Attached files

| file | filename |

|---|---|

| 8-K - 8-K - DARLING INGREDIENTS INC. | dar-20170517x8k.htm |

Investor Presentation

Spring 2017

Randall C. Stuewe, Chairman and CEO

Patrick C. Lynch, EVP Chief Financial Officer

Melissa Gaither, VP IR and Global Communications

Exhibit 99.1

This presentation contains “forward-looking” statements regarding the business operations and prospects of Darling Ingredients Inc., including its Diamond Green

Diesel joint venture, and industry factors affecting it. These statements are identified by words such as “believe,” “anticipate,” “expect,” “estimate,” “intend,”

“could,” “may,” “will,” “should,” “planned,” “potential,” “continue,” “momentum,” “assumption,” and other words referring to events that may occur in the

future. These statements reflect Darling Ingredient’s current view of future events and are based on its assessment of, and are subject to, a variety of risks and

uncertainties beyond its control, each of which could cause actual results to differ materially from those indicated in the forward-looking statements. These

factors include, among others, existing and unknown future limitations on the ability of the Company's direct and indirect subsidiaries to make their cash flow

available to the Company for payments on the Company's indebtedness or other purposes; global demands for bio-fuels and grain and oilseed commodities,

which have exhibited volatility, and can impact the cost of feed for cattle, hogs and poultry, thus affecting available rendering feedstock and selling prices for the

Company’s products; reductions in raw material volumes available to the Company due to weak margins in the meat production industry as a result of higher feed

costs, reduced consumer demand or other factors, reduced volume from food service establishments, or otherwise; reduced demand for animal feed; reduced

finished product prices, including a decline in fat and used cooking oil finished product prices; changes to worldwide government policies relating to renewable

fuels and greenhouse gas emissions that adversely affect programs like the Renewable Fuel Standards Program (RFS2), low carbon fuel standards (LCFS) and tax

credits for biofuels both in the Unites States and abroad; possible product recall resulting from developments relating to the discovery of unauthorized

adulterations to food or food additives; the occurrence of Bird Flu including, but not limited to H5N1 flu, bovine spongiform encephalopathy (or "BSE"), porcine

epidemic diarrhea ("PED") or other diseases associated with animal origin in the United States or elsewhere; unanticipated costs and/or reductions in raw material

volumes related to the Company’s compliance with the existing or unforeseen new U.S. or foreign regulations (including, without limitation, China) affecting the

industries in which the Company operates or its value added products (including new or modified animal feed, Bird Flu, PED or BSE or similar or unanticipated

regulations); risks associated with the renewable diesel plant in Norco, Louisiana owned and operated by a joint venture between Darling Ingredients and Valero

Energy Corporation, including possible unanticipated operating disruptions and issues related to the announced expansion project; difficulties or a significant

disruption in our information systems or failure to implement new systems and software successfully, including our ongoing enterprise resource planning project;

risks relating to possible third party claims of intellectual property infringement; increased contributions to the Company’s pension and benefit plans, including

multiemployer and employer-sponsored defined benefit pension plans as required by legislation, regulation or other applicable U.S. or foreign law or resulting

from a U.S. mass withdrawal event; bad debt write-offs; loss of or failure to obtain necessary permits and registrations; continued or escalated conflict in the

Middle East, North Korea, Ukraine or elsewhere; uncertainty regarding the likely exit of the U.K. from the European Union; and/or unfavorable export or import

markets. These factors, coupled with volatile prices for natural gas and diesel fuel, climate conditions, currency exchange fluctuations, general performance of the

U.S. and global economies, disturbances in world financial, credit, commodities and stock markets, and any decline in consumer confidence and discretionary

spending, including the inability of consumers and companies to obtain credit due to lack of liquidity in the financial markets, among others, could negatively

impact the Company's results of operations. Among other things, future profitability may be affected by the Company’s ability to grow its business, which faces

competition from companies that may have substantially greater resources than the Company. The Company’s announced share repurchase program may be

suspended or discontinued at any time and purchases of shares under the program are subject to market conditions and other factors, which are likely to change

from time to time. Other risks and uncertainties regarding Darling Ingredients Inc., its business and the industries in which it operates are referenced from time to

time in the Company’s filings with the Securities and Exchange Commission. Darling Ingredients Inc. is under no obligation to (and expressly disclaims any such

obligation to) update or alter its forward-looking statements whether as a result of new information, future events or otherwise.

Safe Harbor Statement

2

3

…thus growing shareholder value.

Our strategy is to be…

We BUILD, ACQUIRE and DEVELOP businesses within geographies

where we can achieve a sustainable Top 3 market position within 5 years…

the Global Leader

in the production of the highest quality

sustainable protein and nutrient-recovered ingredients.

markets to satisfy a growing population.

FOOD

FEED

FUEL

Supplying ingredients for the

4

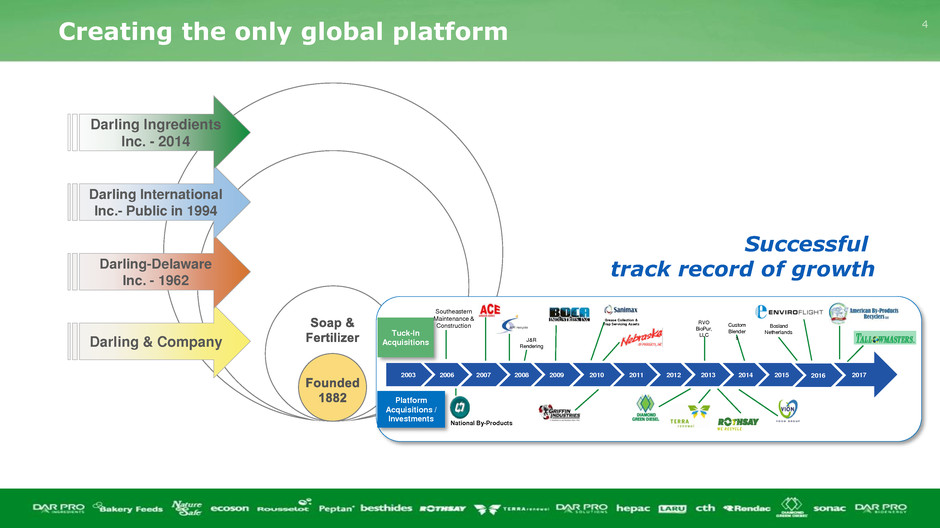

Darling & Company

Darling-Delaware

Inc. - 1962

Darling International

Inc.- Public in 1994

Darling Ingredients

Inc. - 2014

Creating the only global platform

Southeastern

Maintenance &

Construction

2003 2006 2008 2010 2017

Tuck-In

Acquisitions

Platform

Acquisitions /

Investments

2011 2012 2013 2014

J&R

Rendering

National By-Products

Grease Collection &

Trap Servicing Assets

201520092007

Bosland

Netherlands

Custom

Blender

s

RVO

BioPur,

LLC

Successful

track record of growth

2016

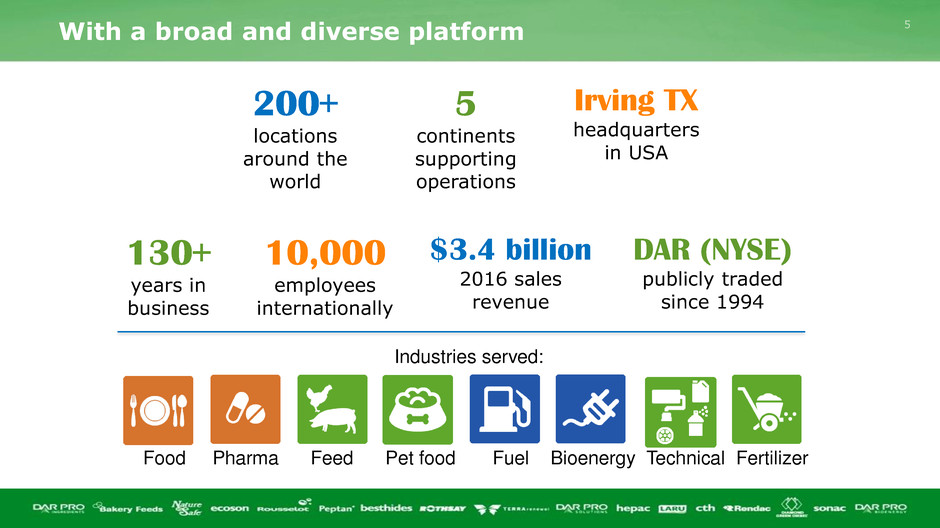

5

continents

supporting

operations

130+

years in

business

200+

locations

around the

world

10,000

employees

internationally

$3.4 billion

2016 sales

revenue

Irving TX

headquarters

in USA

DAR (NYSE)

publicly traded

since 1994

With a broad and diverse platform

Food Pharma Feed Pet food Fuel Bioenergy Technical Fertilizer

Industries served:

5

A unique platform to view the world

and see opportunities where others can not.

2014

Growth from

Vion Ingredients

acquisition for

an International

footprint

A world of growth

6

7

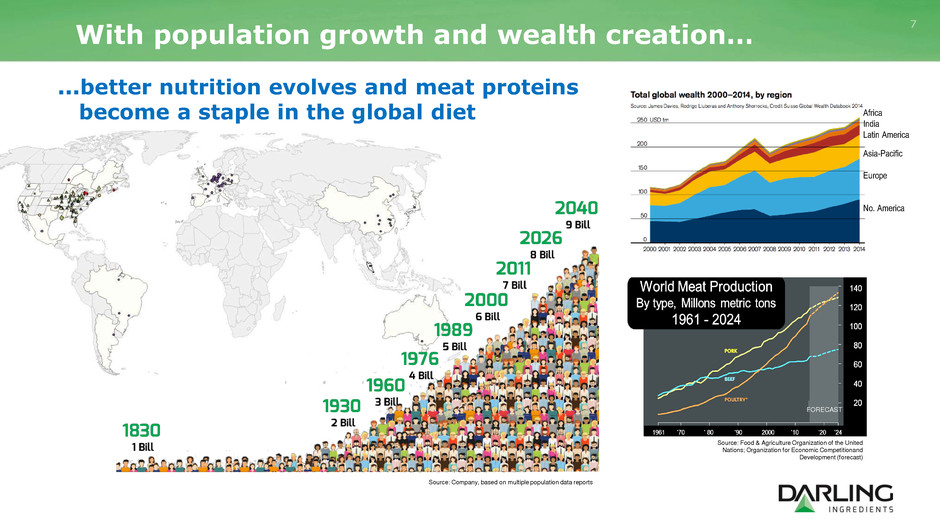

...better nutrition evolves and meat proteins

become a staple in the global diet

With population growth and wealth creation…

Source: Company, based on multiple population data reports

Source: Food & Agriculture Organization of the United

Nations; Organization for Economic Competitionand

Development (forecast)

FORECAST

Africa

India

Latin America

Asia-Pacific

Europe

No. America

8

258 million MT and growing at ~1% annually…

(per USDA)

...generating ~100 million tons of meat by-products globally.

• Darling Ingredients processes ~10 million tons of the world’s

meat by-products...

creating a tremendous opportunity for both

organic and acquisitive growth!

DAR

Global Meat Production 2016

DAR processes 10% of world’s animal by-products

Global meat consumption produces

significant by-products that must be safely handled

Only ~60% of the animal is

consumed in western cultures !

9

Offering a diversified and unique portfolio

Processed 1.18 million MTProcessed 7.97 million MTProcessed 1.08 million MT

**Processed amounts are for 2016

~$1 billion

Food company

Edible raw material

10Recognized brands creating Food, Feed and Fuel ingredients

~$500 million

Fuel company

Note: Includes DGD

Not fit for human or

animal consumption

FOOD FEED FUEL

Inedible raw material

~$2 billion

Feed company

A defined model of identified and managed risk

70%

20%

5%

5%

FEED

Spread Managed Margin

Commodity Exposed

Shared Margin

Fee for Service

100%

FOOD

Spread Managed Margin

100%

FUEL

Fee for Service

Fee for

Service

• Competition

• Government

regulations

Commodity

Exposed

• Fat price

• Soymeal price

• Corn Price

Spread

Managed

Margin

• Raw material

availability

• Food demand

• Pharma demand

Shared

Margin

• Fat price

• Poultry meal

pet food spread

price

BUSINESS DRIVERS

11

12

FEEDFOOD

FUEL(1)

Alternative

Ingredients

Corn

Palm Oil

Soybean Meal

Raw Meat

Availability

Beef

Pork

Chicken

Currency

Euro

RMB

CAD

REAL

Global Business Drivers

EBITDA

Margin

Adjusted

EBITDA (1)

A portfolio of spread managed businesses

$28.0

$32.3

$28.7

$39.1 $38.6 $37.4

$25.3

$30.0 $31.7

10.4%

11.4%

10.7%

14.4%

15.6%

13.7%

9.7% 10.7%

11.8%

0%

5%

10%

15%

20%

25%

30%

$0.0

$10.0

$20.0

$30.0

$40.0

$50.0

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Q1

2017

$75.5 $75.9 $76.5

$54.4 $58.3

$83.5

$78.9 $73.9 $74.5

13.8% 14.3% 14.6%

11.5% 12.2%

15.4% 14.8% 13.7% 13.5%

0%

5%

10%

15%

20%

25%

30%

$0.0

$20.0

$40.0

$60.0

$80.0

$100.0

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Q1

2017

$9.1 $8.6

$7.0

$19.2

$13.0 $13.8 $12.9

$18.0

$10.4

16.0%

18.5%

11.8%

29.4% 23.4% 22.2% 21.4%

26.2%

17.4%

0%

10%

20%

30%

40%

50%

$0.0

$5.0

$10.0

$15.0

$20.0

$25.0

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Q1

2017

US$ (millions)

(1) Fuel Segment shows blenders tax credit earned prospectively and reported in

quarterly earnings in 2016. In 2015 the blenders tax credit was approved in Q4.

In 2017 the blenders tax credit has not yet been approved.

13Evaluating both organic and acquisitive growth

FEED

A- Rendering plant

A- Rendering plant

A- Rendering plant

B- Rendering plants (3)

B- Organic fertilizer

B- Soldier fly plant

B- Blood plant

B- Blood plant

B- Wet pet food plant

FUEL

A- Waste hauler

B- Biodiesel expansion

B- Digester

B- Digester

B- DGD expansion

FOOD

A- Gelatin

B- Blood expansion

B- Gelatin expansion

B- Gelatin expansion

B- Peptan plant

B- Peptan expansion

B- Blood plant

A- Acquire

B- Build

USA

(9)

Canada

(3)

Brazil

(2)

China

(3)

Far East

(1)

Global

(1)

Europe

(4)

California LCFS Carbon Reduction Program

Baseline Carbon Intensity start 2016 = 102.01

Held constant 2013 through 2015

CA Diesel gallon consumption forecasted at

4 billion gallons in 2020

Source:

www.arb.ca.gov/regat/2015/lcfs2015/lcfs15appb.pdf

Carbon Credit Avg. Price $/gallon

in years 2013, 2014, 2015, 2016

$0.71

July - Dec

$0.52

Fiscal

$1.01

Fiscal

$0.30

Fiscal

14

DGD JV Debt History

DGD Renewable Gallon Capacity/Sold Gallons

$0

$100

$200

$300

2012 2013 2014 2015 2016 2017 2018

$225.4 $221.3 $212.8

$148.8

$70.8 $61.5

Total Debt

Net

Debt

Free

2018

$0.69

$1.29

$1.13 $1.08

$0.60

$1.25 $1.25

Average …

$0.00

$0.50

$1.00

$1.50

$2.00

2013 2014 2015 2016 2017 2018 2019

EBITDA per Gallon Renewable Diesel

Expansion Assumption

based on $1.25 per

gallon EBITDA

Assumptions and References:

• Carbon Credit Avg. Pricing per The Jacobsen index – average pricing for 2013 only includes July – December 2013 (6 months)

• LCFS Carbon Reduction Program per the California Air Resources Board

• Start-up of the DGD expansion in 2Q 2018

• EBITDA assumption for 2018 thru 2019 is $1.25/gal EBITDA rate times projected gallons sold

• Expansion Capex projected to be $191.3 mm over 2016 to 2018

• 2017 EBITDA per gallon rate does not include the retrospective blenders tax credit

• Assumes sale of full production

• Total debt projections assume continued application of available cash to pay down debt

Note: 2017-2019 Gallons based on projection expansion capacity

Actual Actual Actual Actual ------------Assumptions------------

2014 2015 2016 2017 2018 2019

EBITDA $163.3 $177.0 $174.4 $96.0 $247.4 $343.8

Expansion - Capex $0.0 $0.0 ($6.6) ($89.7) ($95.0) $0.0

Regular - Capex ($ 3.3) ($1.5) ($36.7) ($20.6) ($31.8) ($5.2)

Working Capital ($44.0)

Free Cash Flow $150.0 $175.5 $137.7 ($14.3) $76.6 $338.6

Expansion AssumptionHistoricalActual Actual Actual AssumptionActual AssumptionActual

Fueled by increasing contributions from DGD Expansion

E

x

p

a

n

s

io

n

A

s

s

u

m

p

ti

o

n

s

Carbon intensity is lifecycle emissions

(“well-to-wheels”), referring to

how much total pollution is generated in the production,

transport, storage and

use of a transportation fuel.

http://www.deq.state.or.us/aq/cleanFuel/qa.htm

(“Released” refers to GHG a plant emits from

the daily operation).

“Captured” represents the equivalent GHG that

would have been released if the raw material had

been landfilled, composted, incinerated or left on

open land, vs rendering process)

* Gooding, C.H. 2012. Data for the Carbon Footprinting of

Rendering Operations. Journal of Industrial Ecology. Vol 16,

No.2.

Carbon intensity of

our plant processes

15

DGD and DAR to benefit from LCFS

o LCFS (State) is separate rule from RFS2 (Federal)

o Mandates reduction of carbon intensity in transportation fuels

(in effect in California, Oregon, parts of Canada and other countries)

o California has mandated a 10% reduction by 2020, to help reduce

carbon dioxide emissions

o LCFS measurements begin at source

o Darling’s biodiesel and renewable diesel can be used to

satisfy the LCFS requirements

o We produce the feedstocks with highest green premium

o This additional demand for low carbon fuels will

increase the value of the fats and oils we produce

o DGD will reach new expanded production to service LCFS

Biofuel

Mandates

Globally

http://globalrfa.org/biofuels-map/

Global LCFS will drive margins

Countries participating in

some form of a Low Carbon

Fuel Standard. California

represents ~12% of all

U.S. transportation fuel

needs.

16

*Excludes annual maintenance capex of approximately $10 mm.

Diamond Green Diesel @ 275 million gallons

Renewable Diesel

$206.25

$275.00

$343.75

$412.50

$-

$100.00

$200.00

$300.00

$400.00

$500.00

0.75 1.00 1.25 1.50

T

o

ta

l

D

G

D

e

n

ti

ty

E

B

IT

D

A

Cash Generation by DGD

EBITDA/Gallon:

A de-levered and expanded DGD combined

with our core business will create:

• Additional deleveraging power

• Growth capital

• Opportunity to return capital to shareholders

Transforming and creating new earnings power

2014 2015 2016 Q1 2017

Total Debt Paid Down ($ Millions) $122.3 $118.2 $169.7

DGD Dividend to Darling – $25.0 $25.0 $25.0

Total Leverage Debt Ratio 4.02 4.32 3.69 3.46

Darling Debt Pay Down and Ratio

EIBTDA: 3-Year Average (2014-2016) $430.0

Capex: 3-Year Average (2 14-2016) (235.0)

Interest (80.0)

Cash Taxes (25.0)

Working Capital Improvement (Assumed) $10.0

$100.0

Darling Ingredients Core Business

Estimated FCF ($ in millions)

EBITDA: 3-Year Average (2014-2016)

17All while responsibly making the planet a better place

OUR COMMITMENT TO SUSTAINABILITY

18

…IS VISIBLE AND PART OF OUR OPERATIONS …DRIVEN BY METRICS (2018)

to

SAFE

FOOD & FEED

• Innovations

• Product recalls

• Complete traceability

• Food Safety programs

NEW INNOVATIVE DIETARY

PROTEIN SOURCES

IMPROVING FEED INTAKE

OF YOUNG ANIMALS

to

CLEAN

AIR & WATER

• Net clean water returned

• GHG reductions

• Green energy

• Bio fuel productionTURNING WASTE WATER INTO A

VALUABLE RESOURCE

THE NEXT GENERATION OF

RENEWABLE FUEL... TODAY

to

COMMUNITIES

& WORK

PLACES

• Accident reporting

• Environmental

Compliance

• Community support

• Darling University

CREATING AN ECOLOGICAL

BUFFER ZONE

ASSISTING FAMILIES

LEFT HOMELESS

OUR

COMMITMENT

Corporate Social Responsibility

OUR WORLD OF COMMITMENT

19

…thus growing shareholder value.

Our strategy is to be…

We BUILD, ACQUIRE and DEVELOP businesses within geographies

where we can achieve a sustainable Top 3 market position within 5 years…

the Global Leader

in the production of the highest quality

sustainable protein and nutrient-recovered ingredients.

markets to satisfy a growing population.

FOOD

FEED

FUEL

Supplying ingredients for the

20The talents and processes we possess

• Experienced, international management

• Operational excellence

• 130+ year history

• Track record of strong performance

• Strong balance sheet and cash flow

• Good risk management

• Global growth opportunities

• Innovative R&D around the world

• Commitment to sustainable practices

21

o view the world with a long-term horizon

o see meat production grow at or above population growth

o expand, build and acquire facilities within these

protein growth geographies

omaintain our strong model, generating predictable cash

o reduce our debt and keep a strong balance sheet

o deploy capital with a 15-20% ROCE

o invest in new technologies and processes to make

world-class value added ingredients

omaintain and grow our global marketshare

o be socially responsible throughout our journey

o develop people to support our growth!

To accomplish this journey, we will…

22

Creating sustainable food, feed and fuel

ingredients for a growing population

DAR—

A GLOBAL GROWTH

PLATFORM

FOR

GENERATIONS

TO COME

23

24

Consolidated Earnings

Q1 2017 Overview

Year over Year

• Global volumes up 4.3% over Q1 2016

• Global pricing increased across most business lines

• Food segment reduction related to challenges in South

American gelatin business

• SG&A expense higher due to incremental one time

administrative cost related to equity award accounting

• Received $25mm partner dividend from Diamond

Green Diesel (DGD)

• Working Capital steady for the quarter

Sequential

• Consistent and improved performances across Feed

and Food segments

• Fuel segment one-time items recorded in Q4 2016 and

absence of the blenders tax credit

US$ (millions) except per share price

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue 779.6$ 877.3$ 853.9$ 887.3$ 3,398.1$ 880.1$

Gross Margin 180.7 200.2 182.7 192.8 756.4 190.4

Gross Margin % 23.2% 22.8% 21.4% 21.7% 22.3% 21.6%

SG&A 81.5 76.2 76.5 79.9 314.0 87.9

SG&A Margin % 10.5% 8.7% 9.0% 9.0% 9.2% 10.0%

Operating Income 26.7 54.5 35.5 35.4 152.1 31.4

EBITDA(1) 98.9 124.0 106.2 112.8 441.9 102.5

EBITDA Margin % 12.7% 14.1% 12.4% 12.7% 13.0% 11.6%

Net income attributable to Darling 1.1$ 32.0$ 28.7$ 40.5$ 102.3$ 5.8$

Earnings per share (fully diluted) 0.01$ 0.19$ 0.17$ 0.25$ 0.62$ 0.04$

(1) Does not inlcude U c nsolidated Subsidiaries EBITDA.

24

25

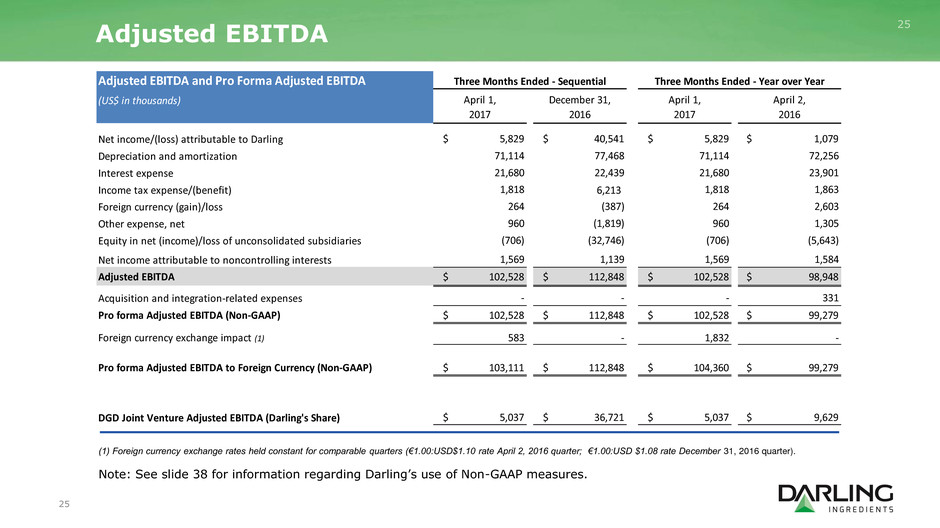

Adjusted EBITDA

(1) Foreign currency exchange rates held constant for comparable quarters (€1.00:USD$1.10 rate April 2, 2016 quarter; €1.00:USD $1.08 rate December 31, 2016 quarter).

Adjusted EBITDA and Pro Forma Adjusted EBITDA

(US$ in thousands) April 1, December 31, April 1, April 2,

2017 2016 2017 2016

Net income/(loss) attributable to Darling $ 5,829 $ 40,541 $ 5,829 $ 1,079

Depreciation and amortization 71,114 77,468 71,114 72,256

Interest expense 21,680 22,439 21,680 23,901

Income tax expense/(benefit) 1,818 6,213 1,818 1,863

Foreign currency (gain)/loss 264 (387) 264 2,603

Other expense, net 960 (1,819) 960 1,305

Equity in net (income)/loss of unconsolidated subsidiaries (706) (32,746) (706) (5,643)

Net income attributable to noncontrolling interests 1,569 1,139 1,569 1,584

Adjusted EBITDA $ 102,528 $ 112,848 $ 102,528 $ 98,948

Acquisition and integration-related expenses - - - 331

Pro forma Adjusted EBITDA (Non-GAAP) $ 102,528 $ 112,848 $ 102,528 $ 99,279

Foreign currency exchange impact (1) 583 - 1,832 -

Pro forma Adjusted EBITDA to Foreign Currency (Non-GAAP) $ 103,111 $ 112,848 $ 104,360 $ 99,279

DGD Joint Venture Adjusted EBITDA (Darling's Share) $ 5,037 $ 36,721 $ 5,037 $ 9,629

Three Months Ended - Sequential Three Months Ended - Year over Year

Note: See slide 38 for information regarding Darling’s use of Non-GAAP measures.

25

26Balance Sheet Highlights and Debt Summary

Balance Sheet Highlights

Leverage Ratios

Debt Summary

April 1, 2017 Actual Credit Agreement

Total Debt to EBITDA: 3.46 5.50

(US$, in thousands) April 1, 2017

Cash (includes restricted cash of $282) 139,162$

Accounts receivable 389,864

Total Inventories 342,114

Net working capital 475,507

Net property, plant and equipment 1,532,583

Total assets 4,719,661

Total debt 1,752,461

Shareholders' equity 2,103,837$

(US$, in thousands) April 1, 2017

Amended Credit Agreement

Revolving Credit Facility -$

Term Loan A 119,835

Term Loan B 576,076

5.375% Senior Notes due 022 492,667

4.750% Euro Senior Notes due 2022 541,639

Other Notes and Obligations 22,244

Total Debt: 1,752,461$

4

6

8

10

12

14

16

18

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Q1

2017

27

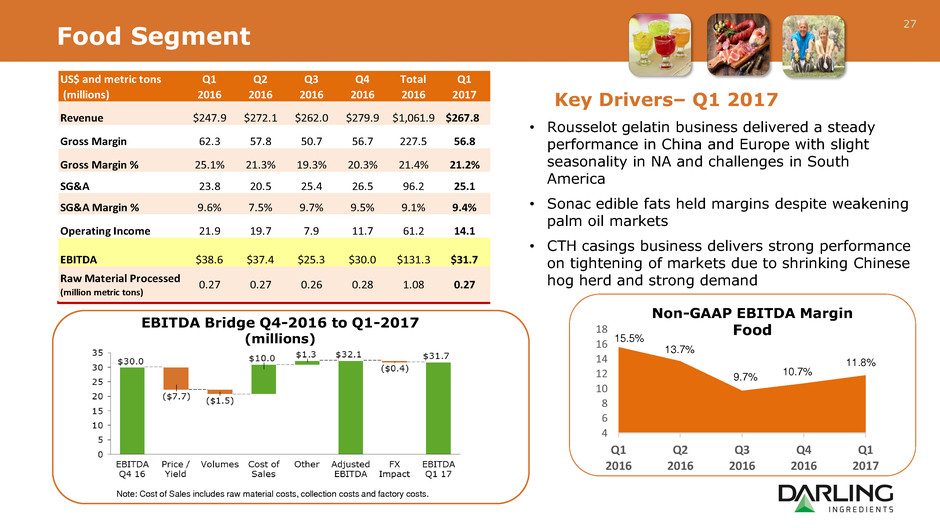

Food Segment

Key Drivers– Q1 2017

• Rousselot gelatin business delivered a steady

performance in China and Europe with slight

seasonality in NA and challenges in South

America

• Sonac edible fats held margins despite weakening

palm oil markets

• CTH casings business delivers strong performance

on tightening of markets due to shrinking Chinese

hog herd and strong demand

US$ and metric tons

(millions)

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $247.9 $272.1 $262.0 $279.9 $1,061.9 $267.8

Gross Margin 62.3 57.8 50.7 56.7 227.5 56.8

Gross Margin % 25.1% 21.3% 19.3% 20.3% 21.4% 21.2%

SG&A 23.8 20.5 25.4 26.5 96.2 25.1

SG&A Margin % 9.6% 7.5% 9.7% 9.5% 9.1% 9.4%

Operating Income 21.9 19.7 7.9 11.7 61.2 14.1

EBITDA $38.6 $37.4 $25.3 $30.0 $131.3 $31.7

Raw Material Proces ed

(million metric tons)

0.27 0.27 0.26 0.28 1.08 0.27

Note: Cost of Sales includes raw material costs, collection costs and factory costs.

Non-GAAP EBITDA Margin

Food

EBITDA Bridge Q4-2016 to Q1-2017

(millions) 15.5%

13.7%

9.7%

10.7%

11.8%

12.2%

15.4% 14.8%

13.7% 13.5%

28

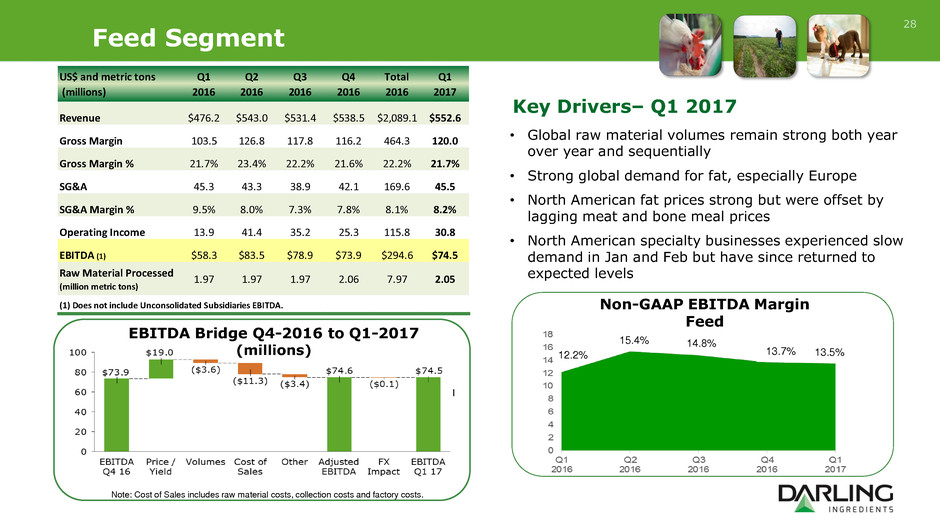

Feed Segment

Note: Cost of Sales includes raw material costs, collection costs and factory costs.

EBITDA Bridge Q4-2016 to Q1-2017

(millions)

US$ and metric tons

(millions)

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $476.2 $543.0 $531.4 $538.5 $2,089.1 $552.6

Gross Margin 103.5 126.8 117.8 116.2 464.3 120.0

Gross Margin % 21.7% 23.4% 22.2% 21.6% 22.2% 21.7%

SG&A 45.3 43.3 38.9 42.1 169.6 45.5

SG&A Margin % 9.5% 8.0% 7.3% 7.8% 8.1% 8.2%

Operating Income 13.9 41.4 35.2 25.3 115.8 30.8

EBITDA (1) $58.3 $83.5 $78.9 $73.9 $294.6 $74.5

Raw Material Processed

(million metric tons)

1.97 1.97 1.97 2.06 7.97 2.05

(1) Does not include Unconsolidated Subsidiaries EBITDA.

Key Drivers– Q1 2017

Non-GAAP EBITDA Margin

Feed

• Global raw material volumes remain strong both year

over year and sequentially

• Strong global demand for fat, especially Europe

• North American fat prices strong but were offset by

lagging meat and bone meal prices

• North American specialty businesses experienced slow

demand in Jan and Feb but have since returned to

expected levels

29

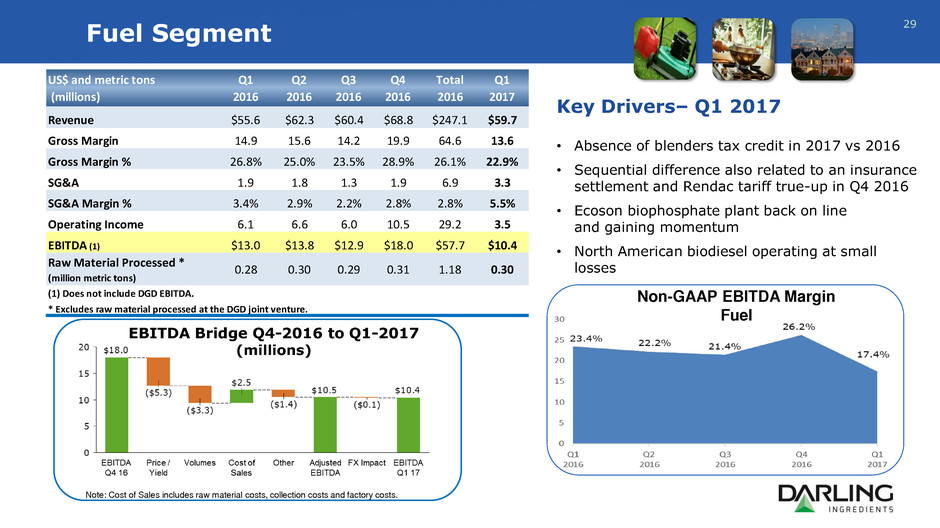

Fuel Segment

Key Drivers– Q1 2017

• Absence of blenders tax credit in 2017 vs 2016

• Sequential difference also related to an insurance

settlement and Rendac tariff true-up in Q4 2016

• Ecoson biophosphate plant back on line

and gaining momentum

• North American biodiesel operating at small

losses

US$ and metric tons

(millions)

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $55.6 $62.3 $60.4 $68.8 $247.1 $59.7

Gross Margin 14.9 15.6 14.2 19.9 64.6 13.6

Gross Margin % 26.8% 25.0% 23.5% 28.9% 26.1% 22.9%

SG&A 1.9 1.8 1.3 1.9 6.9 3.3

SG&A Margin % 3.4% 2.9% 2.2% 2.8% 2.8% 5.5%

Operating Income 6.1 6.6 6.0 10.5 29.2 3.5

EBITDA (1) $13.0 $13.8 $12.9 $18.0 $57.7 $10.4

Raw Material Process d *

(million metric tons)

0.28 0.30 0.29 0.31 1.18 0.30

(1) Does not include DGD EBITDA.

* Excludes raw material processed at the DGD joint venture.

EBITDA Bridge Q4-2016 to Q1-2017

(millions)

Note: Cost of Sales includes raw material costs, collection costs and factory costs.

Non-GAAP EBITDA Margin

Fuel

Creating sustainable food, feed and fuel ingredients for a growing population

31Food Segment - Historical

US$ and metric tons

(millions)

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Total

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $270.2 $283.4 $269.2 $272.1 $1,094.9 $247.9 $272.1 $262.0 $279.9 $1,061.9 $267.8

Gross Margin 53.5 60.2 54.8 62.9 231.4 62.3 57.8 50.7 56.7 227.5 56.8

Gross Margin % 19.8% 21.2% 20.4% 23.1% 21.1% 25.1% 21.3% 19.3% 20.3% 21.4% 21.2%

SG&A 25.5 27.9 26.1 23.8 103.3 23.8 20.5 25.4 26.5 96.2 25.1

SG&A Margin % 9.4% 9.8% 9.7% 8.7% 9.4% 9.6% 7.5% 9.7% 9.5% 9.1% 9.4%

Operating Income 10.8 15.5 11.6 23.3 61.2 21.9 19.7 7.9 11.7 61.2 14.1

EBITDA $28.0 $32.3 $28.7 $39.1 $128.1 $38.6 $37.4 $25.3 $30.0 $131.3 $31.7

EBITDA Margin % 10.4% 11.4% 10.7% 14.4% 11.7% 15.6% 13.7% 9.7% 10.7% 12.4% 11.8%

Raw Material Processed

(millions of metric tons)

0.27 0.28 0.26 0.26 1.07 0.27 0.27 0.26 0.28 1.08 0.27

32

Feed Segment - Historical

US$ and metric tons

(millions)

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Total

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $547.5 $529.4 $525.2 $472.2 $2,074.3 $476.2 $543.0 $531.4 $538.5 $2,089.1 $552.6

Gross Margin 123.5 124.5 116.2 96.7 460.9 103.5 126.8 117.8 116.2 464.3 120.0

Gross Margin % 22.6% 23.5% 22.1% 20.5% 22.2% 21.7% 23.4% 22.2% 21.6% 22.2% 21.7%

SG&A 48.0 48.7 39.7 42.2 178.6 45.3 43.3 38.9 42.1 169.6 45.5

SG&A Margin % 8.8% 9.2% 7.6% 8.9% 8.6% 9.5% 8.0% 7.3% 7.8% 8.1% 8.2%

Operating Income 35.4 35.4 35.6 10.1 116.5 13.9 41.4 35.2 25.3 115.8 30.8

EBITDA $75.5 $75.9 $76.5 $54.4 $282.3 $58.3 $83.5 $78.9 $73.9 $294.6 $74.5

EBITDA Margin % 13.8% 14.3% 14.6% 11.5% 13.6% 12.2% 15.4% 14.8% 13.7% 14.1% 13.5%

Raw Material Processed

(millions of metric tons)

1.87 1.83 1.86 1.89 7.45 1.97 1.97 1.97 2.06 7.97 2.05

33

Feed Ingredients Segment

Change in Net Sales – Year over Year (1Q 2016 over 1Q 2017)

Change in Net Sales – Three Months Ended (Sequential 4Q16 over 1Q17)

(1) Rendering Net Sales- Other category includes hides, pet food, and service charges

(2) Other Net Sales category includes trap services, industrial residual services and organic fertilizer

Change in Net Sales - 4Q16 to 1Q17

Fats Proteins Other (1)

Total

Rendering

Used

Cooking Oil Bakery Other (2) Total

Net Sales Three Months Ended December 31, 2016 151.1$ 192.9$ 69.1$ 413.1$ 47.7$ 55.7$ 22.1$ 538.6$

Changes:

Increase/(Decrease) in sales volumes (1.2) (4.3) - (5.5) 0.9 (0.7) - (5.3)

Increase/(Decrease) in finished product prices 8.4 10.3 - 18.7 (4.6) 1.1 - 15.2

Decrease due to currency exchange rates (0.3) (0.7) (0.6) (1.6) - - - (1.6)

Other change - - 5.1 5.1 - - 0.6 5.7

Total Change: 6.9 5.3 4.5 16.7 (3.7) 0.4 0.6 14.0

Net Sales Three Months Ended April 1, 2017 158.0$ 198.2$ 73.6$ 429.8$ 44.0$ 56.1$ 22.7$ 552.6$

Rendering Sales

Fats Proteins Other (1)

Total

Renderin

g

Used

Cooking

Oil Bakery Other (2) Total

Net Sales T ree Months Ended April 2, 2016 125.3$ 172.0$ 66.6$ 363.9$ 34.4$ 54.5$ 23.4$ 476.2$

Changes:

Increase/(Decrease) in sales volumes 13.0 17.3 - 30.3 (0.8) 0.4 - 29.9

Incr ase/(D crease) in fi ished roduct prices 20.3 10.6 - 30.9 10.5 1.2 - 42.6

Decrease due to currency exchange rates (0.6) (1.7) (1.6) (3.9) (0.1) - - (4.0)

Other change - - 8.6 8.6 - - (0.7) 7.9

Total Change: 32.7 26.2 7.0 65.9 9.6 1.6 (0.7) 76.4

Net Sales Three Months Ended April 1, 2017 158.0$ 198.2$ 73.6$ 429.8$ 44.0$ 56.1$ 22.7$ 552.6$

Rendering Sales

Change in N t Sales - 1Q16 t 1Q17

34

Jacobsen, Wall Street Journal and Thomson Reuters

Historical Pricing

QTR. Over QTR. Year Over Year

Comparison Q4-2016 Q1-2017 % Q1-2016 Q1-2017 %

Average Jacobsen Prices (USD) Avg. Avg. Change Avg. Avg. Change

Bleachable Fancy Tallow - Chicago Renderer / cwt $30.77 $31.35 1.9% $27.07 $31.35 15.8%

Yellow Grease - Illinois / cwt $23.05 $23.78 3.2% $21.25 $23.78 11.9%

Meat and Bone Meal - Ruminant - Illinois / ton $223.24 $270.69 21.3% $220.98 $270.69 22.5%

Poultry By-Product Meal - Feed Grade - Mid South / ton $281.43 $287.42 2.1% $249.10 $287.42 15.4%

Poultry By-Product Meal - Pet Food - Mid South / ton $571.09 $635.89 11.3% $506.31 $635.89 25.6%

Feathermeal - Mid South / ton $356.91 $422.94 18.5% $277.21 $422.94 52.6%

Average Wall Street Journal Prices (USD)

Corn - Track Central IL #2 Yellow / bushel $3.30 $3.45 4.5% $3.55 $3.45 -2.8%

Average Thomson Reuters Prices (USD)

Palm oil - CIF Rotterdam / metric ton $752 $765 1.7% $632 $765 21.0%

Soy meal - CIF Rotterdam / metric ton $360 $368 2.2% $328 $368 12.2%

2016 Finished Pr duct Pricing

Feed S gment Ingredients January February March Q1 Avg. April May June Q2 Avg. July August Sept. Q3 Avg. Oct. Nov. Dec. Q4 Avg. Year Avg.

Bleachable Fancy Tallow - icago Renderer / cwt $23.53 $27.10 $ 0.09 $27.07 $32.93 $32.81 $31.64 $32.57 $29.95 $28.00 $28.00 $28.59 $28.43 $32.00 $32.00 $30.77 $29.75

Yellow Grease - Illinois / c t $19.03 $20.89 $ .51 $21.25 $26.40 $27.56 $25.95 $26.77 $24.54 $23.86 $23.71 $24.01 $23.31 $22.76 $22.96 $23.05 $23.77

Meat and Bo e Meal - Ru i ant - Illinois / ton $184.74 $198.38 $ 2.84 $220.98 $314.17 $305.00 $356.59 $328.26 $378.75 $325.98 $272.02 $325.56 $230.00 $219.88 $217.26 $223.24 $274.51

Poultry By-Product Meal - Feed Grade - Mid South/ton $247.1 $235.00 $ 63.64 $249.10 $308.10 $296.79 $307.73 $305.58 $380.88 $392.83 $313.33 $364.37 $277.50 $277.50 $288.21 $281.43 $300.12

Poultry By-Product Meal - Pet Food - Mid South/ton $498.03 $497.50 $521.48 $506.31 $573.81 $505.83 $588.64 $557.81 $649.38 $596.30 $534.17 $593.47 $533.33 $551.25 $628.45 $571.09 $557.17

Feathermeal - Mid South / ton $255.39 $244.88 $325.45 $277.21 $409.88 $319.05 $342.73 $358.91 $476.88 $452.61 $362.98 $432.57 $325.00 $344.25 $400.95 $356.91 $356.40

2016 Cash Corn Pricing

Competing Ingredient for Bakery Feeds and Fats January February March Q1 Avg. April May June Q2 Avg. July August Sept. Q3 Avg. Oct. Nov. Dec. Q4 Avg. Year Avg.

Corn - Track Central IL #2 Yellow / bushel $3.58 $3.54 $ .52 $3.55 $3.63 $3.77 $3.85 $3.75 $3.28 $3.09 $3.10 $3.16 $3.28 $3.29 $3.32 $3.30 $3.44

European Benchmark Pricing

2016 January February March Q1 Avg. April May June Q2 Avg. July August Sept. Q3 Avg. Oct. Nov. Dec. Q4 Avg. Year Avg.

Palm oil - CIF Rotterdam / metric ton $565 $646 $686 $632 $720 $702 $684 $702 $648 $719 $749 $705 $718 $748 $789 $752 $697.75

Soy meal - CIF Rotterdam / metric ton $339 $326 $320 $328 $341 $420 $465 $409 $439 $399 $372 $403 $363 $358 $360 $360 $375.08

2016 Average Thomson Reuters Prices (USD)

2016 Average Jacobsen Prices (USD)

2016 Average Wall Street Journal Prices (USD)

2017 Finished Product Pricing

Feed Segment Ingredients January February March Q1 Avg. April

Bleachable Fancy Tallow - Chicago Renderer / cwt $32.00 $31.68 $30.50 $31.35 $30.74

Yellow Grease - Illinois / cwt $23.42 $23.70 $24.16 $23.78 $24.61

Meat and Bone Meal - Ruminant - Illinois / ton $258.03 $289.74 $273.91 $270.69 $268.82

Poultry By-Product Meal - Feed Grade - Mid South/ton $290.00 $293.68 $280.00 $287.42 $284.74

Poultry By-Product Meal - Pet Food - Mid South/ton $648.68 $615.13 $644.02 $635.89 $699.34

Feathermeal - Mid South / ton $455.00 $431.84 $386.74 $422.94 $383.95

2017 Cash Corn Pricing 2017 Average Wall Street Journal Prices (USD)

Competing Ingredient for Bakery Feeds and Fats January February arch Q1 Avg. April

Corn - Track Central IL #2 Yellow / bushel $3.46 $3.49 $3.41 $3.45 $3.38

2017 European Benchmark Pricing

Palm Oil - Competing ingredient for edible fats in Food Segment

Soy meal - Competing ingredient for protein meals in Feed Segment January February March Q1 Avg. April

Palm oil - CIF Rotterdam / metric ton $804 $772 $719 $765 $672

Soy meal - CIF Rotterda / metric ton $371 $374 $359 $368 $347

2017 Average Jacobsen Prices (USD)

2017 Average Thomson Reuters Prices (USD)

34

35Fuel Segment - Historical

(1) Pro forma Adjusted EBITDA assumes blenders tax credit was received during quarters earned in 2015 and Q1 2017 for comparison to 2016 when the blenders tax credit was prospective.

US$ and metric tons

(millions)

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Total

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

Revenue $57.0 $46.5 $59.3 $65.4 $228.2 $55.6 $62.3 $60.4 $68.8 $247.1 $59.7

Gross Margin 13.2 6.3 11.4 20.2 51.1 14.9 15.6 14.2 19.9 64.6 13.6

Gross Margin % 23.1% 13.5% 19.2% 30.9% 22.4% 26.8% 25.0% 23.5% 28.9% 26.1% 22.9%

SG&A 4.0 (2.3) 4.5 1.1 7.3 1.9 1.8 1.3 1.9 6.9 3.3

SG&A Margin % 7.0% -4.9% 7.6% 1.7% 3.2% 3.4% 2.9% 2.2% 2.8% 2.8% 5.5%

Operating Income 2.5 2.0 0.2 12.5 17.2 6.1 6.6 6.0 10.5 29.2 3.5

EBITDA 9.1 8.6 7.0 19.2 43.9 13.0 13.8 12.9 18.0 57.7 10.4

Pro forma Adjusted EBITDA (1) $10.2 $10.6 $9.1 $14.0 $43.9 $13.0 $13.8 $12.9 $18.0 $57.7 $12.2

EBITDA Margin % 16.0% 18.5% 11.8% 29.4% 19.2% 23.4% 22.2% 21.4% 26.2% 23.4% 17.4%

Raw Material Processed *

(millions of metric tons)

0.30 0.29 0.27 0.31 1.17 0.28 0.30 0.29 0.31 1.18 0.30

*Excludes raw material processed at the DGD joint venture.

Diamond Green Diesel (50% Joint Venture)

US$ (millions)

Q1

2015

Q2

2015

Q3

2015

Q4

2015

Total

2015

Q1

2016

Q2

2016

Q3

2016

Q4

2016

Total

2016

Q1

2017

EBITDA (Darling's share) $2.3 $7.9 ($8.3) $86.6 $88.5 $9.6 $18.3 $22.5 $36.7 $87.2 $5.0

Pro forma Adjusted EBITDA (1) $19.6 $30.2 $11.7 $27.0 $88.5 $9.6 $18.3 $22.5 $36.7 $87.2 $21.4

36

• JV with Intrexon – April 2016

• Announced construction of commercial-scale production site May 2017

Black soldier fly larvae for a sustainable, cost-effective and complete

aquaculture feed source

o Larvae feed off limited-use waste streams*; produce frass which is used as a high-

protein, low-fat feed ingredient – for aquaculture and animal feed

o Larvae is processed into meal that’s 40% protein/46% fat; oils can be extracted

raising protein to over 70% (aquaculture feed)

o Targeted primarily as feed for aquaculture, reducing dependency on fish and fish oil

as an aquaculture food source

o Frass can also be used as a natural, animal-safe fertilizer (N-P-K – 5%-3%-2%)

*uses co-products from ethanol production, breweries, and pre-consumer food waste

“We produce the

insect proteins to

feed the fish, to

feed the people.”

37

European categories for rendering of animal by-products:

• C3 – food-grade material, for food and feed products

• C2 – unfit for food or animal feed, can be used as fertilizer

• C1 – must be destroyed; used to generate green energy

Note: List excludes administrative and dedicated sales offices.

Locations by Continent and Process

Process USA Canada Europe China S. America Australia Total:

Feed Ingredients Segment

Rendering - (C3 By-producs & UCO) 35 5 18 58

Transfer Stations 54 54

Protein Blending 4 4

Bakery 10 10

Used Cooking Oil (processing only) 8 1 9

Pet Food 3 1 4

Environmental Services 4 4

Blood Processing 1 4 5 1 11

Fertilizer 1 1

Hides 3 3 6

Food Ingredients Segment

Gelatin - Rousselot 2 4 4 3 13

Food Grade Fat Processing 6 6

Casings - CTH 4 1 5

Bone Processing 2 2

Haprin Processing - Hepac 1 1

Fuel Ingredients Sement

Disposal Rendering - Rendac - (C1 & C2) 6 6

Digestion Operation 1 1

Biodiesel 1 1 2

Renewable Diesel (DGD unconsol idated JV) 1 1

127 6 51 10 3 1 198

Under Construction:

Blood processing - Germany 1

Digestion operat n - Belgium 1

Black Soldier Fly La v facility 1

38

Adjusted EBITDA is presented here not as an alternative to net income, but rather as a measure of the Company’s operating

performance and is not intended to be a presentation in accordance with GAAP. Since EBITDA (generally, net income plus

interest expenses, taxes, depreciation and amortization) is not calculated identically by all companies, this presentation may not

be comparable to EBITDA or adjusted EBITDA presentations disclosed by other companies. Adjusted EBITDA is calculated in this

presentation and represents, for any relevant period, net income/(loss) plus depreciation and amortization, goodwill and long-lived

asset impairment, interest expense, (income)/loss from discontinued operations, net of tax, income tax provision, other

income/(expense) and equity in net loss of unconsolidated subsidiary. Management believes that Adjusted EBITDA is useful in

evaluating the Company’s operating performance compared to that of other companies in its industry because the calculation of

Adjusted EBITDA generally eliminates the effects of financing income taxes and certain non-cash and other items that may vary

for different companies for reasons unrelated to overall operating performance.

As a result, the Company’s management uses Adjusted EBITDA as a measure to evaluate performance and for other

discretionary purposes. However, Adjusted EBITDA is not a recognized measurement under GAAP, should not be considered as

an alternative to net income as a measure of operating results or to cash flow as a measure of liquidity, and is not intended to be

a presentation in accordance with GAAP. In addition to the foregoing, management also uses or will use Adjusted EBITDA to

measure compliance with certain financial covenants under the Company’s Senior Secured Credit Facilities and 5.375% Notes

and 4.75% Notes that were outstanding at April 1, 2017. However, the amounts shown in this presentation for Adjusted EBITDA

differ from the amounts calculated under similarly titled definitions in the Company’s Senior Secured Credit Facilities and 5.375%

Notes and 4.75% Notes, as those definitions permit further adjustments to reflect certain other non-recurring costs and non-cash

charges and cash dividends from the DGD Joint Venture. Additionally, the Company evaluates the impact of foreign exchange on

operating cash flow, which is defined as segment operating income (loss) plus depreciation and amortization.