Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Independence Contract Drilling, Inc. | a8-kinvestorpresentation10.htm |

Investor Presentation

October 11, 2016

www.icdrilling.com

Preliminary Matters

Various statements contained in this presentation, including those that express a belief, expectation or intention, as well as those that are not statements of historical fact, are forward-looking statements. These forward-looking

statements may include projections and estimates concerning the timing and success of specific projects and our future revenues, income and capital spending. Our forward-looking statements are generally accompanied by words such

as “estimate,” “project,” “predict,” “believe,” “expect,” “anticipate,” “potential,” “plan,” “goal,” “will” or other words that convey the uncertainty of future events or outcomes. The forward-looking statements in this presentation speak

only as of the date of this presentation; we disclaim any obligation to update these statements unless required by law, and we caution you not to rely on them unduly. We have based these forward-looking statements on our current

expectations and assumptions about future events. While our management considers these expectations and assumptions to be reasonable, they are inherently subject to significant business, economic, competitive, regulatory and other

risks, contingencies and uncertainties, most of which are difficult to predict and many of which are beyond our control. These and other important factors, including those discussed under “Risk Factors” and “Management’s Discussion

and Analysis of Financial Condition and Results of Operations” included in the Company’s filings with the Securities and Exchange Commission, including the Company’s Annual Report on Form 10-K, may cause our actual results,

performance or achievements to differ materially from any future results, performance or achievements expressed or implied by these forward-looking statements. These risks, contingencies and uncertainties include, but are not limited

to, the following:

• our inability to implement our business and growth strategy;

• a sustained decrease in domestic spending by the oil and natural gas exploration and production industry;

• decline in or substantial volatility of crude oil and natural gas commodity prices;

• fluctuation of our operating results and volatility of our industry;

• inability to maintain or increase pricing on our contract drilling services;

• delays in construction or deliveries of our new land drilling rigs;

• the loss of our customer, financial distress or management changes of potential customers or failure to obtain contract renewals and additional customer contracts for our drilling services;

• an increase in interest rates and deterioration in the credit markets;

• our inability to raise sufficient funds through debt financing and equity issuances needed to fund our planned rig construction projects;

• our inability to comply with the financial and other covenants in debt agreements that we may enter into as a result of reduced revenues and financial performance;

• a substantial reduction in borrowing base under our revolving credit facility as a result of a decline in the appraised value of our drilling rigs;

• overcapacity and competition in our industry; unanticipated costs, delays and other difficulties in executing our long-term growth strategy;

• the loss of key management personnel;

• new technology that may cause our drilling methods or equipment to become less competitive;

• labor costs or shortages of skilled workers;

• the loss of or interruption in operations of one or more key vendors;

• the effect of operating hazards and severe weather on our rigs, facilities, business, operations and financial results, and limitations on our insurance coverage;

• increased regulation of drilling in unconventional formations;

• the incurrence of significant costs and liabilities in the future resulting from our failure to comply with new or existing environmental regulations or an accidental release of hazardous substances into the environment;

• the potential failure by us to establish and maintain effective internal control over financial reporting;

• lack of operating history as a contract drilling company; and

• uncertainties associated with any registration statement, including financial statements, we may be required to file with the SEC.

All forward-looking statements are necessarily only estimates of future results, and there can be no assurance that actual results will not differ materially from expectations, and, therefore, you are cautioned not to place undue reliance on

such statements. Any forward-looking statements are qualified in their entirety by reference to the factors discussed throughout this presentation. Further, any forward-looking statement speaks only as of the date on which it is made, and

we undertake no obligation to update any forward-looking statement to reflect events or circumstances after the date on which the statement is made or to reflect the occurrence of unanticipated events.

EBITDA and Adjusted EBITDA are supplemental non-GAAP financial measures that are used by management and external users of the Company’s financial statements, such as industry analysts, investors, lenders and rating agencies.

The Company defines “EBITDA” as earnings (or loss) before interest, taxes, depreciation, and amortization, and it defines “Adjusted EBITDA” as EBITDA before stock-based compensation, and non-cash asset impairments and gain (or

loss) on asset disposition. EBITDA and Adjusted EBITDA are not measures of net income as determined by U.S. generally accepted accounting principles (“GAAP”).

The Company’s management believes EBITDA and Adjusted EBITDA are useful because such measures allow the Company and its stockholders to more effectively evaluate its operating performance and compare the results of its

operations from period to period and against its peers without regard to its financing methods or capital structure. The Company excludes the items listed below from net income (loss) in calculating EBITDA and Adjusted EBITDA

because these amounts can vary substantially from company to company within the Company’s industry depending upon accounting methods and book values of assets, capital structures and the method by which the assets were

acquired. EBITDA and Adjusted EBITDA should not be considered alternatives to, or more meaningful than, net income (loss), the most closely comparable financial measure calculated in accordance with GAAP or as an indicator of the

Company’s operating performance or liquidity. Certain items excluded from Adjusted EBITDA are significant components in understanding and assessing a company’s financial performance, such as a company’s cost of capital and tax

structure, as well as stock-based compensation and the historic costs of depreciable assets, none of which are components of Adjusted EBITDA. The Company’s presentation of EBITDA and Adjusted EBITDA should not be construed

as an inference that its results will be unaffected by unusual or non-recurring items. The Company’s computations of EBITDA and Adjusted EBITDA may not be comparable to other similarly titled measures of other companies.

2

ICD Rig Location(3)

1. A pad-optimal rig consists of four key drilling and two key moving attributes: 1,500 hp, bi-fuel capable, 7500psi high pressure mud systems, AC VFD drive, an omni-directional walking system and ability to undertake fast conventional rig moves safely.

2. Includes 200 Series ShaleDriller® rigs. Excludes 100 Series rigs. Final 100 Series rig scheduled for conversion when market conditions improve.

3. Idle rigs depicted as located in Galayda Yard/Houston, Texas.

4. Market data as of 10/7/16. Credit facility, debt and cash balances as of 6/30/16.

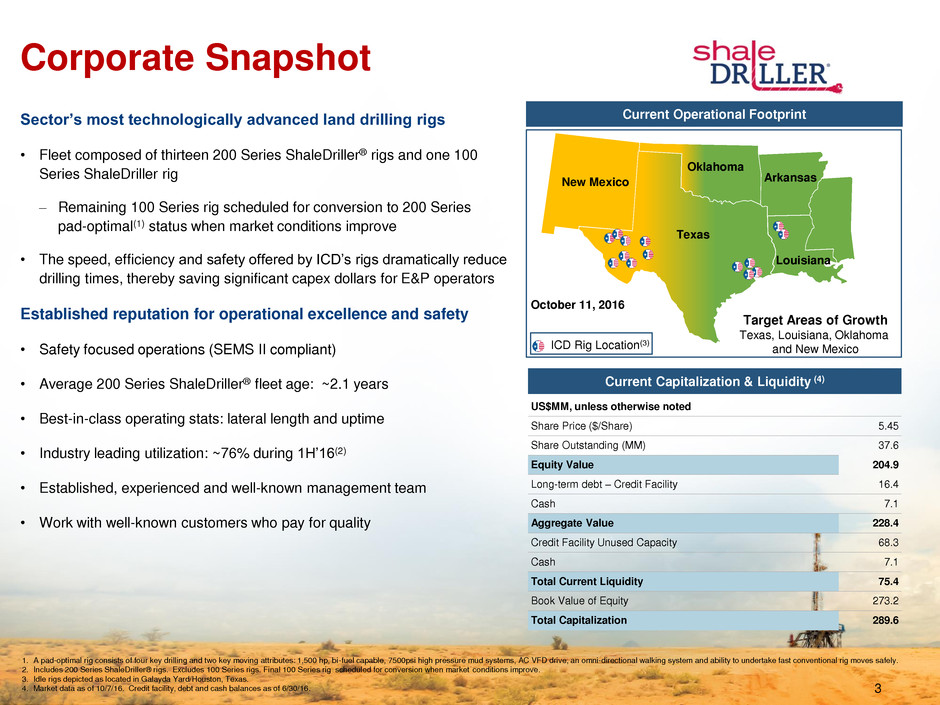

Corporate Snapshot

Sector’s most technologically advanced land drilling rigs

• Fleet composed of thirteen 200 Series ShaleDriller® rigs and one 100

Series ShaleDriller rig

‒ Remaining 100 Series rig scheduled for conversion to 200 Series

pad-optimal(1) status when market conditions improve

• The speed, efficiency and safety offered by ICD’s rigs dramatically reduce

drilling times, thereby saving significant capex dollars for E&P operators

Established reputation for operational excellence and safety

• Safety focused operations (SEMS II compliant)

• Average 200 Series ShaleDriller® fleet age: ~2.1 years

• Best-in-class operating stats: lateral length and uptime

• Industry leading utilization: ~76% during 1H’16(2)

• Established, experienced and well-known management team

• Work with well-known customers who pay for quality

Current Operational Footprint

Current Capitalization & Liquidity (4)

US$MM, unless otherwise noted

Share Price ($/Share) 5.45

Share Outstanding (MM) 37.6

Equity Value 204.9

Long-term debt – Credit Facility 16.4

Cash 7.1

Aggregate Value 228.4

Credit Facility Unused Capacity 68.3

Cash 7.1

Total Current Liquidity 75.4

Book Value of Equity 273.2

Total Capitalization 289.6

3

Texas

Oklahoma

Arkansas

Louisiana

New Mexico

Target Areas of Growth

Texas, Louisiana, Oklahoma

and New Mexico

October 11, 2016

Operational Update

• Since 2Q’16:

- Reactivated five rigs from idle/standby status

- Rig upgrades (two 7500psi upgrades, one 3rd mud pump upgrade)

• Entered 4Q’16 with 10 rigs earning revenue, including one rig on a

standby basis. Increase in inquiry levels across all of ICD target

markets for reactivation of idle rigs.

• Additional rig reactivations relative to expectations bring forward

reactivation/hiring costs into 3Q’16.

• Organizational update: consolidation of Galayda yard – field

operations without reducing rig build capabilities.

4

ICD is a leader in the rig replacement cycle – pad-optimal rigs are critical

in the progression of the U.S. unconventional drilling evolution

With industry leading fleet utilization, ICD is a rig provider of choice

By driving faster cycle times, ICD’s rigs bend the E&P cost curve down

ICD’s standardized fleet supports lower capital intensity

Modular construction gives ICD a low cost rig fleet and provides a

compounding capital advantage

ICD’s “Big Data” collection capability allows ICD to participate in the

next wave in drilling technology innovation

ICD’s rigs provide revenues and EBITDA with low maintenance capital

expenditures and tax burden

Key Differentiators Driving ICD’s

Compelling Value Proposition

5

9%

38%

29%

13%

11%

Competitor 4 Competitor 3 Competitor 2 Competitor 1 ICD (ShaleDriller®)

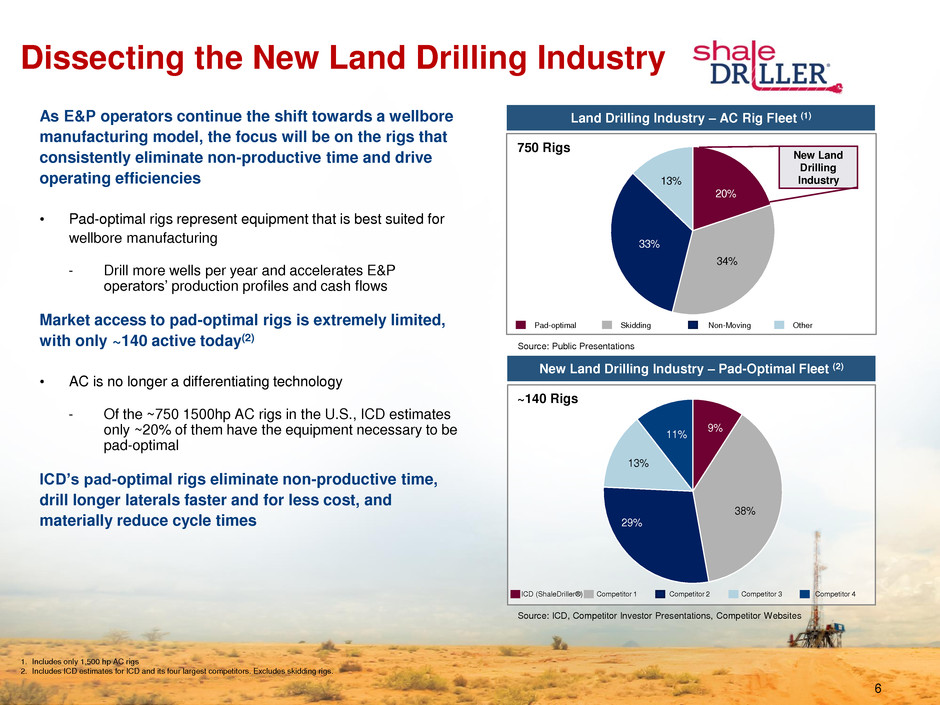

Dissecting the New Land Drilling Industry

6

20%

34%

33%

13%

New Land Drilling Industry – Pad-Optimal Fleet (2)

Land Drilling Industry – AC Rig Fleet (1)

1. Includes only 1,500 hp AC rigs

2. Includes ICD estimates for ICD and its four largest competitors. Excludes skidding rigs.

750 Rigs

Pad-optimal Skidding Non-Moving Other

New Land

Drilling

Industry

Source: ICD, Competitor Investor Presentations, Competitor Websites

As E&P operators continue the shift towards a wellbore

manufacturing model, the focus will be on the rigs that

consistently eliminate non-productive time and drive

operating efficiencies

• Pad-optimal rigs represent equipment that is best suited for

wellbore manufacturing

- Drill more wells per year and accelerates E&P

operators’ production profiles and cash flows

Market access to pad-optimal rigs is extremely limited,

with only ~140 active today(2)

• AC is no longer a differentiating technology

- Of the ~750 1500hp AC rigs in the U.S., ICD estimates

only ~20% of them have the equipment necessary to be

pad-optimal

ICD’s pad-optimal rigs eliminate non-productive time,

drill longer laterals faster and for less cost, and

materially reduce cycle times

~140 Rigs

Source: Public Presentations

High Pressure Mud Pumps

Pad-Optimal Rig Characteristics -

As Defined by E&P Operators

Omni-Directional Walking System

• Allows rig to move in any direction quickly between wellheads, rapidly and efficiently adjusts to

misaligned wellbores, walks over raised well heads and increases safety

• Superior to skidding systems which can only move to properly aligned wells in a straight line

• Self-leveling capabilities

1,500 hp Drawworks

• Rigs powered with 1,500 hp drawworks are well suited to the majority of unconventional resource

formations

• Ideally sized for drilling longer laterals while occupying a small footprint on the job site

Bi-Fuel Capabilities

• Operator can change between diesel or natural gas mix

• Use of natural gas/diesel blend can result in major savings

• Reduces carbon emissions

• High pressure mud pumps allow for drilling mud to be pumped through extended horizontal laterals

• Necessary for drilling the long laterals required by complex horizontal drilling programs

7

Fast Moving

• Specifically designed to reduce cycle times (reduces rig-move time between drilling locations)

• Designed to minimize truck loads (and times) required for moves between drilling sites; complete move

in 48 hours (4 daylight days or less)

AC Programmable

• Uses a variable frequency drive that allows for precise computer control of key drilling parameters

during operations, providing accurate drilling through the wellbore

• AC rigs drill faster with less open hole time and superior wellbore geometry vs. mechanical or SCR rigs

• In today’s market, it is no longer a differentiating feature, it is a requirement

Value Proposition of ICD’s

ShaleDriller® Rig

• Mechanical and SCR rigs have shorter bit life, higher

wellbore deviation and longer open hole times – they drill

slower and with less precision than ICD’s ShaleDriller®

AC rigs

‒ Cycle time reductions gained using ICD’s

ShaleDriller® rigs bend the drilling cost curve

down

• Performance attributes like omni-directional walking, bi-

fuel capable, 1,500 hp drawworks, high pressure mud

systems, and fast moving capabilities are a rare

combination

‒ Only ~140 of these pad-optimal rigs are estimated

to be active in the North American fleet(1)

‒ ICD’s rig fleet has these capabilities, allowing for

operations on the largest pad drilling sites – even with

misaligned wellbores and uneven pads

As commodity prices rise, pad-optimal rigs will be in

short supply (and high demand) while legacy rigs will

continue to be a liability to drilling contractors without

pure-play, high-spec fleets

Pad Optimal ShaleDriller® vs. Non-Pad-Optimal

8

Pad Optimal ShaleDriller® vs. Legacy / SCR

• Legacy AC rigs move slower and cannot accommodate

complex pad drilling applications

• Pad-optimal rigs provide:

‒ Omni-directional walking – can move around complex

pads efficiently

‒ Ability to drill longer laterals

‒ Long, accurate gauge wells – completable

‒ Faster drilling times

‒ Self leveling, with no additional equipment required

‒ Able to adjust quickly to misaligned wellbores

‒ Minimizes formation damage

‒ Elimination of non-productive time and costs

‒ Fastest moving between wells and pads

Pad-optimal rigs provide the industry’s best value

proposition, even at higher dayrates

1. Includes ICD estimates for ICD and its four largest competitors. Excludes skidding rigs.

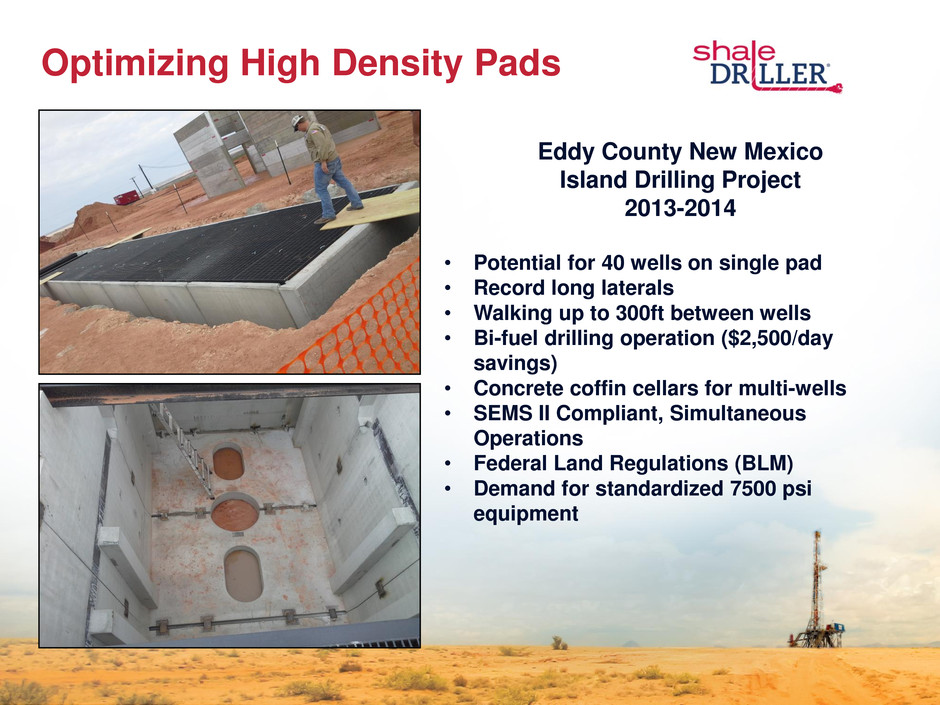

Optimizing High Density Pads

Eddy County New Mexico

Island Drilling Project

2013-2014

• Potential for 40 wells on single pad

• Record long laterals

• Walking up to 300ft between wells

• Bi-fuel drilling operation ($2,500/day

savings)

• Concrete coffin cellars for multi-wells

• SEMS II Compliant, Simultaneous

Operations

• Federal Land Regulations (BLM)

• Demand for standardized 7500 psi

equipment

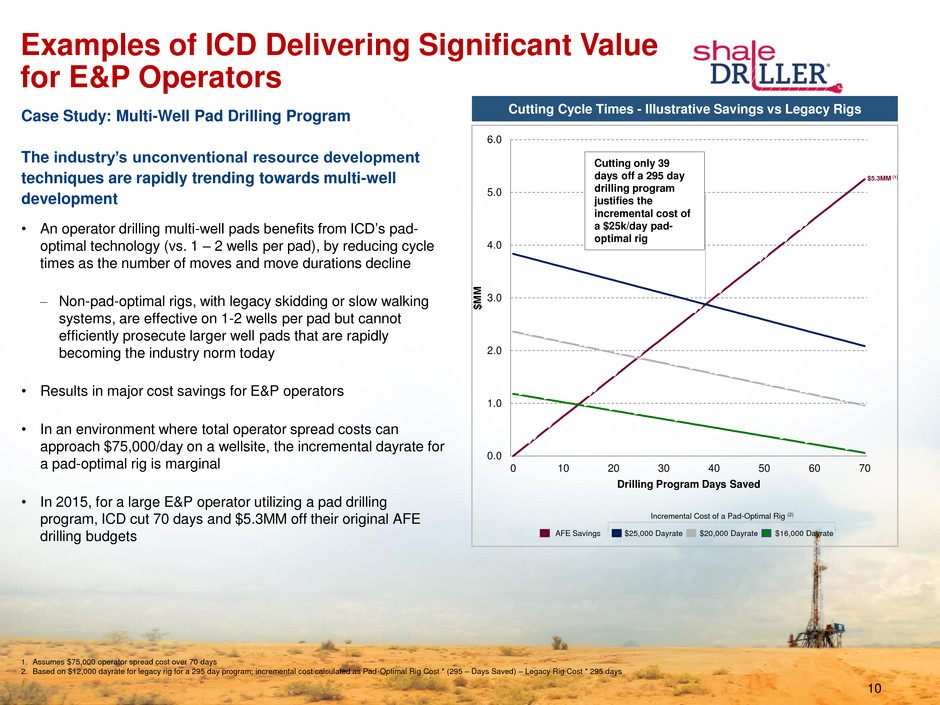

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0 10 20 30 40 50 60 70

$

M

M

Drilling Program Days Saved

Cutting only 39

days off a 295 day

drilling program

justifies the

incremental cost of

a $25k/day pad-

optimal rig

$16,000 Dayrate

$20,000 Dayrate $25,000 Dayrate

Incremental Cost of a Pad-Optimal Rig (2)

AFE Savings

Examples of ICD Delivering Significant Value

for E&P Operators

Cutting Cycle Times - Illustrative Savings vs Legacy Rigs

1. Assumes $75,000 operator spread cost over 70 days

2. Based on $12,000 dayrate for legacy rig for a 295 day program; incremental cost calculated as Pad-Optimal Rig Cost * (295 – Days Saved) – Legacy Rig Cost * 295 days

10

Case Study: Multi-Well Pad Drilling Program

The industry’s unconventional resource development

techniques are rapidly trending towards multi-well

development

• An operator drilling multi-well pads benefits from ICD’s pad-

optimal technology (vs. 1 – 2 wells per pad), by reducing cycle

times as the number of moves and move durations decline

‒ Non-pad-optimal rigs, with legacy skidding or slow walking

systems, are effective on 1-2 wells per pad but cannot

efficiently prosecute larger well pads that are rapidly

becoming the industry norm today

• Results in major cost savings for E&P operators

• In an environment where total operator spread costs can

approach $75,000/day on a wellsite, the incremental dayrate for

a pad-optimal rig is marginal

• In 2015, for a large E&P operator utilizing a pad drilling

program, ICD cut 70 days and $5.3MM off their original AFE

drilling budgets

$5.3MM (1)

86%

14%

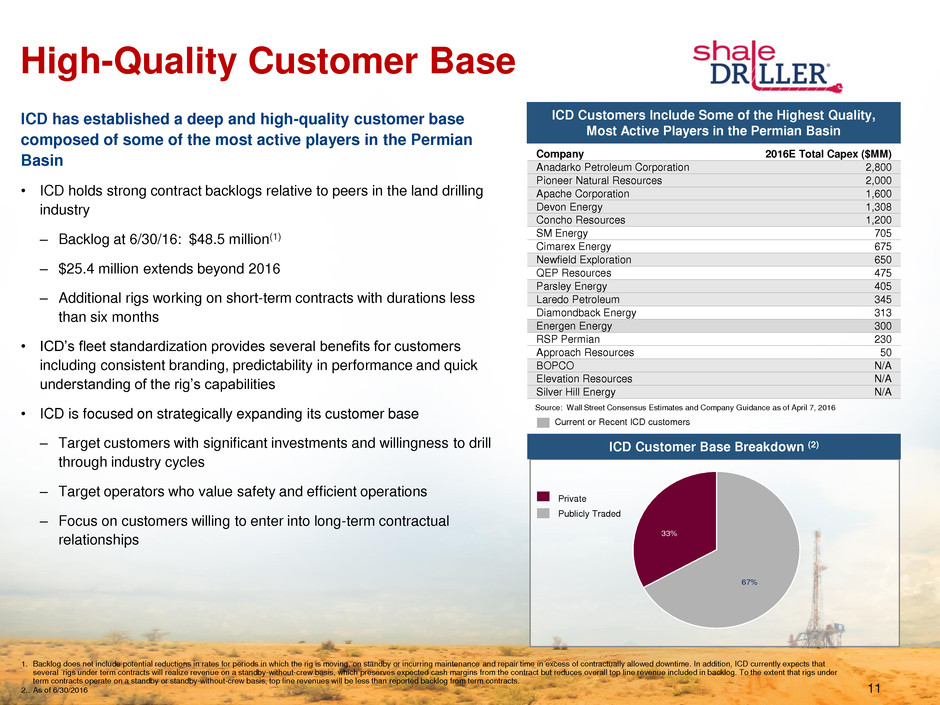

Current or Recent ICD customers

High-Quality Customer Base

Company 2016E Total Capex ($MM)

Anadarko Petroleum Corporation 2,800

Pioneer Natural Resources 2,000

Apache Corporation 1,600

Devon Energy 1,308

Concho Resources 1,200

SM Energy 705

Cimarex Energy 675

Newfield Exploration 650

QEP Resources 475

Parsley Energy 405

Laredo Petroleum 345

Diamondback Energy 313

Energen Energy 300

RSP Permian 230

Approach Resources 50

BOPCO N/A

Elevation Resources N/A

Silver Hill Energy N/A

Source: Wall Street Consensus Estimates and Company Guidance as of April 7, 2016

ICD Customers Include Some of the Highest Quality,

Most Active Players in the Permian Basin

ICD has established a deep and high-quality customer base

composed of some of the most active players in the Permian

Basin

• ICD holds strong contract backlogs relative to peers in the land drilling

industry

– Backlog at 6/30/16: $48.5 million(1)

– $25.4 million extends beyond 2016

– Additional rigs working on short-term contracts with durations less

than six months

• ICD’s fleet standardization provides several benefits for customers

including consistent branding, predictability in performance and quick

understanding of the rig’s capabilities

• ICD is focused on strategically expanding its customer base

– Target customers with significant investments and willingness to drill

through industry cycles

– Target operators who value safety and efficient operations

– Focus on customers willing to enter into long-term contractual

relationships

11

ICD Customer Base Breakdown (2)

Publicly Traded

Private

1. Backlog does not include potential reductions in rates for periods in which the rig is moving, on standby or incurring maintenance and repair time in excess of contractually allowed downtime. In addition, ICD currently expects that

several rigs under term contracts will realize revenue on a standby-without-crew basis, which preserves expected cash margins from the contract but reduces overall top line revenue included in backlog. To the extent that rigs under

term contracts operate on a standby or standby-without-crew basis, top line revenues will be less than reported backlog from term contracts.

2.. As of 6/30/2016

33%

67%

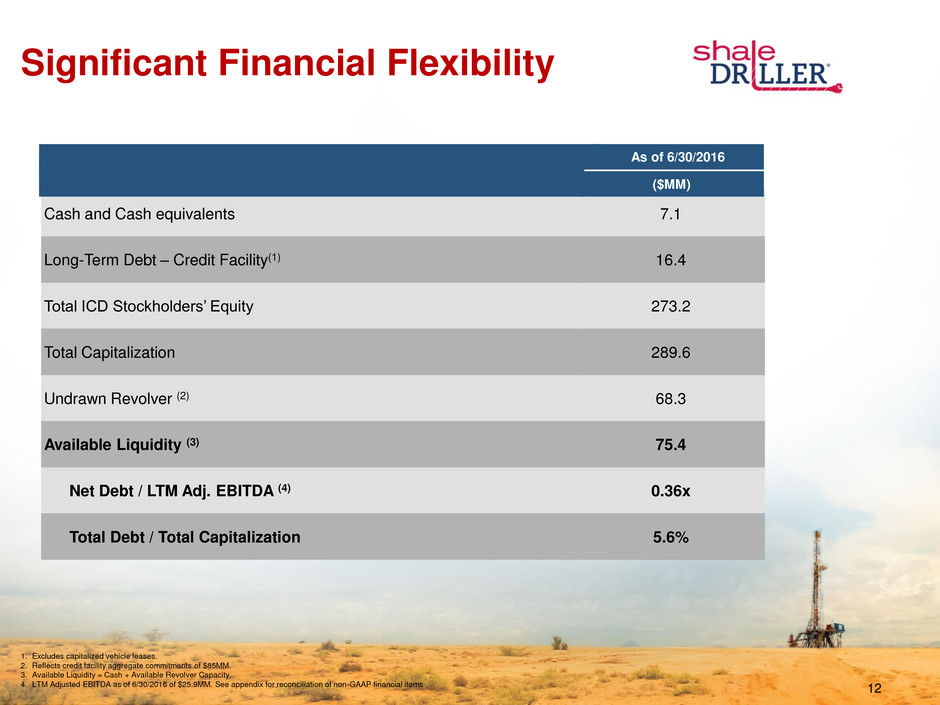

Significant Financial Flexibility

12

Cash and Cash equivalents 7.1

Long-Term Debt – Credit Facility(1) 16.4

Total ICD Stockholders’ Equity 273.2

Total Capitalization 289.6

Undrawn Revolver (2) 68.3

Available Liquidity (3) 75.4

Net Debt / LTM Adj. EBITDA (4) 0.36x

Total Debt / Total Capitalization 5.6%

($MM)

As of 6/30/2016

1. Excludes capitalized vehicle leases.

2. Reflects credit facility aggregate commitments of $85MM.

3. Available Liquidity = Cash + Available Revolver Capacity.

4. LTM Adjusted EBITDA as of 6/30/2016 of $25.9MM. See appendix for reconciliation of non-GAAP financial items

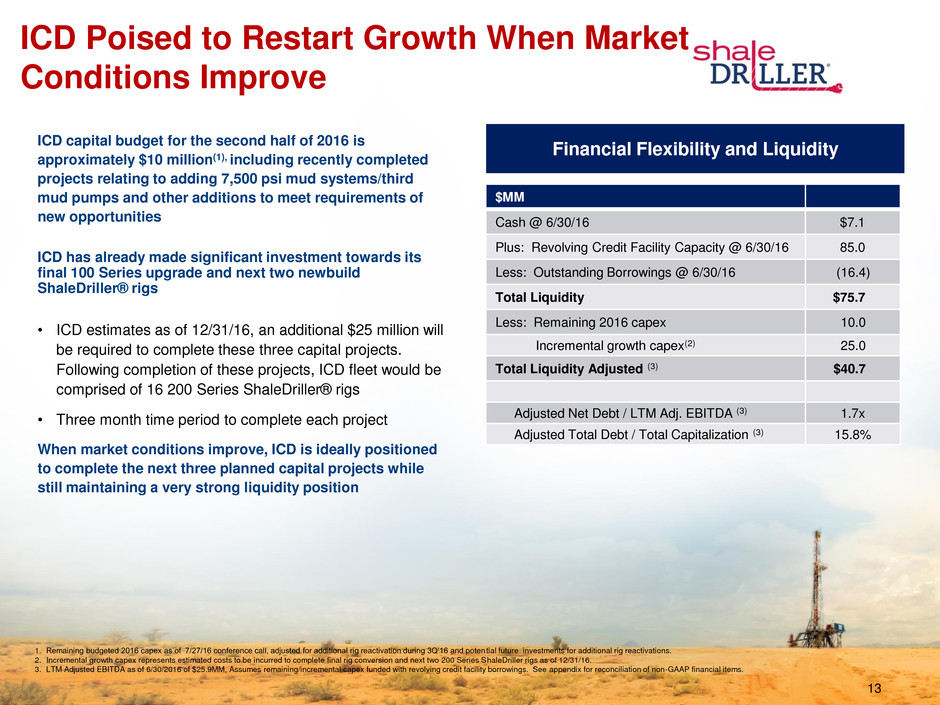

ICD Poised to Restart Growth When Market

Conditions Improve

ICD capital budget for the second half of 2016 is

approximately $10 million(1), including recently completed

projects relating to adding 7,500 psi mud systems/third

mud pumps and other additions to meet requirements of

new opportunities

ICD has already made significant investment towards its

final 100 Series upgrade and next two newbuild

ShaleDriller® rigs

• ICD estimates as of 12/31/16, an additional $25 million will

be required to complete these three capital projects.

Following completion of these projects, ICD fleet would be

comprised of 16 200 Series ShaleDriller® rigs

• Three month time period to complete each project

When market conditions improve, ICD is ideally positioned

to complete the next three planned capital projects while

still maintaining a very strong liquidity position

13

Financial Flexibility and Liquidity

1. Remaining budgeted 2016 capex as of 7/27/16 conference call, adjusted for additional rig reactivation during 3Q’16 and poten tial future investments for additional rig reactivations.

2. Incremental growth capex represents estimated costs to be incurred to complete final rig conversion and next two 200 Series ShaleDriller rigs as of 12/31/16.

3. LTM Adjusted EBITDA as of 6/30/2016 of $25.9MM, Assumes remaining/incremental capex funded with revolving credit facility borrowings. See appendix for reconciliation of non-GAAP financial items.

$MM

Cash @ 6/30/16 $7.1

Plus: Revolving Credit Facility Capacity @ 6/30/16 85.0

Less: Outstanding Borrowings @ 6/30/16 (16.4)

Total Liquidity $75.7

Less: Remaining 2016 capex 10.0

Incremental growth capex(2) 25.0

Total Liquidity Adjusted (3) $40.7

Adjusted Net Debt / LTM Adj. EBITDA (3) 1.7x

Adjusted Total Debt / Total Capitalization (3) 15.8%

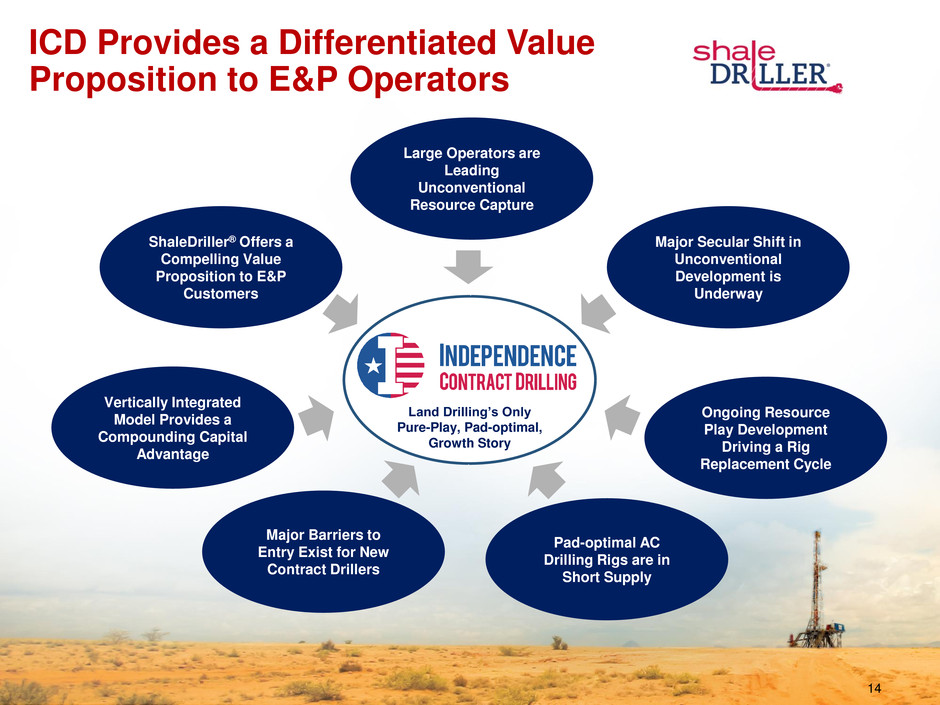

Land Drilling’s Only

Pure-Play, Pad-optimal,

Growth Story

Large Operators are

Leading

Unconventional

Resource Capture

Major Secular Shift in

Unconventional

Development is

Underway

Ongoing Resource

Play Development

Driving a Rig

Replacement Cycle

Pad-optimal AC

Drilling Rigs are in

Short Supply

Major Barriers to

Entry Exist for New

Contract Drillers

Vertically Integrated

Model Provides a

Compounding Capital

Advantage

ShaleDriller® Offers a

Compelling Value

Proposition to E&P

Customers

ICD Provides a Differentiated Value

Proposition to E&P Operators

14

Non-GAAP Financial Measures

15

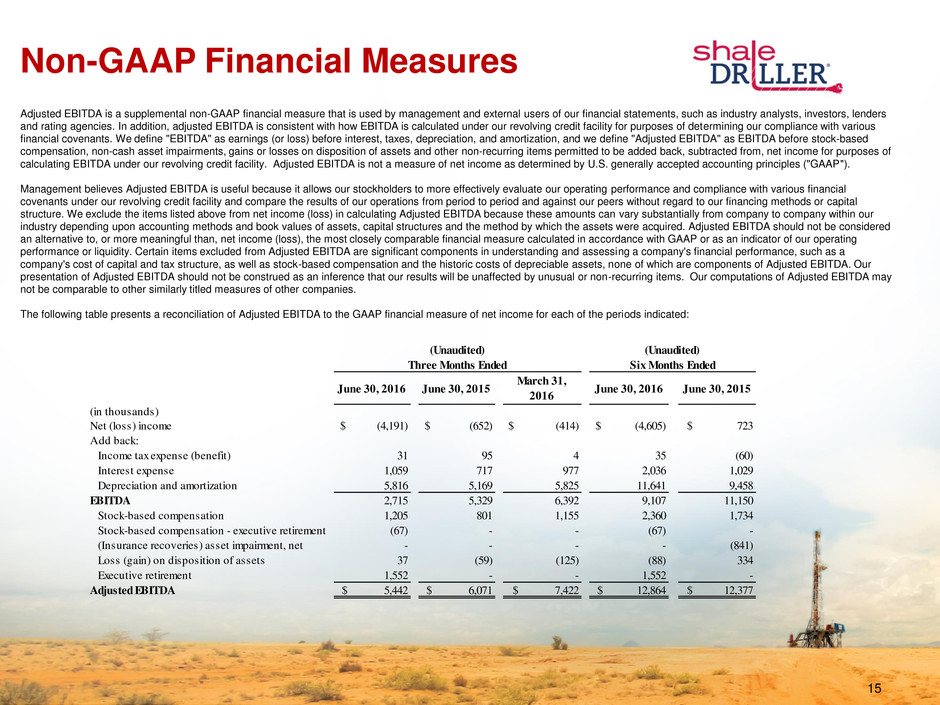

Adjusted EBITDA is a supplemental non-GAAP financial measure that is used by management and external users of our financial statements, such as industry analysts, investors, lenders

and rating agencies. In addition, adjusted EBITDA is consistent with how EBITDA is calculated under our revolving credit facility for purposes of determining our compliance with various

financial covenants. We define "EBITDA" as earnings (or loss) before interest, taxes, depreciation, and amortization, and we define "Adjusted EBITDA" as EBITDA before stock-based

compensation, non-cash asset impairments, gains or losses on disposition of assets and other non-recurring items permitted to be added back, subtracted from, net income for purposes of

calculating EBITDA under our revolving credit facility. Adjusted EBITDA is not a measure of net income as determined by U.S. generally accepted accounting principles ("GAAP").

Management believes Adjusted EBITDA is useful because it allows our stockholders to more effectively evaluate our operating performance and compliance with various financial

covenants under our revolving credit facility and compare the results of our operations from period to period and against our peers without regard to our financing methods or capital

structure. We exclude the items listed above from net income (loss) in calculating Adjusted EBITDA because these amounts can vary substantially from company to company within our

industry depending upon accounting methods and book values of assets, capital structures and the method by which the assets were acquired. Adjusted EBITDA should not be considered

an alternative to, or more meaningful than, net income (loss), the most closely comparable financial measure calculated in accordance with GAAP or as an indicator of our operating

performance or liquidity. Certain items excluded from Adjusted EBITDA are significant components in understanding and assessing a company's financial performance, such as a

company's cost of capital and tax structure, as well as stock-based compensation and the historic costs of depreciable assets, none of which are components of Adjusted EBITDA. Our

presentation of Adjusted EBITDA should not be construed as an inference that our results will be unaffected by unusual or non-recurring items. Our computations of Adjusted EBITDA may

not be comparable to other similarly titled measures of other companies.

The following table presents a reconciliation of Adjusted EBITDA to the GAAP financial measure of net income for each of the periods indicated:

June 30, 2016 June 30, 2015

March 31,

2016

June 30, 2016 June 30, 2015

(in thousands)

Net (loss) income $ (4,191) $ (652) $ (414) $ (4,605) $ 723

dd back:

I c m x xp (benefit) 31 95 4 35 (60)

Int rest xpe s 1,059 717 977 2,036 1,029

D pr i ion an mortization 5,816 5,169 5,825 11,641 9,458

E ITDA 2,715 5,329 6,392 9,107 11,150

Stock-based compensation 1,205 801 1,155 2,360 1,734

Stock-based compensation - executive retirement (67) - - (67) -

(Insurance recoveries) asset impairment, net - - - - (841)

Loss (gain) on disposition of assets 37 (59) (125) (88) 334

Executive retirement 1,552 - - 1,552 -

Adjusted EBITDA $ 5,442 $ 6,071 $ 7,422 $ 12,864 $ 12,377

(Unaudited)

Six Months EndedThree Months Ended

(Unaudited)

178

178

178

178

210

224

38

84

124

110

0

50

0

62

126

0

32

96

16