Attached files

| file | filename |

|---|---|

| 8-K - 8-K - BASIC ENERGY SERVICES, INC. | a8-kinvestorpresentation.htm |

O U R L I F E ’ S WO R K I S T H E L I F E O F T H E W E L L ™ Investor Presentation October 2018

Forward-Looking Statements This presentation contains forward-looking statements. Basic has based Important factors that may affect Basic’s expectations, estimates or these forward-looking statements largely on its current expectations and projections include: projections about future events and financial trends affecting the financial condition of its business. These forward-looking statements are subject to a A decline in or substantial volatility of oil and gas prices, and any number of risks, uncertainties and assumptions, including, among other related changes in expenditures by its customers things, the risk factors discussed in this presentation and other factors, most of which are beyond Basic’s control. The effects of future acquisitions on its business The words “believe,” “may,” “estimate,” “continue,” “anticipate,” “intend,” Changes in customer requirements in markets or industries it serves “plan,” “expect” and similar expressions are intended to identify forward- looking statements. All statements other than statements of current or Competition within its industry historical fact contained in this presentation are forward-looking statements. General economic and market conditions Although Basic believes that the forward-looking statements contained in Its access to current or future financing arrangements this presentation are based upon reasonable assumptions, the forward- looking events and circumstances discussed in this presentation may not Its ability to replace or add workers at economic rates occur and actual results could differ materially from those anticipated or implied in the forward-looking statements. Environmental and other governmental regulations Additional important risk factors that could cause actual results to differ Non-GAAP Financial Measures materially from expectations are disclosed in Item 1A of Basic’s Form 10-K This presentation contains certain non-GAAP financial measures. A for the year ended December 31, 2017 and subsequent Form 10-Q’s filed reconciliation of each such measure to the most comparable GAAP with the SEC. While Basic makes these statements and projections in good measure is presented in the Appendix hereto. We use “EBITDA” and faith, neither Basic nor its management can guarantee that the transactions “Adjusted EBITDA“, non-GAAP financial measures, for internal reporting will be consummated or that anticipated future results will be achieved. and providing guidance on future results. These measures are not Basic’s forward-looking statements speak only as of the date of this measures of financial performance under GAAP. We strongly advise presentation. Unless otherwise required by law, Basic undertakes no investors to review our financial statements and publicly filed reports in their obligation to publicly update or revise any forward-looking statements, entirety and not rely on any single financial measure. See the Appendix for whether as a result of new information, future events or otherwise. a reconciliation of these measures to GAAP. 2

Company Overview

Basic Energy Services, Inc. – At a Glance Balanced & Diversified Product Portfolio ‹ Well servicing and water logistics levered to production ‹ Completions & remedial levered to new drilling and well recompletions ‹ Strong presence in most prolific U.S. oil basins Improved Liquidity with No Near-Term Debt Maturities ‹ Recently completed refinancing freed up $47 million in restricted cash with new ABL facility (1) ‹ Pro forma ~$90 mm in cash (after accrued interest and associated fees) (1) ‹ Recent refinancing extends debt maturity profile with $300 million senior secured notes due 2023 Core Business Strengthening with Increasing Production Volumes ‹ More multi-well pads mean more wells to maintain for ongoing production ‹ Well service rig is the increasingly preferred completion method for long lateral wells ‹ Increasing production volumes result in increasing water disposal Capital & Strategic Initiatives Drive Increasing Efficiencies ‹ Investments targeting core businesses with high return profiles ‹ Rationalizing business by divesting non-core service lines to streamline G&A ‹ De-lever through retained cash flows and investment discipline, taking advantage of $732 mm in NOL carry forwards (1) 1. As of June 30, 2018 4

Proven Operating Strategy Our Life’s Work is the Life of the Well TM Basic supports customer Diversified service offering with Strong market position wellsite activities from initial emphasis on stable producing in the most prolific U.S. drilling to plugging & wells, and optionality to oil basins abandonment capitalize on growth with increasing U.S. oil production The right fleet and the right people in the right basins to support financial returns for the Life of the Well. 5

Extensive Footprint in Prolific Basins Significant Exposure to Major Oil Basins with >80% Revenue Exposure to Oil and Liquids Activity Core Regions 5 1 Permian 2 Eagle Ford 4 3 Mid-Continent 6 3 4 Niobrara 1 5 Williston 2 6 California 6

Primary Service Lines Completion & Remedial Well Servicing Water Logistics Services Increasingly preferred completion One of the most extensive networks Pumping services for cementing, method for longer laterals of SWDs acidizing, squeeze-cementing (workover), fracturing Periodic major maintenance and Trucking and access to third-party and re-fracturing renovation to sustain or pipelines to transport produced improve production waste water to SWDs Rental and Fishing Tools (“RAFT”) for drilling, workovers and remedial Routine maintenance of down-hole Water sourcing, storage, recycling, equipment to return well and chemical treatment Snubbing and coiled-tubing for to production completions and workovers Pipeline and SWD design with Plugging and abandonment installation/construction Used extensively in well service operations 25% of 1H18 total revenues 24% of 1H18 total revenues 50% of 1H18 total revenues Note: Excludes Contract Drilling segment, which contributed ~1% of revenue for TTM ended 2Q18 7

Company Overview % of Total Direct Overview by Segment Margin by Activity* (1H 2018) Well Services Diversified Business Across the Well Lifecycle 310 workover rigs Leading high-spec workover fleet of 272 rigs Well Water Servicing ° Utilization of 82% in 2Q18 Logistics 22% ° Equipped for completions activity 28% Vertically-integrated cost savings and flexibility Contract with in-house maintenance and refurbishment Drilling 1% capabilities Completion and Remedial Services Water Logistics 49% 85 SWDs with connections to an extensive third- party pipeline network 882 trucks and 3,218 fluid storage tanks Coiled Tubing Cement 19% & Acid Pipelines contributed ~23% of total SWD water (9% of total company 19% volumes and ~40% of SWD Permian water volumes direct margin (9% of total company C&R Direct direct margin in 2Q18 Margin Rental and Fishing Tools (1) Breakdown Hydraulic 38% Completion and Remedial Fracturing (19% of total company direct margin 24% 13 rental & fishing tool stores, 36 snubbing units (12% of total company and 18 coiled tubing units (10 units 2” diameter or direct margin larger) Company Profile As of 10/1/18 NYSE Ticker BAS ~516k hydraulic horsepower (“HHP”) focused on Current Share Price $10.06 Mid-Continent and SCOOP/STACK Shares Outstanding 26.5 mm Market Capitalization $267.9 mm *Calculated as revenue minus direct operating costs Enterprise Value (PF as of 6/30/18) $551.6 mm Note: Equipment and asset counts as of 6/30/18 30-Day Daily Trading Volume 305,322 1. Includes nitrogen and snubbing 8

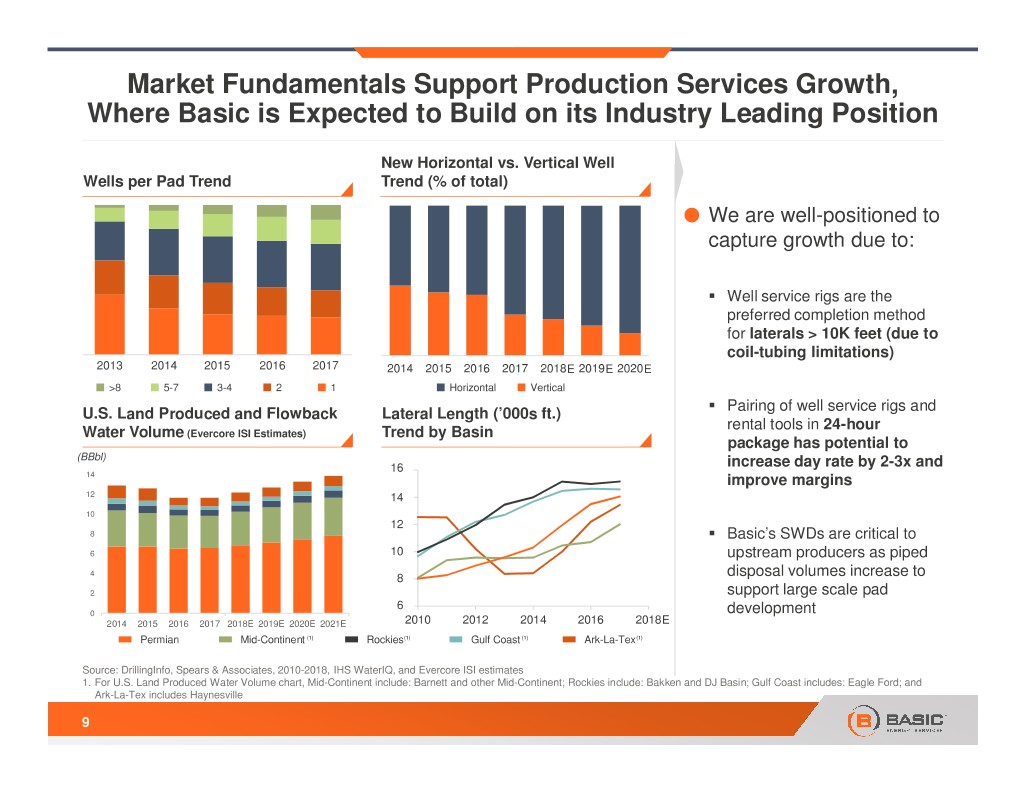

Market Fundamentals Support Production Services Growth, Where Basic is Expected to Build on its Industry Leading Position New Horizontal vs. Vertical Well Wells per Pad Trend Trend (% of total) We are well-positioned to capture growth due to: ° Well service rigs are the preferred completion method for laterals > 10K feet (due to coil-tubing limitations) 2013 2014 2015 2016 2017 2014 2015 20162017 2018E 2019 E 2020 E >8 5-7 3-4 2 1 Horizontal Vertical ° Pairing of well service rigs and U.S. Land Produced and Flowback Lateral Length (’000s ft.) rental tools in 24-hour Water Volume (Evercore ISI Estimates) Trend by Basin package has potential to (BBbl) 16 increase day rate by 2-3x and 14 improve margins 12 14 10 12 8 ° Basic’s SWDs are critical to 6 10 upstream producers as piped 4 8 disposal volumes increase to 2 support large scale pad 6 0 development 2014 2015 2016 2017 2018E 2019E 2020E 2021E 2010 2012 2014 2016 2018 E Permian Mid-Continent (1) Rockies (1) Gulf Coast (1) Ark-La-Tex (1) Source: DrillingInfo, Spears & Associates, 2010-2018, IHS WaterIQ, and Evercore ISI estimates 1. For U.S. Land Produced Water Volume chart, Mid-Continent include: Barnett and other Mid-Continent; Rockies include: Bakken and DJ Basin; Gulf Coast includes: Eagle Ford; and Ark-La-Tex includes Haynesville 9

Core, Production-Levered Businesses Have Differentiated Scale Estimated High-Spec Well Service Rigs (1) Salt Water Disposal Wells Scale in high-spec rigs with utilization near or at labor Basic’s large SWD footprint in the Permian and other U.S. oil basins is constraints should mean continued improvement in pricing expected to allow for continued water-by-pipe development for disposing of produced volumes (Number of Active High-Spec Rigs) Public Companies (Number of Wells) Total SWD Wells Permian SWD Wells 350 140 120 300 120 272 250 226 100 85 200 80 66 150 138 135 60 125 100 40 35 42 26 26 32 18 16 50 32 20 15 21 11 13 20 7 18 4 16 15 13 11 7 0 0 BAS Public Public Public Public Private Private Private Public BAS Public Private Private Private Public Private Private Private Private (2) (3) Company A Company B Company C Company D Company A Company B Company C Company 1 Company 2 Company 1 Company 2 Company 3 Company 3 Company 4 Company 5 Company 6 Company 7 Note: High-Spec rigs include Class IV or higher, definition per AESC with 102’ masts or taller and 210k lb hook load capacity or greater Source: SEC Filings, Company Presentations and Websites, Basic Estimates 1. Excludes idle and warm stacked rigs 2. Does not specify the number of rigs which are Class IV or higher, definition per AESC with 102’ masts or taller and 210k lb hook load capacity or greater 3. Permian SWDs not disclosed 10

Production Service Businesses are Continuing to Recover Well Service Rig Hours SWD Volumes Rig Hours (‘000s) Total SWD Volumes (MBbls) Utilization (1) Pipeline Volume (MBbls) • Invest in new 190 100% 10,000 equipment 9,270 182 8,977 8,628 8,424 • Expand into new8,098 175 7,966 169 80% 8,000 165 160 markets 162 82% 76% * 160 158 • Maximize utilization 55% 72% 60% 6,000 54% to increase market 52% 145 share • Develop40% new4,000 service 130 offerings 1,921 2,064 20% 2,000 1,609 115 1,551 1,560 1,191 100 0% 0 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 Avg. 421 421 421 310* 310 310 # of Rigs Source: Company Filings *On December 31, 2017, we classified 111 rigs from our current fleet as “cold-stacked”, reducing our total active rig fleet to 310 rigs, and removed these rigs from the active rig count 1. Based on a 55-hour week 11

Core Business Trends and Outlook Well Servicing appears to have passed an inflection point, with improved utilization and rates driving margins higher ° Several opportunities to increase rates remain, with several rate increases implemented Well throughout the quarter Servicing ° Number of 24-hour packages remains strong, averaging 24 for 2Q ° Equipment rentals associated with completions and larger workovers can double or triple overall rate paid on jobs (booked as C&R segment revenue) Transition of water disposal volumes to pipe continues, with pipelines contributing 23% of total water volumes and ~40% of SWD Permian water volumes in 2Q18 Water Logistics ° Higher margin business with less operational risk than trucking ° Recurring, long-term steady revenue with development upside Rental and fishing tools (“RAFT”) benefiting from 24-hour packages; rentals are booked in this segment Completion Coiled tubing activity focused on drilling out frac plugs along with cementing, acid and snubbing and seeing stability and positive outlook Remedial Hydraulic fracturing assets have been repositioned from the Permian to the Mid-Con, which provides scale in an attractive market 12

Operational Update 2Q18 1Q18 4Q17 Well servicing rig hours 181,600 168,500 159,500 Well servicing utilization rate 82% 76% 53% Number of well servicing rigs – end of period 310 310 421 Pipeline Water Volumes (in thousands) 2,064 1,551 1,921 Fluid services truck hours 486,800 479,600 492,800 Weighted Average Number of fluid service trucks 903 960 967 Total pressure pumping HHP – end of period 516,465 522,565 522,565 Total frac HHP – end of period 407,800 413,300 413,300 Coiled tubing units – end of period 18 18 18 Notes: HHP is hydraulic horsepower. On December 31, 2017, we classified 111 rigs from our current fleet as “cold-stacked”, reducing our total active rig fleet to 310 rigs, and removed these rigs from the active rig count 13

Well Servicing Well Servicing Rigs Facilitate Down Hole Activity Revenue Segment Direct Margin* 310 Rigs by Market Area** Inactive $100 $30 30% Appalachia 6% 2% $90 $25 25% California $80 5% $70 $20 20% Ark-La-Tex $60 5% $50 $15 15% Gulf Coast Permian $40 Millions Millions $10 10% 10% Basin $30 46% $20 $5 5% $10 Mid-Continent $0 0% $0 12% 1Q14 2Q15 3Q16 4Q17 Rock Mtns. 1Q14 2Q15 3Q16 4Q17 Gross Profit Gross Margin 14% Workover Completion Service Work P&A Periodic major maintenance and Well preparation for production after Routine maintenance of down-hole Plugging and abandonment renovation to sustain or improve successful drilling of a well; packaged equipment to return well to production of depleted wells production; deferred maintenance ancillary equipment is a differentiator activity increasing *Calculated as revenue minus direct operating costs **As of 6/30/18; on 12/31/17, we classified 111 rigs from our current fleet as “cold-stacked”, reducing our total active rig fleet to 310 rigs, and removed these rigs from the active rig count 14

Well Servicing Fleet Overview Fleet Metrics Fleet Distribution by Class 247 250 200 272 Class IV or 150 Larger Rigs 100 32 50 21 4 2 4 0 Class 1 Class II Class III Class IV Class V Class VI *As of 12/31/2017 Active Rig Class by Region 310 Well Service Rigs Larger, late model equipment deployed in most active basins Fleet ranges from 200HP-900HP rigs 150 ° 272 rigs or 88% of the fleet are late model Class IV (102’ Mast 120 or taller / 210k lb hook load capacity or greater), Class V, and Class VI rigs 90 60 ° All Class IV and V rigs are capable of longer lateral horizontal projects 30 0 87% of the Class IV / V / VI and 79% of the total fleet are Rocky Mtn. California Permian Gulf Coast Appalachia Central Taylor brand rigs Class I Class II Class III Class IV Class V Class VI *As of 12/31/2017 *On December 31, 2017, we classified 111 rigs from our current fleet as “cold-stacked”, reducing our total active rig fleet to 310 rigs, and removed these rigs from the active rig count 15

Well Service Company of Choice BAS operates the largest domestic fleet of active high-spec well service rigs Quarterly Rig Hours Indexed to 1Q16 vs Public US Peers 180% 160% 140% 120% 100% 80% 1Q16 2Q 3Q 4Q 1Q17 2Q 3Q 4Q 1Q18 2Q18 BAS Peer 1 Peer 2 Peer 3 Source: Public filings, Company press releases Note: Peer 3 hourly rig data indexed to 4Q16, earliest date for which that data is available 16

Well Servicing is Rapidly Becoming a 24-Hour Operation 24 Hour Rig Packages ° Bundling of Basic’s rental and fishing tools with a 24-hour well service job has been well received by customers ° Packages vary and include additional Basic crew, hydraulic catwalk, 10k pump, swivel and/or snubbing and BOP 30 25 20 15 10 5 0 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 Permian Rockies Gulf Coast Central Appalachia California 17

Water Logistics Basic’s Integrated Fluid Service Business Anchored by Access to an Expansive SWD Network Revenue $100 One of the largest networks of SWDs in the industry $90 $80 Water sourcing and storage $70 $60 SWD design and installation $50 Millions $40 Integrated truck fleet and SWD portfolio also $30 connected to third-party pipeline network $20 $10 Pipeline design and infrastructure construction $0 1Q14 2Q14 3Q14 4Q14 1Q15 2Q15 3Q15 4Q15 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 Water recycling and chemical treatment programs Segment Direct Margin* 882 Trucks & 85 SWDs by Market Area** $30 35% 11% $25 30% Ark-La-Tex 25% 24 $20 SWDs 20% 15% $15 15% Gulf Coast 11 SWDs $10 10% 32 54% Millions $5 5% SWDs Permian Basin 15% 13 $0 0% SWDs Mid-Continent 5 1Q14 2Q15 3Q16 4Q17 SWDs Gross Profit Gross Margin 12% **As of 6/30/18; truck Rocky Mtns. distribution shown as %’s *Calculated as revenue minus direct operating costs 18

Paradigm Shift from Trucks to Pipe for Midstream Transport of Produced Water to Our SWD Network Basic’s SWD Trend - Trucked Volumes vs. Piped Volumes Note: Piped vs. Trucked not Drawn to Scale ° Longer laterals and pad drilling are shifting produced water disposal from trucking to fixed-infrastructure pipelines to drive maximum efficiency ° Basic’s 85 SWDs and associated, largely customer-built pipelines provide a competitive advantage ° Pipeline activity is longer-term, recurring revenue with higher margins ° Basic’s strategy is to build out Basic- owned pipelines in the future, continuing to support key upstream customers ° Trucking provides a bridge to pipeline build out and serves as a competitive advantage for Basic in the short to Jul-18 Jul-17 Jul-16 Oct-17 Apr-18 Oct-16 Apr-17 Apr-16 Jan-18 Jun-18 Jan-17 Jun-17 Jan-16 Jun-16 Feb-18 Mar-18 Feb-17 Mar-17 Feb-16 Mar-16 Aug-17 Sep-17 Nov-17 Dec-17 Aug-16 Sep-16 Nov-16 Dec-16 May-18 May-17 medium term May-16 Total Trucked Piped Water Linear (Total Trucked) Linear (Piped Water) 19

Specialized Completion & Production Services Support drilling, workover and production C&RS Revenue by Service Line processes Fishing tools and rental equipment for drilling $120,000 and workover processes, including 24-hour packages $90,000 Coiled tubing and nitrogen services for completion, $60,000 remedial and P&A applications 000s) (in $30,000 ° 18 coiled tubing units, including 10, 2” diameter or larger $0 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 Snubbing services to allow “live-well” completion Frac Cementing Acid Coil RAFT and workover operations Tubular services Pumping services for cementing, acidizing, Segment Direct Margin Progression * squeeze-cementing (workover), fracturing and re-fracturing activities 35.0% 30.0% 31.7% 25.0% 30.0% ° ~516k total HHP 24.4% 20.0% 23.8% 12.4% 20.3% • ~408k HHP devoted to frac 15.0% 9.3% 18.5% 14.2% 16.4% • ~108k HHP for acid/cementing/other 10.0% 5.0% ° Repositioned Permian frac fleets to the Mid-Continent 0.0% -5.0% providing Basic with scale in an attractive market -10.0% -15.0% ° Spreads currently booked through 3Q 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 in the Mid-Con, including the SCOOP/STACK Frac Cementing Acid Coil RAFT Note: Equipment and asset counts as of 6/30/18 *Calculated as revenue minus direct operating costs 20

Overview of Strategic Realignment Initiatives ° Reposition assets to enhance Utilization + Margins core operating regions ° Enhance 24-hour rental packages with controlled ramp Margins with 2-year pay back period of asset base StrategicStrategic ° SWD/pipeline projects where InitiativesInitiatives demand is outstripping Revenue + Margin opportunities capacity ° Convert SWDs from internal Revenue + Margin opportunities use to open-market access ° SG&A to target of 10%-12% Margin and cash flow of revenue 21

Financial Overview

2Q18 Update Capital expenditures (including capital leases) for 2Q18 totaled $24.4 million ° Maintenance/sustaining expenditures were $21.5 million ° Expansion projects and other totaled $2.9 million At June 30, 2018 total liquidity stood at $45.4 million plus restricted cash of $47.1 million Adjusted EBITDA* Cash Flow From Operations $45 $100 $32.4 $28.8 $30 $27.0 $50 $23.3 $24 $21 $15 $18.3 $5 $15 $0 ($0) $5.1 ($13) $3.2 ($21) ($21) $0.9 ($30) $0 ($50) ($8.3) ($9.2) ($80) ($15) ($100) 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18 2Q18 Predecessor Successor Predecessor Successor Free Cash ($25) ($28) ($41) ($89) ($39) ($8) $1 $9 ($11) $4 Flow** Source: Company filings Note: Dollars in millions *See Appendix for reconciliation of Adjusted EBITDA to nearest comparable GAAP measure **Free Cash Flow calculated as Cash Flow From Operations less the Purchase of Property and Equipment, excluding capital leases 23

3Q18 Outlook Despite revenue trending higher in the early part of the third quarter, the strategic realignment initiative could result in choppiness as we move assets and close underperforming yards Production-oriented segment revenue pricing gains are likely to continue in the mid-single digit range for Well Servicing and low single digits for Water Logistics Well service utilization remains well above 80%, with two recently relocated 24-hour rigs and crews quickly going back to work in higher-demand regions Large disposal projects in the Permian Basin present significant pipeline opportunities for the Water Logistics segment in 2H18 RAFT is expected to remain stable in 3Q relative to 2Q levels, with Appalachia-based rigs and rental equipment relocated to Permian Basin and Mid-Continent 24

Financial Policy & Targets Maintain a conservative financial position for operational flexibility and resilience through market cycles ° Goal for minimum liquidity (cash plus revolver availability) of $100 million ° Goal of long-term leverage under 2.0x Position Basic for long-term financial success to execute on strategic initiatives Continue to rationalize non-core assets to provide additional liquidity and deleveraging Disciplined management with a focus on cash flow generation 25

Basic Investment Highlights Diversified service offerings for U.S. oil and natural gas producers Modern and maintained fleet routinely outperforms on reliability; vertically-integrated well service business The largest active high-spec well service rig fleet and one of the largest networks of SWDs in the Permian and other prolific U.S. oil basins Production Services currently experiencing strong momentum in activity levels Experienced management team with long-lasting customer relationships Providing a safe work environment is a top priority 26

Appendix

Historical Financial Summary ($ in millions) Predecessor Predecessor Successor Successor Successor 2015 2016 Q1 2017 Q2 2017 Q3 2017 Q4 2017 2017 Q1 2018 Q2 2018 Income Statement Well Servicing $217.2 $164.0 $48.6 $53.1 $54.6 $54.5 $210.8 $57.5 $64.4 Water Logistics 258.6 191.7 50.2 50.7 52.3 55.5 208.8 56.5 59.7 Completion & Remedial Services 307.6 184.6 80.4 107.4 123.7 122.0 433.4 117.6 126.9 Contract Drilling 22.2 7.2 2.8 2.1 2.8 3.3 11.0 3.0 2.3 Total Revenue $805.6 $547.5 $182.0 $213.3 $233.5 $235.3 $864.0 $234.7 $253.4 % Growth (46.0%) (32.0%) 17.1% 17.2% 9.4% 9.4% 7.3% (0.3%) 8.0% Well Servicing $32.3 $23.7 $7.7 $11.3 $11.4 $10.5 $40.9 $9.3 $14.7 Water Logistics 62.4 30.2 8.7 9.2 11.1 11.3 40.2 15.6 15.7 Completion & Remedial Services 62.5 25.8 13.2 26.2 39.2 36.7 115.3 27.9 26.4 Contract Drilling 5.5 0.2 0.4 0.3 0.3 0.4 1.3 0.5 0.6 Total Direct Margin $162.7 $79.8 $29.9 $46.9 $61.9 $58.9 $197.6 $53.3 $57.4 % of Revenue 20.2% 14.6% 16.4% 22.0% 26.5% 25.0% 22.9% 22.7% 22.7% G&A Expenses $143.5 $135.3 $34.2 $36.0 $39.2 $37.0 $146.5 $41.0 $51.5 Adj. EBITDA (1) $38.0 ($11.5) $3.2 $18.3 $32.4 $28.8 $82.8 $23.3 $27.0 Cash Flow From Operations $95.5 ($151.5) ($12.9) ($0.5) $15.2 $24.1 $25.9 $4.5 $20.6 Total Capex (excl. capital leases) (70.6) (32.7) (25.9) (7.8) (14.6) (15.1) (63.4) (15.4) (16.3) Free Cash Flow $24.9 ($184.2) ($38.8) ($8.3) $0.7 $9.1 ($37.4) ($10.9) $4.3 Summary Balance Sheet Successor Cash $46.7 $98.9 $50.6 $34.2 $43.2 $38.5 $33.8 $30.7 Total Debt (incl. capital leases) (2) 886.1 223.2 236.7 253.9 320.2 315.2 327.4 327.9 Source: Company Filings 1. See Appendix for reconciliation of Adjusted EBITDA to nearest comparable GAAP measure 2. Total debt includes capital leases, unamortized discounts, premiums and deferred financing costs 28

Non-GAAP Reconciliation ($ in millions) Predecessor Predecessor Predecessor Successor Successor Successor 2015 Q1 2016 Q2 2016 Q3 2016 Q4 2016 2016 Q1 2017 Q2 2017 Q3 2017 Q4 2017 2017 Q1 2018 Q2 2018 Net Loss ($241.7) ($83.3) ($89.9) ($92.1) $141.9 ($123.4) ($38.6) ($23.9) ($13.8) ($20.3) ($96.7) ($30.5) ($40.1) Income Tax Provision (Benefit) ($131.3) ($4.5) $0.7 $0.0 - ($3.9) $0.4 - ($1.7) ($0.3) ($1.7) ($0.1) 0.3 Interest Expense 67.9 20.7 22.5 23.9 29.4 96.6 9.1 9.2 8.9 10.3 37.4 11.3 12.7 Depreciation & Amortization 241.5 56.2 54.8 53.1 54.1 218.2 25.4 26.0 29.5 31.4 112.2 30.2 31.2 EBITDA ($63.7) ($11.0) ($11.9) ($15.0) $225.4 $187.5 ($3.7) $11.2 $22.8 $21.1 $51.3 $10.9 $4.1 (Gain) Loss on Sale of Assets $1.6 ($0.1) $0.3 ($0.1) $0.9 $1.0 ($0.5) ($0.2) 0.0 0.9 $0.3 $1.8 $1.9 Restructuring Costs - - - 10.5 10.3 20.7 1.6 1.0 - - 2.7 - - Vesting of Equity Compensation - - - - 18.9 18.9 - - - - - - - Due Diligence on M&A Activities - - - - - - - - 3.7 0.5 4.2 - - Goodwill Impairment 81.9 - - 0.6 - 0.6 - - - - - - - Customer Audit Settlement 4.5 - - - - - - - - - - - - Retention Expense - - - 2.7 3.6 6.3 1.4 - - - 1.4 - - Non-cash stock compensation 13.7 2.8 2.3 2.2 10.3 17.7 4.4 6.3 5.9 6.3 23.0 6.8 6.0 Audit-related state sales & use tax - - - - - - - - - - - - 6.0 Executive Retirement - - - - - - - - - - - - 3.9 Bad Debt - - - - - - - - - - - - 3.1 Strategic Consulting - - - - - - - - - - - 0.5 2.0 Costs for pulled bond offering - - - - - - - - - - - 1.8 - Executive bonus - - - - - - - - - - - 1.6 - Reorganization Items - - - - (264.3) (264.3) - - - - - - - (1) Adj. EBITDA $38.0 ($8.3) ($9.2) $0.9 $5.1 ($11.5) $3.2 $18.3 $32.4 $28.8 $82.8 $23.3 $27.0 EBITDA means earnings before interest, taxes, depreciation and amortization. Adjusted EBITDA is further adjusted to exclude (i) impairment of goodwill, (ii) customer audit, (iii) retention expense, (iv) due diligence for corporate development activities, (v) restructuring costs, (vi) reorganization items, net, (vii) vesting of predecessor equity compensation, (viii) the gain or loss on the disposal of assets, (ix) non-cash stock compensation, (x) audit-related state sales and use tax, (xi) executive retirement, (xii) bad debt costs, (xiii) strategic consulting costs, (xiv) costs in connection with withdrawn bond offering, (xv) executive bonus payments, and (xvi) reorganization items. 1. The Adjusted EBITDA calculation includes an add-back for non-cash stock compensation, which is consistent with Basic’s Adjusted EBITDA calculation for 1Q and 2Q 2018, and an add-back for strategic consulting costs, which is consistent with Basic’s Adjusted EBITDA calculation for 2Q 2018. Starting with the 8-Ks filed to announce financial and operating results for 1Q and 2Q 2018, Basic began including each of non-cash stock compensation and strategic consulting costs, respectively, as an adjustment to calculate Adjusted EBITDA, and similar adjustments have been made in this presentation for prior periods for comparability purposes. As a result, the financial results reflected in this presentation for Adjusted EBITDA for 2015 through 1Q 2018 will not reconcile with previously filed financial results reflected for Adjusted EBITDA for those time periods 29

O U R L I F E ’ S WO R K I S T H E L I F E O F T H E W E L L ™