Attached files

| file | filename |

|---|---|

| EX-21.1 - EXHIBIT 21.1 - GLOBAL BRASS & COPPER HOLDINGS, INC. | brss-12312017xex211.htm |

| EX-32.1 - EXHIBIT 32.1 - GLOBAL BRASS & COPPER HOLDINGS, INC. | brss-12312017xex321.htm |

| EX-31.2 - EXHIBIT 31.2 - GLOBAL BRASS & COPPER HOLDINGS, INC. | brss-12312017xex312.htm |

| EX-31.1 - EXHIBIT 31.1 - GLOBAL BRASS & COPPER HOLDINGS, INC. | brss-12312017xex311.htm |

| EX-23.1 - EXHIBIT 23.1 - GLOBAL BRASS & COPPER HOLDINGS, INC. | brss-12312017xex231.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

__________________________________________________________

FORM 10-K

__________________________________________________________

x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2017

or

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File No. 001-35938

__________________________________________________________

GLOBAL BRASS AND COPPER HOLDINGS, INC.

(Exact name of registrant as specified in its charter)

__________________________________________________________

Delaware | 06-1826563 | |

(State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification Number) | |

475 N. Martingale Road Suite 1050 Schaumburg, IL | 60173 | |

(Address of principal executive offices) | (Zip Code) | |

(847) 240-4700

(Registrant’s telephone number, including area code)

__________________________________________________________

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer | ¨ | Accelerated filer | x |

Non-accelerated filer | ¨ (Do not check if a smaller reporting company) | Smaller reporting company | ¨ |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ¨

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No ý

The aggregate market value of the registrant’s common stock held by non-affiliates of the registrant on June 30, 2017, the last business day of the registrant’s most recently completed second fiscal quarter, was approximately $653.0 million (based upon the closing price per share of the registrant’s common stock on the New York Stock Exchange on that date).

On February 16, 2018, there were 21,998,188 shares of common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Registrant’s definitive Proxy Statement, which will be filed with the Securities and Exchange Commission within 120 days after December 31, 2017, are incorporated by reference in Part III of this Form 10-K.

Table of Contents

Item 1. | ||

Item 1A. | ||

Item 1B. | ||

Item 2. | ||

Item 3. | ||

Item 4. | ||

Item 5. | ||

Item 6. | ||

Item 7. | ||

Item 7A. | ||

Item 8. | ||

Item 9. | ||

Item 9A. | ||

Item 9B. | ||

Item 10. | ||

Item 11. | ||

Item 12. | ||

Item 13. | ||

Item 14. | ||

Item 15. | ||

Item 16. | ||

i

PART I

Item 1. Business.

Our Company

Global Brass and Copper Holdings, Inc. (“Holdings,” the “Company,” “we,” “us,” or “our”) was incorporated in Delaware on October 10, 2007. We commenced commercial operations on November 19, 2007 following the acquisition of the metals business from Olin Corporation. The majority of our operations are managed through three reportable operating segments: Olin Brass, Chase Brass and A.J. Oster.

We are a leading value-added converter, fabricator, processor and distributor of specialized non-ferrous products, including a wide range of sheet, strip, foil, rod, tube and fabricated metal component products. While we primarily process copper and copper alloys, we also reroll and form certain other metals such as stainless steel, carbon steel and aluminum. Using processed scrap, virgin metals and other refined metals, we engage in metal melting and casting, rolling, drawing, extruding, welding and stamping to fabricate finished and semi-finished alloy products. Key attributes of copper and copper alloys are conductivity, corrosion resistance, strength, malleability, cosmetic appearance and bactericidal properties.

Unlike traditional metals companies, particularly those that engage in mining, smelting and refining activities, we are purely a metal converter, fabricator, processor and distributor, and we do not attempt to generate profits from fluctuations in metal prices. Our financial performance is primarily driven by metal conversion economics, not by the underlying movements in the price of copper and the other metals we use. Through our “balanced book” approach (as further described under “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Key Business Principles Affecting Our Results of Operations —Balanced Book”), we strive to match the timing, quantity and price of our metal sales with the timing, quantity and price of our replacement metal purchases. This practice, along with our toll processing operations and last-in, first-out (“LIFO”) inventory accounting methodology, substantially reduces the financial impact of metal price movements on our earnings and operating margins.

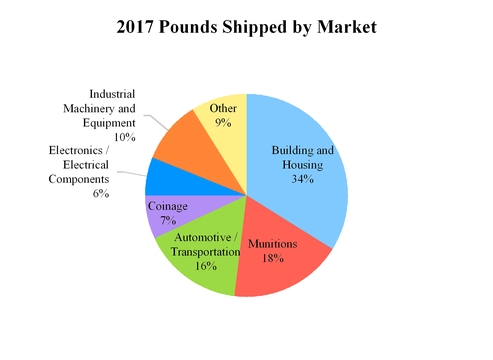

Our products are used in a variety of applications across diversified markets, including the building and housing, munitions, automotive, transportation, coinage, electronics / electrical components, industrial machinery and equipment, signage, and general consumer markets. We access these markets through direct mill sales, our captive distribution network and third-party distributors. We hold the exclusive production and distribution rights in North America for a lead-free brass rod product, which we sell under the Green Dot® and Eco Brass® brand names. We believe we are the only domestic copper and brass sheet manufacturer with captive distribution and service center operations, a competitive advantage that allows us to service and access customers with a wide variety of volume and service needs.

We service nearly 4,500 customers in 28 countries across four continents. We employ approximately 1,900 people and operate 16 manufacturing facilities and distribution centers across the United States (“U.S.”), Puerto Rico and Mexico.

We own 80% of a value-added service center in Guangzhou, China (“Olin Luotong Metals” or “OLM”); the other 20% is owned by Chinalco Luoyang Copper Co. Ltd. (“Chinalco”). Through Olin Luotong Metals, together with our sales offices in China and Singapore, we supply our products in China and throughout Asia.

1

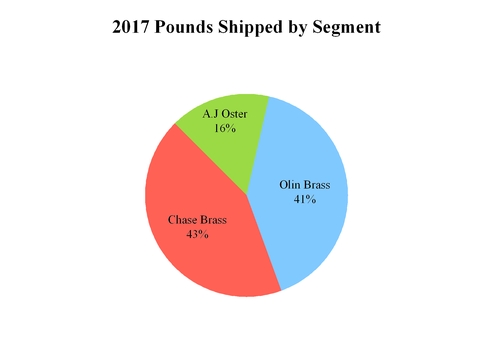

The following charts show the percentage of our shipments by segment, as well as the primary markets for our products and the percentage of shipments. Pounds shipped by market represent management’s estimate of the markets in which our customers participate. Additionally, pounds shipped by market reflect our allocation of Chase Brass shipments to distributors, job shops and forging shops. See Item 1, “Business—Chase Brass.”

2

Segments Overview

We have three reportable operating segments: Olin Brass, Chase Brass and A.J. Oster.

|  |  | |

Activities | ● Leading manufacturer, fabricator and converter | ● Leading manufacturer and supplier | ● Leading processor and distributor |

Products | ● Specialized copper and brass sheet, strip, foil, tube, and fabricated products | ● Brass rod, including environmentally friendly alloys | ● Primarily copper, brass, and aluminum sheet, strip and coated products |

Key Markets | ● Building and Housing | ● Building and Housing | ● Building and Housing |

● Automotive | ● Transportation | ● Automotive | |

● Electronics / Electrical Components | ● Electronics / Electrical Components | ● Electronics / Electrical Components | |

● Munitions | ● Industrial Machinery and Equipment | ||

● Coinage | |||

All of our segments sell to the building and housing market. While demand within this market is affected by new residential housing, existing home sales and commercial construction, all of which are seasonal and dependent on overall economic conditions, the correlation between housing statistics and our sales is not entirely direct. Our key products are typically installed near the completion of construction, meaning there is an inherent lag time compared to housing starts, and sales of our building and housing products can be affected by factors such as housing mix (unit size, unit price point and the mix of multi-family versus single-family construction). Sales of our products can also be impacted by changes in the composition of materials and fixtures used in construction as well as import and export dynamics.

Further information about our business segments and the geographic areas of our operations can be found in “Note 4, Segment Information.”

Olin Brass

In addition to manufacturing, fabricating and converting specialized copper and brass sheet, strip, foil, tube and fabricated products, Olin Brass also rerolls and forms other alloys such as stainless steel, carbon steel and aluminum. Sheet and strip is generally manufactured from copper and copper-alloy scrap.

Olin Brass manufactures its wide variety of products through four sites in North America. It is not uncommon for Olin Brass to produce 50 different alloys, approximately 30% of which could be high performance alloys (“HPAs”).

Olin Brass’s integrated brass mill in East Alton, Illinois is its main operating facility, which melts metal and produces strip products that are either sold directly to external customers, sold to its affiliate, A.J. Oster, or shipped to Olin Brass’s downstream operations for further value-added processing. Olin Brass’s downstream operations include:

• | a stamping operation located in East Alton; |

• | a rolling mill in Waterbury, Connecticut with rolling, annealing, leveling, plating and slitting capabilities for various products (“Somers Thin Strip”), including stainless steel thin strip; |

• | a manufacturing facility in Bryan, Ohio specializing in products sold in the automotive and electronics / electrical components markets; and |

• | a manufacturing facility in Cuba, Missouri that produces high frequency welded copper-alloy tube for heat transfer, utility, decorative, automotive and plumbing applications. |

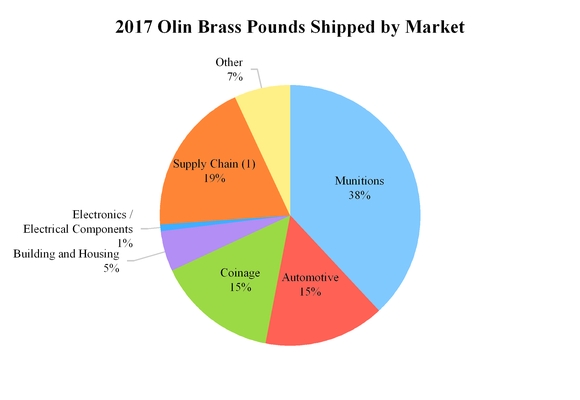

Olin Brass’s products are sold to original equipment manufacturers (“OEMs”), other external customers, distributors / rerollers or to its affiliate, A.J. Oster. In 2017, approximately 19% of Olin Brass’s products were shipped to distribution customers, which includes its affiliate A.J. Oster. In 2017, approximately 17% of Olin Brass’s domestic copper-based shipments were to A.J. Oster.

3

The following chart shows the primary markets for Olin Brass’s products and the percentage of shipments.

(1) | Shipments to A.J. Oster are reflected in the supply chain market and are eliminated in consolidation. |

Munitions Market

Olin Brass manufactures products utilized in both the military and commercial munitions markets, such as strip and cups, that are used to produce shot shells, bullet jackets, centerfire, rimfire and small caliber military munitions.

Customers in this market include major munitions producers in the U.S., including those producing small caliber ammunition for the U.S. military. Demand within this market is affected by the U.S. government’s security policies and troop size, as well as consumer demand for firearms and munitions. While munitions demand is predominantly domestic, occasional opportunities arise to supply U.S. alliance partners with these products.

Coinage Market

Olin Brass supplies strip for use in the production of coins (no pennies) primarily for the United States Mint, for which we are a key supplier contracted into 2022. We have been a highly regarded supplier to the United States Mint for over 40 years as our long-term contracts have historically been renewed at termination.

The demand within this market is affected by the level of activities in retail transactions, the use of vending machines, and the trends affecting forms of payment.

Automotive Market

Olin Brass manufactures both strip and fabricated products used as electronic and electrical connectors for use in automobiles. These products are made with HPAs, suitable for applications requiring high reliability, high temperature and low insertion force. For example, these electrical connectors, along with lead frames manufactured by us, are used in junction boxes, wiring harnesses, ignition and battery systems, lighting and media systems within vehicles.

Customers in this market include primary automotive connector suppliers in the U.S. Historically the business in this market remained largely regional in the U.S. Demand within this market is affected by the level of consumer spending on automobiles, which is significantly dependent on overall economic conditions and the amount of electrical components contained within automobiles.

4

Building and Housing Market

Olin Brass manufactures a variety of strip, welded tube and stamped parts used in commercial and residential buildings, such as faucets, locksets, decorative door hardware and hinges, which require workability, corrosion resistance and attractive appearance. Olin Brass also manufactures strip for products requiring high electrical conductivity, such as plug outlets, switches, lamp shells, other wiring devices, industrial controls, circuit breakers and switchgears. These products are generally manufactured with copper and copper-alloy sheet and strip, both HPAs and standard alloys, as well as copper-alloy welded tube.

Customers in this market are OEMs producing building and housing products. Olin Brass also supplies building and housing products in China through Olin Luotong Metals.

Electronics / Electrical Components Market

Olin Brass manufactures strip used in integrated circuit sockets for circuit boards, electrical connectors for laptop computers and similar devices, consumer electronics and appliances, and foils for flexible circuit applications. The strip manufactured in this market is high in HPA content and is sold directly to end-use customers and distributors.

Customers in this market are primarily electronics manufacturers that operate globally. A portion of these customers is serviced through A.J. Oster, and the remainder is supplied directly by Olin Brass, with its Somers Thin Strip facility providing the foil products on a global scale.

Demand within this market is affected by consumer spending on electronics, which may fluctuate significantly as a result of economic conditions.

International

The Olin Brass segment exported 19.1 million pounds into markets that primarily serve the building and housing, automotive and electronics / electrical components markets.

Asia

Included within our Olin Brass business, our Asian operations provide service, distribution and sales activities to meet the growing demand for copper alloys in that region. These activities are conducted through two of our subsidiaries, Olin Luotong Metals (“OLM”) in China and GBC Metals Asia Pacific PTE (“GMAP”) in Singapore. These operations source materials from Olin Brass, as well as other copper and brass mills, such as Chinalco and DOWA Metaltech Co. LTD (“Dowa Metaltech”). In 2017, these Asian operations generated $44.0 million of net sales, or 6% of the Olin Brass segment’s net sales. On a pounds basis, our Asian operations sold 9.9 million pounds (4% of the Olin Brass segment’s sales) of product into Asia through OLM and GMAP, primarily into key electronics markets.

Others

The remainder of Olin Brass’s international sales are primarily to Mexico, Canada and European countries and were 9.2 million pounds (4% of the Olin Brass segment’s sales) in 2017.

Chase Brass

Chase Brass primarily manufactures solid brass rod, in round, hexagonal and other shapes, ranging from 1/4 inch to 4 1/2 inches in diameter. Brass rod is generally manufactured from copper or copper-alloy scrap and all of Chase Brass’s rod is manufactured at its Montpelier, Ohio facility. Chase Brass customers machine, bore out, or otherwise process the rod for various applications used in a variety of markets. Brass rod is primarily used for forged and machined products, such as valves and fittings. Key attributes of brass rod include its machinability, corrosion resistance and moderate strength.

Chase Brass has been able to capitalize on opportunities arising from regulation limiting lead content in potable water plumbing fixtures. Our green product portfolio, including Eco Brass®, has grown significantly over the past few years as customers switch from leaded to non or low-leaded products in certain applications.

5

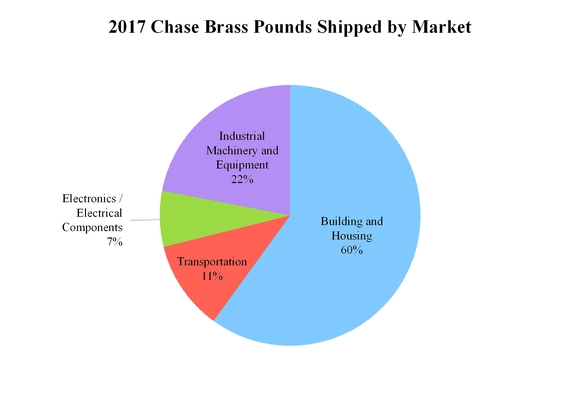

The following chart shows the primary markets for Chase Brass’s products and our estimates of the percentage of shipments for each. We believe that substantially all of the electronics / electrical components shipments below are associated with the building and housing and transportation markets.

Building and Housing Market

Chase Brass manufactures brass rod for use in faucets, valves and fittings used in residential and commercial construction.

Chase Brass produces a number of low-lead and lead-free products, or “green portfolio” products, which comply with certain state and federal laws that became effective in January 2014. This legislation defines the allowed level of lead content in products used in plumbing and drinking water applications. Chase Brass’s Green Dot® rod, Eco Brass® rod and Eco Brass® ingot products are part of the green portfolio, and Chase Brass is the exclusive licensee of the intellectual property rights for their production, sale and distribution in North America. Chase Brass also manufactures other non-patented green portfolio products. Green portfolio products accounted for approximately 20% of pounds shipped by Chase Brass in 2017.

Industrial Machinery and Equipment Market

Chase Brass manufactures brass rod which is further machined into industrial valves and fittings. Demand within this market is affected by capital spending levels, U.S. gross domestic product (“GDP”) growth and industrial production growth in the U.S.

Customers in this market include various major diversified manufacturers and a variety of screw machine companies supporting OEMs.

Transportation Market

Chase Brass manufactures brass rod for applications in heavy trucks and automobiles. Specific applications include heavy truck braking systems, tire valves, temperature sensors and various truck and automotive fittings. Demand within this market is affected by levels of transportation activity, levels of maintenance capital spending by transportation companies and the level of commercial truck fleet replacement activity, all of which are affected significantly by overall economic conditions. Customers in this market include major OEMs in the transport industry and customers who support domestic automotive production.

6

Electronics / Electrical Components Market

Chase Brass manufactures brass rod used for telecommunication applications, including products such as coaxial connectors and traps and filters for cable television, as well as larger connectors supporting the cell tower industry. Demand within this market is affected by consumer spending, new home construction, and technologies affecting communication devices and methods, such as wi-fi. Customers within this market include major manufacturers of specialty products for use in home and commercial construction, both of which are very dependent on overall economic conditions. We believe a significant portion of shipments in this market segment are directly associated with the building and housing market and transportation markets.

International

Chase Brass primarily supplies products within North America, and generated $46.8 million in net sales (8% of the Chase Brass segment’s net sales) to Canada and Mexico in 2017. Sales to Canada and Mexico were 23.9 million pounds (11% of the Chase Brass segment’s sales) in 2017.

A.J. Oster

A.J. Oster has historically been a processor and distributor of primarily copper and copper-alloy sheet, strip, and foil. However, with the acquisition of the Alumet business on November 1, 2017, A.J. Oster significantly expanded its product portfolio into aluminum sheet and coated aluminum products. The acquisition also deepened its presence in the signage (aluminum) and roofing (copper and copper-alloy) markets within the building and housing industry. A.J. Oster historically operated six strategically located service centers in the U.S., Puerto Rico, and Mexico and, with the Alumet acquisition, added five more service centers, including those in the South and Southeast where A.J. Oster had no presence.

Key A.J. Oster competitive advantages are: short lead-times with high reliability, high level of service, small-quantity deliveries, high quality metal, and a broad alloy breadth offering, including HPAs from Olin Brass. These capabilities, combined with A.J. Oster’s operations of precision slitting, hot tinning, traverse winding, cutting, coating, and special packaging, provide value to a broad customer base.

In 2017, Olin Brass provided A.J. Oster with 54% of its copper-based products. Aurubis AG (“Aurubis”) is A.J. Oster’s second largest supplier after Olin Brass, supplying approximately 26% of A.J. Oster’s copper-based products in 2017. Many of the coils purchased from Olin Brass and Aurubis are full-width and require slitting.

7

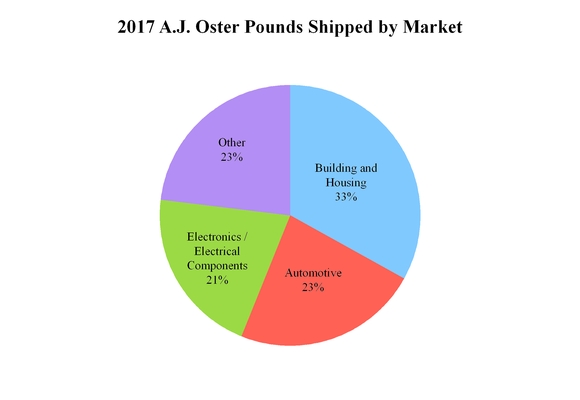

The following chart shows the primary markets for A.J. Oster’s products and the percentage of shipments for each.

Building and Housing Market

A.J. Oster distributes copper-alloy strip and aluminum foil used for products in commercial and residential applications. The primary applications are electrical, hardware, signage, and roofing.

Electrical products are primarily for wiring devices. Other electrical applications include switchgears, switches, controls and circuit breakers. Several of our customers for these products are in Puerto Rico or Mexico. A.J. Oster’s capabilities are well-suited for these geographic locations and the stringent service requirements of the electrical market because A.J. Oster is able to provide customers with high-quality metals, in less-than-truckload quantities, and can deliver products shortly after receiving orders.

Hardware products include products such as faucets, window trim, locksets, hinges and kick plates.

A.J. Oster provides aluminum coated products into the signage industry for a wide variety of government and commercial purposes.

With the Alumet acquisition, A.J. Oster now provides copper and copper-alloy sheet and strip product into the architectural roofing industry for both commercial and residential buildings.

Automotive Market

A.J. Oster distributes copper-alloy strip and aluminum foil used in automobiles. Primary customer products are electrical connectors, automotive trim and heat exchangers.

A.J. Oster’s subsidiary in Queretaro, Mexico is strategically and geographically well-positioned to take advantage of the growing number of second-tier automobile component suppliers in Mexico.

Demand within this market is affected by the level of consumer spending on automobiles, which is significantly dependent on overall economic conditions.

8

Electronics / Electrical Components Market

A.J. Oster distributes copper-alloy strip used for electrical connectors in computers, consumer electronics and automobiles.

The demand within this market is affected by consumer spending and trends in electronics, which may fluctuate significantly as a result of economic conditions.

International

A.J. Oster operates a service center in central Mexico. The facility is located in Queretaro in the center of Mexico’s industrial triangle marked by Mexico City, Monterey and Guadalajara and is easily accessible by highway connections to the U.S.

Automotive sub-suppliers that consume copper-alloy strip are now locating facilities in central Mexico in order to support primary automotive manufacturing.

Net sales from A.J. Oster Mexico were $44.8 million during 2017 (14% of A.J. Oster segment’s net sales). Pounds shipped from A.J. Oster Mexico were 9.8 million and comprised 12% of the A.J. Oster segment’s sales.

Raw Materials and Supply

We manufacture our products from scrap metal (both internally generated and externally sourced) or virgin raw materials. During 2017, 92% of our metal came from scrap metal, and the remainder came from virgin raw materials.

We purchase virgin raw materials, including copper cathode, at a premium on the London Metal Exchange (“LME”) or Commodities Exchange (“COMEX”) or directly from key dealers that support producers around the world. Although virgin raw materials are more expensive compared to scrap, we use them to ensure quality production of certain alloys, especially HPAs.

Customers

Our customer base is broadly diversified across North America geographies and our end markets, as previously discussed. In 2017, we sold approximately 14,000 different stock keeping units (“SKUs”) to nearly 4,500 customers.

Also in 2017, net sales from our foreign entities were $88.8 million, or 6% of our net sales. We have long-term relationships with our customers, many of which are secured through short-term contracts. Our relationships with many of our significant customers have lasted more than 30 years.

All three of our operating segments had customers to whom sales activity constituted more than 10% of net sales during 2017. Olin Brass generated 23% of its total net sales from one customer and 14% of its total net sales from another customer. A.J. Oster generated 18% of its total net sales from one customer. Chase Brass generated 21% of its total net sales from one customer. On a consolidated basis, we did not generate more than 10% of our net sales from any one customer in 2017.

Competition

We compete with other companies on price, service, quality, breadth, and availability of product. We believe we have been able to compete effectively because of our high levels of service, breadth of product offering, knowledgeable and trained sales force, modern equipment, proximity to customers, and economies of scale.

The North American market for brass and copper strip and sheet and brass rod consists of a few large participants and a few smaller competitors for Olin Brass and Chase Brass. A.J. Oster’s competition consists of a number of smaller competitors. Our international competitors are based principally in Europe (for Olin Brass and A.J. Oster) and Asia (for Chase Brass).

9

Our largest competitors in each of the markets in which we operate are the following:

• | Aurubis and PMX Industries, Inc.: manufacturers of copper and copper-alloys in the form of strip, sheet and plate (Olin Brass competitor); |

• | ThyssenKrupp Materials NA, Copper and Brass Sales Division: processor and distributor of copper, brass, stainless and aluminum products; Wieland Metals, Inc.: re-roll mill and service center for copper and copper-alloy strip (A.J. Oster competitor); and |

• | Mueller Industries, Inc.: manufacturer of brass rod (Chase Brass competitor). |

We use data published by independent industry associations and management estimates to determine our market share. Using this information, in 2017, we estimate our market share as follows:

• | Olin Brass accounted for 30% of North American shipments (including shipments to A.J. Oster) of copper and brass alloys in the form of sheet, strip and plate; |

• | A.J. Oster accounted for 36% of North American shipments of copper and brass, sheet and strip products from distribution centers and rerolling facilities; and |

• | Chase Brass accounted for 53% of North American shipments of brass rod, not including imports. |

Corporate

Our Corporate expenditures include compensation for corporate executives and officers, corporate office and administrative salaries, and professional fees for accounting, tax and legal services. Corporate also includes interest expense, state and federal income taxes, overhead costs that management has not allocated to the operating segments, share-based compensation expense, gains and losses associated with certain acquisitions and dispositions and the elimination of intercompany sales and balances.

Government Regulation and Environmental Matters

Bactericidal Products

Through its membership in and the stewardship program of the Copper Development Association Inc. (“CDA”), Olin Brass has completed the required Federal Environmental Protection Agency (“EPA”) and applicable state registration processes that allow it to market its CuVerro® products with certain approved bactericidal claims. Laboratory testing has shown that bactericidal copper touch surfaces made with CuVerro® kill more than 99.9% of bacteria within two hours. We believe that Olin Brass’s copper-based CuVerro® materials are in compliance, in all material respects, with EPA standards for products recognized by the EPA as having bactericidal properties.

Even though the marketing of copper products as bactericidal started in 2008, the manufacturers of such products are still in the process of determining what specific bactericidal claims may be made in compliance with the EPA’s and Federal Insecticide, Fungicide and Rodenticide Act’s (“FIFRA”) requirements. Therefore, there remains some uncertainty when determining whether a particular marketing approach is consistent with the EPA registration requirements. The stewardship program required under the EPA registration is an industry-wide activity, and the actions of other CDA members could jeopardize the marketing of all bactericidal copper products registered through the CDA (including CuVerro®).

Environmental

Our operations are subject to a number of federal, state and local laws and regulations relating to the protection of the environment and to workplace health and safety. In particular, our operations are subject to extensive federal, state and local laws and regulations governing the creation, transportation, use, release and disposal of wastes, air and water emissions, the storage and handling of hazardous substances, environmental protection, remediation, workplace exposure and other matters. Hazardous materials used in and activities undertaken by our operations include general commercial lubricants, cleaning solvents, cutting oils, air emissions from paints and coatings, storage of hazardous materials, and utilization of septic systems.

We believe that we are in substantial compliance with all applicable environmental, workplace health, and safety laws and do not currently anticipate that we will be required to expend any substantial amounts in the foreseeable future in order to meet such requirements. We have a number of properties located in or near heavy industrial or light industrial use areas; accordingly, these properties may have been contaminated by pollutants which may have migrated from neighboring facilities or have been released by prior occupants for which we may become liable under various laws and regulations. Some of our properties have been affected by releases of cutting oils and similar materials and we are investigating and

10

remediating such known contamination pursuant to applicable environmental laws. The costs of these clean-ups have not been material in the past.

In January 2018, one of our Olin Brass operations experienced a leak of mineral oil at its Waterbury, Connecticut facility. Our personnel, the Waterbury fire department, the US EPA, the Connecticut DEEP, and remediation contractors responded immediately. While remediation efforts continue, we do not believe, at this time, this incident will materially affect our long-term financial stability or cash flows.

Pursuant to the agreement, dated November 19, 2007, by which we purchased our current operating locations from Olin Corporation, Olin Corporation agreed to retain responsibility for a wide range of liabilities under environmental laws arising out of existing contamination on our properties, and agreed to indemnify us without limitation with respect to these liabilities. Specifically, Olin Corporation retained responsibility for:

• | compliance with all obligations to perform investigations and remedial action required under the Connecticut Real Property Transfer Act at properties in Connecticut; |

• | pending corrective action / compliance obligations under the Federal Resource Conservation and Recovery Act for certain areas of concern at our East Alton, Illinois facility; and |

• | all obligations under environmental laws arising out of 24 additional specifically identified areas of concern on various of our properties. |

Olin Corporation also retained complete responsibility for all liabilities arising out of then pending governmental inquiries relating to environmental matters; for “any liability or obligation in connection with a facility of the Business to the extent related to pre-Closing human exposure to Hazardous Materials, including asbestos-containing materials”; and for “any liability or obligation in connection with the off-site transportation or disposal of Hazardous Materials arising out of any pre-Closing operations of the Business.”

Since 2007, Olin Corporation has continued to perform environmental remedial actions on our properties, including the East Alton, Illinois and Waterbury, Connecticut properties, and continues to work closely with us to address matters covered by the indemnity. Because of the Olin Corporation indemnity, we have not been required to engage in any significant environmental cleanup activity on our properties and do not currently have any material reserves established to address environmental remedial requirements.

Employees

The following table shows the composition of our workforce by operating segment and Corporate as of December 31, 2017.

Employees | % of Total | |||||

Olin Brass | 1,163 | 60 | % | |||

A.J. Oster | 422 | 22 | % | |||

Chase Brass | 319 | 17 | % | |||

Corporate | 22 | 1 | % | |||

Total | 1,926 | 100 | % | |||

As of December 31, 2017, 1,074, or approximately 56%, of our employees at various sites were members of unions. We have generally maintained good relationships with all unions and employees, which has been an important aspect of our ability to be competitive in our industry. Generally, our various agreements with unions in the United States have contractual terms which range from 1 to 5 years.

Historically, we have succeeded in negotiating new collective bargaining agreements without a strike and we have not experienced any work stoppages at any of our facilities. Our union agreement governing a substantial portion of our employees at Olin Brass was renewed in 2017 and will not expire until 2022. We believe we will continue to be able to renew the outstanding collective bargaining agreements upon acceptable terms.

11

Research and Development

Our staff of scientists in metallurgy and electrochemistry intends to continue to invest in research and development to develop new products and expand our value-added services to meet our customers’ needs.

Our research and development expenditures were not material in any of the last three years.

Risk Management and Insurance

The primary risks in our operations are personal injury, property damage, transportation, criminal acts, risks associated with international operations, directors’ and officers’ liability and general commercial liabilities. We are insured against general commercial liabilities (including business interruption), workers’ compensation liabilities, automobile accidents (including injury to employees and physical damage of goods and property and employer liabilities), directors’ and officers’ liability, crime, foreign risks, environmental liability, ocean cargo liability and flood through insurance policies provided by various insurance companies up to amounts we consider sufficient to protect against losses due to claims associated with these risks.

Safety

Consistent with other strategic initiatives, we strive to achieve a ‘Best in Class’ performance status for employee safety. A number of our locations participate in the Occupational Safety and Health Administration (“OSHA”) sponsored Voluntary Protection Program, or VPP. The Safety Excellence / VPP initiative shifts the safety paradigm to an aggressive proactive approach that stresses strong employee participation and collaboration, management accountability, employee training and hazard elimination as core foundational elements. In 2016, our A.J. Oster facility in Yorba Linda, California was recognized as a VPP Star site. This recognition reflects the facility’s achievement in the development, implementation and continuous improvement of their safety and health management system resulting in injury and illness rates that are below the national averages for the industry.

Patents, Trademarks and Other Intellectual Property Rights

Chase Brass has exclusive intellectual property licenses, the longest of which extends to 2027, to produce and sell Eco Brass® rod and ingot in North America, granted by Mitsubishi Shindoh Company, Ltd., the Japanese company that owns the relevant intellectual property rights. The most popular versions of Eco Brass® are protected through May 2019. We have sublicensed our rights to three sublicensees, none of which is currently a competitor of any of our subsidiaries or segments. These sublicensing arrangements are valid until the expiration of the relevant patents in North America.

We license certain intellectual property from companies in Germany, Japan and China.

We own a number of other U.S. and foreign patents, trademarks and licenses relating to certain of our products and processes. We actively protect our proprietary rights by the use of trademark, copyright, and patent registrations. Additionally, we license the marks OLIN BRASS and OLIN METALS for metal products from Olin Corporation. These licenses continue unless we breach the license agreement. We also license stylized versions of these marks from Olin Corporation and the license to the stylized version includes an annual termination option by either party.

We license the intellectual property rights related to certain proprietary alloy systems to other major brass mills around the world, including Dowa Metaltech.

Government Contract

The United States Mint is and has been a significant customer of Olin Brass since 1969. We have a contractual arrangement to supply nickel and brass coinage strip to multiple United States Mint facilities. We renewed this contract in 2017 and expect to renew again when it expires in 2022. However, the United States Mint can terminate our contract in whole or in part when it is in the best interest of the United States Mint to do so and any damages payable to us by the United States Mint for such termination would not include lost profits.

12

Seasonality

There is a slight decrease in our net sales in the fourth quarter as a result of the decrease in demand due to customer shutdowns for the holidays and year-end maintenance of plants and inventory by customers. We also typically experience slight working capital increases in the first fiscal quarter as our customers build inventory to serve the seasonal building and housing market.

Available Information

Our website address is http://www.gbcholdings.com. We make available on our website, free of charge, the periodic reports that we file with or furnish to the Securities and Exchange Commission (“SEC”), as well as all amendments to these reports, as soon as reasonably practicable after such reports are filed with or furnished to the SEC. We also make available on our website or in printed form upon request, free of charge, our Corporate Governance Guidelines, Code of Business Conduct and Ethics, charters for the standing committees of our Board of Directors and other information related to the Company. We are not including the information contained on our website as a part of, or incorporating it by reference into, this report.

The public may read and copy any materials that we file with the SEC at the SEC’s Public Reference Room at 100 F Street, N.E., Washington D.C. 20549. The public may obtain information about the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. The SEC maintains an internet site (http://www.sec.gov) that contains reports, proxy and information statements and other information related to issuers that file electronically with the SEC.

13

Item 1A. Risk Factors.

We are exposed to various risks as we operate our businesses. To provide a framework to understand our operating environment, we are providing a brief explanation of the more significant risks associated with our businesses. Although we have tried to identify and discuss key risk factors, others could emerge in the future.

Risks Related to Our Business

We are exposed to the cyclicality of the U.S. and certain foreign economies as well as fluctuations in certain industries. Our future growth also depends, to a significant extent, on improvements in the general economic conditions and the conditions of our markets.

Many of our products are used in industries that are, to varying degrees, cyclical and have historically experienced periodic downturns due to factors such as economic conditions, energy prices, the availability of credit, consumer sentiment, demand and other factors beyond our control. These economic and industry downturns have resulted in diminished product demand and excess capacity for our products. Any future economic disruptions may negatively impact our markets or the consumers served by those markets, which would adversely affect our operating results.

A significant amount of our volume is tied to the building and housing sector. If the housing, remodeling and residential and commercial construction markets stagnate or deteriorate, demand from such markets for our products, especially our brass rod products, is likely to be adversely affected. Any recovery in such markets may not necessarily directly correlate with increased sales or profitability. In addition, competition from imports and other sources may also dampen the effects of any such recovery on our results of operations.

Similarly, the automotive market has in the past experienced significant downturns in connection with, or in anticipation of, declines in general economic conditions, the availability and cost of credit, the cost of fuel, and technological developments in the auto industry.

The coinage and general consumer markets are also affected by economic cycles, legislation, and trends in electronic commerce. Demand for coinage-related products generally increases with the number of cash transactions that occur, and the number of cash transactions generally increases during periods of economic growth. Demand for consumer goods is also very sensitive to economic conditions and drives demand in our electronics / electrical components market.

The munitions market is generally not correlated to any general economic indicators and thus, has a high degree of volatility.

We also buy a significant portion of our raw materials from scrap dealers at prices which are often quoted as a discount to prevailing publicly traded market prices for such commodities. These discounts, or scrap spreads, can fluctuate based on many different conditions, including domestic and international forces beyond our control. Since we include these scrap spreads in the non-metal conversion fee or Adjusted Sales component of our revenue, our financial results are therefore also subject to fluctuation due to these same conditions.

Failure to maintain our balanced book approach would cause increased volatility in our profitability and our operating results and may result in significant losses.

We use our balanced book approach to substantially eliminate the impact on our operating margins of metal price fluctuations affecting the cost of the metal raw materials used in manufacturing our products. Such fluctuations can significantly affect our operating margins. Under our balanced book approach, we seek to match the timing, quantity and price of the metal component of net sales with the timing, quantity and price of replacement metal purchases on all of our non-toll sales. We use a combination of matching price date of shipment terms, firm price terms and derivatives transactions to achieve our balanced book. See “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Key Business Principles Affecting Our Results of Operations—Balanced Book.”

We may not be able to maintain our balanced book approach if our customers become unwilling to bear metal price risk through the matching of price date of shipment terms. We may also not be able to find counterparties for the derivatives transactions entered into in connection with firm price terms, and the cost of those derivatives transactions may increase such that entering into such transactions is no longer cost-effective to us. If we fail to maintain our balanced book approach, we may be forced to accept higher replacement prices, which could generate losses and would increase volatility in our results of operations.

14

However, our balanced book approach does not reduce the impact of the volatility in metal prices on our working capital requirements. Metal prices impact our investment in working capital because our collection terms with our customers are longer than our payment terms to our suppliers. As a result, when metal prices are rising, even if the number of pounds of metal we process does not change, working capital may be negatively affected as we are required to draw more on our cash or available financing sources to pay for raw materials. As a result, our liquidity may be negatively affected by increasing metal prices. See “Management’s Discussion and Analysis of Operating Results and Financial Condition—Key Business Principles Affecting Our Results of Operations—Metal Cost.”

Limited access to raw materials, infrastructure or energy could negatively affect our business, financial condition or results of operations or cash flows.

Among other things, our success depends on our ability to secure a sufficient and constant supply of raw materials and energy and access to infrastructure adequate to fulfill our business needs.

We depend on scrap for our operations and acquire our scrap inventory from numerous sources. These suppliers generally are not bound by long-term contracts and have no obligation to sell scrap metals to us. If an adequate supply of scrap metal is not available to us, we may be forced to use a larger amount of more expensive virgin raw materials which would materially adversely affect our ability to meet customer needs in a timely manner, our results of operations, and our financial condition.

We may experience disruptions in the supply of energy as a result of delivery curtailments to industrial customers due to extremely cold weather. We may also experience disruptions or increases in cost with respect to our access to water, electrical power, transport and wastewater treatment services and other infrastructure (including those subject to our transition services agreement with the parent of our predecessor). An inability to find an adequate and timely supply of raw materials or adequate and cost-effective access to infrastructure could have a material adverse effect on our profit margin, and in turn on our business, financial condition, results of operations or cash flows.

In 2017, the cost of energy and utilities represented approximately 7% of our non-metal cost of sales and prices can be volatile. As a result, our energy and utility costs may fluctuate dramatically, and we may not be able to mitigate the effect of higher energy and utility costs on our business, financial condition, results of operations, and cash flows. Although we attempt to mitigate short-term volatility in energy and utility costs through the use of derivatives contracts, we may not be able to eliminate the long-term effects of such cost volatility. Furthermore, in an effort to offset the effect of increasing costs, we may have also limited our potential benefit from declining costs.

Covenants under our debt agreements impose operating and financial restrictions. Failure to comply with these covenants could have a material adverse effect on our business, financial condition, results of operations or cash flows.

The agreement governing our asset-based revolving loan facility (“ABL Facility”) and the agreement covering our term loan facility that matures on July 18, 2023 (“Term Loan B Facility”) contain various covenants that limit or prohibit our ability, among other things, to:

• | incur or guarantee additional indebtedness; |

• | pay dividends on our capital stock or redeem, repurchase, retire or make distributions in respect of our capital stock or subordinated indebtedness or make certain other restricted payments; |

• | make certain loans, acquisitions, capital expenditures or investments; |

• | sell certain assets, including stock of our subsidiaries; |

• | enter into certain sale and leaseback transactions; |

• | create or incur certain liens; |

• | consolidate, merge, sell, transfer or otherwise dispose of all or substantially all of our assets; |

• | enter into certain transactions with our affiliates; and |

• | engage in certain business activities. |

The agreement governing the ABL Facility also contains a financial covenant that requires us to maintain a fixed charge coverage ratio that is tested whenever excess availability, as defined in such agreement, falls below a certain level. For more information regarding these covenants, please see “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Liquidity and Capital Resources—Outstanding Indebtedness.”

The agreement governing the Term Loan B Facility also contains a financial covenant that requires us to maintain a total debt leverage ratio that is tested quarterly.

15

A violation of covenants may result in default or an event of default under our debt agreements.

Upon the occurrence of an event of default under the agreement governing the ABL Facility or the Term Loan B Facility, our outstanding indebtedness may become immediately due and payable and we may lose access to further credit under our ABL Facility. If we are unable to repay our indebtedness, the lenders under such facilities may proceed against the collateral granted to them to secure such indebtedness. Substantially all of our assets are pledged as collateral under the ABL Facility and the Term Loan B Facility. If the lenders under either facility, as applicable, accelerate the repayment of borrowings, such acceleration would have a material adverse effect on our business, financial condition, results of operations or cash flows. Furthermore, cross-default provisions in the ABL Facility and the Term Loan B Facility provide that any default under the other facility or other significant debt agreements could trigger a cross-default under the ABL Facility or the Term Loan B Facility, as applicable. If we are unable to repay the amounts outstanding under these agreements or obtain replacement financing on acceptable terms, which ability will depend in part upon the impact of economic conditions on the liquidity of credit markets, our creditors may exercise their rights and remedies against us and the assets that serve as collateral for the debt, including initiating a bankruptcy proceeding.

For a more detailed description on the limitations on our ability to incur additional indebtedness and our compliance with financial covenants, please see “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Liquidity and Capital Resources—Outstanding Indebtedness.”

Our sales volumes, financial results, and financial condition could be reduced if we were to lose order volumes from any of our largest customers.

Our five largest customers were responsible for approximately 31% of our net sales in 2017. A loss of order volumes from any major customer could negatively affect our business, financial condition or results of operations by lowering sales volumes, increasing costs and lowering profitability. Order volumes from customers could decrease for a variety of reasons including loss of industry share, customer production outages, technological obsolescence of our products, or other competitive factors. Our balance sheet reflected an allowance for doubtful accounts totaling $1.0 million at December 31, 2017. If adverse economic and market conditions impair the ability of our customers to pay us in the future, our allowance for doubtful accounts and write-offs of accounts receivable from the Company’s customers may increase in the future, which could materially and adversely affect our financial condition and results of operations.

In addition, we will not be entitled to lost profits should the United States Mint voluntarily terminate our contract prior to the contractual end date in 2022.

Our business could be disrupted if our customers shift either their manufacturing or sourcing offshore.

Much of our business depends on maintaining close geographical proximity to our customers because the costs of transporting metals across large distances can be prohibitive. If customers, especially those in the automotive, electrical, and building and housing industries, relocate the production of or source their products from foreign locations, we may lose business to foreign competitors or suffer deterioration in our business.

Competition and changes in trade tariffs could adversely affect our business, financial condition and results of operations.

We are engaged in a highly competitive industry. Each of our segments competes with a limited number of companies. The Olin Brass segment competes with domestic and foreign manufacturers of copper and brass alloys in the form of strip, sheet and foil. The Chase Brass segment competes with domestic as well as foreign manufacturers of brass rod and beginning in 2013, encountered increased competition from foreign rod suppliers. The A.J. Oster segment primarily competes with distributors, mills and processors of copper and brass products. Furthermore, we believe that domestic sales to customers that are not made by major companies, including us, are fragmented among many smaller companies. In the future, these smaller companies may choose to combine, creating a more significant domestic competitor against our business. We may be required to explore additional initiatives in each of our segments in order to maintain our sales volume at a competitive level. Increased competition in any of the fields in which our segments operate could adversely affect our business, financial condition and results of operations.

In December 2017, the U.S. Department of Commerce announced anti-dumping and countervailing duties on aluminum foil products from China. China previously served 22% of the U.S. aluminum foil market but was effectively priced out as a supplier to U.S. companies due to these duties. This resulted in significantly higher domestic prices as well as decreased supply with U.S. producers. Our inability to pass through these price increases and the reduced supply from U.S. producers

16

could adversely affect the performance of our business or shipments to customers. In addition, there are further trade cases pending that could result in additional price increases and constrained availability.

In addition, anti-dumping orders impose import duties on copper and brass products from France, Germany, Italy and Japan which allow us and our domestic competitors to compete more fairly against French, German, Italian and Japanese producers in the U.S. copper and brass product market. On March 21, 2012, the International Trade Commission (“ITC”) Commissioners voted to continue anti-dumping orders for brass sheet and strip from Germany, Italy, France and Japan. While domestic manufacturers lobby for the continued extension of these orders, if they expire, import duties on metal products from these countries will be significantly reduced, increasing the ability of such foreign producers to compete with our products domestically. Additionally, on March 15, 2012, the United States-Korea Free Trade Agreement (“KORUS FTA”) became effective, which largely eliminates tariffs on Korean industrial products imported to the United States. The reduction in prices of Korean products resulting from the KORUS FTA has increased the ability of Korean manufacturers to compete with our products and has had a negative effect on our business. Furthermore, the termination of any anti-dumping orders or other changes to international trade regimes could adversely affect our business, financial condition and results of operations.

Adverse developments in our relationship with our employees could have a material adverse effect on our business, financial condition, results of operations and cash flows.

As of December 31, 2017, we had 1,926 employees, 1,074, or approximately 56%, of whom at various sites were members of unions. Our primary union contracts expire in 2020 and 2022. Our union agreements are a meaningful determinant of our labor costs and are very important to our ability to maintain flexibility to fulfill our customers’ needs. As we attempt to renew our collective bargaining agreements, labor negotiations may not conclude successfully and, in that case, may result in a significant increase in the cost of labor or may result in work stoppages or labor disturbances, disrupting our operations. Any such cost increases, stoppages or disturbances could have a material adverse effect on our business, financial condition, results of operations and cash flows by limiting plant production, sales volumes and profitability.

Our participation in multi-employer union pension plans may have a material adverse effect on our financial performance.

We are required to make contributions to the IAM National Pension Plan (“IAM Plan”), a multi-employer pension plan that covers certain of our union employees. Our obligations may be impacted by the funded status of the plan, the plan’s investment performance, changes in the participant demographics, financial stability of contributing employers and changes in actuarial assumptions. In addition, if a participating employer becomes insolvent and ceases to contribute to a multiemployer plan, the unfunded obligation of the plan will be borne by the remaining participating employers. Under current law, an employer that withdraws or partially withdraws from a multi-employer pension plan may incur withdrawal liability to the plan. If, in the future, we choose to withdraw from the multi-employer pension plan in which we participate, we will likely need to record withdrawal liabilities, which could negatively impact our financial performance in the applicable periods.

Our operations are subject to risks of natural disasters, acts of war, terrorism or widespread illness at our domestic and international locations, any one of which could result in a business stoppage and negatively affect our business, financial condition or results of operations.

Our business operations depend on our ability to maintain and protect our facilities, computer systems and personnel. Our facilities and transportation for our employees are susceptible to damage from earthquakes and other natural disasters such as fires, floods, hurricanes, tornadoes and similar events. We have facilities located throughout North America, including in Illinois, Ohio, Connecticut, Rhode Island, Missouri, California, Puerto Rico and Mexico, as well as in China. We take precautions to safeguard our facilities, including obtaining insurance and maintaining health and safety protocols. However, a natural disaster, such as a tornado, fire, flood, hurricane or earthquake, could cause a substantial interruption in our operations, damage or destroy our facilities or inventory and cause us to incur additional expenses. The insurance we maintain against natural disasters may not be adequate to cover our losses in any particular case, which would require us to expend significant resources to replace any destroyed assets, thereby harming our financial condition and prospects significantly.

For example, Olin Brass’s manufacturing facilities and A.J. Oster’s California facility are located near geologic fault zones, and therefore are subject to greater risk of earthquakes which could result in increased costs and a disruption in our operations, which could harm our operating results and financial condition significantly. Our facility in East Alton, Illinois

17

is located in a flood zone, and all of our facilities in the Midwestern United States are subject to the risk of tornadoes and damaging winds. A.J. Oster’s facility in Puerto Rico is subject to hurricanes. Should earthquakes or other catastrophes, such as fires, tornadoes, hurricanes, floods, power outages, communication failures or similar events disable our facilities, we do not have readily available alternative facilities from which we could continue our operations, and any resulting stoppage could have a negative effect on our operating results. Acts of terrorism, widespread illness and war could also have a negative effect at our international and domestic facilities.

Any prolonged disruptions, failures, or inability to operate our business, manufacturing facilities, or equipment, including those arising from information technology related incidents, could have a material adverse effect on our business, financial condition, results of operations and cash flows.

Our ability to satisfy our customers’ orders in an efficient manner and to effectively manage inventory levels is dependent on the proper operation of our business, facilities, equipment, and information technology environment and tools. On-time delivery and accurate order fulfillment are essential to maintaining customer satisfaction and generating repeat business. Any prolonged equipment failures, supplier caused production delays, quality control incidents, network outages, information technology system failures or implementations, damage or disruption due to natural disasters, inclement weather conditions, acts of war, terrorism or widespread illness, temporary facility closures, or other disruptions in operations such as a major fire or major equipment breakdown at our manufacturing facilities could materially disrupt our operations and thereby adversely affect our business, financial condition, and results of operations. In addition, we may not have adequate insurance to cover all losses.

We do not have redundancy in our operations on certain critical pieces of equipment, including the Olin Brass hot and cold mills and Chase Brass extruders. If this equipment were damaged, we would have to make alternative arrangements to replicate these processes, which could be costly and result in manufacturing delays, which could materially adversely affect our business, financial condition and results of operations.

The increased use of substitute materials and miniaturization may adversely affect our business.

In many applications, copper and other commodities may be replaced by other materials such as aluminum, stainless steel, plastic and other materials and the use of copper and other commodities may be reduced by the miniaturization of components. Increased prices of copper could encourage our customers to use substitute materials and / or miniaturization to limit the amount of copper in their products and applications in an attempt to control their overall product costs. For example, historically, there has been discussion over reducing or eliminating copper content in coins in reaction to the rising prices of copper. Such increased use of substitute materials and / or miniaturization could have a material adverse effect on prices and demand for our products.

If we fail to develop or enhance our products to satisfy evolving customer demands, our business, operating results, financial condition and prospects may be harmed significantly.

The market for copper and copper-alloy products is characterized by changing technologies, periodic new product introductions and evolving customer and industry standards and demands. To achieve market acceptance for our products, we must effectively and timely anticipate and adapt to customer requirements, new technologies and production methods, and offer products and services that meet customer demands.

18

A portion of our net sales is derived from our international operations, which exposes us to certain risks inherent in doing business abroad.

In the aggregate, our international operations accounted for 6% of our net sales in 2017. We have operations in China through Olin Luotong Metals and in Singapore through our subsidiary GBC Metals Asia Pacific PTE. In addition, we have various licensing agreements around the world and our products are distributed globally. We plan to continue to explore opportunities to expand our international operations. Our international operations generally are subject to risks, including:

• | changes in U.S. and international governmental regulations, trade restrictions and laws, including tax laws and regulations; |

• | currency exchange rate fluctuations; |

• | tariffs and other trade barriers; |

• | the potential for nationalization of enterprises or government policies favoring local production; |

• | interest rate fluctuations; |

• | high rates of inflation; |

• | currency restrictions and limitations on repatriation of profits; |

• | differing protections for intellectual property and enforcement thereof; |

• | divergent environmental laws and regulations; |

• | political, economic and social instability; |

• | unfamiliarity with foreign laws and regulations and ability to enforce obligations of foreign counterparties; |

• | difficulties in staffing and managing international operations and labor unrest; |

• | language and cultural barriers; |

• | natural disasters and widespread illness; |

• | geopolitical conditions, such as terrorist attacks, war, or other military action; and |

• | a divergence between the price of copper on the copper exchange in China and the LME, and the COMEX. |

The occurrence of any of these events could cause our costs to rise, limit growth opportunities or have a negative effect on our operations and our ability to plan for future periods, and subject us to risks not generally prevalent in North America.

New governmental regulations or legislation, or changes in existing regulations or legislation, may subject us to significant costs, taxes and restrictions on our operations.

Our operations are subject to a wide variety of U.S. federal, state, local and non-U.S. laws and regulations, including those relating to taxation, international trade and competition and firearms.

For example, the Olin Brass segment provides strip and cups to both the military and commercial munitions markets. In 2017, the shipments by Olin Brass to the munitions market accounted for 38% of its total shipments. The private use of firearms is subject to extensive regulation. Any restriction on the use of firearms and ammunition could affect the demand for munitions, and in turn could negatively affect our business, financial condition or results of operations. Moreover, any changes in the government budget or policy over military spending may adversely affect our contracts with customers in the munitions market.

Changes in U.S. or foreign tax laws, including possibly with retroactive effect, and audits by tax authorities could result in unanticipated increases in our tax expense and affect profitability and cash flows. From time to time, legislative initiatives are proposed in the U.S., such as the repeal of the election to use LIFO or to lower the U.S. corporate tax rate. The repeal of LIFO accounting for tax purposes could result in a substantial cash tax liability, which could adversely impact our liquidity and financial condition. Furthermore, such a repeal could result in an increase in the volatility of our earnings, a greater disparity between our earnings and net sales in our financial statements, and an increase in the costs associated with our derivative transactions to mitigate metal price fluctuations.

Our operations expose our employees to risk of injury or death. We may be subject to claims that are not covered by, or exceed, our insurance. Additional safety measures or rules imposed by regulatory agencies may reduce productivity, require additional capital expenditure or reduce profitability.

Because of the type manufacturing activities conducted at our facilities, there exists a risk of injury or death to our employees or other visitors, notwithstanding the safety precautions we take. Despite policies and standards that are designed to minimize such risks, we may nevertheless be unable to avoid material liabilities, civil or regulatory, for any employee death or injury that may occur in the future. These types of incidents may not be covered by or may exceed our insurance coverage and may have a material adverse effect on our results of operations and financial condition.

19

Our ability to retain our senior management team is critical to the success of our business, and failure to do so could materially adversely affect our business, financial condition, results of operations and cash flows.

We are dependent on our senior management team to remain competitive in our industry. We have employment contracts or severance agreements with members of our senior management team. Failure to renew the employment contracts or other agreements of a significant portion of our senior management team could have a material adverse effect on our business, financial condition, results of operations and cash flows. Members of our senior management team are subject to employment conditions or arrangements that permit the employees to terminate their employment without notice. We do not maintain any life insurance policies for our benefit covering our key employees.

If our senior management team were not able to dedicate adequate time to our business, due to personal or other factors, if we lose or suffer an extended interruption in the services of a significant portion of our senior management team, or if a significant portion of our senior management team were to terminate employment within a short period it could have a material adverse effect on our business, financial condition, results of operations and cash flows. In addition, the market for qualified individuals may be highly competitive and we may not be able to attract and retain qualified personnel to replace or succeed members of our senior management team, should the need arise.

Environmental costs could decrease our net cash flow and adversely affect our profitability.

Our operations are subject to extensive regulations governing, amongst other things, the creation, use, transportation and disposal of wastes and hazardous substances, air and water emissions, remediation, workplace exposure and other environmental matters. The costs of complying with such laws and regulations, including participation in assessments and clean-ups of sites, as well as internal voluntary programs, can be significant and will continue to be so for the foreseeable future. Additionally, evolving regulatory standards and expectations could result in increased litigation and / or increased costs of compliance with environmental laws, all of which could have a material and adverse effect on our business, financial condition, results of operations and cash flows.

Environmental matters for which we may be liable may arise in the future at our present sites, at previously owned sites, sites previously operated by us, sites owned by our predecessors or sites that we may acquire in the future. Our operations or liquidity in a particular period could be affected by certain health, safety or environmental matters, including remediation costs and damages related to several sites. Because a number of our properties are located in or near industrial or light industrial use areas, we may be liable for any contamination by pollutants which may have migrated to our facility from neighboring facilities or have been released by prior occupants. Some of our properties have been affected by releases of cutting oils and similar materials, and we are investigating and remediating such known contamination pursuant to applicable environmental laws. The costs of these clean-ups have not been material in the past. We are not currently subject to any material claims or notices with respect to clean-up or remediation under CERCLA or similar laws for contamination at our leased or owned properties or at any off-site location. However, we cannot rule out the possibility that we could be notified of such claims in the future. It is also possible that we could be identified by the Environmental Protection Agency, a state agency or one or more third parties as a potentially responsible party under CERCLA or under analogous state laws.

In January 2018, one of our Olin Brass operations experienced a leak of mineral oil at its Waterbury, Connecticut facility. Our personnel, the Waterbury fire department, the US EPA, the Connecticut DEEP, and remediation contractors responded immediately. While remediation efforts continue, we do not believe, at this time, this incident will materially affect our long-term financial stability or cash flows.

On November 19, 2007, we acquired the assets and operations relating to the worldwide metals business of Olin Corporation. Olin Corporation agreed to retain liability arising out of then existing conditions on certain of our properties for any remedial actions required by environmental laws, and agreed to indemnify us for all or part of a number of other environmental liabilities. Since 2007, Olin Corporation has been performing remedial actions at the facilities in East Alton, Illinois and Waterbury, Connecticut, and has been participating in remedial actions at our other properties as well. If Olin Corporation were to stop its environmental remedial activities at our properties, we could be required to assume responsibility for these activities, the cost of which could be material. For additional information concerning the indemnity granted to us by Olin Corporation for environmental liabilities, see “Business—Government Regulation and Environmental Matters.”

20

We may be subject to litigation that could strain our resources and distract management.

From time to time, we are involved in a variety of claims, lawsuits and other disputes arising in the ordinary course of business. It is not feasible to predict the outcome of all pending suits and claims, and the ultimate resolution and the cost of and time spent in defending ourselves in these matters as well as future lawsuits could have a material adverse effect on our reputation, business, financial condition, results of operations, cash flows or reputation.

Failure to protect, or uncertainty regarding the validity, enforceability or scope of, our intellectual property rights or the expiration of our intellectual property rights could impair our competitive position.

We rely on a combination of patents, trademarks, trade secrets and other intellectual property rights, in addition to contractual rights, to protect the intellectual property we use in making our business successful. It is possible that our intellectual property rights could be challenged, invalidated, violated or made obsolete by our competitors or third parties, or our pending patent applications may not be granted, thereby hurting our success.