Attached files

| file | filename |

|---|---|

| EX-21.1 - EX-21.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex2113a21d7.htm |

| EX-32.2 - EX-32.2 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex3228da208.htm |

| EX-32.1 - EX-32.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex3215ec58b.htm |

| EX-23.2 - EX-23.2 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex232adf652.htm |

| EX-23.1 - EX-23.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex23189a273.htm |

| EX-99.1 - EX-99.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex991968d4a.htm |

| EX-31.1 - EX-31.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex311dc03f8.htm |

| EX-95.1 - EX-95.1 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex95174abe8.htm |

| EX-31.2 - EX-31.2 - UNITED STATES LIME & MINERALS INC | uslm-20151231ex3122752b7.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10‑K

|

(Mark One) |

|

|

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

|

For the fiscal year ended December 31, 2015 |

|

|

OR |

|

|

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission File Number 000‑4197

United States Lime & Minerals, Inc.

(Exact name of Registrant as specified in its charter)

|

Texas |

75‑0789226 |

|

5429 LBJ Freeway, Suite 230, Dallas, Texas |

75240 |

Registrant’s telephone number, including area code: (972) 991‑8400

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT:

|

Title of Each Class |

Name of Each Exchange on Which Registered |

|

Common Stock, $0.10 par value |

The NASDAQ Stock Market LLC |

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT: None

Indicate by check mark if the Registrant is a well‑known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☒

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes ☐ No ☒

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Exchange Act during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the Registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S‑T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☒ No ☐

Indicate by a check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S‑K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10‑K or any amendment of this Form 10‑K. ☐

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, non‑accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b‑2 of the Exchange Act. (Check one):

|

Large Accelerated Filer ☐ |

Accelerated Filer ☒ |

Non‑accelerated Filer ☐ |

Smaller Reporting Company ☐ |

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b‑2 of the Exchange Act). Yes ☐ No ☒

The aggregate market value of Common Stock held by non‑affiliates computed as of the last business day of the Registrant’s quarter ended June 30, 2015: $118,877,546.

Number of shares of Common Stock outstanding as of March 3, 2016: 5,563,669.

DOCUMENTS INCORPORATED BY REFERENCE

Part III incorporates information by reference from the Registrant’s definitive Proxy Statement to be filed for its 2016 Annual Meeting of Shareholders. Part IV incorporates certain exhibits by reference from the Registrant’s previous filings.

|

|

|

Page |

|

|

Part I |

|

|

1 |

||

|

12 |

||

|

17 |

||

|

17 |

||

|

17 |

||

|

17 |

||

|

|

Part II |

|

|

18 |

||

|

20 |

||

|

MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

20 |

|

|

30 |

||

|

31 |

||

|

CHANGES IN AND DISAGREEMENTS WITH ACCOUNTANTS ON ACCOUNTING AND FINANCIAL DISCLOSURE |

57 |

|

|

57 |

||

|

57 |

||

|

|

Part III |

|

|

58 |

||

|

58 |

||

|

SECURITY OWNERSHIP OF CERTAIN BENEFICIAL OWNERS AND MANAGEMENT AND RELATED STOCKHOLDER MATTERS |

58 |

|

|

CERTAIN RELATIONSHIPS AND RELATED TRANSACTIONS, AND DIRECTOR INDEPENDENCE |

58 |

|

|

58 |

||

|

|

Part IV |

|

|

59 |

||

|

62 |

||

ii

General.

United States Lime & Minerals, Inc. (the “Company,” the “Registrant,” “We” or “Our”), which was incorporated in 1950, conducts its business through two segments, Lime and Limestone Operations and Natural Gas Interests.

The Company’s principal corporate office is located at 5429 LBJ Freeway, Suite 230, Dallas, Texas 75240. The Company’s telephone number is (972) 991‑8400, and its internet address is www.uslm.com. The Company’s annual reports on Form 10‑K, quarterly reports on Form 10‑Q, current reports on Form 8‑K and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), as well as the Company’s definitive proxy statement filed pursuant to Section 14(a) of the Exchange Act, are available free of charge on the Company’s website as soon as reasonably practicable after the Company electronically files such material with, or furnishes it to, the Securities and Exchange Commission (the “SEC”).

Lime and Limestone Operations.

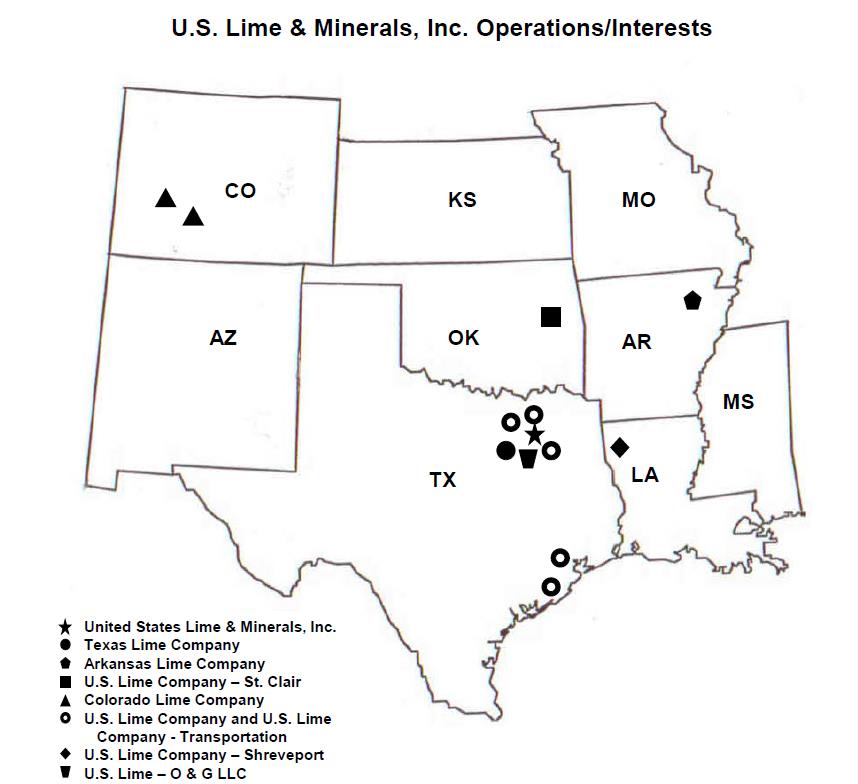

Business and Products. The Company, through its Lime and Limestone Operations, is a manufacturer of lime and limestone products, supplying primarily the construction (including highway, road and building contractors), environmental (including municipal sanitation and water treatment facilities and flue gas treatment processes), industrial (including paper and glass manufacturers), metals (including steel producers), roof shingle, oil and gas services and agriculture (including poultry and cattle feed producers) industries. The Company is headquartered in Dallas, Texas and operates lime and limestone plants and distribution facilities in Arkansas, Colorado, Louisiana, Oklahoma and Texas through its wholly owned subsidiaries, Arkansas Lime Company, Colorado Lime Company, Texas Lime Company, U.S. Lime Company, U.S. Lime Company—Shreveport, U.S. Lime Company—St. Clair and U.S. Lime Company—Transportation.

The Company extracts high‑quality limestone from its open‑pit quarries and an underground mine and then processes it for sale as pulverized limestone, quicklime, hydrated lime and lime slurry. Pulverized limestone (also referred to as ground calcium carbonate) (“PLS”) is produced by applying heat to dry the limestone, which is then ground to granular and finer sizes. Quicklime (calcium oxide) is produced by heating limestone to very high temperatures in kilns in a process called calcination. Hydrated lime (calcium hydroxide) is produced by reacting quicklime with water in a controlled process. Lime slurry (milk of lime) is a suspended solution of calcium hydroxide produced by mixing quicklime with water in a lime slaker.

PLS is used in the production of construction materials such as roof shingles and asphalt paving, as an additive to agriculture feeds, in the production of glass, as a soil enhancement, in flue gas treatment for utilities and other industries requiring scrubbing of emissions for environmental purposes and for mine safety dust in coal mining operations. Quicklime is used primarily in metal processing, in flue gas treatment, in soil stabilization for highway, road and building construction, as well as for oilfield roads and drill sites, in the manufacturing of paper products and in municipal sanitation and water treatment facilities. Hydrated lime is used primarily in municipal sanitation and water treatment facilities, in soil stabilization for highway, road and building construction, in flue gas treatment, in asphalt as an anti‑stripping agent, as a conditioning agent for oil and gas drilling mud, in the production of chemicals and in the production of construction materials such as stucco, plaster and mortar. Lime slurry is used primarily in soil stabilization for highway, road and building construction.

Product Sales. In 2015, the Company sold almost all of its lime and limestone products in the states of Arizona, Arkansas, Colorado, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Mississippi, Missouri, New Mexico, Oklahoma, Pennsylvania, Tennessee, and Texas. Sales were made primarily by the Company’s nine sales employees who call on current and potential customers and solicit orders, which are generally made on a purchase‑order basis. The Company also receives orders in response to bids that it prepares and submits to current and potential customers.

1

Principal customers for the Company’s lime and limestone products are construction customers (including highway, road and building contractors), environmental customers (including municipal sanitation and water treatment facilities and flue gas treatment processes), industrial customers (including paper manufacturers and glass manufacturers), metals producers (including steel producers), roof shingle manufacturers, oil and gas services companies, and poultry and cattle feed producers. During 2015, the strongest demand for the Company’s lime and limestone products was from construction customers, environmental customers, industrial customers, metals producers, roof shingle manufacturers and oil and gas services companies.

Approximately 700 customers accounted for the Company’s sales of lime and limestone products during 2015. No single customer accounted for more than 10% of such sales. The Company is generally not subject to significant customer demand and credit risks as its customers are considerably diversified as to geographic location and industry concentration. However, given the nature of the lime and limestone industry, the Company’s profits are very sensitive to changes in sales volume and prices.

Lime and limestone products are transported by truck and rail to customers generally within a radius of 400 miles of each of the Company’s plants. All of the Company’s 2015 sales were made within the United States.

Order Backlog. The Company does not believe that backlog information accurately reflects anticipated annual revenues or profitability from year to year.

Seasonality. The Company’s sales have typically reflected seasonal trends, with the largest percentage of total annual shipments and revenues normally being realized in the second and third quarters. Lower seasonal demand normally results in reduced shipments and revenues in the first and fourth quarters. Inclement weather conditions generally have a negative impact on the demand for lime and limestone products supplied to construction‑related customers, as well as on the Company’s open‑pit quarrying operations.

Limestone Reserves. The Company’s limestone reserves contain at least 96% calcium carbonate (CaCO3). The Company has two subsidiaries that extract limestone from open‑pit quarries: Texas Lime Company (“Texas Lime”), which is located near Cleburne, Texas, and Arkansas Lime Company (“Arkansas Lime”), which is located near Batesville, Arkansas. U.S. Lime Company—St. Clair (“St. Clair”) extracts limestone from an underground mine located near Marble City, Oklahoma. Colorado Lime Company (“Colorado Lime”) owns property containing limestone deposits at Monarch Pass, located 15 miles west of Salida, Colorado. Existing crushed stone stockpiles on the property are being used to provide feedstock to the Company’s plants in Salida and Delta, Colorado. Access to all properties is provided by paved roads and, in the case of Arkansas Lime and St. Clair, also by rail.

Texas Lime operates a quarry, located on approximately 3,200 acres of land that contains known high‑quality limestone reserves in a bed averaging 28 feet in thickness, with an overburden that ranges from 0 to 50 feet. Texas Lime also has mineral interests in approximately 560 acres of land adjacent to the northwest boundary of its property. The reserves, as of December 31, 2015, were approximately 18 million tons of proven recoverable reserves plus approximately 75 million tons of probable recoverable reserves. Assuming the current level of production and recovery rate is maintained, the Company estimates that these reserves are sufficient to sustain operations for more than 75 years.

Arkansas Lime operates two quarries and has hydrated lime and limestone production facilities on a second site linked to the quarries by its own standard‑gauge railroad. The quarries cover approximately 1,050 acres of land located in Independence County, Arkansas containing a known deposit of high‑quality limestone reserves (the “Batesville Quarry”). The average thickness of the high‑quality limestone bed is approximately 60 feet, with an average overburden thickness of approximately 30 feet. The reserves for the Batesville Quarry, as of December 31, 2015, were approximately 15 million tons of proven recoverable reserves. In 2005, the Company acquired approximately 2,500 acres of land in nearby Izard County, Arkansas (the “North Quarry”). The high‑quality reserves on these 2,500 acres, as of December 31, 2015, were approximately 76 million tons of probable recoverable reserves. The Company continues to assess the costs required to improve the transportation infrastructure between the North Quarry and Arkansas Lime’s production facilities and other development costs to prepare the North Quarry for mining. Assuming the current level of production and recovery rate is maintained, the Company estimates that its total reserves in Arkansas are sufficient to sustain operations for more than 60 years.

2

St. Clair, acquired by the Company in December 2005, operates an underground mine located on approximately 700 acres it owns containing high‑quality limestone reserves. The reserves, as of December 31, 2015, were approximately 12 million tons of probable recoverable reserves on the 500 acres. Assuming the current level of production and recovery rate is maintained, the Company estimates that the probable recoverable reserves are sufficient to sustain operations for more than 25 years. In addition, St. Clair also has the right to mine the high‑quality limestone contained in approximately 1,500 adjacent acres pursuant to long‑term mineral leases. Although limestone is being mined from a portion of the leased properties, the Company has not conducted a drilling program to identify and categorize reserves on the 1,500 leased acres.

During 2015, the Company produced approximately 3 million tons of limestone from its quarries and mine.

Colorado Lime acquired the Monarch Pass Quarry in November 1995 and has not carried out any mining on the property. A review of the potential limestone resources has been completed by independent geologists; however, the Company has not initiated a drilling program. Consequently, it is not possible to identify and categorize reserves. The Monarch Pass Quarry, which had been operated for many years until the early 1990s, contains a mixture of limestone types, including high‑quality calcium limestone and dolomite. Assuming the current level of production is maintained, the Company estimates that the remaining crushed stone stockpiles on the property are sufficient to supply its plants in Salida and Delta, Colorado for approximately 15 years.

Quarrying and Mining. The Company extracts limestone by the open‑pit method at its Texas and Arkansas quarries. The Monarch Pass Quarry is also an open‑pit quarry, but is not being mined at this time. The open‑pit method consists of removing any overburden comprising soil and other substances, including inferior limestone, and then extracting the exposed high‑quality limestone. The Company removes such overburden by utilizing both its own employees and equipment and those of outside contractors. Open‑pit mining is generally less expensive than underground mining. The principal disadvantage of the open‑pit method is that operations are subject to inclement weather and overburden removal. The limestone is extracted by drilling and blasting, utilizing standard mining equipment. At its St. Clair underground mine, the Company mines limestone using room and pillar mining. The Company has no knowledge of any recent changes in the physical quarrying or mining conditions on any of its properties that have materially affected its quarrying or mining operations, and no such changes are anticipated.

Plants and Facilities. After extraction, limestone is crushed and screened and, in the case of PLS, ground and dried, or, in the case of quicklime, processed in kilns. Quicklime may then be further processed in hydrators and slakers to produce hydrated lime and lime slurry. The Company processes and distributes lime and/or limestone products at five plants, four lime slurry facilities and two terminal facilities. All of its plants and facilities are accessible by paved roads, and, in the case of the Arkansas Lime and St. Clair plants and the terminal facilities, also by rail.

The Texas Lime plant has an annual capacity of approximately 470 thousand tons of quicklime from two preheater rotary kilns. The plant also has PLS equipment, which, depending on the product mix, has the capacity to produce approximately 800 thousand tons of PLS annually.

The Arkansas plant is situated at the Batesville Quarry. Utilizing three preheater rotary kilns, this plant has an annual capacity of approximately 630 thousand tons of quicklime. Arkansas Lime’s PLS and hydrating facilities are situated on a tract of 290 acres located approximately two miles from the Quarry, to which it is connected by a Company‑owned, standard‑gauge railroad. The PLS equipment, depending on the product mix, has the capacity to produce approximately 300 thousand tons of PLS annually.

The St. Clair plant has an annual capacity of approximately 180 thousand tons of quicklime from two rotary kilns, one of which is not a preheater kiln. The plant also has PLS equipment, which has the capacity to produce approximately 150 thousand tons of PLS annually. In the fourth quarter 2013, the Company received the necessary air permit from the Oklahoma Department of Environmental Quality to replace the non‑preheater kiln with the construction of a new, more fuel‑efficient kiln. The Company continues to assess technical feasibility, economics and market demand before making a decision regarding the modernization of the St. Clair plant.

The Company also maintains lime hydrating and bagging equipment at the Texas, Arkansas and St. Clair plants. Storage facilities for lime and limestone products at each plant consist primarily of cylindrical tanks, which are

3

considered by the Company to be adequate to protect its lime and limestone products and to provide an available supply for customers’ needs at the expected volumes of shipments. Equipment is maintained at each plant to load trucks and, at the Arkansas Lime and St. Clair plants, to load railroad cars.

Colorado Lime operates a limestone grinding and bagging facility with an annual capacity of approximately 125 thousand tons, located on approximately three and one‑half acres of land in Delta, Colorado, and a limestone drying, grinding and bagging facility, with an annual capacity of approximately 40 thousand tons, located on eight acres of land in Salida, Colorado. The Salida property is leased from the Union Pacific Railroad for a five‑year term ending June 2019.

During 2015, the Company’s utilization rate was approximately 57% of its aggregate approximate annual production capacity for the plants in its Lime and Limestone Operations.

U.S. Lime Company (“US Lime”) uses quicklime to produce lime slurry and has two facilities, including a new distribution terminal, which is connected to a railroad, established in 2015 southwest of Houston, Texas, to serve the Greater Houston area construction market and three facilities to serve the Dallas‑Ft. Worth Metroplex. The Company established U.S. Lime Company—Transportation (“Transportation”) primarily to deliver the Company’s products to its customers and facilities in the Dallas‑Ft. Worth Metroplex. In December 2014, US Lime acquired the land and buildings, and Transportation acquired the trucks, trailers and other equipment, owned by a Houston, Texas trucking company operation that had exclusively delivered the Company’s products to its customers and slurry facilities. The land purchased included the site leased for US Lime’s Houston slurry facility. Transportation utilizes the acquired assets to deliver its products to the Company’s customers and facilities and does not haul for third parties.

U.S. Lime Company—Shreveport operates a distribution terminal in Shreveport, Louisiana, which is connected to a railroad, to provide lime storage, hydrating, slurrying and distribution capacity to service markets in Louisiana and East Texas.

The Company believes that its plants and facilities are adequately maintained and insured.

Employees. At December 31, 2015, the Company employed 323 persons and is a party to two collective bargaining agreements. The collective bargaining agreements for our Arkansas and Texas facilities expire in January and November 2017, respectively. The Company believes that its employee relations are good.

Competition. The lime industry is highly regionalized and competitive, with price, quality, ability to meet customer demands and specifications, proximity to customers, personal relationships and timeliness of deliveries being the prime competitive factors. The Company’s competitors are predominantly private companies.

The lime industry is characterized by high barriers to entry, including: the scarcity of high‑quality limestone deposits on which the required zoning and permitting for extraction can be obtained; the need for lime plants and facilities to be located close to markets, paved roads and railroad networks to enable cost‑effective production and distribution; clean air and anti‑pollution regulations, including those related to greenhouse gas emissions, which make it more difficult to obtain permitting for new sources of emissions, such as lime kilns; and the high capital cost of the plants and facilities. These considerations reinforce the premium value of operations having permitted, long‑term, high‑quality limestone reserves and good locations and transportation relative to markets.

Lime producers tend to be concentrated on known high‑quality limestone formations where competition takes place principally on a regional basis. The industry as a whole has expanded its customer base, and while the steel industry and environmental‑related users, including utility plants, are the largest market sectors, it also counts chemical users and other industrial users, including paper manufacturers and highway, road and building contractors, among its major customers.

However, in recent years, the lime industry has experienced reduced demand from certain industries, including the steel industry. In addition, utility plants are, in some instances, choosing to use more natural gas for power generation instead of coal, which reduces their demand for lime and limestone for flue gas treatment processes. These reductions in demand have resulted in increased competitive pressures, including pricing competition, in the industry.

4

Consolidation in the lime industry has left the three largest companies accounting for more than two‑thirds of North American production capacity. In addition to the consolidations, and often in conjunction with them, many lime producers have undergone modernization and expansion and development projects to upgrade their processing equipment in an effort to improve operating efficiency. The Company’s Texas and Arkansas modernization and expansion projects, its acquisitions of the St. Clair operations in Oklahoma and the lime slurry operations in Texas, and its development projects in Arkansas should allow the Company to continue to remain competitive, protect its markets and position itself for the future. In addition, the Company will continue to evaluate internal and external opportunities for expansion, growth and increased profitability, as conditions warrant or opportunities arise. The Company may have to revise its strategy or otherwise find ways to enhance the value of the Company, including entering into strategic partnerships, mergers or other transactions.

Impact of Environmental Laws. The Company owns or controls large areas of land, upon which it operates limestone quarries, an underground mine, lime plants and other facilities with inherent environmental responsibilities and environmental compliance costs and liabilities, including capital, maintenance and operating costs with respect to pollution control equipment, the cost of ongoing monitoring programs, the cost of reclamation and remediation efforts and other similar environmental costs and liabilities.

The Company’s operations are subject to various federal, state, and local laws and regulations relating to the environment, health and safety, and other regulatory matters, including the Clean Air Act, the Clean Water Act, the Resource Conservation and Recovery Act and the Comprehensive Environmental Response, Compensation, and Liability Act (“Environmental Laws”). These Environmental Laws grant the United States Environmental Protection Agency (the “EPA”) and state governmental agencies the authority to promulgate and enforce regulations that could result in substantial expenditures on pollution control, waste management, permitting and compliance activities. The failure to comply with Environmental Laws may result in administrative and civil penalties, injunctive relief, and criminal prosecution. The Company has not been named as a potentially responsible party in any federal superfund cleanup site or state-led cleanup site.

The rate of change of Environmental Laws continues to be rapid, and compliance can require significant expenditures. For example, federal legislation required the Company’s plants with operating kilns to apply for Title V operating permits that have significant ongoing compliance monitoring costs. In addition to the Title V permits, other environmental operating permits are required for the Company’s operations, and such permits are subject to modification during the permit renewal process, and to revocation. Raw materials and fuels used to manufacture lime products contain chemicals and compounds, such as trace metals, that may be classified as hazardous substances. In October 2015, the EPA issued a final rule lowering the National Ambient Air Quality Standards (“NAAQS”) for ground-level ozone from 75 parts per billion to 70 parts per billion. The final rule requires states to revise their State Implementation Plans (“SIP”) to achieve the new standard. At this point, it is unclear what specific SIP revisions will be proposed. It is possible, however, that the EPA could adopt new SIP revisions that would result in increased compliance costs and liabilities and make permitting of major modifications more difficult. In 2010, the EPA adopted new NAAQS for sulfur dioxide and nitrogen dioxide. If the Company makes major modifications of any of its lime plants, the New Source Review (discussed below) permitting process may entail modeling and, potentially, installation of additional emission controls to demonstrate compliance with those new NAAQS.

As of January 1, 2010, the EPA required large emitters of greenhouse gases, including the Company’s plants, to collect and report greenhouse gas emissions data. The EPA indicated it will use the data collected through the greenhouse gas reporting rules to decide whether to promulgate future greenhouse gas emission limits or possible taxes. On May 13, 2010, the EPA issued a final rule “tailoring” its New Source Review permitting and Federal Operating Permit programs to apply to facilities with certain thresholds of greenhouse gas emissions. This “Tailoring Rule” was challenged in court, and on June 23, 2014, the United States Supreme Court struck down the Tailoring Rule in Utility Air Regulatory Group v. Environmental Protection Agency. In its decision, the Court held that the EPA may not impose permitting requirements on facilities based solely on their emissions of greenhouse gasses. But, the Court also held that the EPA may regulate greenhouse gas emissions if a facility is otherwise subject to permitting based on the emissions of conventional, non-greenhouse gas pollutants. Thus, any new facilities or major modifications to existing facilities that exceed the federal New Source Review emission thresholds for conventional pollutants may be required to use “best available control technology” and energy efficiency measures to minimize greenhouse gas emissions. On December 19, 2014, the EPA issued guidance stating that the agency would exercise its enforcement discretion to not pursue

5

enforcement of the terms and conditions of the portion of the permitting regulations struck down by the Supreme Court in Utility Air Regulatory Group.

Although the timing and impact of climate change legislation and of regulations limiting greenhouse gas emissions are uncertain, the consequences of such legislation and regulation are potentially significant for the Company because the production of CO2 is inherent in the manufacture of lime through the calcination of limestone and combustion of fossil fuels. Future rulemaking following the Utility Air Regulatory Group decision could affect New Source Review permitting and, thereby, increase the time and costs of plant upgrades and expansions. The passage of climate change legislation, and other regulatory initiatives by the Congress, the states or the EPA that restrict or tax emissions of greenhouse gases, could also adversely affect the Company. There is no assurance that changes in the law or regulations will not be adopted, such as the imposition of a carbon tax, a cap-and-trade program requiring the Company to purchase carbon credits, or other measures that would require reductions in emissions or changes to raw materials, fuel use or production rates that could have a material adverse effect on the Company’s financial condition, results of operations, cash flows and competitive position.

In the courts, several cases have been filed and decisions issued that may increase the risk of claims being filed by third parties against companies for their greenhouse gas emissions. Such cases may seek to challenge air permits, to force reductions in greenhouse gas emissions or to recover damages for alleged climate change impacts to the environment, people and property.

The Company incurred capital expenditures related to environmental matters of approximately $0.5 million, $1.0 million and $0.4 million in 2015, 2014 and 2013, respectively. The Company’s recurring costs associated with managing environmental permitting and waste recycling and disposal (e.g., used oil and lubricants) and maintaining pollution control equipment amounted to approximately $1.0 million, $0.9 million and $0.8 million in 2015, 2014 and 2013, respectively.

The Company recognizes legal reclamation and remediation obligations associated with the retirement of long‑lived assets at their fair value at the time the obligations are incurred (“Asset Retirement Obligations” or “AROs”). Over time, the liability for AROs is recorded at its present value each period through accretion expense, and the capitalized cost is amortized over the useful life of the related asset. Upon settlement of the liability, the Company either settles the ARO for its recorded amount or recognizes a gain or loss. AROs are estimated based on studies and the Company’s process knowledge and estimates, and are discounted using an appropriate interest rate. The AROs are adjusted when further information warrants an adjustment. The Company believes its accrual of $2.1 million for AROs at December 31, 2015 is reasonable.

6

Map of United States Lime & Minerals, Inc. Operations/Interests.

Natural Gas Interests.

Interests. The Company, through its wholly owned subsidiary, U.S. Lime Company—O & G, LLC (“U.S. Lime O & G”), has royalty interests ranging from 15.4% to 20% and a 20% non‑operating working interest with respect to oil and gas rights on the Company’s approximately 3,800 acres of land located in Johnson County, Texas, in the Barnett Shale Formation. These interests are derived from the Company’s May 2004 oil and gas lease agreement (the “O & G Lease”) with EOG Resources, Inc. (“EOG”) with respect to oil and gas rights on its Texas Lime property that will continue on currently producing wells so long as EOG is producing natural gas from such wells as set forth in the O & G Lease.

During the fourth quarter 2005, drilling of the first natural gas well under the O & G Lease was completed, and natural gas production began in February 2006. A total of 34 wells have been drilled under the O & G Lease, but one of

7

the wells ceased production in 2011 and has been plugged and abandoned. The Company’s overall average revenue interest is 34.7% in the 33 wells currently producing under the O & G Lease.

In November 2006, through U.S. Lime O & G, the Company entered into a drillsite and production facility lease agreement and subsurface easement (the “Drillsite Agreement”) with XTO Energy Inc. (“XTO”), which has an oil and gas lease covering approximately 538 acres of land contiguous to the Company’s Johnson County, Texas property. Pursuant to the Drillsite Agreement, the Company receives a 3% royalty interest and a 12.5% non-operating working interest, resulting in a 12.4% revenue interest, in the six XTO wells drilled from a padsite located on the Company’s property.

U.S. Lime O & G has no direct employees and is not the operator of any wells drilled on the properties subject to either the O & G Lease or the Drillsite Agreement (the “O & G Properties”). The only decision that the Company has the right to make is whether to participate as a non‑operating working interest owner and pay its proportionate share of the costs of drilling, completing, working over and operating a well.

No wells have been completed on the O & G Properties since 2011. Given current market prices for natural gas and natural gas liquids, there are no present plans to drill additional wells on the O & G Properties.

Regulation. Many aspects of the production, pricing and marketing of natural gas are regulated by federal and state agencies. Legislation affecting the natural gas industry is under constant review for amendment or expansion, which frequently increases the regulatory burden on affected members of the industry.

Oil and gas development and production operations are subject to various types of regulation at the federal, state and local levels that may impact the Company’s royalty and non‑operating working interests. Such regulation includes:

|

· |

requiring permits for the drilling of wells; |

|

· |

numerous federal and state safety requirements; |

|

· |

environmental requirements; |

|

· |

property taxes and severance taxes; and |

|

· |

specific state and federal income tax provisions. |

The TCEQ has adopted regulations limiting air emissions from oil and natural gas production in the Barnett Shale, where the O & G Properties are located. The EPA has adopted greenhouse gas monitoring and reporting regulations applicable to the petroleum and natural gas industry that require persons that hold state drilling permits that will result in annual greenhouse gas emissions of 25,000 metric tons or more to report annually those emissions from certain sources. The EPA has indicated that it will use data collected through the reporting rules to decide whether to promulgate future greenhouse gas emission limits. Future changes to greenhouse gas regulations could affect the relative competitiveness of, and therefore the demand for, natural gas and other fossil fuels.

Hydraulic fracturing is a technique used to produce oil and natural gas from shale, including the Barnett Shale Formation. The drilling on the Company’s O & G Properties has involved hydraulic fracturing. On April 18, 2012, the EPA issued new final regulations under the New Source Performance Standards and National Emission Standards for Hazardous Air Pollutants. Since January 2015, these regulations have required owners and operators of newly hydraulically fractured wells to use so-called “green completion” technology to reduce methane and volatile organic compound emissions during completion activities. On August 18, 2015, the EPA proposed a suite of regulations that would reduce methane and volatile organic compound emissions from oil and gas wells and associated equipment. If finalized, these regulations could increase the costs of oil and gas exploration and production activities.

Hydraulic fracturing has historically been regulated by state oil and natural gas commissions. However, the EPA has asserted federal regulatory authority over certain hydraulic fracturing activities involving diesel under the Safe Drinking Water Act (“SDWA”). In February 2014, the EPA issued permitting guidance for oil and gas hydraulic fracturing activities using diesel fuels, which included a broad definition of diesel covering a variety of oils that are not

8

diesel but that have similar carbon-chain molecules. The EPA has also stated that it plans to investigate the treatment of wastewater from hydraulic fracturing for the purpose of setting new standards for discharges from natural gas drilling to publicly owned treatment works. In addition, certain other governmental reviews have been conducted or are underway that focus on environmental aspects of hydraulic fracturing practices, including a four-year study by the EPA that concluded in 2015. Other agencies, including the Department of Energy, the Council on Environmental Quality, the Energy Information Administration, and the Department of the Interior, have also conducted hydraulic fracturing studies. These completed and ongoing reviews, depending on their scope and results, could spur initiatives to further regulate hydraulic fracturing under the SDWA or other regulatory programs.

Additionally, the Congress, the EPA and various states have proposed or adopted legislation regulating or requiring disclosure regarding hydraulic fracturing in connection with drilling operations. For example, pursuant to legislation adopted by the State of Texas in June 2011, the Texas Railroad Commission enacted a rule in December 2011, requiring disclosure of certain information regarding additives, chemical ingredients, concentrations and water volumes used in hydraulic fracturing. Local governments have, in recent years, increased regulatory scrutiny of oil and gas operations. For example, in November 2014, the City of Denton, Texas, which lies within the Barnett Shale Formation area, passed a ballot initiative banning hydraulic fracturing. While the Denton initiative is currently being challenged in court, other local governments may attempt to pass similar measures in the future. These new laws or regulations affecting hydraulic fracturing could adversely affect the cost of drilling and production from the O & G Properties.

Customers and Pricing. The pricing of natural gas sales is primarily determined by supply and demand in the marketplace and can fluctuate considerably. As the Company is not the operator of the wells drilled on the O & G Properties, it has limited access to timely information, involvement and operational control over the volumes of natural gas produced and sold and the terms and conditions, including price, on which such volumes are marketed and sold, all of which is controlled by the operators. Although the Company has the right to take its portion of natural gas production in kind, it currently has elected to have its natural gas production marketed by the operators.

The prices that the Company receives for its natural gas production is also affected by the amount of natural gas liquids included in the natural gas and the prices for those liquids. There has been a general decline in prices for natural gas and natural gas liquids in recent years due principally to increased supply.

Drilling Activity. No new wells have been completed since 2011, and there are no present plans to drill additional wells on the O & G Properties. The Company cannot predict the number of additional wells that ultimately will be drilled, if any, or their results.

Production Activity. The number of gross and net producing wells and production activity for the years ended December 31, 2015, 2014 and 2013 are as follows:

|

|

|

2015 |

|

2014 |

|

2013 |

|

|||||||||

|

|

|

Gross |

|

Net(2) |

|

Gross |

|

Net(2) |

|

Gross |

|

Net(2) |

|

|||

|

Producing wells(1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O & G Lease |

|

|

33 |

|

6.6 |

|

|

33 |

|

6.6 |

|

|

33 |

|

6.6 |

|

|

Drillsite Agreement |

|

|

6 |

|

0.8 |

|

|

6 |

|

0.8 |

|

|

6 |

|

0.8 |

|

|

Total |

|

|

39 |

|

7.4 |

|

|

39 |

|

7.4 |

|

|

39 |

|

7.4 |

|

|

Natural gas production volume (BCF) |

|

|

0.7 |

|

|

|

|

0.8 |

|

|

|

|

1.0 |

|

|

|

|

Average sales price per MCF(3) |

|

$ |

3.41 |

|

|

|

$ |

6.28 |

|

|

|

$ |

5.86 |

|

|

|

|

Total cost of revenues per MCF(4) |

|

$ |

2.97 |

|

|

|

$ |

2.91 |

|

|

|

$ |

2.92 |

|

|

|

|

(1) |

Although a total of 34 wells have been drilled under the O & G Lease, one well ceased production in 2011 and has been plugged and abandoned. |

|

(2) |

The number of net wells is required to be calculated based on the Company’s non-operating working interests percentages multiplied by the number of gross wells and does not consider the Company’s royalty interests percentages in each well. |

|

(3) |

Average sales price per MCF includes sales prices of natural gas liquids contained in the natural gas. |

9

|

(4) |

Includes taxes other than income taxes. |

Delivery Commitments. There are no delivery commitments for the Company’s natural gas production to which U.S. Lime O & G is a party.

Internal Controls Over Reserves Estimates. The Company’s policies regarding internal controls over the recording of reserve estimates require reserves to be in compliance with the SEC definitions and guidance and prepared in accordance with generally accepted petroleum engineering principles. In each of the years 2015, 2014 and 2013, the Company retained DeGolyer and MacNaughton, independent third‑party petroleum engineers, to perform appraisals of 100% of its proved reserves in compliance with these standards.

Reserves. The following table reflects the proved developed, proved undeveloped and total proved reserves (all of which are located in Johnson County, Texas), future estimated net revenues and standardized measure at December 31, 2015, 2014 and 2013. The reserves and future estimated net revenues are based on the reports prepared by DeGolyer and MacNaughton. Proved developed reserves included 39 producing wells at each of December 31, 2015, 2014 and 2013, respectively. The Company’s proved reserves have not been filed with, or included in, any reports to any federal agency, other than those filed with the SEC.

|

|

|

2015(2) |

|

2014(2) |

|

2013(2) |

|

|||||||||||||||||||||

|

|

|

Developed |

|

Undeveloped |

|

Total |

|

Developed |

|

Undeveloped |

|

Total |

|

Developed |

|

Undeveloped |

|

Total |

|

|||||||||

|

Proved natural gas reserves (BCF) |

|

|

5.3 |

|

|

— |

|

|

5.3 |

|

|

6.7 |

|

|

— |

|

|

6.7 |

|

|

7.6 |

|

|

— |

|

|

7.6 |

|

|

Proved natural gas liquids and condensate reserves (MMBBLS) |

|

|

0.7 |

|

|

— |

|

|

0.7 |

|

|

1.0 |

|

|

— |

|

|

1.0 |

|

|

1.1 |

|

|

— |

|

|

1.1 |

|

|

Future estimated net revenues (in thousands) |

|

$ |

13,897 |

|

$ |

— |

|

$ |

13,897 |

|

$ |

36,830 |

|

$ |

— |

|

$ |

36,830 |

|

$ |

37,597 |

|

$ |

— |

|

$ |

37,597 |

|

|

Standardized measure(1) (in thousands) |

|

$ |

5,286 |

|

$ |

— |

|

$ |

5,286 |

|

$ |

13,288 |

|

$ |

— |

|

$ |

13,288 |

|

$ |

13,578 |

|

$ |

— |

|

$ |

13,578 |

|

|

(1) |

This present value data should not be construed as representative of fair market value, since such data is based upon projected cash flows, which do not provide for escalation or reduction of natural gas prices or for escalation or reduction of expenses and capital costs. |

|

(2) |

The reserve estimates as of December 31, 2015, 2014 and 2013 utilized 12‑month average pricing, as required by accounting principles generally accepted in the United States of America, of $2.80, $4.61 and $3.88 per MCF of natural gas and $14.92, $30.20 and $29.95 per BBL of natural gas liquids, respectively. |

Undeveloped Acreage. Since the Company is not the operator, it has limited information regarding undeveloped acreage and does not know how many acres the operators classify as undeveloped acreage, if any, or the number of wells that ultimately will be drilled on the O & G Properties.

Glossary of Certain Oil and Gas Terms. The definitions set forth below shall apply to the indicated terms as used in this Report. All volumes of natural gas referred to herein are stated at the legal pressure base of the state or area where the reserves exist and at 60 degrees Fahrenheit and in most instances are rounded to the nearest major multiple.

“BBL” means a standard barrel containing 42 United States gallons.

“BCF” means one billion cubic feet under prescribed conditions of pressure and temperature and represents a basic unit for measuring the production of natural gas.

“Depletion” means (i) the volume of hydrocarbons extracted from a formation over a given period of time, (ii) the rate of hydrocarbon extraction over a given period of time expressed as a percentage of the reserves existing at the beginning of such period, or (iii) the amount of cost basis at the beginning of a period attributable to the volume of hydrocarbons extracted during such period.

10

“Formation” means a distinct geologic interval, sometimes referred to as the strata, which has characteristics (such as permeability, porosity and hydrocarbon saturations) that distinguish it from surrounding intervals.

“Future estimated net revenues” means the result of applying current prices of oil and natural gas to future estimated production from oil and natural gas proved reserves, reduced by future estimated expenditures, based on current costs to be incurred, in developing and producing the proved reserves, excluding overhead.

“MCF” means one thousand cubic feet under prescribed conditions of pressure and temperature and represents a basic unit for measuring the production of natural gas.

“MMBBLS” means one million BBLS.

“Operator” means the individual or company responsible for the exploration, development and production of an oil or natural gas well or lease.

“Proved oil and gas reserves” are those quantities of oil and natural gas, which, by analysis of geoscience and engineering data, can be estimated with reasonable certainty to be economically producible from a given date forward, from known reservoirs, and under existing economic conditions, operating methods, and government regulations, prior to the time at which contracts providing the right to operate expire, unless evidence indicates that renewal is reasonably certain, regardless of whether deterministic or probabilistic methods are used for the estimation. The project to extract the hydrocarbons must have commenced or the operator must be reasonably certain that it will commence the project within a reasonable time.

|

(i) |

The area of the reservoir considered as proved includes: (A) The area identified by drilling and limited by fluid contacts, if any, and (B) Adjacent undrilled portions of the reservoir that can, with reasonable certainty, be judged to be continuous with it and to contain economically producible oil or gas on the basis of available geoscience and engineering data. |

|

(ii) |

In the absence of data on fluid contacts, proved quantities in a reservoir are limited by the lowest known hydrocarbons as seen in a well penetration unless geoscience, engineering, or performance data and reliable technology establishes a lower contact with reasonable certainty. |

|

(iii) |

Where direct observation from well penetrations has defined a highest known oil elevation and the potential exists for an associated gas cap, proved oil reserves may be assigned in the structurally higher portions of the reservoir only if geoscience, engineering, or performance data and reliable technology establish the higher contact with reasonable certainty. |

|

(iv) |

Reserves that can be produced economically through application of improved recovery techniques (including, but not limited to, fluid injection) are included in the proved classification when: (A) Successful testing by a pilot project in an area of the reservoir with properties no more favorable than in the reservoir as a whole, the operation of an installed program in the reservoir or an analogous reservoir, or other evidence using reliable technology establishes the reasonable certainty of the engineering analysis on which the project or program was based; and (B) The project has been approved for development by all necessary parties and entities, including governmental entities. |

|

(v) |

Existing economic conditions include prices and costs at which economic producibility from a reservoir is to be determined. The price shall be the average price during the 12‑month period prior to the ending date of the period covered by the report, determined as an unweighted arithmetic average of the first‑day‑of‑the‑month price for each month within such period, unless prices are defined by contractual arrangements, excluding escalations based upon future conditions. |

“Royalty” means an interest in an oil and gas lease that gives the owner of the interest the right to receive a portion of the production from the leased acreage (or of the proceeds of the sale thereof), but generally does not require the owner to pay any portion of the costs of drilling or operating the wells on the leased acreage.

11

“Severance tax” means an amount of tax, surcharge or levy recovered by governmental agencies from the gross proceeds of oil and natural gas sales. Severance tax may be determined as a percentage of proceeds or as a specific amount per volumetric unit of sales. Severance tax is usually withheld from the gross proceeds of oil and natural gas sales by the first purchaser (e.g., pipeline or refinery) of production.

“Standardized measure of discounted future net cash flows” (also referred to as “standardized measure”) means the value of future estimated net revenues, calculated in accordance with SEC guidelines, to be generated from the production of proved reserves net of estimated production and future development costs, using prices and costs at the date of estimation, without future escalation, and estimated income taxes, and without giving effect to non‑property related expenses such as general and administrative expenses, debt service and depreciation, depletion and amortization, and discounted using an annual discount rate of 10%.

“Undeveloped acreage” means acreage on which wells have not been drilled or completed to a point that would permit the production of commercial quantities of oil and natural gas regardless of whether such acreage contains proved reserves.

“Working interest” means a real property interest entitling the owner to receive a specified percentage of the proceeds of the sale of oil and natural gas production or a percentage of the production, but requires the owner of the working interest to bear the cost to explore for, develop and produce such oil and natural gas.

General.

Both of our business segments are affected by general economic conditions in the U.S. and specific economic conditions in particular industries.

General economic conditions in the United States in recent years have reduced demand for our lime and limestone products. Specifically, demand from our oil and gas services, steel and industrial customers decreased during 2015. The significant decreases in oil and natural gas prices have resulted in a substantial decline in drilling activity, which has reduced demand from our oil and gas services customers for our lime products. Our steel customers have reduced their purchase volumes due to the ongoing difficult economic conditions in that industry, including a reduced demand for drill pipe and casing from the oil and gas industry. The overall reduction in demand for lime and limestone products has also resulted in increased competitive pressures, including pricing pressures, from other lime producers.

Reduced prices for natural gas and natural gas liquids have also resulted in drastically reduced revenues from our Natural Gas Interests. However, we have benefited from lower energy costs in our Lime and Limestone Operations segment.

For us to maintain or increase our profitability, we must maintain or increase our revenues and improve cash flows and continue to control our operational and selling, general and administrative expenses. If we are unable to maintain our revenues and control our costs in these difficult economic times, our financial condition, results of operations, cash flows and competitive position could be materially adversely affected.

We may be adversely affected by any disruption in, or failure of, our information technology systems, including due to cybersecurity risks and incidents.

We rely upon the capacity, reliability and security of our information technology (“IT”) systems for our manufacturing, financial and administrative functions. We also face the challenge of supporting our IT systems and implementing upgrades when necessary.

Our IT systems security measures are focused on the prevention, detection and remediation of damage from computer viruses, natural disasters, unauthorized access, cyber‑attack and other similar disruptions. However, our IT systems may remain vulnerable to damage despite our implementation of security measures that we feel protect our IT systems. Any failure, accident or security breach involving our IT systems could result in disruption to our operations. A

12

material breach in the security of our IT systems could negatively impact our manufacturing operations or financial and administrative functions, or result in the compromise of personal information of our employees, customers or suppliers. To the extent any such failure, accident or security breach results in disruption to our operations or loss or disclosure of, or damage to, our data or confidential information, our reputation, business, results of operations and financial condition could be materially adversely affected.

Lime and Limestone Operations.

In the normal course of our Lime and Limestone Operations, we face various business and financial risks that could have a material adverse effect on our financial position, results of operations, cash flows and competitive position. Not all risks are foreseeable or within our ability to control.

These risks arise from various factors, including, but not limited to, fluctuating demand for our lime and limestone products, including as a result of downturns in the economy and construction, industrial and steel industries, and possible reduced demand from coal-fired utility plants, increased competitive pressures from other lime producers, changes in legislation and regulations, including Environmental Laws, health and safety regulations and requirements to renew or obtain operating permits, our ability to produce and store quantities of lime and limestone products sufficient in amount and quality to meet customer demands and specifications, the success of our modernization, expansion and development strategies, including our ability to sell our increased lime capacity at acceptable prices, our ability to execute our strategies and complete projects on time and within budget, our ability to integrate, refurbish and/or improve acquired facilities, our access to capital, volatile costs, especially fuel, electricity, transportation and freight costs, inclement weather and the effects of seasonal trends.

We receive most of our coal and petroleum coke by rail, so the availability of sufficient solid fuels to run our plants could be diminished significantly in the event of major rail disruptions. Domestic coal and petroleum coke may also be exported, which can increase competition and prices for the domestic supply. In addition, our freight costs to deliver our lime and limestone products are high relative to the value of our products, and although our freight costs declined slightly during 2015, they have mostly increased in recent years. Our costs for delivery of solid fuels, as well as our products, also increase as demand for rail and trucking by other industries increases, and recent Department of Transportation rules reduce the availability of rail cars and trucks to deliver solid fuels to our plants and deliver our products to our customers. If we are unable to continue to pass along our variable coal, petroleum coke, diesel, natural gas, electricity, transportation and freight costs to our customers, our financial condition, results of operations, cash flows and competitive position could be materially adversely affected.

We quote on a delivered price basis to certain customers, which requires us to estimate future delivery costs. Our actual delivery costs may exceed these estimates, which would reduce our profitability.

Delivery costs are impacted by the price of diesel. Although diesel prices declined during 2015, when they do increase we incur additional fuel surcharges from freight companies that cannot be passed on to our customers that have been quoted a delivered price. A material increase in the price of diesel could have a material adverse effect on the Company’s profitability.

Governmental fiscal and budgetary constraints and legislative impasses have in the past, and may in the future, adversely impact our financial condition and results of operations in various ways.

Governmental fiscal and budgetary constraints and legislative impasses may adversely impact our financial condition and results of operations in various ways, including possibly reduced funding for transportation programs by federal, state and local governmental agencies, which could reduce demand for our lime and limestone products from our construction customers.

Our mining and other operations are subject to operating risks that are beyond our control, which could result in materially increased operating expenses and decreased production and shipment levels that could materially adversely affect our Lime and Limestone Operations and their profitability.

We mine limestone in open pit and underground mining operations and process and distribute that limestone through our plants and other facilities. Certain factors beyond our control could disrupt our operations, adversely affect

13

production and shipments and increase our operating costs, all of which could have a material adverse effect on our results of operations. These include geological formation problems that may cause poor mining conditions, variability of chemical or physical properties of our limestone, an accident or other major incident at a site that may cause all or part of our operations to cease for some period of time and increase our expenses, mining, processing and plant equipment failures and unexpected maintenance problems that may cause disruptions and added expenses, strikes, job actions or other work stoppages that may disrupt our operations or those of our suppliers, contractors or customers and increase our expenses, and adverse weather conditions and natural disasters, such as heavy rains, flooding, ice storms, freezing weather, drought and other natural events, that may affect operations, transportation or customers.

If any of these conditions or events occurs, our operations may be disrupted, we could experience a delay or halt of production or shipments, our operating costs could increase significantly and we could be exposed to fines, penalties, assessments and other liabilities. If our insurance coverage is limited or excludes a given condition or event, we may not be able to recover in full the losses that may incur as a result of such conditions or events, some of which may be substantial.

We incur environmental compliance costs and liabilities, including capital, maintenance and operating costs, with respect to pollution control equipment, the cost of ongoing monitoring programs, the cost of reclamation and remediation efforts and other similar costs and liabilities relating to our compliance with Environmental Laws, and we expect these costs and liabilities to continue to increase, including possible new costs, taxes and limitations on operations such as those related to possible climate change initiatives, including regulation of greenhouse gas emissions. Similar environmental costs and liabilities may also be faced by our customers.

The rate of change of Environmental Laws has been rapid over the last decade, and we may face possible new costs and liabilities, taxes and limitations on operations, including those related to climate change initiatives. We believe our expenditure requirements for future environmental compliance, including complying with the new nitrogen dioxide, sulfur dioxide and particulate matter emission limitations under the NAAQS and regulation of greenhouse gas emissions, will continue to increase as operating, reporting and other environmental standards increase. Discovery of currently unknown conditions and unforeseen costs and liabilities could require additional expenditures.

The regulation of greenhouse gas emissions remains an issue for the Company and some of its customers. There is no assurance that changes in the law or regulations will not be adopted, such as the imposition of a carbon tax, a cap-and-trade program requiring companies to purchase carbon credits, or other measures that would require reductions in emissions or changes to raw materials, fuel use or production rates, that could have a material adverse effect on the Company’s financial condition, results of operations, cash flows and competitive position. More stringent regulation of greenhouse gas emissions could also adversely affect the competitiveness of some of the Company’s customers, including coal-fired power plants, and indirectly the demand for our lime and limestone products. For example, our utility customers may switch from coal to natural gas for power generation for environmental regulatory as well as cost reasons, thus reducing demand for our lime and limestone products for flue gas treatment processes.

We intend to comply with all Environmental Laws and believe our accrual for environmental costs and liabilities at December 31, 2015 is reasonable. Because many of the requirements are subjective and therefore not quantifiable or presently determinable, or may be affected by additional legislation and rulemaking, including those related to climate change and greenhouse gas emissions, there is no assurance or certainty that we will be able to continue or renew our operating permits, or to successfully secure new permits in connection with our modernization and expansion and development projects, and it is not possible to accurately predict the aggregate future costs and liabilities relating to environmental compliance and their effect on our financial condition, results of operations, cash flows and competitive position.

To maintain our competitive position, we may need to continue to increase the efficiency of our operations and expand production capacity, obtain financing for any such projects and acquisitions at reasonable interest rates and acceptable terms and sell any resulting increased production at acceptable prices.

We may undertake various modernization and expansion and development projects and acquisitions. These may require that we incur additional debt, which may not be available to us at all or at reasonable interest rates or on acceptable terms. Given current and projected demand for lime and limestone products, we cannot guarantee that any

14

such project or acquisition would be successful, that we would be able to sell any resulting increased production at acceptable prices or that any such sales would be profitable.

Although prices for our lime and limestone products have been relatively firm in recent years, pricing competition has increased. We are unable to predict future demand and prices, given the general economic conditions in the U.S. and specific economic conditions in particular industries, and cannot provide any assurance that current levels of demand and prices will continue or that any future increases in demand or prices can be maintained.

The lime industry is highly regionalized and competitive.

Our competitors are predominately large private companies. The primary competitive factors in the lime industry are price, quality, ability to meet customer demands and specifications, proximity to customers, personal relationships and timeliness of deliveries, with varying emphasis on these factors depending upon the specific product application. To the extent that one or more of our competitors becomes more successful with respect to any key competitive factor, our financial condition, results of operations, cash flows and competitive position could be materially adversely affected.

Natural Gas Interests.

Our natural gas reserves are depleting assets, and we have no ability to explore for new reserves, nor at current market prices are there any present plans to drill additional wells on the O&G Properties.

Revenues from our Natural Gas Interests depend in large part on the quantity of natural gas produced from the O & G Properties. Our 39 producing wells will naturally experience declines in production rates due to depletion of their natural gas reserves, and the operators may determine to temporarily shut in or to plug and abandon a producing well if they believe that it is no longer economical to continue production from the well. We have no ability to explore for new reserves, and at current market prices for natural gas and natural gas liquids, there are no present plans to drill additional wells on the O & G Properties, thus limiting our Natural Gas Interests revenues to production from our existing wells.

Historically, the markets for natural gas have been volatile and may continue to be volatile in the future.

Various factors that are beyond our control will affect the demand for, and prices of, natural gas, such as:

|

· |

the worldwide and domestic supplies of natural gas; |

|

· |

the development of new technologies and reserves of natural gas in the United States; |

|

· |

the price and level of U.S. exports and imports; |

|

· |

the level of consumer and industrial demand; |

|

· |

the price and availability of alternative fuels; |

|

· |

the availability of pipeline capacity; |

|

· |

weather conditions; |

|

· |

domestic and foreign governmental regulations and taxes; and |

|

· |

the overall economic environment. |

The natural gas industry is cyclical in nature and tends to reflect general economic and gas supply and demand conditions. Recent technological advances, such as hydraulic fracturing, have enabled the industry to access additional reserves and have greatly increased the current supply of natural gas in the United States and elsewhere, resulting in lower natural gas and natural gas liquids prices. Lower natural gas prices may reduce the amount of natural gas that is economical for our operators to produce on the O & G Properties, or cause them to shut in wells for extended periods of time or to plug and abandon wells. Reduced prices and production could further reduce our revenues and cash flows from our Natural Gas Interests and thus could have an adverse effect on our gross profit from our Natural Gas Interests.

15

We do not control production operations on the O & G Properties, which could impact our Natural Gas Interests.

As the owner of royalty and non‑operating working interests, our ability to influence production from the O & G Properties is severely limited. All decisions related to production on the O & G Properties will be made by the operators and may be influenced by factors beyond our control, including but not limited to natural gas prices, pipeline capacities, interest rates, budgetary considerations and general industry and economic conditions.

The occurrence of an operational risk or uncertainty that materially impacts the operations of the operators of the O & G Properties could have an adverse effect on the amount we receive in connection with our interests in production from the O & G Properties, which could have an adverse effect on our gross profit from our Natural Gas Interests.

Our natural gas gross profit is affected by production and other costs, some of which are outside of our control, and possible unitizations.

The Natural Gas Interests gross profit that comes from our non-operating working interests, and to a lesser extent our royalty interests, is directly affected by increases in production and other costs, as well as unitizations of existing wells. Some of these costs are outside our control, including production costs, costs of regulatory compliance and severance and other similar taxes. Other expenditures are dictated by business necessity, such as working over existing wells to increase recovery rates.

A natural disaster, accident or catastrophe could damage pipelines, gathering systems and other facilities that service wells on the O & G Properties, which could substantially limit operations and adversely affect our gross profit from our Natural Gas Interests.

If pipelines, gathering systems or other facilities that serve the O & G Properties are damaged by any natural disaster, accident, catastrophe or other event, revenues from our Natural Gas Interests could be significantly interrupted. Any event that interrupts the production, gathering or transportation of our natural gas, or which causes us to share in significant expenditures not covered by insurance, could adversely impact our gross profit from our Natural Gas Interests. We do not carry business interruption insurance on our Natural Gas Interests.

The O & G Properties are geographically concentrated, which could cause our gross profit from our Natural

Gas Interests to be adversely impacted by regional events, including natural disasters and reduced pipeline capacity resulting from production from other wells in the area.

The O & G Properties are all natural gas properties located exclusively in the Barnett Shale Formation. Because of this geographic concentration, any regional events, including natural disasters and production from other wells in the area, that increase costs, reduce availability of equipment, supplies or pipeline capacity, reduce demand or limit production could adversely impact our gross profit from our Natural Gas Interests more than if the Properties were more geographically diversified.

The number of prospective natural gas purchasers and methods of delivery for our gas are also considerably less than would otherwise exist from a more geographically diverse group of interests.

Governmental policies, laws and regulations could have an adverse impact on the O & G Properties and our natural gas business.

The O & G Properties and our natural gas business are subject to federal, state and local laws and regulations relating to the oil and natural gas industry, as well as regulations relating to health and safety matters. These laws and regulations can have a significant impact on the costs and amount of our production.

16

Environmental costs and liabilities and changing environmental regulation associated with the O & G Properties could adversely affect our gross profit from our Natural Gas Interests.

As with other companies engaged in the ownership and production of natural gas, we expect to have some risk of exposure to environmental costs and liabilities. The costs and liabilities associated with environmental compliance or remediation could reduce the gross profits we would receive from our Natural Gas Interests. The O & G Properties are subject to extensive federal, state and local regulatory requirements relating to environmental affairs, health and safety and waste management.

Increased regulation of natural gas production could increase our production costs on the O & G Properties and adversely affect our gross profit from our Natural Gas Interests. Third parties could also pursue legal actions to enforce compliance or assert claims for damages. Further, under certain environmental laws and regulations, the operators and owners of the underlying properties could also be subject to joint and several, strict liability for the removal or remediation of released materials or property contamination from drilling, including hydraulic fracturing, or waste disposal, regardless of whether the operators or owners were responsible for the release or contamination or if the operations were in compliance with all applicable laws.

It is likely that our expenditures in connection with environmental matters, as part of normal capital expenditure programs, will affect the profitability of the O & G Properties. Future Environmental Law developments, such as stricter laws, regulations or enforcement policies, including climate change legislation mandating specific near‑term and long‑range reductions in greenhouse gas emissions, could significantly increase the costs of production from the O & G Properties and adversely affect our gross profit from our Natural Gas Interests.

ITEM 1B. UNRESOLVED STAFF COMMENTS.

None

Reference is made to Item 1 of this Report for a description of the properties of the Company, and such description is hereby incorporated by reference in answer to this Item 2. As disclosed in Note 3 of Notes to Consolidated Financial Statements, the Company’s plants and facilities and reserves are subject to encumbrances to secure the Company’s loans.

Information regarding legal proceedings is set forth in Note 9 of Notes to Consolidated Financial Statements and is hereby incorporated by reference in answer to this Item 3.

ITEM 4. MINE SAFETY DISCLOSURES.

Under Section 1503(a) of the Dodd‑Frank Wall Street Reform and Consumer Protection Act and Item 104 of Regulation S‑K, each operator of a coal or other mine is required to include disclosures regarding certain mine safety results in its periodic reports filed with the SEC. The operation of the Company’s quarries, underground mine and plants is subject to regulation by the federal Mine Safety and Health Administration (“MSHA”) under the Federal Mine Safety and Health Act of 1977. The required information regarding certain mining safety and health matters, broken down by mining complex, for the year ended December 31, 2015 is presented in Exhibit 95.1 to this Report.