Attached files

| file | filename |

|---|---|

| EX-99.1 - EXHIBIT 99.1 - AK STEEL HOLDING CORP | exhibit991-2018q4earni.htm |

| 8-K - 8-K - AK STEEL HOLDING CORP | form8-kearnings2018q4.htm |

Fourth Quarter 2018 Financial Results January 28, 2019 C r e a t i n g I n n o v a t i v e S t e e l S o l u t i o n s © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

AK Steel Executive Management Team . Roger Newport Chief Executive Officer . Kirk Reich President and Chief Operating Officer . Jaime Vasquez Vice President – Finance and Chief Financial Officer S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 2 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Forward-Looking Statements Certain statements made or incorporated by reference in this earnings release reflect management’s estimates and beliefs and are intended to be “forward-looking statements” identified in the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. Words such as “expects,” “anticipates,” “believes,” “intends,” “plans,” “estimates” and other similar references to future periods typically identify forward-looking statements. The company cautions readers that forward-looking statements reflect the company’s current beliefs and judgments, but are not guarantees of future performance or outcomes. They are based on a number of assumptions and estimates that are inherently affected by economic, competitive, regulatory, and operational risks, uncertainties and contingencies that are beyond the company’s control, and upon assumptions about future business decisions and conditions that may change. Forward-looking statements are only predictions and involve risks and uncertainties, resulting in the possibility that actual events or performance will differ materially from such predictions as a result of certain risk factors. Such factors that could cause the company’s actual results and financial condition to differ materially from the results contemplated by such forward-looking statements include reduced selling prices, shipments and profits associated with a highly competitive and cyclical industry; domestic and global steel overcapacity; risks related to U.S. government actions on Section 232 and 301, NAFTA and/or other trade agreements, treaties or policies; changes in the cost of raw materials, supplies and energy; the company’s significant amount of debt and other obligations; severe financial hardship or bankruptcy of one or more of the company’s major customers or key suppliers; the company’s significant proportion of sales to the automotive market; reduced demand in key product markets due to competition from aluminum or other alternatives to steel; excess inventory of raw materials; supply chain disruptions or poor quality of raw materials or supplies; production disruption or reduced production levels; the company’s healthcare and pension obligations; not reaching new labor agreements on a timely basis; major litigation, arbitrations, environmental issues and other contingencies; regulatory compliance and changes; climate change and greenhouse gas emissions; conditions in the financial, credit, capital and banking markets; the company’s use of derivative contracts to hedge commodity pricing volatility; potential permanent idling of facilities; inability to fully realize benefits of margin enhancement initiatives; information technology security threats, cybercrime and exposure of private information; the company’s failure to achieve expected benefits of the Precision Partners acquisition and/or to integrate Precision Partners successfully; changes in tax laws and regulations; and risks associated with the closure of Ashland Works, including without limitation risks related to a failure to achieve the estimated savings, loss of existing or future business as a result of transitioning (or seeking to transition) products to other coating lines, costs or actions resulting from closure negotiations with the labor union at Ashland Works, higher than expected closure costs, and unanticipated operational issues as a result of producing products at other coating lines; as well as those risks and uncertainties discussed in more detail in the company’s Annual Report on Form 10-K for the year ended December 31, 2017, and its subsequent Quarterly Reports on Form 10-Q and Current Reports on Form 8-K filed with or furnished to the Securities and Exchange Commission. As such, the company cautions readers not to place undue reliance on forward-looking statements, which speak only to the company’s plans, assumptions and expectations as of the date hereof. The company undertakes no obligation to publicly update any forward-looking statement, except as required by law. S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 3 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Roger Newport Chief Executive Officer S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Strong Performance in 2018 . Net Income $186 million . Adjusted Net Income $201 million . Adjusted EBITDA $563 million Best Performance Since 2008 Note: See Appendix for reconciliations of non-GAAP financial measures S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 5 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Protecting Our Most Important Asset – Our People . Three facilities achieved zero OSHA recordables for OSHA Recordable Frequency 4Q 2018 . One facility achieved zero OSHA recordables for the 3.00 year 2018 . 2.33 2.37 One facility achieved zero occupational injuries for 2.01 2.00 1.87 the year 2018 1.69 1.67 1.38 1.55 1.55 1.45 1.36 1.00 0.64 0.45 0.41 0.36 0.29 0.25 0.33 0.32 0.26 0.25 0.26 0.00 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 AISI AK Steel OSHA Recordable Frequency is number of injuries per 200,000 employee hours Notes: Based upon most current American Iron and Steel Institute (AISI) data available through 3Q 2018. AK Steel data represents steelmaking operations; 2015 and forward includes Dearborn Works. S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 6 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Strategic Path . $680 million of debt refinanced and maturities extended since 2016 Strengthened . Capital Reduced debt and legacy liabilities by a total of nearly $200 million in 2018 Structure . Pension annuitizations to-date of ~$500 million . Major investment completed at Middletown Works hot-end Enhanced . Mansfield melt shop upgrade and installed new technology at caster Core Business . New state-of-the-art stainless coil build up line planned at Coshocton Works . Launched new products, including NEXMET® AHSS coated products for automotive Expanded and TRAN-COR® X for electrical transformers; various customer trials are underway Growth . Acquired Precision Partners – tool design and build/hot stamping/cold stamping Platform . Investing to increase downstream revenues and profits S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 7 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Enhancing Asset Utilization . Plan to close the Ashland Works facility by the end of 2019 − Blast furnace and ‘hot-end’ were idled more than three years ago − Transition of hot dip galvanizing coating line production to other AK Steel operations in U.S. . Employees will be offered open positions at other facilities . Increase utilization of other AK Steel coating lines in the U.S. . Once fully implemented, these actions are expected to result in annual savings of over $40 million S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 8 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Investing in the Future Maintenance and Capital Investment Strategic $1,600 $1,500 $1,400 $1,200 $1,200 $1,000 $800 $800 $800 $800 ($ Millions) ($ $600 $400 $200 $0 2014 2015 2016 2017 2018 Note: 2014 includes Dearborn for full year S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 9 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Steel Market Update . Overall economic conditions remain solid North America Light Vehicle Production . (Vehicles in Millions) Automotive market remains healthy 17.8 17.1 17.0 17.1 17.1 17.4 . Spot market pricing for carbon steels remain at healthy levels . Service center inventories are balanced with demand 2016 2017 2018 2019E 2020E 2021E U.S. Housing Starts U.S. Non-Residential Construction Fixed Investment (Millions) ($ Billions) 1.40 $2,981 $2,713 $2,824 $2,908 1.33 $2,411 $2,539 1.26 1.29 1.18 1.21 2016 2017 2018 2019E 2020E 2021E 2016 2017 2018 2019E 2020E 2021E Source: AK Steel estimates S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 10 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Kirk Reich President and Chief Operating Officer S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Strategic Capital Investments Cost Benefit Sustainability Growth . Dearborn Works Melt Shop . Rockport Works Pickling . Mansfield Works Caster . Coshocton Works Coil Build Up Line . AK Tube . Precision Partners About one-third of 2019 capital investments for growth and improvements S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 12 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Downstream Operations – Platform for Growth . Downstream Revenues* Continued development of Advanced High-Strength ($ Millions) Steel tubing and stamping applications $800 $615 . Improved downstream performance in 2018 $600 $400 $358 ‒ AK Tube achieved record results $214 $200 ‒ Precision Partners awarded record level of future $0 business 2016 2017 2018 * Includes tubular products, components and other revenues . Proactive moves improved stamping operations in 4Q and set foundation for strong 2019 . Capital investments in tooling and stamping operations to support growth in 2019 and beyond . Downstream operations expected to continue growth in 2019 S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 13 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

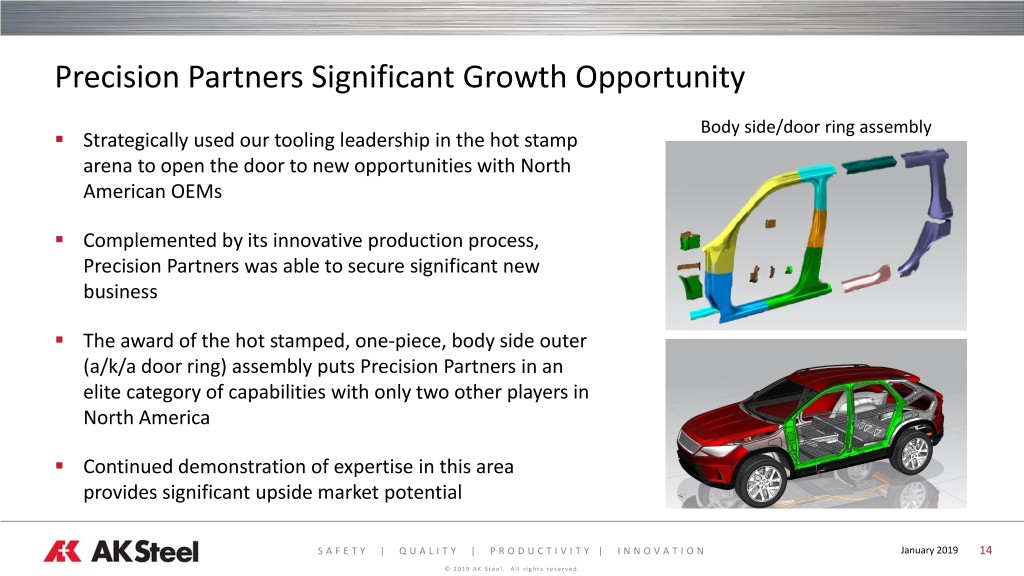

Precision Partners Significant Growth Opportunity Body side/door ring assembly . Strategically used our tooling leadership in the hot stamp arena to open the door to new opportunities with North American OEMs . Complemented by its innovative production process, Precision Partners was able to secure significant new business . The award of the hot stamped, one-piece, body side outer (a/k/a door ring) assembly puts Precision Partners in an elite category of capabilities with only two other players in North America . Continued demonstration of expertise in this area provides significant upside market potential S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 14 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Successful Customer Contract Renegotiations . Carbon automotive contracts − Improved pricing and expanded margins − Positioned on the right platforms − Improving mix of High-Strength Steel products − Continued progress on adoption of new, Advanced High-Strength Steel grades . Carbon non-automotive contracts and spot business subject to direction of spot market pricing . Specialty steel contracts complete and expected to cover cost pressures and increase margins overall S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 15 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Jaime Vasquez Vice President – Finance and Chief Financial Officer S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Fourth Quarter 2018 Financial Highlights ($ Millions, except per share and per ton) Y-o-Y Y-o-Y 4Q 2017 3Q 2018 4Q 2018 Improvement Improvement Flat-Rolled Shipments (in 000s of tons) 1,337 1,424 1,389 52 4% Flat-Rolled Average Selling Price Per Ton $1,024 $1,114 $1,106 $82 8% Net Sales $1,495.6 $1,735.6 $1,677.1 $181.5 12% Net Income (Loss) ($80.4) $67.2 $33.5 $113.9 NM Adjusted Net Income (Loss) ($24.1) $67.2 $48.0 $72.1 NM Adjusted EBITDA $67.4 $160.8 $135.5 $68.1 101% Adjusted EBITDA Margin 4.5% 9.3% 8.1% 3.6 points 80% Earnings (Loss) Per Share – Diluted ($0.26) $0.21 $0.11 $0.37 NM Adjusted Earnings (Loss) Per Share – Diluted ($0.08) $0.21 $0.16 $0.24 NM Notes: . 2017 and prior recast to reflect retrospective adjustments from certain accounting changes, including switch from LIFO . See Appendix for reconciliations of non-GAAP financial measures S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 17 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Consolidated Adjusted EBITDA Bridge – 3Q 2018 to 4Q 2018 $200 $175 $161 $150 $5 $1 $16 $136 $125 $12 $3 ($ ($ Millions) $100 $75 $50 3Q 2018 Actual Sales Rate & Raw Materials & Operations Downstream Other 4Q 2018 Actual Volume/Mix Energy S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 18 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Balance Sheet and Cash Flow Highlights . Solid free cash flow generation resulted in a $116 million Pension/OPEB Liabilities Reduced By 29% reduction in debt in 2018 ($ Millions) . $1,500 Maintain focus on strengthening balance sheet $1,225 . $1,135 Completed ~$280 million pension asset and liability transfer $934 $1,000 $868 in October 2018 . Pension/OPEB liability reduction of $66 million in 2018 $500 . Working capital was a source of $25 million cash in 4Q and $0 $14 million for full year 2015 2016 2017 2018 Consistent Capital Investments Manageable Pension Contributions ($ Millions) ($ Millions) $200 ~$170 - $190 $75 $153 $152 $150 $128 $50 $50 $50 $44 $45 $99 $50 $100 $24 $25 $50 $0 $0 $0 2015 2016 2017 2018 2019E 2015 2016 2017 2018 2019E 2020E 2021E S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 19 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

2019 Full Year Guidance Estimates . Net income attributable to AK Steel of ~$160 to $180 million Flat-Rolled Shipments . Adjusted EBITDA in the range of $515 to $535 million, ~50% (000s tons) expected to be generated in the first half of the year 8,000 6,974 . 5,936 5,683 Based on January 2019 average carbon hot rolled coil spot 6,000 5,596 market price of ~$720 4,000 . Every $10 change in the carbon hot roll coil spot market price, adjusted EBITDA and net income impacted by ~$5 to $7 million 2,000 . Excludes effect of the charge for Ashland Works closure costs 0 expected to be recorded in 1Q 2015 2016 2017 2018 Flat-Rolled Average Selling Price Per Ton Adjusted EBITDA ($ Millions) $1,200 $1,091 $600 $563.4 $1,022 $528.5 $955 $929 $500 $472.8 $900 $400 $600 $300 $180.4 $200 $300 $100 $0 $0 2015 2016 2017 2018 2015 2016 2017 2018 Note: 2017 and prior recast to reflect retrospective adjustments from certain accounting changes, including switch from LIFO The company's guidance is based on AK Steel’s current estimates and may change based on business conditions and other factors. There are many other items that could affect the company’s 2019 results, as outlined in the Forward-Looking Statements slide of this presentation, including developments in the domestic and global economies, in the company’s business, in trade actions and the imposition of tariffs, and in the businesses of the company’s customers, suppliers and competitors. S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 20 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

2019 Other Guidance Items . Earnings per share of ~$0.51 to $0.57 . Flat-rolled shipments ~5.9 million tons . Average flat-rolled selling price roughly the same as 2018 . Major maintenance outages ~$70 to $80 million . Depreciation and amortization ~$210 million* . Cash interest expense of ~$135 million . Total interest expense of ~$155 million . Pension and OPEB income ~$20 to $25 million** . OPEB payments of ~$40 million . Minimal cash and book taxes . Working capital expected to be slight use of cash * Includes $20 million for SunCoke ** Includes ~$6 million expense reported in Cost of Products Sold/Selling and Administrative expenses The company's guidance is based on AK Steel’s current estimates and may change based on business conditions and other factors. There are many other items that could affect the company’s 2019 results, as outlined in the Forward-Looking Statements slide of this presentation, including developments in the domestic and global economies, in the company’s business, in trade actions and the imposition of tariffs, and in the businesses of the company’s customers, suppliers and competitors. S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N 21 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Ashland Works Financial Impact . Expect to incur a charge of ~$80 million in 1Q 2019 − Primarily termination of take-or-pay agreements and employee unemployment and benefit costs . Estimated cash impact and timing − $15 million in 2019 − $30 million in 2020 − $35 million spread over several years thereafter . Expect to incur additional cash costs in 2019 related to closure of the facility of ~$10 million, which will decline in future years, plus $4 million of accelerated depreciation . Once fully implemented, annual savings of more than $40 million are expected S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 22 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Roger Newport Chief Executive Officer S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

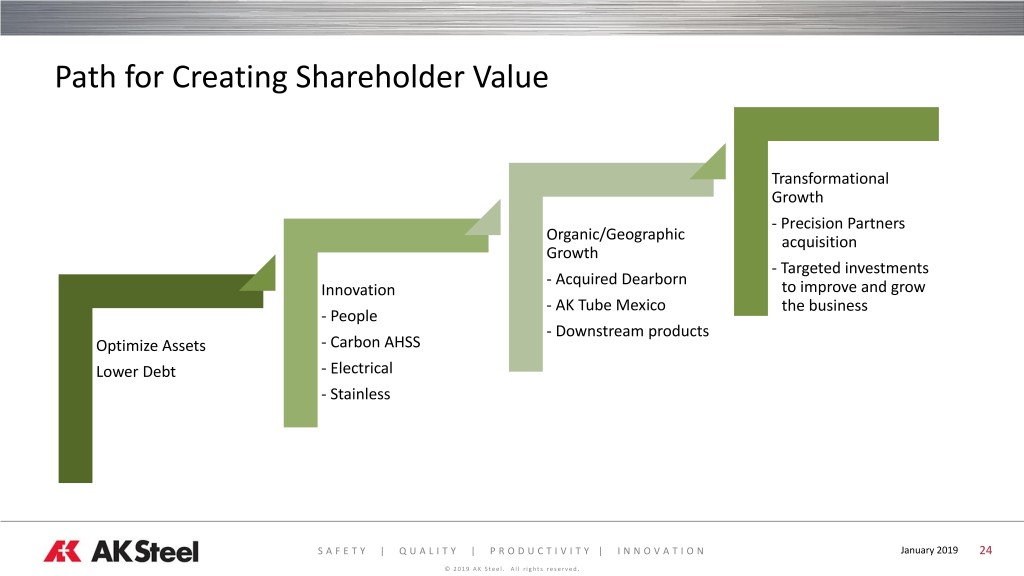

Path for Creating Shareholder Value Transformational Growth - Precision Partners Organic/Geographic acquisition Growth - Targeted investments - Acquired Dearborn Innovation to improve and grow - AK Tube Mexico the business - People - Downstream products Optimize Assets - Carbon AHSS Lower Debt - Electrical - Stainless S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 24 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Strategy Create Shareholder Value By: Driving further Transforming our growth – Commercializing operations to organically and innovative significantly through products and improve our acquisitions – into services competitive cost new markets and position downstream business S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 25 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

THANK YOU! S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Appendix S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Investor Contact S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 28 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Strengthening Our Foundation Best Financial Performance in a Decade Mansfield Works Acquired Melt Shop Precision Partners Improvements Launched New Opened New Record Downstream NEXMET™ AHSS Research and Earnings Innovation Center Products Began Portfolio Strengthened Lowered Debt Reduction Optimization Capital Interest Costs Structure Idled Ashland Completed Major Acquired Completed Dearborn Hot-end Hot-end Operations Pension De-risking Dearborn AHSS Investment Operations Investments 2014 2015 2016 2017 2018 S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 29 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

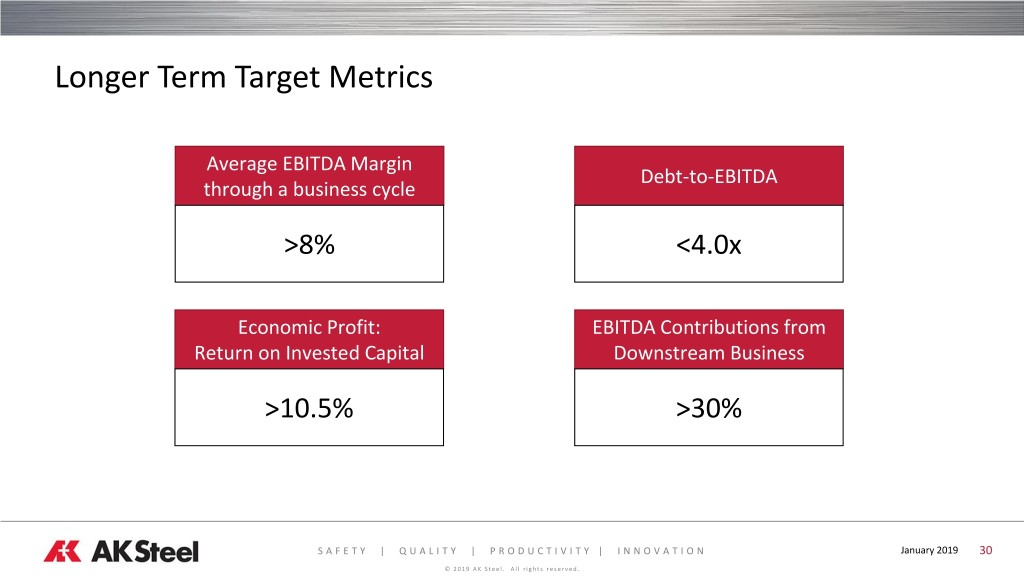

Longer Term Target Metrics Average EBITDA Margin Debt-to-EBITDA through a business cycle >8% <4.0x Economic Profit: EBITDA Contributions from Return on Invested Capital Downstream Business >10.5% >30% S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 30 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

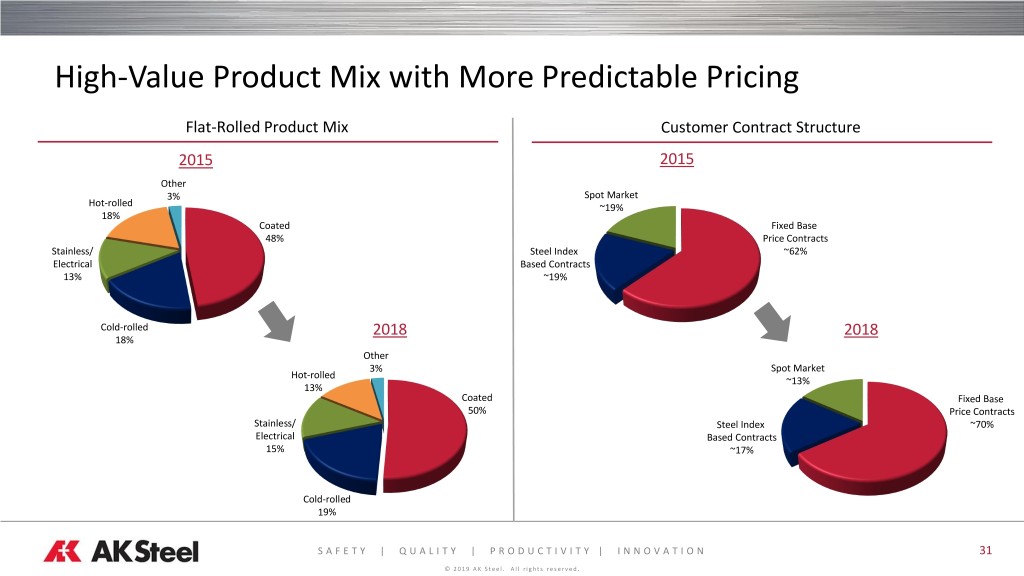

High-Value Product Mix with More Predictable Pricing Flat-Rolled Product Mix Customer Contract Structure 2015 2015 Other 3% Spot Market Hot-rolled ~19% 18% Coated Fixed Base 48% Price Contracts Stainless/ Steel Index ~62% Electrical Based Contracts 13% ~19% Cold-rolled 2018 2018 18% Other 3% Spot Market Hot-rolled ~13% 13% Coated Fixed Base 50% Price Contracts Stainless/ Steel Index ~70% Electrical Based Contracts 15% ~17% Cold-rolled 19% S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N 31 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Full Year 2018 Financial Highlights ($ Millions, except per share and per ton) Y-o-Y Y-o-Y 2017 2018 Improvement Improvement Flat-Rolled Shipments (in 000s of tons) 5,596 5,683 87 2% Flat-Rolled Average Selling Price Per Ton $1,022 $1,091 $69 7% Net Sales $6,080.5 $6,818.2 $737.7 12% Net Income $103.5 $186.0 $82.5 80% Adjusted Net Income $159.8 $200.5 $40.7 25% Adjusted EBITDA $528.5 $563.4 $34.9 7% Adjusted EBITDA Margin 8.7% 8.3% (40 bps) -5% Earnings Per Share – Diluted $0.32 $0.59 $0.27 84% Adjusted Earnings Per Share – Diluted $0.50 $0.64 $0.14 28% Notes: . 2017 and prior recast to reflect retrospective adjustments from certain accounting changes, including switch from LIFO . See Appendix for reconciliations of non-GAAP financial measures S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 32 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Significantly Improved Debt Profile ($ Millions) December 31, 2015 December 31, 2018 Total Debt: $2.4 billion $700 $150 $150 $537 Total Debt: $2.0 billion $7 $406 $406 $380 $380 $392 $335 $290 $275 $550 $530 $149 $62 $62 $30 $7 $30 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 Credit Facility Senior Notes Senior Secured Notes Industrial Revenue Bonds . Free cash flow generation allowed for a $116 million reduction of debt in 2018 Note: Excludes unamortized debt discount and issuance costs S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 33 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

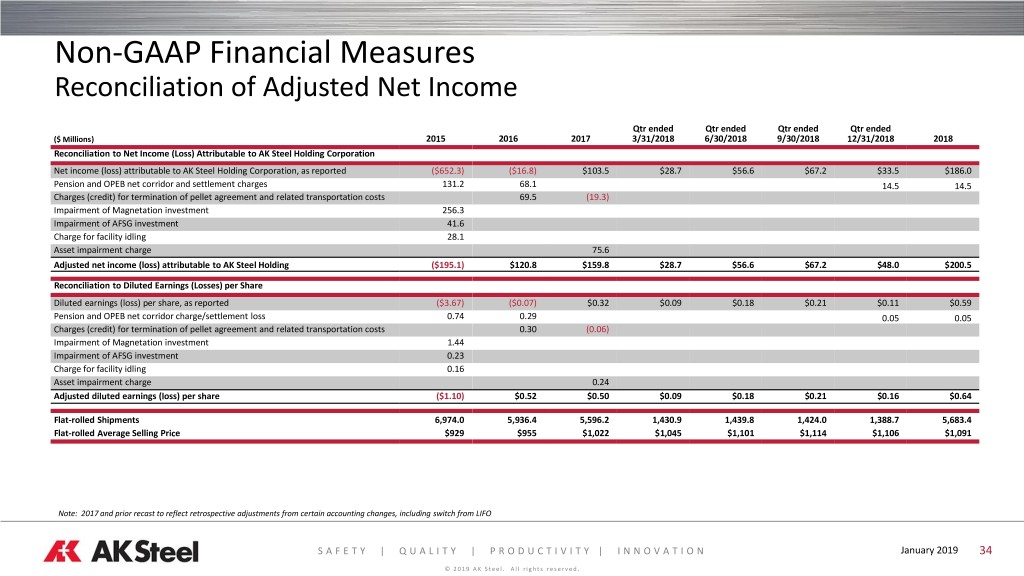

Non-GAAP Financial Measures Reconciliation of Adjusted Net Income Qtr ended Qtr ended Qtr ended Qtr ended ($ Millions) 2015 2016 2017 3/31/2018 6/30/2018 9/30/2018 12/31/2018 2018 Reconciliation to Net Income (Loss) Attributable to AK Steel Holding Corporation Net income (loss) attributable to AK Steel Holding Corporation, as reported ($652.3) ($16.8) $103.5 $28.7 $56.6 $67.2 $33.5 $186.0 Pension and OPEB net corridor and settlement charges 131.2 68.1 14.5 14.5 Charges (credit) for termination of pellet agreement and related transportation costs 69.5 (19.3) Impairment of Magnetation investment 256.3 Impairment of AFSG investment 41.6 Charge for facility idling 28.1 Asset impairment charge 75.6 Adjusted net income (loss) attributable to AK Steel Holding ($195.1) $120.8 $159.8 $28.7 $56.6 $67.2 $48.0 $200.5 Reconciliation to Diluted Earnings (Losses) per Share Diluted earnings (loss) per share, as reported ($3.67) ($0.07) $0.32 $0.09 $0.18 $0.21 $0.11 $0.59 Pension and OPEB net corridor charge/settlement loss 0.74 0.29 0.05 0.05 Charges (credit) for termination of pellet agreement and related transportation costs 0.30 (0.06) Impairment of Magnetation investment 1.44 Impairment of AFSG investment 0.23 Charge for facility idling 0.16 Asset impairment charge 0.24 Adjusted diluted earnings (loss) per share ($1.10) $0.52 $0.50 $0.09 $0.18 $0.21 $0.16 $0.64 Flat-rolled Shipments 6,974.0 5,936.4 5,596.2 1,430.9 1,439.8 1,424.0 1,388.7 5,683.4 Flat-rolled Average Selling Price $929 $955 $1,022 $1,045 $1,101 $1,114 $1,106 $1,091 Note: 2017 and prior recast to reflect retrospective adjustments from certain accounting changes, including switch from LIFO S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 34 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

Non-GAAP Financial Measures Reconciliation of Adjusted EBITDA Qtr ended Qtr ended Qtr ended Qtr ended 2019 Guidance ($ Millions) 2015 2016 2017 3/31/2018 6/30/2018 9/30/2018 12/31/2018 2018 Low High Net income (loss) attributable to AK Steel Holding ($652.3) ($16.8) $103.5 $28.7 $56.6 $67.2 $33.5 $186.0 $160.0 $180.0 Net income (loss) attributable to NCI 62.8 66.0 61.4 16.1 15.7 17.7 8.6 58.1 55.0 55.0 Income tax expense (benefit) (6.3) (16.9) (2.2) (4.9) (0.5) 1.4 (2.2) (6.2) 10.0 10.0 Interest expense, net 171.7 162.6 150.9 37.4 37.7 37.6 38.0 150.7 155.0 155.0 Depreciation and amortization 224.4 221.4 236.3 61.3 58.6 58.4 58.7 237.0 210.0 210.0 EBITDA ($199.7) $416.0 $549.9 $138.6 $168.1 $182.3 $136.6 $625.6 $590.0 $610.0 Less: EBITDA of NCI (a) 77.1 80.8 77.7 19.9 19.7 21.5 15.6 76.7 75.0 75.0 Pension and OPEB net corridor charges / settlement loss 131.2 68.1 14.5 14.5 Charges (credit) for termination of pellet agreement and related transportation costs 69.5 (19.3) Impairment of Magnetation investment 256.3 Impairment of AFSG investment 41.6 Charge for facility idling 28.1 Asset impairment charge 75.6 Adjusted EBITDA $180.4 $472.8 $528.5 $118.7 $148.4 $160.8 $135.5 $563.4 $515.0 $535.0 Adjusted EBITDA margin 2.7% 8.0% 8.7% 7.2% 8.5% 9.3% 8.1% 8.3% (a) The reconciliation of EBITDA of noncontrolling interest to net income attributable to noncontrolling interests is as follows: Net income (loss) attributable to noncontrolling interests $62.8 $66.0 $61.4 $16.1 $15.7 $17.7 $8.6 $58.1 $55.0 $55.0 Depreciation 14.3 14.8 16.3 3.8 4.0 3.8 7.0 18.6 20.0 20.0 EBITDA of noncontrolling interests $77.1 $80.8 $77.7 $19.9 $19.7 $21.5 $15.6 $76.7 $75.0 $75.0 Note: 2017 and prior recast to reflect retrospective adjustments from certain accounting changes, including switch from LIFO S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 35 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .

S A F E T Y | Q U A L I T Y | P R O D U C T I V I T Y | I N N O V A T I O N January 2019 © 2 0 1 9 A K S t e e l . A l l r i g h t s r e s e r v e d .