Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Mueller Water Products, Inc. | mwa-20210225.htm |

Where Intelligence Meets Infrastructure® Gabelli Annual Pump, Valve & Water Systems Symposium February 25, 2021

2 NON-GAAP Financial Measures In an effort to provide investors with additional information regarding the Company’s results as determined under GAAP, the Company also provides non-GAAP information that management believes is useful to investors. These non-GAAP measures have limitations as analytical tools, and securities analysts, investors and other interested parties should not consider any of these non-GAAP measures in isolation or as a substitute for analysis of the Company’s results as reported under GAAP. These non- GAAP measures may not be comparable to similarly titled measures used by other companies. The Company presents adjusted net income, adjusted net income per diluted share, adjusted operating income, adjusted operating margin, adjusted EBITDA and adjusted EBITDA margin as performance measures because management uses these measures in evaluating the Company’s underlying performance on a consistent basis across periods and in making decisions about operational strategies. Management also believes these measures are frequently used by securities analysts, investors and other interested parties in the evaluation of the Company’s recurring performance. The Company presents net debt and net debt leverage as performance measures because management uses them in evaluating its capital management, and the investment community commonly uses them as measures of indebtedness. The Company presents free cash flow because management believes it is commonly used by the investment community to measure the Company’s ability to create liquidity. The calculations of these non-GAAP measures and reconciliations to GAAP results are included as an attachment to this presentation and have been posted online at www.muellerwaterproducts.com. The Company does not reconcile forward-looking adjusted EBITDA to the comparable GAAP measure, as permitted by Regulation S-K, because certain items, e.g., expenses related to corporate development activities, pension benefits and corporate restructuring, may have not yet occurred, are out of the Company’s control and/or cannot be reasonably predicted without unreasonable efforts. Additionally, such reconciliation would imply a degree of precision and certainty regarding relevant items that may be confusing to investors. Such items could have a substantial impact on GAAP measures of the Company's financial performance.

3 Forward-Looking Statements This presentation contains certain statements that may be deemed “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. All statements that address activities, events or developments that the Company intends, expects, plans, projects, believes or anticipates will or may occur in the future are forward-looking statements, including, without limitation, statements regarding outlooks, projections, forecasts, trend descriptions, the COVID-19 pandemic, go-to-market strategies, operational excellence, acceleration of new product development, end market performance, net sales performance, adjusted operating income and adjusted EBITDA performance, margins, capital expenditure plans, litigation outcomes, capital allocation and growth strategies, and future warranty charges. Forward-looking statements are based on certain assumptions and assessments made by the Company in light of the Company’s experience and perception of historical trends, current conditions and expected future developments. Actual results and the timing of events may differ materially from those contemplated by the forward-looking statements due to a number of factors, including the extent, duration and severity of the impact of the COVID-19 pandemic on the Company’s operations and results, including effects on the financial health of customers (including collections), the Company and the financial/capital markets, government-mandated facility closures, COVID- 19 related facility closures and other manufacturing restrictions, logistical challenges and supply chain interruptions, potential litigation and claims emanating from the COVID-19 pandemic, and health, safety and employee/labor issues in Company facilities around the world; regional, national or global political, economic, market and competitive conditions; cyclical and changing demand in core markets such as municipal spending; government monetary or fiscal policies; residential and non-residential construction, and natural gas distribution; manufacturing and product performance; expectations for changes in volumes, continued execution of cost productivity initiatives and improved pricing; warranty exposures (including the adequacy of warranty reserves); the Company’s ability to successfully resolve significant legal proceedings, claims, lawsuits or government investigations; compliance with environmental, trade and anti-corruption laws and regulations; changing regulatory, trade and tariff conditions; failure to achieve expected cost savings, net sales expectations, profitability expectations and manufacturing efficiencies from our large capital investments in Chattanooga and Kimball, Tennessee and Decatur, Illinois and plant closures; the failure to integrate and/or realize any of the anticipated benefits of recent acquisitions or divestitures; and other factors that are described in the section entitled “RISK FACTORS” in Item 1A of the Annual Report on Form 10-K (all of which risks may be amplified by the COVID-19 outbreak). Forward-looking statements do not guarantee future performance and are only as of the date they are made. The Company undertakes no duty to update its forward-looking statements except as required by law. Undue reliance should not be placed on any forward-looking statements. You are advised to review any further disclosures the Company makes on related subjects in subsequent Forms 10-K, 10-Q, 8-K and other reports filed with the U.S. Securities and Exchange Commission.

4 Mueller Water Products at a Glance KEY PRODUCTS (2) END MARKETS (2) • Founded over 160 years ago • Spun off from Walter Industries in 2006 • Listed on NYSE (MWA) June 1, 2006 • Divested U.S. Pipe (April 2012) and Anvil (Jan. 2017) • Acquired Singer Valve (Feb. 2017) and Krausz Industries (Dec. 2018) • Paid and settled Walter Tax Liability for $22.2 million with no future obligations (Nov. 2019) $ in millions Net sales $989.0 Adjusted EBITDA $197.9 % of net sales 20.0% Cash Flow from Operations $186.8 Free Cash Flow $118.7 Total Debt $447.7 Total Cash $223.0 Net Debt to Adjusted EBITDA 1.1 x Total Liquidity $336.4 LTM FINANCIALS (1) (1) Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021. (2) Key product categories and end market data based on fiscal 2020 information and estimates and includes sales for Infrastructure and Technologies segments. <10% Natural gas utilities AS OF DECEMBER 31, 2020 60-65% Repair and replacement of municipal water systems 25-30% Residential construction Brass Products Hydrants & Gate Valves Specialty Valve & Repair Technologies HISTORY % of Consolidated Net Sales WATER-FOCUSED COMPANY WITH APPROXIMATELY TWO-THIRDS OF NET SALES RELATED TO REPAIR AND REPLACEMENT ACTIVITIES OF UTILITIES

5 Investment Highlights • Leading brand and municipal market specification positions • Large installed base of iron gate valves and fire hydrants • Comprehensive distribution network and strong end-user relationships • Low-cost manufacturing operations using lost foam process • Favorable market dynamics in municipal and residential end-markets • Aging infrastructure with increasing public awareness driving need for investment requiring a $1.7 trillion investment, according to the American Water Works Association(1) • End-markets served by limited number of suppliers • Enhanced operational excellence initiatives delivering ongoing productivity improvements • Prioritizing capital investments to modernize manufacturing facilities, equipment and processes to drive margin expansion and continued investment in product development • Potential adoption of technology-enabled products by water utilities to actively diagnose, monitor and control the delivery of drinking water • Proprietary fixed leak detection, pipe condition assessment, smart metering and software offerings for utilities to have flexible and scalable platform for infrastructure monitoring • Flexible balance sheet with 1.1x net debt leverage and ample liquidity with $336.4 million available • Enabling growth through capital investments and acquisitions, while historically returning cash to shareholders through dividends and share repurchases LONG-TERM END MARKET DYNAMICS CONTINUE TO IMPROVE LEVERAGING STRENGTHS TO INCREASE TECHNOLOGY-ENABLED PRODUCTS MODERNIZING MANUFACTURING AND DRIVING OPERATIONAL EXCELLENCE TO DELIVER MARGIN EXPANSION FLEXIBLE BALANCE SHEET AND STRONG CASH FLOW STRONG COMPETITIVE POSITION (1) American Water Works Association, Buried No Longer: Confronting America’s Water Infrastructure Challenge 2012

6 End Market Performance* • Experienced strong end market demand during first quarter • Benefitted from the growth in residential construction and municipal end markets continue to be resilient • Distributors increased inventory levels during the quarter resulting from anticipated demand and impact of pricing actions Key Takeaways Residential Construction • Residential construction end market very strong in the quarter, evidenced by 30% increase in single family housing starts • Builders anticipate continued strong demand this year and are increasing their lot inventories • While there are some near-term headwinds from the pandemic and supply-side challenges, believe that residential construction will continue to experience strong growth this year Municipal Water Repair and Replacement • Overall municipal end market remains resilient; project-portion of the market continues be impacted by delays to varying degrees • Customers continue to prioritize critical network maintenance and existing infrastructure projects • Not seeing any cancellations; do see some delays in the approvals or implementation of new projects • Continue to expect that the project-related portion of the municipal water market will remain challenged as budgets adjust to the impacts from the pandemic; impacts some product categories like metering, leak detection and specialty valve products • Now that we are past the election cycle, remain hopeful that additional federal stimulus efforts will help municipalities get through this challenging period relatively quickly, so they can continue to address their aging distribution networks * Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021.

7 Mueller Water Products in a Strong Position vs. Great Recession • Reduced leverage by >2 turns since 2008, providing flexibility to invest in the business and return capital to shareholders through the cycle • Addressed legacy liabilities including exiting multi-employer pension plans and settling the Walter Tax Liability with no future obligations CONSERVATIVE CAPITAL STRUCTURE • Estimate two-thirds of net sales relate to repair and replacement activities of utilities • Residential construction made up about 25% to 30% of our consolidated net sales in fiscal 2020 compared with approximately 50% in fiscal 2007 CORE PRODUCTS FOR NON- DISCRETIONARY REPAIR AND REPLACEMENT • Created more focused company after selling U.S. Pipe and Anvil with increased proportion of products for municipal repair and replacement market • Additional sales primarily come from residential construction and project-related municipal work FOCUSED COMPANY SERVING CRITICAL NEEDS FOR WATER UTILITIES • Impressive longevity, working with our customers for over a century to ensure they have the vital products and services they need to deliver clean, safe drinking water • Generated solid cash flows throughout the cycle evidenced by consistently paying a quarterly dividend, even during the Great Recession LONG HISTORY AND CONSISTENT CASH FLOW GENERATION

8 Remain Focused on Executing Key Strategies to Grow and Enhance Our Business Where Intelligence Meets Infrastructure® Mueller is committed to manufacturing innovative products and creating smart solutions that will solve future challenges, whether it's at the source, at the plant, below the ground, on the street or in the cloud. Every day, we help deliver safe, clean drinking water to millions of people. Our Commitment to Sustainability As we look to the future, our commitment to advancing our environmental, social and governance (ESG) goals will remain at the forefront of how we operate our business and positively impact our world.

9 Commitment to Sustainability • Released first ESG Report this past December • Inaugural report reflects how sustainability has been an integral part of Mueller Water Products for many years • While highlighting our sustainability achievements to date, discussed some of the ongoing initiatives to strengthen Mueller’s focus and commitment to sustainability • Entire organization is committed to minimizing our water and energy footprints while delivering smart products that are more efficient for our customers and safer for the environment As we look to the future, our commitment to advancing our environmental, social and governance (ESG) goals will remain at the forefront of how we operate our business and positively impact our world. To learn more about Mueller Water Products’ ESG efforts, please visit the ESG page on our website.

Products and Markets

11 Strong Position in Broader Water Market Leading Product Positions in Key Product Categories (1) (1) Company estimates based on internal analysis and information from trade associations and distributor networks, where available. (2) Company filings and presentations. Fire Hydrants Iron Gate Valves Butterfly Valves Brass Products #1 Product Position A.Y. McDonald ACIPCO DeZURIK Ford Meter Box McWane #1 Product Position #1 Product Position #2 Product Position With over 160 years in the water utility market, Mueller Water Products has a large installed base of products used by customers for new construction and repair and replacement Water-Related Revenue as a % of Total Revenue (2) 100% 100% 99% 90% 89% 85% 69% 59% 49% PNR AQUA AOS MWA BMI XYL WTS FELE RXN Mueller Water Products is a water-focused company with approximately two-thirds of net sales related to repair and replacement activities of utilities Water Treatment, Filtration, Aquatics/Pool, Point-of-Use Water & Wastewater Treatment Solutions K ey P ro du ct s Hot Water Heaters & Boilers, Water Treatment Hydrants, Iron Gate & Butterfly Valves, Brass Products, Pipe Repair & Leak Detection, Metering Water Metering Water Transportation, Treatment, Testing and Metering Commercial & Residential Water Products Water Pumping Systems Behind-the-Wall Plumbing

12 Mueller is Uniquely Positioned to Address Opportunities with Utilities with its Leading Infrastructure Products and Installed Base

13 U.S. Water Infrastructure Requires Substantial Long-term Investment U.S. Water Infrastructure CAPEX and Investment GapRepair & Replacement Market (1) American Water Works Association, Buried No Longer: Confronting America’s Water Infrastructure Challenge 2012 (2) ASCE: 2017 Report Card for America’s Infrastructure (3) The EPA Clean Water and Drinking Water Infrastructure Gap Analysis 2002 (4) Bluefield Research 2019, U.S. Municipal Water Infrastructure Forecast Report (5) American Society of Engineers (ASCE): The Economic Benefits of Investing in Water Infrastructure • Restoring existing water systems and expanding them to serve a growing population through 2050 will require a $1.7 trillion investment (1) • ASCE grade for drinking water infrastructure is D and grade for wastewater infrastructure is D+ (2) • EPA analysis indicates the need to address aging transmission and distribution pipes is accelerating (see chart below); valves and hydrants are generally replaced along with pipe replacement and repair (3) 2019 2039 • Spending on Water & Wastewater CAPEX in U.S. is >$50B (4) • ASCE estimates that the current annual investment gap expected to increase from $81B to $136B in 2039 (5) Accelerating Need Funding Gap $81B Funding Gap $136B CAPEX CAPEX

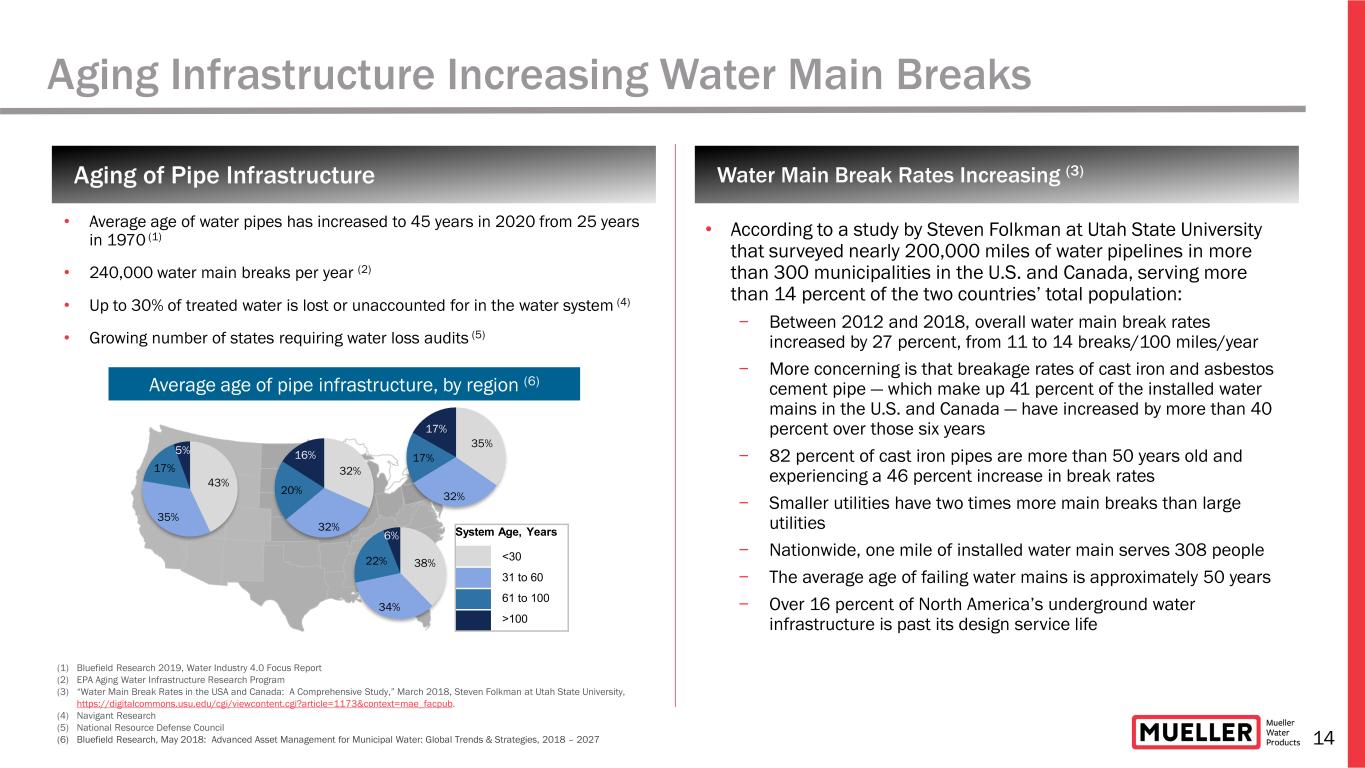

14 Aging Infrastructure Increasing Water Main Breaks (1) Bluefield Research 2019, Water Industry 4.0 Focus Report (2) EPA Aging Water Infrastructure Research Program (3) “Water Main Break Rates in the USA and Canada: A Comprehensive Study,” March 2018, Steven Folkman at Utah State University, https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=1173&context=mae_facpub. (4) Navigant Research (5) National Resource Defense Council (6) Bluefield Research, May 2018: Advanced Asset Management for Municipal Water: Global Trends & Strategies, 2018 – 2027 • Average age of water pipes has increased to 45 years in 2020 from 25 years in 1970 (1) • 240,000 water main breaks per year (2) • Up to 30% of treated water is lost or unaccounted for in the water system (4) • Growing number of states requiring water loss audits (5) 38% 34% 22% 6% 43% 35% 5% 17% 32% 32% 20% 16% System Age, Years <30 31 to 60 61 to 100 >100 35% 32% 17% 17% Water Main Break Rates Increasing (3)Aging of Pipe Infrastructure • According to a study by Steven Folkman at Utah State University that surveyed nearly 200,000 miles of water pipelines in more than 300 municipalities in the U.S. and Canada, serving more than 14 percent of the two countries’ total population: − Between 2012 and 2018, overall water main break rates increased by 27 percent, from 11 to 14 breaks/100 miles/year − More concerning is that breakage rates of cast iron and asbestos cement pipe — which make up 41 percent of the installed water mains in the U.S. and Canada — have increased by more than 40 percent over those six years − 82 percent of cast iron pipes are more than 50 years old and experiencing a 46 percent increase in break rates − Smaller utilities have two times more main breaks than large utilities − Nationwide, one mile of installed water main serves 308 people − The average age of failing water mains is approximately 50 years − Over 16 percent of North America’s underground water infrastructure is past its design service life Average age of pipe infrastructure, by region (6)

15 Funding Water Utilities Infrastructure Repair (1) Bluefield Research 2019, Water Industry 4.0 Focus Report (2) Bluefield Research 2019, U.S. Private Water Utilities Report (3) RAND Corporation 2017 Report titled “Not Everything is Broken” (4) American Water Works Association 2016 Water and Wastewater Rate Survey (5) Bureau of Labor Statistics (6) Securities Industry and Financial Markets Association (SIFMA) Sources of Funding for U.S. Utilities • >50,000 water utilities and >14,000 wastewater utilities in U.S. and Canada (1) • Around 1,100 water utilities, <2.5% of the total, serve approximately 60% of the estimated population served (>200M) (1) • Approximately 14% of the U.S. population served by privately-owned water systems, including investor-owned utilities (IOU) (2) Water Utilities in North America Market Tier (by population served) # Water Utilities % of Total Utilities Estimated Population Served % of Population Served >250,000 158 0.3% 109.3M 32.1% 50,000 – 250,000 981 1.9% 93.3M 27.4% 3,300 – 50,000 8,725 17.2% 109.9M 32.3% <3,300 40,889 80.6% 27.7M 8.1% Distribution of Water Utilities in North America(1) • For U.S. utilities, 96% funded at state and local government level (3) • Majority of utilities have service connection fees and/or capital recovery charges, with median fees of about $6,400 (4) • CPI for water and sewerage maintenance increased 3.1% for 12 months ended December 2020 (5) • U.S. municipal bond issuance for year-to-date October 2020 period is 25.0% higher (6) • U.S. Federal government provides incentives for water utility projects such as Drinking Water State Revolving Funds (DWSRF) and Water Infrastructure Finance and Innovation Act (WIFIA) administered by the Environmental Protection Agency (EPA) Historical Water Rates vs. Other Utilities(5) 0 100 200 300 400 500 600 1 9 5 5 1 9 6 0 1 9 6 5 1 9 7 0 1 9 7 5 1 9 8 0 1 9 8 5 1 9 9 0 1 9 9 5 2 0 0 0 2 0 0 5 2 0 1 0 2 0 1 5 2 0 2 0 CPI Water CPI Nat Gas CPI Postage CPI Electricity CPI All Items CPI Utilities (NSA 1982-1984 = 100)

16 Need for Digital Water Solutions Expected to Accelerate “COVID-19 is an inflection point for long-term resilience, digital transformation of water sector. The U.S. & Canada digital water market is expected to sustain sizeable top-line losses in the immediate aftermath of the COVID-19 outbreak, but the pandemic is ultimately expected to drive greater demand for digital solutions going forward.” Bluefield Research April 2020 Note Climate Change, Water Scarcity and Population Growth • Aging workforce at U.S. & Canada water & wastewater utilities is projected to see significant retirements over the next ten years • Increasing consumer awareness and demand for water quality and usage information (1) Bluefield Research Note from April 15, 2020, “Pandemic Represents Watershed Moment for U.S. & Canada Digital Water Market” (2) Bluefield Research 2019, Water Industry 4.0 Focus Report (3) EPA Aging Water Infrastructure Research Program (4) “Water Main Break Rates in the USA and Canada: A Comprehensive Study,” March 2018, Steven Folkman at Utah State University. “Between 2012 and 2018, overall water main break rates increased by 27% from 11.0 to 14.0 breaks/(100 miles)/year (5) Navigant Research (6) National Resource Defense Council (7) U.S. Drought Monitor as of February 16, 2021 (includes contiguous 48 states) • Increased frequency of extreme climate events elevating importance of infrastructure resiliency and water management • 64% of U.S. experiencing drought or abnormally dry conditions (7) • Water scarcity awareness has increased conservation and use of low-flow appliances pressuring utility budgets • Population growth and migration trends leading to increased urbanization Aging Workforce and Consumer Awareness Aging Infrastructure and Non-Revenue Water • Average age of water pipes has increased to 45 years in 2020 from 25 years in 1970 (2) • 240,000 water main breaks per year with 27% increase in break rates since 2012 (3,4) • Up to 30% of treated water is lost or unaccounted for in the water system (5) • Growing number of states requiring water loss audits (6) In this COVID- Accelerated scenario, digital spend grows at a 12-year CAGR of 8.7%, compared to 6.5%. In other words, the COVID- 19 crisis is projected to advance the U.S. &. Canada digital water market by at least two to three years by the late 2020s.(1) Key Drivers for Digital Water Solutions

17 Broad-line of Technology-enabled Products • Currently have a number of products addressing these categories, including Echologics' pipe condition assessment services and fixed leak detection solutions, advanced meters and communication equipment, smart hydrants, pressure and water quality monitors, and most recently, our Sentryx™ software platform Digital Water Category Growth vs. Total Digital Water Market (1) Information Management ++++ Network Management ++ Work & Asset Management + Metering & Customer Management − Plant Management − − − − Current Product Offerings Acoustic Fixed Leak Detection & Pipe Condition Assessment Infrastructure Monitoring Software SentryxTM (1) Bluefield Research 2019, Water Industry 4.0 Focus Report. Estimated CAGR of 6.5% for North American Digital Water Market between 2019 and 2030. Water Quality Monitoring Pressure Monitoring & Control AMR, AMI, Remote Disconnect Meters, Communications

18 Expect capital expenditures as a % of consolidated net sales to decrease to less than 4% after the completion of the new brass foundry in Decatur, IL Modernizing Manufacturing Facilities • Three transformational projects account for approximately $130M of capital spending and expected to drive approximately $30M of annualized incremental gross profit through combination of efficiencies and sales growth, after all are completed − Modernizing facilities, equipment and processes will expand gross margins with broader product capabilities and operational efficiencies − Driving improvements in environmental impact using less resources and manufacturing waste * Consolidated capital expenditures includes Infrastructure, Technologies and Corporate segments. Periods prior to FY18 exclude Anvil. ** Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021. $80 - $90 Three Large Projects Project Location Expected Completion(1) Large Casting Foundry Chattanooga, TN 2020 Brass Foundry Decatur, IL 2023 Specialty Valve Manufacturing Kimball, TN 2023 (1) Represents timing of full project completion and not timing of full annualized benefit from efficiencies and sales from new products $27.2 $31.5 $40.6 $55.7 $86.6 $67.7 3.4% 3.9% 4.9% 6.1% 8.9% 7.0% 0.0% 2.0% 4.0% 6.0% 8.0% 10.0% $0 $20 $40 $60 $80 $100 $120 FY15 FY16 FY17 FY18 FY19 FY20 FY21** % o f C on so lid at ed N et S al es C ap ita l E xp en di tu re s Capital Expenditures* ($ in millions)

Financial Performance

20 Q1 2021 Consolidated Financial Highlights* • Net sales of $237.4M increased $24.8M, or 11.7%, primarily driven by increased shipment volumes across most of our product lines and higher pricing • Gross profit increased $5.8M, or 8.0%, to $78.4M with a gross margin of 33.0% − Gross margin decreased 110 basis points versus the prior year as benefits from higher shipment volumes and pricing were more than offset by unfavorable manufacturing performance, including approximately $1.5M of additional expenses related to the pandemic, and higher costs associated with inflation • Adjusted operating income of $29.2M increased $6.5M, or 28.6%, as compared with $22.7M in the prior year − Increase primarily due to higher sales, partially offset by unfavorable manufacturing performance and higher costs associated with inflation − Estimated expense impact from the pandemic was a benefit of about $0.3M in the quarter; benefits from lower SG&A expenses were partially offset by additional manufacturing expenses in the quarter associated with addressing the pandemic • Adjusted EBITDA of $44.7M increased $7.3M, or 19.5%, leading to adjusted EBITDA margin of 18.8% with a 29% conversion margin − For the last twelve months, adjusted EBITDA was $197.9M, or 20.0% of net sales • Increased adjusted net income per share 37.5% to $0.11 compared with $0.08 in the prior year $ in millions except per share amounts First Quarter 2021 2020 Net sales $ 237.4 $ 212.6 Gross profit $ 78.4 $ 72.6 Gross margin 33.0% 34.1% Adj. operating income $ 29.2 $ 22.7 Adj. operating margin 12.3% 10.7% Adj. EBITDA $ 44.7 $ 37.4 Adj. EBITDA margin 18.8% 17.6% Adj. net income per share $ 0.11 $ 0.08 * Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021. 1Q21 results exclude strategic reorganization and other charges of $1.4 million, and tax benefits of $0.4 million 1Q20 results exclude strategic reorganization and other charges of $2.4 million, $0.2 million of interest associated with the Walter Energy Accrual and tax benefits of $0.6 million

21 Full-Year Fiscal 2021 Outlook* • Anticipate that strong growth in the residential construction end market will more than offset any temporary delays in the project-related portions of the municipal end market due to the pandemic • Updated annual guidance takes into account our strong first quarter performance, backlog, and current expectations for our end markets, price and inflation • Increased annual guidance for consolidated net sales growth to be between 4% and 6% as compared to previous guidance for net sales to be between flat and 3% higher • Raised expectations for adjusted EBITDA growth to be between 5% and 8% − Moderated conversion margin expectations due to anticipated operational challenges resulting from the pandemic and higher cost inflation that will continue throughout the year − Continue to expect to generate positive free cash flow for the full year • Guidance assumes pandemic’s impact lessens during the second half of fiscal 2021 as compared with the prior year period * Expectations for other financial metrics for full-year 2021 provided with Q1FY21 earnings press release on February 3, 2021.

22 Free Cash Flow* • Net cash provided by operating activities for the first quarter 2021 improved $46.5M to $34.1M, primarily driven by improvements in working capital management • First quarter 2020 included the $22.2M payment associated with the Walter Energy payment* • Invested $15.6M in capital expenditures during Q1FY21, comparable to the $15.2M we spent in the first quarter of 2020 • Free cash flow for the first quarter improved $46.1M to $18.5M compared with negative free cash flow of $27.6M in the first quarter of the prior year ($27.6) $18.5 $15.2 $15.6 ($12.4) $34.1 ($40.0) ($30.0) ($20.0) ($10.0) $0.0 $10.0 $20.0 $30.0 $40.0 Q1FY20** Q1FY21 $ in m ill io ns Capital expenditures Free cash flow Cash provided by (used in) operating activities * Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021. ** Both cash used in operating activities and free cash flow for Q1FY20 include the pre-tax $22.2M payment (FY20 impact of $16.6M net of the tax benefit) associated with the Walter Energy tax settlement

23 Strong Balance Sheet and Ample Liquidity* • Moody’s: Ba2 Corporate Rating, Ba3 Notes Rating, Stable Outlook • S&P: BB Corporate and Notes Ratings, Stable OutlookCredit Rating Debt Structure Debt Maturities Financial Covenants • $450M of 5.5% Senior Unsecured Notes (matures June 2026) • Asset based lending agreement (“ABL”) provides up to $175M revolving credit facility subject to borrowing base (LIBOR + 200 basis points) with none outstanding (terminates July 29, 2025) • No financial maintenance covenants on Senior Unsecured Notes • ABL not subject to any financial maintenance covenants unless excess availability is less than the greater of $17.5M and 10% of the Loan Cap; consolidated Fixed Charge Ratio permitted to be <1x unless threshold is triggered Net Debt Leverage & Liquidity • $224.7M net debt with total debt of $447.7M** and total cash of $223.0M • Net debt leverage was 1.1x at December 31, 2020 vs. 1.5x at December 31, 2019 • No debt maturities prior to June 2026 • $336.4M of total liquidity including $113.4M of excess availability under the ABL, based on December 31, 2020 data * Provided with Q1FY21 earnings press release and presentation on February 3 & 4, 2021. ** 5.5% Senior Unsecured Notes include $4.7M of deferred financing costs Well-Prepared to Deal with Ongoing Challenges from Pandemic $0 $0 $0 $0 $0 $450 $0 $100 $200 $300 $400 $500 FY21 FY22 FY23 FY24 FY25 FY26 $ in m ill io ns No debt repayments prior to June 2026

24 Balanced and Disciplined Capital Allocation • Strong balance sheet, liquidity and cash flow to support our strategies • Maintaining balanced approach to capital allocation to strengthen and grow the business through capital investments and bolt-on acquisitions • Continuing to return cash to our shareholders, primarily through our ongoing quarterly dividend – Board of Directors recently increased quarterly dividend by 5% – Ended voluntary suspension on share repurchases instituted as a cautionary measure resulting from the pandemic Shareholders 30% Balance Sheet 13% Strategic Investments 57% $223M to Shareholders - $123M dividends - $100M share repurchases Cash Allocation since December 31, 2016 (Through September 30, 2020) $435M to Strategic Investments - $262M capital expenditures - $173M acquisitions (1) (2) (1) Includes consolidated capital expenditures and cash paid for acquisition of Krausz Industries and Singer (excludes proceeds from sales of assets) (2) Includes debt retirement and pension plan payments ($35 million pension settlement in Q4FY17 and $2 million to exit Canadian and multiemployer plans), and includes $22.2 million payment for Walter Tax Settlement) Capital Allocation Priorities

25 Investment Highlights LONG-TERM END MARKET DYNAMICS CONTINUE TO IMPROVE LEVERAGING STRENGTHS TO INCREASE TECHNOLOGY-ENABLED PRODUCTS MODERNIZING MANUFACTURING AND DRIVING OPERATIONAL EXCELLENCE TO DELIVER MARGIN EXPANSION FLEXIBLE BALANCE SHEET AND STRONG CASH FLOW STRONG COMPETITIVE POSITION

Supplemental Data

27 History of Strong Financial Performance $793 $801 $826 $916 $968 $964 $0 $200 $400 $600 $800 $1,000 $1,200 FY15 FY16 FY17 FY18 FY19 FY20 Consolidated Net Sales ($ in millions) $143 $156 $164 $180 $198 $191 18.1% 19.5% 19.8% 19.7% 20.5% 19.8% 0.0% 5.0% 10.0% 15.0% 20.0% 25.0% $0 $50 $100 $150 $200 $250 $300 $350 $400 FY15 FY16 FY17 FY18 FY19 FY20 Consolidated Adjusted EBITDA (1) and Adjusted EBITDA Margin ($ in millions) NOTE: See SEC Filings for Segment Results and Reconciliation of Non-GAAP to GAAP Performance Measures (1) Adjusted EBITDA excludes other charges of $51.7M in FY2015, $23.8M in FY2016, $21.2M in FY2017, $19.7M in FY2018, $43.3M in FY2019 and $13.2M in FY2020. • Over last five years (FY15 to FY20), delivered 4.0% net sales CAGR with 5.9% adjusted EBITDA CAGR • Adjusted EBITDA margin improved 170 bps. over the last five years (FY15 to FY20)

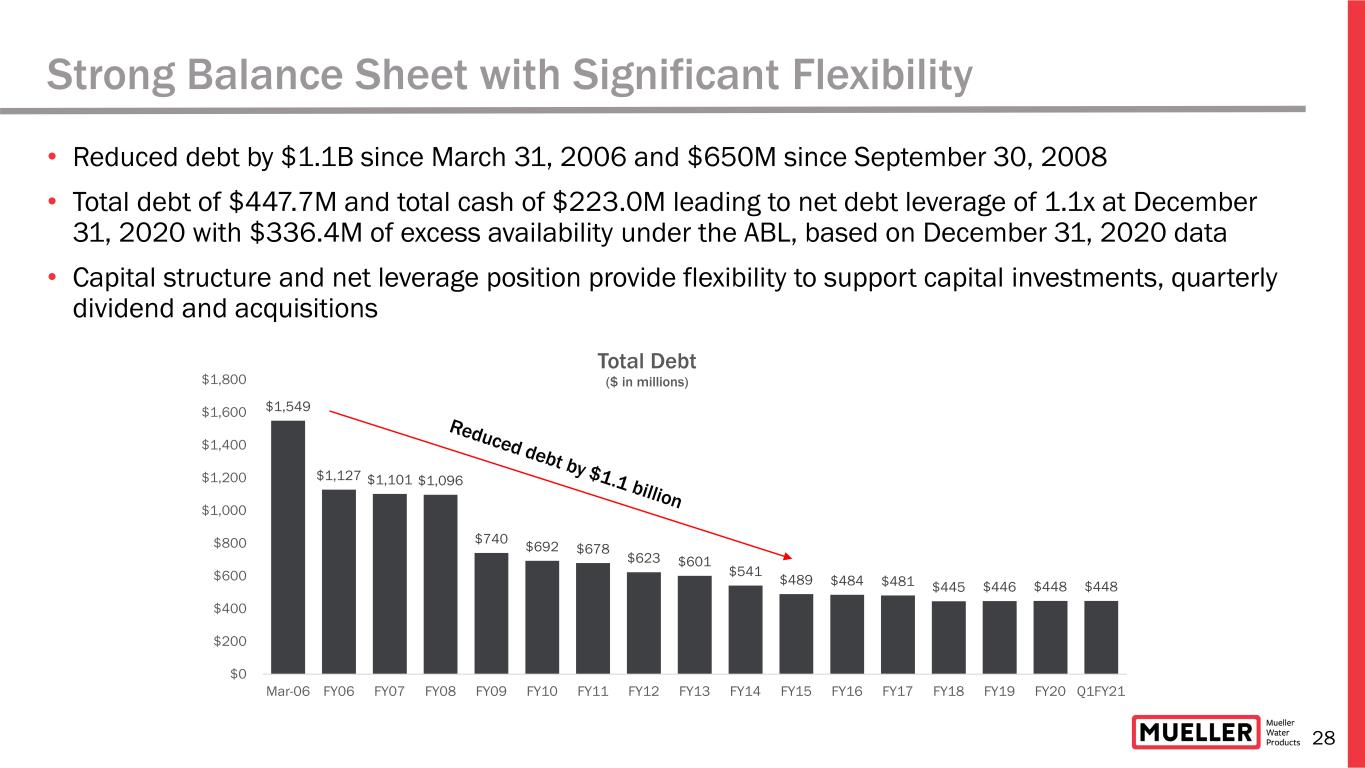

28 Strong Balance Sheet with Significant Flexibility • Reduced debt by $1.1B since March 31, 2006 and $650M since September 30, 2008 • Total debt of $447.7M and total cash of $223.0M leading to net debt leverage of 1.1x at December 31, 2020 with $336.4M of excess availability under the ABL, based on December 31, 2020 data • Capital structure and net leverage position provide flexibility to support capital investments, quarterly dividend and acquisitions $1,549 $1,127 $1,101 $1,096 $740 $692 $678 $623 $601 $541 $489 $484 $481 $445 $446 $448 $448 $0 $200 $400 $600 $800 $1,000 $1,200 $1,400 $1,600 $1,800 Mar-06 FY06 FY07 FY08 FY09 FY10 FY11 FY12 FY13 FY14 FY15 FY16 FY17 FY18 FY19 FY20 Q1FY21 Total Debt ($ in millions)

29 Segment Results and Reconciliation of Non-GAAP to GAAP Performance Measures (UNAUDITED) Quarter ended December 31, 2020 Infrastructure Technologies Corporate Consolidated (dollars in millions, except per share amounts) Net sales $ 215.9 $ 21.5 $ — $ 237.4 Gross profit $ 73.7 $ 4.7 $ — $ 78.4 Selling, general and administrative expenses 32.0 6.2 11.0 49.2 Strategic reorganization and other charges 0.1 — 1.3 1.4 Operating income (loss) $ 41.6 $ (1.5) $ (12.3) $ 27.8 Operating margin 19.3 % (7.0)% 11.7 % Capital expenditures $ 14.7 $ 0.8 $ 0.1 $ 15.6 Reconciliation of non-GAAP performance measures to GAAP performance measures: Net income $ 16.7 Strategic reorganization and other charges 1.4 Income tax benefit of adjusting items (0.4) Adjusted net income $ 17.7 Weighted average diluted shares outstanding 158.8 Adjusted net income per diluted share $ 0.11

30 Segment Results and Reconciliation of Non-GAAP to GAAP Performance Measures (UNAUDITED) (1) We do not allocate interest or income taxes to our segments. Quarter ended December 31, 2020 Infrastructure Technologies Corporate Consolidated (dollars in millions, except per share amounts) Net income $ 16.7 Income tax expense (1) 5.8 Interest expense, net (1) 6.1 Pension benefit other than service (0.8) Operating income (loss) $ 41.6 $ (1.5) $ (12.3) 27.8 Strategic reorganization and other charges 0.1 — 1.3 1.4 Adjusted operating income (loss) 41.7 (1.5) (11.0) 29.2 Pension benefit other than service — — 0.8 0.8 Depreciation and amortization 12.5 2.1 0.1 14.7 Adjusted EBITDA $ 54.2 $ 0.6 $ (10.1) $ 44.7 Adjusted operating margin 19.3 % (7.0)% 12.3 % Adjusted EBITDA margin 25.1 % 2.8 % 18.8 % Reconciliation of net debt to total debt (end of period): Current portion of long-term debt $ 1.1 Long-term debt 446.6 Total debt 447.7 Less cash and cash equivalents 220.8 Less restricted cash 2.2 Net debt $ 224.7 Net debt leverage (net debt divided by trailing twelve months’ adjusted EBITDA) 1.1x Reconciliation of free cash flow to net cash provided by operating activities: Net cash provided by operating activities $ 34.1 Less capital expenditures (15.6) Free cash flow $ 18.5

31 Segment Results and Reconciliation of Non-GAAP to GAAP Performance Measures (UNAUDITED) Quarter ended December 31, 2019 Infrastructure Technologies Corporate Consolidated (dollars in millions, except per share amounts) Net sales (1) $ 192.3 $ 20.3 $ — $ 212.6 Gross profit (1) $ 68.0 $ 4.6 $ — $ 72.6 Selling, general and administrative expenses 32.5 6.4 11.0 49.9 Strategic reorganization and other charges — — 2.4 2.4 Operating income (loss) $ 35.5 $ (1.8) $ (13.4) $ 20.3 Operating margin 18.5 % (8.9)% 9.5 % Capital expenditures $ 14.5 $ 0.6 $ 0.1 $ 15.2 Reconciliation of non-GAAP performance measures to GAAP performance measures: Net income $ 10.3 Walter Energy Accrual 0.2 Strategic reorganization and other charges 2.4 Income tax benefit of adjusting items (0.6) Adjusted net income $ 12.3 Weighted average diluted shares outstanding 158.7 Adjusted net income per diluted share $ 0.08 (1) Net sales and gross profit associated with certain products have been reclassified as Technologies segment items to conform to the current period presentation.

32 Segment Results and Reconciliation of Non-GAAP to GAAP Performance Measures (UNAUDITED) (1) We do not allocate interest or income taxes to our segments. Quarter ended December 31, 2019 Infrastructure Technologies Corporate Consolidated (dollars in millions, except per share amounts) Net income $ 10.3 Income tax expense (1) 3.1 Interest expense, net (1) 7.4 Walter Energy Accrual 0.2 Pension benefit other than service (0.7) Operating income (loss) $ 35.5 $ (1.8) $ (13.4) 20.3 Strategic reorganization and other charges — — 2.4 2.4 Adjusted operating income (loss) 35.5 (1.8) (11.0) 22.7 Pension benefit other than service — — 0.7 0.7 Depreciation and amortization 12.0 2.0 — 14.0 Adjusted EBITDA $ 47.5 $ 0.2 $ (10.3) $ 37.4 Adjusted operating margin 18.5 % (8.9)% 10.7 % Adjusted EBITDA margin 24.7 % 1.0 % 17.6 % Reconciliation of net debt to total debt (end of period): Current portion of long-term debt $ 0.9 Long-term debt 445.5 Total debt 446.4 Less cash and cash equivalents 140.7 Net debt $ 309.6 Net debt leverage (net debt divided by trailing twelve months’ adjusted EBITDA) 1.5x Reconciliation of free cash flow to net cash used in operating activities: Net cash used in operating activities $ (12.4) Less capital expenditures (15.2) Free cash flow $ (27.6)

Where Intelligence Meets Infrastructure®