Attached files

| file | filename |

|---|---|

| EX-32.2 - EXHIBIT 32.2 - Jason Industries, Inc. | ex-322x12312016.htm |

| EX-32.1 - EXHIBIT 32.1 - Jason Industries, Inc. | ex-321x12312016.htm |

| EX-31.2 - EXHIBIT 31.2 - Jason Industries, Inc. | ex-312x12312016.htm |

| EX-31.1 - EXHIBIT 31.1 - Jason Industries, Inc. | ex-311x12312016.htm |

| EX-23 - EXHIBIT 23 - Jason Industries, Inc. | ex-23x12312016.htm |

| EX-21 - EXHIBIT 21 - Jason Industries, Inc. | ex-21x12312016.htm |

| EX-12 - EXHIBIT 12 - Jason Industries, Inc. | ex-12x12312016.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

ý ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2016

¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

Commission File Number: 001-36051

JASON INDUSTRIES, INC.

(Exact name of registrant as specified in its charter

Delaware | 46-2888322 | |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification Number) | |

833 East Michigan Street Suite 900 Milwaukee, Wisconsin 53202 |

(Address of principal executive offices) |

(414) 277-9300 |

(Registrant’s telephone number, including area code) |

Securities registered pursuant to Section 12(b) of the Act: | ||

Common Stock, $0.0001 par value per share | The NASDAQ Stock Market LLC | |

Warrants to purchase Common Stock | The NASDAQ Stock Market LLC | |

(Title of class) | (Name of exchange on which registered) | |

Securities registered pursuant to Section 12(g) of the Act: None | ||

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Date File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer ¨ | Accelerated filer ý | |

Non-accelerated filer ¨ | Smaller reporting company ¨ | |

(Do not check if a smaller reporting company) | ||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No ý

The aggregate market value of the voting and non-voting stock held by non-affiliates of the registrant, as of July 1, 2016, the last business day of the registrant’s most recently completed second fiscal quarter, was approximately $65.5 million (based upon the closing price of $3.64 per share on The NASDAQ Stock Market as of such date). Solely for the purposes of this disclosure, shares of common stock held by executive officers and directors of the registrant as of such date have been excluded because such persons may be deemed to be affiliates. This determination of executive officers and directors as affiliates is not necessarily a conclusive determination for any other purposes.

There were 25,886,203 shares of common stock issued and outstanding as of February 23, 2017.

Documents Incorporated by Reference

Portions of the registrant’s definitive proxy statement relating to its 2017 Annual Meeting of Shareholders (the “2017 Proxy Statement”) are incorporated by reference into Part III of this Annual Report on Form 10-K. The 2017 Proxy Statement will be filed with the U.S. Securities and Exchange Commission within 120 days after the end of the fiscal year to which this report relates.

JASON INDUSTRIES, INC.

TABLE OF CONTENTS

1

Cautionary Note Regarding Forward-Looking Statements

Unless otherwise indicated, references to “Jason Industries,” the “Company,” “we,” “our” and “us” in this Annual Report on Form 10-K refer to Jason Industries, Inc. and its consolidated subsidiaries.

This report contains forward-looking statements within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1995. Specifically, forward-looking statements may include statements relating to the Company’s future financial performance, changes in the markets for the Company’s products, the Company’s expansion plans and opportunities, and other statements preceded by, followed by or that include the words “estimate,” “plan,” “project,” “forecast,” “intend,” “expect,” “anticipate,” “believe,” “seek,” “target” or similar expressions.

These forward-looking statements are based on information available to the Company as of the date of this report and current expectations, forecasts and assumptions, and involve a number of judgments, risks and uncertainties. Accordingly, forward-looking statements should not be relied upon as representing the Company’s views as of any subsequent date, and the Company does not undertake any obligation to update forward-looking statements to reflect events or circumstances after the date they were made, whether as a result of new information, future events or otherwise, except as may be required under applicable securities laws.

As a result of a number of known and unknown risks and uncertainties, the Company’s actual results or performance may be materially different from those expressed or implied by these forward-looking statements. Some factors that could cause actual results to differ include the following:

• | level of demand for the Company’s products; |

• | competition in the Company’s markets; |

• | the Company’s ability to grow and manage growth profitably; |

• | the Company’s ability to access additional capital; |

• | changes in applicable laws or regulations; |

• | the Company’s ability to attract and retain qualified personnel; |

• | the possibility that the Company may be adversely affected by other economic, business, and/or competitive factors; and |

• | other risks and uncertainties indicated in this report, including those discussed under “Risk Factors” in Item 1A of Part I of this report, as such may be amended or supplemented in Part II, Item 1A, “Risk Factors”, of the Company’s subsequently filed Quarterly Reports on Form 10-Q. |

Introductory Note

On June 30, 2014, the Company (formerly known as Quinpario Acquisition Corp.) and Jason Partners Holdings Inc. (“Jason”) completed a transaction in which JPHI Holdings Inc. (“JPHI”), a majority owned subsidiary of the Company, acquired 100 percent of the capital stock of Jason from its then current owners, Saw Mill Capital, LLC, Falcon Investment Advisors, LLC and other investors (the “Business Combination”). In connection with the closing of the Business Combination, the Company changed its name to Jason Industries, Inc., and commenced trading of its common stock and warrants under the symbols, “JASN” and “JASNW”, respectively, on The NASDAQ Stock Market. This transaction is further described in Note 2 to the Company’s consolidated financial statements included herein.

PART I

ITEM 1. BUSINESS

Corporate History

Jason Industries, a Delaware corporation, was originally formed in May 2013 as a blank check company under the name Quinpario Acquisition Corp. (“QPAC”) for the purpose of effecting a merger, capital stock exchange, asset acquisition, stock purchase, reorganization or similar business combination involving QPAC and one or more businesses. Until the consummation of the Business Combination, QPAC’s securities were traded on The NASDAQ Stock Market (“Nasdaq”) under the ticker symbols “QPAC,” “QPACU” and “QPACW.”

On June 30, 2014, the Company completed the Business Combination pursuant to a stock purchase agreement, dated as of March 16, 2014 (the “Purchase Agreement”), that provided for the acquisition of all of the capital stock of Jason, the indirect parent company of Jason Incorporated, by JPHI from Jason Partners Holdings LLC (“Seller”) and certain members of Seller. In connection with the Business Combination, the Company entered into new senior secured credit facilities with a syndicate of lenders led by Deutsche Bank AG New York Branch, as administrative agent, in the aggregate amount of approximately $460.0

2

million, which was primarily used to refinance Jason Incorporated’s existing indebtedness, pay transaction fees and expenses and pay a portion of the purchase price under the Purchase Agreement. The purchase price under the Purchase Agreement was also funded with cash held in our trust account, the contribution of Jason common stock to JPHI by certain members of Seller and certain directors and management of Jason Incorporated (collectively, the “Rollover Participants”) in exchange for JPHI stock, and the proceeds from the sale of our 8% Series A Convertible Perpetual Preferred Stock (the “Series A Preferred Stock”) in a private placement that closed simultaneously with the Business Combination.

Following the Business Combination, Jason Incorporated became an indirect majority-owned subsidiary of the Company and our only significant asset, with the Rollover Participants indirectly owning 16.9% of Jason Incorporated and the Company indirectly owning 83.1% of Jason Incorporated. We also changed our name from “Quinpario Acquisition Corp.” to “Jason Industries, Inc.” and continued the listing of our Common Stock and Warrants on Nasdaq under the symbols “JASN” and “JASNW,” respectively, effective July 1, 2014.

Through October 2016, the Rollover Participants owned 16.9% of Jason Incorporated. In November and December of 2016 and the first quarter of 2017, certain Rollover Participants exchanged their JPHI stock for Company common stock, which decreased the Rollover Participant’s ownership percentage in JPHI to 0% as of February 23, 2017.

Presentation of Financial and Operating Data

The Business Combination was accounted for using the acquisition method of accounting under the provisions of Accounting Standards Codification Topic 805, “Business Combinations.” Accordingly, we are treated as the legal and accounting acquirer and Jason is treated as the legal and accounting acquiree. However, Jason is considered to be our accounting predecessor, and therefore unless otherwise indicated, the financial information and operating data presented in this Annual Report on Form 10-K is that of Jason Partners Holdings Inc.

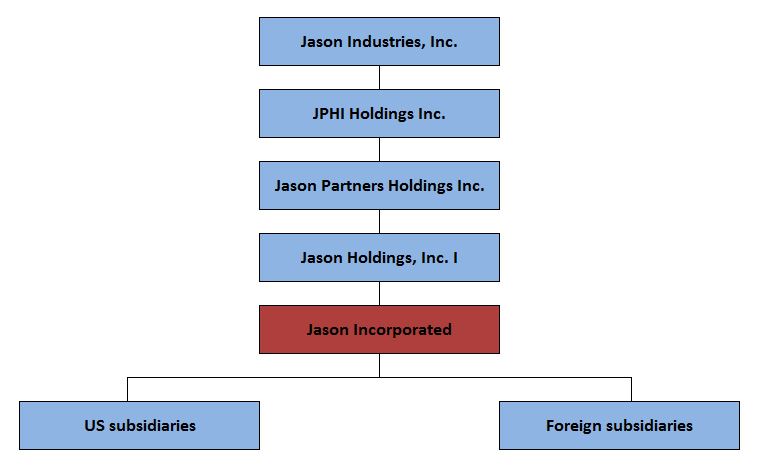

Organizational Chart

The following chart sets forth our organizational structure as of February 23, 2017:

Our Business

Jason Industries is a global industrial manufacturing company with significant market share positions in each of its four businesses: seating, finishing, acoustics and components. Jason Incorporated was founded in 1985 and today provides critical components and manufacturing solutions to customers across a wide range of end markets, industries and geographies through a global network of 34 manufacturing facilities and 14 sales offices, warehouses and joint venture facilities throughout the United States and 14 foreign countries. The Company has embedded relationships with long standing customers, superior scale and resources and specialized capabilities to design and manufacture specialized products on which our customers rely.

The Company focuses on markets with sustainable growth characteristics and where it is, or has the opportunity to become, the industry leader. The Company’s seating segment supplies seating solutions to equipment manufacturers in the motorcycle, lawn and turf care, industrial, agricultural, construction and power sports end markets. The finishing segment focuses on the production of industrial brushes, buffing wheels, buffing compounds, and abrasives that are used in a broad range of industrial and infrastructure applications. The acoustics segment manufactures engineered non-woven, fiber-based

3

acoustical products for the automotive industry. The components segment is a diversified manufacturer of expanded and perforated metal components and subassemblies for smart utility meters.

Jason Incorporated History

The formation of Jason Incorporated’s platform began in 1985 when it completed the buyout of three businesses, collectively generating $71.6 million of revenue, from AMCA International, a manufacturing conglomerate that served a variety of industries. The acquired businesses consisted of (i) Osborn Manufacturing, the largest manufacturer of industrial brushes in the United States; (ii) Janesville Products, the largest manufacturer of automotive acoustical fiber insulation in the United States; and (iii) Jackson Buff, the largest manufacturer of industrial buffs in the United States, each of which has a history spanning decades.

Description of Business Segments

Jason Industries’ global industrial platform encompasses a diverse group of industries, geographies and end markets. Through our four business segments, we deliver an array of industrial consumables and critical manufactured components to a number of industries, including industrial equipment, motorcycles, lawn and turf care, rail, automotive and smart meters. The highly fragmented nature of the Company’s end markets creates growth opportunities given our established global footprint and leading share positions. Our businesses serve multiple industries and can be categorized under four businesses: seating, finishing, acoustics and components.

Net sales are distributed amongst the four segments as follows:

Successor | Combined* | |||||||

Year ended December 31, | ||||||||

2016 | 2015 | 2014 | ||||||

Net sales | ||||||||

Seating | 22.8 | % | 25.0 | % | 24.5 | % | ||

Finishing | 27.9 | % | 27.0 | % | 26.7 | % | ||

Acoustics | 35.4 | % | 30.8 | % | 31.1 | % | ||

Components | 13.9 | % | 17.2 | % | 17.7 | % | ||

100.0 | % | 100.0 | % | 100.0 | % | |||

*We have combined our net sales in the period June 30, 2014 through December 31, 2014 with our predecessor’s net sales in the period January 1, 2014 through June 29, 2014. Net sales were not affected by acquisition accounting.

See more information regarding our segments and sales by geography within Part II, Item 8, Note 16 to the Consolidated Financial Statements.

Seating

Market/Industry Overview

The Company’s product line includes motorcycle seats; operator seats for the construction, agriculture, lawn and turf care and other industrial equipment markets; and seating for the power sports market. The market for seating products is dominated by several large domestic and international participants, who are often awarded contracts as the sole supplier for a particular motorcycle, riding lawn mower or other construction, agriculture or material handling platform. We believe that competition is based mostly on innovative styling, manufacturing flexibility, quality, prices and delivery.

Motorcycle production has experienced a decline in the past year, and we believe demand in the global motorcycle market will be flat to down modestly in 2017. Demand for lawn and turf care equipment is primarily dependent on weather and trends in personal consumption expenditures, recreational and leisure activities, and residential and commercial real estate construction and sales. The market for lawn and turf care equipment has remained relatively flat in the past year and we expect it to mirror general economic conditions.

Key Products

Through the seating business, which represented 22.8% of the Company’s 2016 revenue, the Company provides seating solutions for a variety of applications, including motorcycle, agricultural, construction, industrial, lawn and turf care, and power sports. The seating business was established in 1995 through the acquisition of Milsco Manufacturing Company, which has provided high-quality seats since 1934. The seating business operates under the Milsco brand, which was originally established as a harness maker in 1924 and, early in its history, gained notice as the first company to put padded seating on tractors and farm equipment.

4

The seating business offers a distinct vertically integrated operating model, which includes a full range of functions, such as research and development, design and engineering, manufacturing of components and final assembly. Through our broad manufacturing capabilities and high quality products, we have established longstanding relationships with our top customers, which average over 30 years.

Finishing

Market/Industry Overview

The Company’s product lines are comprised of industrial brushes, polishing buffs and compounds, and abrasives used primarily in the metalworking, welding and construction industries. The market for finishing products is highly fragmented with most participants having single or limited product lines and serving specific geographic markets. While the finishing business competes with numerous domestic and international companies across a variety of product lines, we do not believe that any one competitor directly competes with us on all of our product lines. We believe we are the only market participant that reaches all regions of the world. End users of finishing products are broadly diversified across many sectors of the economy. In the long-term, the finishing market is closely tied to overall growth in industrial production, which we believe has fundamental long-term growth potential.

The finishing market is also characterized by the need for sophisticated manufacturing equipment, the ability to produce a broad number of niche products and the flexibility in manufacturing operations to adapt to ever-changing customer demands and schedules. We believe entry into markets by competitors with lower labor costs, including foreign competitors, will be limited because labor is a relatively small portion of total manufacturing costs. The cost of labor, manufacturing, shipping and logistics is dramatically rising in countries such as China and customers continue to have increasing demand for shorter lead times and lower inventory and carrying costs.

Key Products

Through the finishing business, which represented 27.9% of the Company’s 2016 revenue, Jason Industries produces and supplies industrial brushes, buffing wheels and buffing compounds, and abrasives. We established the finishing business in 1985 by acquiring the business of Osborn Manufacturing, which has been in operation since 1889. Our products are used in a variety of applications with no single customer or industry accounting for a significant portion of business revenue. The Company has strategic facilities located globally, including labor-intensive production sites in low-cost locations such as China, Portugal, Romania, Mexico and Taiwan.

The finishing business is a one-stop provider of standard and customized brush, buffing wheel and buffing compound, and abrasives products used across multiple industries, including aerospace, engineering, plastic, finishing, building, leisure, steel, hardware, welding and naval, among others. Our broad product suite is composed of brush types used for a variety of applications, including power, maintenance, strip, punch, and roller brushes. These products are marketed under leading brand names that include Osborn®, Sealeze® and Dendix®. Our buff products are sold under the Jackson®, Lea®, JacksonLea®, Langsol® and Unipol® brands and are comprised of industrial buffs and abrasives used primarily to finish parts requiring a high degree of luster and/or a satin or textured surface. In addition to manufacturing buffs, the Company also produces the industry’s broadest product line of buffing compounds available in liquid or bar form that are customized to specific end use requirements. Our abrasives products are marketed under the DRONCO® and Osborn® brands and include bonded abrasives such as cutting and grinding wheels and flap discs, as well as diamond cutting wheels and tools. We also service customers with products complementing our brush, polishing, and abrasives lines, including heavy-duty idler rollers for high-capacity precision load handling sold under the Load Runners® brand.

The Company has representatives who reach more than 30,000 customers in approximately 130 countries worldwide. During 2016, the finishing segment derived approximately 61% of finishing sales from North America and the majority of the remaining revenue from Europe and South America. We service our diverse customer base through U.S. facilities in Ohio, Indiana, California and Virginia and 13 foreign countries, including joint ventures in China and Taiwan. Our manufacturing and service locations allow us to work on a regional and local basis with customers to develop custom products and provide significant technical support, resulting in strong relationships with our top customers that average 25 years. In addition, the Company has invested in state-of-the-art laboratories in Richmond, Indiana and Burgwald, Germany to provide further technical design capabilities for its North American and European customers.

Acoustics

Market/Industry Overview

The market for automotive acoustical products is dominated by several large domestic and international participants. These participants are often awarded contracts as the sole supplier for a particular automotive platform. Competition includes manufacturers of mechanically bonded non-woven products, resin-bonded products and urethane foam. Competition is based

5

on innovative styling, price, acoustical performance and weight. Engineering, design and innovation are key distinguishing factors because acoustical products represent a small percentage of the total cost to manufacture an automobile.

Growth in the automotive acoustics market is driven by increasing demand for enhanced acoustics and improved noise, vibration and harshness characteristics within the automotive market. As overall vehicle quality has improved, consumers have increasingly equated quality with the acoustic performance of a vehicle. As a result, car manufacturers have expended significant capital for sophisticated acoustical testing systems and laboratories. In addition, an increasing regulatory focus on reducing vehicle mass, increasing fuel-efficiency and stringent end of vehicle life recycling standards have driven the penetration of non-woven materials that are lighter than other acoustical products and that utilize recycled post-industrial textile fibers and recycled PET containers. The replacement of interior and exterior products previously served by plastic-based materials has created a trend in new vehicle designs to substitute structured non-woven acoustical products with vehicle manufacturers, which has helped to expand non-woven acoustical content per vehicle.

Key Products

Through the acoustics business, which represented 35.4% of the Company’s 2016 revenue, we manufacture engineered non-woven, fiber-based acoustical products primarily for the automotive industry. The acoustics business was established in 1985 through the acquisition of Janesville Products, which has developed extensive design and manufacturing expertise over its 140 year history that allows it to provide custom acoustical solutions for each vehicle platform it serves. We market our products as being lighter, improving acoustical performance, enhancing aesthetics, and being easier to install than other acoustical products manufactured by our competitors. As a result, our products are used in a large share of light vehicles manufactured in North America today, including 10 of 2016’s top 20 models.

We believe the acoustics business offers the broadest product line of value-added, higher margin components used in a wide range of vehicles, including automobiles, sport utility vehicles and light trucks, as well as in the industrial and transportation markets. The Company has focused on developing premier lightweight fiber-based solutions that provide competitive or superior acoustical properties. Our production of non-woven fiber-based products is organized by the form in which it is supplied: (i) die cut, (ii) molded, (iii) rolls and blanks, and (iv) other non-woven products.

The acoustics business operates principally as an automotive Original Equipment Manufacturer (“OEM”) and Tier-1 supplier. Recently, the Company has focused on increasing sales directly to automotive OEMs, which allows us to integrate our technology and value-added capabilities within OEM organizations. These efforts have shifted sales to what we believe is a more desirable balance between OEMs and Tier-1 suppliers while also broadening the number of vehicle platforms that utilize the Company’s products. Additionally, the Company has increased its North American content per vehicle on a compound annual growth rate of approximately 4% over the past three years. Substantially all automotive products are sole sourced by customers for a particular vehicle and are used for the life of the platform.

Components

Market/Industry Overview

The market for component products is highly fragmented with most participants having single or limited product lines, serving specific geographic markets or providing niche capabilities applicable to a limited customer base. While there are numerous competitors with limited product offerings, there are only a few national and international competitors of a size comparable to the components business. While we compete with certain domestic and international competitors across a portion of our product lines, we believe that no one competitor directly competes with us across all of our product lines. End users of component products are broadly diversified across many sectors of the economy.

Demand in the components market is influenced by the broader industrial manufacturing market, as well as trends in the perforated and expanded metal, rail and outdoor power equipment industries. The best gauge of domestic industrial production is the U.S. Industrial Production Index, which measures the monthly level of output arising from the manufacturing, mining and gas sectors.

Key Products

Through the components business, which represented 13.9% of the Company’s 2016 revenue, we manufacture a broad range of expanded and perforated metal components and subassemblies. The Company is a provider of components that are used in a broad array of products, including smart meters, hardware, railcars and off-road equipment. The components business was originally acquired in 1993 through the purchase of the Koller Group, a producer of metal formed components such as stampings, subassemblies, wire forms and expanded metal products. Today, the components business operates through the Metalex and Morton brands, as we made the strategic decision to discontinue certain product lines and selling under the Assembled Products brand in 2016.

Within each of the components business product categories, our strategy is to have engineers work alongside customers to create value-added components and solutions for various end products. Our engineering resources, manufacturing

6

capabilities and low cost production availability through our operations in Mexico provide opportunities to deliver value to customers. These characteristics drive long-standing relationships with our top customers that average over 20 years.

Competitive Strengths

The Company believes the following key characteristics provide a competitive advantage and position us for future growth:

Established Industry Leader Across Our Four Businesses

The Company’s businesses have developed leading positions across various niche markets. For example, in our turf care seats, buffing wheels and buffing compounds and automotive acoustical insulation product lines, we believe we are more than twice the size of the next largest direct competitor. The Company’s market share positions have created a stable platform upon which to grow. Our products’ significant brand recognition helps to sustain our market share positions. The Company’s products are often viewed as a brand of choice for quality, dependability, value and continuous innovation. In several niche markets, the Company is the only provider of certain products or manufacturing capabilities. We have served many of our customers for over 25 years. Despite leading positions in many of our markets, we face competitive challenges in others. In the Company’s finishing and components segments, we believe certain of our competitors are small and family-owned, operate with lower operating expenses, have lower profit expectations and/or supply lower cost commodity products, which allows such competitors to provide lower cost products and compete with us on pricing. In our seating segment, specifically with respect to highly technical seats for the agricultural and construction vehicle markets, the cost to customers of switching from a current supplier’s products to ours is high, and we believe certain of our competitors have established long-term and entrenched relationships with such customers. These costs and relationships make it challenging to convince such customers to purchase products from us instead of from their existing supplier.

Superior Design & Manufacturing Solutions

The Company has a track record of providing customers with innovative, customized solutions through production flexibility and collaboration with their design and manufacturing teams. We have consistently refined manufacturing processes to incorporate design technologies that improve design capabilities, breadth of product offering, product quality and manufacturing efficiency.

Across our businesses, we maintain teams of designers and a diverse product selection in numerous geographic regions, which allows us to respond quickly to real-time customer needs. Our versatile design and manufacturing capabilities enable us to deliver differentiated and highly-customized solutions for customers by leveraging experienced engineering staff and technologically advanced manufacturing equipment. We believe our diverse product offerings and customized design and manufacturing capabilities have made us a preferred choice within many industries and an entrenched key solutions provider to customers. Some of the Company’s competitors focus on commodity products and lower-value-added products that appeal to certain end users and markets.

We believe we have become a partner at each stage in product development, which has deepened our relationships with an already entrenched customer base and driven revenue growth from existing accounts and new customers.

Scalable Business Philosophy

We use a consistent strategy and focus and deploy capital and resources across our businesses to projects with the highest returns on invested capital. Through corporate strategic planning initiatives, we annually assess our three-year outlook and goals, by using a policy deployment matrix disseminated throughout the organization. The Company’s management utilizes the strategic plan and resulting policy deployment matrix to develop an annual budget and profit plan and monitors progress towards long-term strategic goals.

Across the Company’s businesses, our management team is focused on enhancing product innovation, efficiency, global accessibility and competitiveness. Shared best practices serve to continually improve the processes and products that our customers depend on by delivering customized, value-added solutions across the platform. This global reach offers customers a consistent and fully integrated manufacturing partner capable of serving their needs on a global, regional and local basis.

Diverse, Global Footprint with Growing Presence in Emerging Markets

The Company maintains 34 global manufacturing locations, consisting of 14 in the United States and 20 in foreign countries, giving each business a strong international presence. Approximately 30% of the Company’s 2016 revenue was generated from products manufactured outside of the United States. In addition, our global presence enables us to take advantage of low-cost manufacturing at our facilities in China, India, Romania, Mexico, Portugal and other countries and to meet the needs of local customers with operations in those regions. The Company continues to build upon its established presence in low-cost production locations through the expansion of owned operations and the development of joint ventures and sourcing relationships in Asia, Eastern Europe and Mexico. Our management believes that this global footprint also

7

provides channels of organic growth through the introduction of products into new markets. Our management frequently evaluates our manufacturing, warehouse, distribution and sales locations to identify revenue enhancement opportunities, optimize production costs and ensure proximity to key customers.

Growth Strategies

The Company is focused on delivering sustained profitable growth through a number of avenues. Our growth initiatives are developed based on strategic plans conducted on an annual basis within each business. These plans are regularly reviewed and updated by our leadership team. As a result, we have a uniform strategy that focuses all of our resources on the following key initiatives:

Margin Growth

We are focused on continuous improvement in our profit margins through the development of higher-margin products, continued operational improvements and active product portfolio management. We anticipate our strategy of shifting toward innovative higher-value engineered products will continue to improve our pricing power and profitability. Among other initiatives, the Company is focused on redesigning products to reduce materials costs, continuing to reduce labor-intensive manufacturing processes and reducing logistics costs, which have traditionally been a significant component of overall costs and an important consideration when choosing its strategic manufacturing locations.

The Company is focused on creating operational effectiveness at each of its business segments through deployment of lean principles and implementation of continuous operational improvement initiatives. While many of these activities have focused on implementing shop floor improvements, we have also targeted our selling and administrative functions in order to reduce the cost of serving our customers. The Company is also focused on improving profitability through an active evaluation of customer pricing and a reduction in the number of parts and product variations that are produced. While these initiatives may result in lower overall sales, they are focused on creating shareholder value through higher margins and profitability, as well as lower inventory levels and working capital requirements.

Market Share Gains

While our four businesses pursue growth within new and existing markets through customized strategies targeted for the markets we serve, all businesses are tasked with identifying and pursuing key growth opportunities through new products, end markets, geographies and sales channels. Management believes we have the potential to increase market share due to the highly fragmented nature of our end markets. Each business has identified specific opportunities to expand market share, with associated incremental revenue targets.

Product Innovation

Management believes that the Company’s strategy of developing innovative products will position us for continued growth. Working in collaboration with key customers, the design and manufacture of customized products that deliver value will support this growth. We believe that developing new products will allow us to deepen our value-added relationships with customers, open new opportunities for revenue generation, improve pricing power and enhance profitability. The Company has a focused and dedicated strategy for continuous innovation, which is supported by sophisticated manufacturing capabilities and engineering expertise. Such research and development costs incurred in the development of new products or significant improvements to existing products were $4.2 million in the year ended December 31, 2016, $5.0 million in the year ended December 31, 2015, $2.1 million in the period June 30, 2014 through December 31, 2014, and $2.7 million in the period January 1, 2014 through June 29, 2014. This continued focus on innovation has driven many successful new product introductions, which we believe will enable continued growth.

Acquisitions

The Company uses acquisitions to increase revenues with existing customers and to expand revenues to both new markets and customers. The Company intends to only pursue an acquisition if it is accretive to EBITDA (earnings before interest, income taxes, depreciation and amortization) margins post-synergies, has a strategic focus that aligns with our core strategy and generates the appropriate estimated return on investment as part of our capital resource and allocation process.

Customers

The Company has an entrenched base of blue chip customers that are leaders in their respective markets. Our customer relationships often span decades in each business. Additionally, our customer base is diversified. In our finishing segment, no customers were at or above 10% of the revenue of such segment. In our seating segment, only three customers were at or above 10% of the revenues of such segment. In our acoustics and components segments, only two customers were at or above 10% of the revenues of such segments. Across all of Jason Industries, no customers were at or above 10% of 2016 , 2015 or 2014 revenues. In 2016, our five largest customers represent a combined 30% of 2016 revenues.

8

Suppliers and Raw Materials

Polyurethane foam, vinyl, plastics, steel, polyester fiber, bicomponent fiber and machined fiber are the primary raw materials that we use to manufacture our products. There are a limited number of domestic and foreign suppliers of these raw materials. The Company generally orders supplies on a purchase order basis. Although our contracts and long term arrangements with our customers generally do not expressly allow us to pass through increases in our raw materials, energy costs and other inputs to our customers, we endeavor to discuss price adjustments with our customers on a case by case basis where it makes business sense. For the year ended December 31, 2016, the spend with our top three material suppliers accounted for less than 10% of total material spend and our largest supplier accounts for approximately 3% of total spend. The Company makes an ongoing effort to reduce and contain raw material costs. We do not engage in raw material commodity hedging contracts. The Company attempts to reflect raw material price changes in the sale price of our products.

Seasonality

We experience seasonality of demand for our products in the seating business. Due to our experience in this market, we have adapted our business operations to manage this seasonality. The business also depends upon general economic conditions and other market factors beyond our control, and the Company serves customers in cyclical industries. See “Seasonality and Working Capital” in the accompanying “Management’s Discussion and Analysis of Financial Condition and Results of Operations” contained herein for further discussion.

Employees

As of December 31, 2016, the Company had approximately 4,400 employees and manufactured products in 34 locations around the world. Approximately 62% of the seating segment’s hourly employees and 42% of the components segment’s hourly employees are unionized. Contracts are negotiated on a local basis, significantly mitigating the risk of a company-wide or segment level work stoppage. Additionally, approximately 1,000 of the Company’s employees reside in Europe, where trade union membership is common. We believe we have a strong relationship with our employees, including those represented by labor unions.

Environmental Matters

The Company’s operations and facilities are subject to extensive federal, state, local and foreign laws and regulations related to pollution and the protection of the environment, health, safety and natural resources, including those governing, among other things, emissions to air, discharges to water, the use, generation, handling, storage, treatment and disposal of hazardous substances and wastes and other materials and the remediation of contaminated sites. The operation of manufacturing plants entails risks in these areas, and a failure by the Company to comply with applicable environmental laws and regulations, or to obtain and comply with the permits required for its operations, could result in civil or criminal fines, penalties, enforcement actions, third party claims for property damage and personal injury, requirements to clean up property or to pay for the capital or operating costs of cleanup, or regulatory or judicial orders enjoining or curtailing operations or requiring corrective measures, including the installation of pollution control equipment or remedial actions. Moreover, if applicable environmental, health and safety laws and regulations, or the interpretation or enforcement thereof, become more stringent in the future, the Company could incur capital or operating costs beyond those currently anticipated.

Compliance with environmental laws has not historically had a material adverse effect on the Company’s capital expenditures, earnings or competitive position, and we anticipate that such compliance will not have a material effect on its business or financial condition in the future.

Available Information

The Company’s Internet website address is www.jasoninc.com. The Company makes available free of charge (other than an investor’s own Internet access charges) through its Internet website its Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K, and amendments to those reports, on the same day they are electronically filed with, or furnished to, the U.S. Securities and Exchange Commission (the “SEC”). The Company is not including the information contained on or available through its website as a part of, or incorporating such information by reference into, this Annual Report on Form 10-K.

9

Executive Officers of the Registrant

The following table sets forth information concerning our executive officers as of February 23, 2017:

Name | Age | Position | ||

Brian K. Kobylinski | 50 | President and Chief Executive Officer | ||

Sarah C. Lauber | 45 | Senior Vice President and Chief Financial Officer | ||

Thomas L. Doerr, Jr. | 41 | Vice President, General Counsel and Secretary | ||

John J. Hengel | 58 | Vice President—Finance, Treasurer and Assistant Secretary | ||

Srivas Prasad | 48 | Senior Vice President and General Manager—Acoustics | ||

Steven G. Carollo | 45 | Senior Vice President and General Manager—Components | ||

Brian K. Kobylinski has served as President and Chief Executive Officer since December 2016. Prior to being named Chief Executive Officer, Mr. Kobylinski served as President & Chief Operating Officer since April 8, 2016. Prior to joining Jason Industries, Mr. Kobylinski served as Executive Vice President, Energy Segment and China for Actuant Corporation (“Actuant”) based in Milwaukee, Wisconsin. During his 23 years with Actuant, Mr. Kobylinski progressed through a number of management roles, including Vice President - Industrial and Energy Segments, Vice President – Business Development and Global Business Leader – Hydratight. Mr. Kobylinski received his masters of business administration from the University of Wisconsin - Madison and his bachelors of art from St. Norbert College.

Sarah C. Lauber has served as Senior Vice President since January 2016 and as our Chief Financial Officer since April 20, 2015. Prior to joining Jason Industries, Mrs. Lauber served as Vice President, Financial Planning and Analysis at Regal-Beloit Corporation from 2011 until April 2015. Mrs. Lauber previously served as Chief Financial Officer of A.O. Smith Corporation’s Electrical Products Company (“EPC”), a $700 million global manufacturer of electric motors for residential and commercial applications, from 2002 until EPC was acquired by Regal-Beloit in 2011. Mrs. Lauber began her career as an accountant at KPMG, and is a certified public accountant and member of the AICPA. Mrs. Lauber earned a Bachelor of Science in administration, with an accounting concentration, from California State University, San Bernardino, and an Executive Master of Business Administration from Northwestern University, Kellogg School of Management.

Thomas L. Doerr, Jr. has served as Vice President since January 2016 and as our General Counsel and Secretary since November 9, 2015. Prior to joining Jason Industries, Mr. Doerr served as Associate General Counsel for The Manitowoc Company, Inc. where he was responsible for overseeing the legal matters for Manitowoc’s crane segment. Mr. Doerr joined Manitowoc in 2006 as legal counsel; in 2008 he expatriated to London, England, and in 2009 to Lyon, France where he was serving as Assistant General Counsel - International and responsible for all legal matters for both Manitowoc’s crane segment and Manitowoc’s foodservice segment in Europe, Middle East, Africa and Asia Pacific. After spending four years abroad, Mr. Doerr moved back to the United States and assumed global legal responsibility for Manitowoc’s crane segment. Prior to joining Manitowoc, Mr. Doerr was most recently with the law firm von Briesen & Roper, s.c. in the firm’s Milwaukee office. Mr. Doerr is a graduate of Marquette University Law School and the University of St. Thomas.

John J. Hengel has served as our Vice President—Finance, Treasurer and Assistant Secretary since June 30, 2014 and previously served as Vice President of Finance of Jason Incorporated since 1999. Prior to joining Jason Incorporated, Mr. Hengel was a director in the audit and business advisory services practice at PricewaterhouseCoopers LLP from 1992 to 1999. Mr. Hengel is a Certified Public Accountant and a member of both the American and Wisconsin Institutes of Certified Public Accountants. He holds a Bachelor of Science in accounting from Carroll University.

Srivas Prasad has served as our Senior Vice President and General Manager—Acoustics since December 2016. Prior to that, Mr. Prasad served as Senior Vice President and General Manager - Seating and Acoustics since January 2016 and as President of our Seating segment since June 30, 2014 (and previously served in the same position of Jason Incorporated since April 2014). Prior to serving as the President of the Seating segment, he served as Vice President—Business Development at Jason Incorporated from 2011 to 2014 and held key leadership positions in Jason Incorporated’s Acoustics segment from 2006 to 2010. Mr. Prasad holds a Bachelor’s degree in engineering from Bangalore University and a Masters in engineering from Lamar University.

Steven G. Carollo has served as our Senior Vice President and General Manager—Components since December 2016. Prior to that, Mr. Carollo served as the Senior Vice President and General Manager - Finishing and Components since January 2016 and as Vice President and General Manager of our Components segment since June 30, 2014 (and previously served in the same position of Jason Incorporated since July 2012). Prior to serving as the Vice President and General Manager of the Components segment, he served as Vice President and General Manager at Assembled Products from 2006 to 2013 and held key leadership positions in Jason Incorporated’s Acoustic and Components segments from 1994 to 2006. Mr. Carollo holds a Bachelor’s degree in Accounting from Central Michigan University and a Masters in Business Administration from the University of Notre Dame.

10

ITEM 1A. RISK FACTORS

An investment in our securities involves a high degree of risk. You should consider carefully all of the risks described below and all of the other information contained in this report before deciding to invest in our securities. If any of the events or developments described below occur, our business, financial condition and/or results of operations could be negatively affected. In that case, the trading price of our securities could decline, and you could lose all or part of your investment.

Risk Factors Relating to Our Business

We are affected by developments in the industries in which our customers operate.

We derive our revenues largely from customers in the following industry sectors: agricultural, automotive, motorcycles, construction and industrial manufacturing. Factors affecting any of these industries in general, or any of our customers in particular, could adversely affect us because our revenue growth largely depends on the continued growth of our customers’ businesses in their respective industries. These factors include:

• | seasonality of demand for our customers’ products which may cause our manufacturing capacity to be underutilized for periods of time; |

• | our customers’ failure to successfully market their products, to gain or retain widespread commercial acceptance of their products or to compete effectively in their industries; |

• | loss of market share for our customers’ products, which may lead our customers to reduce or discontinue purchasing our products and to reduce prices, thereby exerting pricing pressure on us; |

• | economic conditions in the markets in which our customers operate, in particular, the United States and Europe, including recessionary periods such as the 2008/2009 global economic downturn; and |

• | product design changes or manufacturing process changes that may reduce or eliminate demand for the components we supply. |

We expect that future sales will continue to depend on the success of our customers. If economic conditions and demand for our customers’ products deteriorate, we may experience a material adverse effect on our business, operating results and financial condition.

Some of our business segments are cyclical. A downturn or weakness in overall economic activity can have a material negative impact on us.

Historically, sales of products that we manufacture have been subject to cyclical variations caused by changes in general economic conditions. During recessionary periods, we have been adversely affected by reduced demand for our products. In addition, the strength of the economy generally may affect the rates of expansion, consolidation, renovation and equipment replacement in the industries we serve.

Volatility in the prices of raw materials and energy prices and our ability to pass along increased costs to our customers could adversely affect our results of operations.

The prices of raw materials critical to our business and performance, such as steel, are based on global supply and demand conditions. Certain raw materials used by us, including polyurethane foam, vinyl, plastics, steel, polyester fiber, bicomponent fiber and machined fiber are only available from a limited number of suppliers, and it may be difficult to find alternative suppliers at the same or similar costs. Although our contracts and long term arrangements with our customers generally do not expressly allow us to pass through increases in our raw materials, energy costs and other inputs to our customers, we endeavor to discuss price adjustments with our customers on a case by case basis where it makes business sense. While we strive to pass through the price of raw materials to our customers (other than increases in order amounts which are subject to negotiation), we may not be able to do so in the future, and volatility in the prices of raw materials may affect customer demand for certain products. In addition, we, along with our suppliers and customers, rely on various energy sources for a number of activities connected with our business, such as the transportation of raw materials and finished products. Energy and utility prices, including electricity and water prices, and in particular prices for petroleum-based energy sources, are volatile. Increased supplier and customer operating costs arising from volatility in the prices of energy sources, such as increased energy and utility costs and transportation costs, could be passed through to us and we may not be able to increase our product prices sufficiently or at all to offset such increased costs. The impact of any volatility in the prices of energy or the raw materials on which we rely, including the reduction in demand for certain products caused by such price volatility, could result in a loss of revenue and profitability and adversely affect our results of operations.

11

We compete with numerous other manufacturers in each of our segments and competition from these providers may affect the profitability of our business.

The industries we serve are highly competitive. We compete with numerous companies that manufacture finishing, seating, automotive acoustics and components products. Many of our competitors have international operations and significant financial resources and some have substantially greater manufacturing, research and design and marketing resources than us. These competitors may, among others:

• | respond more quickly to new or emerging technologies; |

• | have greater name recognition, critical mass or geographic market presence; |

• | be better able to take advantage of acquisition opportunities; |

• | adapt more quickly to changes in customer requirements; |

• | devote greater resources to the development, promotion and sale of their products; |

• | be better positioned to compete on price for their products, due to any combination of low-cost labor, raw materials, components, facilities or other operating items, or willingness to make sales at lower margins than us; |

• | consolidate with other competitors in the industry which may create increased pricing and competitive pressures on our business; and |

• | be better able to utilize excess capacity which may reduce the cost of their products or services. |

Competitors with lower cost structures may have a competitive advantage when bidding for business with our customers. We also expect our competitors to continue to improve the performance of their current products or services, to reduce prices of their existing products or services and to introduce new products or services that may offer greater performance and improved pricing. Additionally, we may face competition from new entrants to the industry in which we operate. Any of these developments could cause a decline in sales and average selling prices, loss of market share of our products or profit margin compression.

We face risks related to sales through distributors and other third parties.

We sell a portion of our products through third parties such as distributors, agents and channel partners (collectively referred to as distributors). Using third parties for distribution exposes us to many risks, including competitive pressure, concentration, credit risk, and compliance risks. Distributors may sell products that compete with our products, and we may need to provide financial and other incentives to focus distributors on the sale of our products. We may rely on one or more key distributors for a product, and the loss of these distributors could reduce our revenue. Distributors may face financial difficulties, including bankruptcy, which could harm our collection of accounts receivable and financial results. Violations of the Foreign Corrupt Practices Act or similar laws by distributors or other third-party intermediaries could have a material impact on our business. Failing to manage risks related to our use of distributors may reduce sales, increase expenses, and weaken our competitive position.

We may not be able to maintain our engineering, technological and manufacturing expertise.

The markets for our products are characterized by changing technology and evolving process development. The continued success of our business will depend upon our ability to:

• | hire, retain and expand our pool of qualified engineering and technical personnel; |

• | maintain technological leadership in our industry; |

• | successfully anticipate or respond to changes in manufacturing processes in a cost-effective and timely manner; and |

• | successfully anticipate or respond to changes in cost to serve in a cost-effective and timely manner. |

We cannot be certain that we will develop the capabilities required by our customers in the future. The emergence of new technologies, industry standards or customer requirements may render our equipment, inventory or processes obsolete or uncompetitive. We may have to acquire new technologies and equipment to remain competitive. The acquisition and implementation of new technologies and equipment may require us to incur significant expense and capital investment, which could reduce our margins and affect our operating results. When we establish or acquire new facilities, we may not be able to maintain or develop our engineering, technological and manufacturing expertise due to a lack of trained personnel, effective training of new staff or technical difficulties with machinery. Failure to anticipate and adapt to customers’ changing technological needs and requirements or to hire and retain a sufficient number of engineers and maintain engineering, technological and manufacturing expertise may have a material adverse effect on our business.

12

We may be unable to realize the expected benefits of capital expenditures, which could adversely affect our profitability and operations.

We expect to continue to invest in our business through capital expenditures to support our facilities and purchases of production equipment and acquisitions. There can be no assurance that these investments will generate any specific return on investment.

Our goodwill and other intangible assets represent a substantial amount of our total assets. A decline in future operating performance at one or more of our reporting units could result in the further impairment of goodwill or other intangible assets, which could have a material adverse effect on our financial condition and results of operations.

At December 31, 2016, goodwill and other intangible assets totaled $186.4 million, or approximately 32% of our total assets. The goodwill results from our acquisitions, representing the excess of cost over the fair value of the net tangible and other identifiable intangible assets we have acquired. We assess annually whether there has been impairment in the value of our goodwill. If future operating performance at one or more of our reporting units were to fall below current or planned levels, we could be required to recognize a non-cash charge to operating earnings for goodwill (at our finishing reporting unit) or record an impairment charge related to other intangible assets. In the fourth quarter of 2016, the Company recorded charges of $63.3 million for the impairment of goodwill. Given the continued significance of the Company’s goodwill and intangible assets, any additional significant goodwill or intangible asset impairment could reduce earnings in such period and have a material adverse effect on our financial condition and results of operations.

Divestitures and discontinued operations could negatively impact our business, and contingent liabilities from businesses that we sell could adversely affect our financial results.

As part of our portfolio management process, we review our operations for businesses which may no longer be aligned with our strategic initiatives and long-term objectives. Divestitures pose risks and challenges that could negatively impact our business. For example, when we decide to sell a business, we may be unable to do so on satisfactory terms and within our anticipated time-frame, and even after reaching a definitive agreement to sell a business, the sale may be subject to satisfaction of pre-closing conditions, which may not be satisfied, as well as regulatory and governmental approvals, which may prevent us from completing a transaction on acceptable terms. In addition, the impact of the divestiture on our revenue and net earnings may be larger than projected, which could distract management, and disputes may arise with buyers. Dispositions may also involve continued financial involvement, as we may be required to retain responsibility for, or agree to indemnify buyers against contingent liabilities related to businesses sold, such as lawsuits, tax liabilities, product liability claims or environmental matters. Under these types of arrangements, performance by the divested businesses or other conditions outside our control could affect our future financial results.

If we fail to develop new and innovative products or if customers in our markets do not accept them, our results could be negatively affected.

Our products must be kept current to meet our customers’ needs. To remain competitive, we therefore must develop new and innovative products on an ongoing basis. If we fail to make innovations or the market does not accept our new products, our sales and results would likely suffer. We invest significantly in the research and development of new products. These expenditures do not always result in products that will be accepted by the market. To the extent they do not, whether as a function of the product or the business cycle, we will have increased expenses without significant sales to benefit us. Failure to develop successful new products may also cause potential customers to purchase competitors’ products, rather than invest in products manufactured by us.

The potential impact of failing to deliver products on time could increase the cost of the products.

In most instances, we guarantee that we will deliver a product by a scheduled date. If we subsequently fail to deliver the product as scheduled, we may be held responsible for cost impacts and/or other damages resulting from any delay. To the extent that these failures to deliver may occur, the total damages for which we could be liable could significantly increase the cost of the products; as such, we could experience reduced profits or, in some cases, a loss for that contract. Additionally, failure to deliver products on time could result in damage to customer relationships, the potential loss of customers, and reputational damage which could impair our ability to attract new customers.

Increasing costs of doing business in many countries in which we operate may adversely affect our business and financial results.

Increasing costs such as labor and overhead costs in the countries in which we operate may erode our profit margins and compromise our price competitiveness. Historically, the low cost of labor in certain of the countries in which we operate has been a competitive advantage but labor costs in these countries, such as China, have been increasing. Our profitability also depends on our ability to manage and contain our other operating expenses such as the cost of utilities, factory supplies, factory space costs, equipment rental, repairs and maintenance and freight and packaging expenses. In the event we are unable to

13

manage any increase in our labor and other operating expenses in an environment where revenue does not increase proportionately, our financial results would be adversely affected.

Our international scope will require us to obtain financing in various jurisdictions.

We operate manufacturing facilities in the United States and 14 foreign countries, which creates financing challenges for us. These challenges include navigating local legal and regulatory requirements associated with obtaining debt or equity financing in the respective foreign jurisdictions in which we operate. In the event that we are not able to obtain financing on satisfactory terms in any of these jurisdictions, it could significantly impair our ability to run our foreign operations on a cost effective basis or to grow such operations. Failure to manage such challenges may adversely affect our business and results of operations.

We have operations in many countries and such operations may be subject to a number of risks specific to these countries.

Our international operations across many different jurisdictions may be subject to a number of risks specific to these countries, including:

• | less flexible employee relationships which can be difficult and expensive to terminate; |

• | labor unrest; |

• | political and economic instability (including war and acts of terrorism); |

• | inadequate infrastructure for our operations (i.e., lack of adequate power, water, transportation and raw materials); |

• | health concerns and related government actions; |

• | risk of governmental expropriation of our property; |

• | less favorable, or relatively undefined, intellectual property laws; |

• | unexpected changes in regulatory requirements and laws; |

• | longer customer payment cycles and difficulty in collecting trade accounts receivable; |

• | export duties, tariffs, import controls and trade barriers (including quotas); |

• | adverse trade policies or adverse changes to any of the policies of either the United States or any of the foreign jurisdictions in which we operate; |

• | adverse changes in tax rates or regulations; |

• | legal or political constraints on our ability to maintain or increase prices; |

• | burdens of complying with a wide variety of labor practices and foreign laws, including those relating to export and import duties, environmental policies and privacy issues; |

• | inability to utilize net operating losses incurred by our foreign operations against future income in the same jurisdiction; |

• | economies that are emerging or developing, that may be subject to greater currency volatility, negative growth, high inflation, limited availability of foreign exchange and other risks; and |

• | ability to repatriate cash on a tax effective basis. |

These factors may harm our results of operations, and any measures that we may implement to reduce the effect of volatile currencies and other risks of our international operations may not be effective. In our experience, entry into new international markets requires considerable management time as well as start-up expenses for market development, hiring and establishing office facilities before any significant revenue is generated. As a result, initial operations in a new market may operate at low margins or may be unprofitable.

Our international sales and operations are subject to applicable laws relating to trade, export controls and foreign corrupt practices, the violation of which could adversely affect our operations.

We are subject to applicable international trade, customs, export controls and economic sanctions laws and regulations of the United States and other countries and the Foreign Corrupt Practices Act and other anti-bribery laws that generally bar bribes or unreasonable gifts to foreign governments or officials. Changes in such laws may restrict our business practices, including cessation of business activities in sanctioned countries or with sanctioned entities, and may result in modifications to compliance programs. Violation of these laws or regulations could result in sanctions or fines and could have a material adverse effect on our financial condition, results of operations and cash flows.

14

We are subject to risks of currency fluctuations and related hedging operations, and the devaluation of the currencies of countries in which we conduct our manufacturing operations, particularly the Euro, that may negatively affect the profitability of our business.

We report our financial results in U.S. dollars. Approximately 30% of our net sales in 2016 were in currencies other than the U.S. dollar. Changes in exchange rates among other currencies, especially the Euro to the U.S. dollar, may negatively affect our net sales, cost of sales, gross profit and net income where our expenses and revenues are denominated in different currencies. We cannot predict the effect of future exchange rate fluctuations. We may from time to time use financial instruments, primarily short-term forward contracts, to hedge Euro and other currency commitments arising from foreign currency obligations. Where possible, we endeavor to match our non-functional currency exchange requirements to our receipts. If our hedging activities are not successful or if we change or reduce these hedging activities in the future, we may experience significant unexpected expenses from fluctuations in exchange rates.

We depend on our key executive officers, managers and skilled personnel and may have difficulty retaining and recruiting qualified employees.

Our success depends to a large extent upon the continued services of our executive officers, senior management personnel, managers and other skilled personnel and our ability to recruit and retain skilled personnel to maintain and expand our operations. We could be affected by the loss of any of our executive officers who are responsible for formulating and implementing our business plan and strategy. In addition, we need to recruit and retain additional management personnel and other skilled employees. However, competition is high for skilled technical personnel among companies that rely on engineering and technology, and the loss of qualified employees or an inability to attract, retain and motivate additional skilled employees required for the operation and expansion of our business could hinder our ability to conduct design, engineering and manufacturing activities successfully and develop marketable products. We may not be able to attract the skilled personnel we require or retain those whom we have trained at our own cost. If we are not able to do so, our business and our ability to continue to grow could be negatively affected and we could face additional competition from those who leave and work for our competitors.

Many of our customers do not commit to long-term production schedules, which makes it difficult for us to schedule production accurately and achieve maximum efficiency of our manufacturing capacity.

Generally, our customers do not commit to long-term contracts. Many of our customers do not commit to firm production schedules and we continue to experience reduced lead-times in customer orders. Additionally, customers may change production quantities or delay production with little lead-time or advance notice. Therefore, we rely on and plan our production and inventory levels based on our customers’ advance orders, commitments or forecasts, as well as our internal assessments and forecasts of customer demand. The volume and timing of sales to our customers may vary due to, among other factors:

• | variation in demand for or discontinuation of our customers’ products; |

• | our customers’ attempts to manage their inventory; |

• | design changes; |

• | changes in our customers’ manufacturing strategies; and |

• | acquisitions of or consolidation among customers. |

The variations in volume and timing of sales make it difficult to schedule production and optimize manufacturing capacity. This uncertainty may require us to increase staffing and incur other expenses in order to meet an unexpected increase in customer demand, potentially placing a significant burden on our resources. Additionally, an inability to respond to such increases may cause customer dissatisfaction, which may negatively affect our customers’ relationships.

Further, in order to secure sufficient production scale, we may make capital investments in advance of anticipated customer demand. Such investments may lead to low utilization levels if customer demand forecasts change and we are unable to utilize the additional capacity. Because fixed costs make up a large proportion of our total production costs, a reduction in customer demand can have a significant adverse impact on our gross profits and operating results. Additionally, we order materials and components based on customer forecasts and orders and suppliers may require us to purchase materials and components in minimum quantities that exceed customer requirements, which may have an adverse impact on our gross profits and operating results. In the past, anticipated orders from some of our customers have failed to materialize and delivery schedules have been deferred as a result of changes in our customers’ business needs. We have also allowed long-term customers to delay orders to absorb excess inventory. Such order fluctuations and deferrals may have an adverse effect on our business, operating results and/or financial conditions.

15

We may incur additional expenses and delays due to technical problems or other interruptions at our manufacturing facilities.

Disruptions in operations due to technical problems or other interruptions such as floods or fire would adversely affect the manufacturing capacity of our facilities. Such interruptions could cause delays in production and cause us to incur additional expenses such as charges for expedited deliveries for products that are delayed. Additionally, our customers have the ability to cancel purchase orders in the event of any delays in production and may decrease future orders if delays are persistent. Additionally, to the extent that such disruptions do not result from damage to our physical property, these may not be covered by our business interruption insurance. Any such disruptions may adversely affect our business, operations, and financial results.

We may be unable to realize the expected benefits of our restructuring actions, which could adversely affect our profitability and operations.

In order to align our resources with our growth strategies, operate more efficiently and control costs, we have periodically announced restructuring plans, which include workforce reductions, plant closures and consolidations, asset impairments and other cost reduction initiatives. On March 1, 2016, as part of a strategic review of organizational structure and operations, the Company announced a global cost reduction and restructuring program. This program includes entering into severance and termination agreements with employees and footprint rationalization activities, including exit and relocation costs for the consolidation and closure of plant facilities and lease termination costs. These activities were ongoing during 2016 and are expected to be completed in 2017. We may undertake additional restructuring actions and workforce reductions in the future. As these plans and actions are complex, unforeseen factors could result in expected savings and benefits to be delayed or not realized to the full extent planned, and our operations and business may be disrupted.

The operations of our manufacturing facilities may be disrupted by union activities and other labor-related problems.

We have labor unions at certain of our facilities. As of December 31, 2016, we had approximately 500 unionized personnel in the United States. For such employees, we have entered into collective bargaining agreements with the respective labor unions. In the future, such agreements may limit our ability to contain increases in our labor costs as our ability to control future labor costs depends partly on the outcome of wage negotiations with our employees. Any future collective bargaining agreements may lead to further increases in our labor costs. Although our employees in certain other facilities are currently not unionized, there can be no assurance that they will continue to remain as such.

Union activities and other labor-related problems not linked to union activities may disrupt our operations and adversely affect our business and results of operations. We cannot provide any assurance that we will not be affected by any such labor unrest, or increase in labor cost, or interruptions to the operations of our existing manufacturing plants or new manufacturing plants that we may set up in the future. Any disruptions to our manufacturing facilities as a result of labor-related disturbances could affect our ability to meet delivery and efficiency targets resulting in an adverse effect on our customer relationships and our financial results. Such disruptions may not be covered by our business interruption insurance.

Any disruption in our information systems could disrupt our operations and would be adverse to our business and financial operations.

We depend on various information systems to support our customers’ requirements and to successfully manage our business, including managing orders, supplies, accounting controls and payroll. Any inability to successfully manage the procurement, development, implementation or execution of our information systems and back-up systems, including matters related to system security, reliability, performance and access, as well as any inability of these systems to fulfill their intended purpose within our business, could have an adverse effect on our business and financial performance. Such disruptions may not be covered by our business interruption insurance.

Security breaches and other disruptions could compromise our information and expose us to liability, which would cause our business and reputation to suffer.