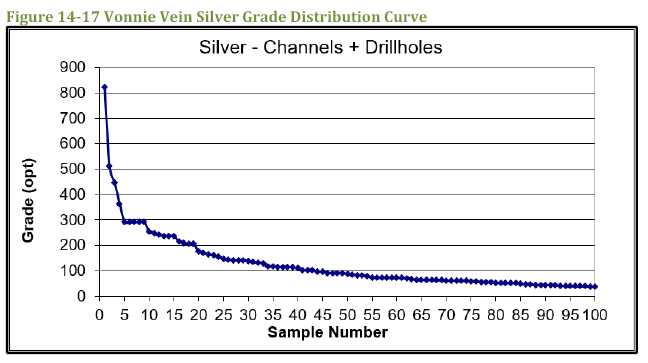

| Figure 14-17 Vonnie Vein Silver Grade Distribution Curve | 167 |

| Practical Mining LLC | February 5, 2018 |

| Page 14 | Summary | Klondex Mines Ltd. |

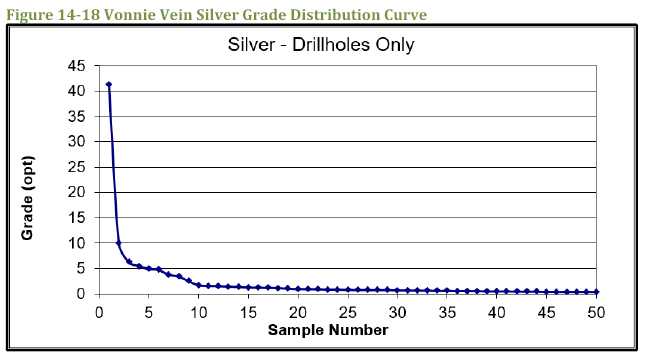

| Figure 14-18 Vonnie Vein Silver Grade Distribution Curve | 167 |

| Figure 14-19 Gold probability plot in Basalt – Low-grade mineralization | 168 |

| Figure 14-20 Vonnie Vein Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 170 |

| Figure 14-21 Karen Vein Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 170 |

| Figure 14-22 Joyce Vein Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 170 |

| Figure 14-23 Dikes Domain - Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 171 |

| Figure 14-24 Andesite Domain - Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 172 |

| Figure 14-25 Upper Tuff Domain - Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 172 |

| Figure 14-26 Basalt Domain - Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 173 |

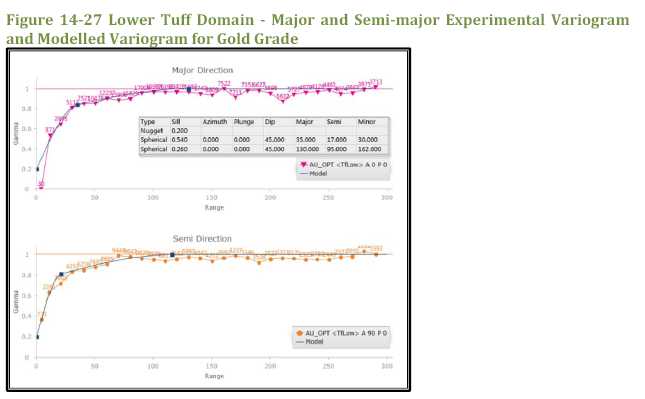

| Figure 14-27 Lower Tuff Domain - Major and Semi-major Experimental Variogram and Modelled Variogram for Gold Grade | 173 |

| Figure 14-28 Spatial Location Fire Creek Resource Block Models – Main and Zeus | 176 |

| Figure 14-29 Void Percentage on the Joyce Vein | 181 |

| Figure 14-30 Minability Code Overview | 182 |

| Figure 14-31 Minability Index Legend for Gold and Silver Grade | 183 |

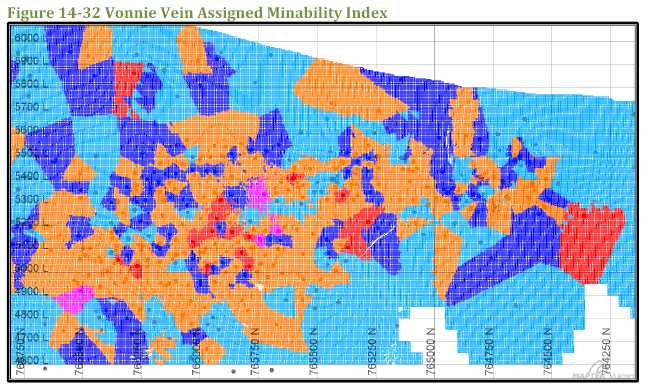

| Figure 14-32 Vonnie Vein Assigned Minability Index | 183 |

| Figure 14-33 Joyce Vein Assigned Minability Index | 184 |

| Figure 14-34 Karen Vein Assigned Minability Index | 184 |

| Figure 14-35 Vonnie Vein Mining Extent | 185 |

| Figure 14-36 Joyce Vein Mining Extent | 186 |

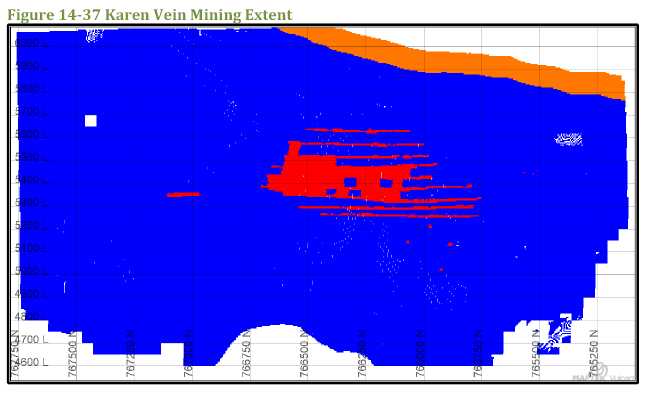

| Figure 14-37 Karen Vein Mining Extent | 186 |

| Figure 14-38 Mine Depletion of Veins for Open Pit | 187 |

| Figure 14-39 Legend Gold or Silver Grade | 193 |

| Figure 14-40 Vonnie Vein Comparison of Composite and Estimated Block Gold Grades | 194 |

| Figure 14-41 Vonnie Vein Comparison of Composite and Estimated Block Silver Grades | 194 |

| Figure 14-42 Joyce Vein Comparison of Composite and Estimated Block Gold Grades | 195 |

| Figure 14-43 Joyce Vein Comparison of Composite and Estimated Block Silver Grades | 195 |

| Figure 14-44 Karen Vein Comparison of Composite and Estimated Block Gold Grades | 196 |

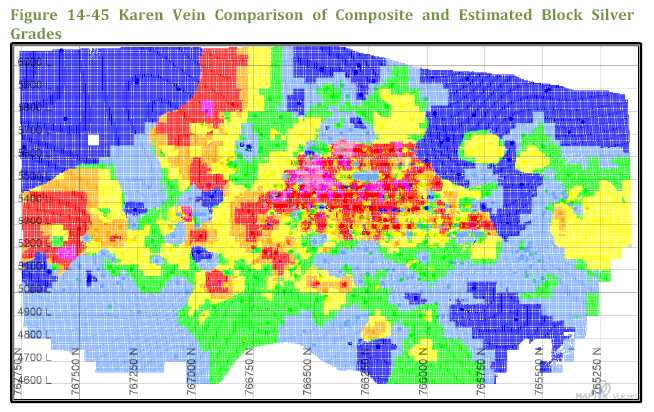

| Figure 14-45 Karen Vein Comparison of Composite and Estimated Block Silver Grades | 196 |

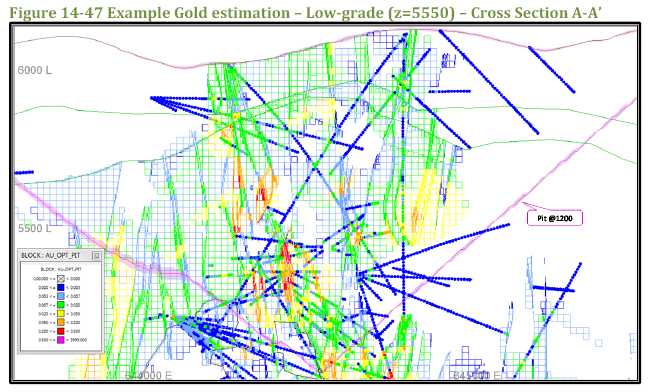

| Figure 14-46 Example Gold estimation – Low-grade (z=5550) | 197 |

| Figure 14-47 Example Gold estimation – Low-grade (z=5550) – Cross Section A-A’ | 198 |

| Figure 14-48 Gold Swath Plot of the Vonnie Vein along the North Axis | 199 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 15 |

| Lander County, Nevada |

| Figure 14-49 Gold Swath Plot of the Vonnie Vein along the Z Axis | 199 |

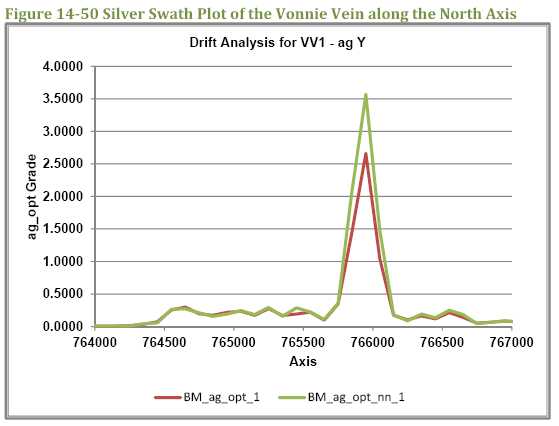

| Figure 14-50 Silver Swath Plot of the Vonnie Vein along the North Axis | 200 |

| Figure 14-51 Silver Swath Plot of the Vonnie Vein along the Z Axis | 200 |

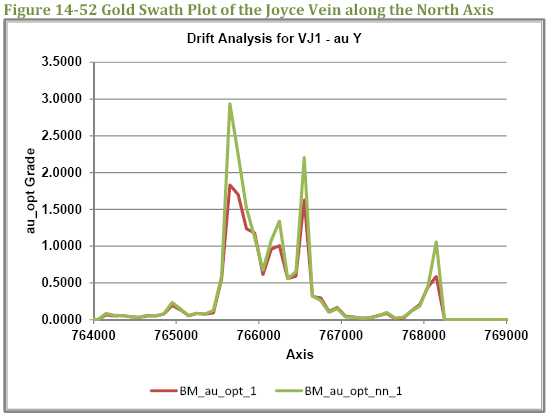

| Figure 14-52 Gold Swath Plot of the Joyce Vein along the North Axis | 201 |

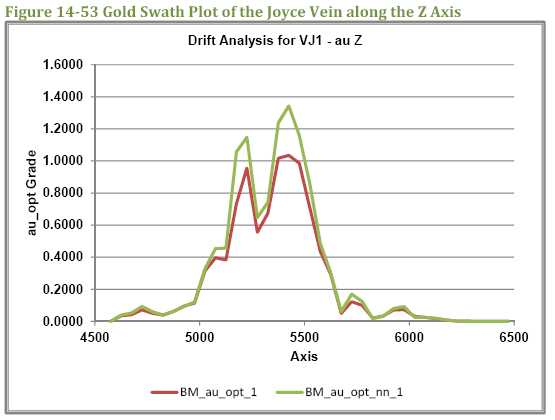

| Figure 14-53 Gold Swath Plot of the Joyce Vein along the Z Axis | 201 |

| Figure 14-54 Silver Swath Plot of the Joyce Vein along the North Axis | 202 |

| Figure 14-55 Silver Swath Plot of the Joyce Vein along the Z Axis | 202 |

| Figure 14-56 Gold Swath Plot of the Karen Vein along the North Axis | 203 |

| Figure 14-57 Gold Swath Plot of the Karen Vein along the Z Axis | 203 |

| Figure 14-58 Silver Swath Plot of the Karen Vein along the North Axis | 204 |

| Figure 14-59 Silver Swath Plot of the Karen Vein along the Z Axis | 204 |

| Figure 14-60 Gold Swath Plot of the Basalt domain along the North Axis | 206 |

| Figure 14-61 Gold Swath Plot of the Basalt domain along the East Axis | 206 |

| Figure 14-62 Gold Swath Plot of the Basalt domain along the Z Axis | 207 |

| Figure 14-63 Smoothing Checks for the Vonnie Vein | 208 |

| Figure 14-64 Smoothing Checks for the Joyce Vein | 209 |

| Figure 14-65 Smoothing Checks for the Karen Vein | 209 |

| Figure 14-66 Smoothing Checks for Gold - Low-grade at Basalt domain | 210 |

| Figure 15-1 Existing Workings, Reserve Excavations Long Section Looking East | 220 |

| Figure 16-1 Existing Development and Vein Traces at the 5400 Elevation | 221 |

| Figure 16-2 Long Section View of a Typical End Slice Stope | 223 |

| Figure 16-3 Cross Section Looking North Through the Joyce Vein and Vonnie Vein Showing Drift-and Fill-Mining, Stope Development Drifting and Designed Stopes | 224 |

| Figure 16-4 Joyce Vein Long Section Looking West Showing Existing Mine Workings and Reserves Mine Plan | 228 |

| Figure 16-5 Vonnie Vein Long Section Looking West Showing Existing Mine Workings and Reserves Mine Plan | 228 |

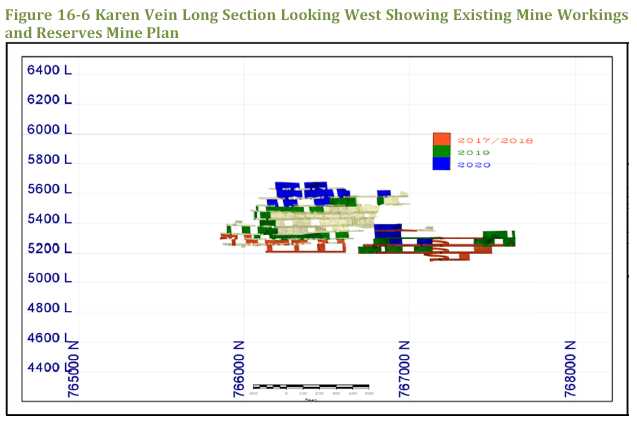

| Figure 16-6 Karen Vein Long Section Looking West Showing Existing Mine Workings and Reserves Mine Plan | 229 |

| Figure 16-7 Vein 20 Long Section Looking West Showing Existing Mine Workings and Reserves Mine Plan | 229 |

| Figure 17-1 Process Facility Flow Sheet (Klondex, 2015) | 234 |

| Figure 18-1 Site Facilities | 243 |

| Figure 19-1 Historical Monthly Average Gold and Silver Prices and 36 Month Trailing Average | 244 |

| Figure 21-1 Cutoff Grade Sensitivity to Gold Price | 250 |

| Figure 22-1 8% NPV Sensitivity | 254 |

| Figure 22-2 Profitability Index Sensitivity | 254 |

| Practical Mining LLC | February 5, 2018 |

| Page 16 | Summary | Klondex Mines Ltd. |

List of Abbreviations

| A | Ampere | kA | kiloamperes |

| AA | atomic absorption | kCFM | thousand cubic feet per minute |

| A/m2 | amperes per square meter | Kg | Kilograms |

| AGP | Acid Generation Potential | km | kilometer |

| Ag | Silver | km2 | square kilometer |

| ANFO | ammonium nitrate fuel oil | kWh/t | kilowatt-hour per ton |

| ANP | Acid Neutralization Potential | LOI | Loss On Ignition |

| Au | Gold | LoM | Life-of-Mine |

| AuEq | gold equivalent | m | meter |

| btu | British Thermal Unit | m2 | square meter |

| °C | degrees Celsius | m3 | cubic meter |

| CCD | counter-current decantation | masl | meters above sea level |

| CIL | carbon-in-leach | mg/L | milligrams/liter |

| CoG | cut-off grade | mm | millimeter |

| cm | centimeter | mm2 | square millimeter |

| cm2 | square centimeter | mm3 | cubic millimeter |

| cm3 | cubic centimeter | MME | Mine & Mill Engineering |

| cfm | cubic feet per minute | Moz | million troy ounces |

| ConfC | confidence code | Mt | million tonnes |

| CRec | core recovery | MTW | measured true width |

| CSS | closed-side setting | MW | million watts |

| CTW | calculated true width | m.y. | million years |

| ° | degree (degrees) | NGO | non-governmental organization |

| dia. | diameter | NI 43-101 | Canadian National Instrument 43-101 |

| EIS | Environmental Impact Statement | oz | Troy Ounce |

| EMP | Environmental Management Plan | opt | Troy Ounce per short ton |

| FA | fire assay | % | percent |

| Ft | Foot | PLC | Programmable Logic Controller |

| Ft2 | Square foot | PLS | Pregnant Leach Solution |

| Ft3 | Cubic foot | PMF | probable maximum flood |

| g | Gram | POO | Plan of Operations |

| g/L | gram per liter | ppb | parts per billion |

| g-mol | gram-mole | ppm | parts per million |

| g/t | grams per tonne | QAQC | Quality Assurance/Quality Control |

| ha | hectares | RC | reverse circulation drilling |

| HDPE | Height Density Polyethylene | ROM | Run-of-Mine |

| HTW | horizontal true width | RQD | Rock Quality Description |

| ICP | induced couple plasma | SEC | U.S. Securities & Exchange Commission |

| ID2 | inverse-distance squared | Sec | second |

| ID3 | inverse-distance cubed | SG | specific gravity |

| ILS | Intermediate Leach Solution | SPT | Standard penetration test |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 17 |

| Lander County, Nevada |

| 1. |

Summary |

Practical Mining LLC was engaged by Klondex Gold & Silver Mining Company (KGS or Klondex), U.S. subsidiary of Canadian based Klondex Mines Ltd. (Klondex or the Company), to prepare an updated Technical Report (TR) in accordance with National Instrument 43-101 (NI 43-101) of the Canadian Securities Administrators. Practical Mining’s evaluation of the Fire Creek Project (Fire Creek or the Project), located in Lander County, Nevada, is presented herein. This TR, dated the 5th day of February 2018, with an effective date of November 30, 2017, updates the previous underground mineral resource and mineral reserve estimates and presents an initial open pit mineral resource estimate.

| 1.1. |

Property Description |

The Project is located primarily in Lander County, Nevada with a small portion of the Project boundary in Eureka County, Nevada, approximately 63 miles west of Elko, Nevada. The Project comprises private fee lands (both leased and owned) and unpatented lode mining claims. The land position includes approximately 18,400 acres of unpatented federal lode mining claims, 3,208 acres of private fee land and 429 acres of mineral leases. Overall, the Fire Creek land package is approximately 22,000 acres.

| 1.2. |

Geology |

The deposit is an epithermal deposit vertically-zoned within high-angle northwest striking structures, low-sulfidation, hosted in a mid-Miocene basalt package. Gold mineralization occurs in two habits: shallow structurally-controlled gold in variably altered Tertiary basalt and primarily native gold in steeply dipping quartz-calcite veins or structures. A package of middle-Miocene basalt and basaltic andesite flows has been cut by high-angle normal faults related to both Northern Nevada Rift (NNR) and Basin and Range extension that form grabens and half-grabens which are the structural controls in the district.

High-grade gold mineralization has been delineated between approximately 4,900 feet and 5,700 feet above mean sea level (AMSL) and is open up and down dip as well as on strike. Lower-grade gold mineralization occurs from the surface. Vein textures, gangue minerals, and alteration are typical of low-sulfidation systems. Widespread propylitic alteration grades to argillic alteration proximal to veins and/or other structural fluid conduits. Elevated mineralization is often spatially associated with the argillic alteration zone. Gold mineralization often occurs along discrete horizons within veins. An opaline silica cap is discontinuously preserved above the deeper mineralization. Mineralized faults near the opaline silica were targeted by early prospecting and later shallow drilling by previous operators in the 1980’s.

| Practical Mining LLC | February 5, 2018 |

| Page 18 | Summary | Klondex Mines Ltd. |

| 1.3. |

History |

Table 1-1 Chronology of Ownership of the Fire Creek Project

| Dates | Company | Details |

| 1967 | Union Pacific Resources | Drilled two core holes. |

| 1974 to 1975 | Placer Development Ltd. | Drilled 22 rotary holes. |

| 1975 | Klondex Mines Ltd. | Acquired the property. 1980-1983 drilled 64 rotary holes. 1981 gold test production. |

| 1984 | Minex Resources, Inc. | Leased the property from Klondex, drilled 13 rotary holes. |

| 1986 to 1987 | Alma American Mining Company (“Alma”) | Leased the property from Klondex, drilled 64 rotary holes. |

| 1988 | Aurenco Joint Venture (“Aurenco JV”) | Aurenco JV formed between Black Beauty Mining and Covenanter Mining. |

| 1988 to 1990 | Aurenco JV | Leased the property from Klondex. |

| 1990 to 1995 | Klondex Mines Ltd. | No activity. |

| 1995 to 1996 | North Mining Inc. (“North Mining”) | Leased the property from Klondex. Drilled 67 holes, performed IP and HEM surveys. |

| 1996 to 2004 | Klondex Mines Ltd. | No activity. |

| 2004 to 2012 | Klondex Mines Ltd. | Began a deep exploration program. Development commenced in 2011. |

| 2012 to 2015 | Klondex Mines Ltd. | New Management and Board of Directors in 2012, ongoing exploration, development and bulk sampling |

| 2016 to Present | Klondex Mines Ltd. | Received Record of Decision for the Environmental Assessment from the Bureau of Land Management in February 2016, began commercial production |

Drill programs conducted by Klondex have extended the known strike length of the high-grade veins to the east and west and identified a large zone of disseminated mineralization proximal to the veins.

This TR updates the Project mineral resource estimate and mineral reserves estimate. The TR incorporates the technical information available through November 30, 2017, which is the effective date of the TR.

| 1.4. |

Mineral Resource Estimate |

The mineral resource estimate is based on data from 1,474 surface and underground drill holes totaling 1,022,230 feet and completed through November 30, 2017. This estimate also includes 6,398 channel samples from underground drifting.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 19 |

| Lander County, Nevada |

Wire frame models were constructed for 56 vein sets that strike approximately N15°W and dip steeply to both the east and west. The vein models were constructed by digitally contouring surfaces along planes of data points defined by drill hole intercepts and underground channel samples. Each data point is identified as a particular side of a particular vein (hanging wall or footwall), and software is used to contour surfaces between corresponding points. Hanging wall and footwall surfaces are then combined to form a solid wire frame. Assay values were composited into 10-foot lengths and truncated at the vein hanging wall and footwall. Only composites flagged as representing vein material were used in the grade estimation. A grade capping scheme based on resource category and vein was employed. Grades were assigned to individual blocks using the Inverse Distance Cubed method (ID3).

Low-grade disseminated mineralization was modelled based on lithological controls and a low-grade shell to determine potentially mineralized host rock from un-mineralized host rock. Assay values were composited into ten-foot lengths and truncated at the vein contacts. Only composites flagged as being outside the veins were used in the grade estimation. A grade capping scheme based on resource category and lithology based domain was employed. Grades were assigned to individual blocks using the Ordinary Kriging method (OK).

Each domain was assigned a specific search orientation based on their respective approximate dip and dip direction. Measured blocks require a minimum of four channel samples within an average anisotropic search radius of 40 feet. Indicated blocks required three drill hole intercepts within 100 feet. Inferred blocks required two drill intercepts within 300 feet. Grades were estimated only for blocks contained within the modeled veins. Vein block extents were created five feet along strike and five-feet vertically down dip. Perpendicular to strike, the block extents were limited to the width of the vein with 0.2 to five-foot resolution. This method allows veins as narrow as 0.2 foot to be modeled precisely. Block sizes in the low grade disseminated material were defined at 20x20x20ft and sub-blocked to the vein and lithological contacts.

| Practical Mining LLC | February 5, 2018 |

| Page 20 | Summary | Klondex Mines Ltd. |

Mineral resources for veins were estimated for only blocks within the modeled vein wireframes. Low-grade mineralization immediately adjacent to the veins was also modeled from the vein contact out to the margin of the low-grade shell. In all cases, the vein boundary with the low-grade mineralization was treated as a “hard” boundary, and composite assay data from the vein was not used to estimate the low-grade breccia mineralization.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 21 |

| Lander County, Nevada |

The mineralized vein arrays extend over 5,000 feet along strike and from near surface to 1,000 feet in depth. These vein arrays are open both along strike and in some areas up and down dip.

A density of 0.0774 tons per cubic foot was used for all veins. This value was derived from 15 samples collected from the Joyce Vein and Vonnie Vein and analyzed by SGS North America, Inc. (SGS) of Elko, Nevada; an independent laboratory. The SGS (Elko) laboratory forms part of the SGS Minerals' global group of laboratories. The SGS (Elko) laboratory is not independently certified by a standards association but is associated with the SGS (Vancouver) laboratory, which is an ISO 9001:2008 accredited facility. For the low grade disseminated material the densities were defined from average densities for each lithological unit, based on 10,569 density core samples. Densities vary between 0.0571 (upper tuff) to 0.0716 (basalt).

Table 1-2 Underground Mineral Resources as of November 30, 2017

| AuEq | AuEq | ||||||

| Vein Name | kton | Au opt | Ag opt | opt | Au koz | Ag koz | koz |

| Measured | |||||||

| Joyce | 65 | 1.260 | 1.152 | 1.276 | 82 | 75 | 83 |

| Karen | 57 | 1.389 | 1.334 | 1.407 | 79 | 76 | 80 |

| Vonnie | 14 | 1.177 | 1.074 | 1.192 | 16 | 15 | 16 |

| Honey Runner | 5.4 | 0.675 | 0.418 | 0.680 | 3.6 | 2.2 | 3.6 |

| Hui Wu | 2.0 | 0.352 | 0.205 | 0.355 | 0.7 | 0.4 | 0.7 |

| 05 | 0.1 | 0.976 | 0.053 | 0.977 | 0.1 | 0.0 | 0.1 |

| 06 | 0.4 | 0.400 | 1.255 | 0.417 | 0.2 | 0.5 | 0.2 |

| 07 | 0.2 | 0.284 | 1.090 | 0.299 | 0.1 | 0.3 | 0.1 |

| 12 | 1.4 | 0.482 | 0.256 | 0.485 | 0.7 | 0.4 | 0.7 |

| 13 | 2.4 | 0.676 | 0.393 | 0.681 | 1.7 | 1.0 | 1.7 |

| 16 | 0.5 | 0.457 | 0.331 | 0.462 | 0.2 | 0.2 | 0.2 |

| 18 | 0.6 | 0.509 | 0.151 | 0.511 | 0.3 | 0.1 | 0.3 |

| 21 | 0.2 | 0.259 | 0.059 | 0.259 | 0.1 | 0.0 | 0.1 |

| 31 | 1.3 | 0.516 | 0.416 | 0.522 | 0.7 | 0.6 | 0.7 |

| 37 | 1.2 | 0.611 | 0.248 | 0.614 | 0.7 | 0.3 | 0.7 |

| 39 | 0.3 | 0.381 | 0.142 | 0.383 | 0.1 | 0.0 | 0.1 |

| 45 | 0.8 | 0.533 | 0.339 | 0.538 | 0.4 | 0.3 | 0.5 |

| 55 | 0.8 | 0.537 | 0.487 | 0.544 | 0.5 | 0.4 | 0.5 |

| 58 | 0.4 | 0.273 | 0.405 | 0.279 | 0.1 | 0.2 | 0.1 |

| 59 | 0.1 | 0.487 | 0.505 | 0.494 | 0.1 | 0.1 | 0.1 |

| Practical Mining LLC | February 5, 2018 |

| Page 22 | Summary | Klondex Mines Ltd. |

| AuEq | AuEq | ||||||

| Vein Name | kton | Au opt | Ag opt | opt | Au koz | Ag koz | koz |

| 60 | 0.1 | 0.499 | 0.280 | 0.503 | 0.1 | 0.0 | 0.1 |

| 63 | 0.1 | 0.482 | 0.481 | 0.488 | 0.0 | 0.0 | 0.0 |

| Total Measured | 154 | 1.215 | 1.118 | 1.230 | 187 | 172 | 189 |

| Indicated | |||||||

| Joyce | 79 | 0.742 | 0.941 | 0.755 | 59 | 74 | 60 |

| Karen | 92 | 0.495 | 0.449 | 0.501 | 46 | 42 | 46 |

| Vonnie | 52 | 0.538 | 0.664 | 0.547 | 28 | 34 | 28 |

| Honey Runner | 73 | 0.455 | 0.354 | 0.460 | 33 | 26 | 34 |

| Hui Wu | 11 | 0.481 | 0.275 | 0.485 | 5 | 3 | 5 |

| 05 | 2.8 | 0.446 | 0.192 | 0.448 | 1.2 | 0.5 | 1.3 |

| 06 | 15 | 0.407 | 1.133 | 0.423 | 6.1 | 17 | 6.3 |

| 07 | 9.5 | 0.622 | 0.509 | 0.629 | 5.9 | 4.8 | 6.0 |

| 08 | 6.0 | 0.822 | 0.531 | 0.829 | 5.0 | 3.2 | 5.0 |

| 09 | 6.8 | 0.886 | 0.247 | 0.889 | 6.0 | 1.7 | 6.0 |

| 12 | 4.1 | 0.558 | 0.240 | 0.561 | 2.3 | 1.0 | 2.3 |

| 13 | 3.7 | 0.481 | 0.377 | 0.486 | 1.8 | 1.4 | 1.8 |

| 14 | 3.1 | 0.286 | 0.393 | 0.292 | 0.9 | 1.2 | 0.9 |

| 16 | 23 | 0.512 | 0.458 | 0.518 | 12 | 11 | 12 |

| 18 | 2.3 | 0.313 | 0.242 | 0.316 | 0.7 | 0.6 | 0.7 |

| 21 | 17 | 0.387 | 0.537 | 0.394 | 6.5 | 9.0 | 6.6 |

| 22 | 4.2 | 0.472 | 0.411 | 0.478 | 2.0 | 1.7 | 2.0 |

| 24 | 0.1 | 0.549 | 0.658 | 0.558 | 0.1 | 0.1 | 0.1 |

| 27 | 9 | 0.364 | 0.270 | 0.368 | 3.3 | 2.4 | 3.3 |

| 30 | 6.1 | 0.464 | 0.300 | 0.468 | 2.8 | 1.8 | 2.8 |

| 31 | 23 | 0.481 | 0.331 | 0.486 | 11 | 7.5 | 11 |

| 37 | 1.2 | 0.469 | 0.196 | 0.472 | 0.6 | 0.2 | 0.6 |

| 39 | 13 | 0.666 | 0.533 | 0.674 | 8.8 | 7.0 | 8.9 |

| 41 | 0.9 | 0.236 | 0.232 | 0.239 | 0.2 | 0.2 | 0.2 |

| 45 | 2.5 | 0.281 | 0.256 | 0.284 | 0.7 | 0.6 | 0.7 |

| 46 | 1.0 | 0.235 | 0.768 | 0.246 | 0.2 | 0.8 | 0.3 |

| 55 | 1.2 | 0.738 | 0.473 | 0.745 | 0.9 | 0.6 | 0.9 |

| 58 | 4.1 | 0.441 | 0.498 | 0.448 | 1.8 | 2.0 | 1.8 |

| 59 | 3.8 | 0.652 | 0.380 | 0.657 | 2.5 | 1.4 | 2.5 |

| 60 | 5.9 | 0.378 | 0.416 | 0.384 | 2.2 | 2.5 | 2.3 |

| 61 | 19 | 0.430 | 0.690 | 0.439 | 8.3 | 13 | 8.5 |

| 63 | 14 | 0.541 | 0.623 | 0.550 | 7.6 | 8.7 | 7.7 |

| 64 | 4.8 | 0.449 | 0.933 | 0.462 | 2.2 | 4.5 | 2.2 |

| 68 | 3.1 | 0.351 | 0.702 | 0.361 | 1.1 | 2.2 | 1.1 |

| 69 | 12 | 0.371 | 0.478 | 0.377 | 4.5 | 5.8 | 4.6 |

| 70 | 2.6 | 0.234 | 0.487 | 0.241 | 0.6 | 1.2 | 0.6 |

| Total Indicated | 532 | 0.526 | 0.554 | 0.534 | 280 | 295 | 284 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 23 |

| Lander County, Nevada |

| AuEq | AuEq | ||||||

| Vein Name | kton | Au opt | Ag opt | opt | Au koz | Ag koz | koz |

| Measured and Indicated | |||||||

| Joyce | 144 | 0.976 | 1.036 | 0.990 | 141 | 149 | 143 |

| Karen | 149 | 0.834 | 0.785 | 0.845 | 124 | 117 | 126 |

| Vonnie | 65 | 0.672 | 0.750 | 0.682 | 44 | 49 | 45 |

| Honey Runner | 79 | 0.470 | 0.358 | 0.475 | 37 | 28 | 37 |

| Hui Wu | 13 | 0.461 | 0.264 | 0.464 | 6.0 | 3.4 | 6.0 |

| 05 | 2.9 | 0.469 | 0.186 | 0.472 | 1.4 | 0.5 | 1.4 |

| 06 | 15 | 0.407 | 1.137 | 0.423 | 6.2 | 17 | 6.5 |

| 07 | 10 | 0.614 | 0.524 | 0.621 | 6.0 | 5.1 | 6.0 |

| 08 | 6.0 | 0.822 | 0.531 | 0.829 | 5.0 | 3.2 | 5.0 |

| 09 | 6.8 | 0.884 | 0.247 | 0.887 | 6.0 | 1.7 | 6.0 |

| 12 | 5.5 | 0.539 | 0.244 | 0.542 | 3.0 | 1.3 | 3.0 |

| 13 | 6.1 | 0.559 | 0.383 | 0.564 | 3.4 | 2.3 | 3.4 |

| 14 | 3.1 | 0.286 | 0.393 | 0.292 | 0.9 | 1.2 | 0.9 |

| 16 | 24 | 0.511 | 0.455 | 0.517 | 12 | 11 | 12 |

| 18 | 2.9 | 0.352 | 0.224 | 0.355 | 1.0 | 0.7 | 1.0 |

| 21 | 17 | 0.385 | 0.530 | 0.392 | 6.5 | 9.0 | 6.7 |

| 22 | 4.2 | 0.472 | 0.411 | 0.478 | 2.0 | 1.7 | 2.0 |

| 24 | 0.1 | 0.549 | 0.658 | 0.558 | 0.1 | 0.1 | 0.1 |

| 27 | 9.1 | 0.364 | 0.270 | 0.368 | 3.3 | 2.4 | 3.3 |

| 30 | 6.1 | 0.464 | 0.300 | 0.468 | 2.8 | 1.8 | 2.8 |

| 31 | 24 | 0.483 | 0.336 | 0.488 | 12 | 8.0 | 12 |

| 37 | 2.4 | 0.539 | 0.222 | 0.543 | 1.3 | 0.5 | 1.3 |

| 39 | 13 | 0.661 | 0.525 | 0.668 | 8.9 | 7.1 | 9.0 |

| 41 | 1.0 | 0.236 | 0.228 | 0.239 | 0.2 | 0.2 | 0.2 |

| 45 | 3.4 | 0.344 | 0.277 | 0.347 | 1.2 | 0.9 | 1.2 |

| 46 | 1.0 | 0.235 | 0.768 | 0.246 | 0.2 | 0.8 | 0.3 |

| 55 | 2.0 | 0.654 | 0.479 | 0.660 | 1.3 | 1.0 | 1.3 |

| 58 | 4.5 | 0.425 | 0.489 | 0.432 | 1.9 | 2.2 | 1.9 |

| 59 | 3.9 | 0.647 | 0.384 | 0.652 | 2.5 | 1.5 | 2.6 |

| 60 | 6.0 | 0.381 | 0.414 | 0.386 | 2.3 | 2.5 | 2.3 |

| 61 | 19 | 0.430 | 0.690 | 0.439 | 8.3 | 13 | 8.5 |

| 63 | 14 | 0.541 | 0.623 | 0.550 | 7.6 | 8.8 | 7.7 |

| 64 | 4.8 | 0.449 | 0.932 | 0.462 | 2.2 | 4.5 | 2.2 |

| 68 | 3.1 | 0.351 | 0.702 | 0.361 | 1.1 | 2.2 | 1.1 |

| 69 | 12 | 0.371 | 0.478 | 0.377 | 4.5 | 5.8 | 4.6 |

| 70 | 2.6 | 0.234 | 0.487 | 0.241 | 0.6 | 1.2 | 0.6 |

| Total Meas. and Ind. | 686 | 0.681 | 0.680 | 0.690 | 467 | 467 | 474 |

| Inferred | |||||||

| Practical Mining LLC | February 5, 2018 |

| Page 24 | Summary | Klondex Mines Ltd. |

| AuEq | AuEq | ||||||

| Vein Name | kton | Au opt | Ag opt | opt | Au koz | Ag koz | koz |

| Joyce | 49 | 0.354 | 0.881 | 0.366 | 17 | 43 | 18 |

| Karen | 41 | 0.343 | 0.479 | 0.350 | 14 | 20 | 14 |

| Vonnie | 25 | 0.792 | 0.394 | 0.797 | 20 | 10 | 20 |

| Honey Runner | 29 | 0.386 | 0.400 | 0.391 | 11 | 12 | 11 |

| Hui Wu | 0.2 | 0.348 | 0.066 | 0.349 | 0.1 | 0.0 | 0.1 |

| 05 | 1.0 | 0.361 | 0.183 | 0.363 | 0.3 | 0.2 | 0.3 |

| 06 | 27 | 0.460 | 0.490 | 0.467 | 12 | 13 | 12 |

| 08 | 4.4 | 0.257 | 0.158 | 0.259 | 1.1 | 0.7 | 1.1 |

| 09 | 60 | 0.438 | 0.166 | 0.441 | 27 | 10 | 27 |

| 14 | 0.3 | 0.358 | 0.368 | 0.363 | 0.1 | 0.1 | 0.1 |

| 16 | 62 | 0.412 | 0.259 | 0.415 | 26 | 16 | 26 |

| 18 | 17 | 0.478 | 0.169 | 0.481 | 8.1 | 2.9 | 8.2 |

| 19 | 0.3 | 0.219 | 0.300 | 0.223 | 0.1 | 0.1 | 0.1 |

| 21 | 6.1 | 0.287 | 0.503 | 0.294 | 1.7 | 3.1 | 1.8 |

| 22 | 23 | 0.530 | 0.425 | 0.536 | 12 | 10 | 12 |

| 23 | 36 | 0.444 | 0.131 | 0.446 | 16 | 4.7 | 16 |

| 24 | 148 | 0.534 | 0.675 | 0.544 | 79 | 100 | 81 |

| 25 | 54 | 0.558 | 0.295 | 0.562 | 30 | 16 | 30 |

| 26 | 50 | 0.319 | 0.159 | 0.321 | 16 | 8.0 | 16 |

| 27 | 5.6 | 0.331 | 0.198 | 0.334 | 1.8 | 1.1 | 1.9 |

| 28 | 11 | 0.311 | 0.588 | 0.319 | 3.3 | 6.2 | 3.4 |

| 30 | 107 | 0.422 | 0.368 | 0.427 | 45 | 39 | 46 |

| 31 | 2.0 | 0.421 | 0.153 | 0.423 | 0.8 | 0.3 | 0.8 |

| 39 | 1.5 | 0.873 | 0.734 | 0.884 | 1.3 | 1.1 | 1.3 |

| 41 | 21 | 0.272 | 0.728 | 0.282 | 5.8 | 16 | 6.0 |

| 45 | 22 | 0.274 | 0.319 | 0.279 | 6.0 | 6.9 | 6.1 |

| 58 | 26 | 0.551 | 0.429 | 0.557 | 14 | 11 | 15 |

| 59 | 2.7 | 0.490 | 0.236 | 0.493 | 1.3 | 0.6 | 1.3 |

| 60 | 25 | 0.340 | 0.447 | 0.346 | 8.4 | 11 | 8.6 |

| 61 | 31 | 0.371 | 0.571 | 0.379 | 11 | 18 | 12 |

| 63 | 3.1 | 0.313 | 0.298 | 0.317 | 1.0 | 0.9 | 1.0 |

| 64 | 2.5 | 0.599 | 1.908 | 0.625 | 1.5 | 4.8 | 1.6 |

| 66 | 43 | 0.337 | 1.192 | 0.354 | 15 | 51 | 15 |

| 67 | 49 | 0.319 | 0.333 | 0.324 | 15 | 16 | 16 |

| 68 | 28 | 0.238 | 0.291 | 0.242 | 6.7 | 8.1 | 6.8 |

| 69 | 18 | 0.360 | 0.190 | 0.362 | 6.6 | 3.5 | 6.6 |

| 70 | 9.3 | 0.253 | 0.392 | 0.258 | 2.3 | 3.6 | 2.4 |

| 72 | 26 | 0.388 | 0.092 | 0.389 | 10 | 2 | 10 |

| 73 | 74 | 0.967 | 0.260 | 0.971 | 72 | 19 | 72 |

| Total Inferred | 1,142 | 0.457 | 0.430 | 0.463 | 522 | 491 | 529 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 25 |

| Lander County, Nevada |

| Notes: | ||

| 1. |

Mineral resources have been calculated at a gold price of $1,400/troy ounce and a silver price of $19.83 per troy ounce; | |

| 2. |

Mineral resources are calculated at a grade thickness cut-off grade of 0.974 Au equivalent opt-feet and a diluted Au equivalent cut-off grade of 0.228 opt; | |

| 3. |

Mineral Resources have been calculated using metallurgical recoveries for gold and silver of 94% and 92% respectively; | |

| 4. |

Gold equivalent ounces were calculated based on one ounce of gold being equivalent to 72.12 ounces of silver; | |

| 5. |

The minimum mining width is defined as four-feet or the vein true thickness plus two-foot, whichever is greater; | |

| 6. |

Mineral resources include dilution to achieve mining widths and an additional 7% unplanned dilution. | |

| 7. |

Mineral resources include allowance for 5% mining losses; | |

| 8. |

Mineral resources are inclusive of mineral reserves; | |

| 9. |

Underground Mineral Resources are Exclusive of Open Pit Mineral Resources; | |

| 10. |

Mineral resources, which are not mineral reserves, do not have demonstrated economic viability. The estimate of mineral resources may be materially affected by environmental, permitting, legal, title, socio-political, marketing, or other relevant factors; and | |

| 11. |

The quantity and grade of reported inferred mineral resources in this estimation are uncertain in nature and there is insufficient exploration to define these inferred mineral resources as an indicated or measured mineral resource and it is uncertain if further exploration will result in upgrading them to an indicated or measured mineral resource category. | |

Table 1-3 Open Pit Mineral Resources as of November 30, 2017

| Cut Off | Material | |||||||

| AuEq opt | Type | kton | Au opt | Ag opt | AuEq opt | Au koz | Ag koz | AuEq koz |

| Indicated | ||||||||

| Oxide | 10,023 | 0.023 | 0.038 | 0.023 | 229 | 386 | 231 | |

| 0.012 | Mixed | 27,085 | 0.030 | 0.065 | 0.030 | 807 | 1,769 | 818 |

| Total | 37,109 | 0.028 | 0.058 | 0.028 | 1,036 | 2,155 | 1,049 | |

| Oxide | 12,241 | 0.021 | 0.036 | 0.021 | 251 | 490 | 253 | |

| 0.010 | Mixed | 30,637 | 0.027 | 0.062 | 0.027 | 842 | 1,909 | 854 |

| Total | 42,877 | 0.025 | 0.055 | 0.025 | 1,093 | 2,350 | 1,108 | |

| Oxide | 21,476 | 0.014 | 0.029 | 0.015 | 310 | 617 | 314 | |

| 0.005 | Mixed | 42,980 | 0.022 | 0.055 | 0.022 | 925 | 2,350 | 941 |

| Total | 64,457 | 0.019 | 0.046 | 0.019 | 1,236 | 2,967 | 1,255 | |

| Inferred | ||||||||

| Oxide | 2,249 | 0.027 | 0.038 | 0.027 | 60 | 86 | 61 | |

| 0.012 | Mixed | 25,313 | 0.039 | 0.101 | 0.040 | 983 | 2,557 | 1,000 |

| Total | 27,561 | 0.038 | 0.096 | 0.038 | 1,043 | 2,643 | 1,060 | |

| Oxide | 2,872 | 0.023 | 0.035 | 0.023 | 66 | 100 | 67 | |

| 0.010 | Mixed | 28,835 | 0.035 | .096 | 0.035 | 1019 | 2,782 | 1,037 |

| Total | 31,707 | 0.034 | 0.091 | 0.035 | 1,085 | 2,882 | 1,104 | |

| Oxide | 5,792 | 0.015 | 0.027 | 0.015 | 84 | 154 | 85 | |

| 0.005 | Mixed | 41,053 | 0.027 | 0.085 | 0.027 | 1,101 | 3,482 | 1,123 |

| Total | 46,845 | 0.025 | 0.078 | 0.026 | 1,185 | 3,637 | 1,209 | |

| Practical Mining LLC | February 5, 2018 |

| Page 26 | Summary | Klondex Mines Ltd. |

| Notes: | ||

| 1. |

Mineral resources are calculated at a gold price of US$1,400 per ounce and a silver price of US$19.83 per ounce; | |

| 2. |

Metallurgical recoveries for gold and silver are 65% and 30%, respectively for oxide mineralization and 60% and 25% respectively for mixed mineralization; | |

| 3. |

One ounce of gold is equivalent to 152.94 ounces of silver; | |

| 4. |

Mineral Resources include 10% dilution and 5% mining losses; | |

| 5. |

Cut off grades for the Mineral Resources are 0.01opt AuEq opt.; | |

| 6. |

The effective date for the Mineral Resource is November 30, 2017; | |

| 7. |

Open Pit Mineral Resources are Exclusive of Underground Mineral Resources; | |

| 8. |

Mineral Resources which are not Mineral Reserves have not yet demonstrated economic viability. The estimate of mineral resources may be materially affected by environmental, permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues, and; | |

| 9. |

The quantity and grade of reported Inferred Resources in this estimation are uncertain in nature and there has been insufficient exploration to define these Inferred Resources as an Indicated or Measured Mineral Resource and it is uncertain if further exploration will result in upgrading them to an Indicated or Measured Mineral Resource category. | |

| 1.5. |

Mineral Reserve Estimate |

Excavation designs for stopes, stope development drifting, and access development were created using Vulcan software. Stope designs were aided by the Vulcan Stope Optimizer Module. The stope optimizer produces the stope cross section which maximizes value within given geometric engineering and geotechnical constraints.

Design constraints included a four-foot minimum mining width for long-hole stopes with development drifts spaced at 40-foot vertical intervals. Stope development drift dimensions are planned 12 feet high with a minimum width of six feet. Drift and fill dimensions are the same as those for stope development.

Table 1-4 Mineral Reserves as of November 30. 2017

| Au | Ag | Au Equiv. | |||||

| Tons | Au Eq | Ounces | Ounces | Ounces | |||

| Vein Designation | (000's) | Au opt | Ag opt | opt | (000's) | (000's) | (000's) |

| Proven Reserves | |||||||

| Joyce | 52 | 1.089 | 1.005 | 1.102 | 57.0 | 52.6 | 57.7 |

| Karen | 45 | 1.105 | 1.151 | 1.120 | 49.6 | 51.7 | 50.3 |

| Vonnie | 6 | 1.298 | 0.952 | 1.311 | 8.2 | 6.0 | 8.3 |

| 20 | 3 | 0.441 | 0.304 | 0.445 | 1.2 | 0.8 | 1.2 |

| 6 | 0.5 | 0.330 | 1.045 | 0.344 | 0.2 | 0.5 | 0.2 |

| 14 | 0.7 | 0.535 | 0.179 | 0.537 | 0.4 | 0.1 | 0.4 |

| 13 | 0.4 | 0.256 | 0.126 | 0.258 | 0.1 | - | 0.1 |

| 37 | 0.4 | 0.430 | 0.187 | 0.432 | 0.2 | 0.1 | 0.2 |

| Proven Reserves | 108 | 1.079 | 1.033 | 1.092 | 116.8 | 111.9 | 118.3 |

| Probable Reserves | |||||||

| Joyce | 37 | 0.808 | 0.873 | 0.819 | 30.0 | 32.4 | 30.4 |

| Karen | 59 | 0.380 | 0.363 | 0.385 | 22.4 | 21.4 | 22.7 |

| Vonnie | 9 | 0.980 | 0.709 | 0.990 | 8.7 | 6.3 | 8.7 |

| 20 | 41 | 0.375 | 0.327 | 0.380 | 15.2 | 13.3 | 15.4 |

| 12 | 6 | 0.888 | 0.250 | 0.891 | 5.1 | 1.4 | 5.1 |

| 63 | 9 | 0.469 | 0.643 | 0.478 | 4.2 | 5.8 | 4.3 |

| 61 | 9 | 0.438 | 0.440 | 0.444 | 4.0 | 4.0 | 4.0 |

| 6 | 9 | 0.391 | 1.205 | 0.407 | 3.6 | 11.1 | 3.8 |

| 18 | 8 | 0.424 | 0.381 | 0.429 | 3.5 | 3.1 | 3.5 |

| 8 | 4 | 0.910 | 0.598 | 0.918 | 3.4 | 2.3 | 3.5 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 27 |

| Lander County, Nevada |

| Au | Ag | Au Equiv. | |||||

| Tons | Au Eq | Ounces | Ounces | Ounces | |||

| Vein Designation | (000's) | Au opt | Ag opt | opt | (000's) | (000's) | (000's) |

| 36 | 5 | 0.501 | 0.255 | 0.505 | 2.3 | 1.1 | 2.3 |

| 14 | 4 | 0.338 | 0.284 | 0.341 | 1.2 | 1.0 | 1.2 |

| 59 | 2 | 0.632 | 0.332 | 0.637 | 1.1 | 0.6 | 1.2 |

| 55 | 3 | 0.352 | 0.279 | 0.356 | 1.0 | 0.8 | 1.0 |

| 13 | 1 | 0.709 | 0.213 | 0.711 | 0.9 | 0.3 | 0.9 |

| 31 | 2 | 0.391 | 0.191 | 0.394 | 0.8 | 0.4 | 0.8 |

| 64 | 2 | 0.432 | 1.415 | 0.451 | 0.7 | 2.4 | 0.8 |

| 5 | 1 | 0.404 | 0.183 | 0.407 | 0.6 | 0.3 | 0.6 |

| 7 | 1 | 0.409 | 0.327 | 0.414 | 0.5 | 0.4 | 0.5 |

| Probable Reserves | 211 | 0.517 | 0.514 | 0.524 | 109.1 | 108.3 | 110.6 |

| Proven & Probable Reserves | |||||||

| Joyce | 89 | 0.972 | 0.950 | 0.985 | 86.9 | 85.0 | 88.1 |

| Karen | 104 | 0.694 | 0.704 | 0.703 | 72.1 | 73.2 | 73.1 |

| Vonnie | 15 | 1.113 | 0.810 | 1.124 | 16.9 | 12.3 | 17.0 |

| 20 | 43 | 0.379 | 0.326 | 0.384 | 16.4 | 14.1 | 16.6 |

| 12 | 6 | 0.888 | 0.250 | 0.891 | 5.1 | 1.4 | 5.1 |

| 63 | 9 | 0.469 | 0.643 | 0.477 | 4.2 | 5.8 | 4.3 |

| 61 | 9 | 0.438 | 0.440 | 0.444 | 4.0 | 4.0 | 4.0 |

| 6 | 10 | 0.388 | 1.197 | 0.404 | 3.8 | 11.6 | 3.9 |

| 18 | 8 | 0.423 | 0.381 | 0.428 | 3.5 | 3.1 | 3.5 |

| 8 | 4 | 0.910 | 0.598 | 0.918 | 3.4 | 2.3 | 3.5 |

| 36 | 5 | 0.501 | 0.255 | 0.505 | 2.3 | 1.1 | 2.3 |

| 14 | 4 | 0.370 | 0.267 | 0.374 | 1.6 | 1.1 | 1.6 |

| 59 | 2 | 0.632 | 0.332 | 0.637 | 1.1 | 0.6 | 1.2 |

| 55 | 3 | 0.352 | 0.279 | 0.356 | 1.0 | 0.8 | 1.0 |

| 13 | 2 | 0.603 | 0.192 | 0.605 | 1.0 | 0.3 | 1.0 |

| 31 | 2 | 0.391 | 0.191 | 0.394 | 0.8 | 0.4 | 0.8 |

| 64 | 2 | 0.431 | 1.412 | 0.450 | 0.7 | 2.4 | 0.8 |

| 5 | 1 | 0.404 | 0.183 | 0.407 | 0.6 | 0.3 | 0.6 |

| 7 | 1 | 0.409 | 0.327 | 0.414 | 0.5 | 0.4 | 0.5 |

| 37 | 0.6 | 0.327 | 0.163 | 0.330 | 0.2 | 0.1 | 0.2 |

| Proven & Probable Reserves | 319 | 0.708 | 0.690 | 0.717 | 226.0 | 220.2 | 228.9 |

| Notes: | |

| 1. |

Mineral reserves have been estimated with a gold price of $1,200/ounce and a silver price of $17.00/ounce; |

| 2. |

Metallurgical recoveries for gold and silver are 93% and 88% respectively; |

| 3. |

Gold equivalent ounces are calculated on the basis of one ounce of gold being equivalent to 74.60 ounces of silver; |

| 4. |

Mineral reserves are estimated at a cutoff grade of 0.288 Au opt and an incremental cutoff grade of 0.090 Au opt, and; |

| 5. |

Mine losses of 5% and unplanned mining dilution of 10% have been applied to the designed mine excavations. |

| 1.6. |

Cash Flow Analysis and Economics |

The reserves mine plan was evaluated using constant dollar cash flow analysis, and the results are summarized in Table 1-5. The high-grade of the Mineral Reserves and the low capital requirements produce a 3.9 profitability index (PI) calculated at an 8% discount rate with an Net Present Value (NPV) of $73M.

| Practical Mining LLC | February 5, 2018 |

| Page 28 | Summary | Klondex Mines Ltd. |

Table 1-5 Key Operating and After Tax Financial Statistics

| Material Mined and Processed (kt) | 319 |

| Avg. Gold Grade (opt) | 0.71 |

| Avg. Silver Grade (opt) | 0.69 |

| Contained Gold (koz) | 226 |

| Contained Silver (koz) | 220 |

| Avg. Gold Metallurgical Recovery | 93% |

| Avg. Silver Metallurgical Recovery | 88% |

| Recovered Gold (koz) | 210 |

| Recovered Silver (koz) | 194 |

| Reserve Life (years) | 3.1 |

| Operating Cost ($/ton) | $351 |

| Cash Cost ($/oz) 1. | $582 |

| Total Cost ($/oz) 1. | $716 |

| Gold Price ($/oz) | $1,200.00 |

| Silver Price ($/oz) | $17.00 |

| Capital Costs ($ Millions) | $28.2 |

| Payback Period (Years) | NA |

| Cash Flow ($ Millions) | $88 |

| 5% Discounted Cash Flow ($ Millions) | $78 |

| 8% Discounted Cash Flow ($ Millions) | $73 |

| Profitability Index (8%) 2. | 3.9 |

| Internal Rate of Return | NA |

| Notes: | ||

| 1. |

Net of Byproduct Sales, and; | |

| 2. |

Profitability index (PI), is the ratio of payoff to investment of a proposed project. It is a useful tool for ranking projects because it allows you to quantify the amount of value created per unit of investment. A profitability index of 1 indicates break even. | |

| 1.7. |

Conclusions |

Fire Creek is a modern, mechanized narrow vein mine. Mining is executed with a high degree of care and precision. The workforce is well trained and organized. Management and technical staff are dedicated to producing ore of the highest possible quality at the lowest cost.

The data density required to classify mineral resources as measured or indicated is only achievable by sill development and closely spaced underground drilling. This limits mineral reserves to only those veins in or immediately adjacent to the mine workings. In the opinion of the authors of this TR, additional potential exists to extend mineral reserves along strike in both directions as underground access is developed. As the footprint of the mine grows and the number of available mining areas grows with it, the mining rate can be increased, and cost reductions may be realized through economies of scale.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 29 |

| Lander County, Nevada |

The conventional Merrill Crowe mill facility of the Midas Mine is an efficient well maintained modern mineral processing plant capable of processing 1,200 tons per day (tpd). The plant operates with a minimum crew which results in cost reductions when operated at capacity. The underutilized processing capacity can accept increased mine production from the Fire Creek, Midas and Hollister Mines as well as third party processing agreements.

Capital requirements for the Project are minimal. Ongoing mine development comprises the majority of capital costs, and the ability to access multiple veins from common development greatly reduces the unit cost per ounce.

In the opinion of the authors of this TR, the high-grade reserves in the mine plan provide a high return and will sustain profitable operations with up to 40% adverse variations in metal prices, operating or capital costs. The total cost per ounce, including capital expenditures and net of byproduct sales, is $716 per ounce.

The addition of a disseminated open pit mineral resource adds long term potential to the Project once underground mining is completed in the vicinity of the open pit.

| 1.8. |

Recommendations |

Exploration: Underground drilling should continue in the veins identified near the current development workings to increase the level of confidence in these veins to an indicated classification. Underground exploration development is key to providing the platform to expand mineral resources and mineral reserves. Exploration development should be accelerated to provide the strike length necessary to define five to seven years of underground mine life.

Mine Planning: Expanding the reserve base through the previous comment will allow the development of additional work areas and the potential for increasing the mines production rate. Mine support and overhead costs are relatively fixed and are a large percentage of the total operating cost. A higher production rate can result in economies of scale and lower total cost per ounce.

Ore and Waste Density: A large quantity of density data is being collected and is available to be incorporated into the resource model. This data should be reviewed and interpreted with the same emphasis as is given assay data.

| Practical Mining LLC | February 5, 2018 |

| Page 30 | Introduction | Klondex Mines Ltd. |

| 2. |

Introduction |

| 2.1. |

Terms of Reference and Purpose of this Technical Report |

This TR provides a statement of Mineral Resources and Mineral Reserves for the Project. This evaluation includes measured, indicated, and inferred mineral resources, as well as proven and probable mineral reserves. This TR was prepared in accordance with the requirements of NI 43-101 and Form 43-101F1 (43-101F1) for technical reports.

Mineral resource and mineral reserve definitions are set forth in Section 27 of this TR in accordance with the companion policy to NI 43-101 (43-101CP) of the Canadian Securities Administrators and “Canadian Institute of Mining, Metallurgy and Petroleum (CIM) – Definition Standards for Mineral Resources and Mineral Reserves adopted by CIM Council on May 10, 2014.”

| 2.2. |

Qualification of the Authors |

This TR includes technical evaluations from four independent consultants. The consultants are specialists in the fields of geology, exploration, and open pit and underground mining.

None of the authors has any beneficial interest in Klondex or any of its subsidiaries or in the assets of Klondex or any of its subsidiaries. The authors will be paid a fee for this work in accordance with normal professional consulting practices.

Mr. Odell is the qualified person (QP) for this TR and is cited as “primary author.” All independent QP’s contributing to this report toured the mine and facilities on January 9, 2018.

The QP’s contributing to this report are listed in Table 2-1. The Certificate and Consent Forms are provided in Appendix A: Certification of Authors and Consent Forms.

Table 2-1 Qualified Professionals

| Responsible | ||||

| Company | Name | Title | Discipline | Sections |

| Practical Mining, LLC | Mark Odell | Manager | Mining and mineral resources | All |

| Practical Mining, LLC | Laura Symmes | Sr. Geologist | Geology | 7-12 |

| Practical Mining, LLC | Sarah Bull | Mining Engineer | Mining | 15-16 |

| Practical Mining LLC | Adam Knight | Mining Engineer | Mining | 15-16 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd | Technical Report for the Fire Creek Project, | Page 31 |

| Lander County, Nevada |

| 2.3. |

Sources of Information |

The Klondex staff listed in Table 2-2 contributed to the sections of this report in their area of expertise and have reviewed this TR for accuracy.

Table 2-2 Klondex Contributors

| Name | Title | Discipline |

| Mr. Brian Morris | Exploration VP | Geology |

| Mr. Sid Tolbert | General Manager | Mining |

| Mr. Anthony Botrill | Corporate Resource Manager | Resource Modelling |

| Mr. Agapito Orozco | Sr. Resource Geologist | Resource Modelling |

| Mr. John Marma | Director of Exploration and Geology | Geology |

| Mr. John Spring | Chief Geologist | Geology |

| Ms. Lucy Hill | Director of Environmental Services and Community Relations | Environmental |

| Mr. John Rust | Director of Metallurgy | Metallurgy |

Information sources are documented either within the text and cited in references, or are cited in references only. The primary author believes the information provided by Klondex staff to be accurate based on their work at the Project. The authors asked detailed questions of specific Klondex staff to help verify contributions included in this document.

| 2.4. |

Units of Measure |

The units of measure used in this report are shown in Table 2-2 below. U.S. Imperial units of measure are used throughout this document unless otherwise noted. The glossary of geological and mining related terms is also provided in Section 27 of this TR. Currency is expressed as United States Dollars unless otherwise noted.

Table 2-3 Units of Measure

| US Imperial to Metric conversions |

| Linear Measure |

| 1 inch = 2.54 cm |

| 1 foot = 0.3048 m |

| 1 yard = 0.9144 m |

| 1 mile = 1.6 km |

| Area Measure |

| 1 acre = 0.4047 ha |

| 1 square mile = 640 acres = 259 ha |

| Weight |

| 1 short ton (st) = 2,000 lbs = 0.9071 metric tons |

| 1 lb = 0.454 kg = 14.5833 troy oz |

| Assay Values |

| 1 oz per short ton = 34.2857 g/t |

| 1 troy oz = 31.1036 g |

| 1 part per billion = 0.0000292 oz/ton |

| 1 part per million = 0.0292 oz/ton = 1g/t |

| Practical Mining LLC | February 5, 2018 |

| Page 32 | Introduction | Klondex Mines Ltd. |

| 2.5. |

Coordinate Datum |

Spatial data utilized in analysis presented in this TR are projected to Nevada State Plane Central Zone North American Datum 1983 (NV SPCS) feet truncated to the last six digits. All spatial measurement units used in the mineral resource estimate are U.S. Survey feet.

Historical survey data was collected and reported using several coordinate systems. Survey data was originally collected in North American Datum of 1983 (NAD83) meters as a default in the instrumentation settings, and then the data was converted to NAD83 feet for reports as requested by Klondex staff in Nevada. Klondex’s Nevada staff further converted the data from NAD83 feet to UTM NAD27 Zone 11N feet. Early in 2014, all the Project data was again converted to NV SPCS NAD83 coordinates.

In addition, downhole surveys were collected without compensating for magnetic declination. Klondex staff applied corrections to raw downhole survey data to compensate for the local declination at the Project, which is 12.86 degrees according to the National Oceanic and Atmospheric Administration (NOAA) calculator.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd. | Technical Report for the Fire Creek Project, | Page 33 |

| Lander County, Nevada |

| 3. |

Reliance on Other Experts |

The technical status for the claims and land holding is reliant on information provided by The US Bureau of Land Management and the Lander County Assessors Office. The status of the Klondex environmental program and the permitting process were provided by Ms. Lucy Hill, Director of Environmental Services. The geologic model and block model were completed by Mr. Anthony Bottrill, Klondex Corporate Resource Manager, and Mr Agapito Orozco, Klondex Senior Resource Geologist. Mr. John Rust, Klondex Director of Metallurgy, provided information regarding metallurgical testing and process operating statistics. These contributions have been reviewed by the Authors and they are accurate portrayals of the Project at the time of writing this TR.

Observations made at the Project by the authors included stope mining, development mining, backfill operations, conditions of the underground work areas, mine ventilation system and the water handling system.

The authors reviewed land tenure to verify the nature of the good standing with the Bureau of Land Management (BLM) regarding Klondex’s unpatented lode mining claims. Fee land ownership and fee land leases were reviewed in a title opinion report dated July 30, 2014, written by Erwin & Thompson LLP. This information was supplemented by a review of records from the Lander County Assessor’s Office. The legal status or ownership of the fee properties and/or any agreements that pertain to the Fire Creek mineral deposit as described in Section 4 were provided by Klondex legal counsel for all relevant mining claims. Assumptions made as to accuracy of land tenure are based on the Erwin & Thompson LLP legal opinion.

The opinions expressed in this TR are based on the authors’ field observations and assessment of the technical data supplied by Klondex.

| Practical Mining LLC | February 5, 2018 |

| Page 34 | Property Description and Location | Klondex Mines Ltd. |

| 4. |

Property Description and Location |

| 4.1. |

Property Description |

The Project is located primarily in Lander County, Nevada with a small portion of the Project boundary in Eureka County, Nevada. The Project lies approximately 63 miles west of the major city of Elko, Nevada, USA in a sage and grass covered weathered basalt hillside overlooking Crescent Valley. There are multiple small towns along paved highways within a short commute of the Project, and the northern edge of the residential area of the town of Crescent Valley abuts the mine access road. The Project’s land coverage is approximately 22,000 acres.

| 4.2. |

Property Location |

The Project is located in Lander County, Nevada, approximately 34 miles west of Carlin (63 miles west of Elko) and 16 miles south of Interstate Highway I-80. Figure 4-1 shows the location of the Project. The closest town to the Project is Crescent Valley on Nevada State Highway 306. Access from Elko takes approximately one hour.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd. | Technical Report for the Fire Creek Project, | Page 35 |

| Lander County, Nevada |

| Practical Mining LLC | February 5, 2018 |

| Page 36 | Property Description and Location | Klondex Mines Ltd. |

| 4.3. |

Status of Mineral Titles |

The Project comprises private fee lands (both leased and owned) and unpatented lode mining claims. Figure 4-2 depicts the current land status. The land position shown on Figure 4-2 includes approximately 18,400 acres of unpatented federal lode mining claims, 3,208 acres of private fee land, and 409 acres of mineral leases. Overall, the Fire Creek land package is approximately 22,000 acres.

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd. | Technical Report for the Fire Creek Project, | Page 37 |

| Lander County, Nevada |

Table 4-1 lists the 890 unpatented lode mining claims held by Klondex for the Project. Table 4-2 itemizes fee lands owned by KGS, and Table 4-3 itemizes fee lands leased by KGS. Unpatented claims are in current good standing through September 1, 2018. Leases are in good standing until the lease payment is due.

| Practical Mining LLC | February 5, 2018 |

| Page 38 | Property Description and Location | Klondex Mines Ltd. |

Table 4-1 Summary of Klondex Owned Unpatented Mining Claims (US Department of the Interior 2018)

| Claim Name | Section | Township | Range | Location Date | Number of |

| Claims | |||||

| Wood Tick 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22 | 2 | 30N | 47E | 18-Jul-87 | 13 |

| Wood Tick 24, 26, 28, 30, 32, 34, 36 | 2 | 30N | 47E | 18-Jul-87 | 5 |

| Wood Tick 38, 40, 42, 44, 46, 48, 50, 52 | 36 | 31N | 47E | 21-Jul-87 | 8 |

| G 1-16 | 26 | 30N | 47E | 23-Jan-90 | 16 |

| Deb 2, 4 | 34 | 30N | 47E | 13-Dec-91 | 2 |

| Revenge 2, 20 | 34 | 30N | 47E | 16-Dec-91 | 2 |

| Revenge 4, 6 | 34 | 30N | 47E | 17-Dec-91 | 2 |

| Revenge 10, 12, 14 | 34 | 30N | 47E | 18-Dec-91 | 3 |

| Revenge 22 | 34 | 30N | 47E | 9-Jan-92 | 1 |

| Revenge 8, 28 | 34 | 30N | 47E | 26-Jan-92 | 2 |

| Revenge 16, 18 | 34 | 30N | 47E | 6-Feb-92 | 2 |

| Revenge 24, 26 | 34 | 30N | 47E | 13-Feb-92 | 2 |

| K 1 - 20 1 | 16 | 30N | 47E | 25-Jun-92 | 20 |

| K 21 - 27 2 | 16 | 30N | 47E | 26-Jun-92 | 7 |

| Alan 1-14 | 31 | 30N | 47E | 15-Feb-93 | 14 |

| HS 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, 66 | 12 | 29N | 48E | 23-Oct-93 | 13 |

| HS 48, 50, 52, 54, 56, 58, 60, 62, 64 | 14 | 29N | 48E | 29-Oct-93 | 9 |

| TL, 2, 4, 6 | 20 | 30N | 47E | 10-Nov-93 | 3 |

| TL 8, 10, 12, 14, 16, 18 | 20 | 30N | 47E | 10-Nov-93 | 6 |

| N 2, 4, 6, 8, 10, 12, 14, 16, 18 | 32 | 30N | 47E | 17-Nov-93 | 9 |

| N 20, 22, 24, 26, 28, 30 | 32 | 30N | 47E | 18-Nov-93 | 6 |

| HS 68, 70, 72, 71, 76, 78 | 14 | 29N | 47E | 7-Dec-93 | 6 |

| TL 20, 22, 24, 26 | 20 | 30N | 47E | 21-Jun-94 | 4 |

| FCRA 1- 20 | 26 | 30N | 47E | 28-Sep-95 | 20 |

| T 1 - 10 | 14 | 30N | 47E | 13-Oct-99 | 10 |

| Hondo 1, 3, 5, 7, 9, 11, 13, 15, 18, 20, 22, 24, 26, 28, 30, 32, 157, 158 | 24 | 30N | 47E | 20-Sep-03 | 18 |

| FC 1-18, 38-46 3 | 25, 35, 36 | 30N | 47E | 21-Sep-03 | 27 |

| What If 29-37 | 35, 36 | 30N | 47E | 21-Sep-03 | 9 |

| Deb 1, 3, 5 | 34 | 30N | 47E | 22-Sep-03 | 3 |

| Revenge 1, 11, 13, 15, 17, 19, 21, 23, 25, 27 | 34 | 30N | 47E | 22-Sep-03 | 10 |

| Revenge 3, 5, 7, 9, 29, -31 | 34 | 30N | 47E | 23-Sep-03 | 7 |

| T 19-26 | 10, 11, 14 | 30N | 47E | 23-Sep-03 | 8 |

| T 11-18, 27-36 | 11, 14 | 30N | 47E | 24-Sep-03 | 18 |

| T 38-60 | 3, 10 | 30N | 47E | 05-Oct-03 | 23 |

| T 61-72 | 2, 3, 10 | 30N | 47E | 6-Oct-03 | 12 |

| FCXX 1-40 | 15, 22 | 30N | 47E | 24-Nov-04 | 40 |

| N 1, 3, 11, 13, 19, 21, 23, 25, 27 | 32 | 30N | 47E | 11-Sep-06 | 9 |

| N 5, 7, 9, 15, 17, 29, 31 | 32 | 30N | 47E | 12-Sep-06 | 7 |

| TL 1, 3, 5, 7, 9, 11, 13, 15, 17 | 20 | 30N | 47E | 13-Sep-06 | 9 |

| Practical Mining LLC | February 5, 2018 |

| Klondex Mines Ltd. | Technical Report for the Fire Creek Project, | Page 39 |

| Lander County, Nevada |

| Claim Name | Section | Township | Range | Location Date | Number of |

| Claims | |||||

| TL 19, 21, 23, 25, 27-31 | 20 | 30N | 47E | 14-Sep-06 | 9 |

| CH 1-18 | 30 | 30N | 47E | 19-Sep-06 | 18 |

| TWE 18, 20-36 | 27, 28 | 30N | 47E | 20-Sep-06 | 18 |

| Hondo 2, 4, 6, 8, 10, 12, 14, 16, 17, 19, 21, | |||||

| 23, 25, 27, 29, 31 | 24 | 30N | 47E | 4-Oct-06 | 18 |

| TWE 1-18 | 21, 27, 28 | 30N | 47E | 10-Oct-06 | 18 |

| WT 1, 3, 5, 7, 9, 11, 13, 15, 17, 29, 31, 33, | 2 | 30N | 47E | 31-Oct-06 | 13 |

| 35 | |||||

| WT 37, 39, 41, 43, 45, 47, 49, 51, 53 - 55 | 36 | 31N | 47E | 1-Nov-06 | 11 |

| WT 19, 21, 23, 25, 27 | 2 | 31N | 47E | 7-Nov-06 | 5 |

| WT 56 - 72 | 25, 36 | 31N | 47E | 8-Nov-06 | 17 |

| HS 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, 25, 49, 51, 53, 55, 57, 59, 61, 63, 65 | 11, 12, 14 | 29N | 48E | 3-Sep-09 | 22 |

| HS 67,69, 71, 73, 75, 77, 79, 81, 83 | 14 | 29N | 48E | 24-Nov-09 | 9 |

| Malpais 1-30,265 | 3, 4, 15, 16 | 29N | 47E | 4-Oct-14 | 31 |

| Malpais 221, 223, 225, 227, 229, 231, 233, 235, 237 | 24, 25 | 30N | 46E | 4-Oct-14 | 9 |

| Malpais 210-222, 224, 226, 228, 230, 232 234, 236, 238-264 | 7, 17, 18, 19, 30, 31 | 30N | 47E | 4-Oct-14 | 46 |

| Malpais 31-48, 87-92, 111-164, 201-209, 346, 347 | 3, 4, 5, 6, 7, 8, 16 | 30N | 47E | 5-Oct-14 | 89 |

| Malpais 316- 345 | 28, 29, 31, 32 | 31N | 47E | 5-Oct-14 | 30 |

| Malpais 67, 68, 93, 94 | 1 | 30N | 46E | 6-Oct-14 | 4 |

| Malpais 49-66, 69-86, 95-110, | 3, 4, 6 | 30N | 47E | 6-Oct-14 | 52 |

| Malpais 302-315 | 7, 17, 18 | 31N | 47E | 6-Oct-14 | 14 |

| Malpais 165, 200 | 16 | 30N | 47E | 7-Oct-14 | 36 |

| Malpais 266-301 | 8, 9, 15, 16 | 31N | 48E | 7-Oct-14 | 36 |

| Unpatented Mining Claims | 890 | ||||

| Notes | |||||

| 1. Amended K17 17-Aug-1992, K 18, K20 14-Aug-1992 | |||||

| 2. Amended K22, K 24, K25, K26, K 27 17-Aug-1992 | |||||

| 3. Amended map 8/31/2006 | |||||

Table 4-2 Summary of Owned Fee Land Holdings T30N R47E (Lander County 2018)

| APN | Section | Legal Description | Royalty | Acres |

| 007-090-03 | 1 | NW4SW4SW4 | N/A | 10 |

| 007-070-09 | 5 | NE4NW4/NW4SE4NW4 | N/A | 55.8 |

| 007-070-13 | 5 | LOT 4 | N/A | 46 |

| 007-070-18 | 5 | S2SW4NW4 | N/A | 20 |

| 007-110-01 | 9 | NW4 | N/A | 160 |

| 007-110-10 | 9 | W2NW4SW4 | N/A | 20 |

| 007-110-13 | 9 | E2NE4NE4/SE4NE4/SE4SW4NE4 | N/A | 70 |

| 007-110-22 | 9 | NE4SE4SW4 | N/A | 10 |