Attached files

ANNUAL MEETING 2010

Southwest Iowa Renewable Energy

The following information contains, or may be deemed to contain,

“forward-looking statements” within the meaning of Section 27A of the

Securities Act of 1933, as amended. These forward-looking statements

include all statements regarding the current intent, belief or expectations

regarding matters covered and all statements which are not statements of

historical fact. By their nature, forward-looking statements involve risks

and uncertainties because they relate to events and depend on

circumstances that may or may not occur in the future. The future

results of the issuer may vary from the results expressed in, or implied

by, forward-looking statements, possibly to a material degree. Since these

factors can cause results, performance and achievements to differ

materially from those discussed in this presentation, you are cautioned

not to place undue reliance on the forward-looking statements. Southwest

Iowa Renewable Energy, LLC (“SIRE”) will update these forward-looking

statements to reflect any material changes occurring prior to the

completion of the offering. For a discussion of some of the important

factors that could cause results to differ from those expressed in, or

implied by, the forward-looking statements contained herein, please refer

to SIRE’s Annual Report (SEC File No. 083-00131), in particular, the

“Risk Factors” section. The forward-looking statements in this document

are excluded from the safe harbor protection of Section 27A of the

Securities Act of 1933.

“forward-looking statements” within the meaning of Section 27A of the

Securities Act of 1933, as amended. These forward-looking statements

include all statements regarding the current intent, belief or expectations

regarding matters covered and all statements which are not statements of

historical fact. By their nature, forward-looking statements involve risks

and uncertainties because they relate to events and depend on

circumstances that may or may not occur in the future. The future

results of the issuer may vary from the results expressed in, or implied

by, forward-looking statements, possibly to a material degree. Since these

factors can cause results, performance and achievements to differ

materially from those discussed in this presentation, you are cautioned

not to place undue reliance on the forward-looking statements. Southwest

Iowa Renewable Energy, LLC (“SIRE”) will update these forward-looking

statements to reflect any material changes occurring prior to the

completion of the offering. For a discussion of some of the important

factors that could cause results to differ from those expressed in, or

implied by, the forward-looking statements contained herein, please refer

to SIRE’s Annual Report (SEC File No. 083-00131), in particular, the

“Risk Factors” section. The forward-looking statements in this document

are excluded from the safe harbor protection of Section 27A of the

Securities Act of 1933.

CONFIDENTIALITY

Plant Completion $200,000,000 Investment

FISCAL YEAR 2009 IN REVIEW

SIRE PLANT COST

Millions

Grain and Feed Storage $ 10.0

Rail Loop Track $ 13.0

Steam Line $ 15.5

Turbine $ 5.5

Gas Boilers and Natural Gas $ 7.0

Water Treatment $ 2.0

Land $ 2.0

Infrastructure $ 22.0

Plant Process $123.0

Total $200.0

Cost Per Gallon $ 1.82

GRAIN AND FEED

STORAGE

STORAGE

Total Cost $10.0 Million

Bushel capacity 2.6 Million

1,000,000 Bushel Storage

1,000,000 Bushel Storage

v50,000 bushels/hour unloading

50,000 bushels/hour unloading

vAverage 32,000 bushels/hour

Average 32,000 bushels/hour

vAverage Basis $-(.16) per bushel

Average Basis $-(.16) per bushel

Competition

Competition

vAll truck delivery within 75 mile radius

All truck delivery within 75 mile radius

Downtown Location

Downtown Location

1,600,000 Bushel Storage

1,600,000 Bushel Storage

Feed

vHigh Protein

vHigh Oil

vGolden Color

vExcellent Flow Ability

v13,000 Tons Storage

• 4.0 Tons-Silo

• 9.0 Tons-Building

DDG Load Out

DDG Load Out

13,000 Tons Storage

13,000 Tons Storage

RAIL LOOP TRACK

Looped Track

Looped Track

Freight Advantage-West Coast, Dallas, East Coast

Freight Advantage-West Coast, Dallas, East Coast

Distillers Dried Grain

Lease Cars-200 (Net)

Lease Cars-200 (Net)

Distillers Dried Grain

Lease Cars-200 (Net)

Lease Cars-200 (Net)

10 year lease

10 year lease

FY 2009-35% DDG Rail

FY 2009-35% DDG Rail

FY 2010-42% DDG Rail

FY 2010-42% DDG Rail

Alcohol Leased Cars-325

Alcohol Leased Cars-325

10 Year Lease

10 Year Lease

FY 2009-97% Alcohol Rail

FY 2009-97% Alcohol Rail

FY 2010-93% Alcohol Rail

FY 2010-93% Alcohol Rail

Looped Track

Looped Track

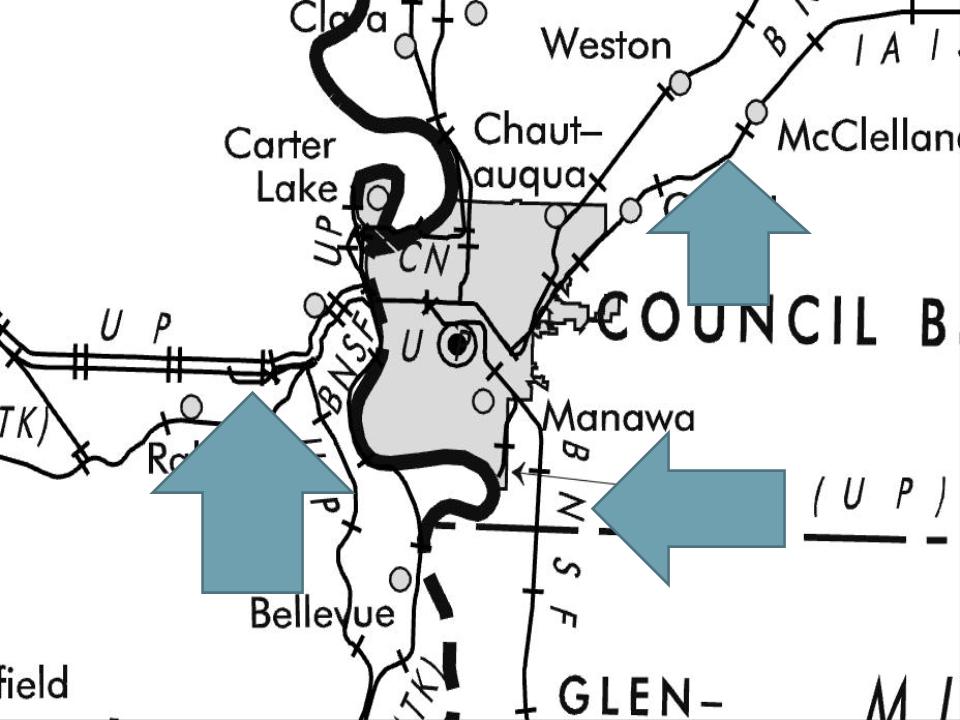

RAIL DATA

v Iowa Interstate Railroad currently handles initial

switching of cars from SIRE.

switching of cars from SIRE.

v This contract allows SIRE direct access to five Class 1

railroads to include

railroads to include

– Union Pacific (Local)

– Burlington Northern (Local)

– Kansas City Southern (Kansas City, KS)

– CSX Railroad (Chicago, IL)

– Norfolk Southern (Chicago, IL)

Locally SIRE can ship cars via IAIS, BN and UP. KCS is

serviced from Omaha/ Council Bluffs through the BN.

CSX and NS are serviced through IAIS in Chicago.

serviced from Omaha/ Council Bluffs through the BN.

CSX and NS are serviced through IAIS in Chicago.

U

P

P

BN

IA

IS

IS

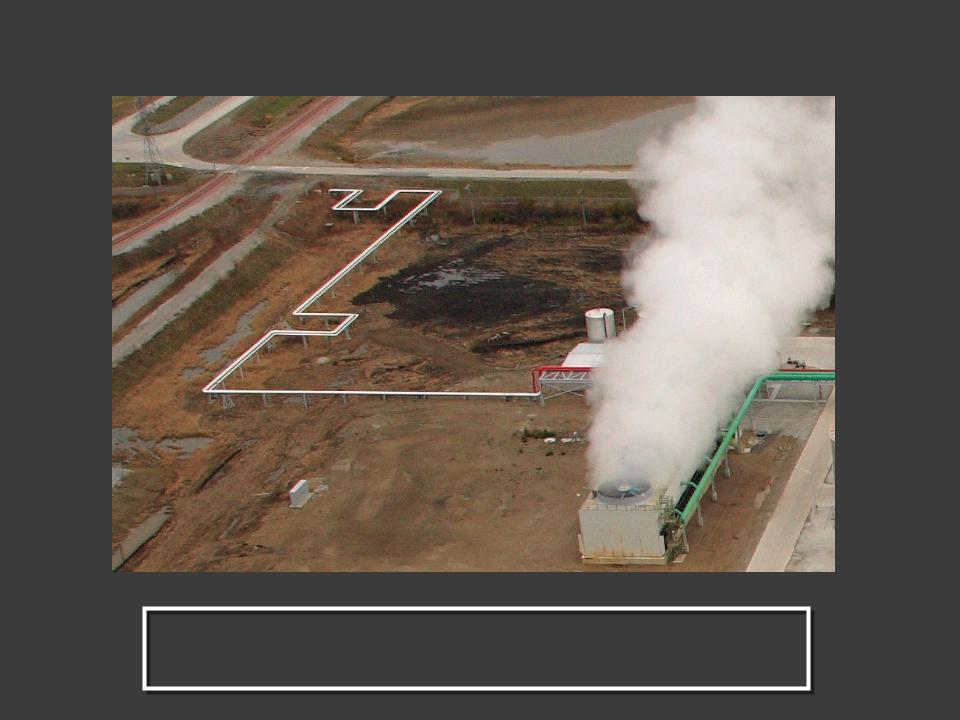

STEAM LINE

10 Year Steam Line Contract

10 Year Steam Line Contract

6,600 Ft.

6,600 Ft.

3 Year Fixed Price + Indexed After 3 Years

3 Year Fixed Price + Indexed After 3 Years

VS.

VS.

Volatile Natural Gas Price

Volatile Natural Gas Price

TURBINE

Steam turbine transferred to MEC December, 2009

Steam turbine transferred to MEC December, 2009

Attractive 5 Year Electric Rate

Attractive 5 Year Electric Rate

BOILER

Natural Gas Boilers

Natural Gas Boilers

Cost-$7,000,000

Cost-$7,000,000

FISCAL YEAR 2009 IN REVIEW

Staff Development and Survival

v Year of challenges and start up

v Employee turnover 31%

Operations

v Started February 2009

v Production ran at 84% of nameplate capacity

v Steam Energy was 35% of MMBTU used

Safety

v Average ERI Safety Audit Score-84%

v Total days without a Lost Time Accident-173 days

Banking

v Completion of banking agreement in August 2009

v EBITDA for Fiscal Year - ($2,900,000)

Geoff Christensen

Gina Chapman and Betty Harmsen

Duane Herperger

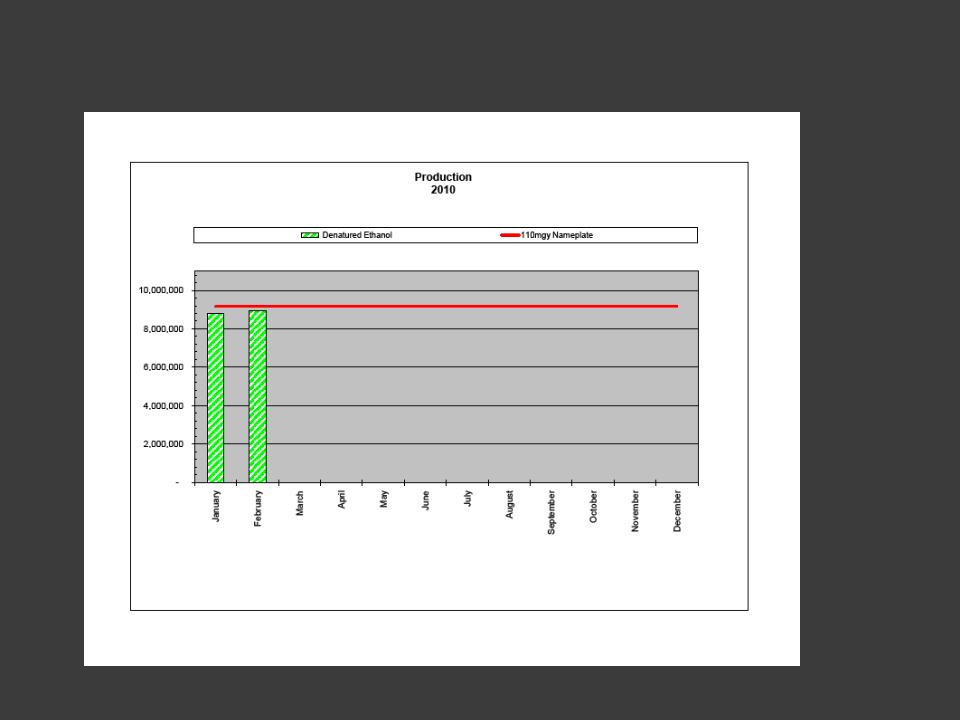

CURRENT FISCAL YEAR 2010 IN REVIEW

Personnel

v Continued development of staff for consistency and stability

v Employee turnover 6%

Continued improvement in Plant Operations

v Production running at 100% of nameplate capacity

v Steam energy is 74% of MMBTU used

Safety

v Average ERI Safety Audit Score-92%

v Total days without a Lost Time Accident-135 on going days

EBITDA

v 3 Months ended December 31, 2010

v + $5,266,000

v Current with all bank obligations

FISCAL YEAR COMPARISON

FY 2009 FY 2010

7 Months 3 Months

Employee Turnover 31% 6%

Operating Capacity 84% 100%

Steam Line MMBTUs VS.

Natural Gas MMBTUs 35% 74%

Safety ERI Score 84% 92%

Consecutive Days W/O Lost Time 173 135 on going

EBITDA ($2,900,000) +$5,266,000

FUTURE OPERATION PLANS

Future Improvements

v Shut down

v Additional grain storage

v Improved water treatment facility

Increased capacity above nameplate

v Minimum capital improvements

v Additional value-added products

• Corn Oil

2010 PRODUCTION

ANNUAL MEETING 2010

Southwest Iowa Renewable Energy