Attached files

| file | filename |

|---|---|

| EX-99.1 - EX-99.1 - ARMSTRONG WORLD INDUSTRIES INC | d875284dex991.htm |

| EX-99.2 - EX-99.2 - ARMSTRONG WORLD INDUSTRIES INC | d875284dex992.htm |

| 8-K - FORM 8-K - ARMSTRONG WORLD INDUSTRIES INC | d875284d8k.htm |

| EX-99.3 - EX-99.3 - ARMSTRONG WORLD INDUSTRIES INC | d875284dex993.htm |

Armstrong

World Industries

Investor

Presentation

February 23, 2015

Exhibit 99.4 |

Our

disclosures

in

this

presentation,

including

without

limitation,

those

relating

to

future

financial

results

guidance

and

the

separation

of

our

flooring

business

from

our

building

products

business,

and

in

our

other

public

documents

and

comments

contain

forward-looking

statements

within

the

meaning

of

the

Private

Securities

Litigation

Reform

Act.

Those

statements

provide

our

future

expectations

or

forecasts

and

can

be

identified

by

our

use

of

words

such

as

"anticipate,"

"estimate,"

"expect,"

"project,"

"intend,"

"plan,"

"believe,"

"outlook,"

"target,"

"predict,"

"may,"

"will,"

"would,"

"could,"

"should,"

"seek,"

and

other

words

or

phrases

of

similar

meaning

in

connection

with

any

discussion

of

future

operating

or

financial

performance

or

the

separation

of

our

businesses.

Forward-looking

statements,

by

their

nature,

address

matters

that

are

uncertain

and

involve

risks

because

they

relate

to

events

and

depend

on

circumstances

that

may

or

may

not

occur

in

the

future.

A

more

detailed

discussion

of

the

risks

and

uncertainties

that

may

affect

our

ability

to

achieve

the

projected

performance

is

included

in

the

“Risk

Factors”

and

“Management’s

Discussion

and

Analysis”

sections

of

our

recent

reports

on

Forms

10-K

and

10-Q

filed

with

the

SEC.

As

a

result,

our

actual

results

may

differ

materially

from

our

expected

results

and

from

those

expressed

in

our

forward-looking

statements.

Forward-looking

statements

speak

only

as

of

the

date

they

are

made.

We

undertake

no

obligation

to

update

any

forward-looking

statements

beyond

what

is

required

under

applicable

securities

law.

The

information

in

this

presentation

is

only effective

as

of

the

date

given,

February

23,

2015,

and

is

subject

to

change.

Any

distribution

of

this

presentation

after

February 23,

2015

is

not

intended

and

will

not

be

construed

as

updating

or

confirming

such

information.

In

addition,

we

will

be

referring

to

“non-GAAP

financial

measures”

within

the

meaning

of

SEC

Regulation

G.

A

reconciliation

of

the

differences

between

these

measures

with

the

most

directly

comparable

financial

measures

calculated

in

accordance

with

GAAP

are

can

be

found

in

our

SEC

filings

and

on

the

Investor

Relations

section

of

our

website

at

www.armstrong.com.

Armstrong

competes

globally

in

many

diverse

markets.

References

to

"market"

or

"share"

data

are

simply

estimations

based

on

a

combination

of

internal

and

external

sources

and

assumptions.

They

are

intended

only

to

assist

discussion

of

the

relative

performance

of

product

segments

and

categories

for

marketing

and

related

purposes.

No

conclusion

has

been

reached

or

should

be

reached

regarding

a

"product

market,"

a

"geographic

market"

or

“market

share,”

as

such

terms

may

be

used

or

defined

for

any

economic,

legal

or

other

purpose.

Safe Harbor Statement |

Basis

of Presentation Explanation •

When reporting our financial results within this presentation, we make several

adjustments. Management uses the non-GAAP measures below in managing the

business and believes the adjustments provide meaningful comparisons of

operating performance between periods. As reported results will be footnoted

throughout the presentation. •

We report in comparable dollars to remove

the effects of currency translation on the P&L.

The budgeted exchange rate for 2014 was

used for all currency translations in 2014 and

prior years. Guidance is presented using the

2015 budgeted exchange rate for the year.

•

We remove the impact of discrete expenses

and income. Examples include plant

closures, restructuring actions, and other

large

unusual

items.

We

also

remove

the

non-cash

impact

of

our

U.S.

Pension

Plan.

•

Taxes for normalized Net Income and EPS

are calculated using a constant 39% for 2014

results and 2015 guidance, which are based

on the expected full year historical tax rate.

All

figures

throughout

the

presentation

are

in

$

millions

unless

otherwise

noted.

Figures

may

not

add

due to rounding.

Comparable

Dollars

Other

Adjustments

Net Sales

Yes

No

Gross Profit

Yes

Yes

SG&A Expense

Yes

Yes

Equity Earnings

Yes

Yes

Operating Income

Yes

Yes

Net Income

Yes

Yes

Cash Flow

No

No

Return on Capital

Yes

Yes

EBITDA

Yes

Yes

What Items Are Adjusted |

Investment Highlights

Diversified $2.5 billion global building products company

with leading positions in most key markets and products

Driving value creation through:

–

Recovery in North America

•

U.S. Commercial is our most profitable business

with

35-45% incremental margins

–

Growth in International Markets

•

Emerging market investments and

recovery in developed markets

–

Leveraging innovation to drive profitable growth

•

Focus on design, environmental leadership, installation

and application enhancements

•

New product benefits to drive improved mix

Focused on creating shareholder value |

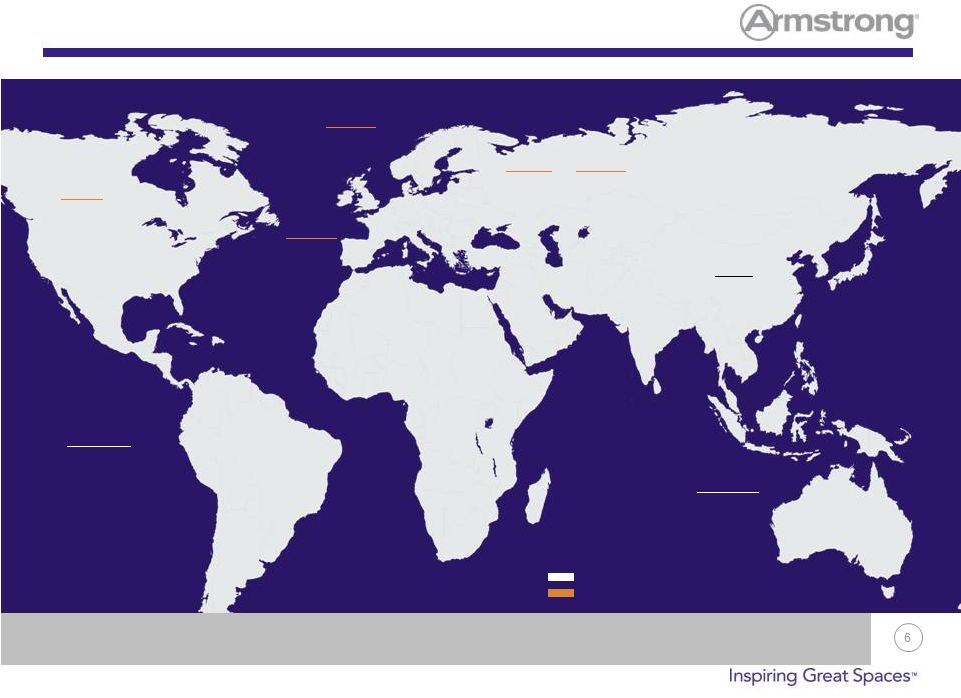

Global Business

Overview |

Armstrong’s Global Manufacturing Footprint

AUSTRALIA

Braeside

St. Helens, OR

Marietta, PA

Pensacola, FL

Somerset, KY

West Plains, MO

Jackson, MS

Vicksburg, MS

Millwood, WV

Hilliard, OH

Macon, GA

Beech Creek, PA

Titusville, PA

Lancaster, PA

Stillwater, OK

Jackson, TN

Oneida, TN

Beverly, WV

Warren, AR

South Gate, CA

Kankakee, IL

USA

Montreal

CANADA

Team Valley

Stafford

UK

Rankwell

AUSTRIA

Pontarlier

FRANCE

Munster

GERMANY

Wujiang*

Shanghai

CHINA

Ceilings has #1 share position in most geographies

Flooring has leading share positions in most geographies

* Two commercial flooring plants are also located in Wujiang

-

Flooring Plant

-

Ceilings Plant |

2014

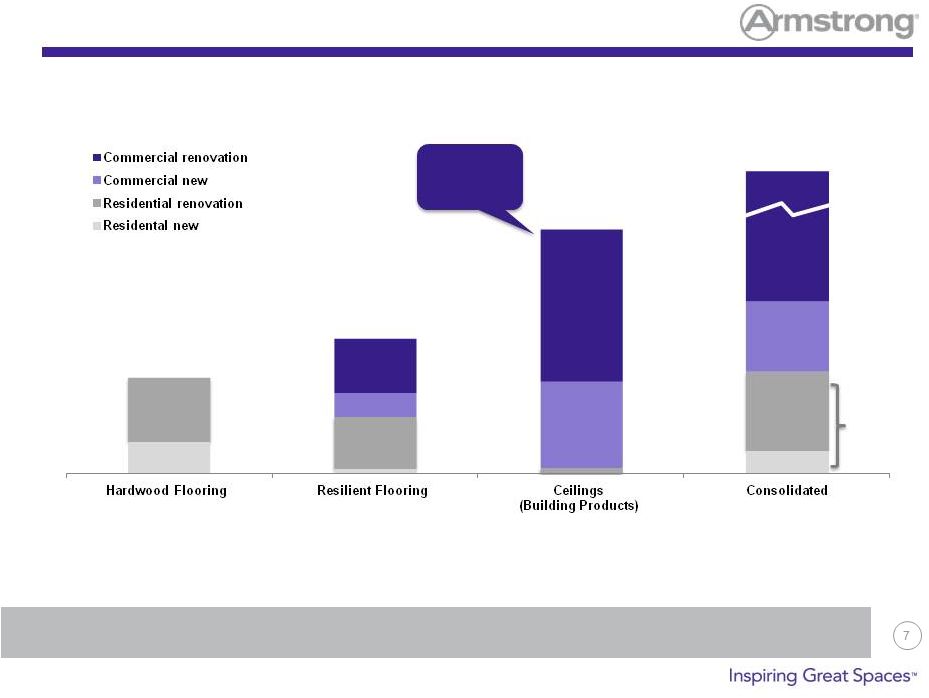

Business Segment and End-Use Profile Diversified revenue profile across

products and end-use applications $715

$510

$1,290

$2,515

45%

20%

25%

10%

60%

35%

5%

65%

35%

40%

5%

40%

15%

North

America

Renovation in

Americas is

~80% |

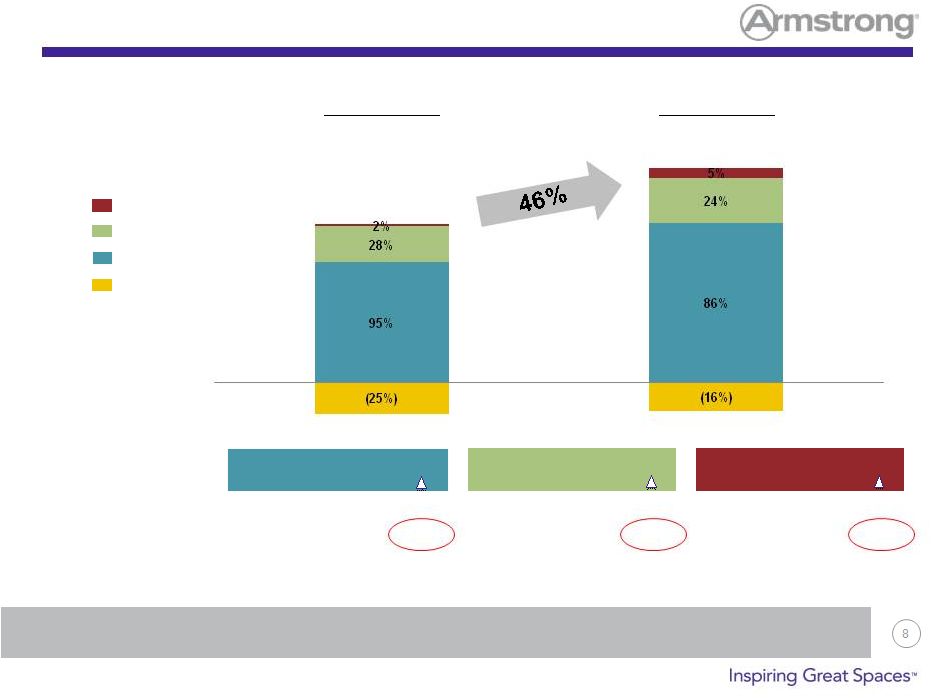

EBITDA

Performance EBITDA growth in all businesses despite challenging macro

environment 2010 EBITDA

2014 EBITDA

$384M

$263M

Worldwide Ceilings

Worldwide Resilient

Wood

2010

2014

2010

2014

2010

2014

Sales

$1.1B

$1.3B

14.1%

$735M

$715M

(2.6%)

$480M

$510M

6.4%

EBITDA as % of Sales

22%

26%

+ 350 bps

10%

13%

+ 290 bps

1%

4%

+ 320 bps

Worldwide Ceilings

Worldwide Resilient

Wood

Corporate |

•

North American plants located in key

distribution areas

Over 20 plants in North America –

aids

in distribution, recycling of product and

customer relationships

•

Ability to capitalize on increased volume

Current plants are running at ~70%

capacity utilization; can support increase

in volume

A 10% increase in volume would require an

increase in production workforce by ~2%

35% –

45% incremental margins

•

Enormous base of existing installations

creates ability to leverage annuity stream

Positioned for a North American Commercial Recovery

Our most profitable market –

recovery drives strong earnings growth |

•

Emerging markets growth investments

Completed three plants in China; 2

commercial flooring plants and mineral

fiber ceilings plant with co-located metal

manufacturing capability

Completed mineral fiber ceilings plant in

Russia

•

Global manufacturing footprint we need

for the coming years is in place

Remain confident on benefits of growth

in key markets, but timing uncertain

•

We have remained agile to market conditions

Ability to redeploy assets based on

regional opportunities

Positioned for Global Growth |

Historic Milestones

Cost

Management

Initiatives*

Capital

Market

Activity

Organic

Investment

Portfolio

Management

Management

2010

2011

2012

2013

2014

New CEO and CFO

Leverage recap

and $800M

special dividend

$500M special

dividend

Announced $150M

cost

out initiative

Cost

out

initiative

raised

to

$165M

and

then

$185M

Cost out initiative

concluded > $200M

in 2012

Simplex ceilings

acquisition

(Architectural

Specialties)

Divestiture of

Cabinets and

Patriot flooring

distribution

businesses

Announced organic

investment in emerging

markets –

began construction of 3

plants in China

New global

Ceilings CEO

New CFO and global Flooring CEO

Both internal promotions

Delivered $50M in manufacturing

productivity in 2013 and 2014 combined

Growth through focus on innovation,

product adjacencies and design.

Exited European Flooring business in

December of 2014

Completed 3 plants in China

Completed Russia plant in early 2015

Announced North American LVT

manufacturing investment with expected

completion in 2015

Repurchased

~5M shares ($260M)

in third quarter of 2013

* Discrete cost out program spanning 2010 through 2012 included Cabinets and

European Flooring business |

12

Creating Two Independent Industry Leaders

[Armstrong World Industries]

•

Global commercial suspended ceiling solutions provider

•

#1 market position in all major geographies

•

Poised to deliver margin expansion driven by recovery in

North American commercial

•

Recently completed investments in expanded sales and

manufacturing capabilities

•

Attractive opportunities for enhanced growth and margins,

including emerging markets

•

23 year WAVE JV delivered $68M of cash dividends and

$65M of equity earnings in 2014

Vic Grizzle

Chief Executive Officer

Key Statistics (2014 Year End)

$1.3B (95/5)

Revenue

(% Commercial vs. Residential)

$330M

*

Adjusted EBITDA

~3,400

Team Members

Worldwide

22

Manufacturing Facilities

in 8

Countries

†

100+

Countries Have Armstrong

Ceilings

[Armstrong Flooring ]

•

Dedicated hard surface flooring products designer and

manufacturer

•

Substantial margin expansion, driven by mix and

operating leverage

•

Positioned to benefit from expected recovery in North

American commercial

•

Significant growth opportunity in Asia

•

Well-positioned for both residential and non-residential

cyclical recoveries

Don Maier

Chief Executive Officer

Key Statistics (2014 Year End)

$1.2B (35/65)

Revenue

(% Commercial vs. Residential)

$114M

*

Adjusted EBITDA

~3,600

Team Members

Worldwide

17

Manufacturing Facilities

in 3

Countries

8,000,000+

Annual Visitors to

Global Websites

*Does not include unallocated corporate expense of $60 million

†

Including the WAVE JV |

•

Final approval of Armstrong’s Board of Directors

•

Receipt of opinion of counsel regarding the tax-free nature of the

separation •

Effectiveness of a Form S-1 filing with the Securities and Exchange

Commission

Principal

Closing

Conditions

Separation Details

•

Expected tax-free spin-off of AFP to current AWI shareholders

•

Expected completion in the first quarter of 2016, subject to customary

conditions

Structure and

Timing

•

Separation Management Office (SMO) to lead transition planning

•

Expect to enter into intercompany agreements for certain shared services

Transition

Management |

Operational

•

Little overlap, no significant

synergies from operating as

combined entity

•

Enhances ability to address

unique customer needs

•

Greater opportunity to build

stronger and more intimate

customer relationships

Enhanced Opportunities To Create Value

Strategic

•

Increases flexibility to

pursue domestic and

international growth

opportunities

•

Sharpens focus on distinct

strategic priorities and

distribution channels

•

Closer alignment of

compensation/incentives to

performance

Financial

•

Optimized capital

structures to match

different risk and cash

flow profiles

•

Direct access to capital

markets to fund growth

agendas

•

Allows investors to better

assess each business on

its own merits

Two Companies With Distinct Operating Models, Market Dynamics, Capital

Needs and Distribution Channels, With Minimal Overlap And Synergies

|

•

Protect

and

grow

our

North American businesses

•

Optimize

our

portfolio

through

ongoing evaluation of strategic

opportunities by business, by

geography and across the company

•

Build

on

our

core

competency

of

driving specifications in the architect

and designer communities while working

with our distribution partners to create

and enhance value

•

Pursue

growth

in

key

international

and emerging markets

•

Seek

adjacent

opportunities

to

expand

our product line and geographic reach

Armstrong’s Business Priorities |

Armstrong

Ceilings

Overview |

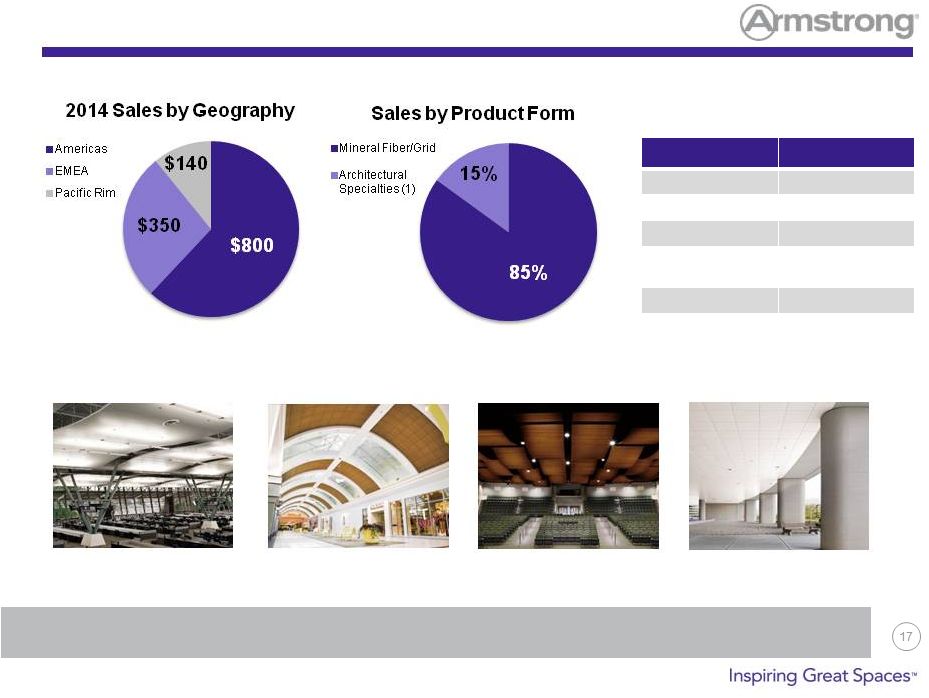

Global Ceilings Revenue and Product Mix

Commercially oriented business with diverse end-use applications

Sales by End-use Segment

Office

Retail

Education

Healthcare

Segment

% of Business

Office

30% -

40%

Retail

15% -

25%

Education

15% -

25%

Transportation /

Other

10% -

20%

Healthcare

5% -

15%

(1) Consists of wood, metal and other alternative material ceilings manufactured or

sourced by the company |

•

Seamless customer relationship –

customers buy an Armstrong ceiling system

•

ROIC >100%

•

Over $290 million in cash dividends

to Armstrong from 2011 to 2014

•

8 Manufacturing plants in 5 countries

•

Products and services help drive

specifications and deliver efficiency

to contractors

WAVE –

Armstrong/Worthington 23 Year JV

Integral to Armstrong Ceiling business success |

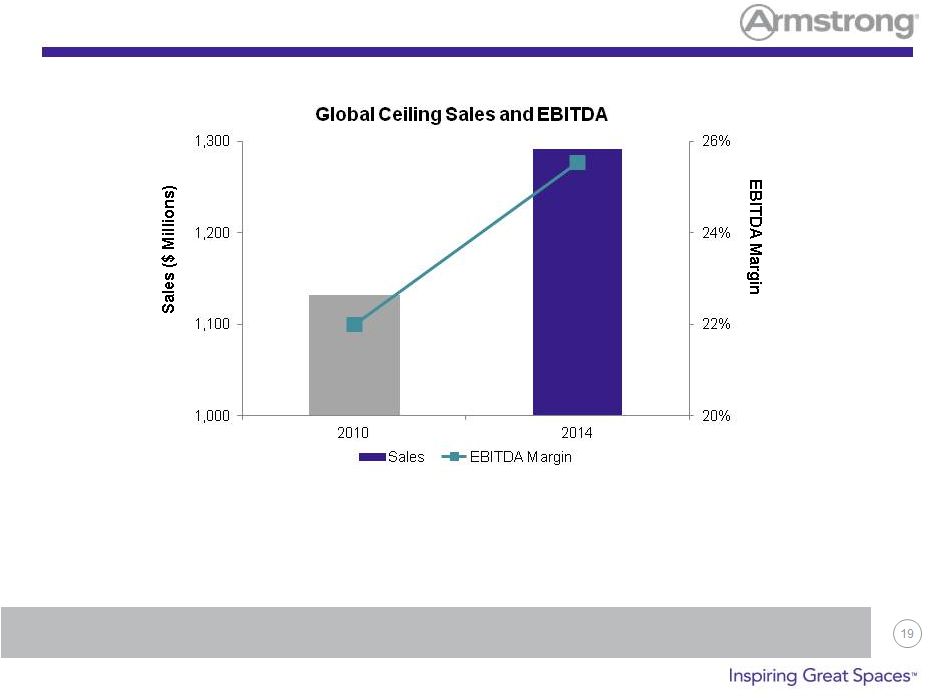

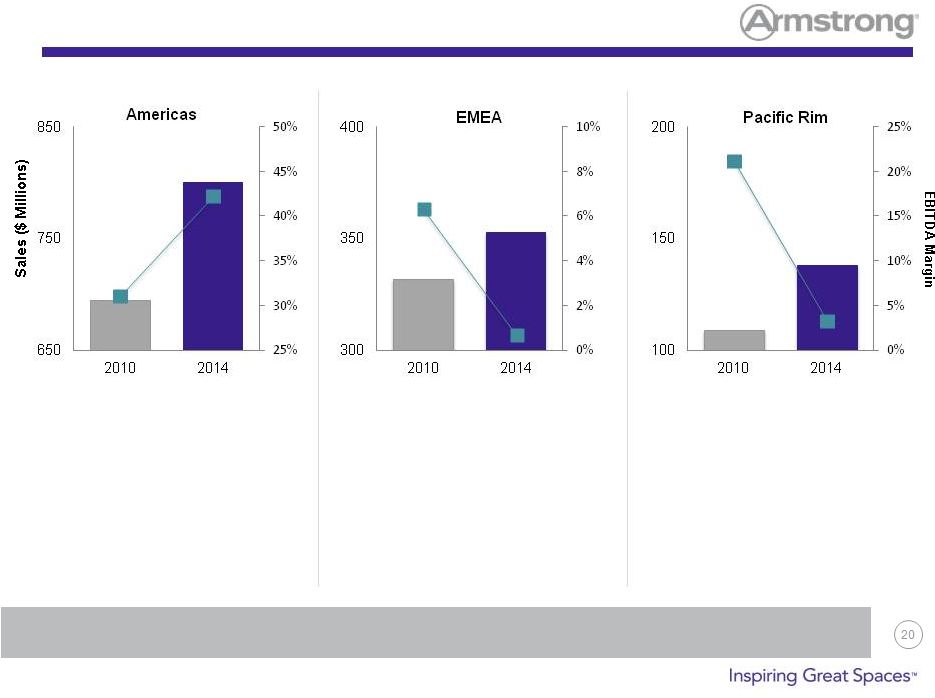

Sales and margin growth despite market challenges

•

Sales up 14% despite flat global volumes

•

EBITDA margins up 350 bps –

price, mix, earnings from WAVE and cost improvement

Global Ceiling Sales and EBITDA |

Regional Mix

Global improvements led by North America

•

~20% sales growth in UK,

Russia and Middle East

•

Offset by market contraction

in Continental Europe

•

Significant Russia plant

start-up investment during

2014

•

Sales +15% despite

lower volumes

•

EBITDA margin expands

1100 bps –

price, mix,

manufacturing productivity,

WAVE earnings

•

Growth in India and China

offset Australia market

decline

•

Completed China plant

including metal capability in

2013 and 2014

•

Capacity in place to serve

future growth in region |

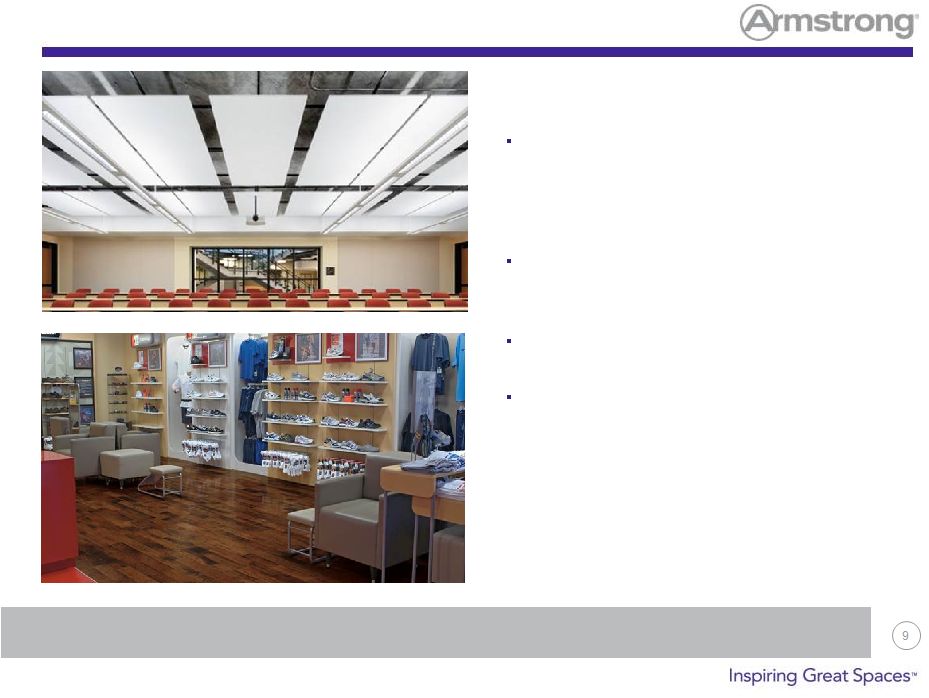

Architectural Specialties (AS) Overview

Enhancing our value to core customers in a differentiated way

•

Specialty ceiling systems targeted at customer

need for a design-oriented aesthetic

•

Same customer as mineral fiber ceilings,

often combined on the same project

•

Many different materials and product forms

•

Lower volume, higher price, sometimes

involving custom design and engineering

What Is AS?

What Makes Armstrong Unique?

Global

footprint

to support

global projects

Broadest portfolio of

on-trend specialty ceiling

solutions in the world

Consistently

high level

of quality

A “high

touch”

service

model

Easiest

To Do

Business

With |

The

AS Financial Equation An attractive ROIC-accretive global growth

engine within the ceilings segment

Big Penetration

Opportunity

Attractive Stand-Alone

Economics

Total Ceilings

Portfolio Synergies

•

$2B

market

opportunity

•

Highly

incremental

–

fragmented regional

competition

•

High incremental

margins

•

Lower fixed asset

intensity = high ROIC

•

Unique multi-product

specifications

•

Customer loyalty

driver

•

“Pull-through”

effect

on core mineral fiber

ceilings |

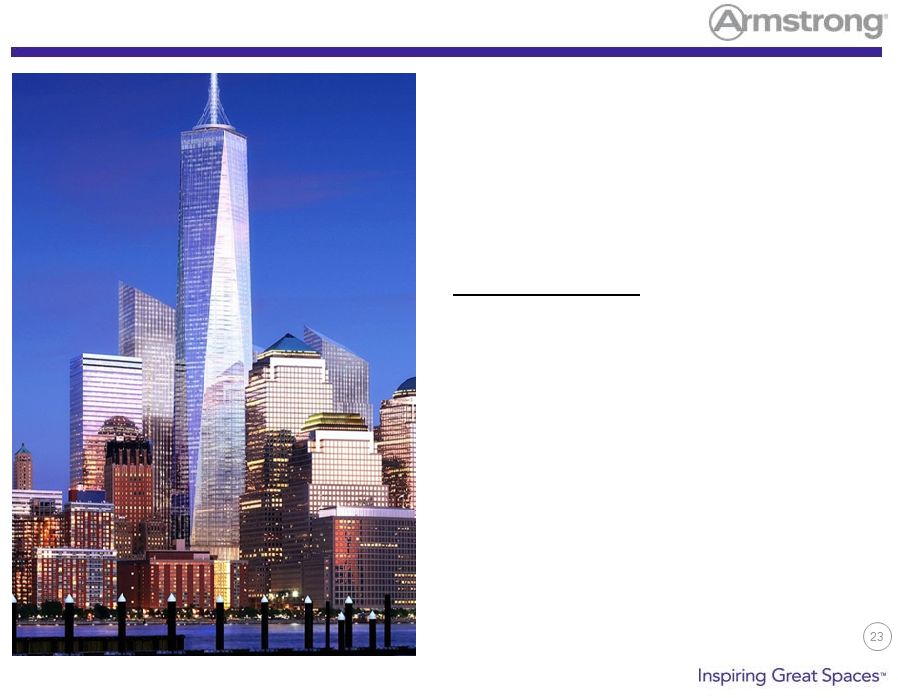

“Freedom Tower”

-

Conde Nast

Recently won the ceilings supply for

Conde Nast, an anchor tenant for this

iconic building, taking 25% of the floors

Why Armstrong:

•

Only company able to combine our

acoustical tile, Architectural Specialties

and grid solutions to effectively meet

customer’s challenging needs

•

Provided design services to enable a

unique visual

•

Ability to support a compressed

construction schedule

Case Study: One World Trade Center |

•

Leverage global reach and scale

•

Win specification game

Multi-product offering …

1-stop shopping

Supported with design services

•

Remodel opportunity

•

Prepared for demand uptick

Global Ceilings Summary |

Armstrong

Flooring

Overview |

Global Flooring Revenue Mix

Balanced exposure to Residential and Commercial recovery

Commercial

35%

Residential

65%

Total Business

Remodel

70%

New

30%

Remodel

75%

New

25%

Commercial

Residential

Office 10% -

20%

Retail 15% -

25%

Education 20% -

30%

Healthcare 20% -

30%

Other 10% -

20%

Commercial Sales by End-Use Segment |

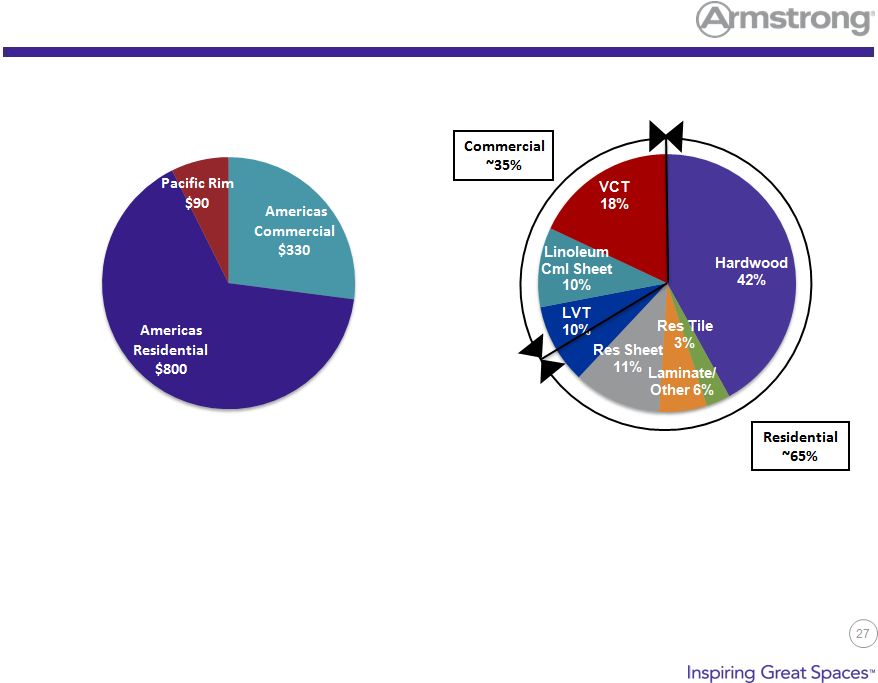

•

> 90% of sales in North America –

the core earnings driver of the business

•

Mix of Commercial and Residential in North America

•

Residential is a North American business –

business outside of North

America is all Commercial

Geographic and Product Mix

2014 Sales by Geography

Total = $1.2B

2014 Sales by Product |

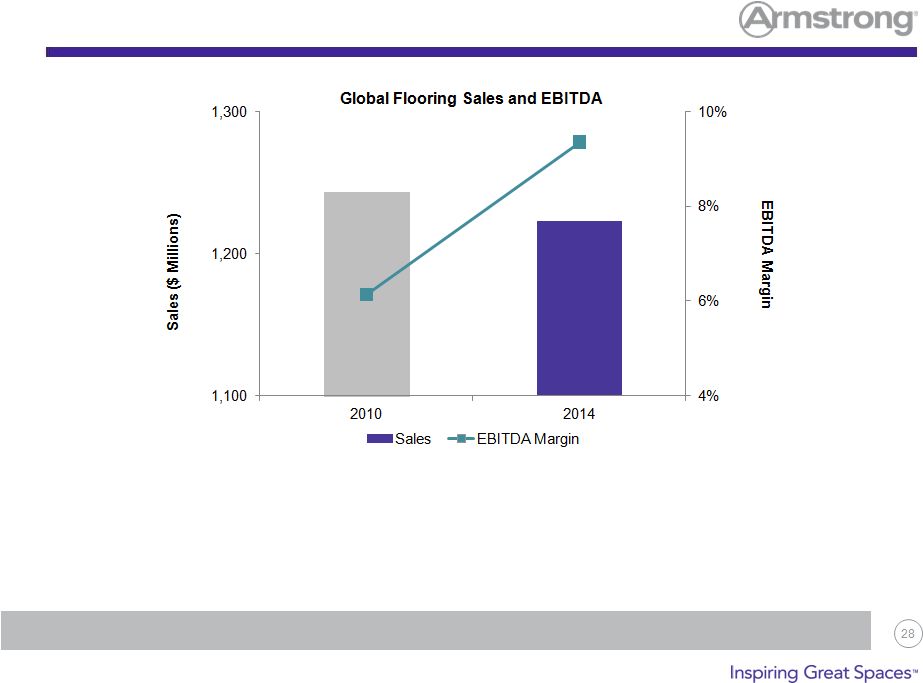

•

Sales down <2% due to volume declines and divestiture of the Patriot

distribution business •

EBITDA margins improve 320 bps despite volume declines and investments in

China Global Flooring Total Sales and EBITDA

Remixing the portfolio to higher margin products |

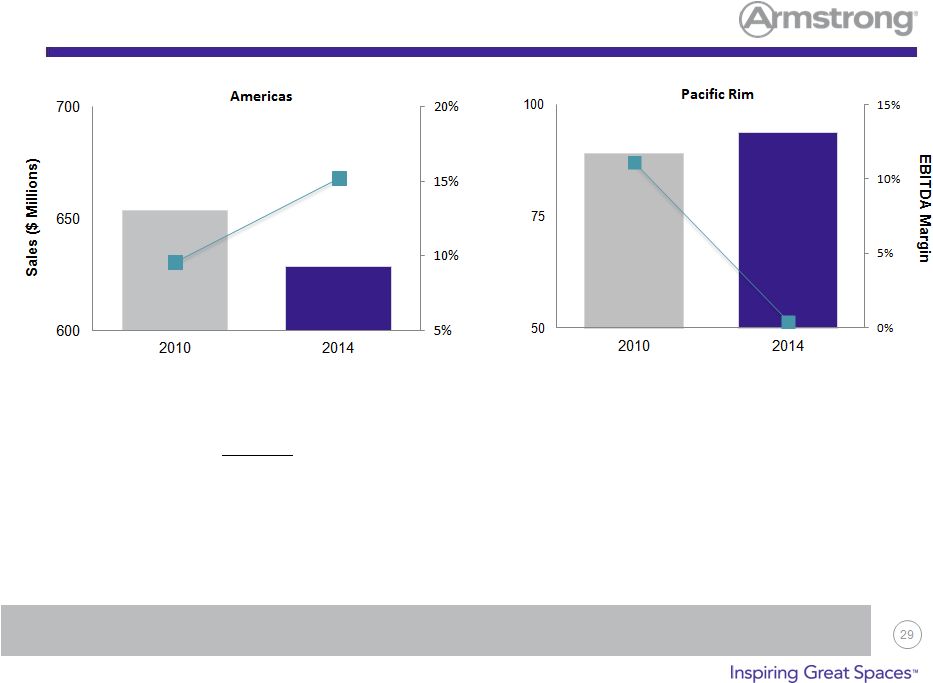

Resilient Flooring

North American performance drives segment profit growth

•

Sales down <4% despite double digit

volume declines

•

Margins

expand

560

bps

despite

negative volume leverage

(manufacturing productivity, mix and

price all improve)

•

Sales are up 5% as weakness

in Australia is offset by growth in

China

•

EBITDA margins impacted by plant

/ commercial investment in China

and Australian weakness |

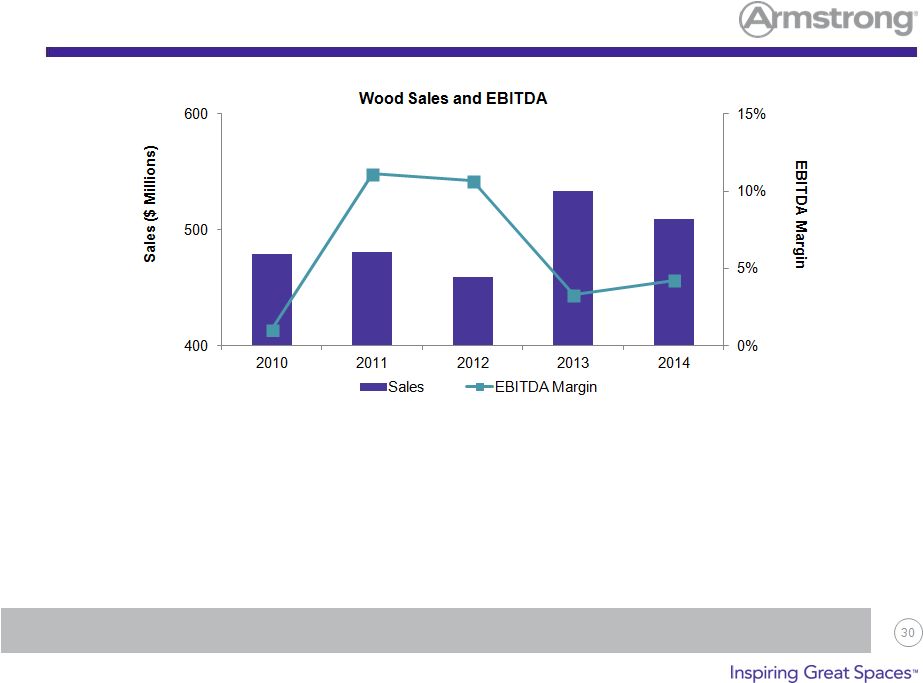

Wood

– A Cyclical Business

Focusing on higher mix products and channels

•

Leadership share in North America

•

At trough volumes in 2011 and 2012, EBITDA margins were +10% and

ROIC was ~8%

•

Nearly $80M in commodity inflation in the last two years

|

Our

Strategy Residential Flooring

Extend leadership share and

returns

Where To Play:

•

Significantly increase share in fast-growing LVT

•

Protect our leading share position in Sheet Vinyl

•

Expand accessories and floor care solutions

Commercial Flooring

Where To Play:

•

Win in the Healthcare, Education and Retail sectors

•

Dramatically increase share in fast-growing LVT

•

Protect our leading share position in VCT in

North America

Protect leadership share and

margins |

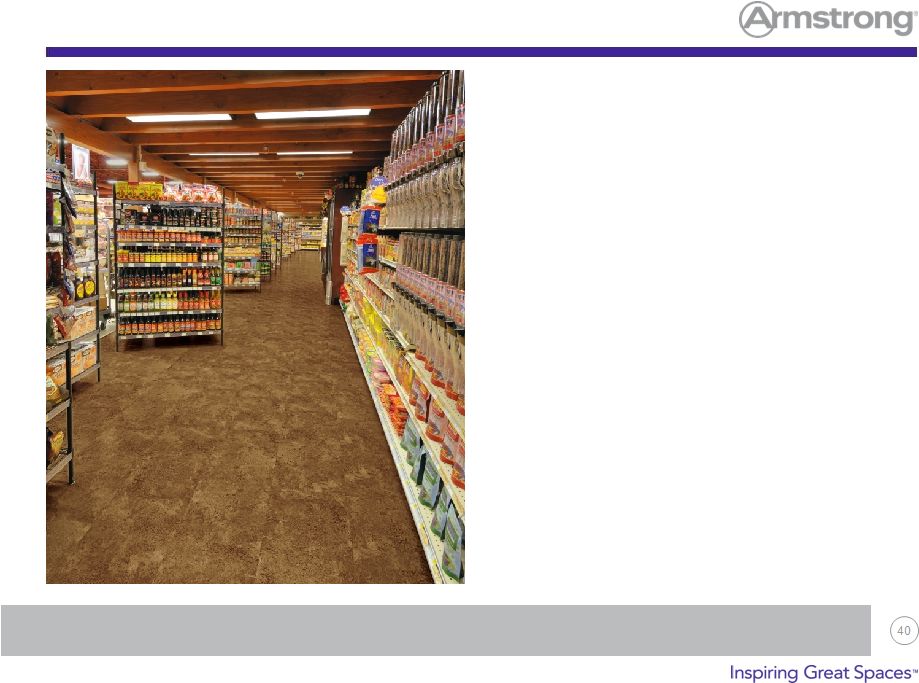

Retail Case Study –

Why Armstrong

Product Solutions •

Design Leadership •

Brand Recognition

•

LVT in all stores / BBT in most stores

•

Bamboo & striated visual

•

Environmental statement (bio-based tiles)

•

Local access, fast installation and easy to maintain

Partnership

Consultative •

Service •

Reliability

•

2012: Striations bio-based tile as a prototype

•

2013: Over 420 stores refurbished

•

2014:

460 locations refurbished (continued expansion 2015)

Sector: Refresh drives traffic –

likely source of pent up demand |

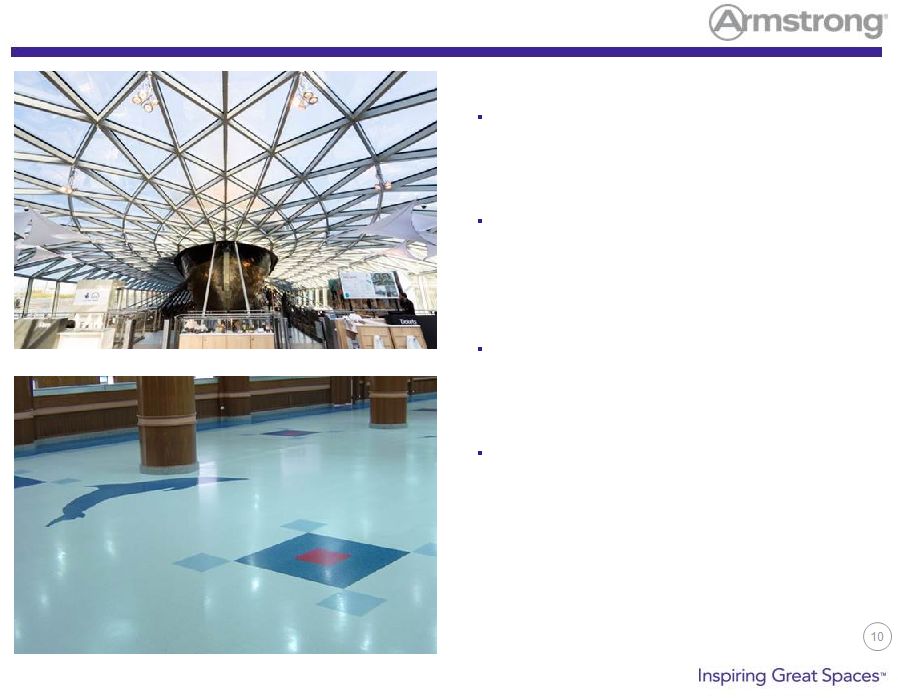

•

Resilient flooring in North America is a

valuable franchise with strong returns and

significant incremental margins

•

Focusing on higher mix/margin products and

channels

•

Growth opportunities in the Pacific Rim

•

Better utilizing our global footprint to lower

costs and speed innovation

•

Exited unprofitable flooring business in

Europe

Armstrong Flooring –

Summary |

Growth through

Innovation |

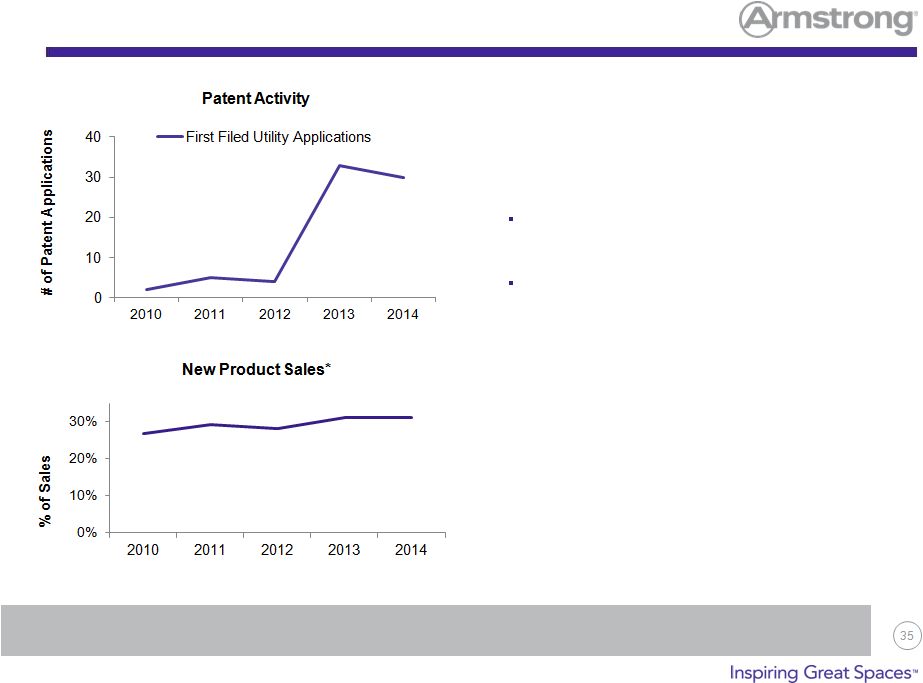

•

Dynamic strategy driven by customer needs

•

Deploying new product development, R&D,

and technical resources globally to the

highest value creation opportunities

Development of global and multi-

generational product platforms

Patent applications increased more than

5x since 2010

•

Differentiation that is valued by customers =

higher margins

•

Innovation is not limited to just new products

but extends to “how”

we do business

Renewed Focus on Innovation

Innovation efforts accelerating

* Metric based on % of total sales for products introduced in the last five years.

|

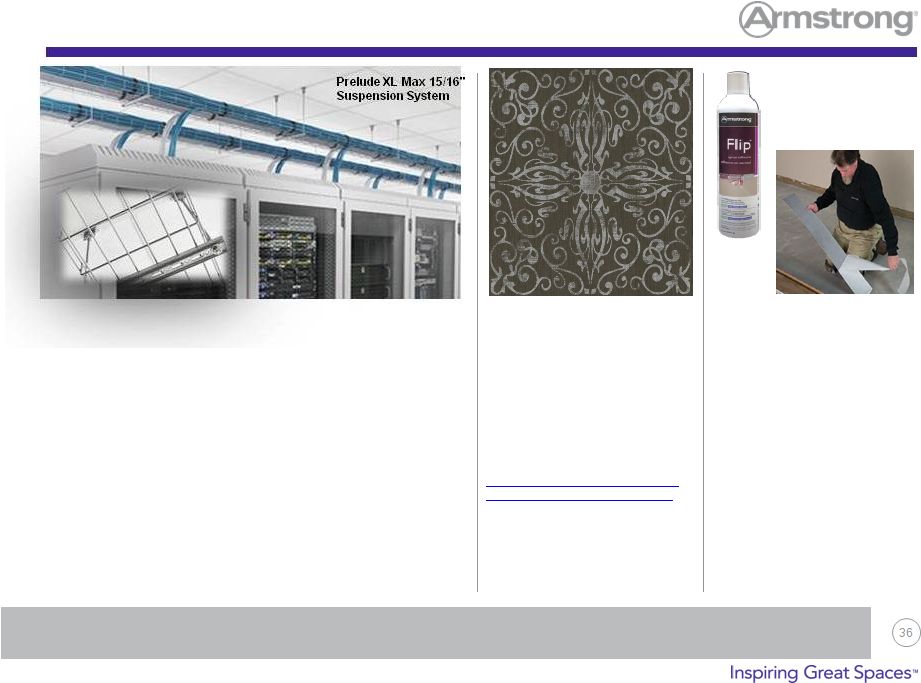

Inspiring Great Spaces through Leadership in Product Innovation

Complete Data Center Ceiling Systems

Prelude XL Max 15/16" Suspension System

Now Supports point loads up to 200 lbs. using 3/8" threaded rod

and integrated hanging clips to provide:

•

Flexible and reconfigurable overhead cable tray and

electrical distribution to meet client needs without a

separate strut channel system.

•

Eliminates unsightly threaded rod penetrations through the

ceiling plane for improved access and aesthetics.

•

Eliminates ceiling penetrations to help minimize unwanted

air infiltration

•

30-Year Limited System Warranty

Custom

colors

available

to

coordinate

with

Ultima®

Create!™

ceiling panels

FLIP™

is a hand-held spray

adhesive. This innovative

flooring spray adhesive allows

contractors and installers to turn

a small room in less time,

returning the area to a functional

revenue-generating space

quicker.

FasTak™

& iset™

are factory

applied adhesive systems for

residential and commercial LVT

NATURAL CREATIONS®

ArborArt®

•

EarthCuts®

•

Mystix®

Luxury Vinyl Tile (LVT)

Natural Creations collection of luxury

vinyl tile was awarded ADEX Gold

for Design Excellence. Natural

Creations offers traditional, rustic

and exotic wood-looks in ArborArt,

EarthCuts and contemporary design

trends in Mystix.

Natural Creations®

Luxury Vinyl Tile

with the I-Set™

Installation System

from Armstrong Commercial

Flooring has also been recognized

by Design Journal and Archinterious

as one of the best products of 2014.

Innovations in installation and design that inspire customers

•

Immediate occupancy,

no wet glue

•

Fast & easy install, repair,

and replace |

Ultima / Optima

Fissured / Cortega

Acoustics (NRC)

Light Reflect

Recycle Content

Anti Mold/Mildew

Warranty

0.70 / 0.90

0.90

86% / 71%

Yes

30 Years

Acoustics (NRC)

Light Reflect

Recycle Content

Anti Mold/Mildew

Warranty

0.55

0.81 / 0.82

41%

No

1 Year

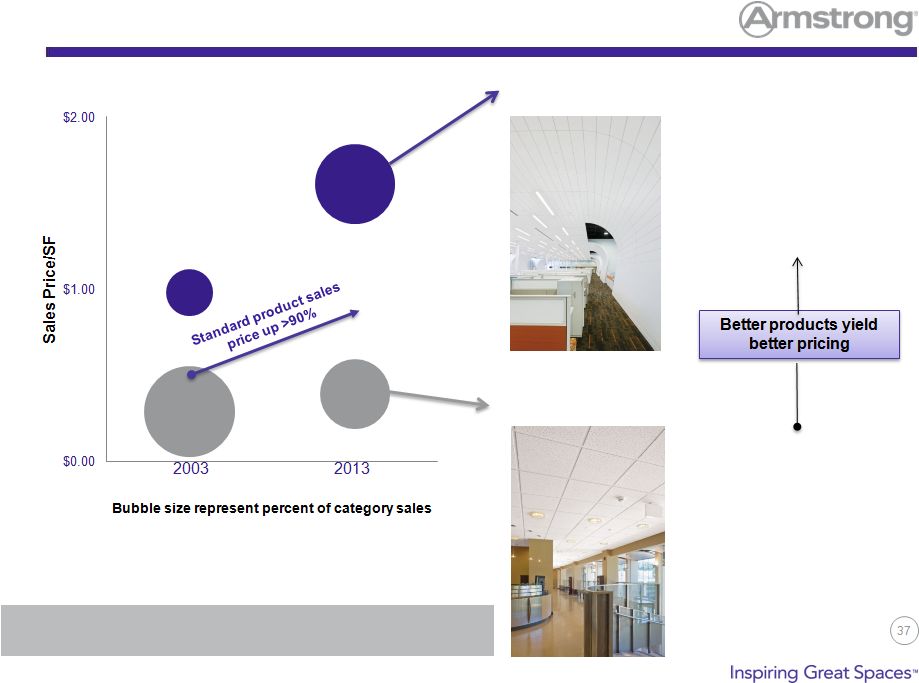

Mix Evolution -

Ceilings Americas

Innovation enables gains in price and mix |

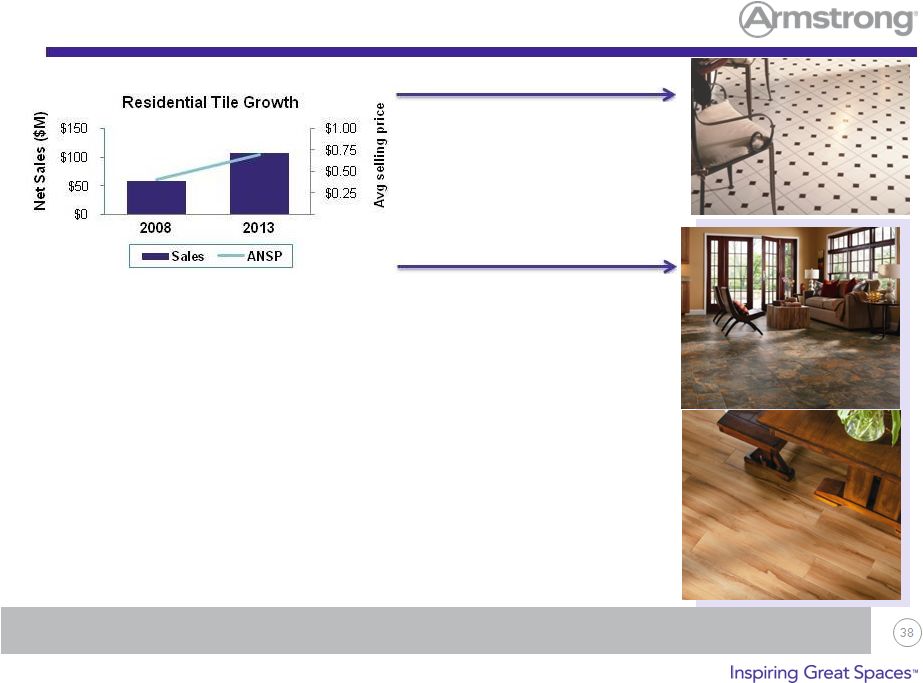

•

Sales CAGR ~5x volume

growth during this time

period

•

Direct Margin $’s grew at a

CAGR of >33%

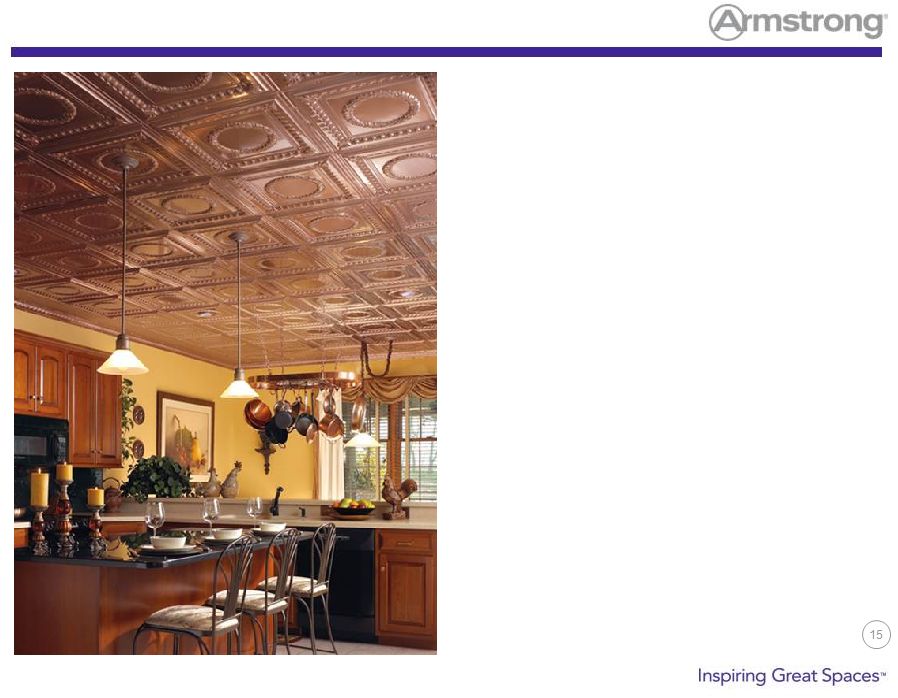

Mix Revolution -

Residential Floor Tile

Innovation

led

growth

driving

“mix

up”

within

the

category

and

improved

profitability

Alterna -

Allegheny Slate

–

Copper Mountain

Luxe with FasTak –

Groveland -

Natural

•

Growth driven by category expansion, product innovation and new

introductions:

•

Alterna, groutable engineered stone tile utilizes proprietary technology to

mimic the detail, texture and variation of natural stone

•

Luxury vinyl plank offerings such as Luxe, Natural Living, Natural

Personality

•

Present & Future Growth

•

Alterna features multiple sizes and wall installation

•

LVT domestic production enables Armstrong to expand offering and

increase speed to market

•

New innovations in installation (FasTak) and evolution of design

establish

Armstrong as the market leader

Standard residential tile

offering in 2008

From:

To: |

Financial

Summary |

•

Positioned to benefit from North American

commercial recovery

•

Capture growth in established international

and emerging markets

•

Maintain a strong balance sheet

Focused on Value Creation

ROIC focused |

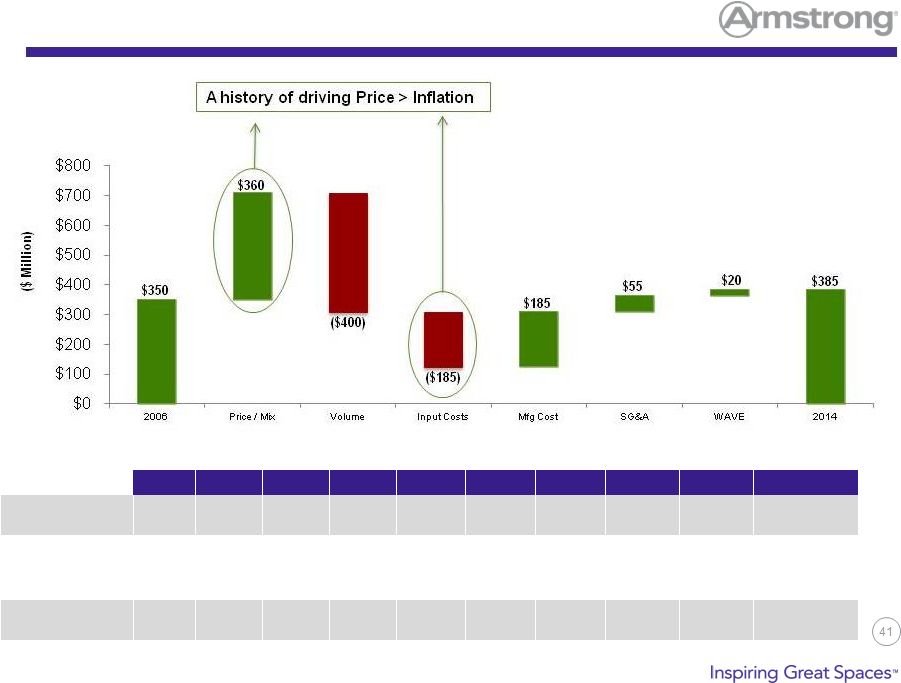

Adjusted EBITDA History

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015 Est.

Sales

$2.94B

$2.97B

$2.81B

$2.35B

$2.34B

$2.43B

$2.40B

$2.51B

$2.52B

$2.53 -

$2.63B

Non-cash U.S.

Pension impact

($50M)

($59M)

($63M)

($58M)

($51M)

($26M)

($12M)

($2M)

$1M

$22 -

$28M

Adjusted EBITDA

$350M

$379M

$349M

$261M

$263M

$349M

$391M

$372M

$384M

$350 -

$390M

EBITDA as % of

Sales

11.9%

12.8%

12.4%

11.1%

11.2%

14.4%

16.3%

14.8%

15.3%

~14.4% |

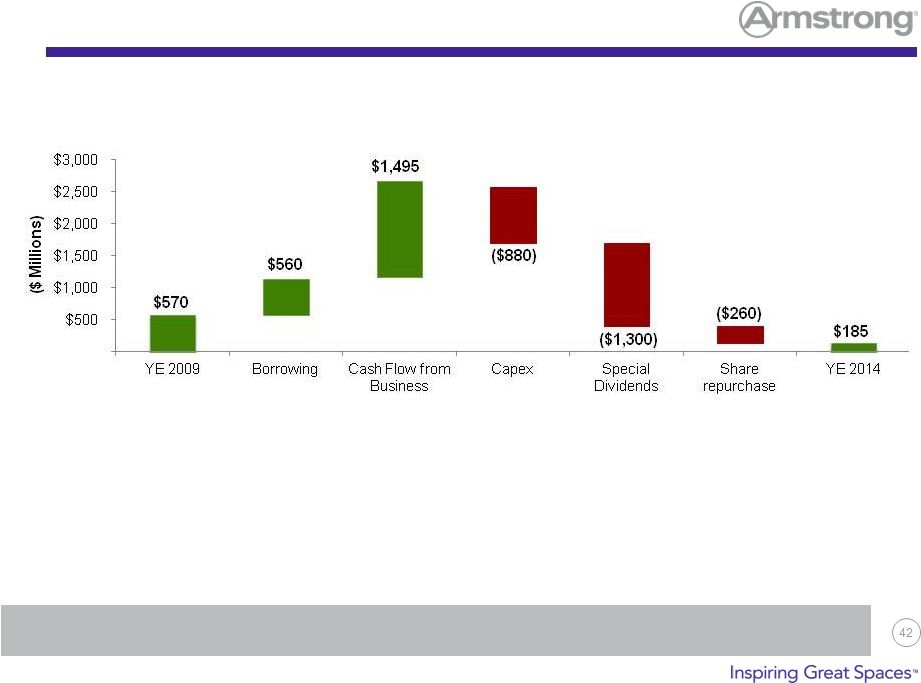

Cash

Flow History Significant cash investments and returns to shareholders

•

Created and maintained an efficient balance sheet

•

Cash generation aided by low cash tax rate from Chapter 11 Net Operating Loss (NOL)

carry-forward •

Prioritized investments in capital expenditures to drive global growth

•

Completed construction of 3 China plants, Russia plant and mineral wool plant with

LVT plant underway

•

Returned surplus cash via special dividends and share repurchase

|

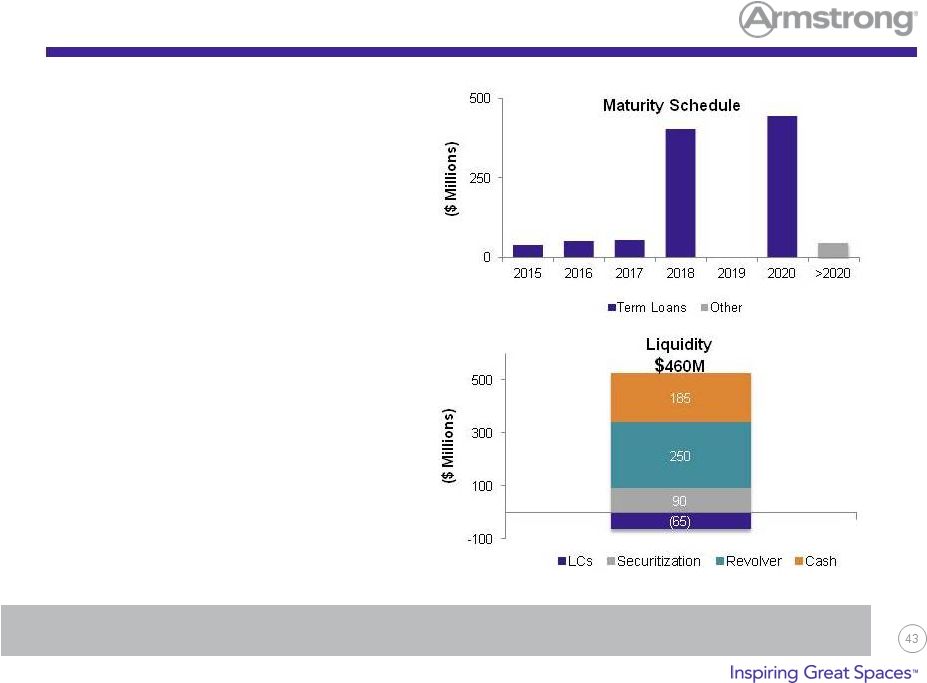

Well-positioned and efficient balance sheet

Balance Sheet –

12/31/14

Net Debt

$860M

LTM EBITDA

$384M

Leverage

2.2x

•

No significant maturities until 2018

•

Considerable covenant headroom

•

Sufficient liquidity

•

Well funded US pension plan;

no contributions in >20 years

Current Leverage |

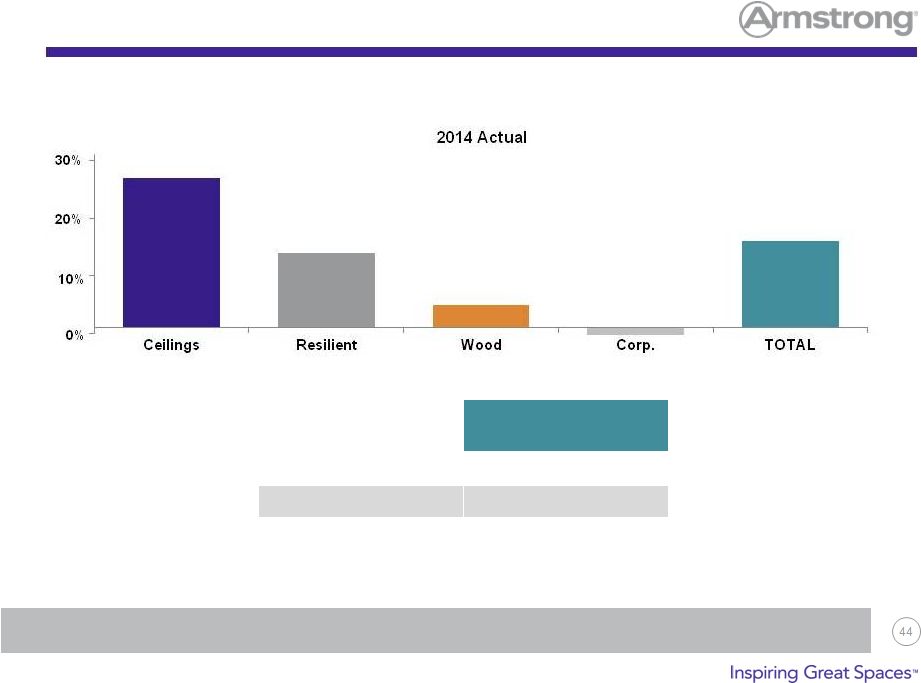

Path

to Growth – Adjusted EBITDA margin

Incremental margins on additional volume can drive margin improvement

Margin on

Incremental Volume

Ceilings

30% -

45%

Resilient

20% -

35%

Wood

20% -

30% |

Investment Highlights

Diversified $2.5 billion global building products company

with leading positions in most key markets and products

Driving value creation through:

–

Recovery in North America

•

U.S. Commercial is our most profitable business

with

35-45% incremental margins

–

Growth in International Markets

•

Emerging market investments and

recovery in developed markets

–

Leveraging innovation to drive profitable growth

•

Focus on design, environmental leadership, installation

and application enhancements

•

New product benefits to drive improved mix

Focused on creating shareholder value |

Financial

Overview

Appendix |

EBITDA Bridge –

Full Year 2014 vs. Prior Year |

2015 Estimate Range

(1)

2014

(2)

Variance

Net Sales

(3)

2,525

to

2,625

2,515

0%

to

4%

Operating Income

(4)

230

to

270

271

(15%)

to

(1%)

EBITDA

350

to

390

389

(10%)

to

0%

Earnings Per Share

(5)

$2.05

to

$2.45

$2.38

(14%)

to

3%

(1)

Guidance is presented using 2015 budgeted foreign exchange rates

(2)

2014 results are presented using 2015 budgeted foreign exchange rates

(3)

2015 and 2014 net sales include the impact of foreign exchange

(4)

As reported Operating Income: $175 -

$215 million in 2015 and $239 million 2014

(5)

As reported earnings per share: $1.25 -

$1.60

in 2015 and $1.83 in 2014

Key Metrics –

Guidance 2015 |

2015

Financial Outlook Sales

(1)

$1,300-$1,350 million; EBITDA $335-$360 million

Sales

(1)

$1,225-$1,275 million; EBITDA $80-$100 million

EBITDA ($65) –

($70)

$45 -

$55 million; Adjusted long-term ETR of ~39%

(2)

$125 -

$150 million

Non-cash:

$22 -

$28 million US pension expense

Cash:

$20 -

$40 million transaction costs

ABP Segment

AFP

Segment

Cash Taxes/ETR

Capital Spending

Exclusions from EBITDA

(1)

Net sales include foreign exchange impact

(2)

As reported ETR of 47% for 2015

Corporate Segment |

Full

Year Adjusted EBITDA to Reported Net Income 2014

2013

V

EBITDA–

Adjusted

$384

$372

$12

Depreciation and Amortization

(118)

(103)

(15)

Operating Income –

Adjusted

$266

$269

($3)

Non-cash impact of U.S. pension

1

(2)

3

Foreign Exchange Movements

(1)

(2)

1

Impairments

13

-

13

Cost Reduction Initiatives

14

7

7

Operating Income –

As Reported

$239

$266

($27)

Interest/Other (Expense)

(54)

(67)

13

EBT

$185

$199

($14)

Tax (Expense)

(83)

(72)

(11)

Net Income

$102

$127

($25) |

Management Team |

Matthew J. Espe, Chief Executive Officer and

President In July 2010, Matthew J. Espe was appointed CEO of

Armstrong World Industries, Inc., in Lancaster, Pennsylvania.

Matt brings 30 years of experience in sales, marketing, distribution and

management with global manufacturing businesses to Armstrong. In his

previous role at Ricoh Americas Corporation, a subsidiary of Ricoh Company,

Ltd., he served as chairman and CEO. Prior, he was chairman and CEO of IKON Office Solutions, Inc.,

a $4 billion office equipment distributor and services provider with 24,000

employees. Ricoh acquired IKON in 2008. Before joining IKON in 2002, Matt

was president and CEO of GE Lighting. In a career that spanned 22 years there,

he managed multiple business units as well as functions including sales,

marketing, distribution and manufacturing. Along with a wealth of

experience, he also brings a finely-tuned global perspective, having led businesses in Europe,

Asia and North America.

Matt is a former director of Unisys Corporation and Graphic Packaging, Inc. He

currently serves on the advisory board

at

the

College

of

Business

and

Economics

at

the

University

of

Idaho

and

on

the

advisory

council

for

Drexel

University's Lebow College of Business, Center for Corporate Governance.

Additionally, Matt is a member of the National Association of Corporate

Directors (NACD) and the Wall Street Journal CEO Council. He graduated from

the University of Idaho with a bachelor's degree in marketing, and received his

MBA from Whittier College. David S. Schulz is senior vice president and CFO

of Armstrong World Industries, Inc., in Lancaster, Pennsylvania.

Mr. Schulz joined Armstrong in 2011 as vice president, finance for Armstrong

Building Products. Prior, he served as CFO of Procter & Gamble

Company’s Americas snacks division, and from 2008 to 2009 as

the

finance

director

for

the

Coffee

business

unit

of

the

J.M.

Smucker

Co.

following

the

merger

of

P&G’s Folgers Coffee Co. with Smucker. His experience covers a wide range

of finance leadership positions encompassing operational finance, planning

and analysis, mergers and acquisitions, and financial reporting. Well known

as a strong business partner, Mr. Schulz actively engages with other

functions to drive improvement. Prior to joining Procter & Gamble, Mr.

Schulz was an officer in the United States Marine Corps.

He

earned

his

bachelor’s

degree

in

finance

from

Villanova

University

in

1987

and

a

master’s

degree

in management from the U.S. Naval Postgraduate School in 1993.

David S. Schulz, Senior Vice President and Chief Financial

Officer |

Don

Maier, Executive Vice President, CEO Armstrong

Floor Products Worldwide Victor Grizzle,

Executive Vice President, CEO Armstrong Building Products

Victor

“Vic”

Grizzle

is

executive

vice

president

and

CEO,

Armstrong

Building

Products,

in

Lancaster,

Pennsylvania.

Mr. Grizzle has 23 years of experience in process improvement, sales, marketing

and global business leadership. He comes to Armstrong from Valmont

Industries, a $2 billion global leader of infrastructure support structures for utility,

telecom and lighting markets, and manufacturer of mechanized irrigation equipment

for large scale farming, where he was

group

president

of

Global

Structures,

Coatings

and

Tubing

since

2005.

Prior

to

Valmont,

Mr.

Grizzle

was

president of the commercial power division of EaglePicher Corporation, a $700

million diversified manufacturer and marketer of advanced technology and

industrial products for space, defense, automotive, filtration, pharmaceutical,

environmental

and

commercial

applications.

Before

that,

he

spent

16

years

at

General

Electric

Corporation.

Mr. Grizzle graduated from California Polytechnic University with a Bachelor of

Science in Mechanical Engineering. Don Maier is the EVP & CEO of

Armstrong Floor Products. He joined Armstrong in January 2010 and was

most recently the senior vice president, Global Operations.

Don came to Armstrong from TPG Capital Advisors, the global buyout group of TPG, a

private investment firm. Prior, he held a steady progression of roles at

Hillenbrand Industries, beginning in 1987 as a manufacturing and product

engineer for subsidiary Batesville Casket Company, and later moving from

product development and marketing leadership roles to vice president, Manufacturing

and Operations. In 2002, he became vice president, Strategy and Business

Development, for a larger Hillenbrand subsidiary, Hill-Rom, a $1.5

billion leading global producer of health care equipment, technology and workflow IT

systems. In 2003, he became vice president and general manager, and in 2005 he was

named senior vice president –

North America. In that role, he had P&L responsibility for a $1.4 billion

business with a $325 million operating budget and $90 million capital

budget. Don is a member of the board of directors of the National Association

of Manufacturers. He holds a bachelor’s degree in Industrial Systems

Engineering from The Ohio State University in Columbus, Ohio, and an MBA,

with a concentration in Marketing, from Xavier University in Cincinnati, Ohio. |

Thomas J. Waters, Vice President Treasury & Investor Relations

Thomas J. Waters is Vice President, Treasury and Investor

Relations of Armstrong World Industries, Inc. Mr.

Waters

joined

Armstrong

in

1998

as

Manager,

Capital

Markets.

Since

then

he

has

held

the

positions

of Director of Investor Relations, General Manager of Finance and IT for Building

Products Europe, General Manager

Financial

Planning

and

Analysis

for

North

American

Floor

Products.

He

was

named

Treasurer

in

2008, and added investor relations responsibilities in 2010.

Prior to Armstrong, Mr. Waters worked for American Airlines in Dallas, TX in both

Treasury and Operational Finance roles.

Mr. Waters earned a BA from Binghamton University, and a MBA from the Walter A.

Haas School of Business at the University of California, Berkeley.

Kristy Olshan is Investor Relations Manager of Armstrong World Industries, Inc.,

in Lancaster, Pennsylvania.

Mrs. Olshan became Investor Relations Manager in December of 2010 and has

responsibility for managing all external investor communications. Mrs.

Olshan joined Armstrong in November of 2008 as External Reporting Manager.

Prior to Armstrong, Mrs. Olshan spent over 5 years in public accounting as

an auditor and advisor to clients in the construction engineering, banking,

utility, and manufacturing industries with a focus on SEC reporting and

Sarbanes-Oxley compliance. Mrs. Olshan is also a Certified Public

Accountant and member of the AICPA. She previously served on the board

as Treasurer of the York Hospital Auxiliary, a Wellspan affiliated non-profit

organization. Mrs. Olshan earned a bachelor of science

with dual degrees in Business Administration and Accounting, and an MBA from

York College of Pennsylvania. Kristy Olshan, Investor

Relations Manager |

Investor Relations Contact Information

Kristy Olshan, CPA, MBA

Investor Relations Manager

Armstrong World Industries

2500 Columbia Avenue

Lancaster, PA

17604

P: 717-396-6354

F: 717-396-6128

E: ksolshan@armstrong.com

Thomas J. Waters

VP, Treasury and Investor Relations

Armstrong World Industries

2500 Columbia Avenue

Lancaster, PA

17604

P: (717) 396-6354

F: (717) 396-6136

E: tjwaters@armstrong.com |