Attached files

| file | filename |

|---|---|

| EX-99.1 - EXHIBIT 99.1 - AK STEEL HOLDING CORP | exhibit991to7517finalinvesto.pdf |

| 8-K - 8-K - AK STEEL HOLDING CORP | form8-kinvestorpresentatio.htm |

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Strategic Acquisition

Precision Partners Holding Company

July 5, 2017

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Forward-Looking Statements

2July 2017

We have made forward-looking statements in this presentation that are based on our management’s beliefs and assumptions and on information available to our management at the time such

statements were made and hereby are identified as “forward-looking statements” for purposes of the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. Forward-looking

statements include information concerning our possible or assumed future results of operations, business strategies, financing plans, competitive position, potential growth opportunities, potential

operating performance improvements, the effects of competition and the effects of future legislation or regulations. Forward-looking statements include all statements that are not historical facts and

can be identified by the use of forward-looking terminology such as the words “believe,” “expect,” “plan,” “intend,” “anticipate,” “estimate,” “predict,” “potential,” “continue,” “may,” “should” or the

negative of these terms or similar expressions.

Actual results may differ materially from those expressed in our forward-looking statements. You should not rely on any forward-looking statements. Forward-looking statements are only predictions and

involve risks and uncertainties, resulting in the possibility that actual events or performance will differ materially from such predictions as a result of certain risk factors, including that our acquisition of

Precision Partners may not be consummated, or may not be consummated in a timely manner; that regulatory approval not be obtained or may only be obtained subject to conditions that are not

anticipated; that we will not integrate Precision Partners successfully following the consummation of the acquisition; and that growth initiatives, cost savings, synergies, accretion to earnings and other

anticipated benefits and opportunities from the acquisition may not be fully realized or may take longer to realize than expected.

In addition, factors that could cause our actual results and financial condition and any benefits from the acquisition, if consummated, to differ materially from the results contemplated by such forward-

looking statements include: reduced selling prices, shipments and profits associated with a highly competitive and cyclical industry; domestic and global steel overcapacity; changes in the cost of raw

materials and energy; our significant amount of debt and other obligations; severe financial hardship or bankruptcy of one or more of our major customers or key suppliers; our significant proportion of

sales to the automotive market; reduced demand in key product markets due to competition from aluminum and other alternatives to steel; excess inventory of raw materials; supply chain disruptions or

poor quality of raw materials; production disruption or reduced production levels; our healthcare obligations; our pension obligations; not reaching new labor agreements on a timely basis; major

litigation, arbitrations, environmental issues and other contingencies; regulatory compliance and changes; climate change and greenhouse gas emission limitations; conditions in the financial, credit,

capital and banking markets; our use of derivative contracts to hedge commodity pricing volatility; potential permanent idling of facilities; inability to fully realize benefits of margin enhancement

initiatives; and information technology security threats and cybercrime.

The risk factors discussed under “Item 1A.—Risk Factors” in AK Holding’s Annual Report on Form 10-K for the year ended December 31, 2016 and under similar headings in AK Holding’s subsequently

filed quarterly reports on Form 10-Q could cause our results to differ materially from those expressed in forward-looking statements. There may be other risks and uncertainties that we are unable to

predict at this time or that we currently do not expect to have a material adverse effect on our business. We expressly disclaim any obligation to update our forward-looking statements other than as

required by law.

Non-GAAP financial measures included in this presentation are certain non-GAAP financial measures designed to complement the financial information presented in accordance with generally accepted

accounting principles in the United States of America because management believes such measures are useful to investors. Because our calculations of these measures may differ from similar measures

used by other companies, you should be careful when comparing our non-GAAP financial measures to those of other companies. A reconciliation of non-GAAP financial measures to GAAP financial

measures is included in an Appendix to this presentation.

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

AK Steel to Acquire Precision Partners Holding Company (“PPHC”)

3July 2017

Snapshot of PPHC

Leading North American engineering, tooling and hot and cold stamping provider of lightweight

parts for the transportation market

Specialist in lightweight, complex, hard-to-manufacture components and assemblies

Acquisition Benefits

Further advances our core focus on product innovation, including in the high-growth automotive

lightweighting space, and enhances our position in advanced high strength steels

Provides a fully integrated downstream platform that further strengthens our close collaboration

with our automotive OEM customers and Tier 1 suppliers

Strong synergies that leverage our materials and metals-forming expertise with PPHC’s

technology and advanced capabilities in tooling and stamping

Adds a proven, experienced management team, providing the foundation for seamless

integration and future growth in lightweighting solutions for automotive and other markets

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

PPHC Overview

4July 2017

Founded in 1955

Eight facilities in North America with a total of more than 1,000

employees, including ~300 engineers and skilled tool makers

Specializes in the design and engineering of tooling and die

making and the stamping of complex automotive components

Broad portfolio of highly-engineered solutions

Technology-focused company

‒ Unique intellectual property and extensive track record of

innovation

‒ Focus on complex, difficult-to-manufacture parts

‒ Results-oriented culture with a proven track record of

providing customer solutions

Full range of manufacturing

capabilities including:

‒ Advanced tool design

technology

‒ 5 hot stamping cells with

9 lines

‒ 85 cold stamping

presses, including 17

“tryout” presses

‒ 123 welding and

assembly cells

‒ 6 laser-cutting machines

‒ E-coating line

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Strategic Logic – Downstream Platform Serving Our Core Market

5July 2017

Creates a premier integrated supplier to the automotive market combining AK Steel’s advanced

materials expertise with PPHC’s leading die design, tool manufacturing and stamping capabilities

Enhances our product offerings with end-to-end solutions and further strengthens our close

collaboration with our automotive OEM and Tier 1 customers

Leverages both AK Steel’s and PPHC’s research and innovation capabilities in both the materials and

metals-forming areas to accelerate our development and innovation efforts in the high growth

automotive lightweighting space

Accelerates introduction of advanced high strength steels and facilitates innovation in fast-growing

hot stamping market

Creates a differentiated, innovative leader in the steel industry

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Terms of the Transaction and Financial Benefits

6July 2017

$360 million in cash, ~7x 2017E Adjusted EBITDA

Acquisition is on a cash-free, debt-free basis

Expected to be accretive to EPS, margins and cash flow in year one

Attractive growth profile with reasonable capital outlays

Currently anticipate permanent financing will include a prudent combination of debt and equity

targeted to maintain current credit metrics

Closing expected in the third quarter of 2017, subject to completion of customary regulatory review

and closing conditions

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Business Capabilities Complement AK Steel

7July 2017

Full-service solution provider, from steel production to designing dies to stamping final parts

Differentiated in-house tooling and product engineering capabilities cater to complex hot and cold

stamped parts

Integrated with extensive tooling capabilities to serve internal stamping requirements as well as

serving OEM and Tier 1 customers

Comprehensive portfolio provides solid platform to serve lightweighting needs of OEMs and Tier 1

suppliers

Serves OEMs directly, as well as through Tier 1 suppliers

Strategically focused on transportation market, including light truck, SUV and CUV platforms

Supplier for 13 of the 15 best-selling vehicle platforms in the U.S.

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Differentiated Business Model

8July 2017

Attractive strategic positionCompetitive attributes

Critical direct supplier to both OEM and Tier 1

customers

Entrenched customer relationships across diverse

platforms

Strategically located, highly efficient and scalable

operating footprint

Favorable industry dynamics driving light-

weighting and safety

Expansive, highly engineered product portfolio

Top-tier, vertically integrated manufacturing

operations

Engineering and tooling expertise drives

operational excellence

Unique hot stamping process capabilities

Proven management team with broad

organizational capabilities

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

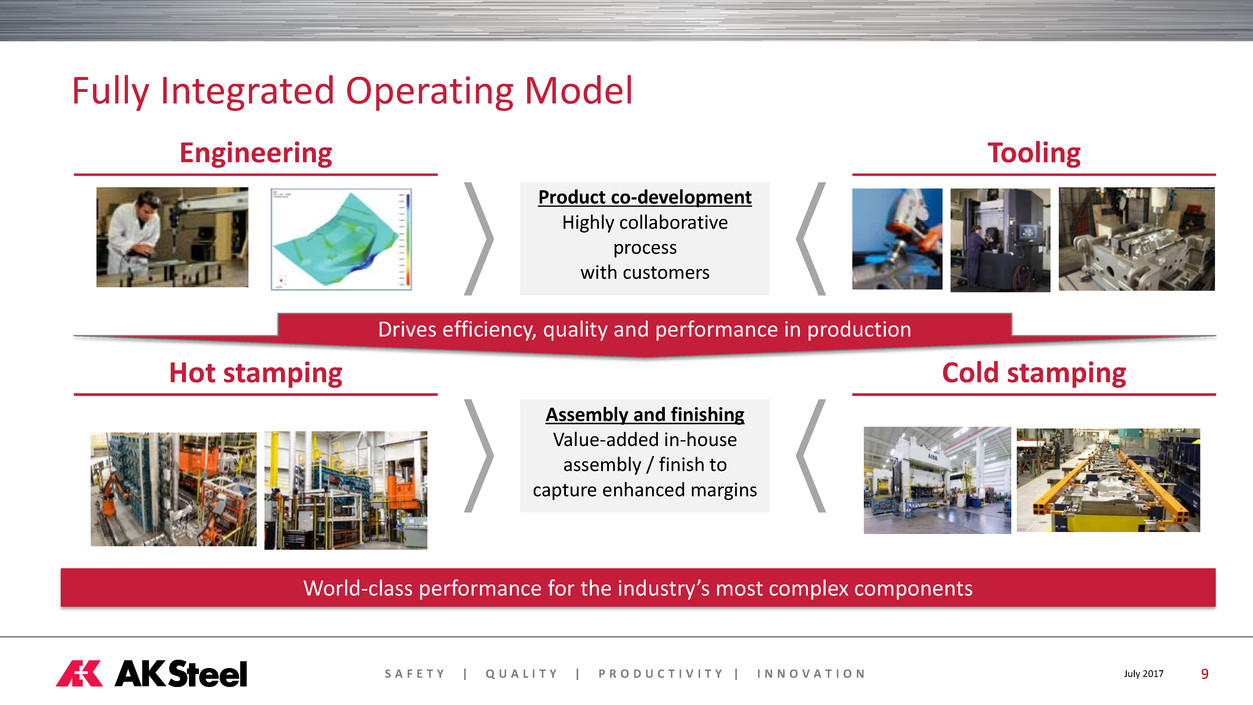

Fully Integrated Operating Model

9July 2017

Hot stamping Cold stamping

Engineering Tooling

Product co-development

Highly collaborative

process

with customers

Assembly and finishing

Value-added in-house

assembly / finish to

capture enhanced margins

Drives efficiency, quality and performance in production

World-class performance for the industry’s most complex components

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Engineering and Tooling Expertise

10July 2017

Simulation software utilized to

validate product designs and

production processes

Expedites development and

production of highly complex parts

Predictive Engineering 17 Die and Stamping Tryout Presses

Strong Technical Foundation Emergency production supportTooling Heritage

Specialists in simplifying complexity

~300 engineers and skilled tool

makers

Automated CNC Tool Machining

Drives efficiency, quality and production performance

High-speed, fully automated

machining capabilities

Increases overall productivity and

efficiency of tool production

Long track record of tool and die

design and manufacturing

Tooling expertise materially

enhances hot stamping production

Tryout presses offer customers

product validation without

disruption to their own production

24-hour production takeover

capabilities

Go-to source for solving the most

challenging die and stamping problems

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Overview of Cold Stamping and Hot Stamping Processes

11July 2017

Hot Stamping Process OverviewCold Stamping Process Overview

Furnace

Single step stamping

Final product

Blank

Progressive step stamping

1

Final product

2 3

Blank

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Cold Stamping – Efficient Production of Complex, High-Strength Components

12July 2017

Provides extensive capability in the production of stamped components

Focused on complex cold stamp components

Leverages advanced tooling capabilities to optimize manufacturing processes

2,000-ton and 3,000-ton large-bed presses enables PPHC to manufacture

components using the strongest and most advanced high strength steels

Cold stamping capabilities complement hot stamping excellence, facilitating

supply of complete lightweighting solutions

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Hot Stamping – Making the Most Complex Components Stronger and Lighter

13July 2017

Hot stamping can produce the most complex components while delivering

significant mass reduction and material strength

‒ Allows advanced high strength steels to be formed into complex

geometries

‒ 30–50% weight savings achievable versus cold stamping mild steels

Hot stamped solutions often reduce the number of total components and

finishing operations

‒ Further reduces weight

‒ Increases overall component strength

Unique hot stamping process capabilities provide a sustainable advantage

to serve our customers

‒ Lower capital requirements, lower operating costs, smaller footprint,

highly automated, increased throughput

‒ Supports large-scale components

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Precision Partners Provides a Platform to Expand Lightweighting Solutions

14July 2017

Expand

geographies

Incremental

services at existing

AK Steel sites

Diversify customer

solutions

Expand customer

collaboration

Expand materials

offering

Accelerate

innovative steel

solutions

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N 15July 2017

PPHC Represents Another Step in Executing our Strategy

Investing resources in higher-value products

− Positioning with customers that align with our “best value” approach

− Minimizing exposure to commoditized products and markets where quality is less valued

Implementing margin enhancement actions

− Dedicating capacity to more profitable products

− Relentless focus on cost and process improvements

Accelerating investment in research and innovation

− Working hand-in-hand with our customers and technical partners

− Substantial expansion and investments in research and innovation

Focusing on downstream, value-added products

− Advances our product innovations in the high growth automotive lightweighting space

− Expand into complementary and synergistic steel processes and products

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N July 2017

Questions & Answers

16

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

Investor Contact Information

17July 2017

Douglas O. Mitterholzer

Assistant Treasurer and

General Manager, Investor Relations

(513) 425-5215

doug.mitterholzer@aksteel.com

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N

THANK YOU!

July 2017 18