Attached files

EXHIBIT 9

|

|

|

|

|

|

| SOLAR QUARTZ TECHNOLOGIES CORP. Rare Solar & Semi-conductor Industry Investment Opportunity New Solar Grade HPQS Production Plant in USA & Australia US Public Company – “OTC: SQTX” (Oct. 2017 Update) |

|

|

|

|

1. The Company

Following the July 2017 completion of its US $530 million take-over by a USA publicly listed corporation, (formerly known as Vanguard Energy Corp), Solar Quartz Technologies Corp.(SQTX) is proceeding to establish its new commercial production level High Purity Quartz Sand (HPQS) factory. HPQS production worldwide never meets the demand from the solar PV crucible and semi-conductor industries. There are only three significant commercial HPQS manufacturers worldwide. The SQTX technology team have a long established and proven track record of their technological production capability of making Solar grade HPQS in compliance with global solar and semiconductor industry quality and purity standards. SQTX’s executive management team has 6-10 years’ experience in all facets of the production of specialised HPQ products critical for the high-end solar and electronics components industry. SQTX has the added advantage of owning its own high purity silica deposits, capable of providing 25 to 30 years supply of HPQ feed-stock for the HPQS products. SQTX is seeking to raise additional development funds of US$38 million, with an initial US$10 million, from an Industry Joint Venture partner, Equity investment or appropriate Debt instrument.

2. High Purity Quartz Sand (HPQS)– Essential Component in PV Solar & all High-end Electronics.

High purity quartz (“HPQ”) and HPQ sands (“HPQS”) are extensively used during the manufacturing of mono-crystalline silicon, through the Czochralski process, as crucibles in which silicon ingots are produced for use in solar cell and all electronics, and semi-conductors. HPQ is the only preferred material for this process and the essential crucibles, as it shares the same element (Si) and is almost non-reactive, assuring high quality silicon ingots. Apart from this, High Purity Quartz (HPQ) also finds primary applications in advanced lighting, telecom, optic and microelectronics industry. HPQS/powders are required for epoxy molding compound (EMC) used in manufacture of most electronic semiconductors, and is a fast growth sector, which includes auto electronics. –

Video Explanation CZOCHRALSKI process for silicon wafer production for Solar PV cell and Electronics Semiconductors from HPQS: https://www.youtube.com/watch?v=xftnhfa-Dmo

HPQS is a critical material necessary for the successful manufacture of Photovoltaic (“PV”) Solar panels, semi-conductors, and other high-end electronics, all of which cannot be manufactured without adequate supplies industry-standard HPQS. For five (5) years the SQTX technical team worked at a previously associated test facility, with two of the world's leading HPQS experts from the US and Germany. They have developed advanced new refining and processing techniques for manufacturing commercial grade purity and quantities of HPQS from the SQTX-owned, high purity quartz silica deposits, located in North Queensland, Australia. One of these experts directly established two (2) of the other three global factories, and has been retained to establish the new SQTX HPQS processing factory. There is always a shortage, globally, in adequate supplies of industry standard HPQ and HPQS, which have directly caused many businesses to fail as a direct result of supply shortages of HPQ and HPQS. It should be noted that Industry requirements for HPQS are not limited to the solar and electronics marketplace there is extensive usage as detailed in Item 11 in the Dropbox Web-link provided on Page 5 below.

| 1 |

3. Australian HPQS Factory

SQTX is currently positioned to establish its new commercial scale (50,000 tons per annum) HPQS factory in Australia where it has substantial equipment and infrastructure already located. Production at the new HPQS Factory will commence 6 to 8 months after receipt of funding and is profitable from the first year of operations.

HP Quartz Factory Processing and Testing HPQS

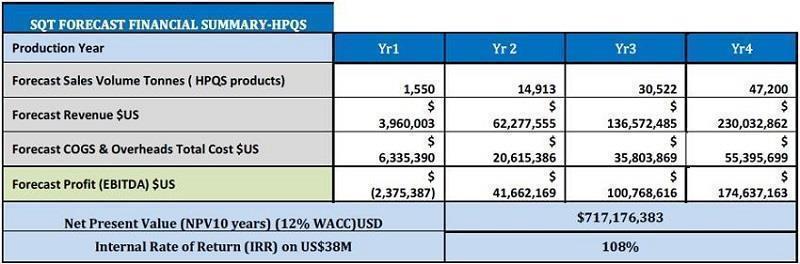

4. Three Stage Investment & High Profit Returns - IRR 108%

The US$ 38 million factory financing is a multi-staged investment, with US$ 10 million required initially to begin construction of the new Townsville, Queensland-located pre-processing plant to facilitate low-end unprocessed sale of quartz rock directly from the Quartz Hill mine site. (SEE DD Dropbox Item 3b) The balance of funds will be due as below herein.

4.1. Stage One – US$ 10 Million – Townsville Pre-Processing Factory “ SQ1” and “SQ5” Products

The initial US$10 million application of funds will be specifically allocated to sponsor the generation of early revenue from sales of un-processed raw quartz directly from the Quartz Hill mine site. The raw quartz rock will be shipped to the new Townsville Pre-Processing Factory for low-cost preparation involving high pressure washing, crushing and sizing, ready for shipping to international markets. SQT management is confident of re-establishing previous US$ 100 Million plus orders from China and several other new emerging markets that require basic HPQ for their own “value adding” production centres. While SQTX considers generation of early sales revenues is a vital function, the Pre-Processing Factory will also produce “SQ5” Feedstock for the new Commercial Scale HPQS Factory to generate sales into the solar industry, semi-conductor and all high-end electronics markets. By building the new Townsville factory, Stage One funding will provide a base for international sales operations focusing on generating high volume, low-end sales revenues from largely unprocessed quartz. The factory is designed with more than enough production capacity to meet both SQ5 feedstock and low-end production demands.

4.2. Stage Two – US$ 20 Million - HPQS Production Factory - “SQ7” Products

These funds will be needed six (6) months after the initial US$10 million. Funds will pay for establishing the fully operational Solar Grade, or Crucible Grade HPQS manufacturing facility. The factory will focus on manufacturing Solar Grade, or Crucible Grade HPQS products to world standard purity grade HPQS, for supply to all high-end electronics manufacturers. The Solar industry utilizes SQ7 HPQS extensively. This operational segment is the most challenging, requiring almost spotless production facilities and high-tech Clean Rooms, to insure ultimate high purity standards in the production process. The SQTX technical team has a previous proven ability to meet these standards and successfully achieve appropriate production quality for solar and crucible grade HPQS.

| 2 |

4.3. Stage Three - US$ 8 million - Factory Up-Grade Semi-Conductor Grade-“SQ9” Products

This funding is scheduled for one year after receipts of the Stage Two funding and will be used to purchase additional high-level refining equipment and meet the cost of facility upgrades to the existing HPQS factory to facilitate production of SQ9 semi-conductor grade HPQ. This grade of HPQ is the highest purity and yields the largest profit margin. It is extensively used in the semiconductor industry for tool wear applications and has consistent market demand. Semi-conductor grade SQ9 requires SQ7 solar grade HPQS as essential feedstock to enable manufacture of SQ9 semi-conductor

5. Completion of US$ 530 Million Reverse Take Over of US OTC PLC – SQTX is USA OTC Public Corp.

Vanguard Energy Corp. (VNGE) completed its US$ 530 Million acquisition of Solar Quartz Technologies Limited, a New Zealand private company, in July 2017, and obtained US Agency FINRA approval of its name change to Solar Quartz Technologies Corp and confirmation of the new stock symbol, “SQTX. Update of the Company audits and filings are currently being prepared and the Company will then look to file an application to uplift SQTX to trade on a more senior exchange OTC:QX, NYSE and/or NASDAQ. Accordingly, the company has a very strong asset base, no finance debt, owns it factory feedstock, and has the advantage of fully trading on the US markets for additional liquidity.

6. OPERATIONAL OVERVIEW – High Purity Quartz Sand (“HPQS”) & Quartz Assets

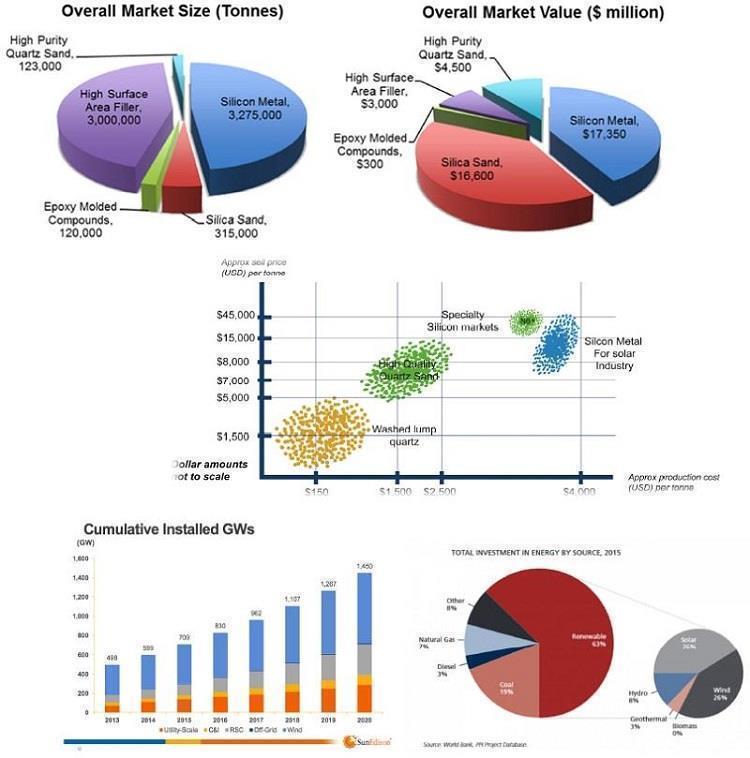

The constant demand for HPQS in high-end global markets has historically always exceeded available supply, and the current “booming” global solar industry, due to the rapid growth of utility scale PV solar farm installations, and micro-grid networks, has substantially increased global demand for HPQS. The re-tooling of the semiconductor industry to produce nano-chips has also increased HPQS demand. Many high-tech industries have had to curtail production and expansion due to the global shortage of HPQS. There are only three (3) commercial scale HPQS factories in the world, with the capability to refine raw quartz into commercial grade HPQS. They are located in the USA, Norway, and the Arctic Circle, collectively producing less than 60% of the world latent demand for HPQS.

SQTX has its own guaranteed supply of raw silica material to convert to HPQS feedstock, from its wholly owned ultra-high purity quartz deposit of 99.99% ultra-pure raw Quartz at its White Springs deposit (Estimated 1.5 million tonnes), located 230 kilometres inland from the major Queensland coastal port of Townsville.

The White Springs material is ideal for processing into HPQS and the estimated tonnage indicates sufficient reserve to fuel 15 to 20 years of processing into electronics grade HPQS. In addition, SQTX also owns the nearby “Quartz Hill” deposit that has an “AusIMM JORC” compliant resource of 14 million tonnes of high purity quartz, ideal to produce polysilicon metal, as well as for solar cell wafer production.

The current global price for Solar Crucible grade HPQS is US$8,000 to US$10,000 per tonne.. The global market price is projected to keep increasing, due to a global shortage of HPQS.

SQTX is also confident we can re-establish pre-existing HPQS sales orders for US$550 million (over 5 years) from five (5) Chinese crucible manufacturers, at a price of US$7,500+ per tonne (potential gross profit US$450 million over five years). Copies available.

The current solar industry global “boom” and the semi-conductor industry re-tooling for nano-tech chips have further increased potential HPQS sales. Existing global HPQS production capacity is unable to meet the current and forecasts future increased demand trends, including that from the main competitor, located in North Carolina, USA.

| 3 |

7. TOWNSVILLE, AUSTRALIA – Quartz Mining & Pre-Processing Factory & Unprocessed Raw Quartz Sales Centre

SQTX has a successful long-term association with its Townsville-based Contract Miner, NORDEV, and has entered into an agreement for NORDEV to mine the raw silica from the nearby White Springs and Quartz Hill deposits, and then freight the raw quartz to Townsville for pre-processing at the new factory being established in Townsville. The raw quartz will undergo minimal crushing, sizing, and mild acid washing to produce a semi-processed feedstock product, labelled as SQ5. The SQ5 product is the feedstock for HPQS production, as well as being suitable in a more refined form for sales to HD and LCD television screen manufacturers, especially those in Korea. SQTX also has access to re-establish a previous sales order for US$180 million of raw quartz (unprocessed & as mined) with a strong possibility of an additional $160 million sale from China. These sales and deliveries would be processed and shipped from the new Townsville facility. Copies of the previous Chinese orders are available.

SQTX is also considering establishing a full-scale commercial HPQS Factory in Townsville, Queensland, subject to further evaluation of cost and other productivity issues, including skilled resource availability at this location, pending securing funding and assessing other local incentives.

White Springs & Quartz Hill Deposits

8. UNIQUE INVESTMENT OPPORTUNITY-US$ 10 million to US$ 38 million

SQTX is seeking to raise US$38 million by way of convertible notes, equity, or JV to establish its new full-scale commercial production factory, to manufacture 50,000 tons per annum of electronics grade HPQS. First full year production, 10,000 t/p/a, increasing to 30,000 t/p/a in the second year, and then 50,000 tpa. The first stage HPQS processing is mainly for HPQS crucible sand for the PV Solar markets (US$8.0k-US$10.0k p/ton). Some crucible grade HPQS will also be utilized for 2nd stage processing into semiconductor grade HPQS, at an extra processing cost of $2,500 per tonne, that sells for US$12K – US$25K per tonne. Production of semi-conductor grade HPQS will be introduced from the 2nd year operations. The early timeframe commencement of operations at the new pre-processing and HPQS processing facility will enable significant early stage revenues to create early profitability, as well as to fund additional costs for semi-conductor grade processing. Production of crucible grade HPQS will begin 6 months after receipt of new funding.

The SQTX investment will produce an IRR of 108% with profits exceeding $100 million in year three (3). SQT has no debt or financial liabilities. Any funding can be secured over the entire US$ 530 Million asset base of SQT.

Upon completion of the planned Uplift to OTC:QX, NYSE or NASDAQ, SQTX will then initiate a US$ 100 - $150 million Secondary Public Offering (IPO) in the US markets to fund the expansion of US operations and to establish the planned new West Coast HPQS factory (production of 50,000 to 100,000 tons per annum).

| 4 |

9. ESTABLISHED COMPARITIVE MARKET VALUE - SUMITOMO JAPAN & RUSSIAN QUARTZ (RQ)

In 2015, Sumitomo Japan completed its purchase of a 28% equity holding for US$52 million in one of the other three (3) HPQS manufacturing factories, known as Russian Quartz (RQ). This producer has significant disadvantages over the SQTX operations, some of which are as follows:

(A) RQ factory only produces 3,000 t/p/a. Sumitomo now planning an increase to 10,000 t/p/a.

(B) RQ factory located in the Arctic Circle can only operate three months of the year.

(C) RQ silica deposits are 30 meters to 90 meters’ underground, substantially higher mining costs.

(D) RQ deposit fractionally less pure than White Springs Silica, extra purification processing cost.

By comparison the SQTX deposits allow for surface mining, or quarrying, that can be operational year-round in ideal climate conditions. In addition, the new SQTX HPQS factory will produce 30,000+ tons of HPQS per year.

The Sumitomo purchase firmly establishes a minimum value of US$200 million for the Russian Quartz operation. The SQTX HPQS processing operations (when fully operational), combined with SQTX’s solely owned silica assets at White Springs and Quartz Hill, indicate a Market Value far more than the Russian Quartz-established US$200 million.

10. TOWNSVILLE JV SOLAR SILICON METAL SMELTER (For Photovoltaic PV cells)

The Quartz Hill 14 million tons high purity quartz deposit was previously the target of a Joint Venture with the largest manufacturer of PV solar panels in Korea. The foundation basis for this agreement was the fact that the unusual high purity of the Quartz Hill deposit provides significant opportunities for cost savings in the smelting of the product into solar grade silicon metal. In addition, SQTX’s sole debt free ownership of this deposit allows for the company to supply the raw quartz for processing at an extremely competitive price, significantly below current market value, for less pure raw quartz currently being used in silicon metal production.

SQT believes there are significant opportunities, given the increased demand for PV solar panels, to negotiate a new joint venture with a major end user of the solar grade silicon metal. SQTX would not entertain establishing a PV silicon metal factory without a major International end-user partner. However, SQT is currently re-exploring this option, and believes it will be successful in attracting an appropriate joint-venture partner that can use the low-cost silicon metal in its own global manufacturing. The original party is now the second or third largest manufacturer of solar panels in the world and we understand they still have interest in the original proposal. There is substantial information regarding this proposal in the SQT Drop-box.

11. EXTENSIVE DUE DILIGENCE & ADDITIONAL INFORMATION

| SQTX DROPBOX WEB-LINK: | Available on Request |

|

|

|

| SQT WEBPAGE LINK: | www.sqt.solar |

|

|

|

| Contact Email: | wd@sqt.solar or rm@sqt.solar Phone +613 8639 5777 |

“A US$38 million investment indicates an exceptional IRR of 108%”

5

SQTX -FINANCIAL SUMMARY

The above figures demonstrate the growth in Solar investment in 2015 and forecast on-going strong growth forecast for PV Solar Industry globally. This trend underpins the significant additional demand that will be required for high purity quartz sand products vital for PV Solar panel production.

Contact Emails: Warren Dillard CEO wd@sqt.solar & Roger May rm@sqt.solar

| 6 |