Attached files

| file | filename |

|---|---|

| EX-99.1 - EXHIBIT 99.1 - Thompson Creek Metals Co Inc. | pressreleaseq12016.htm |

| 8-K - 8-K - Thompson Creek Metals Co Inc. | a8-kq12016.htm |

First Quarter 2016 Financial Results Investor Conference Call May 5, 2016 TSX: TCM OTCQX: TCPTF

2 Webcast Information Webcast: This Webcast can be accessed on the Thompson Creek Metals Company website under the Events Section: www.thompsoncreekmetals.com Q&A Instructions: If you would like to ask a question, please press star 1 on your telephone keypad. If you’re using a speakerphone, please make sure your mute function is turned off to allow your signal to reach the operator.

3 Cautionary Statement Certain statements in this presentation, other than purely historical information are "forward-looking statements" within the meaning of the Private Securities Litigation Reform Act of 1995, Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934, and applicable Canadian securities legislation and are intended to be covered by the safe harbor provided by these regulations. These forward-looking statements can, in some cases, be identified by the use of such terms as "believe," "project," "expect," "anticipate," "estimate," "intend," "strategy," "future," "opportunity," "plan," "may," "should," "will," "would," "will be," "will continue," "will likely result," and similar expressions. Our forward-looking statements may include, without limitation, statements with respect to: future financial or operating performance of the Company or its subsidiaries and its projects; future liquidity; access to existing or future financing arrangements and ability to refinance or reduce debt on favorable terms or at all; future inventory, production, sales, payments from customers, cash costs, capital expenditures and exploration expenditures; future earnings and operating results; expected mining and concentrate grades and recoveries; estimates of mineral reserves and mineral resources, including estimated mine life and annual production; expectations regarding the optimization of Mount Milligan Mine and construction of a permanent secondary crushing circuit, including the effects of secondary crushing; future concentrate shipment dates and shipment sizes; future operating plans and goals, including expected financial and operating results of the molybdenum business; expected costs, including any severance costs; personnel decisions, including reductions in work force; future copper, gold, and molybdenum prices; and future foreign exchange rates.. Where we express an expectation or belief as to future events or results, such expectation or belief is expressed in good faith and believed to have a reasonable basis. However, our forward-looking statements are based on current expectations and assumptions that are subject to risks and uncertainties which may cause actual results to differ materially from future results expressed, projected or implied by those forward-looking statements. Important factors that could cause actual results and events to differ from those described in such forward-looking statements can be found in the section entitled "Risk Factors" in Thompson Creek's Annual Report on Form 10-K, Quarterly Reports on Form 10-Q and other documents filed on EDGAR at www.sec.gov and on SEDAR at www.sedar.com. Although we have attempted to identify those material factors that could cause actual results or events to differ from those described in such forward-looking statements, there may be other factors, currently unknown to us or deemed immaterial at the present time that could cause results or events to differ from those anticipated, estimated or intended. Many of these factors are beyond our ability to control or predict. Given these uncertainties, the reader is cautioned not to place undue reliance on our forward-looking statements. We undertake no obligation to update or revise publicly any forward-looking statements, whether as a result of new information, future events, or otherwise.

4 Overview Jacques Perron President and Chief Executive Officer

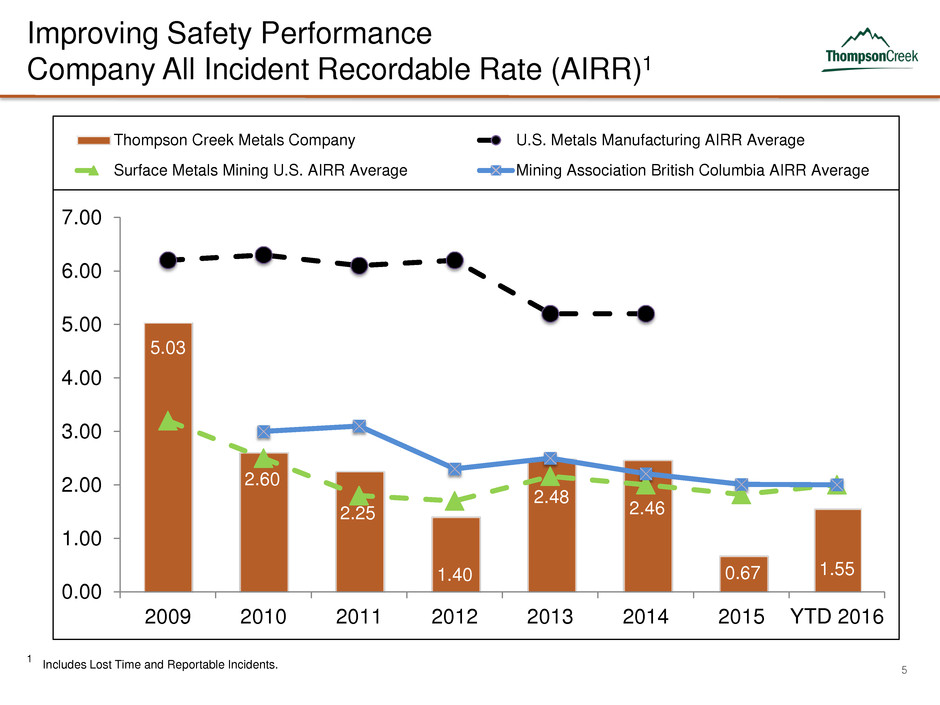

5 Improving Safety Performance Company All Incident Recordable Rate (AIRR)1 1 Includes Lost Time and Reportable Incidents. 5.03 2.60 2.25 1.40 2.48 2.46 0.67 1.55 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 2009 2010 2011 2012 2013 2014 2015 YTD 2016 Thompson Creek Metals Company U.S. Metals Manufacturing AIRR Average Surface Metals Mining U.S. AIRR Average Mining Association British Columbia AIRR Average

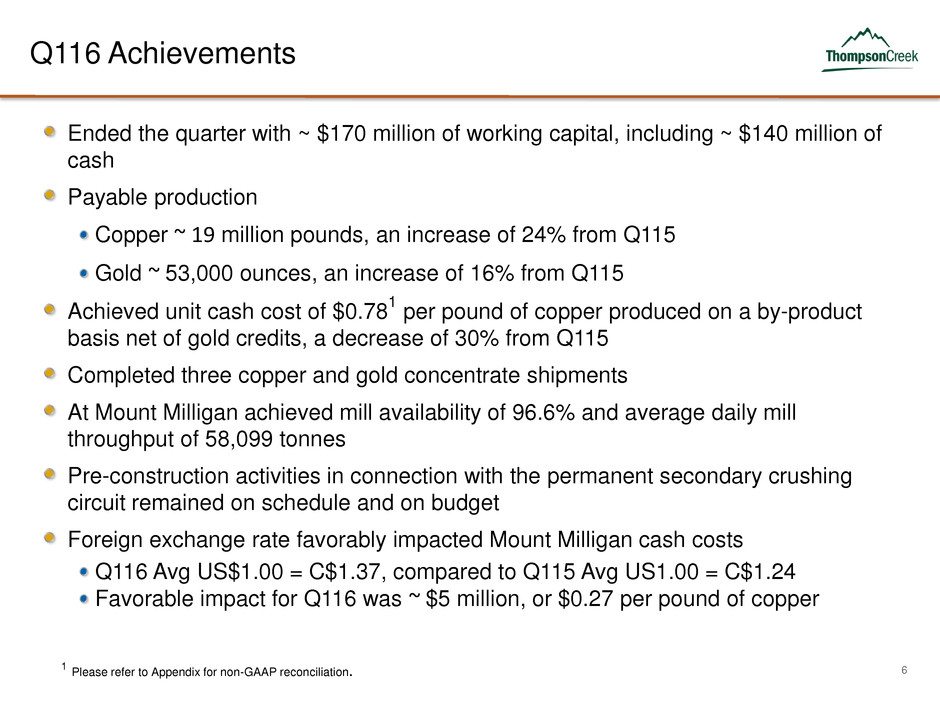

6 Q116 Achievements Ended the quarter with ~ $170 million of working capital, including ~ $140 million of cash Payable production Copper ~ 19 million pounds, an increase of 24% from Q115 Gold ~ 53,000 ounces, an increase of 16% from Q115 Achieved unit cash cost of $0.78 1 per pound of copper produced on a by-product basis net of gold credits, a decrease of 30% from Q115 Completed three copper and gold concentrate shipments At Mount Milligan achieved mill availability of 96.6% and average daily mill throughput of 58,099 tonnes Pre-construction activities in connection with the permanent secondary crushing circuit remained on schedule and on budget Foreign exchange rate favorably impacted Mount Milligan cash costs Q116 Avg US$1.00 = C$1.37, compared to Q115 Avg US1.00 = C$1.24 Favorable impact for Q116 was ~ $5 million, or $0.27 per pound of copper 1 Please refer to Appendix for non-GAAP reconciliation.

7 Financial Review Pam Saxton Executive Vice President and Chief Financial Officer

8 Selected Financial Results 24.6 27.1 $0 $5 $10 $15 $20 $25 $30 $35 $40 Q116 Q115 Non-GAAP EBITDA 97.4 123.0 $0 $20 $40 $60 $80 $100 $120 $140 $160 Q116 Q115 Revenue [millions US$, except per share data] 1. Please refer to Appendix for GAAP net income and reconciliation. 7.4 5.2 $0 $1 $2 $3 $4 $5 $6 $7 $8 $9 $10 Q116 Q115 Operating Income (loss) (15.7) (5.3) -$30 -$20 -$10 $0 $10 $20 Q116 Q115 Operating Cash Flow (Drain) (19.3) (14.2) -$30 -$20 -$10 $0 $10 $20 Q116 Q115 Non-GAAP Adjusted Net Income (loss)1 35.1 (87.2) -$100 -$80 -$60 -$40 -$20 $0 $20 $40 Q116 Q115 Net Income (loss)

9 Q116 Q115 Cash Flow from Operations (15.7) (5.3) Cash (Used) in Investing Activities (15.9) (6.8) Cash (Used) in Financing Activities (6.2) (14.3) Effect of Exchange Rate Changes on Cash 0.1 (1.0) (Decrease) in Cash and Cash Equivalents (37.7) (27.4) Cash and Cash Equivalents, beginning of period 176.8 265.6 Cash and Cash Equivalents, end of period 139.1 238.2 Summary of Statement of Cash Flows [US$ in millions]

10 Since completion of Mount Milligan Mine, reduced debt by $139 million, or ≈13.6% (including net repayments of the Company’s capital leases, excluding deferred financing fees) Reduced Debt by $139 Million over 11 Quarters $1,019 $1,013 $1,004 $984 $977 $945 $939 $898 $892 $885 $880 $800 $850 $900 $950 $1,000 $1,050 Q313 Q413 Q114 Q214 Q314 Q414 Q115 Q215 Q315 Q415 Q116 (US$ in millions)

11 Hedging1 Quantity Sell Price Maturities Through Forward Gold Sales (oz) 4,500 $1,130 Apr 2016 – Jun 2016 Quantity Put Price Call Price Maturities Through Gold Collars (oz) 46,100 $1,050- $1,200 $1,164 - $1,350 Apr 2016 – Dec 2016 1 Information is as of March 31, 2016. Quantity Buy Price Maturities Through Forward Currency Contracts C$71,000,000 $1USD/C$1.38 Apr 2016 – Aug 2016

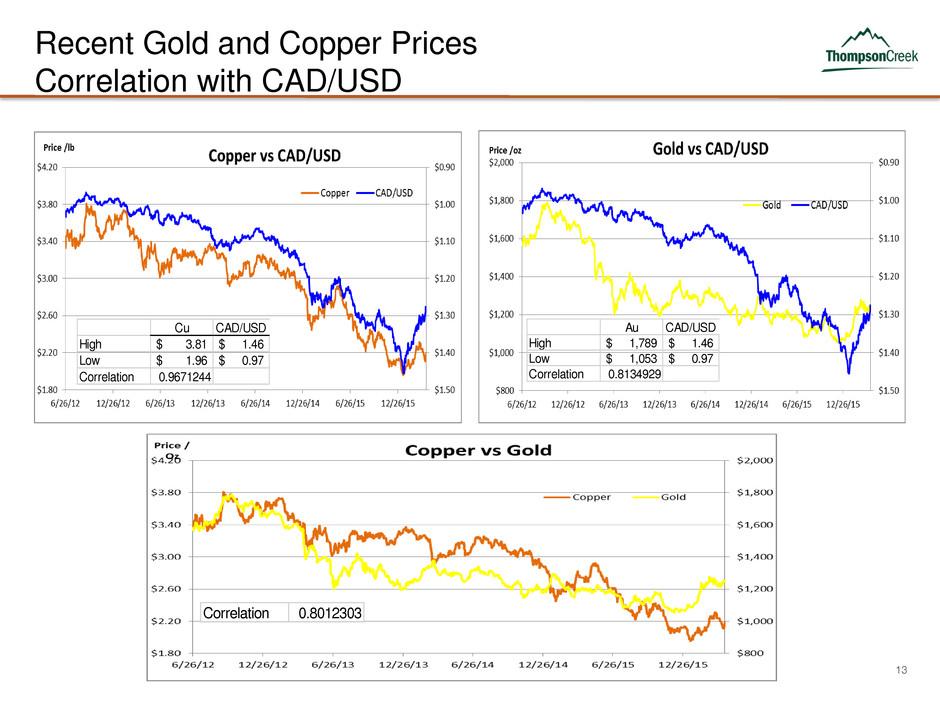

12 Significant Positive Impact on Mount Milligan Margins from US$/C$ Foreign Exchange Rate Current US$/C$ exchange rate continues to have positive impact on Mount Milligan operating costs Approximately 85-90% of costs are in C$ The US$ to C$ average exchange rate for Q116 was US$1.00 = C$1.37. This exchange rate had a positive impact on Mount Milligan operating costs for the first quarter of approximately $5 million, or a positive unit cost impact of $0.27 per pound of copper, compared to applying the average US$1.00 = C$1.24 for the first quarter of 2015 The current US$ to C$ average exchange rate supports margins and somewhat mitigates the effects of copper and gold pricing volatility

13 Recent Gold and Copper Prices Correlation with CAD/USD Cu CAD/USD High 3.81$ 1.46$ Low 1.96$ 0.97$ Correlation 0.9671244 Au CAD/USD High 1,789$ 1.46$ Low 1,053$ 0.97$ Correlation 0.8134929 Correlation 0.8012303

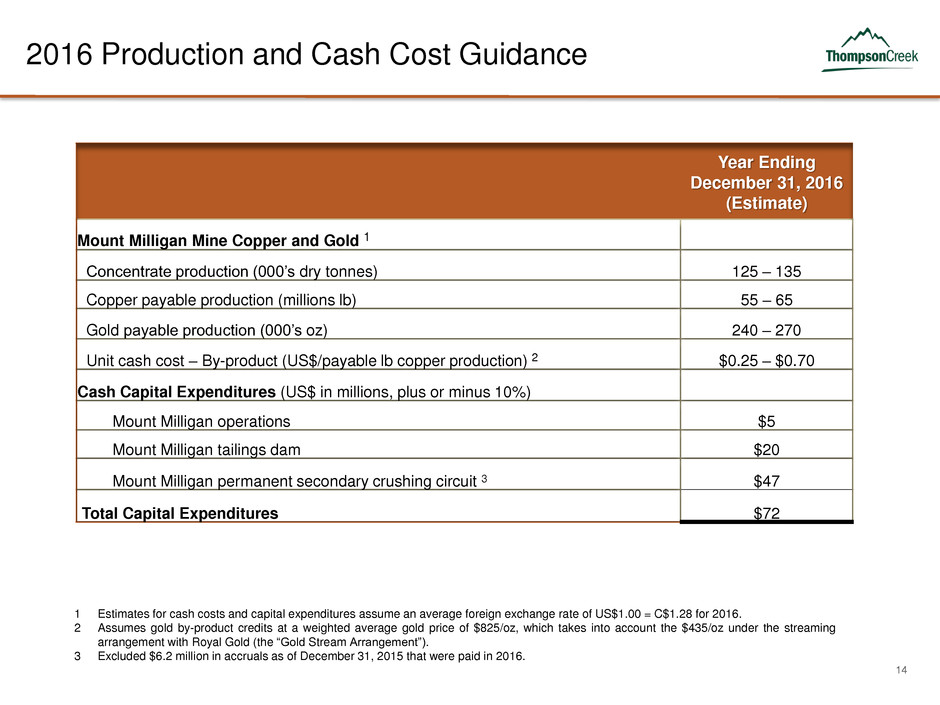

14 2016 Production and Cash Cost Guidance Year Ending December 31, 2016 (Estimate) Mount Milligan Mine Copper and Gold 1 Concentrate production (000’s dry tonnes) 125 – 135 Copper payable production (millions lb) 55 – 65 Gold payable production (000’s oz) 240 – 270 Unit cash cost – By-product (US$/payable lb copper production) 2 $0.25 – $0.70 Cash Capital Expenditures (US$ in millions, plus or minus 10%) Mount Milligan operations $5 Mount Milligan tailings dam $20 Mount Milligan permanent secondary crushing circuit 3 $47 Total Capital Expenditures $72 1 Estimates for cash costs and capital expenditures assume an average foreign exchange rate of US$1.00 = C$1.28 for 2016. 2 Assumes gold by-product credits at a weighted average gold price of $825/oz, which takes into account the $435/oz under the streaming arrangement with Royal Gold (the “Gold Stream Arrangement”). 3 Excluded $6.2 million in accruals as of December 31, 2015 that were paid in 2016.

15 Sales Summary Operations Review Closing Remarks Jacques Perron President and Chief Executive Officer

16 Copper (Cu) and Gold (Au) Sales Q116 vs Q115 1 Please refer to Appendix for non-GAAP reconciliation. Cu Sales (millions lbs) Average Realized Sales Price1 (US$/lb) Au Sales (000’s oz) Average Realized Sales Price1 (US$/oz) Cu Revenue (millions US$) Au Revenue (millions US$) $2.17 $2.47 Q116 Q115 Three Months Ended March 31 Three Months Ended March 31 15.0 14.8 $28.1 $32.2 Q116 Q115 Q116 Q115 44.4 36.8 $45.3 $36.0 Q116 Q115 Q116 Q115 $1,026 $986 Q116 Q115

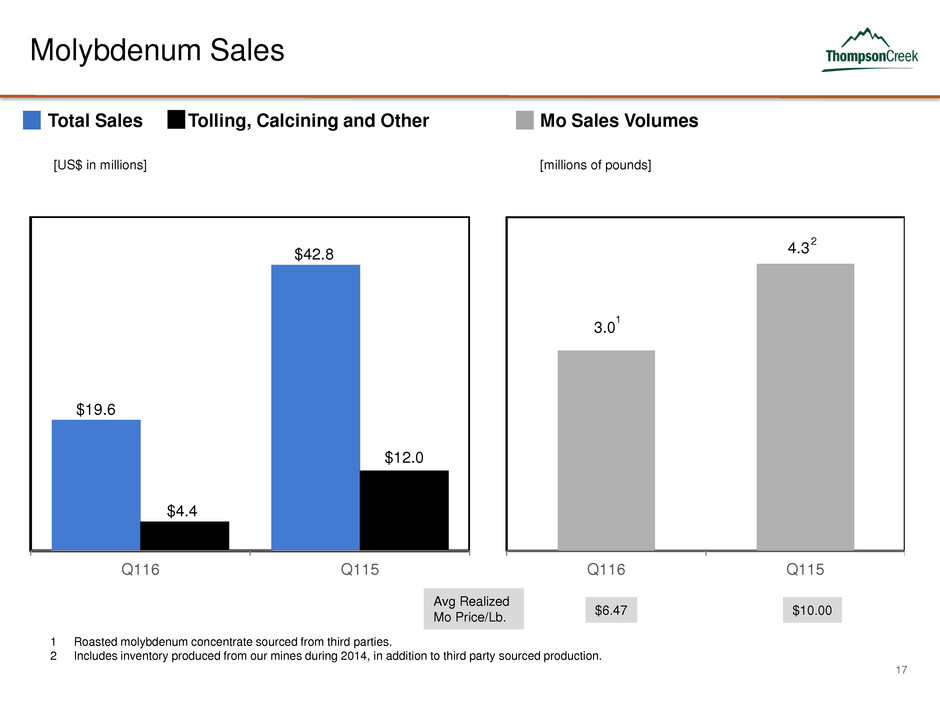

17 Molybdenum Sales Total Sales Tolling, Calcining and Other $19.6 $42.8 $4.4 $12.0 Q116 Q115 3.0 4.3 Q116 Q115 Avg Realized Mo Price/Lb. $10.00 Mo Sales Volumes [US$ in millions] [millions of pounds] $6.47 1 2 1 Roasted molybdenum concentrate sourced from third parties. 2 Includes inventory produced from our mines during 2014, in addition to third party sourced production.

18 Operating Statistics – Q116 and Q115 Copper (Cu) 19.1 15.4 15.0 14.8 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 20.0 Q116 Q115 Cu-Payable Production (millions lbs) Cu-Sales (millions lbs) $0.78 $1.12 $0.00 $0.20 $0.40 $0.60 $0.80 $1.00 $1.20 Q116 Q115 Cu-Cash cost ($/payable lb produced) By-Product1 Q116 Q115 Cu Ore Grade 0.23% 0.26% Cu Recovery 75.0% 79.3% 1 Please refer to Appendix for non-GAAP reconciliation.

19 Operating Statistics – Q116 and Q115 Gold (Au) 53,329 46,119 44,391 36,750 0 10,000 20,000 30,000 40,000 50,000 60,000 Q116 Q115 Au-Payable Production (oz) Au-Sales (oz) $523 $498 $0 $100 $200 $300 $400 $500 $600 Q116 Q115 Au-Cash cost ($/payable oz produced) Co-Product1 Q116 Q115 Au Ore Grade (g/tonne) 0.55 0.63 Au Recovery 59.3% 66.7% 1 Please refer to Appendix for non-GAAP reconciliation.

20 Key Messages Strong working capital of ~ $170 million, including ~ $140 million of cash Low cost copper producer on by-product basis Q116 by-product unit cash cost of $0.78 per pound of copper produced Continuous optimization of Mount Milligan Mine Molybdenum business is expected to generate sufficient revenue to substantially cover care and maintenance costs and maintain option value of assets Remain focused on addressing debt Management continues to work with advisors to evaluate strategic and financial alternatives available to the Company Goal to have a solution in place in advance of debt maturity dates

21 OTCQX: TCPTF TSX:TCM Thompson Creek Metals Company www.thompsoncreekmetals.com Pamela Solly Director, Investor Relations and Corporate Responsibility Phone (303) 762-3526 Email psolly@tcrk.com

22 Appendix

23 Mount Milligan Permanent Secondary Crushing Circuit Provide more reliable throughput levels for the long-term at lower cost compared to temporary secondary crushing circuit Once installed and commissioned, average daily mill throughput expected to increase to approximately 62,500 tonnes Decision recently made to move forward with project construction Capex estimate is $60 – $65 million1, inclusive of $15 million incurred in 2015 2 for engineering and concrete and long lead items 1 Plus or minus 10%. Assumes an exchange rate of US$1.00 = $C1.28 for 2016, and includes the approximately $20 million (plus or minus 10%) for construction of the permanent secondary crushing circuit, as we have made the decision to commence construction. 2 Of the amount incurred in 2015, approximately $6.2 million was accrued as of December 31, 2015 and paid in the first quarter of 2016. US$ Millions1 2016 Long Lead Items $27 Jan – July Construction $18 Apr – Sep Commissioning $2 Sep – Dec Total Capex $47

24 Non-GAAP EBITDA Reconciliation Last Twelve Months 1 Includes gain (loss) from debt extinguishment 2 Certain prior year reclassifications were made to DD&A to conform with current year presentation. (US$ in millions) Q116 Q115 Net income (loss) 35.1 (87.2) (Interest income)/expense, net1 21.0 22.2 Tax expense (benefit) 7.5 (16.7) DD&A 2 19.8 20.0 Accretion 0.6 0.6 (Gain) loss on foreign exchange (59.4) 88.2 Non-GAAP EBITDA 24.6 27.1

25 Non-GAAP Reconciliation Adjusted Net Income (Loss) (US$ in millions, except per share amounts) Three Months Ended Mar 31 2016 Mar 31 2015 Net income (loss) $ 35.1 $ (87.2 ) Add (Deduct): (Gain) loss on foreign exchange (1) (60.6 ) 89.8 Tax (benefit) expense on foreign exchange loss (gain) 6.2 (16.8 ) Non-GAAP adjusted net (loss) income $ (19.3 ) $ (14.2 ) Net (loss) income per share Basic $ 0.16 $ (0.41 ) Diluted $ 0.16 $ (0.41 ) Adjusted net (loss) income per share Basic $ (0.09 ) $ (0.07 ) Diluted $ (0.09 ) $ (0.07 ) Weighted-average shares Basic 222.2 214.4 Diluted 222.2 214.4 (1) Included a foreign exchange gain of $1.2 million and a foreign exchange loss of $1.6 million, presented in income and mining tax expense (benefit) in the Condensed Consolidated Statements of Operations and Comprehensive Income (Loss) for the three months ended March 31, 2016 and March 31, 2015, respectively.

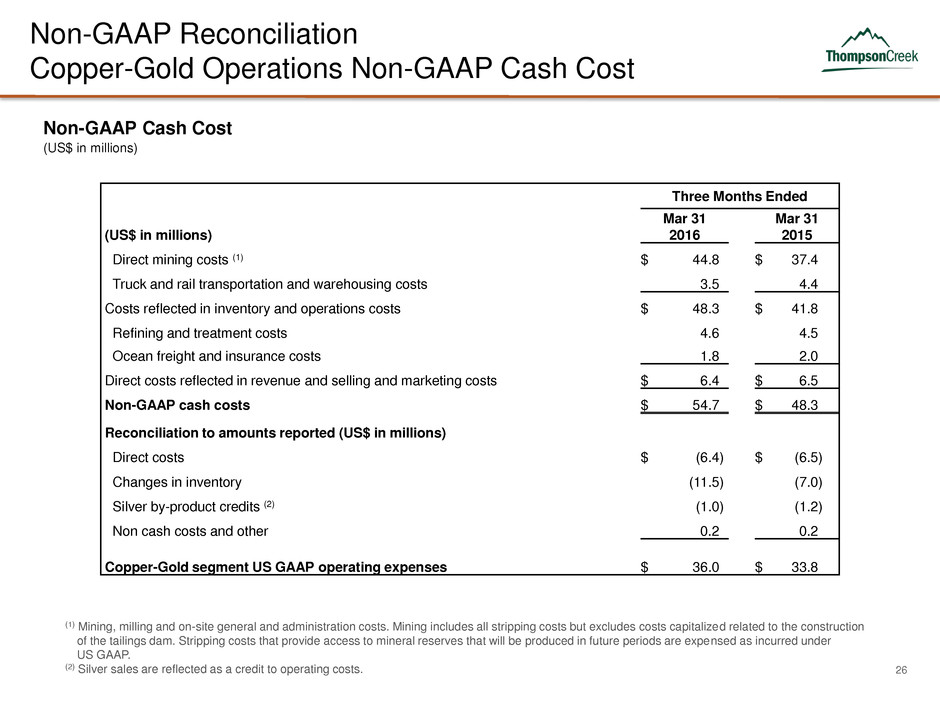

26 Non-GAAP Reconciliation Copper-Gold Operations Non-GAAP Cash Cost (US$ in millions) Non-GAAP Cash Cost Three Months Ended (US$ in millions) Mar 31 2016 Mar 31 2015 Direct mining costs (1) $ 44.8 $ 37.4 Truck and rail transportation and warehousing costs 3.5 4.4 Costs reflected in inventory and operations costs $ 48.3 $ 41.8 Refining and treatment costs 4.6 4.5 Ocean freight and insurance costs 1.8 2.0 Direct costs reflected in revenue and selling and marketing costs $ 6.4 $ 6.5 Non-GAAP cash costs $ 54.7 $ 48.3 Reconciliation to amounts reported (US$ in millions) Direct costs $ (6.4 ) $ (6.5 ) Changes in inventory (11.5 ) (7.0 ) Silver by-product credits (2) (1.0 ) (1.2 ) Non cash costs and other 0.2 0.2 Copper-Gold segment US GAAP operating expenses $ 36.0 $ 33.8 (1) Mining, milling and on-site general and administration costs. Mining includes all stripping costs but excludes costs capitalized related to the construction of the tailings dam. Stripping costs that provide access to mineral reserves that will be produced in future periods are expensed as incurred under US GAAP. (2) Silver sales are reflected as a credit to operating costs.

27 By-Product (US$ in millions, except pounds and per pound amounts) Non-GAAP Reconciliation Copper-Gold Operations By-Product Unit Cost Per Pound Produced Three Months Ended Mar 31 2016 Mar 31 2015 Copper payable production (000's lbs) 19,062 15,405 Non-GAAP cash cost $ 54.7 $ 48.3 Less by-product credits Gold sales (1) $ 45.5 $ 36.2 Gold sales related to deferred portion of Gold Stream Arrangement (2) (6.6 ) (6.4 ) Net gold by-product credits $ 38.9 $ 29.8 Silver by-product credits (3) 1.0 1.2 Total by-product credits $ 39.9 $ 31.0 Non-GAAP cash cost net of by-product credits $ 14.8 $ 17.3 Non-GAAP cash cost per pound, on a by-product basis $ 0.78 $ 1.12 (1) Excluded refining and treatment charges. (2) The three months ended March 31, 2016 included $1.5 million related to five provisional invoices from 2015. The decrease resulted from a downward revision to the rate at which the deferred revenue liability resulting from the Gold Stream Arrangement was amortized. This rate is calculated based on the remaining deferred revenue liability and total ounces of refined gold owed to Royal Gold. (3) Silver sales are reflected as a credit to operating costs.

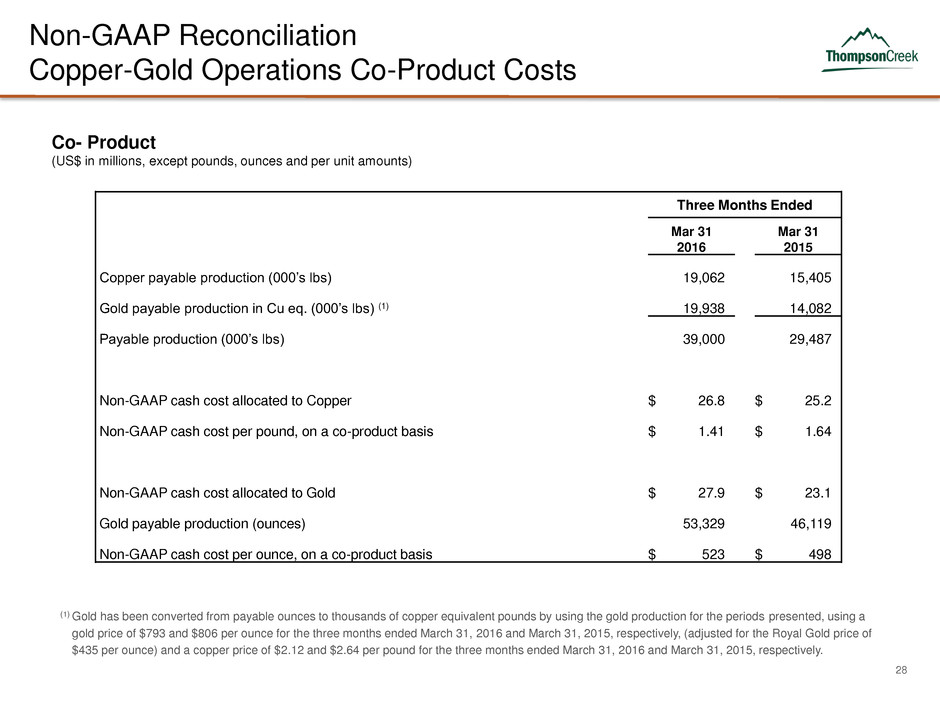

28 Co- Product (US$ in millions, except pounds, ounces and per unit amounts) Non-GAAP Reconciliation Copper-Gold Operations Co-Product Costs Three Months Ended Mar 31 2016 Mar 31 2015 Copper payable production (000’s lbs) 19,062 15,405 Gold payable production in Cu eq. (000’s lbs) (1) 19,938 14,082 Payable production (000’s lbs) 39,000 29,487 Non-GAAP cash cost allocated to Copper $ 26.8 $ 25.2 Non-GAAP cash cost per pound, on a co-product basis $ 1.41 $ 1.64 Non-GAAP cash cost allocated to Gold $ 27.9 $ 23.1 Gold payable production (ounces) 53,329 46,119 Non-GAAP cash cost per ounce, on a co-product basis $ 523 $ 498 (1) Gold has been converted from payable ounces to thousands of copper equivalent pounds by using the gold production for the periods presented, using a gold price of $793 and $806 per ounce for the three months ended March 31, 2016 and March 31, 2015, respectively, (adjusted for the Royal Gold price of $435 per ounce) and a copper price of $2.12 and $2.64 per pound for the three months ended March 31, 2016 and March 31, 2015, respectively.

29 Non-GAAP Reconciliation Copper-Gold Operations Average Realized Sales Prices (US$ in millions, except pounds, ounces and per unit amounts) Three Months Ended (US$ in millions, except pounds, ounces and per unit amounts) Mar 31 2016 Mar 31 2015 Average realized sales price for Copper Copper sales reconciliation ($) Copper sales, excluding adjustments $ 32.1 $ 38.3 Final pricing adjustments (2.4 ) (7.3 ) Mark-to-market adjustments 2.8 5.5 Copper sales, net of adjustments 32.5 36.5 Less Refining and treatment costs 4.4 4.3 Copper sales $ 28.1 $ 32.2 Pounds of Copper sold (000's lb) 14,962 14,791 Average realized sales price for Copper on a per unit basis Copper sales excluding adjustments $ 2.15 $ 2.59 Final pricing adjustments (0.16 ) (0.49 ) Mark-to-market adjustments 0.18 0.37 Average realized Copper sales price per pound sold $ 2.17 $ 2.47

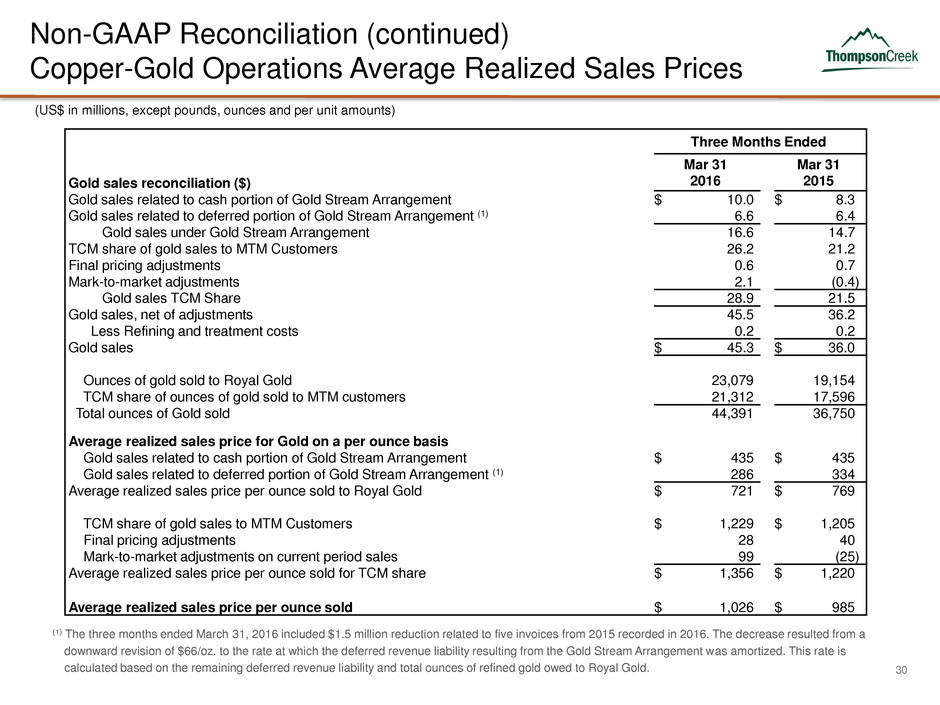

30 Non-GAAP Reconciliation (continued) Copper-Gold Operations Average Realized Sales Prices (US$ in millions, except pounds, ounces and per unit amounts) Three Months Ended Gold sales reconciliation ($) Mar 31 2016 Mar 31 2015 Gold sales related to cash portion of Gold Stream Arrangement $ 10.0 $ 8.3 Gold sales related to deferred portion of Gold Stream Arrangement (1) 6.6 6.4 Gold sales under Gold Stream Arrangement 16.6 14.7 TCM share of gold sales to MTM Customers 26.2 21.2 Final pricing adjustments 0.6 0.7 Mark-to-market adjustments 2.1 (0.4 ) Gold sales TCM Share 28.9 21.5 Gold sales, net of adjustments 45.5 36.2 Less Refining and treatment costs 0.2 0.2 Gold sales $ 45.3 $ 36.0 Ounces of gold sold to Royal Gold 23,079 19,154 TCM share of ounces of gold sold to MTM customers 21,312 17,596 Total ounces of Gold sold 44,391 36,750 Average realized sales price for Gold on a per ounce basis Gold sales related to cash portion of Gold Stream Arrangement $ 435 $ 435 Gold sales related to deferred portion of Gold Stream Arrangement (1) 286 334 Average realized sales price per ounce sold to Royal Gold $ 721 $ 769 TCM share of gold sales to MTM Customers $ 1,229 $ 1,205 Final pricing adjustments 28 40 Mark-to-market adjustments on current period sales 99 (25 ) Average realized sales price per ounce sold for TCM share $ 1,356 $ 1,220 Average realized sales price per ounce sold $ 1,026 $ 985 (1) The three months ended March 31, 2016 included $1.5 million reduction related to five invoices from 2015 recorded in 2016. The decrease resulted from a downward revision of $66/oz. to the rate at which the deferred revenue liability resulting from the Gold Stream Arrangement was amortized. This rate is calculated based on the remaining deferred revenue liability and total ounces of refined gold owed to Royal Gold.