Attached files

| file | filename |

|---|---|

| EX-99.1 - EXHIBIT 99.1 - Hi-Crush Inc. | exhibit991-earningsrelease.htm |

| 8-K - 8-K - Hi-Crush Inc. | q12017-earningsrelease8xk.htm |

INVESTOR PRESENTATION

MAY 2017

Forward Looking Statements

Some of the information included herein may contain forward-looking statements within the meaning of the federal securities

laws. Forward-looking statements give our current expectations and may contain projections of results of operations or of

financial condition, or forecasts of future events. Words such as ―may,‖ ―assume,‖ ―forecast,‖ ―position,‖ ―predict,‖ ―strategy,‖

―expect,‖ ―intend,‖ ―plan,‖ ―estimate,‖ ―anticipate,‖ ―could,‖ ―believe,‖ ―project,‖ ―budget,‖ ―potential,‖ or ―continue,‖ and similar

expressions are used to identify forward-looking statements. They can be affected by assumptions used or by known or

unknown risks or uncertainties. Consequently, no expected results of operations or financial condition or other forward-looking

statements can be guaranteed. When considering these forward-looking statements, you should keep in mind the risk factors

and other cautionary statements in Hi-Crush Partners LP’s (―Hi-Crush‖) reports filed with the Securities and Exchange

Commission (―SEC‖), including those described under Item 1A, ―Risk Factors‖ of Hi-Crush’s Annual Report on Form 10-K for the

fiscal year ended December 31, 2016. Actual results may vary materially. You are cautioned not to place undue reliance on any

forward-looking statements. You should also understand that it is not possible to predict or identify all such factors and should

not consider the risk factors in our reports filed with the SEC or the following list to be a complete statement of all potential risks

and uncertainties. Factors that could cause our actual results to differ materially from the results contemplated by such forward-

looking statements include: whether we are able to complete the Blair acquisition, the volume of frac sand we are able to sell;

the price at which we are able to sell frac sand; the outcome of any litigation, claims or assessments, including unasserted

claims; changes in the price and availability of natural gas or electricity; changes in prevailing economic conditions; and difficulty

collecting receivables. All forward-looking statements are expressly qualified in their entirety by the foregoing cautionary

statements. Hi-Crush’s forward-looking statements speak only as of the date made and Hi-Crush undertakes no obligation to

update or revise its forward-looking statements, whether as a result of new information, future events or otherwise.

2

Strategic Update

Kermit Facility construction. Photo dated April 20, 2017

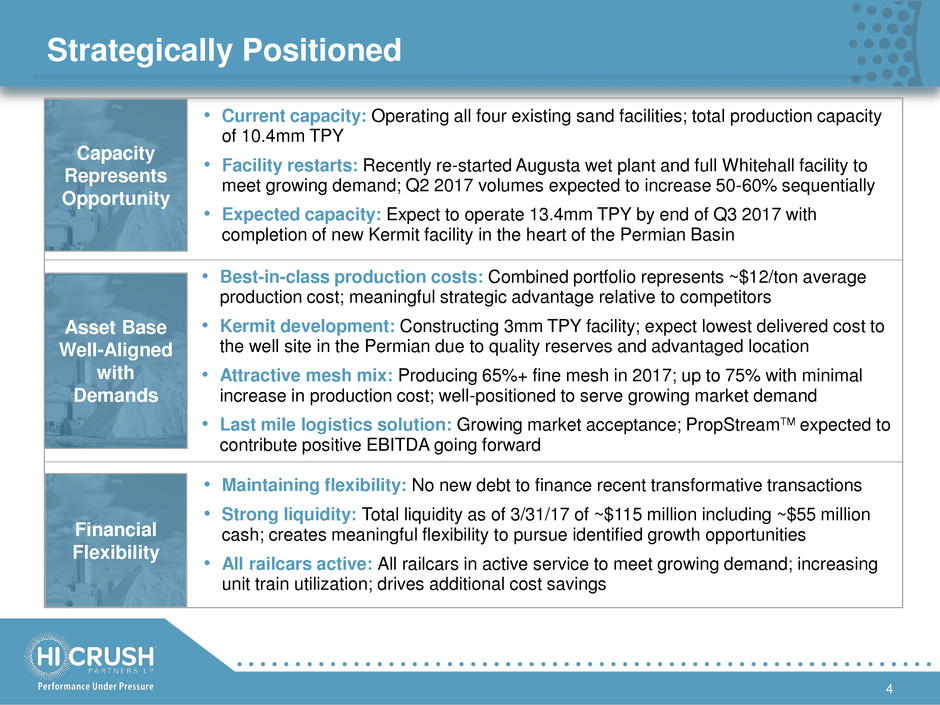

Strategically Positioned

4

Asset Base

Well-Aligned

with

Demands

• Current capacity: Operating all four existing sand facilities; total production capacity

of 10.4mm TPY

• Facility restarts: Recently re-started Augusta wet plant and full Whitehall facility to

meet growing demand; Q2 2017 volumes expected to increase 50-60% sequentially

• Expected capacity: Expect to operate 13.4mm TPY by end of Q3 2017 with

completion of new Kermit facility in the heart of the Permian Basin

Capacity

Represents

Opportunity

• Best-in-class production costs: Combined portfolio represents ~$12/ton average

production cost; meaningful strategic advantage relative to competitors

• Kermit development: Constructing 3mm TPY facility; expect lowest delivered cost to

the well site in the Permian due to quality reserves and advantaged location

• Attractive mesh mix: Producing 65%+ fine mesh in 2017; up to 75% with minimal

increase in production cost; well-positioned to serve growing market demand

• Last mile logistics solution: Growing market acceptance; PropStreamTM expected to

contribute positive EBITDA going forward

Financial

Flexibility

• Maintaining flexibility: No new debt to finance recent transformative transactions

• Strong liquidity: Total liquidity as of 3/31/17 of ~$115 million including ~$55 million

cash; creates meaningful flexibility to pursue identified growth opportunities

• All railcars active: All railcars in active service to meet growing demand; increasing

unit train utilization; drives additional cost savings

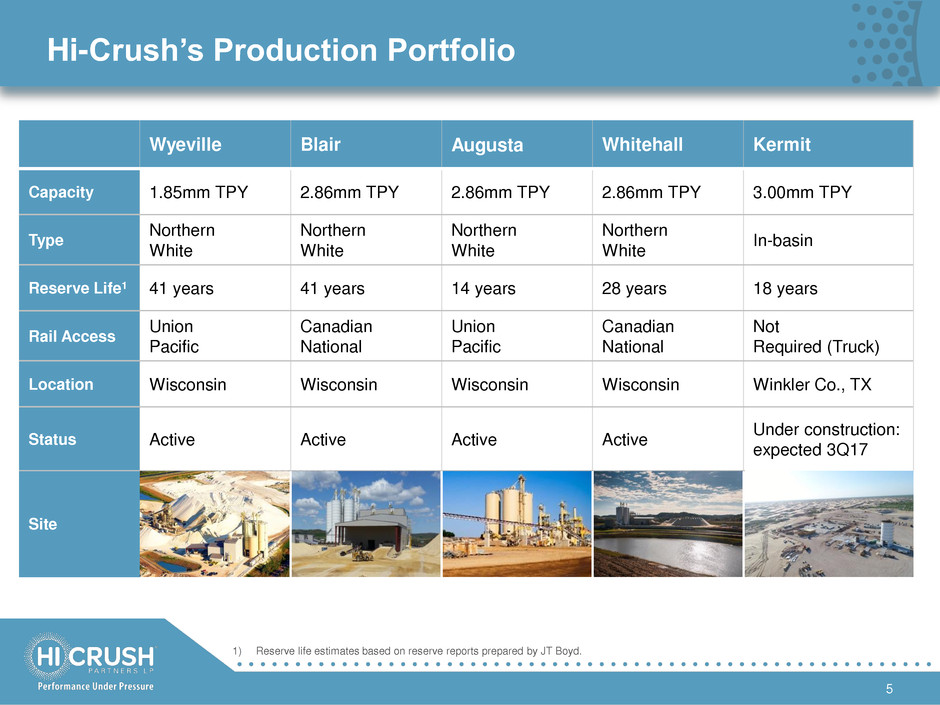

Hi-Crush’s Production Portfolio

5

1) Reserve life estimates based on reserve reports prepared by JT Boyd.

Wyeville Blair Augusta Whitehall Kermit

Capacity 1.85mm TPY 2.86mm TPY 2.86mm TPY 2.86mm TPY 3.00mm TPY

Type

Northern

White

Northern

White

Northern

White

Northern

White

In-basin

Reserve Life1 41 years 41 years 14 years 28 years 18 years

Rail Access

Union

Pacific

Canadian

National

Union

Pacific

Canadian

National

Not

Required (Truck)

Location Wisconsin Wisconsin Wisconsin Wisconsin Winkler Co., TX

Status Active Active Active Active

Under construction:

expected 3Q17

Site

Effective Capacity to Meet Growing Demand

6

Blair

2.86mm TPY

Wyeville

1.85mm TPY

Augusta

2.86mm TPY

Whitehall

2.86mm TPY

Kermit

3.00mm TPY

Fully

Utilized

Partially

Utilized

Restart

(September)

Idle

Not

Owned

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Fully

Utilized

Partially

Utilized

Partially

Utilized

Ramping

Up

Fully

Utilized

Fully

Utilized

Idle

Restart

(March)

Ramping

Up

Fully

Utilized

Fully

Utilized

Not

Owned

Under

Construction

Under

Construction

Ramping

Up

Fully

Utilized

Q3 ‘16 Q4 ‘16 Q1 ‘17 Apr ‘17 Q3 ‘17e Q4 ‘17e

10.4 10.4 10.4 10.4 13.4 13.4 Nameplate Capacity (mm TPY)

Leveraging Our Competitive Advantages

7

1) Facilities and capacity include 3mm TPY Kermit production facility, which is expected to be completed in Q3 2017.

Factor Our Position The Hi-Crush Advantage

Size and

Scale

Five facilities, 13.4mm1

tons of annual capacity

Top-tier supplier with operational flexibility and

ability to meet dynamic customer needs

Supply

Diversity

Leading supplier of

Northern White and in-

basin frac sand

In Q3 2017, expect to operate 13.4mm1 TPY of

low-cost, high-quality production with diversity

of grades and sand types

Low Cost

Market leading cost

structure

Best-in-class cost structure provides

competitive, financial and operational

advantages from mine site to well site

Distribution

Network

Two class-1 rail origins;

strategic and expanding

owned terminal network

Direct access to UP and CN railroads combined

with PropStream last-mile solution extends low-

cost competitive advantages to the well site

Customer

Relationships

Strong, long-term

relationships

Gaining profitable market share through close

partnerships with key customers who are

consolidating their supply sources

Balance

Sheet

Ample liquidity and

significant capital

flexibility

Provides resources if needed; enhances ability

to pursue identified attractive growth

opportunities

Focused

Strategy

A clear strategy to win

long-term

Positioned to profitably capture long-term

market share

Permian Basin Sand Company Acquisition

8

Acquisition Overview

• 55+ million tons of high-quality fine mesh

reserves

• Unique deposit of above-ground sand,

strategically positioned in the heart of the

Permian Basin

• Located within 75-mile radius of significant

Delaware and Midland Basin activity

• Advantaged trucking proximity to key

demand markets; location drives value and

margin premium

• Location and existing infrastructure

address significant barriers to entry for in-

basin supply

• Total consideration of $262mm, funded

with cash from primary common unit

offering and common units to seller

• Closed March 2017

Strategic Alignment

• Constructing purpose-built 3mm TPY

production facility (―Kermit Facility‖)

• Production expected to commence in Q3 2017

• Production costs expected to be in line with all

Hi-Crush facilities

• Contracts with blue chip customers in place for

over 1mm TPY; expect capacity to be

substantially contracted prior to start of

operations

• Year-round operation of wet plant; simplifies

inventory planning process

• Enables expansion of customer base and

enhances service offering

• Opportunity to leverage PropStream

capabilities and avoid logistical bottlenecks;

creates highly efficient mine-to-well solution

servicing all of the Permian basin

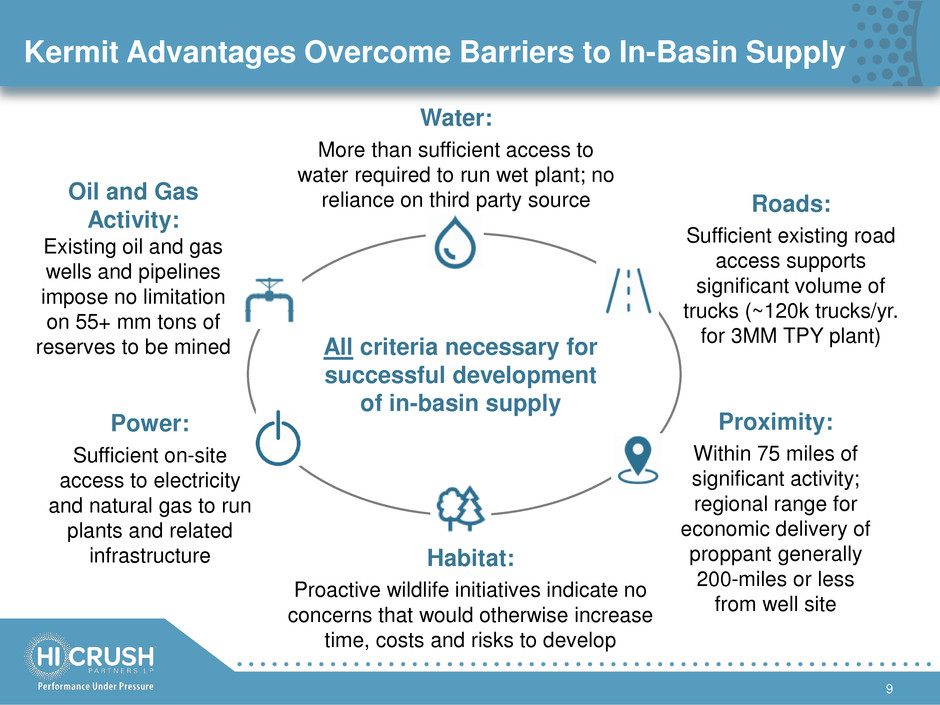

Kermit Advantages Overcome Barriers to In-Basin Supply

9

Roads:

Sufficient existing road

access supports

significant volume of

trucks (~120k trucks/yr.

for 3MM TPY plant)

Proximity:

Within 75 miles of

significant activity;

regional range for

economic delivery of

proppant generally

200-miles or less

from well site

Power:

Sufficient on-site

access to electricity

and natural gas to run

plants and related

infrastructure Habitat:

Proactive wildlife initiatives indicate no

concerns that would otherwise increase

time, costs and risks to develop

Oil and Gas

Activity:

Existing oil and gas

wells and pipelines

impose no limitation

on 55+ mm tons of

reserves to be mined

Water:

More than sufficient access to

water required to run wet plant; no

reliance on third party source

All criteria necessary for

successful development

of in-basin supply

Kermit Facility – Optimally and Uniquely Positioned

10

• Cost advantage: Location and proximity advantage

lowers trucking cost to well, supporting lowest cost

sand - not just in-basin but to well site

• Location: Optimally located to serve both the

Delaware and Midland Basins in the Permian

• Permian activity: Large resource potential with

multiple pay-zones driving outsized activity growth

• Permits: >1,500 horizontal wells permitted within 75-

mile radius of Kermit since January 20171

• Trends: Completion techniques, including longer

laterals and greater proppant loadings maximizes

demand per well

• Demand: Potential frac sand supply shortfall for

Permian demand of 30mm+ tons in 2018 will need to

be filled by a combination of Northern White and

expanded regional supply

• Customers: Multiple large and active operators in

region; source for linked sales with PropStream

100-mile radius of Kermit facility

Delaware Basin counties

Midland Basin counties

Heat map of proppant consumption

Strong Radius of Demand1

1) Source: Navport.

Our Advantage

Pecos Terminal Further Enhances Permian Position

11

• Projected completion date – October 2017

• Complements Kermit facility as incremental

demand in Delaware basin will be supplied by

Northern White sand

• First mover advantage with unit train capable

terminal facility with vertical storage in the

Southern Delaware; also manifest capable with

rail-to-truck operations

• Furthers Hi-Crush strategy of owning and

operating key logistics infrastructure to provide

frac sand from the mine to the well

• Ensures service priority, and creates critical

launching point for last-mile operations, including

PropStream integrated logistics solution

Dedicated rail park and transload terminal for proppant strategically

located in the Delaware Basin

The Pecos Rail Terminal Terminal Overview

Business Update

Volumes Increasing with Utilization to Meet Demand

13

1) Nameplate capacity based on 10.4mm TPY.

898

1,024

1,181

1,482

1,195 1,190

1,409

1,209

963

849

1,083

1,359 1,385

0

400

800

1,200

1,600

2,000

2,400

2,800

Q1 '14 Q2 '14 Q3 '14 Q4 '14 Q1 '15 Q2 '15 Q3 '15 Q4 '15 Q1 '16 Q2 '16 Q3 '16 Q4 '16 Q1 '17 Q2 '17E

000s tons

Volumes Sold

Nameplate Capacity

Q2 2017 volumes expected to increase

50-60% sequentially, run-rate represents

~80-85% of nameplate capacity1

Q1 2017 volumes flat as expected due

to limited wet sand inventory; run-rate

represents ~51% of nameplate capacity

HCLP Quarterly Volumes Sold (000s tons)

Proactively investing through the cycle to meet growing demand

Strong Frac Sand Fundamentals

14

Supportive Fundamentals Targeting of

Shale &

Unconventional

Increased

Horizontal

Drilling

Longer Laterals

Lengths

More Stages per

Foot

More Sand per

Stage

More Wells

Drilled per Rig

GREATER FRAC SAND INTENSITY

Greater frac sand intensity driven by multiple unchanged factors

• Sand intensity trends key driver of

increased demand; ―super fracs‖ growing to

25,000+ tons per well

• Drilled but uncompleted well (―DUC‖)

backlog and represents pent-up demand for

frac sand

• Greenfield and brownfield expansions of

sand supply constrained by multiple factors

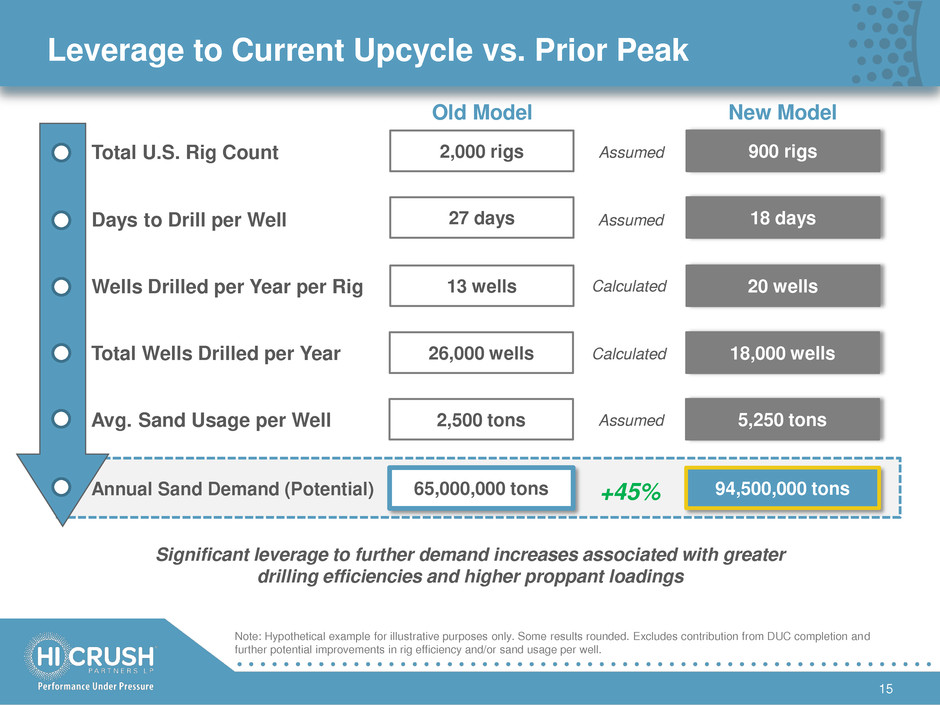

Leverage to Current Upcycle vs. Prior Peak

15

2,000 rigs

27 days

13 wells

26,000 wells

2,500 tons

65,000,000 tons

Total U.S. Rig Count

Days to Drill per Well

Wells Drilled per Year per Rig

Total Wells Drilled per Year

Avg. Sand Usage per Well

Annual Sand Demand (Potential)

Old Model

Note: Hypothetical example for illustrative purposes only. Some results rounded. Excludes contribution from DUC completion and

further potential improvements in rig efficiency and/or sand usage per well.

900 rigs

18 days

20 wells

18,000 wells

5,250 tons

94,500,000 tons

New Model

+45%

Calculated

Calculated

Assumed

Assumed

Assumed

Significant leverage to further demand increases associated with greater

drilling efficiencies and higher proppant loadings

Potential Sand Demand Matrix

16

1) Total U.S. onshore rigs, 2017 YTD average. Source: Baker Hughes.

2) Total U.S. onshore rigs, current as of 4/28/17. Source: Baker Hughes.

3) Estimated average proppant usage per well as of April 2017.

7481 800 850 8532 900 950 1,000

4,500 67 72 77 77 81 86 90

4,750 71 76 81 81 86 90 95

5,000 75 80 85 85 90 95 100

5,2503 79 84 89 90 95 100 105

5,500 82 88 94 94 99 105 110

5,750 86 92 98 98 104 109 115

6,000 90 96 102 102 108 114 120

---------------------------------------------------- Rig Count ------------------------------------------------------

--

--

Sand

Usage/Well

(tons)

-

--

-

• Current onshore rig count of 8532; 2017

YTD average of 7481

• Potential demand upside from drawdown

of DUC inventory; activity not directly

driven by rig activity

Demand Matrix Commentary

• Matrix assumes 18 days to drill; 1 day faster

drill time increases total demand by 4.5MM

TPY (900 total rigs / 5,250 tons/well)

• Average proppant intensity per foot

continues to increase; leading edge

~25,000 tons/well

Logistics Ownership Creates Logistics Flexibility

17

Note: Map does not reflect all third party terminals utilized by Hi-Crush to deliver sand to customers.

• 69% of volumes delivered in-

basin in Q1 2017

• 75%+ of Q1 2017 in-basin

volumes delivered through

Hi-Crush owned and

operated terminals

• Transload priority ensures

highest quality customer

service

• Access to multiple third party

terminals

• Reduced potential for

logistics bottlenecks

• Unit train capabilities at

majority of over 100

origination/destination

pairings

• Expanding in Permian and

other regions; new Pecos

terminal under construction

Bakken

DJ Basin

Permian

MidCon

Eagle

Ford

Marcellus /

Utica

Logistics Network

Kermit facility

Rail-served Sand Facility

Existing Terminal (HCLP owned)

Pecos Terminal (HCLP owned)

Mine-to-Well Sand Facility

Existing Terminal (Third party)

Wisconsin

Augusta

Wyeville

Whitehall

Blair

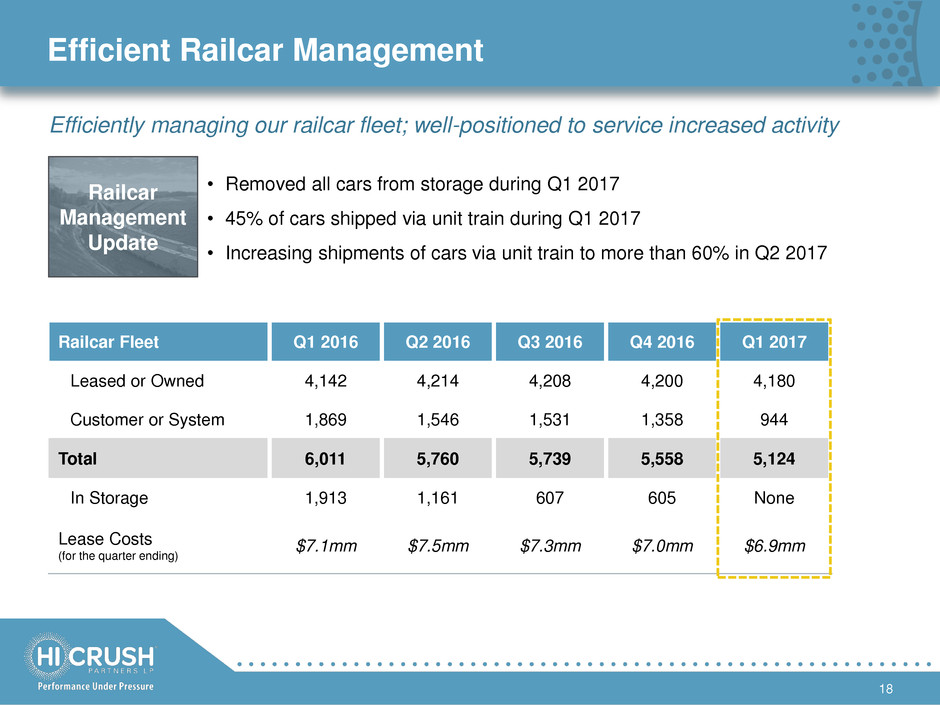

Efficient Railcar Management

18

Railcar Fleet Q1 2016 Q2 2016 Q3 2016 Q4 2016 Q1 2017

Leased or Owned 4,142 4,214 4,208 4,200 4,180

Customer or System 1,869 1,546 1,531 1,358 944

Total 6,011 5,760 5,739 5,558 5,124

In Storage 1,913 1,161 607 605 None

Lease Costs

(for the quarter ending)

$7.1mm $7.5mm $7.3mm $7.0mm $6.9mm

• Removed all cars from storage during Q1 2017

• 45% of cars shipped via unit train during Q1 2017

• Increasing shipments of cars via unit train to more than 60% in Q2 2017

Railcar

Management

Update

Efficiently managing our railcar fleet; well-positioned to service increased activity

PropStream – Streamlining the Supply Chain

19

Differentiated Last-Mile Capabilities

• Developed fully-integrated PropStream delivery

solution to provide containerized mine site to well site

services

• Controls sand quality from origin to the blender hopper

• Purpose-built cubic design – greater tonnage into the

container

• Highly efficient PropBeast™ conveyor systems – up to

20% faster delivery into the blender

• Fully enclosed system reduces particulate matter

emissions by >90% versus pneumatic equipment,

meeting 2018 OSHA requirements today

• Eliminates need for specialized equipment, significantly

reduces capital intensity and other up-front costs

• Fully mobile system of conveyors, containers and

trucks, with a significantly smaller well site footprint

• Lessens well site trucking congestion, reduces or

eliminates demurrage

20

PropStream: Success Achieved in the Market

• No lost-time incidents; greater than

99% uptime performance

• Q1 2017 utilization of 79%; increased

from Q4 2016 utilization of 48%

• 4 crews in Permian and Northeast

currently operating

• Planning for 9 PropStream crews to be

operating by end of 2017

Performance and Strategy

21

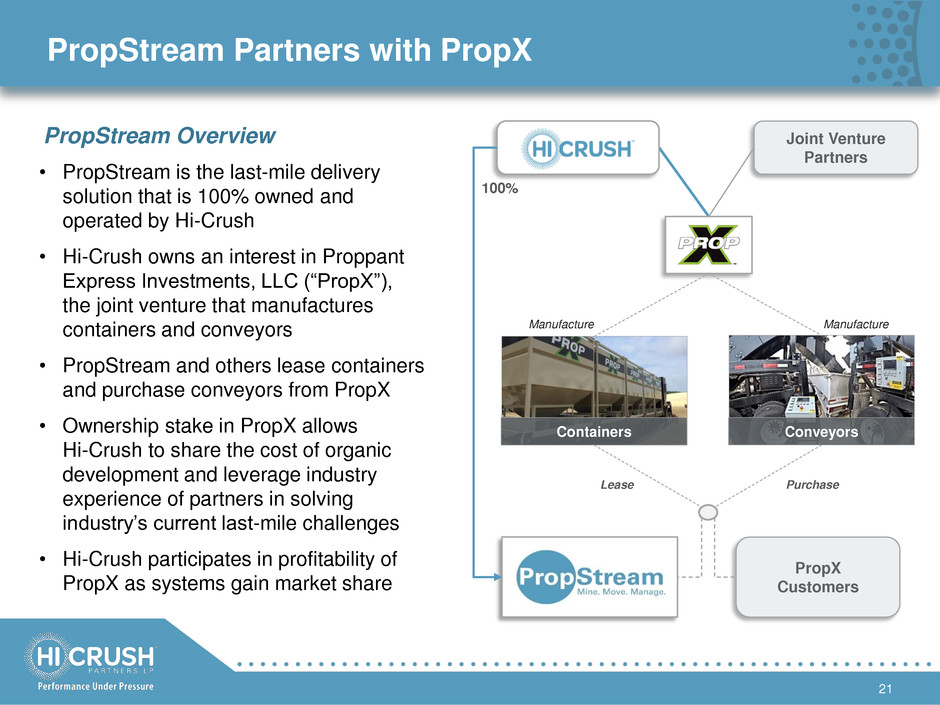

PropStream Partners with PropX

• PropStream is the last-mile delivery

solution that is 100% owned and

operated by Hi-Crush

• Hi-Crush owns an interest in Proppant

Express Investments, LLC (―PropX‖),

the joint venture that manufactures

containers and conveyors

• PropStream and others lease containers

and purchase conveyors from PropX

• Ownership stake in PropX allows

Hi-Crush to share the cost of organic

development and leverage industry

experience of partners in solving

industry’s current last-mile challenges

• Hi-Crush participates in profitability of

PropX as systems gain market share

Joint Venture

Partners

100%

Conveyors Containers

Manufacture Manufacture

Lease Purchase

PropX

Customers

PropStream Overview

PropX Systems Are Poised to Grow Market Share

22

• Rapid market acceptance of containerized last-mile solutions

• Successful roll-out enabling PropX to quickly grow market share

• PropX projected to achieve 10%+ market share within 15 months of launch

Systems Deployed

1 2

9

0

5

10

15

20

25

30

35

Q3 2016 Q4 2016 Q1 2017 Q4 2017

Systems PropStream Third Parties

10%+ Total Market Share

Financial Results

Comparison to Prior Quarters (Q1 2017)

24

$ in 000s, except per unit/ton Q1 2016 Q2 2016 Q3 2016 Q4 2016 Q1 2017

Revenues $ 52,148 $ 38,429 $ 46,556 $ 67,297 $ 83,364

Adjusted EBITDA1 ($ 11,204) ($ 3,401) ($ 3,461) ($ 334) $ 1,911

Average selling price ($/ton) $54 $45 $43 $49 $60

Sales volumes (tons) 962,998 849,263 1,082,974 1,358,511 1,384,887

Contribution margin ($/ton)2 $ 3.61 $ 3.54 $ 4.50 $ 3.51 $ 8.15

Note: Amounts have been recast to include the financial position and results attributable to Hi-Crush Blair LLC, Hi-Crush Whitehall LLC and Other Assets.

1) Adjusted EBITDA is defined as net income (loss) plus depreciation, depletion and amortization and interest and debt expense, net of interest income

adjusted for earnings (loss) from equity method investments and any non-cash impairments of long-lived assets and goodwill. Q1 2017 was impacted

by one-time expenses including $794 of costs associated with storage of idled railcars and costs to place railcars back in active service, $516 of

acquisition related costs in connection with the Whitehall Contribution and $325 of nonrecurring business development expenses.

2) Contribution margin is defined as total revenues less costs of goods sold excluding depreciation, depletion and amortization. Contribution margin

excludes other operating expenses and income, including costs not directly associated with the operations of our business such as accounting, human

resources, information technology, legal, sales and other administrative activities.

• Revenues benefited from the realization of higher pricing beginning in Q4 2016

• Q1 2017 was impacted by $1.6 million of one-time expenses

• As expected, Q1 2017 volumes largely flat sequentially; limited due to wet sand inventory and rapid

demand growth; expect significant improvement in Q2 2017 sequential volumes as plants re-start

• Contribution margin impacted $2 per ton by winter effects; expected to improve in the near-term as

facilities approach 100% of capacity

Improved Liquidity and Financial Flexibility

25

$ in 000s December 31, 2016 March 31, 2017

Cash $ 4,521 $ 55,498

Revolver $ - $ -

Term loan1 189,715 189,490

Other notes payable 6,705 5,743

Total debt $ 196,420 $ 195,233

Net debt $ 191,899 $ 139,735

Revolver availability2 $ 66,368 $ 59,681

Available liquidity3 $ 70,889 $ 115,179

1) Senior secured term loan: $200 mm original face value at L+3.75%; rated Caa1 and B by Moody’s and Standard & Poor’s,

respectively; includes accordion feature to increase capacity to $300 mm. Presented net of discounts and issuance costs.

2) Revolving credit agreement at 3/31/17: $59.7 mm available at L+4.50% ($75 mm capacity less $15.3 mm of LCs); includes

accordion feature to increase capacity to $125 mm.

3) Revolver availability plus cash.

Credit Facility Provides Liquidity and Flexibility

26

1) Calculated as: (Fixed assets book value + eligible accounts receivable and inventory) / total funded debt.

2) Effective Period through June 29, 2017.

3) Leverage and interest coverage ratios for Q2 2017 – Q4 2017 based on annualized figures beginning April 1, 2017.

• Capacity: Total revolver capacity of $75mm

• 2017 Covenants: Leverage ratio maximum

and interest coverage minimum; all with

equity cure provision

• Equity Cure: Equity cure provision

available to cover any covenant shortfalls

• Asset Coverage1: Minimum of 1.0x to draw

funds during Effective Period2

• Permitted Distributions: Limited to 50% of

DCF less scheduled amortization payments

during Effective Period2

5.0x

4.5x

4.0x

3.5x

0x

1x

2x

3x

4x

5x

6x

Q2 2017 Q3 2017 Q4 2017 Q1 2018

$mm

Leverage Ratio Maximum3

and

thereafter

Equity cure provision available to address any

potential EBITDA covenant shortfalls

Credit Facility Terms Covenant Overview

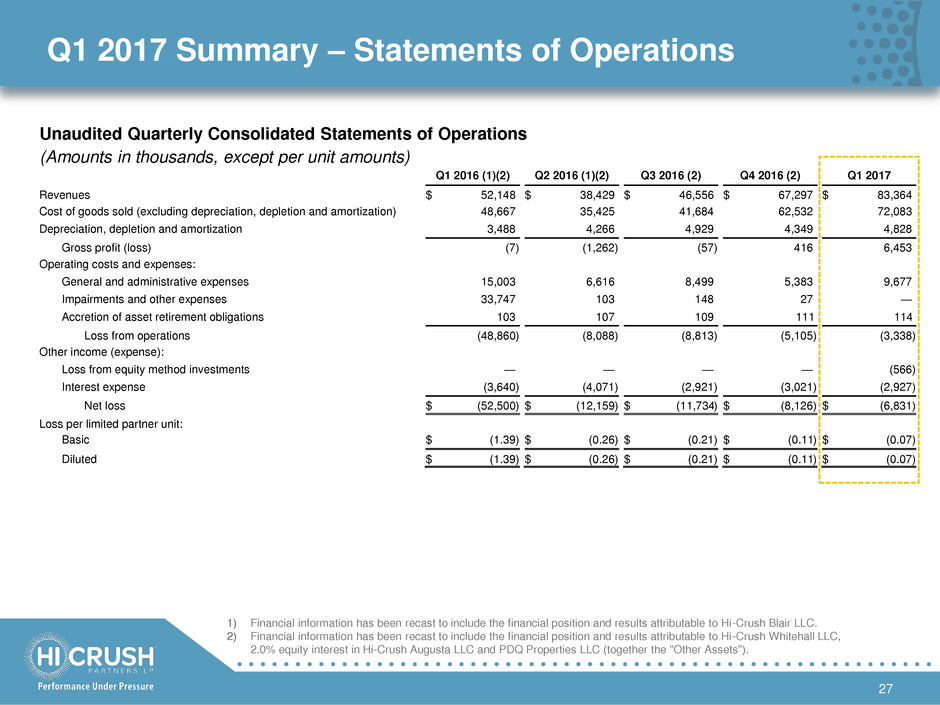

Q1 2017 Summary – Statements of Operations

27

1) Financial information has been recast to include the financial position and results attributable to Hi-Crush Blair LLC.

2) Financial information has been recast to include the financial position and results attributable to Hi-Crush Whitehall LLC,

2.0% equity interest in Hi-Crush Augusta LLC and PDQ Properties LLC (together the "Other Assets").

Unaudited Quarterly Consolidated Statements of Operations

(Amounts in thousands, except per unit amounts)

Q1 2016 (1)(2) Q2 2016 (1)(2) Q3 2016 (2) Q4 2016 (2) Q1 2017

Revenues $ 52,148 $ 38,429 $ 46,556 $ 67,297 $ 83,364

Cost of goods sold (excluding depreciation, depletion and amortization) 48,667 35,425 41,684 62,532 72,083

Depreciation, depletion and amortization 3,488 4,266 4,929 4,349 4,828

Gross profit (loss) (7 ) (1,262 ) (57 ) 416 6,453

Operating costs and expenses:

General and administrative expenses 15,003 6,616 8,499 5,383 9,677

Impairments and other expenses 33,747 103 148 27 —

Accretion of asset retirement obligations 103 107 109 111 114

Loss from operations (48,860 ) (8,088 ) (8,813 ) (5,105 ) (3,338 )

Other income (expense):

Loss from equity method investments — — — — (566 )

Interest expense (3,640 ) (4,071 ) (2,921 ) (3,021 ) (2,927 )

Net loss $ (52,500 ) $ (12,159 ) $ (11,734 ) $ (8,126 ) $ (6,831 )

Loss per limited partner unit:

Basic $ (1.39 ) $ (0.26 ) $ (0.21 ) $ (0.11 ) $ (0.07 )

Diluted $ (1.39 ) $ (0.26 ) $ (0.21 ) $ (0.11 ) $ (0.07 )

Q1 2017 Summary – EBITDA, Adjusted EBITDA & DCF

28

Unaudited EBITDA, Adjusted EBITDA and Distributable Cash Flow

(Amounts in thousands)

1) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated

reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with

the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long-term operating

capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital.

2) The Partnership's historical financial information has been recast to consolidate Hi-Crush Blair LLC, Hi-Crush Whitehall LLC and Other

Assets for the periods leading up to their contribution into the Partnership. For purposes of calculating distributable cash flow

attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recast distributable cash flow earned during

the periods prior to the contributions.

Q1 2016 Q2 2016 Q3 2016 Q4 2016 Q1 2017

Reconciliation of distributable cash flow to net loss:

Net loss $ (52,500 ) $ (12,159 ) $ (11,734 ) $ (8,126 ) $ (6,831)

Depreciation and depletion expense 3,491 4,266 4,932 4,350 4,829

Amortization expense 420 421 420 421 420

Interest expense 3,640 4,071 2,921 3,021 2,927

EBITDA (44,949 ) (3,401 ) (3,461 ) (334 ) 1,345

Loss from equity method investments — — — — 566

Non-cash impairments of goodwill and long-lived assets 33,745 — — — —

Adjusted EBITDA (11,204 ) (3,401 ) (3,461 ) (334 ) 1,911

Less: Cash interest paid (3,246 ) (3,344 ) (2,548 ) (2,649 ) (2,554)

Less: Maintenance and replacement capital expenditures, including

accrual for reserve replacement (1) (1,245 ) (1,164 ) (1,554 ) (1,717 ) (1,845)

Add: Accretion of asset retirement obligations 103 107 109 111 114

Add: Unit-based compensation 930 930 1,155 (395 ) 1,178

Distributable cash flow (14,662 ) (6,872 ) (6,299 ) (4,984 ) (1,196)

djusted for: Distributable cash flow attributable to assets contributed by

the sponsor, prior to the period in which the contribution occurred (2) 835

627

(400 ) 579

1,247

Distributable cash flow attributable to Hi-Crush Partners LP (13,827 ) (6,245 ) (6,699 ) (4,405 ) 51

Less: Distributable cash flow attributable to holders of incentive

distribution rights —

—

—

—

—

Distributable cash flow attributable to limited partner unitholders $ (13,827 ) $ (6,245 ) $ (6,699 ) $ (4,405 ) $ 51

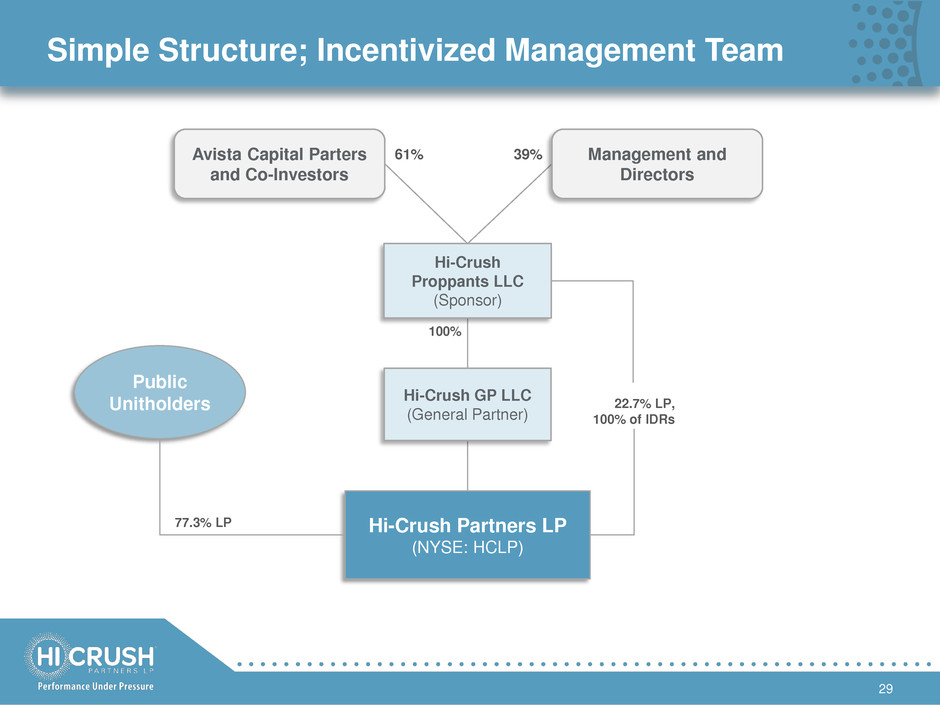

Simple Structure; Incentivized Management Team

29

39% 61%

100%

77.3% LP

22.7% LP,

100% of IDRs

Hi-Crush

Proppants LLC

(Sponsor)

Avista Capital Parters

and Co-Investors

Management and

Directors

Hi-Crush Partners LP

(NYSE: HCLP)

Public

Unitholders

Hi-Crush GP LLC

(General Partner)