Attached files

| file | filename |

|---|---|

| 8-K - 8-K - SOUTH DAKOTA SOYBEAN PROCESSORS LLC | a8-kxnewsletter2017x02x13.htm |

Profits Off From Last Year; Still Solid Returns

One year ago, your South Dakota Soybean Processors

(SDSP) was celebrating a record-breaking year in terms of

earnings. We certainly did not expect those high returns to

last due to changing economic factors in the industry, and

true to form, earnings did come down sharply in 2016. In

spite of that drop, the returns we experienced this past year

were still very solid from a long-term perspective. SDSP

finished the fourth quarter with net income in excess of $2.5

million, bringing the 2016 annual income close to $12.6

million.

Profits were impacted negatively from reduced demand for

soybean meal. While domestic demand was steady, export

demand was down. In addition, this past fall’s crop was

slightly lower in quality from a moisture perspective, and that

impacted SDSP as well. Overall, however, it was still a very

good year.

For the third year in a row, the number of bushels processed

was very strong. In Volga, SDSP processed 28.8 million

bushels, while the Miller plant crushed 2.95 million bushels.

While those numbers are good, Volga’s numbers are lower

than in 2015 primarily due to higher-moisture beans, which

required additional drying time.

Miller plant is running well

In 2015, during the Miller plant’s first year of production,

we processed 973,000 bushels of soybeans. This year that

number shot up to 2.95 million bushels. We are pleased to

announce that more than half of the Miller plant’s capacity

is now dedicated to the processing of identity-preserved,

primarily non-GMO soybeans. Even though the Miller facility

did not return a net profit in 2016, it is cash flowing well and is

generating a net return before depreciation. To help continue

this growth we are actively seeking non-GMO soybeans, both

old and new crop. I encourage you to call SDSP for program

details and current premiums.

Expectations for 2017

Looking ahead we see abundant supplies of soybeans in

South Dakota, which will be beneficial to both the Volga and

Miller facilities. We expect strong demand for our soybean

oil products from both the food and industrial oil sectors and,

due to the relationships we’ve built with our customer base

over the past five years, SDSP looks forward to a number of

opportunities to improve our soybean meal sales’ efforts.

I encourage you to look inside for additional information

on our financials as well as Phase II of our new receiving

complex at Volga. I also want to thank our employees and

producer members for the role each of you play in making

SDSP a company of which we can be proud.

P R O C E S S O R S

February 2017

Volume 11: Issue 1

www.sdsbp.com

SOUTH DAKOTA

Soybean

soybean

p r o c e s s o r s

S O U T H D A K O T A

Tom Kersting

CEO

Tom.Kersting@sdsbp.com

Exhibit 99.1

Condensed statement of operations

For the Year ended december 31, 2016

assets

current assets

cash and cash equivalents $ 11,654,648

trade accounts receivable 20,352,581

inventories 32,393,421

other current assets 3,857,534

total current assets 68,258,184

ProPertY and equiPment 89,832,688

less accumulated dePreciation (45,081,548)

total ProPertY and equiPment, net 44,751,140

other assets

investments in cooPeratives 6,231,233

convertible notes receivable 2,000,000

other long-term assets 1,783

total other assets 8,233,016

total assets $ 121,242,340

LIABILITIES AND MEMBERS’ EQUITY

current liabilities

excess outstanding checks over bank balance $ 6,643,226

current maturities oF long-term debt 59,558

accounts PaYable 1,456,802

accrued commoditY Purchases 35,688,152

other current liabilities 4,615,857

total current liabilities 48,463,595

long-term liabilities 725,818

members’ equitY 72,052,927

total liabilities and members’ equitY $ 121,242,340

Condensed BalanCe sheet

december 31, 2016

net revenues $ 377,931,693

cost oF revenues (363,829,609)

gross ProFit 14,102,084

administrative exPenses (3,445,978)

oPerating ProFit 10,656,106

other income (exPense)

interest exPense (409,331)

other non-oPerating income 2,346,281

total other income (exPense) 1,936,950

net income $ 12,593,056

basic and diluted earnings Per caPital unit $ 0.41

Weighted average number oF units outstanding

For calculation oF basic and diluted earnings

Per caPital unit 30,419,000

MARKETING UPDATE

©2017 South Dakota Soybean Processors, LLC. All Rights Reserved. Published in partnership with VistaComm® (www.VistaComm.com).2

UNAUDITED FINANCIAL STATEMENTS

Capital Units Trading History

period Units traded average high low

2016-Q4 53,000 $3.42 $3.50 $3.39

2016-Q3 47,500 $3.68 $3.75 $3.50

2016-Q2 30,500 $3.60 $3.75 $3.50

2016-Q1 91,000 $3.79 $4.00 $3.59

SDSP Capital Units are traded on an alternative trading system, operated by

Variable Investment Advisors, Inc. (VIA). Offers to buy or sell capital units can

be placed online at www.agstocktrade.com, or by calling VIA at 800-859-3018.

For more details regarding SDSP’s Capital Units Transfer System, please visit

our website at www.sdsbp.com, or email memberinfo@sdsbp.com.

Board to Recommend Operating Agreement Change

At the last annual meeting, SDSP Board of Managers’

member Delbert Tschakert informed attendees of an

issue under study by the board. The issue relates to

the current provision in SDSP’s operating agreement

which limits the maximum ownership percentage per

member to 1.5% of the outstanding membership units.

As many members are aging and addressing their

estate needs, a growing number are expected to

consider selling their shares. In recent years, SDSP

has been approached by institutional-type investors

wishing to take an ownership stake in the company;

however, the 1.5% maximum membership units

provision has been a stumbling block for these

investors as it does not allow them to meet their

minimum investment threshold. Your SDSP board

would like to see these types of investors given the

opportunity to bid for shares as they feel it would

provide greater liquidity and potentially higher unit

prices for all members.

At the Sept. 20, 2016 board meeting, board members

discussed feedback they had received concerning the

issue and moved to propose a change to the operating

agreement to increase the maximum shareholder

ownership from 1.5% to 10% of the outstanding

membership units. Your board feels that other

provisions in the operating agreement, such as the

board of managers’ right to approve or disapprove all

capital unit transactions, as well as the provision of

one vote per member regardless of the number of

units owned, will provide adequate protection from

anyone seeking to gain control of the company by

purchasing membership units. The membership

vote on this proposed change will be held at the

next annual meeting in June.

3

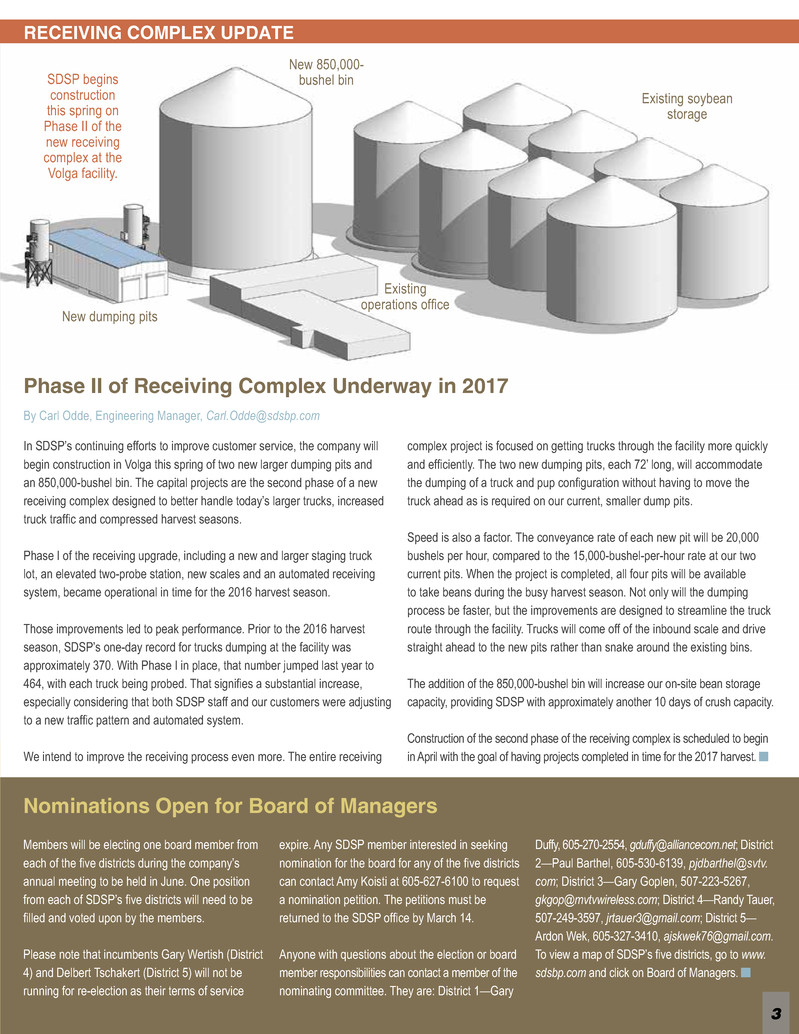

In SDSP’s continuing efforts to improve customer service, the company will

begin construction in Volga this spring of two new larger dumping pits and

an 850,000-bushel bin. The capital projects are the second phase of a new

receiving complex designed to better handle today’s larger trucks, increased

truck traffic and compressed harvest seasons.

Phase I of the receiving upgrade, including a new and larger staging truck

lot, an elevated two-probe station, new scales and an automated receiving

system, became operational in time for the 2016 harvest season.

Those improvements led to peak performance. Prior to the 2016 harvest

season, SDSP’s one-day record for trucks dumping at the facility was

approximately 370. With Phase I in place, that number jumped last year to

464, with each truck being probed. That signifies a substantial increase,

especially considering that both SDSP staff and our customers were adjusting

to a new traffic pattern and automated system.

We intend to improve the receiving process even more. The entire receiving

complex project is focused on getting trucks through the facility more quickly

and efficiently. The two new dumping pits, each 72’ long, will accommodate

the dumping of a truck and pup configuration without having to move the

truck ahead as is required on our current, smaller dump pits.

Speed is also a factor. The conveyance rate of each new pit will be 20,000

bushels per hour, compared to the 15,000-bushel-per-hour rate at our two

current pits. When the project is completed, all four pits will be available

to take beans during the busy harvest season. Not only will the dumping

process be faster, but the improvements are designed to streamline the truck

route through the facility. Trucks will come off of the inbound scale and drive

straight ahead to the new pits rather than snake around the existing bins.

The addition of the 850,000-bushel bin will increase our on-site bean storage

capacity, providing SDSP with approximately another 10 days of crush capacity.

Construction of the second phase of the receiving complex is scheduled to begin

in April with the goal of having projects completed in time for the 2017 harvest.

RECEIVING COMPLEX UPDATE

By Carl Odde, Engineering Manager, Carl.Odde@sdsbp.com

Phase II of Receiving Complex Underway in 2017

Nominations Open for Board of Managers

Members will be electing one board member from

each of the five districts during the company’s

annual meeting to be held in June. One position

from each of SDSP’s five districts will need to be

filled and voted upon by the members.

Please note that incumbents Gary Wertish (District

4) and Delbert Tschakert (District 5) will not be

running for re-election as their terms of service

expire. Any SDSP member interested in seeking

nomination for the board for any of the five districts

can contact Amy Koisti at 605-627-6100 to request

a nomination petition. The petitions must be

returned to the SDSP office by March 14.

Anyone with questions about the election or board

member responsibilities can contact a member of the

nominating committee. They are: District 1—Gary

Duffy, 605-270-2554, gduffy@alliancecom.net; District

2—Paul Barthel, 605-530-6139, pjdbarthel@svtv.

com; District 3—Gary Goplen, 507-223-5267,

gkgop@mvtvwireless.com; District 4—Randy Tauer,

507-249-3597, jrtauer3@gmail.com; District 5—

Ardon Wek, 605-327-3410, ajskwek76@gmail.com.

To view a map of SDSP’s five districts, go to www.

sdsbp.com and click on Board of Managers.

SDSP begins

construction

this spring on

Phase II of the

new receiving

complex at the

Volga facility.

New 850,000-

bushel bin

Existing soybean

storage

Existing

operations office

New dumping pits

100 Caspian Ave

PO Box 500

Volga, SD 57071

soybean

p r o c e s s o r s

S O U T H D A K O T A

Proud of Food Safety Team

For the fifth year running, SDSP has passed its Safe Quality

Food (SQF) certification audit with high marks. In fact, SDSP

achieved its highest score ever, earning 98 out of a possible

100 in the unannounced on-site audit.

The audit team recognized us for the excellence of our

food safety practices and programs. Our new Food Safety

Manager John Wilder and Quality Assurance Manager Susan

Selman did a fantastic job leading us through the audit. John

comes to us from the dry cereal industry, while Susan is our

previous food safety manager. I’m proud of our entire team,

including our refining technicians, for a job well done.

The combined efforts of this team are critical as SDSP

completes its plans and programs with the goal of being

compliant with the Food Safety Modernization Act which goes

into effect in September 2017.

Capital spending to improve meal-loading

at Miller

I invite you to read on page 3 about Phase II of our receiving

complex project in Volga. Our Operations team is also

planning additional projects in 2017, including needed work

in our extraction area at Volga during the August shutdown.

We will also continue to improve the meal loading facility at

Miller. A big step was taken this past December when we

put our rail system into service at Miller. In the past we had

been transporting meal by truck to a third-party loading site in

Tulare, South Dakota. We will now focus on changes that will

further improve our meal-loading capabilities.

Find cash bids at Volga and Miller. Go to sdsbp.com.

Now contracting

non-GMO

soybeans for the

Miller facility. Call

Kari Vander Wal

at 1-888-737-7888

for information

and pricing.

By John Prohaska

Group Operations Manager

John.Prohaska@sdsbp.com

OPERATIONS UPDATE