Attached files

| file | filename |

|---|---|

| 8-K - 8-K INVESTOR PRESENTATION - Chemours Co | a9142016investormeeting.htm |

The Chemours Company

Investor Meetings

September 2016

Exhibit 99.1

This presentation contains forward-looking statements, which often may be identified by their use of words like “plans,”

“expects,” “will,” “believes,” “intends,” “estimates,” targets,” “anticipates” or other words of similar meaning. These

forward-looking statements address, among other things, our anticipated future operating and financial performance,

business plans and prospects, transformation plans, resolution of environmental liabilities, litigation and other

contingencies, plans to increase profitability, our ability to pay or the amount of any dividend, and target leverage that

are subject to substantial risks and uncertainties that could cause actual results to differ materially from those

expressed or implied by such statements. Forward-looking statements are not guarantees of future performance and

are based on certain assumptions and expectations of future events which may not be realized. The matters discussed

in these forward-looking statements are subject to risks, uncertainties and other factors that could cause actual results

to differ materially from those projected, anticipated or implied in the forward-looking statements, as further described in

our filings with the Securities and Exchange Commission, including our annual report on Form 10-K for the fiscal year

ended December 31, 2015. Chemours undertakes no duty to update any forward-looking statements.

This presentation contains certain supplemental measures of performance that are not required by, or presented in

accordance with, generally accepted accounting principles in the United States (“GAAP”). These Non-GAAP measures

include Adjusted Net Income (Loss), Adjusted EPS, Adjusted EBITDA and Free Cash Flow, which should not be

considered as replacements of GAAP. Free Cash Flow is defined as Cash from Operations minus cash used for PP&E

purchases. Further information with respect to and reconciliations of such measures to the nearest GAAP measure can

be found in the appendix hereto.

Management uses Adjusted Net Income (Loss), Adjusted EPS, Adjusted EBITDA and Free Cash Flow to evaluate the

Company’s performance excluding the impact of certain non-cash charges and other special items in order to have

comparable financial results to analyze changes in our underlying business from quarter to quarter.

Historical results prior to July 1, 2015 are presented on a stand-alone basis from DuPont historical results and are

subject to certain adjustments and assumptions as indicated in this presentation, and may not be an indicator of future

performance.

Additional information for investors is available on the company’s website at investors.chemours.com.

Safe Harbor Statement

1

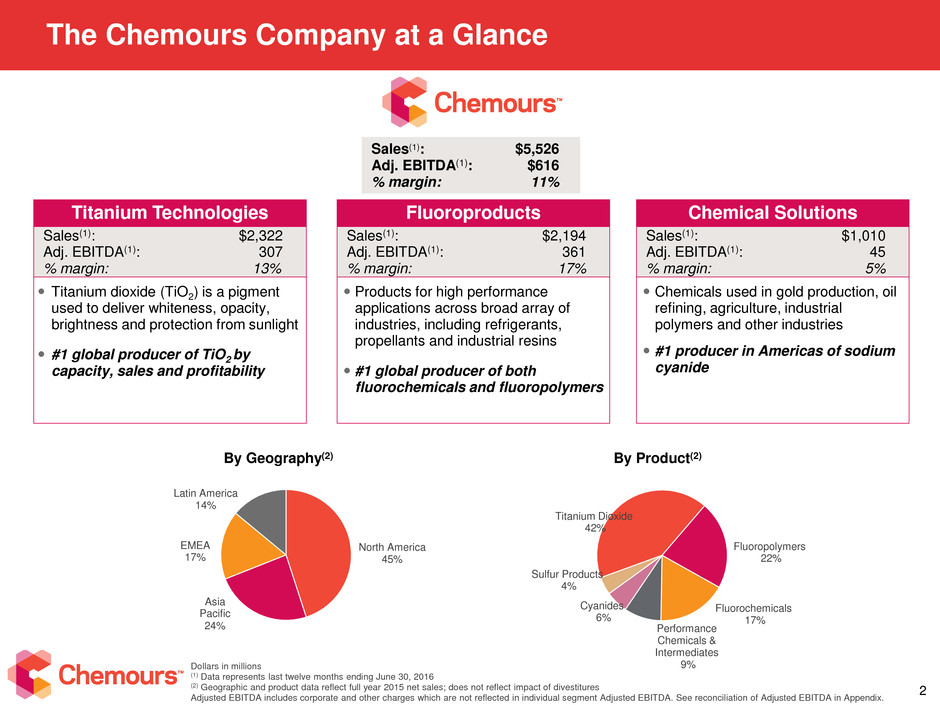

Titanium Dioxide

42%

Fluoropolymers

22%

Fluorochemicals

17%

Performance

Chemicals &

Intermediates

9%

Cyanides

6%

Sulfur Products

4%

Chemicals used in gold production, oil

refining, agriculture, industrial

polymers and other industries

#1 producer in Americas of sodium

cyanide

Titanium dioxide (TiO2) is a pigment

used to deliver whiteness, opacity,

brightness and protection from sunlight

#1 global producer of TiO2 by

capacity, sales and profitability

Products for high performance

applications across broad array of

industries, including refrigerants,

propellants and industrial resins

#1 global producer of both

fluorochemicals and fluoropolymers

The Chemours Company at a Glance

Sales(1): $5,526

Adj. EBITDA(1): $616

% margin: 11%

Titanium Technologies

Sales(1): $2,322

Adj. EBITDA(1): 307

% margin: 13%

Fluoroproducts

Sales(1): $2,194

Adj. EBITDA(1): 361

% margin: 17%

Chemical Solutions

Sales(1): $1,010

Adj. EBITDA(1): 45

% margin: 5%

By Geography(2) By Product(2)

Dollars in millions

(1) Data represents last twelve months ending June 30, 2016

(2) Geographic and product data reflect full year 2015 net sales; does not reflect impact of divestitures

Adjusted EBITDA includes corporate and other charges which are not reflected in individual segment Adjusted EBITDA. See reconciliation of Adjusted EBITDA in Appendix.

2

North America

45%

Asia

Pacific

24%

EMEA

17%

Latin America

14%

3

Transformation Plan Priorities

Refocus

Investments

Concentrate capital spending on investable business portfolio

Announced investment in the next increment of Opteon™ capacity

Rationalize annual capital spending to ~$350M over time

Reduce Costs

Achieved cost reductions of ~$100M in first half of 2016

Anticipating $200M of cost reductions to be realized in 2016 over 2015

Targeting additional cost reduction of $150M in 2017

Optimize The

Portfolio

Grow Market

Positions

Support customer growth in TiO2 through successful Altamira start-up and disciplined approach to pricing

Continue ramp up of Opteon™ product lines in Fluoroproducts

Grow Cyanides business with key customers

Target $150M Adjusted EBITDA growth from Opteon™ and Altamira through 2017

Plan Well Underway to Enhance Adjusted EBITDA by $500M,

Improve Free Cash Flow and Reduce Leverage to ~3x in 2017

Enhance Our

Organization

Foster an entrepreneurial organization

Operate with a simpler structure

Maintain a commitment to a safe and sustainable future

Completed strategic review of Chemical Solutions segment

Closed Aniline, Sulfur and Clean & Disinfect sales, generated ~$695M in gross proceeds

Retaining and improving cost position of Belle, WV site

Altamira

Commercial

Operations

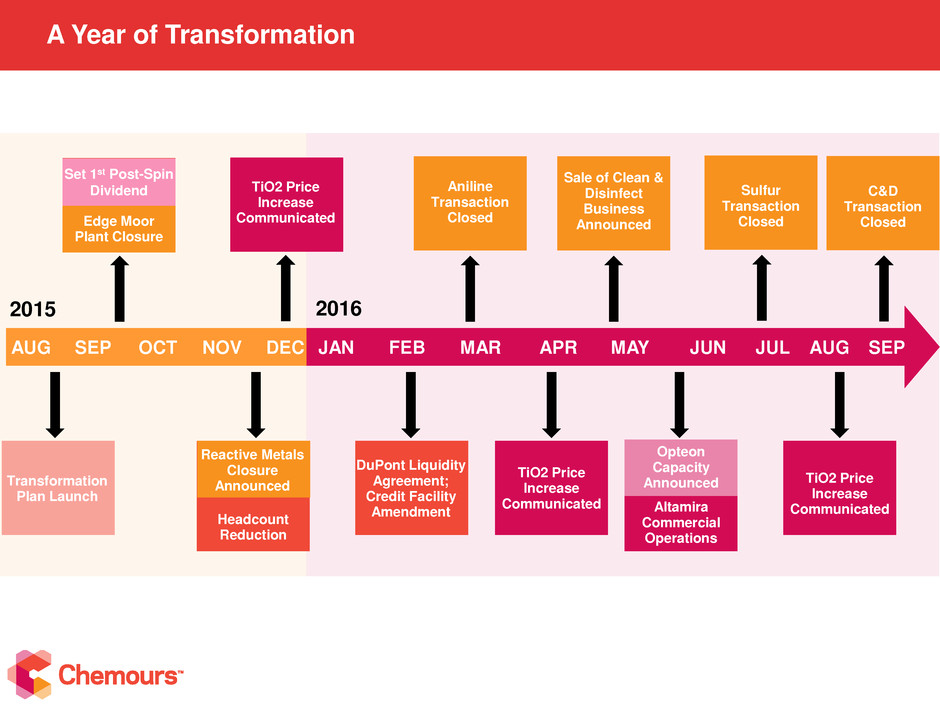

A Year of Transformation

4

AUG SEP OCT NOV DEC JAN FEB MAR APR MAY JUN JUL AUG

TiO2 Price

Increase

Communicated

2015 2016

Set 1st Post-Spin

Dividend

Edge Moor

Plant Closure

Transformation

Plan Launch

Opteon

Capacity

Announced

DuPont Liquidity

Agreement;

Credit Facility

Amendment

TiO2 Price

Increase

Communicated

Aniline

Transaction

Closed

Sale of Clean &

Disinfect

Business

Announced

Reactive Metals

Closure

Announced

Headcount

Reduction

Sulfur

Transaction

Closed

TiO2 Price

Increase

Communicated

C&D

Transaction

Closed

SEP

Titanium Technologies

Paper

14%

Coatings

57%

Plastics

25%

Specialty

4%

North

America

32%

Asia

Pacific

32%

EMEA

22%

Latin

America

14%

Global leader in TiO2 with production capacity

of 1.25 million metric tons(1)

− 4 TiO2 plants with 7 production lines

(1)

− Packaging facility at Kallo, Belgium

− Mineral sands mine at Starke, FL

Industry-leading manufacturing cost position

− Unique chloride technology

− Feedstock flexibility

Strong brand reputation

− Ti-Pure™ sold to ~800 customers globally

Chemours Titanium Technologies Business Overview

Coatings – architectural, industrial,

automotive

Plastics – rigid / flexible packaging,

PVC pipe/windows

Papers – laminate papers, coated

paper/paperboard, sheet

Specialty – rubber, leather, diesel

particulate filters

Geography(3) End Market(3)

Source: Company filings and data. Titanium Technologies: TZMI (2015)

(1) Pro forma for completion of Altamira expansion

(2) TiO2 market share statistics based on volume statistics from company filings and market estimates

(3) Reflects full year 2015 segment net sales

6

Business Overview Chemours is #1 in TiO2 Globally

(2)

18%

13% 13%

9%

8%

5%

3%

Chemours Cristal Huntsman Kronos Tronox Lomon Henan

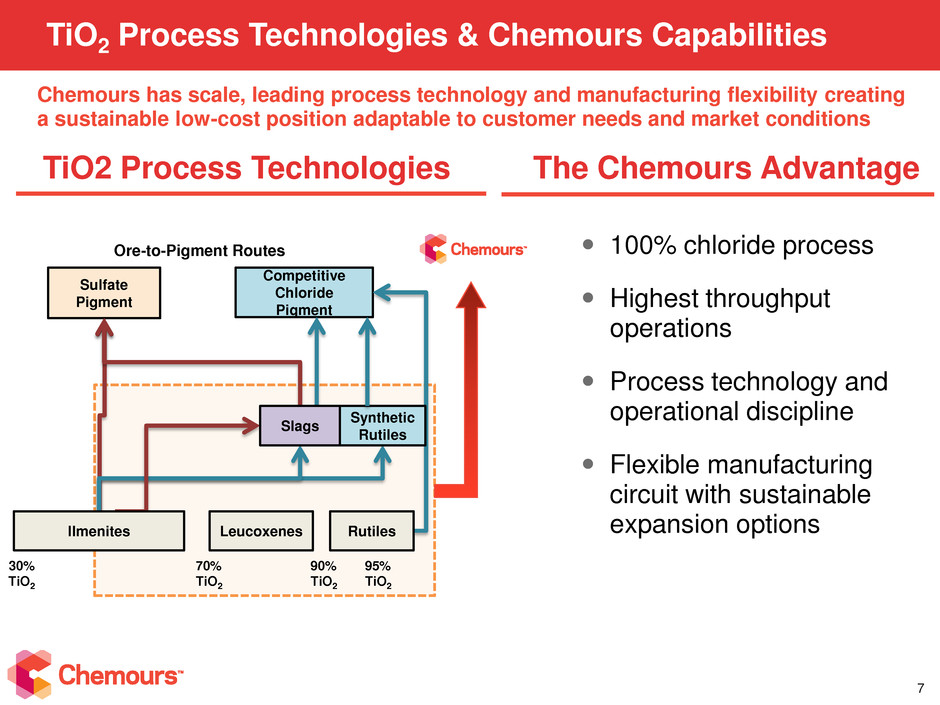

Ore-to-Pigment Routes

30%

TiO2

95%

TiO2

90%

TiO2

70%

TiO2

Sulfate

Pigment

Competitive

Chloride

Pigment

Ilmenites

Slags

Synthetic

Rutiles

Leucoxenes Rutiles

Chemours has scale, leading process technology and manufacturing flexibility creating

a sustainable low-cost position adaptable to customer needs and market conditions

TiO2 Process Technologies & Chemours Capabilities

7

100% chloride process

Highest throughput

operations

Process technology and

operational discipline

Flexible manufacturing

circuit with sustainable

expansion options

TiO2 Process Technologies The Chemours Advantage

Chemours delivers high-quality product to serve customers in attractive

higher value-add segments of the TiO2 market

TiO2 Market Segments Addressed by Producers

8

Source: Chemours Estimates

Quality and performance of TiO2

products differ considerably across

market segments and applications

Segments are supplied by two

manufacturing systems (Regional

and Multinational Producers)

Utilization is higher at

manufacturing facilities supplying

specialty and higher value pigment

segments

Separation remains in multi-

purpose segments based on

pigment quality, product design and

supply capability

Chemours’ product value and cost offer supply security in a stressed TiO2

industry

TiO2 Market: Cost Differentials

9

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

120%

130%

140%

0 500 1,000 2,600 1,800 3,100 3,600 4,100 1,400 4,500 5,000 5,500 6,000

N

o

rmail

z

ied

C

o

st/

p

ric

e

$/

T

o

n

n

e

Realizable Capacity (Metric kT)

Multi-National Producers

2Q16 avg. China

export quality

Range of China

Domestic Cost

China

Export

Chemours

China

Domestic

2Q16 avg. price HQ Global

Source: Chemours estimates based on internal calculations; price estimates from industry sources

2Q16 avg. China

domestic – low

quality

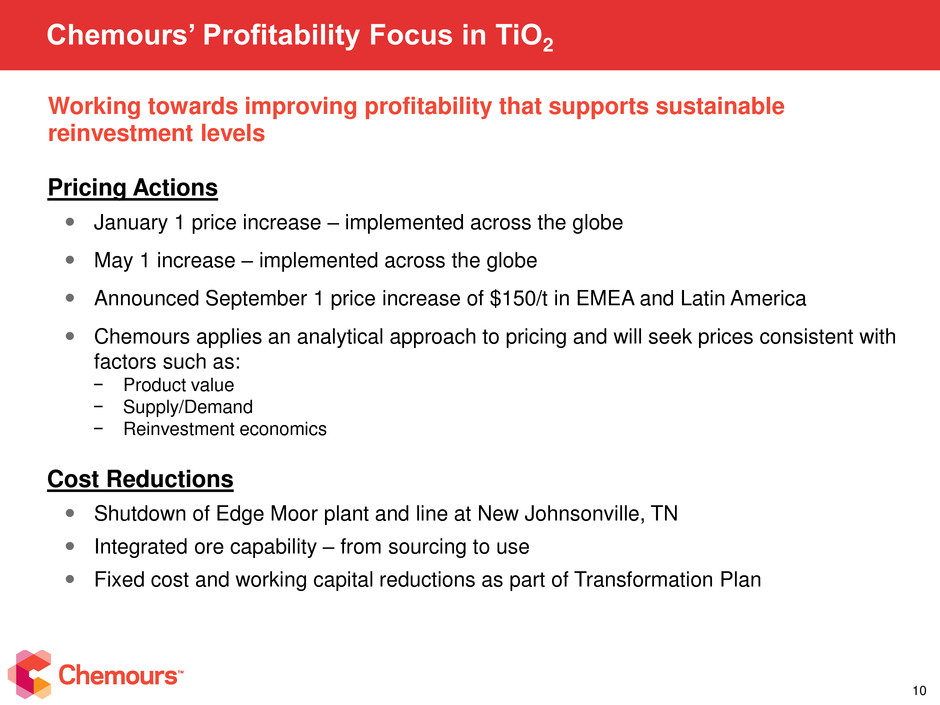

Chemours’ Profitability Focus in TiO2

10

Working towards improving profitability that supports sustainable

reinvestment levels

Pricing Actions

January 1 price increase – implemented across the globe

May 1 increase – implemented across the globe

Announced September 1 price increase of $150/t in EMEA and Latin America

Chemours applies an analytical approach to pricing and will seek prices consistent with

factors such as:

− Product value

− Supply/Demand

− Reinvestment economics

Cost Reductions

Shutdown of Edge Moor plant and line at New Johnsonville, TN

Integrated ore capability – from sourcing to use

Fixed cost and working capital reductions as part of Transformation Plan

Fluoroproducts

Supplies products for high performance

applications across broad array of industries

#1 in Fluoroproducts globally

− Fluorochemicals: #1 in refrigerants, #1 in propellants,

#3 in foaming agents

− Fluoropolymers: #1 in industrial resins, #1 in

fluoropolymer specialties

Key Brands include Teflon™, Freon™, Opteon™,

Krytox ™, Nafion™, Viton™

Fluoroproducts Business Overview

Geography(1) Product(1)

Source: Company filings and data, Fluoroproducts: Company filings and Management estimates

(1)Reflects full year 2015 segment net sales

(2)Fluorochemicals and fluoropolymers market share statistics based on 2015 internal revenue estimates and company filings

(3)Includes 100% contribution from the DuPont-Mitsui Fluorocarbon Company joint venture

12

F

lu

o

ro

chemical

s

F

lu

o

ro

p

o

ly

mer

s

(3)

Fluorochemicals – mainly

refrigerants, propellants, and foam

expansion agent

Fluoropolymers – mainly industrial

resins and downstream products &

coatings

Key End Markets – AC, refrigeration,

automotive, aerospace, wire & cable,

consumer electronics and

telecommunications

22%

17% 17%

8% 7%

Honeywell Arkema Dongyue Mexichem25%

16%

12% 11%

6%

Daikin 3M (Dyneon) Solvay Dongyue

Business Overview Chemours is #1 in Fluoroproducts Globally(2)

North

America

47%

Asia

Pacific

24%

EMEA

18%

Latin

America

11%

Fluoropo

lymers

56%

Fluoroch

emicals

44%

Fast Pace Adoption of Opteon™

13

Opteon™ YF

Next Gen Gas for mobile air-

conditioning

HFO-1336(Z)

Next Gen Liquids for Foams,

Centrifugal Chillers, Organic

Rankine Cycles, High Temp

Heat Pumps

Opteon™ YF blends

Next Gen Gas for Commercial

Refrigeration, Residential/Light

Commercial A/C, Chillers, High

Temp Heat Pump

Market-Leading Portfolio

Opteon™ Technology offers sustainable technology option

in the face of upcoming regulatory deadlines

• Opteon™ Expected to Provide >$100M of Adjusted EBITDA Growth thru 2017

• Growth beyond 2018 will be supplied by facility in Corpus Christi

Opteon™ Revenue Outlook

>$100M Incremental

Adjusted EBITDA

Fluoropolymers: Tailored Solutions for Growth Opportunities

14

Diverse End-Use Applications

Chemours delivers high value fluoropolymer solutions used in

complex and highly demanding applications

Market Dynamics

Demand conditions driven by GDP growth

in North America Europe and slower growth

in China

Weak Euro and Yen in 2015 led to pricing

pressures

Chemours’ strong collaborations in

automotive, telecommunications, and

consumer electronics markets provide solid

base of demand and growth opportunities

Targeted innovation and application

development in fluoropolymer resins and

formulations expected to produce future

customer solutions

Energy Storage – Nafion™

Specialty ion exchange polymer

membrane to store alternative

energy in flow batteries

Consumer Electronics – Teflon™

Faster data speeds & power/data

combination cable designs

Turbo Charger Hoses – Viton™

Enable higher engine temperatures

and advanced technology options to

drive fuel efficiency improvements

Chemical Solutions

Divest

Total gross proceeds of ~$695 million - Average multiple of ~10 – 12x

Minimal net free cash flow impact

Focus to drive out stranded costs as part of Five-Point Transformation Plan

Clean & Disinfect

• Sold to Lanxess for $230 million

• Completed September 2016

Sulfur

• Sold to Veolia for $325 million

• Completed July 2016

Aniline

• Sold to Dow for ~$140 million

• Completed March 2016

Strategic Review of Chemical Solutions Portfolio Complete

16

Strategic Review Results

* Includes Methylamines, Glycolic and Vazo product lines

Close

Reactive Metals

• Expected end of 2016

Retain

Cyanides Belle, WV Site*

Chemours Cyanide Opportunity

17

Americas Sodium Cyanide Market The Chemours Advantage

Aligned with customer values

On-purpose producer, reliable supply

Differentiating product stewardship

Strong logistics network

Long term contracts

9% CAGR

2014

(252 KTons)

2019

(393 KTons)

Imports

NAFTA

Producers

Chemours Imports

NAFTA

Producers

Chemours

Americas NaCN demand forecast to grow at 9%

CAGR over next four years

Remains net import market

Deteriorating ore quality contributes to underlying NaCN

demand growth

Source: Chemours internal estimates

Financial Position

2Q16 Overview

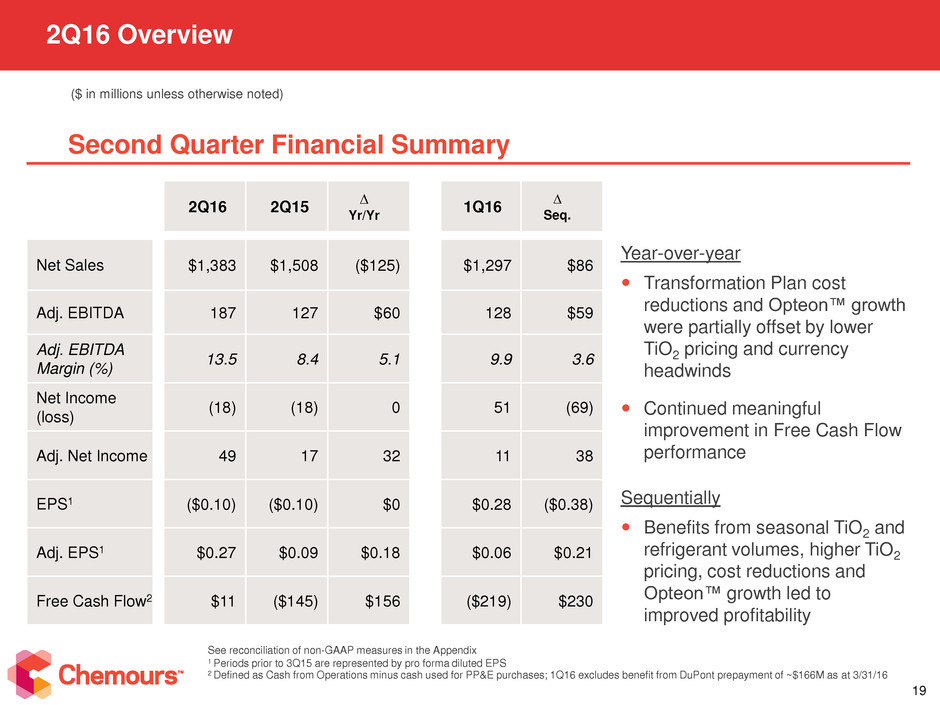

19

Second Quarter Financial Summary

2Q16 2Q15

∆

Yr/Yr

1Q16

∆

Seq.

Net Sales $1,383 $1,508 ($125) $1,297 $86

Adj. EBITDA 187 127 $60 128 $59

Adj. EBITDA

Margin (%)

13.5 8.4 5.1 9.9 3.6

Net Income

(loss)

(18) (18) 0 51 (69)

Adj. Net Income 49 17 32 11 38

EPS1 ($0.10) ($0.10) $0 $0.28 ($0.38)

Adj. EPS1 $0.27 $0.09 $0.18 $0.06 $0.21

Free Cash Flow2 $11 ($145) $156 ($219) $230

($ in millions unless otherwise noted)

See reconciliation of non-GAAP measures in the Appendix

1 Periods prior to 3Q15 are represented by pro forma diluted EPS

2 Defined as Cash from Operations minus cash used for PP&E purchases; 1Q16 excludes benefit from DuPont prepayment of ~$166M as at 3/31/16

Year-over-year

Transformation Plan cost

reductions and Opteon™ growth

were partially offset by lower

TiO2 pricing and currency

headwinds

Continued meaningful

improvement in Free Cash Flow

performance

Sequentially

Benefits from seasonal TiO2 and

refrigerant volumes, higher TiO2

pricing, cost reductions and

Opteon™ growth led to

improved profitability

Liquidity Profile Since Spin

20

$0.0

$1.0

$2.0

$3.0

$4.0

$0.0

$0.5

$1.0

$1.5

$2.0

2Q15 3Q15 4Q15 1Q16 2Q16

Cash Revolver Availability Net Debt

2Q15 3Q15 4Q15 1Q16 2Q16

T

o

ta

l

Liquidit

y

*

($B

)

Net D

e

b

t ($B

)

$0.7B

$3.8B

$1.0B

$3.8B

$1.1B

$3.6B $3.6B $3.5B

$1.2B

$1.1B

*Defined as cash plus revolver availability

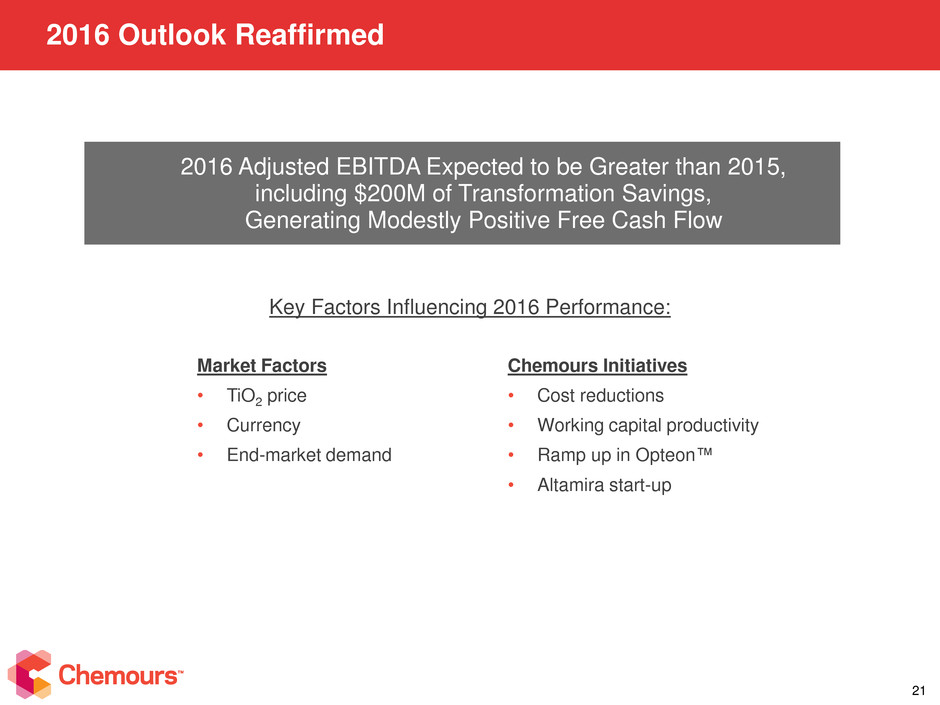

2016 Outlook Reaffirmed

21

2016 Adjusted EBITDA Expected to be Greater than 2015,

including $200M of Transformation Savings,

Generating Modestly Positive Free Cash Flow

Market Factors

• TiO2 price

• Currency

• End-market demand

Chemours Initiatives

• Cost reductions

• Working capital productivity

• Ramp up in Opteon™

• Altamira start-up

Key Factors Influencing 2016 Performance:

Appendix

Quality and performance of TiO2 products differ considerably

across segments of the market that serve different applications

TiO2 Applications

Specialty and High Quality Applications: 40%

Performance polymers, Exterior Architectural Paint,

Automated Tint System Coatings and durable

Industrial coatings

Commands premium due to superior pigment

product design & performance

Pharma, Food and Cosmetics*

Multi-Purpose Applications: 30%

High quality architectural paint, white,

industrial coatings

Commands premium due to interior/exterior durability

and a high level of product consistency

Fit for Use Applications: 20%

Interior arch factory color paint, fibers, non durable

polymer applications

Less stringent batch to batch variability requirements

(lesser pigment quality needs)

Lowest Quality requirement Applications: 10%

Ceramics, road paint

C

h

e

mour

s

Fo

c

u

s

23

* Chemours does not participate in these applications

Segment Net Sales and Adjusted EBITDA (unaudited)

($ in millions unless otherwise noted)

LTM

2Q16 2Q16 1Q16 4Q15 3Q15

Titanium Technologies 2,322$ 596$ 521$ 589$ 616$

Fluoroproducts 2,194 573 531 515 575

Chemical Solutions 1,010 214 245 256 295

TOTAL NET SALES 5,526$ 1,383$ 1,297$ 1,360$ 1,486$

LTM

2Q16 2Q16 1Q16 4Q15 3Q15

Titanium Technologies 307$ 111$ 54$ 62$ 80$

Fluoroproducts 361 105 85 80 91

Chemical Solutions 45 11 10 16 8

Corporate & Other (97) (40) (21) (26) (10)

TOTAL ADJUSTED EBITDA 616$ 187$ 128$ 132$ 169$

LTM

2Q16 2Q16 1Q16 4Q15 3Q15

Titanium Technologies 13.2% 18.6% 10.4% 10.5% 13.0%

Fluoroproducts 16.5% 18.3% 16.0% 15.5% 15.8%

Chemical Solutions 4.5% 5.1% 4.1% 6.3% 2.7%

Corporate & Other 0.0% 0.0% 0.0% 0.0% 0.0%

TOTAL CHEMOURS 11.1% 13.5% 9.9% 9.7% 11.4%

* - Note summation of individual quarters may not sum to LTM figure due to rounding.

SEGMENT NET SALES (UNAUDITED)

SEGMENT ADJUSTED EBITDA (UNAUDITED)

SEGMENT ADJUSTED EBITDA MARGIN (UNAUDITED)

GAAP Net Income (Loss) to Adjusted EBITDA and Adjusted Net

Income Reconciliations

25

($ in millions unless otherwise noted)

LTM

2Q16 2Q16 1Q16 4Q15 3Q15

Net income (loss) attributable to Chemours (82)$ (18)$ 51$ (86)$ (29)$

Non-operating pension and other postretirement employee benefit costs (32) (7) (7) (8) (10)

Exchange losses (gains) 4 14 6 28 (44)

Restructuring charges 250 9 17 85 139

Asset related charges 136 63 - 3 70

(Gain) loss on sale of assets or business (79) 1 (89) 9 -

Transaction costs 24 12 3 9 -

Legal and other charges 26 13 5 8 -

Provision for (benefit from) income taxes relating to reconciling items

1

(116) (38) 25 (43) (60)

Adjusted Net Income 131$ 49$ 11$ 5$ 66$

Net income attributable to noncontrolling interests - - - - -

Interest expense, net 211 50 57 53 51

Depreciation and amortization 275 73 66 66 70

All remaining (benefit from) provision for income taxes 1 (1) 15 (6) 8 (18)

Adjusted EBITDA 616$ 187$ 128$ 132$ 169$

Adjusted earnings per share, basic

2

0.72$ 0.27$ 0.06$ 0.03$ 0.36$

Adjusted earnings per share, diluted

2

0.72$ 0.27$ 0.06$ 0.03$ 0.36$

1 Total of provision for (benefit from) income taxes reconciles to the amount reported in the interim consolidated statement of operations for the three

months ended June 30, 2016, March 31, 2016, September 31, 2015, June 30, 2015, March 31, 2015 and year ended December 31, 2015.

2 On July 1, 2015, E.I. du Pont de Nemours and Company distributed 180,966,833 shares of Chemours' common stock to holders of its common stock.

Basic and diluted earnings per common share for the three months ended March 31, 2015 and June 30, 2015 were calculated using the number of shares

distributed on July 1, 2015.

Free Cash Flow Reconciliation

26

($ in millions unless otherwise noted)

LTM

2Q16 2Q16 1Q16 4Q15 3Q15

C sh provided by (used for) operating activities 541$ 90$ 36$ 302$ 113$

Purchases of property, plant and equipment (400) (79) (89) (127) (105)

FREE CASH FLOW

3

141$ 11$ (53)$ 175$ 8$

3 As of June 30, 2016 and March 31, 2016, remaining DuPont prepayment was ~$131M and ~$166M, respectively. Free Cash Flow excluding the DuPont

prepayment was ($173M) and ($219M) for the six months ended June 30, 2016 and three months ended March 31, 2016, respectively.

27 ©2016 The Chemours Company. Chemours™ and the Chemours Logo are trademarks or registered trademarks of The Chemours Company