Attached files

| file | filename |

|---|---|

| 8-K - 8-K - C&J Energy Services, Inc. | d485443d8k.htm |

1 Exhibit 99.1

Important Disclaimer This presentation contains certain statements and information that may constitute “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. All statements, other than statements of historical fact, that address activities, events or developments that we expect, believe or anticipate will or may occur in the future are forward-looking statements. The words “anticipate,” “believe,” “ensure,” “expect,” “if,” “once” “intend,” “plan,” “estimate,” “project,” “forecasts,” “predict,” “outlook,” “aim,” “will,” “could,” “should,” “potential,” “would,” “may,” “probable,” “likely,” and similar expressions that convey the uncertainty of future events or outcomes, and the negative thereof, are intended to identify forward-looking statements. Forward-looking statements contained in this presentation, which are not generally historical in nature, include those that express a belief, expectation or intention regarding our future activities, plans and goals and our current expectations with respect to, among other things: our ability to successfully integrate O-Tex’s business with our own; our operating cash flows, the availability of capital and our liquidity; our future revenue, income and operating performance; our ability to sustain and improve our utilization, revenue and margins; our ability to maintain acceptable pricing for our services; future capital expenditures; our ability to finance equipment, working capital and capital expenditures; our ability to execute our long-term growth strategy; our ability to successfully develop our research and technology capabilities and implement technological developments and enhancements; and the timing and success of strategic initiatives and special projects. Forward-looking statements are not assurances of future performance and actual results could differ materially from our historical experience and our present expectations or projections. These forward-looking statements are based on management’s current expectations and beliefs, forecasts for our existing operations, experience, expectations and perception of historical trends, current conditions, anticipated future developments and their effect on us, and other factors believed to be appropriate. Although management believes the expectations and assumptions reflected in these forward-looking statements are reasonable as and when made, no assurance can be given that these assumptions are accurate or that any of these expectations will be achieved (in full or at all). Our forward-looking statements involve significant risks, contingencies and uncertainties, most of which are difficult to predict and many of which are beyond our control. Known material factors that could cause actual results to differ materially from those in the forward-looking statements include, but are not limited to, risks associated with the following: the ultimate timing, outcome and results of integrating O-Tex’s business into our business and our ability to realize the anticipated benefits; a decline in demand for our services, including due to declining commodity prices, overcapacity and other competitive factors affecting our industry; the cyclical nature and volatility of the oil and gas industry, which impacts the level of exploration, production and development activity and spending patterns by E&P companies; a decline in, or substantial volatility of, crude oil and gas commodity prices, which generally leads to decreased spending by our customers and negatively impacts drilling, completion and production activity; pressure on pricing for our core services, including due to competition and industry and/or economic conditions, which may impact, among other things, our ability to implement price increases or maintain pricing on our core services; the loss of, or interruption or delay in operations by, one or more significant customers; the failure to pay amounts when due, or at all, by one or more significant customers; changes in customer requirements in markets or industries we serve; costs, delays, regulatory compliance requirements and other difficulties in executing our long-term growth strategy, including those related to; the effects of future acquisitions on our business, including our ability to successfully integrate our operations and the costs incurred in doing so; business growth outpacing the capabilities of our infrastructure; adverse weather conditions in oil or gas producing regions; the effect of environmental and other governmental regulations on our operations, including the risk that future changes in the regulation of hydraulic fracturing could reduce or eliminate demand for our hydraulic fracturing services; the incurrence of significant costs and liabilities resulting from litigation; the incurrence of significant costs and liabilities resulting from our failure to comply, or our compliance with, new or existing environmental regulations or an accidental release of hazardous substances into the environment; the loss of, or inability to attract, key management personnel; a shortage of qualified workers; the loss of, or interruption or delay in operations by, one or more of our key suppliers; operating hazards inherent in our industry, including the significant possibility of accidents resulting in personal injury or death, property damage or environmental damage; accidental damage to or malfunction of equipment; uncertainty regarding our ability to improve our operating structure, financial results and profitability and to maintain relationships with suppliers, customers, employees and other third parties following emergence from bankruptcy and other risks and uncertainties related to our emergence from bankruptcy; our ability to maintain sufficient liquidity and/or obtain adequate financing to allow us to execute our business plan; and our ability to comply with covenants under our new credit facility. For additional information regarding known material factors that could affect our operating results and performance, please see our most recently filed Annual Report on Form 10-K, subsequent Quarterly Reports on Form 10-Q, and recent Current Reports on Form 8-K, which are available at the SEC’s website, http://www.sec.gov. Should one or more of these known material risks occur, or should the underlying assumptions change or prove incorrect, our actual results, performance, achievements or plans could differ materially from those expressed or implied in any forward-looking statement. Readers are cautioned not to place undue reliance on forward-looking statements, which speak only as of the date hereof. All subsequent written or oral forward-looking statements concerning us are expressly qualified in their entirety by the cautionary statements above. We undertake no obligation to publicly update or revise any forward-looking statements after the date they are made, whether as a result of new information, future events or otherwise, except as required by law. All information in this presentation is as of September 30, 2017 unless otherwise indicated. Non-GAAP Financial Measures: This presentation includes Adjusted EBITDA, a measure not calculated in accordance with generally accepted accounting principles in the U.S. ("U.S. GAAP"). Please see slide 19 for a reconciliation of net income (loss), the nearest measure calculated in accordance with U.S. GAAP, or pro forma net income (loss) prepared and presented in accordance with Article 11 of Regulation S-X, to Adjusted EBITDA. 2

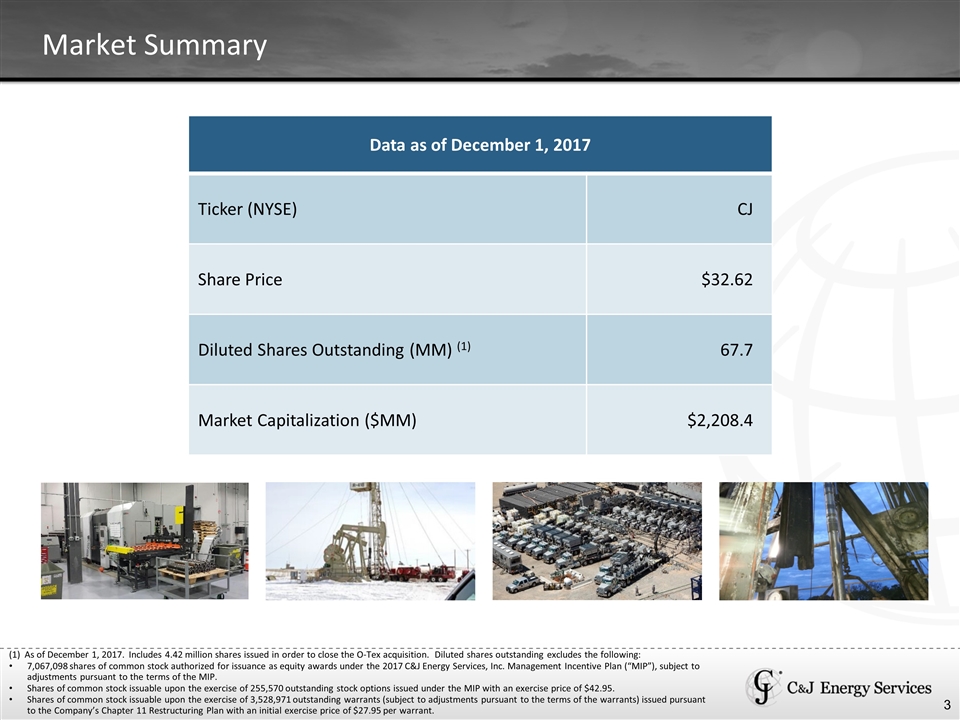

Market Summary 3 Data as of December 1, 2017 Ticker (NYSE) CJ Share Price $32.62 Diluted Shares Outstanding (MM) (1) 67.7 Market Capitalization ($MM) $2,208.4 (1) As of December 1, 2017. Includes 4.42 million shares issued in order to close the O-Tex acquisition. Diluted shares outstanding excludes the following: 7,067,098 shares of common stock authorized for issuance as equity awards under the 2017 C&J Energy Services, Inc. Management Incentive Plan (“MIP”), subject to adjustments pursuant to the terms of the MIP. Shares of common stock issuable upon the exercise of 255,570 outstanding stock options issued under the MIP with an exercise price of $42.95. Shares of common stock issuable upon the exercise of 3,528,971 outstanding warrants (subject to adjustments pursuant to the terms of the warrants) issued pursuant to the Company’s Chapter 11 Restructuring Plan with an initial exercise price of $27.95 per warrant.

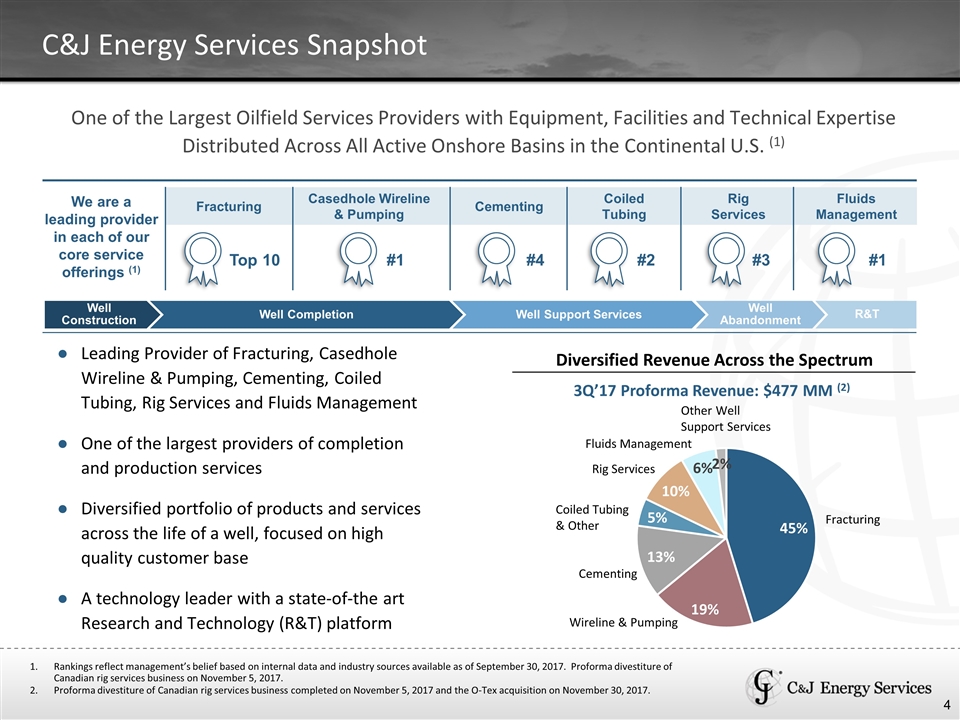

C&J Energy Services Snapshot One of the Largest Oilfield Services Providers with Equipment, Facilities and Technical Expertise Distributed Across All Active Onshore Basins in the Continental U.S. (1) Key Differentiators We are a leading provider in each of our core service offerings (1) Fracturing Casedhole Wireline & Pumping Coiled Tubing Rig Services Fluids Management Top 10 #1 #2 #3 #1 Well Construction Well Completion Well Support Services Well Abandonment Leading Provider of Fracturing, Casedhole Wireline & Pumping, Cementing, Coiled Tubing, Rig Services and Fluids Management One of the largest providers of completion and production services Diversified portfolio of products and services across the life of a well, focused on high quality customer base A technology leader with a state-of-the art Research and Technology (R&T) platform Diversified Revenue Across the Spectrum Fracturing Other Well Support Services Coiled Tubing & Other Fluids Management Wireline & Pumping Cementing Rig Services 3Q’17 Proforma Revenue: $477 MM (2) Rankings reflect management’s belief based on internal data and industry sources available as of September 30, 2017. Proforma divestiture of Canadian rig services business on November 5, 2017. Proforma divestiture of Canadian rig services business completed on November 5, 2017 and the O-Tex acquisition on November 30, 2017. R&T 7 Cementing #4

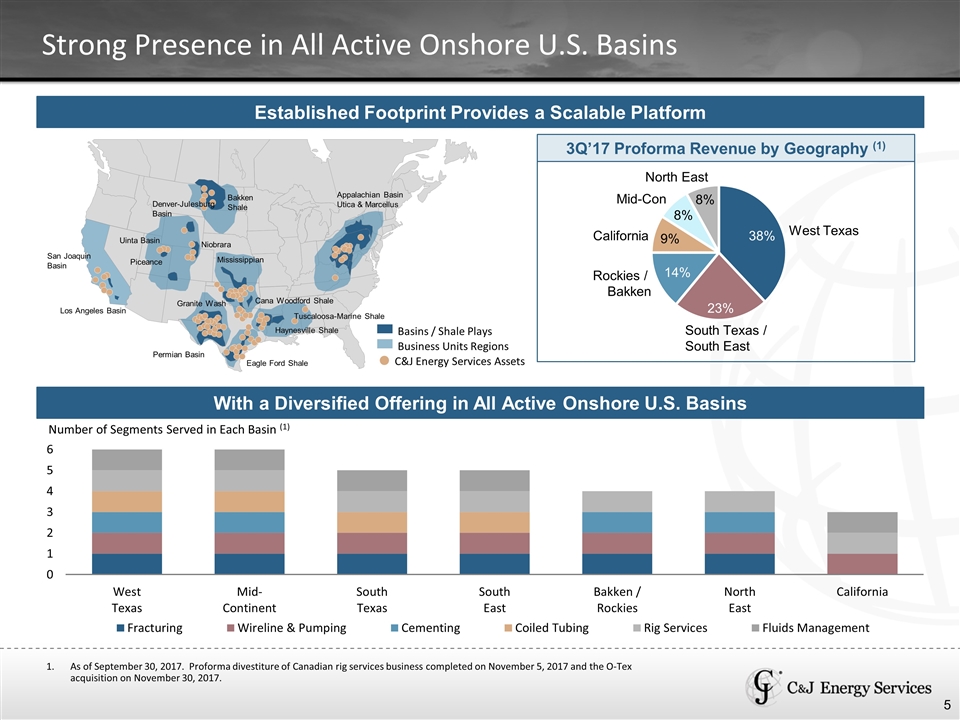

Strong Presence in All Active Onshore U.S. Basins Tuscaloosa-Marine Shale Haynesville Shale Eagle Ford Shale Cana Woodford Shale Permian Basin Granite Wash Mississippian Niobrara Los Angeles Basin San Joaquin Basin Piceance Uinta Basin Denver-Julesburg Basin Bakken Shale Appalachian Basin Utica & Marcellus Basins / Shale Plays Business Units Regions C&J Energy Services Assets West Texas South Texas / South East North East Rockies / Bakken California Mid-Con Number of Segments Served in Each Basin (1) Established Footprint Provides a Scalable Platform With a Diversified Offering in All Active Onshore U.S. Basins 3Q’17 Proforma Revenue by Geography (1) 8 As of September 30, 2017. Proforma divestiture of Canadian rig services business completed on November 5, 2017 and the O-Tex acquisition on November 30, 2017.

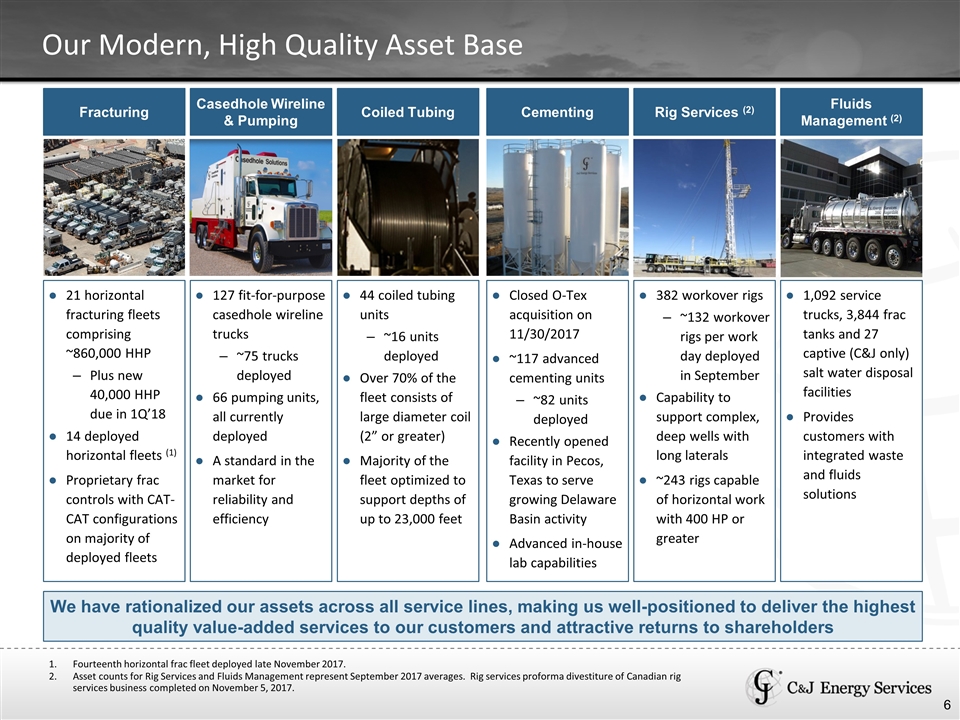

Our Modern, High Quality Asset Base We have rationalized our assets across all service lines, making us well-positioned to deliver the highest quality value-added services to our customers and attractive returns to shareholders Fracturing Casedhole Wireline & Pumping Cementing Rig Services (2) Fluids Management (2) Coiled Tubing 21 horizontal fracturing fleets comprising ~860,000 HHP Plus new 40,000 HHP due in 1Q’18 14 deployed horizontal fleets (1) Proprietary frac controls with CAT-CAT configurations on majority of deployed fleets 127 fit-for-purpose casedhole wireline trucks ~75 trucks deployed 66 pumping units, all currently deployed A standard in the market for reliability and efficiency Closed O-Tex acquisition on 11/30/2017 ~117 advanced cementing units ~82 units deployed Recently opened facility in Pecos, Texas to serve growing Delaware Basin activity Advanced in-house lab capabilities 382 workover rigs ~132 workover rigs per work day deployed in September Capability to support complex, deep wells with long laterals ~243 rigs capable of horizontal work with 400 HP or greater 1,092 service trucks, 3,844 frac tanks and 27 captive (C&J only) salt water disposal facilities Provides customers with integrated waste and fluids solutions 44 coiled tubing units ~16 units deployed Over 70% of the fleet consists of large diameter coil (2” or greater) Majority of the fleet optimized to support depths of up to 23,000 feet 9 Fourteenth horizontal frac fleet deployed late November 2017. Asset counts for Rig Services and Fluids Management represent September 2017 averages. Rig services proforma divestiture of Canadian rig services business completed on November 5, 2017.

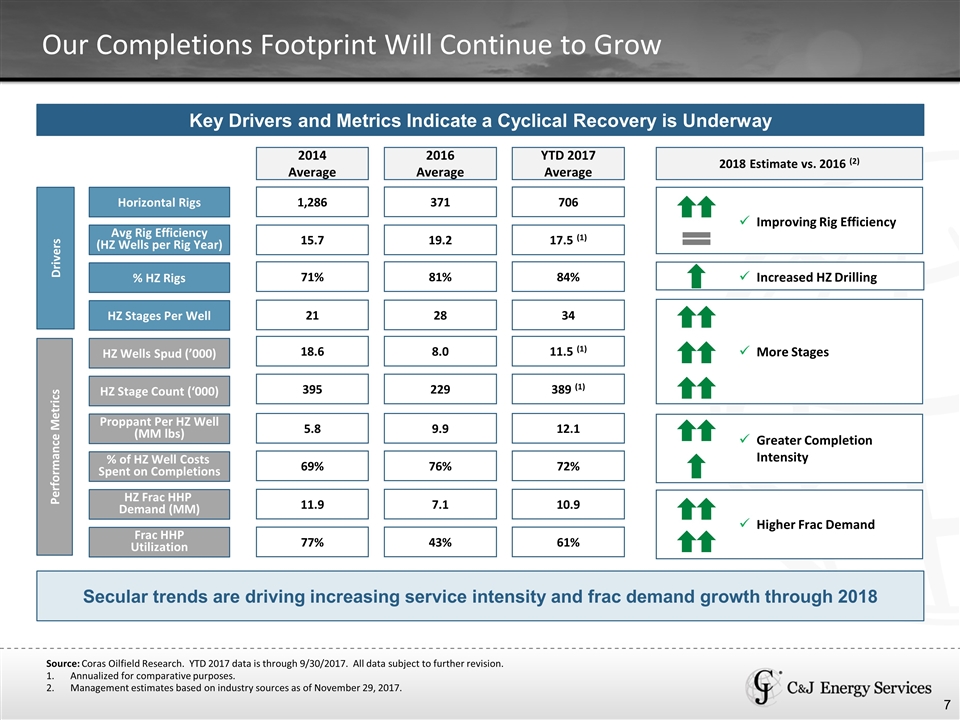

Our Completions Footprint Will Continue to Grow Horizontal Rigs % HZ Rigs Avg Rig Efficiency (HZ Wells per Rig Year) HZ Wells Spud (’000) HZ Stage Count (‘000) HZ Stages Per Well HZ Frac HHP Demand (MM) 2014 Average 2016 Average 2018 Estimate vs. 2016 (2) 371 1,286 81% 71% 19.2 15.7 8.0 18.6 229 395 28 21 7.1 11.9 Frac HHP Utilization 43% 77% Drivers Performance Metrics Improving Rig Efficiency Higher Frac Demand % of HZ Well Costs Spent on Completions 76% 69% Greater Completion Intensity More Stages Increased HZ Drilling Secular trends are driving increasing service intensity and frac demand growth through 2018 Source: Coras Oilfield Research. YTD 2017 data is through 9/30/2017. All data subject to further revision. Annualized for comparative purposes. Management estimates based on industry sources as of November 29, 2017. Key Drivers and Metrics Indicate a Cyclical Recovery is Underway Proppant Per HZ Well (MM lbs) 9.9 5.8 11 YTD 2017 Average 706 84% 17.5 (1) 11.5 (1) 389 (1) 34 10.9 61% 72% 12.1

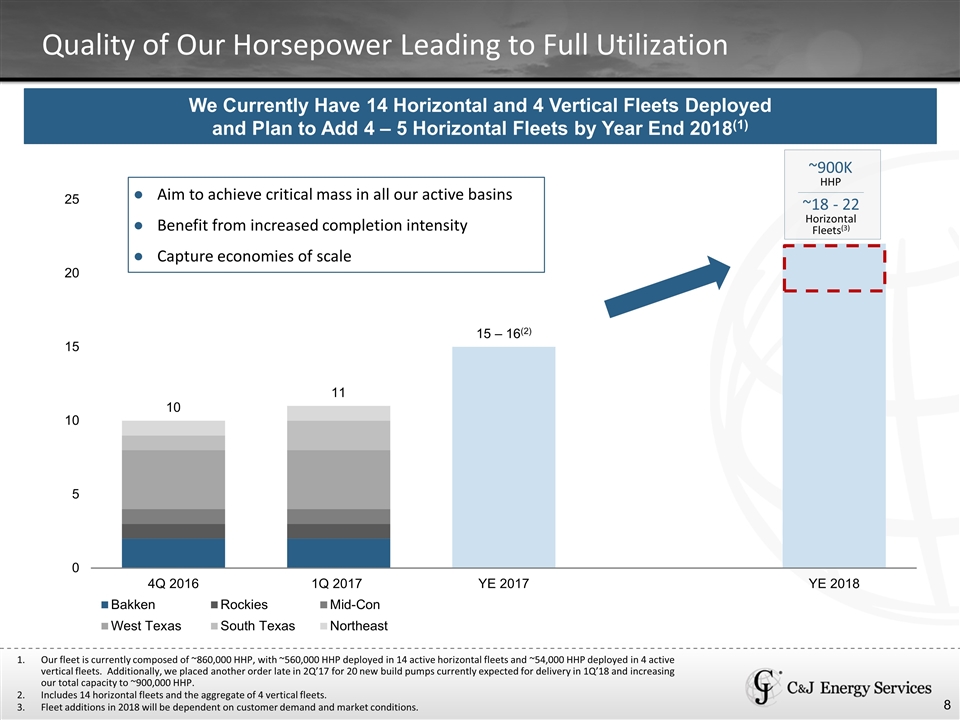

Quality of Our Horsepower Leading to Full Utilization We Currently Have 14 Horizontal and 4 Vertical Fleets Deployed and Plan to Add 4 – 5 Horizontal Fleets by Year End 2018(1) 12 ~900K HHP ~18 - 22 Horizontal Fleets(3) Aim to achieve critical mass in all our active basins Benefit from increased completion intensity Capture economies of scale Our fleet is currently composed of ~860,000 HHP, with ~560,000 HHP deployed in 14 active horizontal fleets and ~54,000 HHP deployed in 4 active vertical fleets. Additionally, we placed another order late in 2Q’17 for 20 new build pumps currently expected for delivery in 1Q’18 and increasing our total capacity to ~900,000 HHP. Includes 14 horizontal fleets and the aggregate of 4 vertical fleets. Fleet additions in 2018 will be dependent on customer demand and market conditions.

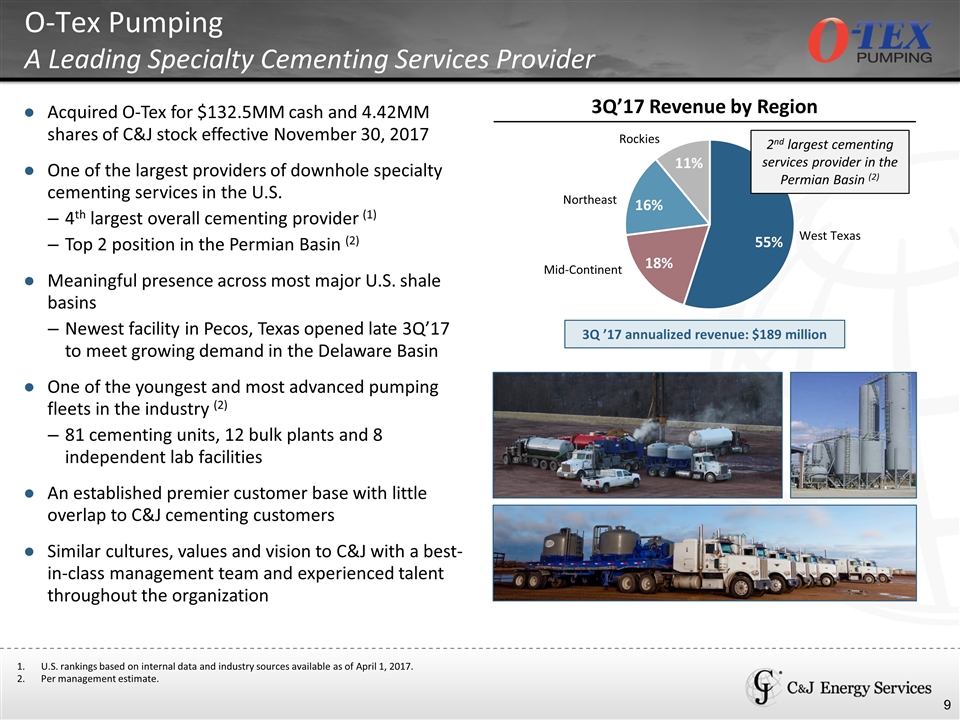

O-Tex Pumping A Leading Specialty Cementing Services Provider Acquired O-Tex for $132.5MM cash and 4.42MM shares of C&J stock effective November 30, 2017 One of the largest providers of downhole specialty cementing services in the U.S. 4th largest overall cementing provider (1) Top 2 position in the Permian Basin (2) Meaningful presence across most major U.S. shale basins Newest facility in Pecos, Texas opened late 3Q’17 to meet growing demand in the Delaware Basin One of the youngest and most advanced pumping fleets in the industry (2) 81 cementing units, 12 bulk plants and 8 independent lab facilities An established premier customer base with little overlap to C&J cementing customers Similar cultures, values and vision to C&J with a best-in-class management team and experienced talent throughout the organization 3Q’17 Revenue by Region U.S. rankings based on internal data and industry sources available as of April 1, 2017. Per management estimate. West Texas Mid-Continent Northeast Rockies 2nd largest cementing services provider in the Permian Basin 3Q ’17 annualized revenue: $189 million

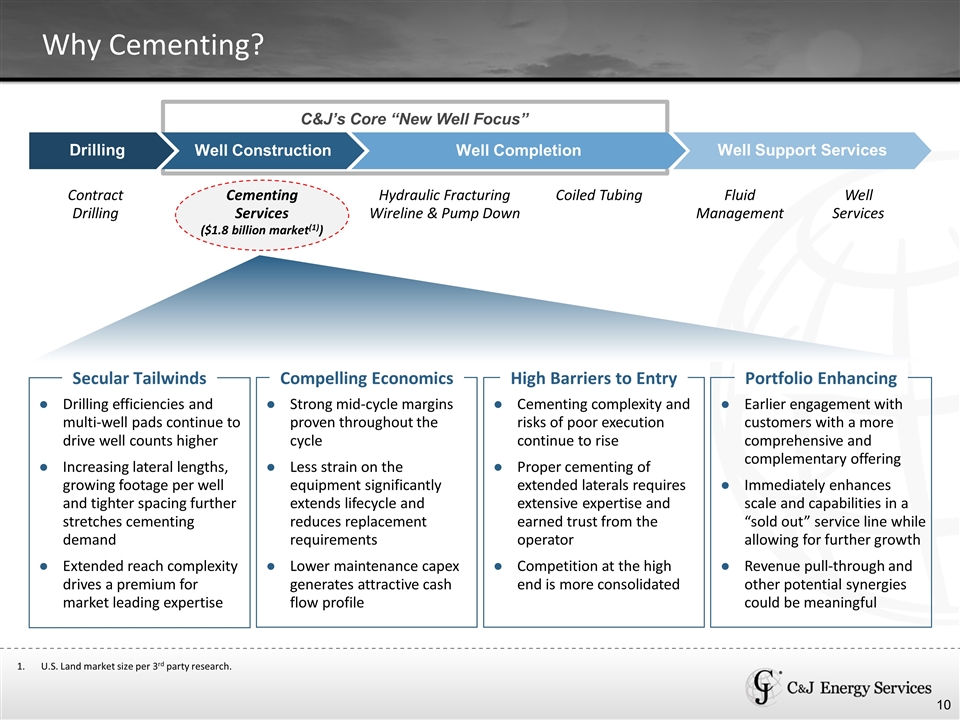

Drilling C&J’s Core “New Well Focus” Why Cementing? Well Completion Well Support Services Contract Drilling Cementing Services ($1.8 billion market(1)) Hydraulic Fracturing Wireline & Pump Down Coiled Tubing Fluid Management Well Services U.S. Land market size per 3rd party research. Secular Tailwinds Compelling Economics High Barriers to Entry Portfolio Enhancing Drilling efficiencies and multi-well pads continue to drive well counts higher Increasing lateral lengths, growing footage per well and tighter spacing further stretches cementing demand Extended reach complexity drives a premium for market leading expertise Strong mid-cycle margins proven throughout the cycle Less strain on the equipment significantly extends lifecycle and reduces replacement requirements Lower maintenance capex generates attractive cash flow profile Cementing complexity and risks of poor execution continue to rise Proper cementing of extended laterals requires extensive expertise and earned trust from the operator Competition at the high end is more consolidated Earlier engagement with customers with a more comprehensive and complementary offering Immediately enhances scale and capabilities in a “sold out” service line while allowing for further growth Revenue pull-through and other potential synergies could be meaningful Drilling Drilling Well Construction

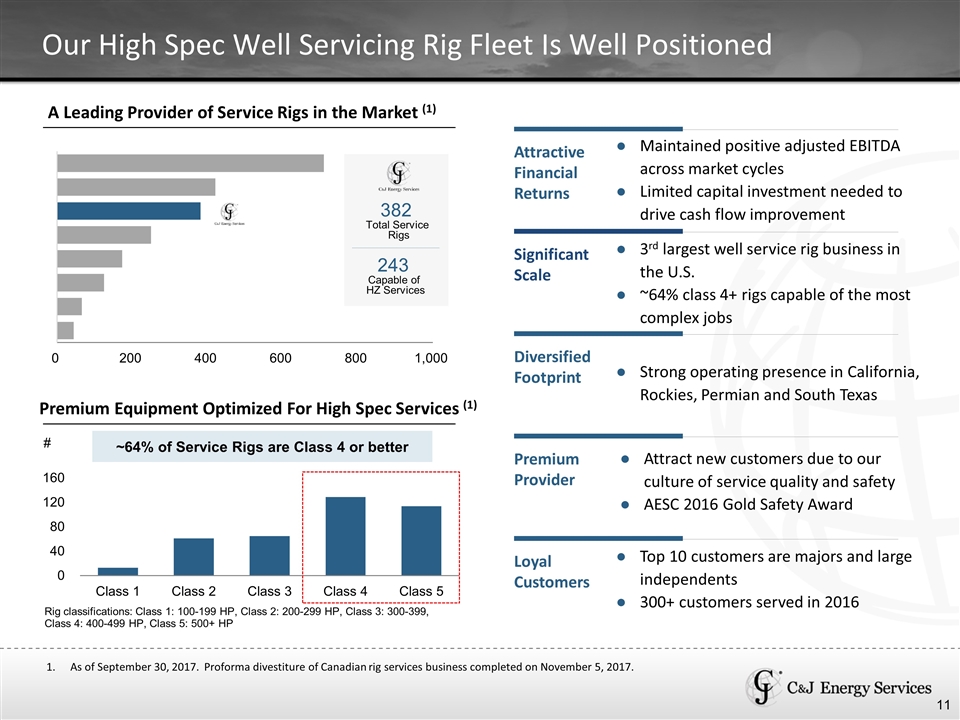

A Leading Provider of Service Rigs in the Market (1) Rig classifications: Class 1: 100-199 HP, Class 2: 200-299 HP, Class 3: 300-399, Class 4: 400-499 HP, Class 5: 500+ HP Our High Spec Well Servicing Rig Fleet Is Well Positioned Premium Equipment Optimized For High Spec Services (1) # ~64% of Service Rigs are Class 4 or better 382 Total Service Rigs 243 Capable of HZ Services 3rd largest well service rig business in the U.S. ~64% class 4+ rigs capable of the most complex jobs Top 10 customers are majors and large independents 300+ customers served in 2016 Strong operating presence in California, Rockies, Permian and South Texas Attract new customers due to our culture of service quality and safety AESC 2016 Gold Safety Award Significant Scale Diversified Footprint Premium Provider Loyal Customers Maintained positive adjusted EBITDA across market cycles Limited capital investment needed to drive cash flow improvement Attractive Financial Returns 14 As of September 30, 2017. Proforma divestiture of Canadian rig services business completed on November 5, 2017.

Long-Term Relationships with High Quality Customers Why Customers Choose C&J? Customers Value Our… Ability to deliver integrated services through our multi-product suite Footprint supports operators with premium acreage in the most active basins Our Relationships Have Spanned the Cycle Our customer base has proven to be reliable through market and company changes Differentiated capabilities and management focus enabled customer retention through financial restructuring successfully completed on January 6, 2017 Diverse customer base - no individual exposure greater than 10% of 2016 revenue Logos from next few pages Core Customers with Deep Ties to C&J Energy Services Diversified service offering and life-of-well capabilities Geographic footprint & scale Reputation for safety & service quality Value-added technology 15

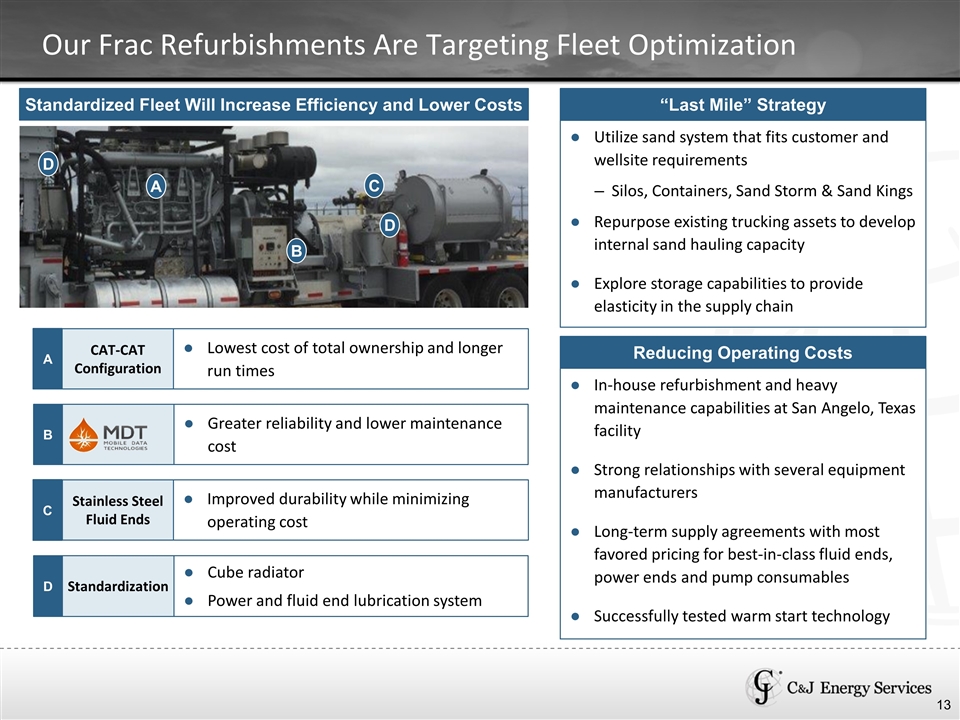

Our Frac Refurbishments Are Targeting Fleet Optimization Standardized Fleet Will Increase Efficiency and Lower Costs B C A D CAT-CAT Configuration A Lowest cost of total ownership and longer run times Standardization D Cube radiator Power and fluid end lubrication system Stainless Steel Fluid Ends C Improved durability while minimizing operating cost Greater reliability and lower maintenance cost B 17 “Last Mile” Strategy Reducing Operating Costs In-house refurbishment and heavy maintenance capabilities at San Angelo, Texas facility Strong relationships with several equipment manufacturers Long-term supply agreements with most favored pricing for best-in-class fluid ends, power ends and pump consumables Successfully tested warm start technology Utilize sand system that fits customer and wellsite requirements Silos, Containers, Sand Storm & Sand Kings Repurpose existing trucking assets to develop internal sand hauling capacity Explore storage capabilities to provide elasticity in the supply chain D

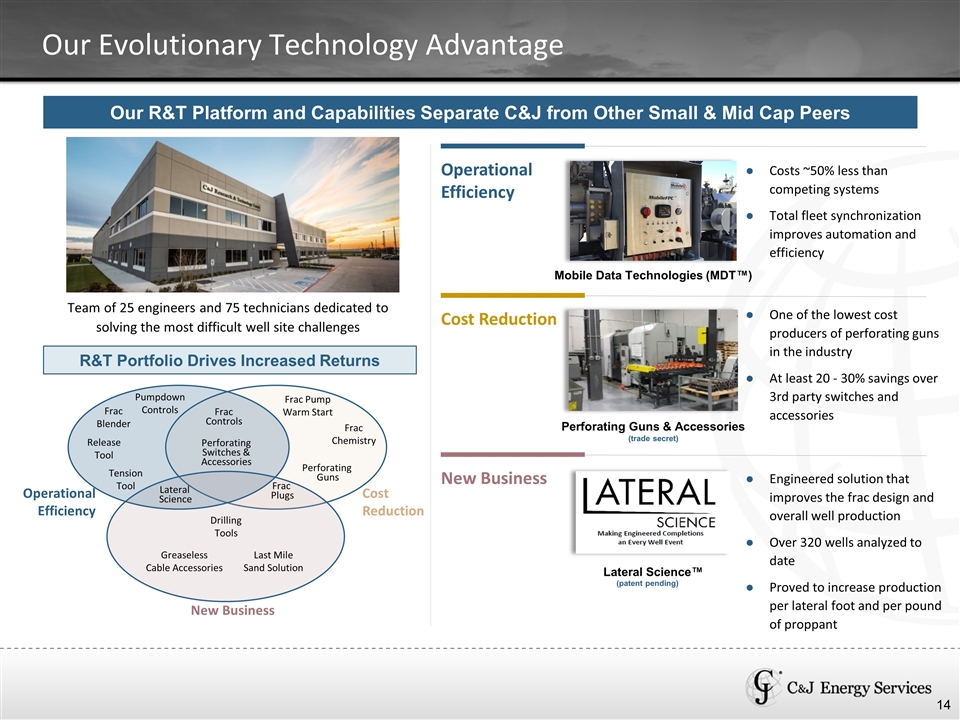

Our Evolutionary Technology Advantage Our R&T Platform and Capabilities Separate C&J from Other Small & Mid Cap Peers Team of 25 engineers and 75 technicians dedicated to solving the most difficult well site challenges R&T Portfolio Drives Increased Returns Perforating Guns Tension Tool Perforating Switches & Accessories Greaseless Cable Accessories Frac Plugs Frac Controls Frac Chemistry Drilling Tools Last Mile Sand Solution Lateral Science Operational Efficiency Cost Reduction New Business Frac Pump Warm Start Pumpdown Controls Release Tool Operational Efficiency New Business Perforating Guns & Accessories Mobile Data Technologies (MDT™) Cost Reduction Lateral Science™ One of the lowest cost producers of perforating guns in the industry At least 20 - 30% savings over 3rd party switches and accessories Engineered solution that improves the frac design and overall well production Over 320 wells analyzed to date Proved to increase production per lateral foot and per pound of proppant Costs ~50% less than competing systems Total fleet synchronization improves automation and efficiency (trade secret) (patent pending) 19 Frac Blender

Financial Review Section 2: 21

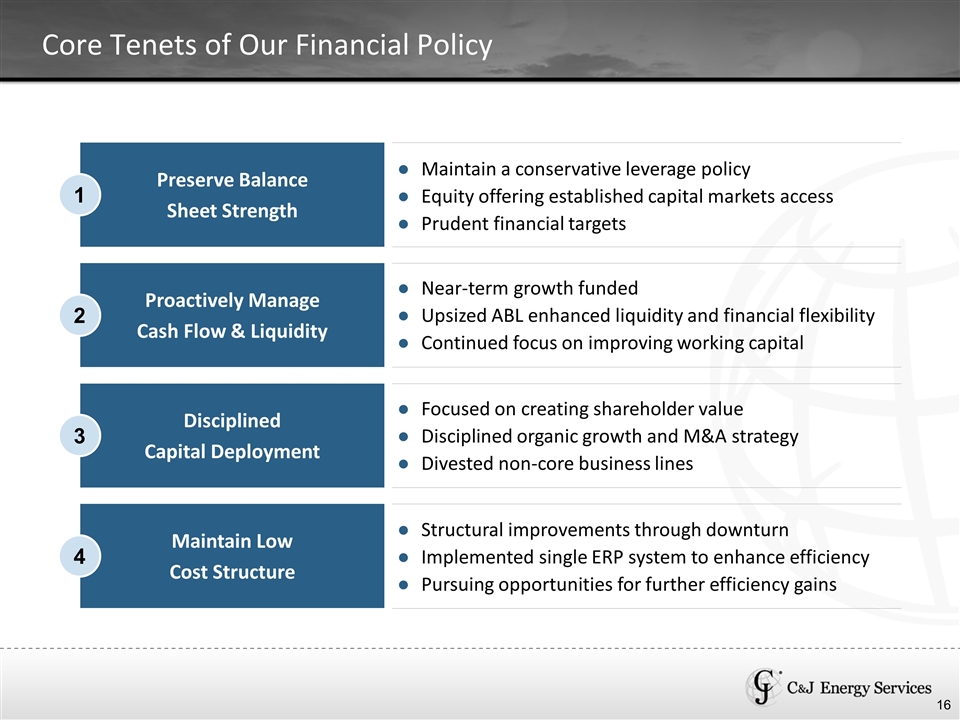

Core Tenets of Our Financial Policy Maintain a conservative leverage policy Equity offering established capital markets access Prudent financial targets Preserve Balance Sheet Strength 1 Near-term growth funded Upsized ABL enhanced liquidity and financial flexibility Continued focus on improving working capital Proactively Manage Cash Flow & Liquidity 2 Focused on creating shareholder value Disciplined organic growth and M&A strategy Divested non-core business lines Disciplined Capital Deployment 3 Structural improvements through downturn Implemented single ERP system to enhance efficiency Pursuing opportunities for further efficiency gains Maintain Low Cost Structure 4 22

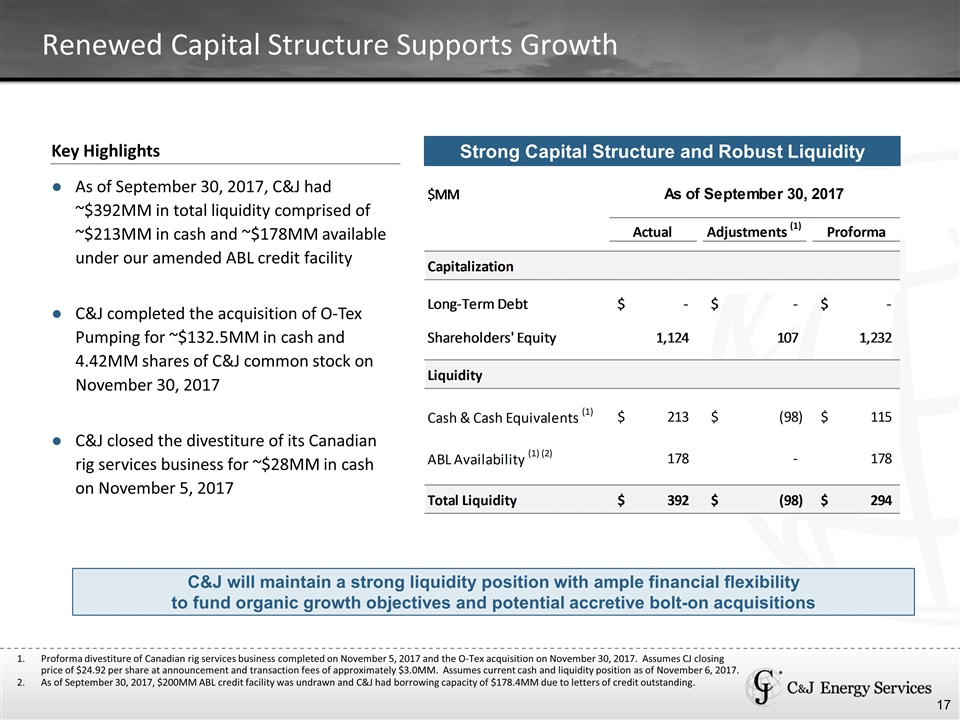

Renewed Capital Structure Supports Growth Proforma divestiture of Canadian rig services business completed on November 5, 2017 and the O-Tex acquisition on November 30, 2017. Assumes CJ closing price of $24.92 per share at announcement and transaction fees of approximately $3.0MM. Assumes current cash and liquidity position as of November 6, 2017. As of September 30, 2017, $200MM ABL credit facility was undrawn and C&J had borrowing capacity of $178.4MM due to letters of credit outstanding. Key Highlights As of September 30, 2017, C&J had ~$392MM in total liquidity comprised of ~$213MM in cash and ~$178MM available under our amended ABL credit facility C&J completed the acquisition of O-Tex Pumping for ~$132.5MM in cash and 4.42MM shares of C&J common stock on November 30, 2017 C&J closed the divestiture of its Canadian rig services business for ~$28MM in cash on November 5, 2017 Strong Capital Structure and Robust Liquidity C&J will maintain a strong liquidity position with ample financial flexibility to fund organic growth objectives and potential accretive bolt-on acquisitions 24 IPO Proceeds 216 $MM As of December 31, 2016 Actual As Adjusted As Further Adjusted Debt Summary Revolving Credit Facility 284.39999999999998 0 0 Five-Year Term Loans 569.25 0 0 Seven-Year Term Loans 480.15 0 0 Debtor-In-Possession Facility 25 0 0 New Credit Facility 0 0 0 Total Debt 1,358 0 0 Liquidity Offering Proceeds 0 0 216 Total Cash 64.582999999999998 175.864 391.86400000000003 ABL Availability (1) 75 65 65 Total Liquidity 139.583 240.864 456.86400000000003 $MM As of September 30, 2017 $MM As of June 30, 2017 Actual Adjustments (1) Proforma Actual Capitalization Capitalization Long-Term Debt $0 $0 $0 Long-Term Debt $0 Shareholders' Equity 1,124.354 107.1464 1,231.5004000000001 Shareholders' Equity 1,112.1289999999999 Liquidity Liquidity Cash & Cash Equivalents (1) $213.124 $-97.823999999999998 $115.3 Cash & Cash Equivalents $252.755 ABL Availability (1) (2) 178.4 0 178.4 ABL Availability (1) 173.4 Total Liquidity $391.524 $-97.823999999999998 $293.7 Total Liquidity $426.15499999999997 $117.124 $1.8239999999999981

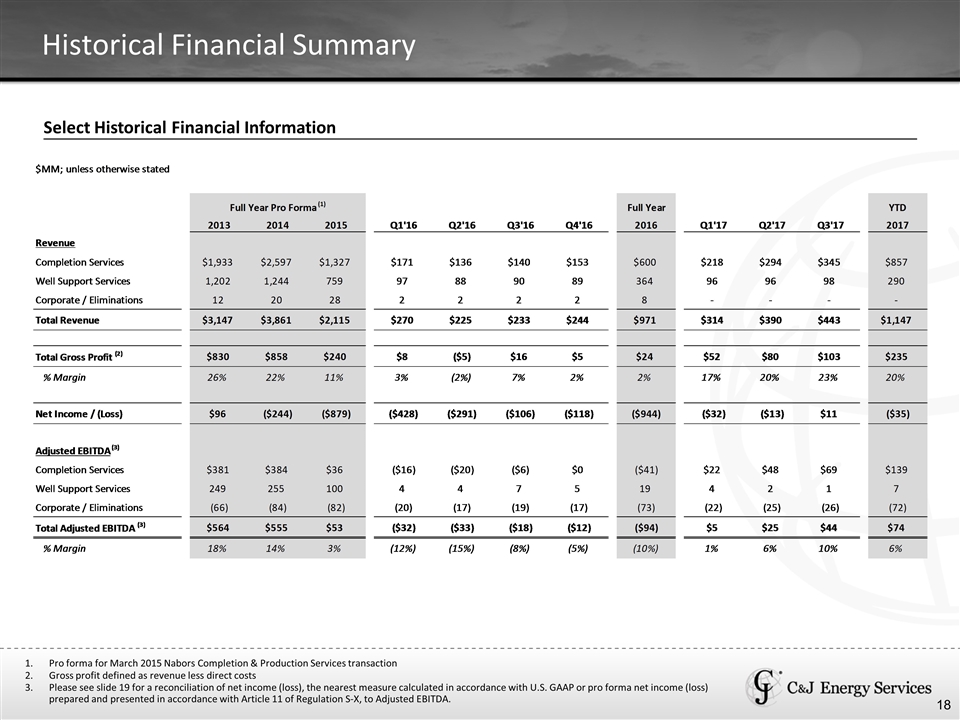

Select Historical Financial Information Historical Financial Summary Pro forma for March 2015 Nabors Completion & Production Services transaction Gross profit defined as revenue less direct costs Please see slide 19 for a reconciliation of net income (loss), the nearest measure calculated in accordance with U.S. GAAP or pro forma net income (loss) prepared and presented in accordance with Article 11 of Regulation S-X, to Adjusted EBITDA. 27 $MM; unless otherwise stated Full Year Pro Forma (1) Full Year YTD 2013 2014 2015 Q1'16 Q2'16 Q3'16 Q4'16 2016 Q1'17 Q2'17 Q3'17 2017 Revenue Completion Services $1,933 $2,597.2102642702171 $1,327.4525147212692 $170.82652248015899 $135.57920742807499 $140.19143702338698 $153.18962048338304 $599.78678741500403 $217.92784690999997 $294.14689596000011 $344.94099999999997 $857.01574287000017 Well Support Services 1,202 1,244.6364575 758.99199700000008 96.952209269999997 87.731653659999992 90.307253650000007 88.77661968000001 363.76773625999999 96.26639385999998 95.996097429999992 97.710999999999999 289.97349128999997 Corporate / Eliminations 12 19.555376120000002 28.225684140000002 1.8365355300000012 1.8570875800000002 2.0380250799999997 1.85548409 7.5871322800000014 0 0 0 0 Total Revenue $3,147 $3,860.8292861402169 $2,114.6701958612689 $269.61526728015895 $225.16794866807501 $232.536715753387 $243.82172425338305 $971.14165595500401 $314.19424076999996 $390.14299339000013 $442.65199999999999 $1,146.9892341600003 Total Gross Profit (2) $830 $858 $240.21864848437193 $7.8493657894470381 $-4.6025614340270407 $15.695862630024902 $4.9438364959150203 $23.886503481359917 $52.450665999999998 $79.670700371925236 $102.672 $234.79336637192523 % Margin 0.26374324753733713 0.22223204819754347 0.1135962709241925 #DIV/0! 2.9113209606526889E-2 -2.044057096603823E-2 6.7498427416816581E-2 2.0276439726828091E-2 2.4596312324663222E-2 0.16693707011133768 0.20420897394480109 0.23194744404182066 0.20470407165057361 Net Income / (Loss) $96.242999999999995 $-,244.18299999999999 $-,879.23099999999999 $-,428.41199999999998 $-,291.11599999999999 $-,106.39 $-,118.371 $-,944.28899999999999 $-32.301000000000002 $-12.720557524603878 $10.5 $-34.521557524603878 Adjusted EBITDA (3) Completion Services $381 $383.91362275465013 $35.87813510048651 $-15.587417381828001 $-19.769047781761014 $-6.0821450211929831 $0.41965746563501621 $-41.018952719146981 $22.479417179886727 $47.719581265396123 $69.010999999999996 $139.20999844528285 Well Support Services 249 254.725123406797 99.771926278551405 3.8384218699999924 4.1522434799999992 6.821339219999996 4.6514792600000012 19.463483829999991 3.8236692900000002 1.9276514699999965 0.78400000000000003 6.5353207599999967 Corporate / Eliminations -66 -83.732395343237002 -82.471886221806997 -20.103776932796013 -17.422541982949959 -18.647053534777999 -16.641065259786981 -72.814437710310955 -21.719420749999983 -24.53702006 -25.896999999999998 -72.153440809999978 Total Adjusted EBITDA (3) $564 $554.90635081821006 $53.17817515723091 $-31.852772444624023 $-33.039346284710973 $-17.907859335970986 $-11.569928534151963 $-94.369906599457948 $4.5836657198867456 $25.110212675396117 $43.898000000000003 $73.591878395282862 % Margin 0.17921830314585319 0.14372724347337462 2.5147266586207476E-2 -0.11814157546028579 -0.14673201261612501 -7.7010889561899859E-2 -4.7452410442837843E-2 -9.7174192890177494E-2 1.4588636980275309E-2 6.4361562557385468E-2 9.9170454442767689E-2 6.4160914683020556E-2 Other Services (BRT, TES, MENA): Reported in Corp/Elims in 2016 Revenue 1.8365355300000012 1.8570875800000002 2.0380250799999997 1.85548376 $7.5871319500000016 $0 Adjusted EBITDA -1.8846303827959996 -1.1995239229499977 -2.1478110447779994 -1.193695349785999 $-6.4256607003099955 $0 Reported in Completion Services in 2017 Revenue 1.384164039999999 0 0 Adjusted EBITDA -0.83359461429497972 -1.7418201104221362 -1.7418201104221362 Other Services -13.05530388 -25.054586980292001 -17.474716728331007 -1.8846303827959996 -1.1995239229499977 -2.1478110447779994 -1.193695349785999 $-6.4256607003099955 $0 Corporate -50.651680559999996 -58.677808362945008 -64.997169493475994 -18.219146550000012 -16.695018059999956 -16.499242489999997 -15.447369910000983 $-66.860777010000959 $0 -63.706984439999999 -83.732395343237016 -82.471886221806997 -20.103776932796013 -17.894541982949953 -18.647053534777996 -16.641065259786981 $-73.286437710310949 $0

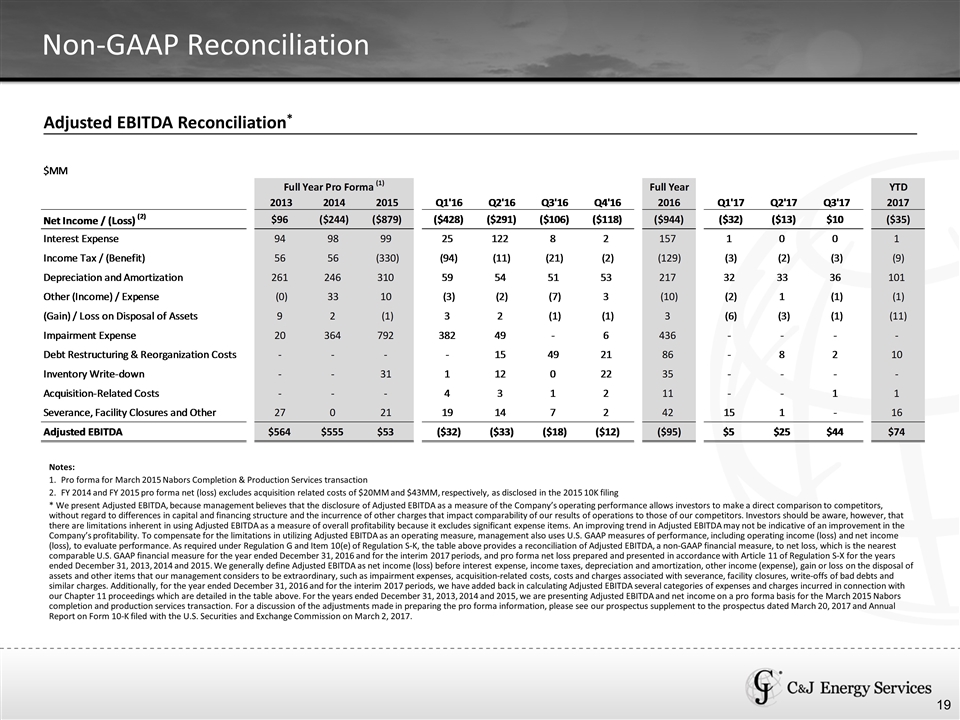

Adjusted EBITDA Reconciliation* Non-GAAP Reconciliation Notes: Pro forma for March 2015 Nabors Completion & Production Services transaction FY 2014 and FY 2015 pro forma net (loss) excludes acquisition related costs of $20MM and $43MM, respectively, as disclosed in the 2015 10K filing * We present Adjusted EBITDA, because management believes that the disclosure of Adjusted EBITDA as a measure of the Company’s operating performance allows investors to make a direct comparison to competitors, without regard to differences in capital and financing structure and the incurrence of other charges that impact comparability of our results of operations to those of our competitors. Investors should be aware, however, that there are limitations inherent in using Adjusted EBITDA as a measure of overall profitability because it excludes significant expense items. An improving trend in Adjusted EBITDA may not be indicative of an improvement in the Company’s profitability. To compensate for the limitations in utilizing Adjusted EBITDA as an operating measure, management also uses U.S. GAAP measures of performance, including operating income (loss) and net income (loss), to evaluate performance. As required under Regulation G and Item 10(e) of Regulation S-K, the table above provides a reconciliation of Adjusted EBITDA, a non-GAAP financial measure, to net loss, which is the nearest comparable U.S. GAAP financial measure for the year ended December 31, 2016 and for the interim 2017 periods, and pro forma net loss prepared and presented in accordance with Article 11 of Regulation S-X for the years ended December 31, 2013, 2014 and 2015. We generally define Adjusted EBITDA as net income (loss) before interest expense, income taxes, depreciation and amortization, other income (expense), gain or loss on the disposal of assets and other items that our management considers to be extraordinary, such as impairment expenses, acquisition-related costs, costs and charges associated with severance, facility closures, write-offs of bad debts and similar charges. Additionally, for the year ended December 31, 2016 and for the interim 2017 periods, we have added back in calculating Adjusted EBITDA several categories of expenses and charges incurred in connection with our Chapter 11 proceedings which are detailed in the table above. For the years ended December 31, 2013, 2014 and 2015, we are presenting Adjusted EBITDA and net income on a pro forma basis for the March 2015 Nabors completion and production services transaction. For a discussion of the adjustments made in preparing the pro forma information, please see our prospectus supplement to the prospectus dated March 20, 2017 and Annual Report on Form 10-K filed with the U.S. Securities and Exchange Commission on March 2, 2017. 28 $MM Full Year Pro Forma (1) Full Year YTD 2013 2014 2015 Q1'16 Q2'16 Q3'16 Q4'16 2016 Q1'17 Q2'17 Q3'17 2017 Net Income / (Loss) (2) $96.242999999999995 $-,244.18299999999999 $-,879.23099999999999 $-,428.41199999999998 $-,291.11599999999999 $-,106.39 $-,118.371 $-,944.28899999999999 $-32.301000000000002 $-12.721 $10.484 $-34.538000000000004 Interest Expense 94.334000000000003 98.49 99.05 25.466999999999999 121.934 8.1579999999999995 1.9059999999999999 157.465 0.69099999999999995 0.41399999999999998 0.17100000000000001 1.276 Income Tax / (Benefit) 56.055999999999997 56.045000000000002 -,330.7799999999997 -94.147000000000006 -11.252000000000001 -21.123000000000001 -2.488 -,129.1000000000002 -3.2360000000000002 -2.3929999999999998 -3.1269999999999998 -8.7560000000000002 Depreciation and Amortization 260.81400000000002 245.80600000000001 310.31299999999999 58.953000000000003 54.283000000000001 51.320999999999998 52.883000000000003 217.44000000000003 31.606000000000002 32.832999999999998 36.271000000000001 100.71 Other (Income) / Expense -5.2999999999999999E-2 32.5 10 -3.319 -2.0030000000000001 -7.0750000000000002 2.8929999999999998 -9.5040000000000013 -1.5620000000000001 1.456 -1.1160000000000001 -1.2220000000000002 (Gain) / Loss on Disposal of Assets 9.1289999999999996 2.37 -0.5 3.202 1.712 -0.69399999999999995 -1.145 3.0749999999999997 -6.056 -3.1360000000000001 -1.3240000000000001 -10.516 Impairment Expense 20 363.57799999999997 791.80700000000002 381.69400000000002 48.712000000000003 0 5.9889999999999999 436.39499999999998 0 0 0 0 Debt Restructuring & Reorganization Costs 0 0 0 0 15.451000000000001 49.137 21.143000000000001 85.730999999999995 0 7.8529999999999998 1.661 9.5139999999999993 Inventory Write-down 0 0 31.109000000000002 1.2669999999999999 11.78 0.35199999999999998 21.951000000000001 35.35 0 0 0 0 Acquisition-Related Costs 0 0 0 3.6890000000000001 3.379 1.4810000000000001 1.9850000000000001 10.533999999999999 0 0 0.879 0.879 Severance, Facility Closures and Other 27.157 0.3 20.5 19.469000000000001 13.895999999999999 6.9250000000000007 1.681 41.971000000000004 15.442 0.80400000000000005 0 16.245999999999999 Adjusted EBITDA $563.68000000000006 $554.90599999999995 $52.969999999999992 $-32.137000000000008 $-33.22399999999999 $-17.908000000000008 $-11.57299999999999 $-94.841999999999899 $4.5839999999999979 $25.109999999999996 $43.899000000000001 $73.592999999999989

The Differentiated U.S. Oilfield Services Company Leading Provider of Products and Services Across the Life of a Well Strong Footprint in All Active Onshore Basins in the Continental U.S. Modern, High-Quality Asset Base and Streamlined Cost Structure Robust Logistics Network Ensures Efficient Operations for Our Customers Long-Term, Established Relationships with Blue-Chip Customer Base Unique Research & Technology Platform Focused on Improving Margins and Assuring Supply Capitalized for Growth – No Leverage and Significant Liquidity Experienced Management Team with Deep Operational Expertise Recognized Leader in Quality, Safety and Reliability Through A Talented Employee Base 1 2 3 4 5 6 7 9 8 30