Attached files

| file | filename |

|---|---|

| EX-32.1 - EX-32.1 - ROCKWELL MEDICAL, INC. | rmti-20161231ex321c08810.htm |

| EX-31.2 - EX-31.2 - ROCKWELL MEDICAL, INC. | rmti-20161231ex312b37b8c.htm |

| EX-31.1 - EX-31.1 - ROCKWELL MEDICAL, INC. | rmti-20161231ex3115e9e2c.htm |

| EX-23.1 - EX-23.1 - ROCKWELL MEDICAL, INC. | rmti-20161231ex231c424b4.htm |

vh

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10‑K

|

(Mark One) |

|

|

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

|

|

|

For the fiscal year ended December 31, 2016 |

|

|

|

|

|

OR |

|

|

|

|

|

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

|

|

|

For the transition period from to |

|

Commission file number 000‑23661

ROCKWELL MEDICAL, INC.

(Exact name of registrant as specified in its charter)

|

Michigan |

38‑3317208 |

|

30142 Wixom Road Wixom, Michigan |

48393 |

(248) 960‑9009

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Title of Each Class: |

|

Name of each exchange on which registered: |

|

Common Stock, no par value |

|

Nasdaq Global Market |

Securities registered pursuant to Section 12(g) of the Act:

(None)

Indicate by check mark if the registrant is a well‑known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S‑T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S‑K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10‑K. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non‑accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b‑2 of the Exchange Act. (Check one):

|

Large accelerated filer ☐ |

Accelerated filer ☒ |

Non‑accelerated filer ☐ |

Smaller reporting company ☐ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b‑2 of the Exchange Act). Yes ☐ No ☒

The aggregate market value of the registrant’s voting and non‑voting common equity held by non‑affiliates of the registrant on June 30, 2016 (computed by reference to the closing sales price of the registrant’s Common Stock as reported on the Nasdaq Global Market on such date) was $318,842,000. For purposes of this computation, shares of common stock held by our executive officers, directors and common shareholders with 10% or more of the outstanding shares of Common Stock were excluded. Such determination should not be deemed an admission that such officers, directors and beneficial owners are, in fact, affiliates.

Number of shares outstanding of the registrant’s Common Stock, no par value, as of February 17, 2017: 51,527,711 shares.

Documents Incorporated by Reference

Portions of the Registrant’s definitive Proxy Statement pertaining to the 2017 Annual Meeting of Shareholders (the “Proxy Statement”) to be filed pursuant to Regulation 14A are herein incorporated by reference in Part III of this Annual Report on Form 10‑K.

References to “Rockwell”, the “Company,” “we,” “us” and “our” are to Rockwell Medical, Inc. and its subsidiaries unless otherwise specified or the context otherwise requires.

Triferic®, CitraPure®, RenalPure® and SteriLyte® are registered trademarks of Rockwell.

Forward Looking Statements

We make forward‑looking statements in this report and may make such statements in future filings with the Securities and Exchange Commission, or SEC. We may also make forward‑looking statements in our press releases or other public or shareholder communications. Our forward‑looking statements are subject to risks and uncertainties and include information about our expectations and possible or assumed future results of our operations. When we use words such as “may,” might,” “will,” “should,” “believe,” “expect,” “anticipate,” “estimate,” “continue”, “predict”, “forecast”, “projected,” “intend” or similar expressions, or make statements regarding our intent, belief, or current expectations, we are making forward‑looking statements. Our forward looking statements also include, without limitation, statements about our competitors, statements regarding the commercialization of our new products, statements regarding our new products such as Triferic and Calcitriol, and statements regarding our anticipated future financial condition, operating results, cash flows and business and financing plans.

We claim the protection of the safe harbor for forward‑looking statements contained in the Private Securities Litigation Reform Act of 1995 for all of our forward‑looking statements. While we believe that our forward‑looking statements are reasonable, you should not place undue reliance on any such forward‑looking statements, which are based on information available to us on the date of this report or, if made elsewhere, as of the date made. Because these forward‑looking statements are based on estimates and assumptions that are subject to significant business, economic and competitive uncertainties, many of which are beyond our control or are subject to change, actual results could be materially different. Factors that might cause such a difference include, without limitation, the risks and uncertainties discussed in this report, including without limitation in “Item 1A—Risk Factors,” and from time to time in our other reports filed with the SEC. Other factors not currently anticipated may also materially and adversely affect our results of operations, cash flows and financial position. We do not undertake, and expressly disclaim, any obligation to update or alter any statements whether as a result of new information, future events or otherwise except as required by law.

1

PART I

Item 1. Business.

General

Rockwell Medical, Inc., incorporated in the state of Michigan in 1996, is a fully‑integrated biopharmaceutical company targeting end‑stage renal disease (“ESRD”) and chronic kidney disease with innovative products and services for the treatment of iron deficiency, secondary hyperparathyroidism and hemodialysis (also referred to as “dialysis”).

Triferic

Rockwell’s lead drug, Triferic was approved by United States Food and Drug Administration (“FDA”) in late January 2015. Triferic is the only FDA-approved therapy indicated to replace iron and maintain hemoglobin in adult hemodialysis patients with chronic kidney disease. Triferic is an innovative iron therapy that replaces the ongoing iron loss that occurs to patients during every hemodialysis treatment, via dialysate. Triferic’s unique mode-of-action enables it to bind to transferrin immediately and completely once entering the blood, where it then is transported to the bone marrow to make hemoglobin.

We are actively marketing and commercializing Triferic in the United States hemodialysis market which is currently the largest market in the world for dialysis products. Feedback from users in the commercial market has been positive and consistent with our clinical program, which demonstrated maintenance of hemoglobin concentration and significant reduction in ESA use.

Because Medicare pays for treatment of the vast majority of all dialysis patients, reimbursement status is important to Rockwell’s ability to successfully commercialize Triferic. Triferic has been approved for reimbursement by the Centers for Medicare & Medicaid Services (“CMS”) as part of the standard “bundled” payment received by dialysis service providers for providing treatment to patients. In late 2015, we requested clarification from CMS on whether Triferic qualified for transitional add-on reimbursement and CMS confirmed to us that Triferic was included as part of the bundle in January 2016. Since that time, we have pursued securing transitional add-on reimbursement status for Triferic which provides separate reimbursement for two years outside of the bundled payment. We believe add-on reimbursement status is warranted for new innovative therapies such as Triferic so that patients have access to them and so that companies will commit the time and monetary resources to innovation in the renal space. We also believe that there is legal support in the Protecting Access to Medicare Act of 2014 for our position, and there is precedent for CMS granting add-on reimbursement status to a recent therapy after initially placing it in the bundle payment. CMS itself has stated that add-on reimbursement status for new innovative therapies is important. Triferic has received strong Congressional support for transitional add-on reimbursement status from multiple members of Congress, who have requested in writing that CMS and the Secretary of the Department of Health and Human Services provide it. Triferic has also received support from patient advocacy groups and dialysis service providers. Management believes there is high likelihood that Triferic receives transitional add-on reimbursement status, and that Triferic will become the standard of care for iron maintenance therapy in both the United States and globally regardless of reimbursement status, but that transitional add-on reimbursement would accelerate sales and adoption in the United States commercial market.

We are working to commercialize Triferic globally and we intend to continue to out-license Triferic to partner companies who we believe are best suited to commercialize Triferic. We executed license agreements in 2016 for Triferic and Calcitriol for the Chinese market as well as the Kingdom of Saudi Arabia and several other Middle East markets. Both markets are large and China is expected to become the largest in the world over the next several years. Commercial sales activity in these markets will commence following regulatory or registration approval. Rockwell retains manufacturing responsibilities for both Triferic and Calcitriol. We have also executed a distribution agreement to market Triferic in Canada, where we anticipate commercial availability in 2019 after regulatory approval. Additionally, we have formed a wholly-owned subsidiary in India to market Triferic where we anticipate market availability in 2018. We remain actively engaged in licensing negotiations for Triferic in a number of other regions and countries. We intend to leverage the development, regulatory and commercial presence and expertise of potential business partners to accelerate sales of our products throughout the world.

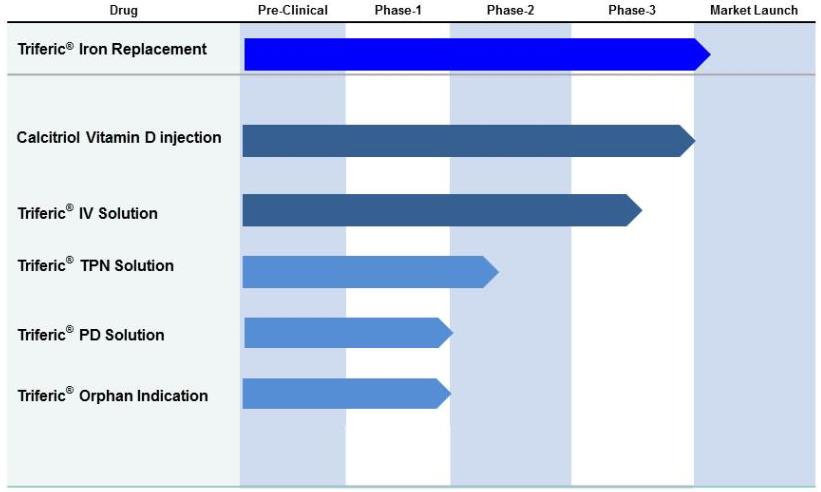

We are currently executing development of Triferic for other clinical indications. These clinical applications include peritoneal dialysis (PD), total parenteral nutrition (TPN) and an orphan indication, that if successful may lead to

2

treating cancer patients. We are also developing an intravenous injection for use in other iron deficiency anemia indications. Rockwell’s drug product pipeline is summarized below by stage of development.

Calcitriol

Rockwell’s FDA approved generic drug, Calcitriol, is for treating secondary hyperparathyroidism in dialysis patients. Calcitriol (active vitamin D) injection is indicated in the management of hypocalcemia in patients undergoing chronic renal dialysis. It has been shown to significantly reduce elevated parathyroid hormone (“PTH”) levels. Reduction of PTH has been shown to result in an improvement in renal osteodystrophy. Based on industry estimates, we believe the United States market for vitamin D therapy for ESRD patients is about $200 million per year. We estimate that there are currently over 60,000,000 vitamin D treatments per year in the ESRD market in the United States. We recently were asked by the FDA to resubmit our manufacturing approval under a Prior Approval Supplement (“PAS”) and we intend to do so. As a result, we anticipate commercial availability during the second half of 2017. We intend to market Calcitriol to hemodialysis providers in the United States and elsewhere as soon as we have sufficient inventory.

Concentrate Business

Rockwell is an established manufacturer and leader in delivering high-quality hemodialysis concentrates/dialysates to dialysis providers and distributors in the United States and abroad. As one of the two major suppliers in the United States, Rockwell’s products are used to maintain human life by removing toxins and replacing critical nutrients in the dialysis patient’s bloodstream. Rockwell has three United States manufacturing/distribution facilities. Rockwell sells its concentrate products in the United States pursuant to an Exclusive Distribution Agreement (the “Distribution Agreement”) with Baxter Healthcare Corporation (“Baxter”) under which Baxter is our exclusive distributor. We have entered into an arbitration proceeding with Baxter related to the Distribution Agreement. See “Item 3 – Legal Proceedings.”

The Hemodialysis Market

3

The great majority of hemodialysis patients receive dialysis treatment three times per week, or approximately 156 times per year. Most patients have their dialysis treatment performed at a free-standing clinic for permanent loss of kidney function; these are called “chronic” patients. Some have their treatment performed at hospitals for temporary loss of kidney function; these are called “acute” patients. A small percent of chronic patients receive their treatment at home; these are called “home” patients. In each setting, a dialysis machine dilutes concentrated solution, such as Rockwell’s concentrate products, with purified water. The resulting solution is called dialysate. Dialysate is pumped through an artificial kidney or filter (called a dialyzer) while the patient's blood is pumped through a semi-permeable membrane inside the dialyzer in the opposite direction the dialysate is flowing. The dialysate infuses calcium, magnesium and bicarbonate into the patient’s blood while removing water and waste. Dialysate generally contains dextrose, sodium chloride, calcium, potassium, magnesium, sodium bicarbonate and citric acid or acetic acid. The patient's physician chooses the proper concentrations required for each patient based on each particular patient's needs.

In addition to using reusable concentrate products, a dialysis provider also uses other products such as blood tubing, fistula needles, dialyzers, drugs, specialized component kits, dressings, cleaning agents, filtration salts and other supplies, many of which we sell.

Dialysis Industry Trends

Hemodialysis is the primary treatment modality employed in the United States with over 90% of all dialysis patients receiving hemodialysis. The Company does not compete in the peritoneal or home dialysis segments. Hemodialysis treatments are primarily performed in freestanding clinics, as well as in some hospitals. The majority of dialysis services are performed by national and regional for profit dialysis chains. Based on data published by the United States Renal Data Systems (“USRDS”) we estimate that there are approximately 7,000 Medicare-certified treatment clinics in the United States. The two largest national for-profit dialysis chains service approximately 70% of the domestic hemodialysis market. According to the most recent statistics published by USRDS, there were approximately 460,000 dialysis patients in the United States as of the end of 2014.

Based on a global market study published by a major dialysis products manufacturer, the global ESRD population receiving some form of treatment was estimated to be over 2.8 million patients at the end of 2016 with the overall global patient population growing approximately 7-8% annually. According to the National Kidney Foundation, 10% of the worldwide population is affected by chronic kidney disease and millions die each year because they do not have access to affordable treatments. We have observed that the ESRD patient population in the United States has grown steadily over the past several decades and, coupled with data provided in that report, we expect the United States dialysis population to grow approximately 3-4% annually over the next several years. The Asia-Pacific market is projected to experience rapid growth in both the incidence of kidney disease and by total treatment in the ESRD population over the decade ahead.

Drug Products

Triferic (Ferric Pyrophosphate Citrate)

Iron deficiency anemia is pervasive for chronic patients receiving dialysis. Triferic is the only FDA approved drug indicated to replace iron and maintain hemoglobin in hemodialysis patients. We believe Triferic will become the standard of care in iron maintenance therapy for dialysis patients and address an important unmet need in the treatment of anemia in ESRD patients.

Triferic is an innovative iron therapy that replaces the iron lost by patients during every hemodialysis treatment. Triferic’s unique mode-of-action enables it to bind to transferrin immediately and completely once entering the blood via dialysate, where it then is transported to the bone marrow to make hemoglobin. Triferic delivers sufficient iron to the bone marrow and maintains hemoglobin without increasing iron stores (ferritin).

To address anemia associated with the ongoing blood losses associated with dialysis, long standing industry practice has been to inject patients with intravenous (“IV”) iron and erythropoiesis stimulating agents (“ESAs”). ESA is synthetic erythropoietin that acts in the bone marrow, together with iron, to increase the production of red blood cells, which carry oxygen throughout the body to nourish tissues and sustain life. Hemoglobin is an important constituent of red blood cells and is composed largely of iron and protein. IV iron was approved for use in hemodialysis patients in the 1990’s as there was no other iron product available that could work effectively with ESA. IV iron products metabolize

4

in the liver. Because of the constant inflammation levels present in hemodialysis patients the great majority of IV iron gets trapped in the patient’s liver, blocked by a protein called hepcidin. In contrast to Triferic, IV iron is unable to bind immediately to transferrin and travel to the bone marrow. IV iron is a repletion therapy, not an iron maintenance therapy.

Triferic is distinctly different from IV iron. Triferic is different in molecular structure, different in mode-of-action (bypassing liver storage) and different in FDA approved indication (to replace iron and maintain hemoglobin). Triferic is an iron maintenance therapy approved to be given to patients every treatment whereas IV iron is a repletion or “rescue” therapy approved to be given only when a patient experiences significant blood loss and has a ferritin level < 200 ng/mL. The current average ferritin level in dialysis patients in the U.S. has increased significantly to in excess of 750 ng/mL according to US-DOPPS Practice Monitor published December 2016. Triferic delivers iron and maintains hemoglobin without increasing iron stores (ferritin).

Triferic has demonstrated an excellent safety profile in its Phase 3 clinical program and has not been attributed to any anaphylaxis in an estimated 200,000 administrations. We received FDA approval to market Triferic in liquid form in 2015 and in powder form in 2016.

Calcitriol (Active Vitamin D) Injection

Calcitriol is a generic active vitamin D and is indicated for the treatment of secondary hyperparathyroidism in dialysis patients. The majority of ESRD patients receive vitamin D on a routine basis using primarily one of two branded drugs or in some cases oral drugs. Clinical data shows Calcitriol to be clinically equivalent in safety and efficacy to the two branded drugs as well as the most potent and physiological vitamin D therapy. We believe the lower cost of Calcitriol will entice dialysis providers to purchase it over current vitamin D options.

Out-Licensing Arrangements for Drug Products

We have made significant progress with our international business development effort for Triferic, including securing a licensing agreement with Wanbang Biopharmaceutical in the first quarter of 2016 for the rights to commercialize Triferic and Calcitriol for ESRD patients in the People’s Republic of China. Under the terms of the Wanbang Agreement, we received an upfront payment of $4 million, which we are recognizing over the term of the agreement. Rockwell may also receive milestone payments of up to an additional $35 million over the life of the agreement in regulatory and revenue milestone payments plus ongoing earnings on product sales.

In the third quarter of 2016, we entered into an exclusive license and manufacturing supply with ARAM Medical for the sale of Triferic and Calcitriol in the Kingdom of Saudi Arabia and a number of other countries in the Middle East for an initial term of 10 years. In consideration for the exclusive rights, ARAM Medical will pay us a $1 million licensing fee and a royalty on product sales, and has committed to annual minimum purchase quantities. ARAM Medical will also assume responsibility for all clinical and regulatory expenses for the countries covered by its agreement. Rockwell retains manufacturing responsibilities for both Triferic and Calcitriol.

Dialysis Concentrate Products

We manufacture, sell, deliver and distribute hemodialysis concentrates, along with a full line of ancillary products abroad. We use Baxter as our exclusive marketer and distributor in the United States and in select foreign markets. Dialysate concentrates accounted for over 95% of our 2016 revenue with ancillary products accounting for most of the remainder. All of our products are manufactured according to Association for the Advancement of Medical Instrumentation and current good manufacturing practices (“cGMP”) guidelines. Our concentrate products are diluted with clean water on-site at the clinic in the dialysis machine, creating dialysate, which works to clean the patient’s blood.

CitraPure Citric Acid Concentrate

Our CitraPure Concentrate is 100% acetate-free, in contrast to the acetate-based products used for many years. Acetate promotes inflammation so its removal is beneficial to the patient. Citrate has anticoagulant properties and has been shown in clinical studies to reduce the need for heparin during dialysis treatment (although CitraPureis not

5

indicated for heparin sparing). is packaged as a liquid and as a dry powder acid concentrate for use with our Dry Acid Concentrate Mixer. CitraPure contains citric acid, sodium chloride, dextrose, magnesium, potassium and calcium. CitraPure is packaged as dry acid concentrate in 25 gallon cases and liquid acid concentrate in 55 gallon drums and four one gallon jugs to a case.

Dri-Sate Dry Acid Concentrate

Our Dri-Sate Concentrate is our original acetate-based product. Dri-Sate is packaged as a dry powder acid concentrate for use with our Dry Acid Concentrate Mixer. Dri-Sate contains acetic acid, sodium chloride, dextrose, magnesium, potassium and calcium. Dri-Sate is packaged as dry acid concentrate in 25 gallon cases.

Renal Pure Liquid Acid Concentrate

Our RenalPure Liquid Concentrate is acetate-based and contains acetic acid, sodium chloride, dextrose, magnesium, potassium and calcium and packaged in 55 gallon drums and four one gallon jugs to a case.

Dry Acid Concentrate Mixer

Our Dry Acid Concentrate Mixer is designed for our CitraPureand Dri-Sate Dry Acid product and enables the clinic to mix acid concentrate on-site. Clinics using Rockwell’s Dry Acid Concentrate products realize numerous advantages, including lower cost per treatment, reduced storage space requirements, reduced number of deliveries and more flexibility in scheduling deliveries, while enabling the Company to reduce distribution and warehousing costs.

RenalPure and SteriLyte Bicarbonate Concentrate

RenalPure bicarbonate is a dry powder mixed on-site at the clinic and is packaged for bulk and individual treatment and SteriLyte bicarbonate is a liquid packaged in four one gallon jugs to a case and is used mainly in acute care settings.

Ancillary Products

We offer a wide range of ancillary products including blood tubing, fistula needles, specialized custom kits, dressings, cleaning agents, filtration salts and other supplies used by hemodialysis providers.

Distribution Agreement with Baxter

Pursuant to the Distribution Agreement, Baxter is our exclusive agent for commercializing our hemodialysis concentrate and ancillary products in the United States and various foreign countries for an initial term of 10 years. We retain sales, marketing and distribution rights for our hemodialysis concentrate products for our international customers and in those countries in which we have an established commercial presence. During the term of the Distribution Agreement, Baxter has agreed not to manufacture or sell any competitive concentrate products in the United States hemodialysis market, other than specified products. The Distribution Agreement does not include any of the Company’s drug products. We are currently involved in arbitration with Baxter regarding various disputes under the Distribution Agreement. See “Item 3 – Legal Proceedings.”

Under the Distribution Agreement, Baxter purchases concentrate-related products from us at pre-determined gross margin-based prices per unit adjusted each year during the term and subject to an annual true up. The Distribution Agreement also requires Baxter to meet minimum annual purchase levels, subject to a cure period and certain other relief, in order to maintain its exclusive distribution rights. The minimum purchase levels increase each year over the term of the Distribution Agreement. Purchases in any contract year that exceed the minimum may be carried forward and applied to future years’ minimum requirements. The Distribution Agreement also contains provisions governing the operating relationship between the parties, our obligations to maintain specified manufacturing capacity and quality levels, remedies, as well as representations, warranties and indemnification obligations of the parties. We will continue to manage customer service, transportation and certain other functions for our current customers through at least December 31, 2017: Baxter will pay us an amount equal to our related costs plus a slight mark-up for these services.

6

The Distribution Agreement also provides that Baxter will pay us, at our discretion, up to $10 million to build a new manufacturing facility in the Pacific time zone that will serve customers in the Western United States. The fee payable in connection with building the facility will be reduced to the extent that the facility is not operational within 12 months after the start of construction. Except for any leased components, we will own and operate the facility when completed. Baxter’s obligation to pay us this amount when we choose to build the facility is being contested in the Baxter arbitration.

Either party may terminate the Distribution Agreement upon the insolvency or material breach of the other party or in the event of a force majeure. In addition, Baxter may also terminate the Distribution Agreement at any time upon 270 days’ prior written notice to us or if (1) prices increase beyond certain thresholds and notice is provided within 45 days after the true up payment is due for the year in which the price threshold is exceeded, (2) a change of control of the Company occurs and 270 days’ notice is provided, or (3) upon written notice that Baxter has been enjoined by a court of competent jurisdiction from selling in the United States any product covered by the Distribution Agreement due to a claim of intellectual property infringement or misappropriation relating to such product. If Baxter terminates the Distribution Agreement under the discretionary termination or the price increase provisions, it would be subject to a limited non-compete obligation in the United States with respect to certain products for a period of two years.

If a “Refund Trigger Event” occurs, we would be obligated to repay a portion of the $20 million upfront fee and any paid portion of the facility fee. A “Refund Trigger Event” means any of the following: (1) a change of control of the Company involving any of certain specified companies; (2) a termination by Baxter due to the Company’s bankruptcy or breach, or due to price increases that exceed the stated thresholds; (3) a termination by either party due to a force majeure; (4) settlement or adjudication of any claim, action or litigation relating to a covered product that materially and adversely affects Baxter’s commercialization of the product; and (5) any regulatory action or ruling relating to a covered product that materially and adversely affects Baxter’s commercialization of the product. In addition, if Baxter terminates the Distribution Agreement because Baxter has been enjoined by a court of competent jurisdiction from selling in the United States any product covered by the Distribution Agreement due to a claim of intellectual property infringement or misappropriation relating to such product prior to the end of 2019, Baxter would be entitled to a partial refund. In no event would more than one refund be required to be paid.

The Distribution Agreement may be extended an additional five years by Baxter if Baxter achieves a specified sales target and pays an extension fee of $7.5 million. If the first extension occurs, the Distribution Agreement term may later be extended an additional five years at Baxter’s option at no additional cost.

Distribution and Delivery Operations

The majority of our domestic dialysis concentrate products are delivered through our subsidiary, Rockwell Transportation, Inc., which operates a fleet of trucks used to deliver products to our customers. Rockwell distribution and delivery will continue to operate under the Distribution Agreement on behalf of Baxter for domestic business. We perform delivery services that are generally not available from common carriers or our competitors, such as stock rotation, non-loading-dock delivery and drum pump-off service. As a result, we believe we offer a higher level of service than other providers. Our drug products are generally delivered by third party drug distributors in the United States.

Sales and Marketing

The top ten dialysis providers treat approximately 380,000 hemodialysis patients in their centers according to an article published by Nephrology News in 2016, which we believe constitutes approximately 83% of the hemodialysis patient population in the United States. Due to the concentrated nature of our customers, we will market our drug products using a small team of skilled salespeople. Our Chief Executive Officer leads and directs our sales team, and handles much of the sales effort with our major accounts.

We market and advertise through trade publications, journals, product literature, industry trade conferences, and the internet. We target our sales and marketing efforts to senior and operating management of dialysis companies, dialysis service providers, nephrologists, clinic administrators, nurses, medical directors and technical and purchasing personnel.

7

Our dialysis concentrate products are sold to customers in the United States through Baxter in accordance with the Distribution Agreement. Our dialysis concentrate products are sold to international customers through independent sales agents, distributors and direct.

Competition

Dialysis Concentrate Solutions and Dialysis Products Market Competition

In the United States, the principal competitor for our concentrate products is Fresenius Medical Care NA, a vertically integrated manufacturer and marketer of dialysis devices, drugs and supplies and dialysis clinic operator, which has substantially greater financial, technical, manufacturing, marketing, and research and development resources than us. Fresenius operates approximately 1,700 clinics and treats approximately 36% of the dialysis patients in the United States. Fresenius also manufactures and sells a full range of renal products, including dialysis machines, dialyzers (artificial kidneys), concentrates and other supplies used in hemodialysis. Fresenius also services clinics owned by others with its products where it commands a market leading position in its key product lines. Fresenius manufactures its concentrate in its own regional manufacturing facilities. Fresenius and Rockwell are the two major dialysis concentrate suppliers in the United States.

Iron Delivery Market Competition

We believe Triferic has potential to become the standard of care for iron maintenance therapy for hemodialysis patients due to its unique mode of action, clinical benefits, ability to lower treatment cost for providers, ease of administration and excellent safety profile. Presently, the IV iron drug Venofer® has the majority of the market for delivering iron to chronic dialysis patients in the United States, but is an iron repletion therapy and not an iron maintenance therapy. Venofer® is owned by Switzerland-based Galenica. Galenica also markets Ferinject® which is primarily used to treat anemia in a non-dialysis setting. Fresenius has a sublicense agreement that allows them to distribute Venofer® to the dialysis market in the United States and Canada. Other IV iron competitors include Sanofi with Ferrlecit® and Watson with a generic IV iron called Nulecit®.

The markets for drug products are highly competitive. Competition in drug delivery systems is generally based on marketing strength, product performance characteristics (i.e., reliability, safety, patient convenience) and product price. Acceptance by dialysis providers and nephrologists is also critical to the success of a product. The first product on the market in a particular therapeutic area typically is able to obtain and maintain a significant market share. In a highly competitive marketplace and with evolving technology, additional product introductions or developments by others could render our products or technologies noncompetitive or obsolete. In addition, pharmaceutical and medical device companies are largely dependent upon health care providers being reimbursed by private insurers and government payors. Drugs approved by the FDA might not receive reimbursement from private insurers or government payors.

Prior to 2011, CMS had historically paid providers for dialysis treatments under the Medicare program in two parts: the composite rate and separately reimbursed drugs and services. The composite rate is payment for the complete dialysis treatment except for physicians’ professional services, separately billed laboratory services and separately billed drugs. CMS began implementation of a fully bundled reimbursement rate in 2011. The bundled rate is a single payment per treatment, thereby eliminating reimbursement for individual drugs and services to providers. Regulations provide that the rate is recalculated each year. As a result, dialysis drugs are now viewed by providers as an additional cost rather than as a source of revenue. We believe Triferic, due to its potential for improved therapeutic response and lower cost of administration, is an attractive therapy under this reimbursement landscape. In addition, we are seeking transitional add-on reimbursement for Triferic which if gained would pay dialysis service providers an additional 6% above their reimbursed cost to cover the expense of new drug adoption.

Vitamin D Therapy Market Competition

We intend to market Calcitriol injection against two competitors with branded vitamin D products and against other generic drug competitors as well as oral forms of vitamin D. Abbott Laboratories markets Zemplar® and Sanofi-Aventis, through its Genzyme subsidiary, markets Hectorol®. Other companies offer oral forms of vitamin D. We believe the dialysis reimbursement law that went into effect in January 2011, along with Calcitriol being the lowest dose vitamin D injection available and our relationships with many dialysis providers gives us an advantage to sell Calcitriol against competitors in the market.

8

Quality Assurance and Control

Dialysis Concentrate Solutions Business

We operate under FDA and cGMP guidelines and place significant emphasis on providing quality products and services to our customers. Our quality management plays an essential role in meeting product quality requirements and FDA guidelines. We have implemented quality systems that involve control procedures that result in rigid conformance to specifications. Our quality systems also include assessments of suppliers of raw materials, packaging components and finished goods, and quality management reviews designed to inform management of key issues that may affect the quality of products, assess the effectiveness of our quality systems and identify areas for improvement.

Technically trained professionals at our production facilities maintain our quality system. To assure quality and consistency of our concentrates, we conduct specific analytical tests during the manufacturing process for each type of product that we manufacture. Prior to shipment, our quality control laboratory at each facility conducts analytical tests to verify that the chemical properties of the concentrates comply with the specifications required by industry standards. Each product is assigned a lot number for tracking purposes.

Drug Manufacturing

We will utilize CMOs to manufacture and package our drug products for sale. These contract manufacturers are FDA registered drug manufacturing establishments. We follow defined procedures to qualify manufacturers of our products and to review and approve all manufactured products to ensure compliance with FDA cGMP regulations.

Government Regulation

The testing, manufacture and sale of our hemodialysis concentrates and the ancillary products we distribute are subject to regulation by numerous governmental authorities, principally the FDA and corresponding state and foreign agencies. Under the Federal Food, Drug and Cosmetic Act, as amended (the “FD&C Act”), and FDA regulations, the FDA regulates the pre‑clinical and clinical testing, manufacture, labeling, distribution and marketing of medical devices. Noncompliance with applicable requirements can result in, among other things, fines, injunctions, civil penalties, recall or seizure of products, total or partial suspension of production, failure of the government to grant pre‑market clearance or pre‑market approval for devices, withdrawal of marketing clearances or approvals and criminal prosecution.

We plan to develop and commercialize selected drug candidates, such as Triferic, other Triferic indications and Calcitriol. The development and regulatory approval process for new drugs and additional indications for approved drugs includes preclinical testing and human clinical trials and is lengthy and uncertain. Before marketing in the United States, any pharmaceutical or therapeutic product must undergo rigorous preclinical testing and clinical trials and an extensive regulatory approval process implemented by the FDA under the FD&C Act.

Moreover, the FDA imposes substantial requirements on new product research and the clinical development, manufacture and marketing of pharmaceutical products, including testing and clinical trials to establish the safety and effectiveness of these products.

Medical Device Approval and Regulation

A medical device may be marketed in the United States only with prior authorization from the FDA unless it is subject to a specific exemption. Devices classified as Class I devices (general controls) or Class II devices (general and special controls) are eligible to seek “510(k) clearance” from the FDA. Such clearance generally is granted when submitted information establishes that a proposed device is “substantially equivalent” in terms of safety and effectiveness to a legally marketed device that is not subject to premarket approval. A legally marketed device is a “pre‑amendment” device that was legally marketed prior to May 28, 1976 (for which a PMA is not required), a device that has been reclassified from Class III to Class I or II, or a device which has been found substantially equivalent through the 510(k) process. The FDA in recent years has been requiring a more rigorous demonstration of substantial equivalence than in the past, including requiring clinical trial data in some cases. For any devices that are cleared through the 510(k) process, modifications or enhancements that could significantly affect safety or effectiveness, or constitute a new or major change in the intended use of the device, will require new 510(k) submissions. We have been

9

advised that it usually takes from three to six months from the date of submission to obtain 510(k) clearance, and may take substantially longer. Our hemodialysis concentrates, liquid bicarbonate and other ancillary products are categorized as Class II devices.

A device which sustains or supports life, prevents impairment of human health or presents a potential unreasonable risk of illness or injury is categorized as a Class III device. A Class III device generally must receive approval through a pre‑market approval (“PMA”) application, which requires proving the safety and effectiveness of the device to the FDA. The process of obtaining PMA approval is expensive and uncertain. We have been advised that it usually takes approximately one year to obtain approval after filing the request, and may take substantially longer.

If human clinical trials of a device are required, whether for a 510(k) submission or a PMA application, and the device presents a “significant risk,” the sponsor of the trial (usually the manufacturer or the distributor of the device) will have to file an investigational device exemption (“IDE”) application prior to commencing human clinical trials. The IDE application must be supported by data, typically including the results of animal and laboratory testing. If the IDE application is approved by the FDA and one or more appropriate Institutional Review Boards (“IRBs”), the device may be shipped for the purpose of conducting the investigations without compliance with all of the requirements of the FD&C Act and human clinical trials may begin. The FDA will specify the number of investigational sites and the number of patients that may be included in the investigation. If the device does not present a “significant risk” to the patient, a sponsor may begin the clinical trial after obtaining approval for the study by one or more appropriate IRBs without the need for FDA approval.

Any devices manufactured or distributed by us pursuant to FDA clearances or approvals are subject to pervasive and continuing regulation by the FDA and certain state agencies. As a manufacturer of medical devices for marketing in the United States we are required to adhere to regulations setting forth detailed cGMP requirements, which include testing, control and documentation requirements. We must also comply with medical device reporting regulations which require that we report to the FDA any incident in which our products may have caused or contributed to a death or serious injury, or in which our products malfunctioned and, if the malfunction were to recur, it would be likely to cause or contribute to a death or serious injury. Under such a scenario, our products may be subject to voluntary recall by us or required recall by the FDA. Labeling and promotional activities are subject to scrutiny by the FDA and, in certain circumstances, by the Federal Trade Commission. The FD&C Act prohibits the marketing of approved medical devices for unapproved uses.

We are subject to routine inspection by the FDA and certain state agencies for compliance with cGMP requirements and other applicable quality system regulations. We are also subject to numerous federal, state and local laws relating to such matters as safe working conditions, manufacturing practices, environmental protection, fire hazard control, transportation and disposal of hazardous or potentially hazardous substances.

We have 510(k) clearance from the FDA to market hemodialysis concentrates in both liquid and powder form. In addition, we have received 510(k) clearance for our Dry Acid Concentrate Mixer.

We must comply with the FD&C Act and related laws and regulations, including cGMP, to retain 510(k) clearances. We cannot assure you that we will be able to maintain our 510(k) clearances from the FDA to manufacture and distribute our products. If we fail to maintain our 510(k) clearances, we may be required to cease manufacturing and/or distributing our products, which would have a material adverse effect on our business, financial condition and results of operations. If any of our FDA clearances are denied or rescinded, sales of our products in the United States would be prohibited during the period we do not have such clearances.

Drug Approval and Regulation

The marketing of pharmaceutical products in the United States, such as Triferic, requires the approval of the FDA. We received FDA approval to market Triferic in January 2015. The FDA has established regulations, guidelines and safety standards which apply to the pre‑clinical evaluation, clinical testing, manufacturing and marketing of our new iron maintenance therapy product and other pharmaceutical products. The steps required before a pharmaceutical product can be produced and marketed for human use include: (i) pre‑clinical studies; (ii) submission to the FDA of an Investigational New Drug Application (“IND”), which must become effective before human clinical trials may commence in the United States; (iii) adequate and well controlled human clinical trials; (iv) submission to the FDA of a New Drug Application (“NDA”) or, in some cases, an Abbreviated New Drug Application (“ANDA”); and (v) review

10

and approval of the NDA or ANDA by the FDA. An NDA generally is required for products with new active ingredients, new indications, new routes of administration, new dosage forms or new strengths. An NDA requires that complete clinical studies of a product’s safety and efficacy be submitted to the FDA, the cost of which is substantial. The costs are often less, however, for new delivery systems which utilize already approved drugs than for drugs with new active ingredients.

An ANDA is a marketing application filed as part of an abbreviated approval process that is available for generic drug products that have been scientifically determined to be “bioequivalent” to an FDA‑approved drug. This requires that the generic drug product have the same amount of active ingredient(s) absorbed in the same amount of time, use indication, route of administration, dosage form and strength as an existing FDA‑approved product. In addition the generic drug product must be manufactured in accordance with cGMP and meet requirements for batch identity, strength, purity and quality. Under applicable regulations, companies that seek to introduce an ANDA product must also certify that the product does not infringe on the approved product’s patent or that such patent has expired. If the applicant certifies that its product does not infringe on the approved product’s patent, the patent holder may institute legal action to determine the relative rights of the parties and the application of the patent, and the FDA may not finally approve the ANDA until a court finally determines that the applicable patent is invalid or would not be infringed by the applicant’s product.

Pre‑clinical studies are conducted to obtain preliminary information on a pharmaceutical product’s efficacy and safety in animal or in vitro models. The results of these studies are submitted to the FDA as part of the IND and are reviewed by the FDA before human clinical trials begin. Human clinical trials may begin 30 days after receipt of the IND by the FDA unless the FDA objects to the commencement of clinical trials.

Human clinical trials are typically conducted in three sequential phases, but the phases may overlap. Phase 1 trials consist of testing the product primarily for safety, metabolism and pharmacologic action in a small number of patients or healthy volunteers at one or more doses. In Phase 2 trials, the safety and efficacy of the product are evaluated in a patient population somewhat larger than the Phase 1 trials with the primary intent of determining the effective dose range. Phase 3 trials typically involve additional testing for safety and clinical efficacy in an expanded population at a large number of test sites. A clinical plan, or protocol, accompanied by documentation from the institutions participating in the trials, must be received by the FDA prior to commencement of each of the clinical trials. The FDA may order the temporary or permanent discontinuation of a clinical trial at any time.

The results of product development and pre‑clinical and clinical studies are submitted to the FDA as an NDA or an ANDA for approval. If an application is submitted, there can be no assurance that the FDA will review and approve the NDA or an ANDA in a timely manner. The FDA may deny an NDA or an ANDA if applicable regulatory criteria are not satisfied or it may require additional testing, including pre‑clinical, clinical and or product manufacturing tests. Even if such data are submitted, the FDA may ultimately deny approval of the product. Further, if there are any modifications to the drug, including changes in indication, manufacturing process, labeling, or a change in a manufacturing facility, an NDA or an ANDA supplement may be required to be submitted to the FDA. Product approvals may be withdrawn after the product reaches the market if compliance with regulatory standards is not maintained or if problems occur regarding the safety or efficacy of the product. The FDA may require testing and surveillance programs to monitor the effect of products which have been commercialized, and has the power to prevent or limit further marketing of these products based on the results of these post‑marketing programs.

Manufacturing facilities are subject to periodic inspections for compliance with regulations and each domestic drug manufacturing facility must be registered with the FDA. Foreign regulatory authorities may also have similar regulations. We expend significant time, money and effort in the area of quality assurance to fully comply with all applicable requirements. FDA approval to manufacture a drug is site specific. In the event an approved manufacturing facility for a particular drug becomes inoperable, obtaining the required FDA approval to manufacture such drug at a different manufacturing site could result in production delays, which could adversely affect our business and results of operations. Manufacturers and distributors must comply with various post‑market requirements, including adverse event reporting, re‑evaluation of approval decisions and notices of changes in the product or in the process or procedures used to manufacture a product.

11

Other Government Regulations

The federal and state governments in the United States, as well as many foreign governments, from time to time explore ways to reduce medical care costs through health care reform. Due to uncertainties regarding the ultimate features of reform initiatives and their enactment and implementation, we cannot predict what impact any reform proposal ultimately adopted may have on the pharmaceutical and medical device industry or on our business or operating results. The Patient Protection and Affordable Care Act (“PPACA”), which was enacted in 2010, imposes excise taxes on manufacturers on the sale of medical devices and pharmaceutical products and requires medical device and pharmaceutical manufacturers annually to report certain financial and ownership relationships they have with physicians and teaching hospitals. The medical device excise tax received a two year moratorium ending December 31, 2017 and its status subsequent to the expiration of the moratorium is unclear. There are various bills pending or that are expected to be introduced in Congress to repeal, replace or modify the PPACA. Most versions would eliminate the medical device tax as early as December 31, 2017. Our activities are subject to various federal, state and local laws and regulations regarding occupational safety, laboratory practices, and environmental protection and may be subject to other present and possible future local, state, federal and foreign regulations.

The approval procedures for the marketing of our products in foreign countries vary from country to country, and the time required for approval may be longer or shorter than that required for FDA approval. We generally depend on our foreign distributors or marketing partners to obtain the appropriate regulatory approvals to market our products in those countries which typically do not require additional testing for products that have received FDA approval.

However, since medical practice and governmental regulations differ across regions, further testing may be needed to support market introduction in some foreign countries. Some foreign regulatory agencies may require additional studies involving patients located in their countries. Even after foreign approvals are obtained, further delays may be encountered before products may be marketed. Issues related to import and export can delay product introduction. Many countries require additional governmental approval for price reimbursement under national health insurance systems.

Product License Agreements

We are party to an in‑license agreement for Triferic that covers issued patents in the United States, the European Union and Japan, as well as other foreign jurisdictions. We licensed the product from a company owned by Dr. Ajay Gupta who subsequently joined us as our Chief Scientific Officer. The license agreement continues for the duration of the underlying patents in each country plus a period of ten years. Patents were issued in the United States in 2004 and extended through 2016 and may be extended thereafter under the Hatch‑Waxman Act. Our request for a term extension is currently under review and is anticipated to be approved. In view of the pending review, the United States Patent and Trademark Office has granted an interim extension on these patents for the period of one year from the original expiration date and would extend through December 31, 2017. The European patent was issued in 2005 and extends through 2017. The Japanese patent was issued in 2007 and extends through 2017. We intend to apply for an extension of our patent exclusivity for up to five years in Europe and Japan. As noted below in “Trademarks and Patents,” the Company has also received patent protection on the pharmaceutical grade formulation of the active pharmaceutical ingredient in Triferic which extends patent protection until 2029.

Our Triferic license agreement requires us to obtain and pay the cost of obtaining FDA approval of the product and patent maintenance expenses in order to realize any benefit from commercialization of the product. In addition, we were obligated to make certain milestone payments during development of the product. As of December 31, 2016, there were no remaining milestones to be completed although we continue to be obligated to pay ongoing royalties.

Trademarks and Patents

We have several trademarks and service marks used on our products and in our advertising and promotion of our products, and we have applied for United States registration of such marks. Most such applications have resulted in registration of such trademarks and service marks.

We were issued a United States patent on the synthesis and formulation of our pharmaceutical grade formulation of Triferic. The United States patent expires on April 17, 2029. Patents have also been granted in Europe,

12

Japan and Canada. We have numerous other patents and patent applications connected to Triferic pending in various countries.

We also own patents in the United States and Canada for our Dry Acid Concentrate method and apparatus for preparing liquid dialysate which expire on September 17, 2019. Expiration of these patents is not expected to have a material impact on our business.

Suppliers

We believe the raw materials and packaging materials for our hemodialysis concentrates, the components for our hemodialysis kits and the ancillary hemodialysis products distributed by us are generally available from several potential suppliers. We intend to engage CMOs for the manufacture and packaging of our drug products. There are several potential CMOs that are able to manufacture and package our drug products and so it is unlikely we will be dependent on any particular CMO. However, the lead time to bring on an additional CMO could be lengthy.

Customers

We operate in one market segment, the hemodialysis market, which involves the manufacture, sale and distribution of hemodialysis products to hemodialysis clinics including pharmaceutical, dialysis concentrates, dialysis kits and other ancillary products used in the dialysis process. In October 2014, we entered into a Distribution Agreement with Baxter and under this agreement Baxter received exclusive distribution rights for our concentrate products in the United States. Rockwell domestic customer contracts for the supply of dialysis concentrate products that permitted assignment to Baxter without customer consent have been assigned to Baxter. As a result, for the years ended December 31, 2016 and 2015, our direct sales to Baxter aggregated approximately 24% and 28% of sales, respectively and we had a receivable from Baxter of $2,430,159 and $2,088,000 as of December 31, 2016 and 2015, respectively.

For the years ended December 31, 2016, 2015 and 2014, one customer, DaVita Healthcare Partners, Inc., accounted for 52% of our sales in 2016, 48% of our sales in 2015 and 49% of our sales in 2014. Our accounts receivable from this customer were $2,224,046 and $2,156,000 as of December 31, 2016 and 2015, respectively. DaVita and Baxter and the accounts administered by Baxter are important to our business, financial condition and results of operations. The loss of any significant accounts could have a material adverse effect on our business, financial condition and results of operations. No other customers accounted for more than 10% of our sales in any of the last three years.

The majority of our international sales in each of the last three years were sales to domestic distributors that were resold to end users outside the United States. Our sales to foreign customers and distributors were less than 5% of our total sales in 2016, 2015 and 2014. Our total international sales, including sales to domestic distributors for resale outside the United States, aggregated 12%, 13% and 13%, of overall sales in 2016, 2015 and 2014, respectively.

Employees

As of December 31, 2016, we had approximately 300 employees, substantially all of whom are full time employees. Our arrangements with our employees are not governed by any collective bargaining agreement. Our employees are employed on an “at‑will” basis.

Research & Development

Over the last several years we have invested heavily in the testing and development of Triferic. We completed human clinical trials and other testing in 2013, and submitted our NDA for Triferic to the FDA in 2014. We received FDA approval for Triferic in January 2015. Since approval of Triferic, we have conducted additional clinical studies of Triferic for other indications, presentation in IV formulation and for a pediatric study of Triferic.

We engaged outside service providers, contract research organizations, consultants and legal counsel to assist us with clinical trials, product development and obtaining regulatory approval. We incurred product development and research costs related to the commercial development, patent approval and regulatory approval of new products, including Triferic, aggregating approximately $5,840,000, $4,961,000 and $7,784,000, in 2016, 2015 and 2014, respectively.

13

Future research and product development spending on the Triferic platform may include clinical testing in connection with peritoneal dialysis, total parenteral nutrition, an orphan indication and a pediatric indication. Future spending on such indications is expected to be minor in relation to the Company’s cash resources.

Where You Can Get Information We File with the SEC

Our internet address is http://www.rockwellmed.com. Our internet address is included as an inactive textual reference only and nothing on the website is incorporated by reference into this Annual Report on Form 10‑K. You can access free of charge on our website all of our reports filed pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended, including our annual reports on Form 10‑K, quarterly reports on Form 10‑Q, current reports on Form 8‑K, and amendments to those reports. These reports are available as soon as practicable after they are electronically filed with the SEC.

The SEC also maintains a website on the internet that contains reports, proxy and information statements and other information regarding issuers, such as us, that file electronically with the SEC. The address of the SEC’s website is http://www.sec.gov.

Item 1A. Risk Factors.

Investing in our common stock involves a high degree of risk and there can be no assurance that future results will meet expectations. You should carefully consider the risks and uncertainties described below before purchasing our common stock. The risks and uncertainties described below are not the only ones facing our company. Additional risks and uncertainties may also impair our business operations. If any of these risks actually occur, our business, financial condition or results of operations would likely suffer. In that case, the trading price of our common stock could fall, and you may lose all or part of the money you paid to buy our common stock.

RISKS RELATED TO OUR DRUG BUSINESS

Although Triferic has been approved by the FDA, we may not be able to commercialize it successfully.

The commercial success of Triferic will depend on a number of factors, including the following:

|

· |

IV iron currently dominates treatment for iron deficiency and Triferic will have to compete against it and possibly other existing and future products; |

|

· |

It may be difficult to gain market acceptance from dialysis chains, anemia managers and nephrologists or such acceptance may be slower than expected. Market acceptance will depend on a number of factors, such as demonstration of Triferic’s safety and efficacy, cost-effectiveness, advantages over existing products, and the reimbursement policies of government and third party payers, including Medicare; |

|

· |

We are seeking transitional add-on reimbursement status from CMS to separately pay for Triferic outside of the standard dialysis bundled payment. Dialysis providers have been slow to adopt Triferic in the absence of such status. In the absence of a favorable determination from CMS, dialysis service providers are likely to adopt Triferic at a much slower rate than if Triferic is granted such status due to the cost of conversion and lack of an immediate financial incentive to adopt Triferic; |

|

· |

Maintaining compliance with ongoing regulatory requirements applicable to Triferic or which apply generally to the manufacturing processes, labeling, packaging, distribution, adverse event reporting, storage, advertising, promotion and recordkeeping applicable to the product; |

|

· |

The effectiveness of our marketing, sales and distribution strategies and operations for development and commercialization, and our ability to execute our marketing strategy without significant additional expenditures; |

14

|

· |

Competitors may engage in anti-competitive practices and other tactics to retain their market share; |

|

· |

Our ability to avoid third party patent interference or patent infringement claims; |

|

· |

A continued acceptable safety profile of Triferic; and |

|

· |

Discovery of previously unknown problems with Triferic or with any third-party manufacturers or manufacturing processes, or failure to comply with regulatory requirements. |

An adverse development with respect to any of the foregoing may have a material adverse effect on our ability to manufacture and market Triferic. These factors are largely beyond our control. Accordingly, we cannot assure you that we will receive transitional add-on reimbursement status for Triferic from CMS or that we will be able to generate significant revenues through the sale of Triferic. If we are not successful in commercializing Triferic, or are significantly delayed in doing so, our entire investment in Triferic may be worthless, our licensing rights could be affected and the price of our common stock could substantially decline. If we are unable to successfully commercialize Triferic and achieve sufficient sales volumes over the next one to two years, we may have to write off a portion of our inventory investment in Triferic. Even if we were successful in commercializing Triferic, due to the highly concentrated nature of the market, our continued success may depend on adoption of Triferic by a few customers.

Triferic is currently limited to use in adult patients receiving hemodialysis treatments and has not been approved for other indications. Regulatory approval for any approved product is limited by the FDA to those specific indications and conditions for which clinical safety and efficacy have been demonstrated, which may limit our ability to market our drug products.

While physicians may choose to prescribe drugs for uses that are not described in the product’s labeling and for uses that differ from those tested in clinical studies and approved by regulatory authorities, our ability to promote the products or encourage our customers to use the products is limited to those indications that are specifically approved by the FDA as safe and effective. Any new indication for an approved product also requires FDA approval. If we are not able to obtain FDA approval for any other indications for Triferic, our ability to effectively market and sell Triferic may be reduced and our business may be adversely affected. Moreover, if our promotional activities fail to comply with the FDA’s regulations or guidelines, we may be subject to warnings from, or enforcement action by, the FDA that may include penalties, fines, injunctions, recall or seizure of products, suspension of production, denial of future regulatory approvals, withdrawal or suspension of existing regulatory approvals, operating restrictions, debarment, exclusion and criminal prosecution, any of which could materially harm our business.

If we do not obtain protection under the Hatch-Waxman Act to extend patent protection for Triferic, our business may be harmed.

The United States Drug Price Competition and Patent Term Restoration Act of 1984, more commonly known as the “Hatch-Waxman Act,” provides that patent holders may apply for an extension of patent term for drugs for a period of up to five years to compensate for time spent in development and regulatory approval. We have applied for an extension, and received a temporary one year extension but there can be no assurance that we will receive the full extension of the patent term provided under the Hatch-Waxman Act for either of the licensed Triferic patents that expired at the end of 2016. If we fail to receive the full extension, our ability to prevent competitors from manufacturing, marketing and selling generic versions of Triferic could be impaired and we would have to rely on the protection afforded us by the United States patent we hold on the synthesis and formulation of our pharmaceutical grade formulation of Triferic which expires in 2029 or on other patents related to Triferic that may be issued to us in the future.

Our Calcitriol contract manufacturer has made changes to the manufacturing process for Calcitriol that require FDA approval prior to commercial sale of Calcitriol. The FDA review process has delayed our launch of Calcitriol and, even if approved, we may not be able to commercialize Calcitriol successfully.

While we have received FDA approval to manufacture a generic version of Calcitriol, our CMO made changes to the process that requires prior FDA approval before the commercial products can be sold that were produced under the process change. Even if approved, we must also meet certain ongoing regulatory requirements for product testing and stability of our commercially marketed products. If our testing does not meet approvable standards, if our CMO cannot

15

make the product in sufficient quantities and on a consistent basis or if we experience operational issues with our CMO, we may not be able to market Calcitriol successfully or the launch may be further delayed.

The market for generic drugs such as Calcitriol is generally very competitive, which may make it difficult for us to capture significant market share. If we have success in capturing market share with Calcitriol, it may attract other entrants to market their own Calcitriol product, which could have a material adverse effect on our future revenues and results of operations. Branded competitors may aggressively lower their prices to maintain market share. Dialysis service providers may seek alternative forms of treatment for this indication.

We may not be successful in obtaining foreign regulatory approvals or in arranging an out-licensing or other venture to realize commercialization of our drug products outside of the United States. Even if we are successful in out-licensing our drug products, the licensees or partners may not be effective at marketing our products in certain markets or at all.

The approval procedures for marketing our new drug products, such as Triferic, outside the United States vary from country to country, can be difficult to obtain and carry the same risks as FDA approval. In particular, regulatory approval in foreign countries may require additional testing and may otherwise be expensive and time consuming to undertake. Even after foreign approvals are obtained, further delays may be encountered before products may be marketed. Many countries require additional government approval for price reimbursement under national health insurance systems.

Even if we obtain the necessary foreign approval in a particular market, we do not have substantial expertise selling and marketing on an international level and therefore may not be successful in realizing commercial value from our products should we attempt to develop international markets ourselves. Our strategy for addressing the need for expertise in obtaining foreign approvals and marketing in foreign markets is to out-license rights to our drugs in markets outside the United States. However, we may not be successful in finding partners in addition to Wanbang, our Chinese market partner, or ARAM Medical, our distributor in the Middle East, who will be willing to invest in our drugs outside the United States or our partners may be unable to obtain the necessary regulatory approvals. If we are not successful in out-licensing our drugs outside of the United States or entering into some other business development arrangement to obtain the necessary approvals to commercialize them, or if our partners are unable to obtain the necessary regulatory approvals, we may be forced to seek regulatory approval and market these products ourselves. If we elect to seek approval ourselves, it may take longer than expected to obtain regulatory approval and to market and manufacture our drugs, and we may decide to delay or abandon development efforts in certain markets.

Any such delay or abandonment, or any failure to receive one or more foreign approvals, may have an adverse effect on the benefits otherwise expected from marketing in foreign countries.

If we are successful in obtaining other business partners to commercialize our products in foreign markets, we will be dependent upon their effectiveness in selling and marketing our products in those foreign markets. These partners may face stiff competition, government price regulations, generic versions of our drug products, violations of our intellectual property rights and other negative events or may otherwise be ineffective in commercializing our products, any of which could reduce the market potential for our products and our success in those markets.

We will rely on third party suppliers for raw materials, packaging components and manufacturing of our drug products. We may not be able to obtain the raw materials, proper components or manufacturing capacity we need, or the cost of the materials, components or manufacturing capacity may be higher than expected, any of which could have a material adverse effect on our expected results of operations, financial position and cash flows.

We may not be able to obtain needed raw materials, packaging components and manufacturing capacity for a variety of reasons, including among others:

|

· |

We may be required to purchase certain raw materials and packaging components from unaffiliated third-party suppliers who may not be able to supply us consistently or at all; |

|

· |

Regulatory requirements or action by regulatory agencies or others, including delays in receiving necessary approvals; |

16

|

· |

Adverse financial or other strategic developments at or affecting a supplier or contract manufacturer; |

|

· |

Unexpected demand for or shortage of raw materials or packaging components; |

|

· |

Failure to comply with cGMP standards which results in quality or product failures, adulteration, contamination and/or recall; |

|

· |

Changes made to manufacturing processes by our contract manufacturers may result in regulatory delays until such changes are approved regulatory authorities; |

|

· |

Limitations in capacity of contract manufacturers; and |

|

· |

Changes in product demand. |

If we are unable to obtain the raw materials, components and manufacturing capacity we require, or if we are charged more than expected for these items, we may not be able to produce the desired quantities of our drug products or our expected gross profit margins may be materially adversely affected.

Before it can be marketed, an investigational drug requires FDA approval, which is a long, expensive process with no guarantee of success.

Performing clinical trials and obtaining FDA approval for any drug can take a long time. Clinical trials typically take many months or years to complete. Once trials are completed and the NDA, is submitted to the FDA, the FDA may find deficiencies in our NDA, may raise safety or efficacy concerns or may otherwise require additional clinical testing or impose other requirements before granting approval, which could significantly delay approval or result in us not receiving approval at all.

Clinical trials and the NDA approval process for any new drug candidate are expensive. If we were to develop new drug candidates and we experience delays, or additional testing or other unplanned requirements are imposed on us, we may need to raise additional capital, which may not be available when needed or may be available only on terms that are not in the best interests of the Company and its shareholders, or which result in substantial dilution of shareholders’ voting power and ownership. New indications of Triferic when submitted to the FDA for approval will require us to pay review fees. If approval is not granted for any new products submitted, our entire investment in the related products may be worthless, any licensing rights could be forfeited and the price of our common stock could substantially decline.

Our drug business will depend on government funding of health care, and changes could impact our ability to be paid in full for our products, increase prices or cause consolidation in the dialysis provider market.

Many dialysis providers receive the majority of their funding from the government and are supplemented by payments from private health care insurers. These providers depend on Medicare and Medicaid funding to be viable businesses. Congress continuously enacts a variety of changes to health insurance and reimbursement, some of which could have a negative impact on Medicare and Medicaid funding, which fund the majority of dialysis costs in the United States, and on reimbursement protocols. If Medicare and Medicaid funding were to be materially decreased, these providers would be severely impacted, increasing our risk of not being paid in full. An increase in our exposure to uncollectible accounts could have a material adverse effect on our financial position, results of operations and cash flows.