Attached files

| file | filename |

|---|---|

| EX-12.1 - EXHIBIT 12.1 - TerraVia Holdings, Inc. | solazyme201510kex121.htm |

| EX-31.1 - EXHIBIT 31.1 - TerraVia Holdings, Inc. | solazyme201510kex311.htm |

| EX-31.2 - EXHIBIT 31.2 - TerraVia Holdings, Inc. | solazyme201510kex312.htm |

| EX-32.1 - EXHIBIT 32.1 - TerraVia Holdings, Inc. | solazyme201510kex321.htm |

| EX-23.1 - EXHIBIT 23.1 - TerraVia Holdings, Inc. | solazyme201510kex231.htm |

| EX-21.1 - EXHIBIT 21.1 - TerraVia Holdings, Inc. | solazyme201510kex211.htm |

| EX-10.23 - EXHIBIT 10.23 - TerraVia Holdings, Inc. | solazyme10k2015ex1023.htm |

| EX-10.24 - EXHIBIT 10.24 - TerraVia Holdings, Inc. | solazyme201510kex1024.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2015

OR

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Transition Period from to

Commission File Number: 001-35189

Solazyme, Inc.

(Exact name of Registrant as specified in its charter)

Delaware | 33-1077078 | |

(State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification Number) | |

Solazyme, Inc.

225 Gateway Boulevard

South San Francisco, CA 94080

(650) 780-4777

(Address and telephone number principal executive offices)

Securities Registered Pursuant to Section 12(b) of the Exchange Act:

Title of Each Class: | Name of Each Exchange on which Registered: | |

Common Stock, par value $0.001 per share | The NASDAQ Global Select Market | |

Securities Registered Pursuant to Section 12(g) of the Exchange Act: None.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Exchange Act during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one.

Large accelerated filer | ¨ | Accelerated filer | x | |||

Non-accelerated filer | ¨ (Do not check if a smaller reporting company) | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act.): Yes ¨ No x

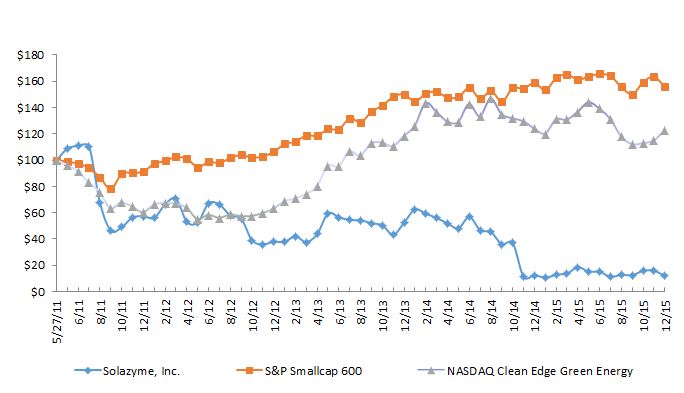

The aggregate market value of the registrant’s common stock, $0.001 par value, held by non-affiliates of the registrant as of June 30, 2015, the last business day of our second fiscal quarter, was approximately $231.4 million based on the closing sale price as reported on the Nasdaq Global Select Market.

As of February 29, 2016, there were 81,947,923 shares of the registrant’s common stock, par value $0.001 per share, outstanding.

Documents Incorporated by Reference

Portions of the registrant’s definitive proxy statement for its 2016 Annual Meeting of Stockholders are incorporated by reference into Part III hereof.

Solazyme, Inc.

Annual Report on Form 10-K

For The Year Ended December 31, 2015

INDEX

PART I | ||||

Item 1 | — | |||

Item 1A | — | |||

Item 1B | — | |||

Item 2 | — | |||

Item 3 | — | |||

Item 4 | — | |||

PART II | ||||

Item 5 | — | |||

Item 6 | — | |||

Item 7 | — | |||

Item 7A | — | |||

Item 8 | — | |||

Item 9 | — | |||

Item 9A | — | |||

Item 9B | — | |||

PART III | ||||

Item 10 | — | |||

Item 11 | — | |||

Item 12 | — | |||

Item 13 | — | |||

Item 14 | — | |||

PART IV | ||||

Item 15 | — | |||

Our registered trademarks include Solazyme®, Soladiesel®RD, Soladiesel®BD, Soladiesel®RD, Thrive®, Algenist® and Alguronic Acid®. This Annual Report on Form 10-K also contains trademarks, service marks and trade names owned by us as well as others.

2

The following discussion and analysis should be read together with our audited consolidated financial statements and the related notes and other financial information appearing elsewhere in this Annual Report on Form 10-K. This Annual Report on Form 10-K contains forward-looking statements reflecting our current expectations and involves risks and uncertainties. In some cases, you can identify forward-looking statements by terminology such as “may,” “will,” “should,” “expect,” “plan,” “anticipate,” “believe,” “estimate,” “predict,” “intend,” “potential” or “continue” or the negative of these terms or other comparable terminology. For example, statements regarding our expectations as to future financial performance, expense levels, future manufacturing capacity, addressable market size, target average selling prices and liquidity sources are forward-looking statements. Our actual results and the timing of events may differ materially from those discussed in our forward-looking statements as a result of various factors, including those discussed below and those discussed in the section entitled “Risk Factors” included in this Annual Report on Form 10-K and in our other filings with the Securities and Exchange Commission (SEC).

PART I

Item 1. Business

Our Company

Our mission at Solazyme is to make products that are better for people and for the planet.

We are a food, nutrition and specialty ingredients company that harnesses the power of algae, the origin of all plants. Our innovation platform uses microalgae to produce high-value triglyceride oils, proteins, fibers, micronutrients and other ingredients.

We have spent over a decade unlocking the power of algae to find and develop valuable oils and powdered ingredients that offer sustainable solutions for the food, personal care and industrials markets. Moving forward, we are refining our focus to food, nutrition and specialty ingredients, and Solazyme will be known as TerraVia™.

We have developed and are commercializing products for specialty food and nutrition ingredients, animal nutrition ingredients and specialty personal care ingredients. We also recently introduced our first consumer-focused food product formulated with our proprietary ingredients.

The unique compositions of our oils, powdered ingredients and other algae-derived products address specific market and customer needs, offering superior performance characteristics and value. For example, one of our first powdered food ingredients can replace dairy fats and eggs in food products providing food and beverage customers with the opportunity for an improved nutritional profile, a reduction in allergens, with improved or maintained taste and texture. As another example, one of our first oil ingredients can replace or improve upon conventional vegetable oils in major markets by providing customers with better nutrition with increased monounsaturated fat, and reduced saturated and polyunsaturated fat content with improved stability and smoke point. In personal care, our unique oils and ingredients are increasingly important to strategic customers in meeting their product requirements, specifically by improving their product performance and supply chains, and helping to meet their global sustainability goals.

Our high-value oils and powdered ingredients are based on a leading microalgae-based innovation platform that we believe offers the unique opportunity to transform our food system by bringing together better nutrition and great taste, along with economic and environmental sustainability. We believe our solutions can enable our customers to improve product performance and nutrition, reduce processing costs and/or improve their products’ sustainability profile. We are committed to improving the lives of people and the planet through the commercialization of our food and specialty ingredients.

Market Need

Increasing global demand for healthy and sustainable oils and fats as well as plant-based protein sources, amplified by the need for improved nutritional and ecological alternatives in existing supply chains, is driving the market need for new alternatives to incumbent food and specialty ingredients throughout the world.

3

We believe urbanization, improved living standards, and changing diets are consumer forces that will drive demand for our food and specialty ingredient products. As the global population continues to grow and more countries adopt a western-style diet, we expect the demand for healthier oils and fats that are sustainably and economically produced to increase. In addition, the problems of heart health, obesity, diabetes and protein deficiencies are increasingly impacting many global sub-populations. Faced with increasing pressure from consumers to improve the nutritional profile of food and beverage products, governments and manufacturers are increasingly looking for innovation and new food ingredient solutions that will better enable reductions in saturated fat, calories, and cholesterol without compromising performance, taste or cost.

The improvement of living standards globally is also driving a critical trend toward increased consumption of proteins. Many Western consumers consider protein consumption to be an effective strategy for weight and energy management. The environmental impact of addressing the increased demand for protein is important. Animal-derived proteins have a significant impact on land use, deforestation and greenhouse gas emissions. To address this demand for protein, food and beverage manufacturers are looking for new, efficiently-produced plant-based sources of protein.

Initiatives focused on fulfillment of corporate sustainability objectives and government mandates also support an increased use of renewable oils and sustainable ingredients. The ongoing demand to improve the sustainability footprint of supply chains across the globe are being driven by not only social and political drivers, but also the need to improve the overall environmental impacts that originate from increased raw material needs. The ability to convert sustainable carbohydrate-rich plant materials into unique high-value oils and materials offers a solution to global demand for a range of products.

Our Strategy

We intend to be a global market leader delivering much needed innovation and sustainability to food, nutrition and specialty ingredients from microalgae. The principal elements of our strategy are:

• | Prioritize market entry in Food, Nutrition and Specialty Ingredients. We intend to focus on high-value food, nutrition and specialty products that generate attractive margins in our target markets while we continue to scale operations at our manufacturing facilities. We have spent over a decade building a leading innovation platform for food and specialty ingredients, obtaining critical regulatory clearance for our core products, producing at commercial scale and validating our products with customers and consumers. All of these efforts align with our goal to capitalize on market demand for healthier oils and ingredients during a time when key trends of plant-based eating and enhanced nutrition are accelerating. |

• | Execute on our customer-driven approach to technology and product development. We will continue to work closely with our partners and customers to understand their requirements and design products to specifically address their needs. It is our intent to provide both branded and unbranded products within food applications that include AlgaVia™ protein and lipid-rich powders, AlgaWise™ food oils and AlgaPur™ specialty oils for personal care. |

• | Enter into sales agreements and additional partnership agreements to advance commercialization efforts. We are currently engaged in development activities with multiple partners in food, nutrition and specialty ingredients. In addition to funding development work and performing application testing, we expect that our partners will enter into long-term commercial supply agreements with us. |

• | Maximize return on manufacturing assets. We have brought large-scale manufacturing of our products online and have invested to establish our manufacturing footprint. This includes a wholly owned facility for food ingredients and new product development in Peoria Illinois. It also includes the large commercial manufacturing facility in Brazil that was built with our joint venture partner, Bunge. We expect to continue to optimize and scale production in these facilities and to continue to execute a capital-efficient strategy by entering agreements whereby our partners will invest capital and operational resources in building and scaling manufacturing capacity, while also providing us access to feedstock. |

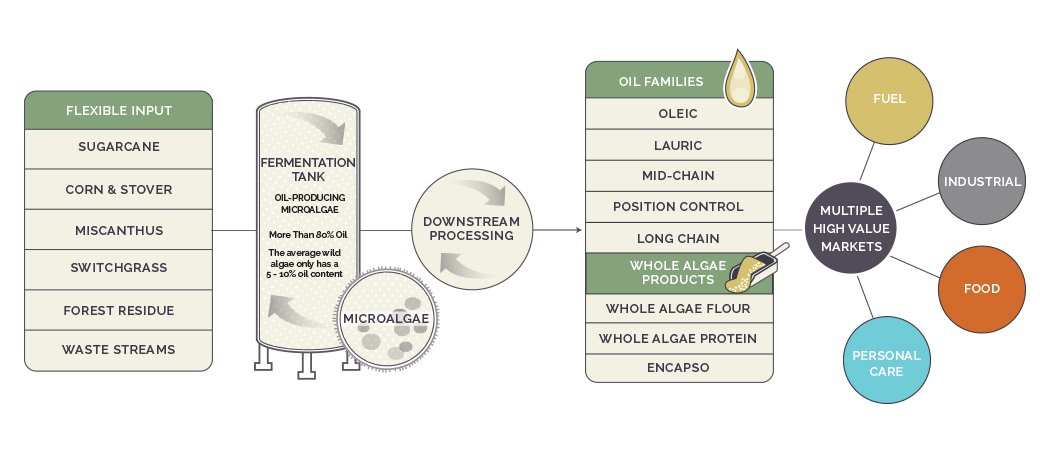

Our Technology

Our process begins by selecting one of our microalgae strains to produce a specific oil or powder (whole algae products and encapsulated oil products). Then, through fermentation, the microalgae convert sugars into the desired end product. Fermentation helps accelerate microalgae’s natural biological process, allowing us to produce large amounts of a desired product in a matter of days. After fermentation, the microalgae go through a few final steps depending on the product, such as

4

drying or standard mechanical oil extraction (pressing), before being shipped to customers in a variety of end markets. Our technology platform enables us to produce a broad array of products and oil profiles with the same infrastructure.

Our platform is feedstock flexible and can utilize a variety of renewable plant-based sugars. We currently use sugarcane-based sucrose and corn-based dextrose as our two primary feedstock sources. Our technology can also support sugar from other sustainable biomass sources including cellulosics, which we believe will represent an important alternative feedstock in the future.

The controlled environment of the standard fermentation tanks enables product purity and allows us to tightly regulate acidity, temperature and other key parameters. Our core competencies include (1) identifying, isolating and further optimizing strains of microalgae to achieve high cell densities, high yields converting sugar to product and high time-based productivity rates compared to other alternatives, and (2) tailoring oil outputs to meet specific market needs.

Some of our oils and all of our AlgaVia™ whole algae products (AlgaVia™ Lipid Rich Powder and AlgaViaTM Protein) are made from native microalgae strains. These strains are selected through a rigorous screening process in which we look at thousands of microalgae, seeking properties that translate into product benefits for our customers.

When we seek to develop unique oils with significant health and performance benefits - for example, oil with a higher flash point to improve the performance of cooking oil or healthier oil with low levels of saturated fat, we apply the tools of biotechnology, including standard genetic engineering techniques, to the algae to develop these oils. These are tools that have been used for decades to generate important drugs, vitamins, foods, hygiene and household products that are broadly used and beneficial for people. We may introduce one or sometimes a few genes from a plant with desired properties, or we might make only modest changes to the microalgae’s existing genes, for example, by shutting off production of an undesired oil component.

We believe that the following advantages of our platform allow us to offer a new source of high-value oil and powdered products to address the major markets served by conventional oils:

• | Large and diverse market opportunities. Because we make oils, we can access the vast markets currently served by petroleum, plant oils and animal fats. In addition, we make proteins, fibers, polysaccharides and micronutrients which are also broadly used in food, nutrition and specialty ingredients. |

• | Cost-competitive at commercial scale. We harness the innate characteristics of microalgae through a proven fermentation process in a controlled environment that we believe is able to produce large volumes of oil, proteins and other macro and micronutrients in a cost-effective, scalable and predictable manner. |

• | Rapid time to market. Our custom-designed oils can improve upon triglyceride oils currently used and can be integrated more quickly into our customers’ platforms because they are chemically similar to existing oils. Additionally, if a customer desires a novel oil profile, our development timelines for new profiles can be on a |

5

scale of several months to several years as opposed to timelines demonstrated with plant-based oils, which are typically on the scale of 10-15 years.

Our Products

Our primary products are oils and fats, powdered ingredients, including proteins, lipids, fibers and micronutrients and other bioproducts. Our products are sold into two main categories as: Food and Nutrition Products and Specialty Ingredients. The inherent flexibility of our technology platform and its broad applicability across multiple industries allow us to approach a wide range of customers across myriad end markets.

Food and Nutrition Products

We believe that some of the largest opportunities and most valuable uses for our oils and powdered ingredients are in food and nutrition. We have developed and commercialized microalgae-based food ingredients that can enhance the nutritional profile and functionality of a wide range of foods and beverages. We currently have two commercial food ingredient platforms with four commercially available products. The AlgaVia™ Microalgae Food Ingredients include a lipid-rich powder and a protein powder, and the AlgaWise™ algae oils family, which currently includes the Ultra Omega-9 Oil and the High Stability Oil. The AlgaVia™ ingredients are new, sustainable sources of food with benefits that can enhance nutrition, performance and taste. AlgaVia™ ingredients are sold to food and beverage manufacturers and foodservice providers through a combination of direct sales, distributors and strategic partnerships. The AlgaWise™ oils are based on unique nutrition and performance characteristics and the oils are among the most sustainably produced cooking oils, with more oil produced per acre of land, and a lower carbon and water footprint than nearly all cooking oils.

Powdered Ingredients

We have developed novel methods of preparing powdered forms of triglyceride oils and vegan proteins, and our powdered ingredients are composed of unmodified whole algae cells. Our whole algae products include:

• | AlgaVia™ Lipid Rich Powder (commonly known as whole algae flour) is a lipid-rich ingredient that can replace or reduce dairy fat, egg yolks and oil in recipes to reduce fat, cholesterol and calories with the added benefits of texture enhancement, water binding and flavor delivery. This is a new fat source that can enable the creation of healthier products with taste and texture similar to or better than foods made with conventional animal or vegetable oils. We believe the total addressable market for our lipid powders is greater than $2.5 billion annually. |

• | AlgaVia™ Protein (commonly known as whole algae protein) is a vegan protein source that is non-allergenic, gluten-free and a sustainable source of high quality protein. This ingredient delivers protein along with a rich collection of fiber, lipids and micronutrients. The protein present in AlgaVia™ protein is protected by the natural cell wall and enables protein fortification in challenging applications such as low pH beverages, dressings and crackers. We believe the total addressable market for our protein powders is greater than $8.0 billion annually. |

Both AlgaVia™ Lipid Rich Powder and Protein can be used across a range of applications such as beverages (ready-to-drink and powdered), bakery, snacks, bars, dressings, sauces and frozen desserts. We have received FDA GRAS “No Questions” letters for each of these powdered ingredients. They may also be sold in other regions/countries including Europe, Mexico, Australia, and New Zealand. Additionally, we successfully produced at scale a new food powder intended for use in animal nutrition applications and this ingredient is intended for commercial launch in 2016.

Oil Ingredients

We have developed a range of food oils that have the potential to improve upon conventionally utilized specialty fats and oils and our high oleic algae oil has received an FDA GRAS "No Questions" letter. Our first high performance food oil captured the 2014 IFT Food Expo Innovation Award. We believe the total addressable market for our food oils is greater than $5.5 billion annually.

Currently, these oils are commercially available in our AlgaWise™ branded food oil platform as:

6

• | AlgaWise™ High Stability algae oil is extremely stable, with zero trans fats and very low levels of polyunsaturates. This oil provides exceptional stability in a wide range of applications such as for use in frying, baking, spreads, coatings, sauces, and dressings. Higher stability means lower systems costs overall and greater simplicity. It can enable longer shelf life with fresher tasting products, longer fry life, and less polymerization in frying and baking. |

• | AlgaWise™ Ultra Omega-9 algae oil exhibits a high level of omega-9 fatty acid, and lowest saturated fat of any commercially available oil. Further, this oil has the highest monounsaturated fat of any commercially available oil and has a neutral flavor with a high smoke point. |

• | Thrive® algae oil, launched as a consumer focused culinary oil, is one of the most sustainably produced cooking oils, with more oil produced per acre of land, and a lower carbon and water footprint than nearly all cooking oils. In 2015, we introduced Thrive® culinary algae oil through a regional test market and via online distribution at www.thrivealgae.com. |

In addition to our commercially available products today, we have a pipeline of additional high value products we expect to launch in the food, nutrition and specialty ingredients markets in 2016 and 2017.

Specialty Ingredients

We believe our renewable oils could be part of the next generation of high performance oils, and our platform enables replacement and enhancement of petroleum, plant, or animal derived oils that are used as raw materials or ingredients. In many cases, we expect to create novel oils and high-performing end products that do not exist in nature or are prohibitively expensive to synthesize today. We are focusing our efforts within the specialty ingredients market predominantly on personal care. These oils typically replace traditional sources that are from plant or animal fats and appear in the home and personal care industries in applications such as surfactants, detergents, soaps, cosmetics and many others. Our specialty ingredients include:

• | AlgaPur™ algae oils are a range of specialty personal care oils including Capric, Lauric and Oleic-based oils that have improved characteristics such as for stability, sensory and hydration for skin and hair benefits. For example, AlgaPur™ high lauric oil is currently used in soaps while AlgaPur™ high stability oleic oil is used in a natural line of body care. |

We have developed a portfolio of innovative and branded microalgae-based products. During our algae strain screening process, we discovered and isolated key compounds that microalgae synthesize to protect themselves against environmental hazards, such as UV exposure, extremes temperatures, and dehydration. Our first major ingredient is Alguronic Acid®, which we have formulated into a full range of skin care products with significant anti-aging benefits. For example, since 2011, we have commercialized our Algenist® anti-aging skin care line currently selling in 21 countries including member countries of the EU, Mexico, Canada and China.

Our Competitive Strengths

We harness the power of microalgae to develop and commercialize breakthrough products. Our key competitive advantages are:

• | Proprietary and innovative technology. We have made significant investments to protect the intellectual property and know-how related to our technology platform, including screening, classical strain development, targeted recombinant strain optimization, product and applications development and manufacturing capabilities. |

• | Premium pricing for custom-designed and unique products. We believe the enhanced value of our oils and powders as compared to conventional ingredients should garner premium pricing. Examples in food and nutrition applications include oils with low levels of polyunsaturates for improved shelf and frying life, structuring fats, like algae-based butter, providing specific melting profiles, and naturally encapsulated protein powders that can enable increased protein incorporation into foods. |

• | Technology proven at scale. We have operated our large-scale fermentations at multiple partner facilities since 2008 and now run our processes routinely in our commercial 128,000 liter fermenters in Peoria and 625,000 liter fermenters at the Solazyme Bunge JV Plant. |

7

• | Established manufacturing capacity. In structuring our capacity and feedstock partnerships, we have deployed a capital efficient strategy to source low-cost financing and predictable feedstock with our partners. For example, for our joint venture with Bunge Global Innovation, LLC in Brazil, significant capital expenditure related to investments for the Solazyme Bunge JV Plant was approved for financing through an 8-year loan from the Brazilian Development Bank (BNDES) at an average interest rate of approximately 4% per annum. |

• | Commercial products. We launched our Algenist® brand within the Personal Care Products market in 2011. The Algenist® product line has grown to 38 SKUs with a number of additional product launches planned for 2016. We commenced commercial scale production of our renewable, custom-designed products manufactured in January 2014 and at the Solazyme Bunge JV Plant in May 2014. As of the end of 2015, we have consolidated commercial production at our Solazyme Bunge JV plant with supplemental product capabilities for AlgaVia™ food powders and developmental oils at our Peoria facility. In addition to our commercially available products today, we have a pipeline of additional high value products we expect to launch in the food, nutrition and specialty ingredients markets in 2016 and 2017. |

• | Feedstock and target market flexibility. Our technology platform provides us with the flexibility to choose from among multiple feedstocks on the input side and multiple specific products (and markets) on the output side, while using the same standard fermentation equipment. A manufacturing facility utilizing a given plant-based sugar feedstock can produce oils with many different products. Conversely, we can produce the same products by processing a variety of plant-based sugar feedstock. This flexibility enables us to choose the optimal feedstock for any particular geography, while also enabling us to produce a variety of products from the same manufacturing facility. |

Significant Partners

Bunge. Since 2011, we have entered multiple Joint Development Agreements (JDAs) with Bunge to jointly develop microbe-derived oils, biomass, and explore the production of such oils and biomass from Brazilian sugarcane feedstock.

In April 2012, we and Bunge formed the Solazyme Bunge JV to build, own and operate the Solazyme Bunge JV Plant, a commercial-scale renewable algae oils production facility adjacent to Bunge's Moema sugar mill in Brazil. Construction of the Solazyme Bunge JV Plant commenced in the second quarter of 2012 and the Solazyme Bunge JV Plant produced its first products on full-scale production lines in May 2014.

In October 2015, we and Bunge entered into an amended and restated joint venture agreement to expand the Solazyme Bunge JV to add worldwide focus on human food and animal nutrition. Also in October 2015, we and Bunge entered into an amended and restated development agreement under which we granted to the Solazyme Bunge JV a worldwide royalty-bearing, field-limited license to all of our technology that is necessary or useful for the manufacture of certain algae oil products. Concurrently with the entry into such agreement, we and Solazyme Bunge JV entered into two funded research programs targeted at completing the development of additional products for the Solazyme Bunge JV. Refer to Note 8 in the accompanying notes to the consolidated financial statements for further discussion on the Solazyme Bunge JV.

ADM. In November 2012, we entered into a strategic collaboration agreement with Archer-Daniels-Midlands Company (“ADM”), establishing a collaboration for the production of algae triglyceride oil products at ADM’s facility in Clinton, Iowa (the “Clinton Facility”). The Clinton Facility produced algae triglyceride oil products using our proprietary technology. In January 2014, we began commercial scale production of our oils at the Clinton Facility. In October 2015, we provided to ADM a notice of termination of the Operating Agreement entered into with ADM in November 2012 related to the production of products at the Clinton Facility. As a result of the termination of the Operating Agreement, the Strategic Collaboration Agreement with ADM terminated on February 26, 2016. Refer to Note 3 and Note 11 in the accompanying notes to our consolidated financial statements for further discussion regarding ADM.

Unilever. In October 2011, we entered into a joint development agreement with Unilever (our fourth agreement altogether), which expanded our current research and development efforts. In September 2015, we and Unilever extended this joint development agreement through September 30, 2017. In September 2013, we and Unilever entered into a commercial supply agreement for up to 10,000 MT of our algae oil. In May 2014, Unilever announced the initial introduction of our sustainable algal oil into one of its biggest soap brands, Lux. In March 2016, we entered into a multi-year global supply agreement with Unilever, which includes a broad portfolio of our algae oils for Unilever to purchase for use in personal care

8

products. Production of these oils will take place at the Solazyme Bunge Renewable Oils facility in Brazil and pricing terms are based upon actual production cost plus a defined contribution margin. The agreement contains certain minimum and maximum sales volumes and is subject to other terms and conditions.

Mitsui. We have a multi-year agreement with Mitsui & Co., Ltd. (Mitsui) to jointly develop triglyceride oils for use primarily in the oleochemical industry. The agreement includes further development of our myristic oil, a valuable raw material in the oleochemical industry, and additional oils that we are developing for the oleochemical and industrial sectors. End use applications may include renewable, high-performance lubricants and other industrial products.

Algenist® Distribution Partners. We have distribution contracts with Sephora S.A. and its affiliates to distribute the Algenist® product line in Sephora stores in the U.S. and other countries. We also sell our Algenist® product line through QVC's multimedia platform. We also have an agreement with ULTA Beauty to sell our Algenist® line in its retail stores throughout the United States.

AkzoNobel. In May 2013, we entered into a joint development agreement with AkzoNobel, a leading global paints and coatings company and a major producer of specialty chemicals, targeting the development and commercial sales of triglyceride oils for use by AkzoNobel in its surface chemistry and decorative paints businesses. Product development efforts began in the second half of 2013, and in July 2014 we entered into a research and development plan with AkzoNobel which extends through June 2017.

Manufacturing Operations

Our process is compatible with commercial-scale, widely-available fermentation and oil recovery equipment. We operate our lab and pilot fermentation and recovery equipment as scaled-down versions of our large commercial engineering designs, such as those used to perform development work under certain agreements with strategic partners and to fulfill commercial supply agreements with certain partners. This allows us to more easily scale up to larger fermentation vessels. We have scaled up our technology platform and have successfully operated at lab (5-15 liter), pilot (600-1,000 liter) and commercial (up to 625,000 liter) fermenter scale. Our existing manufacturing operations are as follows:

• | Our pilot plant in South San Francisco, California, with recovery operations capable of handling material from both 600 and 1,000 liter fermenters, enables us to produce samples of our algae oils for testing and optimization by our partners, as well as to test new process conditions at an intermediate scale. |

• | In 2012, we commissioned our Peoria, Illinois facility (Peoria Facility), to produce algae oil. The Peoria Facility was partially funded with a federal grant that we received from the U.S. Department of Energy (DOE) in December 2009 to demonstrate integrated commercial-scale production of renewable algae-derived fuels. The Peoria Facility has a nameplate capacity of two million liters of oil annually and provides an important platform for continued work on feedstock flexibility and scaling of new algae oils into the marketplace. We have also modified our Peoria Facility to produce food ingredients in conjunction with market development activity. |

• | In May 2014, the Solazyme Bunge JV Plant initiated its first commercial production utilizing full-scale production lines, including 625,000 liter fermenter tanks. The Solazyme Bunge JV Plant leverages our technology and Bunge’s sugarcane milling and natural oil processing capabilities to produce microalgae-based products. In addition, the Solazyme Bunge JV Plant has been designed to be expanded for further production in line with market demand. The facility was constructed as part of our Joint Venture with Bunge, and was financed with equal equity contributions from both Bunge and us and over $100 million (based on the exchange rate at the time of funding approval) in project financing from BNDES. |

• | We utilize contract manufacturing to assist in the production and sale of our Algenist® products, and we closely monitor and advise these contract manufacturers to maintain stringent quality standards for our products. We also produce some active ingredients for Solazyme Personal Care Products at our Peoria Facility. |

Intellectual Property

Our success depends in part upon our ability to obtain and maintain intellectual property protection for our products and technologies, and to operate without infringing the proprietary rights of others. With respect to the former, our policy is to protect our proprietary position through filing for patent applications on inventions, filing for trademark protection on our

9

product names and related materials and methods, and through trade secret protection when and where appropriate. We seek to avoid infringing the proprietary rights of others by: (1) monitoring patents and publications in our product areas; (2) monitoring the technological developments of others; and (3) evaluating and taking appropriate courses of action whenever we identify such developments.

As of December 31, 2015, we own over 50 issued U.S. patents, over 50 issued foreign patents and over 250 pending patent applications filed in the United States and in various foreign jurisdictions. The expiration dates of the issued patents are between 2024 and 2034. Patents that issue, if any, from our currently pending patent applications would be expected to expire twenty years from the date of filing. Our patents and patent applications are directed to compositions such as food products, custom oils, fuel products, chemicals, cosmetics, strains of microbes, and recombinant technologies; methods of manufacturing finished goods and raw materials; and methods of using our raw materials and products. We also protect our proprietary information by requiring our employees, consultants, contractors and other advisors to execute nondisclosure and assignment of invention agreements upon commencement of their respective employments or engagements. Agreements with our employees also prohibit them from bringing the proprietary rights of third parties to us. In addition, we protect our proprietary information through creating written obligations of confidentiality with outside parties who are exposed to confidential information. Where appropriate we also employ material transfer agreements governing the use, intellectual property rights, and transfer of materials such as custom oils when sending them to third parties for purposes such as integration into food applications or conversion into fuels, chemicals and personal care products.

We believe that the creation, when possible and appropriate, of multiple, overlapping mechanisms and forms of protection will offer the possibility of broadest and longest proprietary positions for our products and technologies. It is possible that our current and future patents may be successfully challenged or invalidated in whole or in part. It is also possible that we may not obtain issued patents from our filed applications, and may not be able to obtain patents covering other inventions we seek to protect. Due to uncertainties inherent in prosecuting patent applications, some patent applications may be rejected and we may subsequently abandon them. We may also abandon applications when we determine that a product or method is no longer of interest. It is also possible that we may develop products or technologies that will not be patentable or that the patents of others will limit or preclude our ability to do business. In addition, any patent issued to us may provide us with little or no competitive advantage, in which case we may abandon such patent or license it to another entity.

Government Regulation

Our development and production processes involve the use, generation, handling, storage, transportation and disposal of hazardous chemicals and radioactive and biological materials. We are subject to a variety of environmental, health and safety, federal, state, local and international laws, regulations and permit requirements governing, among other matters, the use, generation, manufacture, transportation, storage, handling and disposal of these materials, in the US, Brazil and other countries where we intend to operate or may operate or sell our products in the future. These laws, regulations and permits can cause delays, require expensive fees, pollution control equipment, capital expenditures or operational changes to limit actual or potential impact of our operations on the environment.

We are also subject to regulation by the Occupational Safety and Health Administration (OSHA), the California and federal Environmental Protection Agency (EPA), and to regulation under the Toxic Substance Control Act (TSCA). OSHA, the California or federal EPA or other government agencies may adopt regulations that affect our research and development programs. In particular, our renewable chemical products may be subject to regulation by government agencies in our target markets. The EPA administers the requirements of the TSCA, which regulates the commercial use of chemicals. Before an entity can manufacture a chemical, it needs to determine whether that chemical is listed in the TSCA inventory. If the substance is listed, then manufacture can commence immediately. If not, then a pre-manufacture notice (PMN) must be filed with the EPA, which has 90 days to review it. Some of the products we produce or plan to produce are on the TSCA inventory, after successful PMN submissions and filed Notice of Commencements (NOC). Others are not yet listed. A similar program exists under the European Chemicals Agency (ECHA) called REACH. Under REACH, we are required to register some of our products with the ECHA, and this process could cause delays or involve significant costs.

The use of recombinant microbes like many of our microbial strains is subject to laws and regulations in many countries. In the US, the EPA regulates the commercial use of recombinant microbes as well as potential products from recombinant microbes. When used in an industrial process, our microalgae strains designed using recombinant technology may be considered new chemicals under TSCA, administered by the EPA. Our microalgae strains designed using recombinant technology will be required to comply with the EPA’s Microbial Commercial Activity Notice (MCAN) process and we have filed MCANs for strains of recombinant microalgae that we use for our chemicals and fuels businesses, which have been dropped from review. We have subsequently filed NOCs for dropped MCANs allowing commercial use of the microalgae in the U.S. In Brazil, engineered microbes are regulated by CTNBio. We have filed applications, and in the future may file additional

10

applications, for approval from CTNBio to import and use engineered microbes in our Brazilian facilities for research and development purposes. In addition, we received several commercial approvals from CTNBio for one of our current microbial strains since October 2013. We expect to encounter regulations concerning engineered microbes in most if not all of the countries in which we may seek to make our fuel and chemical products, however, the scope and nature of these regulations will likely be different from country to country. In February 2014, CTNBio granted a CQB (Certificate of Quality in Biosafety) to the Solazyme Bunge JV Plant for activities including industrial production, import and export, disposal and storage of our key production organisms, allowing the Solazyme Bunge JV Plant to run strains without prior commercial approval, under controlled conditions.

Our fuel products are subject to regulation by various government agencies, including the EPA and the California Air Resources Board in the US and Agencia Nacional do Petroleo in Brazil. We have registered fuels with the EPA and are preparing to secure approval for use of our diesel in Brazil. In addition, we may decide to register our fuel with the California Air Resources Board and the European Commission. Registration with each of these bodies is required for the sale and use of our fuels within their respective jurisdictions. Our jet fuels meet the standards set by ASTM D7566 and may therefore be used in commercial aviation.

The manufacture, sale and use of our foods products are regulated as food ingredients in the United States by the U.S Food and Drug Administration (FDA) under the federal Food, Drug, and Cosmetic Act. Food ingredients are broadly defined as any substance that may become a component, or otherwise affect the characteristics, of food. Food ingredients are regulated as food additives and must be approved through a formal Food Additive Petition (FAP) process or affirmed as substances generally recognized as safe, or GRAS. A substance can be listed or affirmed as GRAS by the FDA or self-affirmed by its manufacturer upon determination by independent qualified experts who generally agree that the substance is GRAS for a particular use. Although the FDA does not officially affirm the GRAS status of ingredients, it does review, at the notifier’s request, the notifier’s determination of ingredients’ GRAS status. FDA endeavors to respond to GRAS notices by issuing a letter that either does not question the basis of the notifier’s determination of GRAS status or concludes that the notice does not provide a sufficient basis for a GRAS determination. Self-affirmation of GRAS status without FDA notification allows the marketing and sale of the ingredient, but reliance on self-affirmation alone may limit its marketability, as many food manufacturers require that the FDA issue a letter confirming that it does not question the notifier’s determination of GRAS status before such manufacturers will purchase food ingredients from third parties. We submitted a GRAS Notice to the FDA for our first algae oil in June 2011, and received a “No Questions” letter from the FDA in June 2012. A panel of qualified experts in the field of food toxicology has determined that an additional oleic algae oil, our second algae oil, is GRAS. We submitted a GRAS Notice for the oleic algae oil in July 2014, and received a “No Questions” letter from the FDA in February 2015. We submitted a GRAS Notice for whole algae flour in the third quarter of 2012 and received a “No Questions” letter from the FDA in June 2013. We also submitted a GRAS Notice for whole algae protein in June 2014 and received a “No Questions” letter from the FDA in December 2014.

Food ingredients that are not suitable for the GRAS affirmation process are regulated as food additives and require the submission of a FAP to the FDA and the FDA’s approval prior to commercialization. The food additive petition process is generally expensive and time consuming, with approval, if secured, taking years. The petition must establish with reasonable certainty that the food additive is safe for its intended use at the level specified in the petition. If a food additive petition is submitted, the FDA may choose to reject the petition or deny any desired labeling claims. Furthermore, the FDA may require the establishment of regulations that necessitate costly and time-consuming compliance procedures. All products may also fall under the jurisdiction of the U.S. Department of Agriculture if the intended applications are for meat, dairy, organic or other specialty food areas.

The sale of ingredients for use in animal feed is regulated by agencies including the FDA Center for Veterinary Medicine, or CVM. CVM requirements for suitability must be met by providing data from studies.

Countries other than the U.S. also regulate the manufacture and sale of food, feed and chemical ingredients. Regulations vary substantially from country to country, and we will be required to comply with applicable regulations in each country in which we choose to market our ingredients. In February 2014, the Sao Paulo State Environmental Department granted a license to operate the Solazyme Bunge JV Plant, which was necessary to begin commercial production. We submitted a dossier for oleic algae oil to the Brazilian food safety agency ANVISA in the first quarter of 2014, and anticipate approval for use in foods in 2016. We received food approval from ANVISA with no restrictions for our whole algae flour in July 2015. We also received a Letter of No Objection from Health Canada for whole algae flour in February 2016.

Our skin and personal care products are also subject to regulation by various government agencies in the countries in which our products are sold. We completed several rounds of testing in connection with launching the Algenist® product line,

11

including Human Repeat Insult Patch Testing. We will continue to evaluate regulatory requirements as we launch new skin and personal care products.

Employees

As of December 31, 2015, we had 229 full-time employees, excluding the employees of our joint venture. Our employees’ roles include research, process development, manufacturing, regulatory affairs, program management, finance, human resources, administration, sales and marketing and business development. None of our employees are covered by collective bargaining agreements and we consider relations with our employees to be good.

Investor Information

Our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, current reports on Form 8-K and any amendments to those reports are available free of charge on the Investor Relations section of our website at http://investors.solazyme.com/sec.cfm as soon as reasonably practicable after they are electronically filed with or furnished to the Securities and Exchange Commission (SEC). The public may read and copy any materials filed us with the SEC at the SEC’s Public Reference Room at 100 F Street, NE, Room 1580, Washington, DC 20549. The public may obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. The SEC maintains an Internet site that contains reports, proxy and information statements and other information regarding issuers that file electronically with the SEC at http://www.sec.gov. Except as expressly set forth in this Annual Report on Form 10-K, the contents of these websites are not incorporated into, or otherwise to be regarded as part of this report.

Item 1A. | Risk Factors. |

You should carefully consider the risks and uncertainties described below before investing in our publicly-traded securities. Additional risks and uncertainties not presently known to us or that our management currently deems immaterial also may impair our business operations. If any of the risks described below were to occur, our business, financial condition, operating results, and cash flows could be materially adversely affected. In such an event, the trading price of our common stock could decline and you could lose all or part of your investment. In assessing these risks and uncertainties, you should also refer to the other information contained in this Report, including our consolidated financial statements and related notes. The risks and uncertainties discussed below also include forward-looking statements, and our actual results may differ substantially from those discussed in these forward-looking statements. See Management’s Discussion and Analysis of Financial Condition and Results of Operations-Forward-Looking Statements.

Risks Related to Our Business and Industry

We have a limited operating history and have incurred significant losses to date, anticipate continuing to incur losses and may never achieve or sustain profitability.

We are an emerging growth company with a limited operating history. We only recently began commercializing our products. To date, a substantial portion of our revenues has consisted of funding from third party collaborative research agreements and government grants. We have generated only limited revenues from commercial sales, which have been principally derived from sales of our personal care products. We expect a significant portion of our future revenues to come from commercial sales in food, nutrition and specialty personal care ingredients.

We have incurred substantial net losses since our inception, including a net loss of $141.4 million during the year ended December 31, 2015. We expect these losses may continue as we ramp up our manufacturing capacity and build out our product pipeline. As of December 31, 2015, we had an accumulated deficit of $609.9 million. We expect to incur additional costs and expenses related to the continued development and expansion of our business, including research and development, the operation of our Peoria Facility, the ramp up and operation of the Solazyme Bunge JV production facility (described below) and other commercial facilities. As a result, our annual and quarterly operating losses may continue.

We, along with our development and commercialization partners, will need to develop products successfully, cost effectively produce them in large quantities, and market and sell them profitably. If we fail to become profitable, or if we are unable to fund our continuing losses, we may be unable to continue our business operations. There can be no assurance that we will ever achieve or sustain profitability.

12

We have generated limited revenues from the sale of our products, and our business may fail if we are not able to successfully commercialize these products.

We have had only limited product sales to date. If we are not successful in further advancing our existing commercial arrangements with strategic partners, developing new arrangements, ramping up or otherwise increasing our manufacturing capacity and securing reliable access to sufficient volumes of low-cost feedstock, we will be unable to generate meaningful revenues from our products. We are subject to the substantial risk of failure facing businesses seeking to develop products based on a new technology.

Certain factors that could, alone or in combination, prevent us from successfully commercializing our products include:

• | our ability to secure reliable access to sufficient volumes of low-cost feedstock; |

• | our ability to achieve commercial-scale production of our products on a cost-effective basis and in a timely manner; |

• | technical or operational challenges with our manufacturing processes or with development of new products that we are not able to overcome; |

• | our ability to consistently manufacture our products within specifications; |

• | our ability to establish and maintain successful relationships with development, feedstock, manufacturing and commercialization partners; |

• | our ability to gain market acceptance of our products with customers and maintain customer relationships; |

• | our ability to sell our products at an acceptable price; |

• | our ability to manage our growth; |

• | our ability to meet applicable regulatory requirements for the production, distribution and sale of our products and to comply with applicable laws and regulations; |

• | actions of direct and indirect competitors that may seek to enter the markets in which we expect to compete or that may seek to impose barriers to one or more markets that we intend to target; and |

• | public concerns about the ethical, legal, environmental and social ramifications of the use of targeted recombinant technology, land use and the potential diversion of resources from food production. |

The production of our microalgae-based products requires fermentable feedstock. The inability to obtain feedstock in sufficient quantities or in a timely and cost-effective manner may limit our ability to produce our products.

A critical component of the production of our microalgae-based products is access to feedstock in sufficient quantities and at an acceptable price to enable commercial production and sale. Other than as described below, we currently purchase feedstock, such as sugarcane-based sucrose and corn-based dextrose, for the production of our products at prevailing market prices.

We do not have any long-term supply agreements or other guaranteed access to feedstock other than for the supply of feedstock to Solazyme Bunge Produtos Renováveis Ltda. (“Solazyme Bunge Renewable Oils” or the “Solazyme Bunge JV”) by our partner, Bunge Global Innovation, LLC and certain of its affiliates (“Bunge”), pursuant to our joint venture arrangement that includes a feedstock supply agreement. As we scale our production, we anticipate that the production of our microalgae-based products will require large volumes of feedstock, and we may not be able to contract with feedstock producers to secure sufficient quantities of feedstock at reasonable costs or at all. For example, sugarcane-based sucrose for the Solazyme Bunge JV facility in Moema, Brazil is being provided by Bunge. Sugar and corn are traded as commodities and are subject to price volatility. While we may seek to manage our exposure to fluctuations in the price of sugar and corn-based dextrose by entering into hedging transactions directly or through our joint venture arrangement, we may not be successful in doing so. If we cannot access feedstock in the quantities we need at acceptable prices, we may not be able to successfully commercialize our food ingredients, fuels, chemicals, encapsulated lubricant and other products, and our business will suffer. If we do not succeed in entering into long-term supply contracts when necessary or successfully hedge against our exposure to fluctuations in the price of feedstock, our costs and profit margins may fluctuate from period to period as we will remain subject to prevailing market prices.

Although our plan is to enter into partnerships, such as the Solazyme Bunge JV, with feedstock providers to supply the feedstock necessary to produce our products, we cannot predict the future availability or price of such feedstock or be sure that

13

our feedstock partners will be able to supply such feedstock in sufficient quantities or in a timely manner. The prices of feedstock depend on numerous factors outside of our or our partners’ control, including weather conditions, government programs and regulations, changes in global demand, rising or falling commodities and equities markets, and availability of credit to producers. Crop yields and sugar content depend on weather conditions such as rainfall and temperature. Variable weather conditions have historically caused volatility in feedstock crop prices due to crop failures or reduced harvests. For example, excessive rainfall can adversely affect the supply of feedstock available for the production of our products by reducing the sucrose content of feedstock and limiting growers’ ability to harvest. Crop disease and pestilence can also occur from time to time and can adversely affect feedstock crop growth, potentially rendering useless or unusable all or a substantial portion of affected harvests. The limited amount of time during which feedstock crops keep their sugar content after harvest poses a risk of spoilage. Also, the fact that many feedstock crops are not themselves traded commodities limits our ability to substitute supply in the event of such an occurrence. If our ability to obtain feedstock crops is adversely affected by these or other conditions, our ability to produce our products will be impaired, and our business will be adversely affected. In the near term we believe Brazilian sugarcane-based sucrose will be an important feedstock for us. Along with the risks described above, Brazilian sugarcane prices may also increase due to, among other things, changes in the criteria set by the Conselho dos Produtores de Cana, Açúcar e Álcool (Council of Sugarcane, Sugar and Ethanol Producers), known as Consecana. Consecana is an industry association of producers of sugarcane, sugar and ethanol that sets market terms and prices for general supply, lease and partnership agreements and may change such prices and terms from time to time. Moreover, Brazil has a developed industry for producing ethanol from sugarcane, and if we have manufacturing operations in Brazil that do not have a partner providing the sugarcane feedstock, such as Bunge as part of the Solazyme Bunge JV, we will need to compete for sugarcane feedstock with ethanol producers. Such changes and competition could result in higher sugarcane prices and/or a significant decrease in the volume of sugarcane available for the production of our products, which could adversely affect our business and results of operations.

We have entered into, and plan to enter into other, arrangements with feedstock producers to co-locate production at their existing mills, and if we are not able to complete and execute on these arrangements in a timely manner and on terms favorable to us, our business will be adversely affected.

In April 2012, we entered into a Joint Venture Agreement with Bunge, forming the Solazyme Bunge JV, which is doing business as Solazyme Bunge Renewable Oils. The Joint Venture Agreement was amended in October 2013 and again in October 2015 to expand the field and product portfolio. The Solazyme Bunge JV produces microalgae-based products in Brazil using our proprietary technology and sugarcane feedstock provided by Bunge. The Solazyme Bunge JV’s production facility is located adjacent to a sugarcane processing mill in Brazil that is owned by Bunge. The acquisition of the facility site by the Solazyme Bunge JV from Bunge has been completed. The purchase of any additional land by the Solazyme Bunge JV would be complex, subject to multiple approvals from governmental authorities and take time to complete. The construction of the Solazyme Bunge JV’s production facility began in June 2012, and the first commercial product from the Solazyme Bunge JV production facility was produced in the second quarter of 2014. Manufacturing operations and processes continue to be optimized as the facility is ramped up. In addition, we have entered into a series of research and development agreements with Bunge and with the Solazyme Bunge JV to, among other things, develop additional products for the Solazyme Bunge JV. The current funded projects extend through December 2018. We intend to continue to expand our manufacturing capacity by entering into additional agreements with feedstock producers that require them to invest some or all of the capital needed to build new production facilities to produce our products. In return, we expect to share in profits anticipated to be realized from the sale of these products.

In November 2012, we and Archer-Daniels-Midland Company ("ADM") entered into a Strategic Collaboration Agreement (“Collaboration Agreement”), establishing a strategic collaboration ("Solazyme/ADM Collaboration") at the ADM facility in Clinton, Iowa (Clinton Facility") for the production of microalgae-based products. Concurrently with the execution of the Collaboration Agreement, we and ADM entered into an operating agreement (the “Operating Agreement”) related to the production of products at the Clinton Facility. On October 29, 2015, we provided notice to ADM of the termination of the Operating Agreement as of February 26, 2016 (the “Termination Date”). On December 28, 2015, we and ADM entered into a Termination Agreement relating to the termination of the Strategic Collaboration. On February 26, 2016, the Operating Agreement and the Collaboration Agreement terminated.

Since the third quarter of 2013, downstream processing of products manufactured at the Clinton Facility had been performed at a finishing facility in Galva, Iowa (“Galva Facility”), which is operated by our long-term partner, a wholly owned subsidiary of American Natural Processors, Inc. (“ANP”) (“Clinton/Galva Facilities”). We and the wholly owned subsidiary of ANP entered a Termination Agreement on December 11, 2015 terminating the contract for services at the Galva Facility as of December 31, 2015. Despite the termination we expect to continue to use the Galva Facility for some downstream processing.

14

Due to the termination of the contracts relating to the Clinton/Galva Facilities, customers that previously had received our products from the Clinton/Galva Facilities may need to qualify our products that are produced at the Solazyme Bunge JV production facility. A failure by the products manufactured at the Solazyme Bunge JV to qualify or otherwise meet the requirements of our customers would adversely affect our business.

There can be no assurance that a sufficient number of other sugar or other feedstock mill owners will accept the opportunity to partner with us for the production of our microalgae-based products. Reluctance on the part of mill owners may be caused, for example, by their failure to understand our technology or product opportunities or their belief that greater economic benefits can be achieved from partnering with others. Mill owners may also be reluctant or unable to obtain needed capital; alternatively, if mill owners are able to obtain debt financing, we may be required to provide a guarantee. Limitations in the credit markets, such as those experienced in the most recent economic downturn or historically in developing nations as a result of government monetary policies designed in response to very high rates of inflation, would impede or prevent this kind of financing and could adversely affect our ability to develop the production capacity needed to allow us to grow our business. Mill owners may also be limited by existing contractual obligations with other third parties, liability, health and safety concerns and additional maintenance, training, operating and other ongoing expenses.

Even if additional feedstock partners are willing to co-locate our production at their mills, they may do so only on economic terms that place more of the cost, or confer less of the economic return, on us than we currently anticipate. If we are not successful in negotiations with mill owners, our cost of securing additional manufacturing capacity may be higher than anticipated in terms of up-front costs, capital expenditure or lost future returns, and we may not gain the manufacturing capacity that we need to grow our business.

Our pursuit of new product opportunities may not be technologically feasible or cost effective, which would limit our ability to expand our product line and sources of revenues.

We have committed, and intend to continue to commit, substantial resources, alone or with collaboration partners, to the development and analysis of new oils and other microalgae-based products by applying classical and recombinant technology to our microalgae strains. There is no guarantee that we will be successful in creating new oil profiles, or other microalgae-based products, that we, our partners or their customers desire. There are significant technological hurdles in successfully applying recombinant and other technology to microalgae, and if we are unsuccessful at developing microalgae strains that produce desirable oils and other microalgae-based products, the number and size of the markets we will be able to address will be limited, our expected profit margins could be reduced and the potential profitability of our business could be compromised.

The successful development of our business depends on our ability to efficiently and cost-effectively produce microalgae-based products at large commercial scale.

Two of the significant drivers of our production costs are the level of productivity and conversion yield of our microalgae strains. For example, with respect to oil, productivity is principally a function of the amount of oil that can be obtained from a given volume over a particular time period. Conversion yield refers to the amount of the desired oil that can be produced from a fixed amount of feedstock. We may not be able to meet our currently expected production cost profile as we ramp up large commercial manufacturing facilities. If we cannot do so, our business could be materially and adversely affected.

Production of both current and future oils and other microalgae-based products will require that our technology and processes be scalable from laboratory, pilot and demonstration projects to large commercial-scale production. We have limited experience constructing, ramping up or managing large, commercial-scale manufacturing facilities. We may not have identified all of the factors that could affect our manufacturing processes. Our technology may not perform as expected when applied at large commercial scale, or we may encounter operational challenges for which we are unable to identify a workable solution. For example, contamination in the production process, equipment failure or accidents, problems with consistent and reliable plant utilities, human error, issues arising from process modifications to reduce costs and adjust product specifications, and other similar challenges could decrease process efficiency, create delays and increase our costs. To date we have employed our technology using fermenters with a capacity of up to approximately 625,000 liters. However, we still need to demonstrate that we can reach our target cost structure, including the achievement of target yields and productivities at approximately 625,000 liter scale in Brazil. We may not be able to scale up our production in a timely manner, on commercially reasonable terms, or at all. If we are unable to manufacture products at a large commercial scale, our ability to commercialize our technology will be adversely affected, and, with respect to any products that we do bring to market, we may not be able to achieve and maintain an acceptable production cost profile, which would adversely affect our ability to reach, maintain and increase the profitability of our business.

We rely in part on third parties for the production and processing of our products. If these parties do not produce and process our products at a satisfactory quality, in a timely manner, in sufficient quantities and at an acceptable cost, our development and commercialization efforts could be delayed or otherwise negatively impacted.

15

Other than our Peoria Facility, we do not wholly own facilities that can produce and process our products other than at small scale. As such, we rely, and we expect to continue to rely, at least partially, on third parties (including partners and contract manufacturers) for the production and processing of our products. We currently have only one manufacturing arrangement for large-scale commercial fermentation: an agreement for the manufacture of certain products by the Solazyme Bunge JV pursuant to a joint venture arrangement. We also have the ability to do smaller-scale commercial fermentation at our Peoria facility.

In addition, we have manufacturing agreements relating to other aspects of our production process. Our current and anticipated future dependence upon our partners and contract manufacturers for the production and processing of our products may adversely affect our ability to develop products on a timely and competitive basis. The failure of any of our counterparties to provide acceptable products could delay the development and commercialization of our products. We or our partners will need to enter into additional agreements for the commercial development, manufacturing and sale of our products. There can be no assurance that we or our partners can do so on favorable terms, if at all. Even if we reach agreements with manufacturing partners to produce and process our products, initially the partners will be unfamiliar with our technology and production processes. We cannot be sure that the partners will have or develop the operational expertise needed to run the equipment and processes required to manufacture our products. Further, we may have limited control over the amount or timing of resources that any partner is able or willing to devote to production and processing of our products.

To date, our products have been produced and processed in quantities sufficient for our development work and initial commercial sales. Even if there is demand for our products at commercial scale, we or our partners may not be able to successfully increase the production capacity for any of our products in a timely or economic manner or at all. In addition, to the extent we are relying on contract manufacturers to produce and process our products, we cannot be sure that such contract manufacturers will have capacity available when we need their services, that they will be willing to dedicate a portion of their production and/or processing capacity to our products or that we will be able to reach acceptable price and other terms with them for the provision of their production and/or processing services. If we, our partners or our contract manufacturers are unable to increase the production capacity for a product when and as needed, the commercial launch of that product may be delayed, or there may be a shortage of supply, which could limit sales, cause us to lose customers and sales opportunities and impair the growth of our business.

In addition, if a facility or the equipment in a facility that produces and/or processes our products is significantly damaged, destroyed or otherwise becomes unavailable, we or our partners may be unable to replace the manufacturing capacity quickly or cost effectively. The inability to enter into manufacturing agreements, the damage or destruction of a facility upon which we or our partners rely for manufacturing or any other delays in obtaining supply would delay or prevent us and/or our partners from further developing and commercializing our products.

We may experience significant delays and/or cost overruns in financing, designing, constructing and ramping up large commercial manufacturing facilities, which could result in harm to our business and prospects.

Our business plan contemplates bringing additional commercial manufacturing capacity online over the next several years. In order to meet our financial requirements for those facilities, we may have to raise additional funds and may be unable to do so in a timely manner, in sufficient amounts and on terms that are favorable to us, if at all. If we fail to raise sufficient funds, our ability to ramp up the Solazyme Bunge JV production facility or construct additional manufacturing facilities could be significantly limited. If this happens, we may be forced to delay the commercialization of our products and we will not be able to successfully execute our business plan, which would harm our business.

Manufacturing operations have begun at the Solazyme Bunge JV production facility adjacent to Bunge’s Moema sugarcane mill in Brazil. The first products from the Solazyme Bunge JV production facility were produced in the second quarter of 2014, and manufacturing operations at the facility are in the process of being optimized and ramped up. We do not expect the facility to reach target nameplate capacity in the near term as the Solazyme Bunge JV continues to optimize manufacturing operations and focuses production on high margin products, and additional capital expenditures may be required to reach nameplate capacity depending on the product mix produced at the Solazyme Bunge JV production facility. Under the joint venture agreements, Bunge has agreed to provide feedstock as well as utility services to the Solazyme Bunge JV production facility. The production facility has experienced, and may continue to experience, intermittent supply of power and steam from Bunge. Bunge and the Solazyme Bunge JV have completed a number of power and steam improvement projects, including the construction of an electrical grid tie-in and the tie-in and activation of a second steam boiler. The Solazyme Bunge JV continues to evaluate the performance of these projects and may take additional actions in the future to further improve power and steam reliability, if necessary. Without consistent and reliable supplies of power and steam to the production facility, production yields will be lower, the ramp up and optimization of the Solazyme Bunge JV production facility will be delayed, our costs will increase and our business and results of operations will be adversely affected.

16

In February 2013, the Solazyme Bunge JV entered into a loan agreement with the Brazilian Development Bank (“BNDES”) for project financing. Funds borrowed under the loan agreement have supported the production facility in Brazil, including a portion of the construction costs of the facility. We have used a portion of our $35.0 million revolving and term loan credit facility (the “HSBC facility”) with HSBC Bank, USA, National Association (“HSBC”) to support a bank guarantee of the BNDES loan. The HSBC facility expires on May 31, 2016, and we may not be successful in replacing the bank guarantee or the facility to support the bank guarantee on substantially similar terms; negotiating the terms of the bank guarantee or the new facility may take longer than anticipated and may contain terms that are not favorable to us. In addition, we may be required to provide a corporate guarantee of a portion of the BNDES loan (in an amount that, when added to the amount supported by our bank guarantee, does not exceed our ownership percentage in the Solazyme Bunge JV). Negotiating the terms of the corporate guarantee documentation may take longer than anticipated and may contain terms that are not favorable to us. The Solazyme Bunge JV may in the future seek additional financing and may not be able to raise sufficient additional funds on favorable terms, if at all. If the Solazyme Bunge JV is unable to secure additional financing, we will be required to fund our portion of the Solazyme Bunge JV’s capital requirements either from existing sources or seek additional financing. The acquisition of the facility site by the Solazyme Bunge JV from Bunge has been completed. The purchase of any additional land by the Solazyme Bunge JV would be complex, subject to multiple approvals of governmental authorities and take time to complete.