Attached files

Exhibit 10.1

|

[BAR CODE]

|

|

|

US008169115B1

|

|

(12)

|

United States Patent

|

(10)

|

Patent No.:

|

US 8,169,115 B1

|

||||||

|

Monfort

|

(45)

|

Date of Patent:

|

May 1, 2012

|

|||||||

|

(54)

|

MOTOR DISTRIBUTOR SYSTEM

|

4,531,072 A *

|

7/1985

|

Weaver et al. ......... 310/162

|

||||||

|

4,635,489 A *

|

111987

|

Imamura et al. .......... 74/7 E

|

||||||||

|

4,654,577 A *

|

3/1987

|

Howard .................. 322/28

|

||||||||

|

4,891,996 A *

|

111990

|

Isozumi et al. ............. 74/6

|

||||||||

|

(76)

|

Inventor:

|

Edward Riggs Monfort, Palm Harbor,

|

4,874,975 A *

|

10/1989

|

Hertrich ................ 310/186

|

|||||

|

FL (US)

|

4,896,550 A *

|

111990

|

Hikichi et al. ............... 74/6

|

|||||||

|

( * )

|

Notice:

|

Subject to any disclaimer, the term of this

|

5,562,566 A *

|

10/1996

|

Yang ......................... 477/3

|

|||||

|

patent is extended or adjusted under 35

|

5,704,250 A *

|

111998

|

Black ..................... 74/89.3

|

|||||||

|

U.S.C. 154(b) by 605 days.

|

5,838,085 A *

|

1111998

|

Roesel et al. .......... 310/113

|

|||||||

|

6,356,817 B1 *

|

3/2002

|

Abe …................... 701122

|

||||||||

|

(21)

|

Appl. No.:

|

12/291,720

|

6,789,438 B2 *

|

9/2004

|

Tanaka et al. ………. 74/7 E

|

|||||

|

7,131,275 B2 *

|

1112006

|

Gustafson .............. 60/788

|

||||||||

|

(22)

|

Filed:

|

Nov. 13, 2008

|

FOREIGN PATENT DOCUMENTS

|

|||||||

|

Related U.S. Application Data

|

JP

|

62131822 A *

|

6/1987

|

|||||||

|

JP

|

2006230142 A *

|

8/2006

|

||||||||

|

(60)

|

Provisional application No. 61/194,304, filed on Sep.

|

* cited by examiner

|

||||||||

|

26, 2008.

|

||||||||||

|

Primary Examiner-Tran Nguyen

|

||||||||||

|

(51)

|

Int. Cl.

|

|||||||||

|

H02K 47100

|

(2006.01)

|

(57)

|

ABSTRACT

|

|||||||

|

F02N 15100

|

(2006.01)

|

|||||||||

|

B60K 6100

|

(2007.10)

|

A cylindrical drive shaft has forward and rearward ends. A

|

||||||||

|

(52)

|

U.S. Cl.

|

....... 310/112; 310/75 R; 74/7 E; 180/65.25

|

fixed cylindrical housing receives the drive shaft, the housing

|

|||||||

|

(58)

|

Field of Classification Search

|

................ 310/75 R,

|

having forward and rearward ends. An axial flux permanent

|

|||||||

|

310/98, 112; 74/7 A, 7 E; 180/65.25, 67.27-67.28;

|

magnet motor encompasses the drive shaft within the hous

|

|||||||||

|

475/153, 265; 477/3

|

ing. The axial flux permanent magnet motor has a radially

|

|||||||||

|

See application file for complete search history.

|

exterior cylinder fixedly secured to the housing and a radially

|

|||||||||

|

interior cylinder secured to the drive shaft for rotation there

|

||||||||||

|

(56)

|

References Cited

|

with. Each axial flux permanent magnet motor has windings

|

||||||||

|

coupled to the exterior cylinder. Each axial flux permanent

|

||||||||||

|

U.S. PATENT DOCUMENTS

|

magnet motor has a permanent magnet fixedly coupled to the

|

|||||||||

|

3,541,363 A *

|

1111970

|

Vettermann et al. ..... 310/49.17

|

interior cylinder. Electrical lines have lower ends coupled to

|

|||||||

|

3,858,308 A *

|

111975

|

Peterson ..................... 29/598

|

the windings and upper ends adapted to be coupled to a source

|

|||||||

|

4,031,421 A *

|

6/1977

|

Geiger ....................... 310/112

|

of potential for energizing the axial flux permanent magnet

|

|||||||

|

4,039,205 A *

|

8/1977

|

Castanier .......... 280/124.109

|

motors.

|

|||||||

|

4,130,769 A *

|

12/1978

|

Karube ........................ 310/46

|

||||||||

|

4,373,147 A *

|

211983

|

Carlson, Jr. ................ 318/48

|

3 Claims, 3 Drawing Sheets

|

|||||||

US 8,169,115 B1

|

1

|

2

|

||

|

MOTOR DISTRIBUTOR SYSTEM

|

A fixed cylindrical housing is provided. The housing has a

|

||

|

forward end. The housing has a rearward end. The housing

|

|||

|

RELATED APPLICATION

|

has a central axis. The central axis is coextensive with the

|

||

|

central axis of the drive shaft. The forward end of the drive

|

|||

|

The present application is based upon pending U.S. Provi

|

5

|

shaft extends forwardly of the forward end of the housing.

|

|

|

sional Application No. 61/194,304 filed Sep. 26, 2008, the

|

The rearward end of the drive shaft extends rearwardly of the

|

||

|

subject matter of which is incorporated herein by reference.

|

rearward end of the housing. The housing has a forward end

|

||

|

cap. The forward end cap is removably coupled to the forward

|

|||

|

BACKGROUND OF THE INVENTION

|

end of the housing. The housing has a rearward end cap. The

|

||

|

10

|

rearward end cap is removably coupled to the forward end of

|

||

|

Field of the Invention

|

the housing. Each end cap has a central aperture. A bearing is

|

||

|

provided. The bearing rotatably supports the drive shaft. The

|

|||

|

The present invention relates to a motor distributor system

|

housing is fabricated of a rigid material. The rigid material is

|

||

|

and more particularly pertains to powering a vehicle by trans

|

chosen from the class of rigid materials. The class of rigid

|

||

|

mitting rotational energy through a drive shaft from an inter

|

15

|

materials includes an aircraft grade aluminum, other metals

|

|

|

nal combustion engine and/or one or more axial flux perma

|

and composite materials.

|

||

|

nent magnet motors, the powering being achieved in an

|

Provided next is a forward universal coupling. The forward

|

||

|

energy conserving manner which is safe, ecological, efficient

|

universal coupling is secured to the forward end of the drive

|

||

|

and economical.

|

shaft. A rearward universal coupling is provided. The rear-

|

||

|

A vehicle equipped with a motor distributor system of the

|

20

|

ward universal coupling is secured to the rearward end of the

|

|

|

present invention includes a drive shaft which is adapted to be

|

drive shaft. The rearward universal coupling is adapted to

|

||

|

powered solely by an internal combustion engine. In the

|

couple to a rear axle and driven wheels. A clutch is provided

|

||

|

alternative the drive shaft is adapted to be powered solely by

|

as an option. The clutch, in the preferred embodiment, is

|

||

|

the axial flux permanent magnetic motor or motors while the

|

provided forwardly of the forward universal coupling. An

|

||

|

internal combustion engine is idling. Lastly, in another alter

|

25

|

internal combustion engine is provided. The internal combus

|

|

|

native, the drive shaft is adapted to be powered jointly by the

|

tion engine is provided forwardly of the clutch. In this manner

|

||

|

combination of the internal combustion engine and the axial

|

activation of the internal combustion engine is adapted to

|

||

|

flux permanent magnetic motor or motors. This combination

|

rotate the drive shaft. Further in this manner the rear axle and

|

||

|

mode can double the horsepower of the vehicle but not the

|

driven wheels are powered.

|

||

|

engine. The axial flux permanent magnetic motor or motors

|

30

|

A support linkage is provided. The support linkage has

|

|

|

are adapted to provide extra power like a supercharger. A user

|

lower ends. The lower ends are coupled to the housing at a

|

||

|

may be racing the car using full power from a 300 horse power

|

central region. The support linkage has upper ends. The upper

|

||

|

internal combustion engine. When the user activates the axial

|

ends are adapted to be coupled to a frame portion of the

|

||

|

flux permanent magnetic motor or motors, a supplemental

|

vehicle. The support linkage has resilient joints. The resilient

|

||

|

300 horsepower is provided whereby the vehicle is being

|

35

|

joints are provided between the upper and lower ends. In this

|

|

|

powered by 600 horsepower. More importantly, however, the

|

manner the housing functions as a brace and also allows the

|

||

|

system of the present invention conserves energy by increas

|

absorption of shocks and vibration during use.

|

||

|

ing the fuel efficiency of a vehicle equipped with such system.

|

A forward and a rearward axial flux permanent magnet

|

||

|

motor are provided next. The motors encompass the forward

|

|||

|

SUMMARY OF THE INVENTION

|

40

|

and rearward portions of the drive shaft within the housing.

|

|

|

Each axial flux permanent magnet motor has a radially exte

|

|||

|

In view of the disadvantages inherent in the known types of

|

rior cylinder. The radially exterior cylinder is fixedly secured

|

||

|

motor distributor systems of known designs and configura

|

to the housing. Each axial flux permanent magnet motor has

|

||

|

tions now present in the prior art, the present invention pro

|

a radially interior cylinder. The radially interior cylinder is

|

||

|

vides an improved motor distributor system. As such, the

|

45

|

secured to the drive shaft for rotation therewith. Each axial

|

|

|

general purpose of the present invention, which will be

|

flux permanent magnet motor has windings. The windings are

|

||

|

described subsequently in greater detail, is to provide a new

|

coupled to the exterior cylinder. Each axial flux permanent

|

||

|

and improved motor distributor system and method which has

|

magnet motor has a permanent magnet. The permanent mag-

|

||

|

all the advantages of the prior art and none of the disadvan-

|

net is fixedly coupled to the interior cylinder. The interior and

|

||

|

tages.

|

50

|

exterior cylinders are fabricated of a rigid, electrically insu

|

|

|

To attain this, the present invention essentially comprises a

|

lating material. The rigid, electrically insulating material is

|

||

|

motor distributor system. First provided is a cylindrical drive

|

chosen from the class of electrically insulating materials. The

|

||

|

shaft. The drive shaft has a central axis. The drive shaft is

|

class of electrically insulating materials includes composite

|

||

|

rotatable around its central axis. The drive shaft has a forward

|

materials and plastic materials.

|

||

|

end. The drive shaft has a rearward end. A center is provided

|

55

|

It should be appreciated that some axial flux permanent

|

|

|

between the forward and rearward ends. The drive shaft is

|

magnet motors have windings and some are made of com

|

||

|

discontinuous at its center. In this manner a forward portion

|

posite material whereas the magnets are placed into the com

|

||

|

and a rearward portion are formed. A connector is provided.

|

posite using windings only on one side. In addition, means

|

||

|

The connector joins the forward and rearward portions.

|

other than windings are adapted to be utilized for conducting

|

||

|

In an alternate embodiment of the invention, a continuous

|

60

|

electricity to the magnets. It should be also appreciated that

|

|

|

drive shaft is utilized. Such continuous drive shaft is preferred

|

the axial flux permanent magnet motors are adapted to be

|

||

|

for smaller, lighter vehicles and vehicles with smaller internal

|

single phase or 3 phase. Further, the axial flux permanent

|

||

|

combustion engines, vehicles requiring less power. It should

|

magnet motors are adapted to be AC or DC.

|

||

|

be understood, therefore, that any number of axial flux per

|

Further provided is a forward fan. The forward fan is pro-

|

||

|

manent magnet motors, from a single one to a large number,

|

65

|

vided within the housing adjacent to the forward end cap. An

|

|

|

could be readily utilized as a function of the vehicle.

|

air inlet is provided. The air inlet is provided within the

|

||

|

housing adjacent to the forward fan. A rearward fan is pro-

|

US 8,169,115 B1

|

3

|

4

|

||

|

vided. The rearward fan is provided within the housing adja-

|

encompasses the drive shaft within the housing. The axial flux

|

||

|

cent to the rearward end cap. An air outlet is provided. The air

|

permanent magnet motor has a radially exterior cylinder fix-

|

||

|

outlet is provided in the housing adjacent to the rearward fan.

|

edly secured to the housing and a radially interior cylinder

|

||

|

Provided last are electrical lines. The electrical lines have

|

secured to the drive shaft for rotation therewith. Each axial

|

||

|

lower ends. The lower ends are coupled to the windings in the

|

5

|

flux permanent magnet motor has windings coupled to the

|

|

|

exterior cylinders. The electrical lines have upper ends. The

|

exterior cylinder. Each axial flux permanent magnet motor

|

||

|

upper ends are adapted to be coupled to a source of electrical

|

has a permanent magnet fixedly coupled to the interior cyl

|

||

|

potential. The electrical potential is adapted to energize the

|

inder. Electrical lines have lower ends coupled to the wind-

|

||

|

axial flux permanent magnet motors. Powering of the vehicle

|

ings and upper ends adapted to be coupled to a source of

|

||

|

is by transmitting rotational energy through the drive shaft

|

10

|

potential for energizing the axial flux permanent magnet

|

|

|

from the internal combustion engine and/or one or more axial

|

motors. Such motors are adapted to include brushes but in the

|

||

|

flux permanent magnet motors.

|

preferred embodiment the motors are brushless.

|

||

|

There has thus been outlined, rather broadly, the more

|

These together with other objects of the invention, along

|

||

|

important features of the invention in order that the detailed

|

with the various features of novelty which characterize the

|

||

|

description thereof that follows may be better understood and

|

15

|

invention, are pointed out with particularity in the claims

|

|

|

in order that the present contribution to the art may be better

|

annexed to and forming a part of this disclosure. For a better

|

||

|

appreciated. There are, of course, additional features of the

|

understanding of the invention, its operating advantages and

|

||

|

invention that will be described hereinafter and which will

|

the specific objects attained by its uses, reference should be

|

||

|

form the subject matter of the claims attached.

|

had to the accompanying drawings and descriptive matter in

|

||

|

In this respect, before explaining at least one embodiment

|

20

|

which there is illustrated preferred embodiments of the inven-

|

|

|

of the invention in detail, it is to be understood that the

|

tion.

|

||

|

invention is not limited in its application to the details of

|

|||

|

construction and to the arrangements of the components set

|

|||

|

forth in the following description or illustrated in the draw

|

BRIEF DESCRIPTION OF THE DRAWINGS

|

||

|

ings. The invention is capable of other embodiments and of

|

25

|

||

|

being practiced and carried out in various ways. Also, it is to

|

The invention will be better understood and objects other

|

||

|

be understood that the phraseology and terminology

|

than those set forth above will become apparent when con

|

||

|

employed herein are for the purpose of descriptions and

|

sideration is given to the following detailed description

|

||

|

should not be regarded as limiting.

|

thereof. Such description makes reference to the annexed

|

||

|

As such, those skilled in the art will appreciate that the

|

30

|

drawings wherein:

|

|

|

conception, upon which this disclosure is based, may readily

|

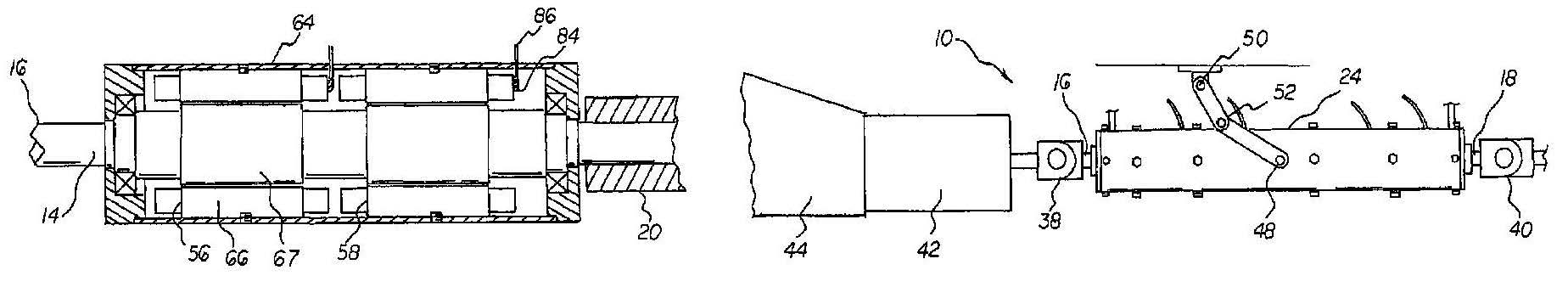

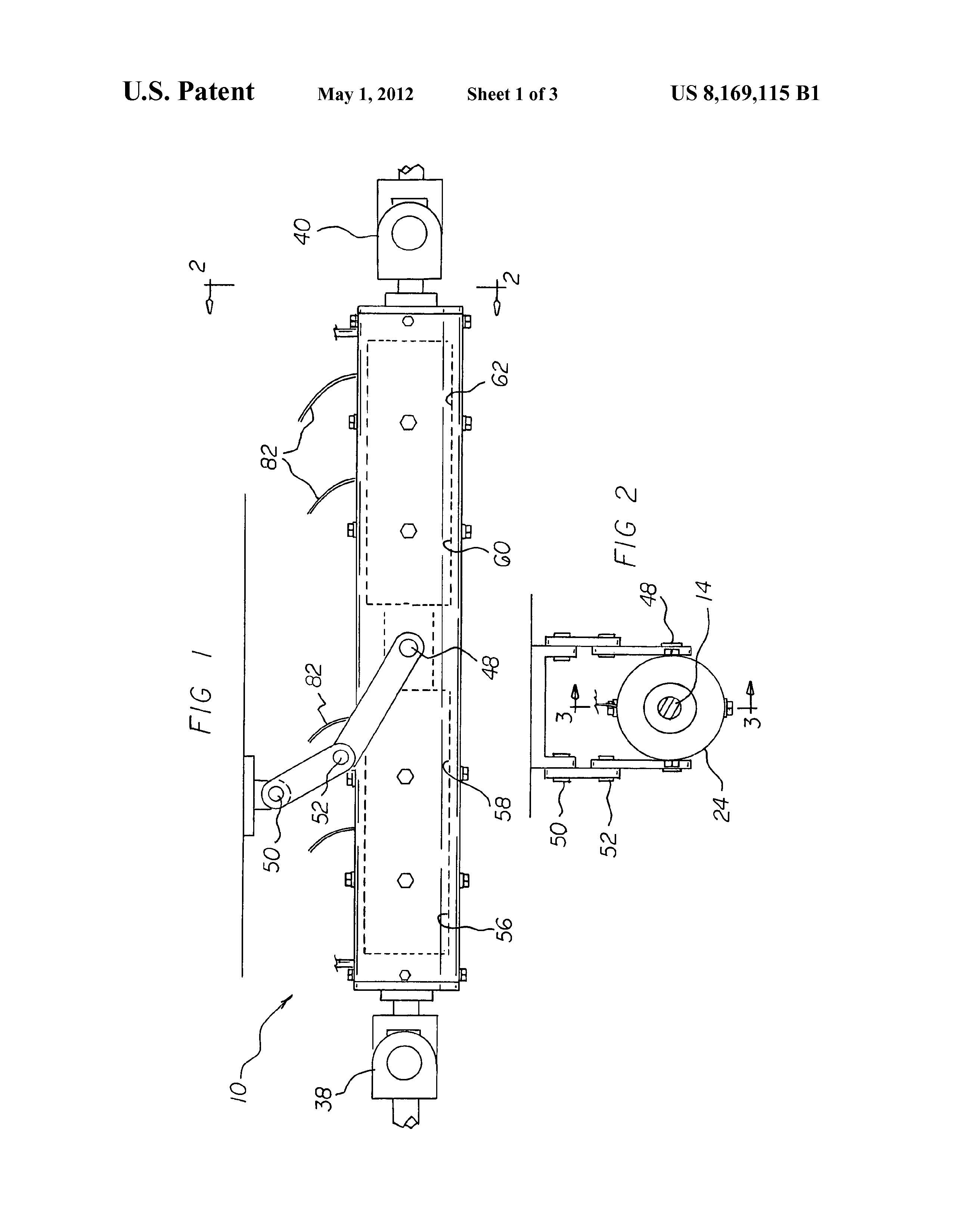

FIG. 1 is a side elevational view of a motor distributor

|

||

|

be utilized as a basis for the designing of other structures,

|

system constructed in accordance with the principles of the

|

||

|

methods and systems for carrying out the several purposes of

|

present invention.

|

||

|

the present invention. It is important, therefore, that the

|

FIG. 2 is a cross sectional view taken along line 2-2 of FIG.

|

||

|

claims be regarded as including such equivalent constructions

|

35

|

1.

|

|

|

insofar as they do not depart from the spirit and scope of the

|

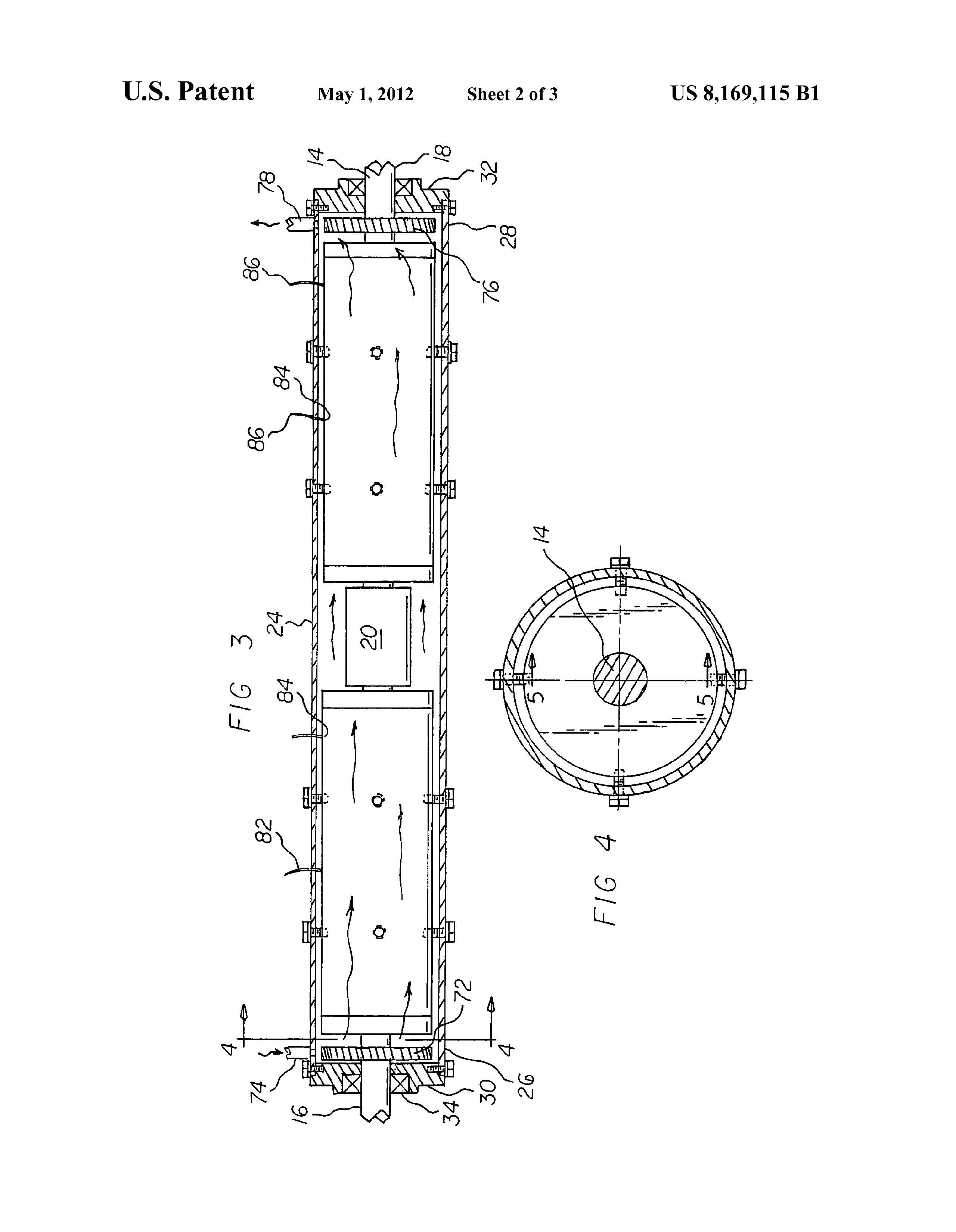

FIG. 3 is a cross sectional view taken along line 3-3 of FIG.

|

||

|

present invention.

|

2.

|

||

|

It is therefore an object of the present invention to provide

|

FIG. 4 is a cross sectional view taken along line 4-4 of FIG.

|

||

|

a new and improved motor distributor system which has all of

|

3.

|

||

|

the advantages of the prior art motor distributor systems of

|

40

|

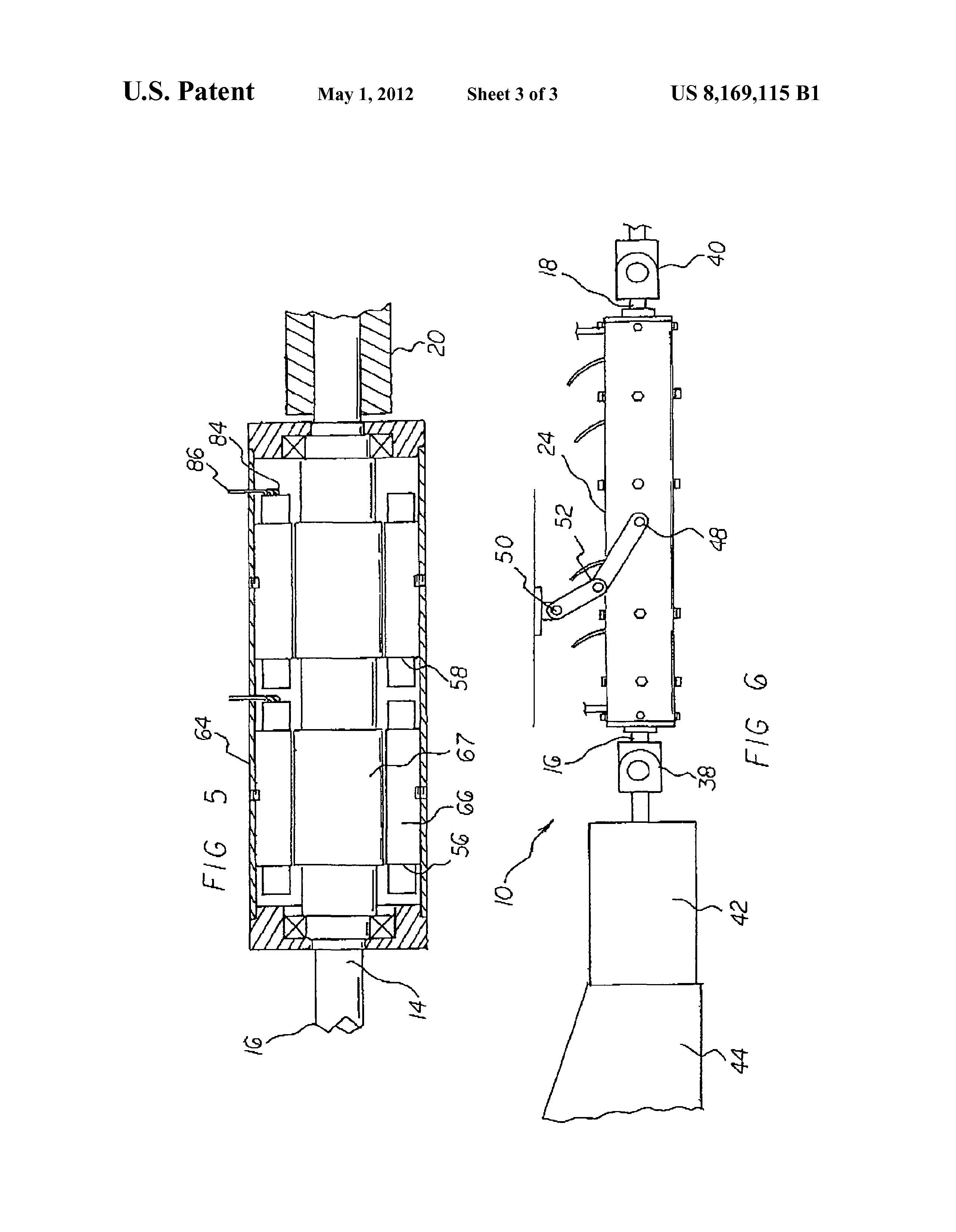

FIG. 5 is a cross sectional view taken along line 5-5 of FIG.

|

|

|

known designs and configurations and none of the disadvan

|

4.

|

||

|

tages.

|

FIG. 6 is a side elevational view similar to FIG. 1 but

|

||

|

It is another object of the present invention to provide a new

|

showing additional components.

|

||

|

and improved motor distributor system which may be easily

|

The same reference numerals refer to the same parts

|

||

|

and efficiently manufactured and marketed.

|

45

|

throughout the various Figures.

|

|

|

It is further object of the present invention to provide a new

|

|||

|

and improved motor distributor system which is of durable

|

DESCRIPTION OF THE PREFERRED

|

||

|

and reliable constructions.

|

EMBODIMENT

|

||

|

An even further object of the present invention is to provide

|

|||

|

a new and improved motor distributor system which is sus-

|

50

|

With reference now to the drawings, and in particular to

|

|

|

ceptible of a low cost of manufacture with regard to both

|

FIG. 1 thereof, the preferred embodiment of the new and

|

||

|

materials and labor, and which accordingly is then suscep

|

improved motor distributor system embodying the principles

|

||

|

tible of low prices of sale to the consuming public, thereby

|

and concepts of the present invention and generally desig

|

||

|

making such motor distributor system economically available

|

nated by the reference numeral10 will be described.

|

||

|

to the buying public.

|

55

|

The present invention, the motor distributor system 10 is

|

|

|

Even still another object of the present invention is to

|

comprised of a plurality of components. Such components in

|

||

|

provide a motor distributor system for powering a vehicle by

|

their broadest context include cylindrical drive shaft, a fixed

|

||

|

transmitting rotational energy through a drive shaft from an

|

cylindrical housing, an axial flux permanent magnet motor,

|

||

|

internal combustion engine and/or one or more axial flux

|

and electrical lines. Such components are individually con

|

||

|

permanent magnet motors, the powering being achieved in an

|

60

|

figured and correlated with respect to each other so as to attain

|

|

|

energy efficient manner which is safe, ecological, efficient

|

the desired objective.

|

||

|

and economical.

|

First provided is a cylindrical drive shaft 14. The drive shaft

|

||

|

Lastly, it is an object of the present invention to provide a

|

has a central axis. The drive shaft is rotatable around its

|

||

|

new and improved motor distributor system. A cylindrical

|

central axis. The drive shaft has a forward end 16. The drive

|

||

|

drive shaft has forward and rearward ends. A fixed cylindrical

|

65

|

shaft has a rearward end 18. A center is provided between the

|

|

|

housing receives the drive shaft, the housing having forward

|

forward and rearward ends. The drive shaft is discontinuous

|

||

|

and rearward ends. An axial flux permanent magnet motor

|

at its center. In this manner a forward portion and a rearward

|

US 8,169,115 B1

|

5

|

6

|

||

|

portion are formed. A connector 20 is provided. The connec

|

motors have windings and some are made of composite mate

|

||

|

tor joins the forward and rearward portions.

|

rial whereas the magnets are placed into the composite using

|

||

|

A fixed cylindrical housing 24 is provided. The housing has

|

windings only on one side. As such, means other than wind

|

||

|

a forward end 26. The housing has a rearward end 28. The

|

ings are adapted to be utilized for conducting electricity to the

|

||

|

housing has a central axis. The central axis is coextensive with

|

5

|

magnets.

|

|

|

the central axis of the drive shaft. The forward end of the drive

|

Further provided is a forward fan 72. The forward fan is

|

||

|

shaft extends forwardly of the forward end of the housing.

|

provided within the housing adjacent to the forward end cap.

|

||

|

The rearward end of the drive shaft extends rearwardly of the

|

An air inlet 74 is provided. The air inlet is provided within the

|

||

|

rearward end of the housing. The housing has a forward end

|

housing adjacent to the forward fan. A rearward fan 76 is

|

||

|

cap 30. The forward end cap is removably coupled to the

|

10

|

provided. The rearward fan is provided within the housing

|

|

|

forward end of the housing. The housing has a rearward end

|

adjacent to the rearward end cap. An air outlet 78 is provided.

|

||

|

cap 32. The rearward end cap is removably coupled to the

|

The air outlet is provided in the housing adjacent to the

|

||

|

forward end of the housing. Each end cap has a central aper

|

rearward fan.

|

||

|

ture. A bearing 34 is provided. The bearing rotatably supports

|

Provided last are electrical lines 82. The electrical lines

|

||

|

the drive shaft. The housing is fabricated of a rigid material.

|

15

|

have lower ends 84. The lower ends are coupled to the wind

|

|

|

The rigid material is chosen from the class of rigid materials.

|

ings in the exterior cylinders. The electrical lines have upper

|

||

|

The class of rigid materials includes an aircraft grade alumi

|

ends 86. The upper ends are adapted to be coupled to a source

|

||

|

num, other metals and composite materials.

|

of electrical potential. The electrical potential is adapted to

|

||

|

Provided next is a forward universal coupling 38. The

|

energize the axial flux permanent magnet motors. In this

|

||

|

forward universal coupling is secured to the forward end of

|

20

|

manner the load on the internal combustion engine is relieved

|

|

|

the drive shaft. A rearward universal coupling 40 is provided.

|

for increased efficiency of the system.

|

||

|

The rearward universal coupling is secured to the rearward

|

Note is taken that the axial flux permanent magnet motors

|

||

|

end of the drive shaft. The rearward universal coupling is

|

are adapted to be single phase or 3 phase. Further, the axial

|

||

|

adapted to couple to a rear axle and driven wheels. A clutch 42

|

flux permanent magnet motors are adapted to be AC or DC.

|

||

|

is optionally provided. The clutch is provided forwardly of

|

25

|

As to the manner of usage and operation of the present

|

|

|

the forward universal coupling. An internal combustion

|

invention, the same should be apparent from the above

|

||

|

engine 44 is provided. The internal combustion engine is

|

description. Accordingly, no further discussion relating to the

|

||

|

provided forwardly of the clutch. In this manner activation of

|

manner of usage and operation will be provided.

|

||

|

the internal combustion engine is adapted to rotate the drive

|

With respect to the above description then, it is to be

|

||

|

shaft. Further in this manner the rear axle and driven wheels

|

30

|

realized that the optimum dimensional relationships for the

|

|

|

are powered.

|

parts of the invention, to include variations in size, materials,

|

||

|

A support linkage is provided. The support linkage has

|

shape, form, function and manner of operation, assembly and

|

||

|

lower ends 48. The lower ends are coupled to the housing at a

|

use, are deemed readily apparent and obvious to one skilled in

|

||

|

central region. The support linkage has upper ends 50. The

|

the art, and all equivalent relationships to those illustrated in

|

||

|

upper ends are adapted to be coupled to a frame portion of the

|

35

|

the drawings and described in the specification are intended to

|

|

|

vehicle. The support linkage has resilient joints 52. The resil

|

be encompassed by the present invention.

|

||

|

ient joints are provided between the upper and lower ends. In

|

Therefore, the foregoing is considered as illustrative only

|

||

|

this manner the housing is allowed to absorb shocks and

|

of the principles of the invention. Further, since numerous

|

||

|

vibration during use.

|

modifications and changes will readily occur to those skilled

|

||

|

A single housing and support linkage is illustrated as the

|

40

|

in the art, it is not desired to limit the invention to the exact

|

|

|

preferred embodiment. It should be understood, however, that

|

construction and operation shown and described, and accord

|

||

|

any number of housings with their contained axial flux per

|

ingly, all suitable modifications and equivalents may be

|

||

|

manent magnet motors is adapted to be utilized in a single

|

resorted to, falling within the scope of the invention.

|

||

|

vehicle with their placement being as needed for the particu

|

What is claimed as being new and desired to be protected

|

||

|

lar application.

|

45

|

by Letters Patent of the United States is as follows:

|

|

|

A forward and a rearward axial flux permanent magnet

|

1. A motor distributor system for powering a vehicle by

|

||

|

motor 56, 58, 60, 62 are provided next. Such motors are

|

transmitting rotational energy through a drive shaft, in a first

|

||

|

brushless in the preferred embodiment, but the motors, in an

|

mode, from an internal combustion engine and, in a second

|

||

|

alternate embodiment of the invention, are adapted to be of

|

mode, from axial flux permanent magnet motors and, in a

|

||

|

the type to utilize brushes. The motors encompass the forward

|

50

|

third mode, from the combination of an internal combustion

|

|

|

and rearward portions of the drive shaft within the housing.

|

engine and axial flux permanent magnet motors, the powering

|

||

|

Each axial flux permanent magnet motor has a radially exte

|

being achieved in an energy conserving manner that is safe,

|

||

|

rior cylinder 64. The radially exterior cylinder is fixedly

|

ecological, efficient and economical, the system comprising,

|

||

|

secured to the housing. Each axial flux permanent magnet

|

in combination:

|

||

|

motor has a radially interior cylinder 66. The radially interior

|

55

|

a cylindrical drive shaft having a central axis, the drive

|

|

|

cylinder is secured to the drive shaft for rotation therewith.

|

shaft having a central axis and being rotatable around the

|

||

|

Each axial flux permanent magnet motor has windings. The

|

central axis, the drive shaft having a forward end and a

|

||

|

windings are coupled to the exterior cylinder. Each axial flux

|

rearward end with a center there between, the drive shaft

|

||

|

permanent magnet motor has a permanent magnet. The per

|

being discontinuous at the center thus forming a forward

|

||

|

manent magnet is fixedly coupled to the interior cylinder. The

|

60

|

portion and a rearward portion with a connector joining

|

|

|

interior and exterior cylinders are fabricated of a rigid, elec

|

the forward and rearward portions;

|

||

|

trically insulating material. The rigid, electrically insulating

|

a fixed cylindrical housing having a forward end and a

|

||

|

material is chosen from the class of electrically insulating

|

rearward end, the housing having a central axis coexten

|

||

|

materials. The class of electrically insulating materials

|

sive with the central axis of the drive shaft, the forward

|

||

|

includes composite materials and plastic materials.

|

65

|

end of the drive shaft extending forwardly of the forward

|

|

|

With regard to an alternate embodiment of the invention, it

|

end of the housing, the rearward end of the drive shaft

|

||

|

should be understood that some axial flux permanent magnet

|

extending rearwardly of the rearward end of the housing,

|

US 8,169,115 B1

|

7

|

8

|

||

|

a forward end cap removably coupled to the forward end

|

2. A motor distributor system comprising:

|

||

|

of the housing, a rearward end cap removably coupled to

|

a cylindrical drive shaft having forward and rearward ends;

|

||

|

the forward end of the housing, a central aperture in each

|

a fixed cylindrical housing receiving the drive shaft, the

|

||

|

end cap with a bearing rotatably supporting the drive

|

housing having forward and rearward ends;

|

||

|

shaft, the housing being fabricated of a rigid material

|

5

|

a plurality of axial flux permanent magnet motors encom

|

|

|

chosen from the class of rigid materials including an

|

passing the drive shaft within the housing, each axial

|

||

|

aircraft grade aluminum, other metals and composite

|

flux permanent magnet motor having a radially exterior

|

||

|

materials;

|

cylinder fixedly secured to the housing and a radially

|

||

|

a forward universal coupling secured to the forward end of

|

interior cylinder secured to the drive shaft for rotation

|

||

|

the drive shaft, a rearward universal coupling secured to

|

10

|

therewith, each axial flux permanent magnet motor hav

|

|

|

the rearward end of the drive shaft, the rearward univer-

|

ing windings coupled to the exterior cylinder, each axial

|

||

|

sal coupled to a rear axle and driven wheels, an optional

|

flux permanent magnet motor having a permanent mag

|

||

|

clutch forwardly of the forward universal coupling with

|

net fixedly coupled to the interior cylinder;

|

||

|

an internal combustion engine forwardly of the clutch

|

electrical lines having lower ends coupled to the windings

|

||

|

activation of internal combustion engine rotatably

|

15

|

and upper ends coupled to a source of potential for

|

|

|

coupling the drive shaft to power the rear axle and driven

|

energizing the axial flux permanent magnet motor; and

|

||

|

wheels;

|

a forward universal coupling secured to the forward end of

|

||

|

a support linkage having lower ends coupled to the housing

|

the drive shaft, a rearward universal coupling secured to

|

||

|

at a central region, the support linkage having upper ends

|

the rearward end of the drive shaft, the rearward univer

|

||

|

coupled to a frame portion of the vehicle, the support

|

20

|

sal coupling to a rear axle and driven wheels, a clutch

|

|

|

linkage having resilient joints between the upper and

|

forwardly of the forward universal coupling with an

|

||

|

lower ends for allowing the housing to absorb shocks

|

internal combustion engine forwardly of the clutch, acti

|

||

|

and vibration during use;

|

vation of the internal combustion engine coupling to

|

||

|

a forward and a rearward axial flux permanent magnet

|

rotate the drive shaft to power the rear axle and driven

|

||

|

motor encompassing the forward and rearward portions

|

25

|

wheels.

|

|

|

of the drive shaft within the housing, each axial flux

|

3. A motor distributor system comprising:

|

||

|

permanent magnet motor having a radially exterior cyl

|

a cylindrical drive shaft having forward and rearward ends·

|

||

|

inder fixedly secured to the housing and a radially inte

|

a fixed cylindrical housing receiving the drive shaft, the

|

||

|

rior cylinder secured to the drive shaft for rotation there

|

housing having forward and rearward ends;

|

||

|

with, each axial flux permanent magnet motor having

|

30

|

a plurality of axial flux permanent magnet motors encom

|

|

|

windings coupled to the exterior cylinder, each axial flux

|

passing the drive shaft within the housing, each axial

|

||

|

permanent magnet motor having a permanent magnet

|

flux permanent magnet motor having a radially exterior

|

||

|

fixedly coupled to the interior cylinder, the interior and

|

cylinder fixedly secured to the housing and a radially

|

||

|

exterior cylinder's being fabricated of a rigid, electrically

|

interior cylinder secured to the drive shaft for rotation

|

||

|

insulating material chosen from the class of electrically

|

35

|

therewith, each axial flux permanent magnet motor hav

|

|

|

insulating materials including composite materials and

|

ing windings coupled to the exterior cylinder, each axial

|

||

|

plastic materials;

|

flux permanent magnet motor having a permanent mag

|

||

|

a forward fan within the housing adjacent to the forward

|

net fixedly coupled to the interior cylinder;

|

||

|

end cap with an air inlet in the housing adjacent to the

|

electrical lines having lower ends coupled to the windings

|

||

|

forward fan, a rearward fan within the housing adjacent

|

40

|

and upper ends coupled to a source of potential for

|

|

|

to the rearward end cap with an air outlet in the housing

|

energizing the axial flux permanent magnet motor;

|

||

|

adjacent to the rearward fan; and

|

a support linkage having lower ends coupled to the housing

|

||

|

electrical lines having lower ends coupled to the windings

|

at a central region, the support linkage having upper ends

|

||

|

in the exterior cylinders and upper ends coupled to a

|

coupled to a frame portion of the vehicle, the support

|

||

|

source of electrical potential, the electrical potential

|

45

|

linkage having resilient joints between the upper and

|

|

|

energizing the axial flux permanent magnet motors to

|

lower ends for allowing the housing to absorb shocks

|

||

|

relieve the load on the internal combustion engine for

|

and vibration during use.

|

||

|

increased efficiency of the system.

|

* * * * *

|