Attached files

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Fiscal Year Ended December 31, 2015

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number: 001-34090

Tesco Corporation

(Exact name of registrant as specified in its charter)

Alberta | 76-0419312 |

(State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification No.) |

11330 Clay Road Suite 350 Houston, Texas | 77041 |

(Address of Principal Executive Offices) | (Zip Code) |

713-359-7000

(Registrant’s telephone number, including area code)

Securities to be registered pursuant to Section 12(b) of the Act:

Title of Each Class | Name of Each Exchange on Which Registered | |

Common Shares, without par value | Nasdaq Stock Market | |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No þ

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes þ No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes þ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer ¨ | Accelerated filer þ |

Non-accelerated filer ¨ (Do not check if a smaller reporting company) | Smaller reporting company ¨ |

Indicate by check mark whether registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No þ

The aggregate market value of voting and non-voting common equity held by non-affiliates of the registrant at the close of business on June 30, 2015 was $209,515,688 based upon the last sales price reported for such date on the NASDAQ Stock Market. For purposes of this disclosure, shares of common stock held by persons who hold more than 5% of the outstanding shares of common stock and shares held by

officers and directors of the registrant as of June 30, 2015 have been excluded as such persons may be deemed to be affiliates. This determination is not necessarily conclusive.

Number of shares of Common Stock outstanding as of February 29, 2016: 39,269,721.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Proxy Statement for the registrant’s 2016 Annual Meeting of Stockholders are incorporated by reference into Part III of this Report on Form 10-K.

TABLE OF CONTENTS

Page | |||

PART I | |||

PART II | |||

PART III | |||

PART IV | |||

PART I

This Annual Report on Form 10-K for the fiscal year ended December 31, 2015 (this "Report") contains "forward-looking statements" within the meaning of Canadian and United States securities laws, including within the safe harbor provisions of the United States Private Securities Litigation Reform Act of 1995. From time to time, our public filings, press releases and other communications by our officers and representatives (such as conference calls and presentations) will contain forward-looking statements. Forward-looking information is often, but not always, identified by the use of words such as "anticipate", "believe," "expect", "plan," "goal," "seek," "strategy," "future," "intend," "forecast," "target," "project," "likely," "may," "will," "should," "could," "estimate," "predict" or similar words suggesting future outcomes or language suggesting an outlook. Forward-looking statements in this Report on Form 10-K include, but are not limited to, statements with respect to expectations of our prospects, future revenue, earnings, activities and technical results.

Forward-looking statements are neither historical facts nor assurances of future performance. Instead, they are based only on our current beliefs, expectations and assumptions regarding the future of our business, future plans and strategies, projections, anticipated events, trends, the economy and other future conditions. The forward-looking statements in this Report are made as of the date it was issued. We do not undertake any obligation to update publicly or to revise any of the included forward-looking statements, whether as a result of new information, future events, or otherwise, except as required by applicable law.

By their very nature, forward-looking statements involve inherent risks and uncertainties, both general and specific and risks that outcomes implied by forward-looking statements will not be achieved. We caution readers not to place undue reliance on these statements as a number of important factors could cause the actual results to differ materially from the beliefs, plans, objectives, expectations and anticipations, estimates and intentions expressed in such forward-looking statements. Therefore, you should not rely on any of these forward-looking statements.

Item 1. Business

General

In this Report the terms "Tesco Corporation," "we," "us," "our," or "the Company," refers to Tesco Corporation and all of its subsidiaries.

Tesco Corporation was organized under the laws of Alberta, Canada on December 1, 1993 through the amalgamation of Shelter Oil and Gas Ltd., Coexco Petroleum Inc., Forewest Industries Ltd. and Tesco Corporation. The Company’s principal executive offices are located at 11330 Clay Road, Suite 350, Houston, Texas 77041, its telephone number is 713-359-7000 and its internet web address is www.tescocorp.com. The Company’s annual reports on Form 10-K, quarterly reports on Form 10-Q and current reports on Form 8-K are available free of charge on our internet website. These reports are posted on our website as soon as reasonably practicable after such reports are electronically filed with the Securities and Exchange Commission ("SEC"). The Company’s Code of Business Conduct and Ethics is also posted on our website. The company’s common stock is traded on the NASDAQ stock exchange under the symbol "TESO".

We are a global leader in the design, assembly and service delivery of technology-based solutions for the upstream energy industry with global operations. With a strong commitment to in-house research and engineering, we seek to change the way wells are drilled by delivering safer and more efficient solutions that add real value by reducing the costs of drilling for, and producing, oil and natural gas. Our product and service offerings consist mainly of equipment sales and services to drilling contractors and exploration and production companies throughout the world.

Prior to the sale of the Casing Drilling business during the second quarter of 2012, our five business segments were:

• | Top Drive – top drive sales, top drive rentals and after-market sales and services; |

• | Tubular Services – automated and conventional tubular services; |

• | Casing Drilling – proprietary Casing Drilling technology; |

• | Research and Engineering – internal research and development activities related to our automated tubular services and top drive model development, as well as the Casing Drilling technology prior to the sale; and |

• | Corporate and Other – including executive management and several global support and compliance functions |

1

Top Drive segment

Our Top Drive segment sells equipment and provides services to drilling contractors and exploration and production companies throughout the world. We provide top drive rental services on a day-rate basis for land and offshore drilling rigs and we also provide after-market sales and support services to our customers.

We primarily assemble top drives based upon our proprietary designs, which are used in drilling operations to rotate the drill string and/or casing while suspended from the derrick above the rig floor. Our top drives offer portability and flexibility, permitting drilling companies to utilize the top drive for drilling all or any portion of a well. We offer for sale a range of portable and permanently installed top drive products that includes both hydraulically and electrically powered machines capable of delivering 400 to 1,350 horsepower, with a rated lifting capacity of 150 to 750 tons. Our systems require fewer people in the drilling process than those involved with conventional kelly drilling with rotary table. With each top drive we sell, we offer installation and support services, including training.

We offer six distinct series of top drive systems, using either hydraulic, induction alternating current ("AC"), or permanent magnet AC technology. We believe that we are an industry leader in the development and provision of both portable and permanently installed top drive systems. Our designs and technology provide very high power density, allowing for a high power to weight ratio. We use AC induction technology and late generation power electronics throughout our entire line up of electric top drives, allowing the end user to specify its preferred power electronics and motor combination and permitting us to select components from a larger vendor base. Our EMI top drive units are available with 150 to 250 ton load path configurations. We also developed our EXI system in response to market demands for a high performance compact electric top drive system, commonly required on modern fast moving rigs frequently used in pad drilling operations. The EXI system has a load path rating of 350 to 400 tons and generates 600 horsepower. In 2015, an 800 horsepower version of the EXI was released, available in both 350 and 400 ton load path configurations. The ESI is our latest model, which has a load path rating of 500 to 750 tons and generates 1,000 to 1,350 horsepower. The HXI is a new generation of our current hydraulic HMI system, incorporating a full suite of operational features and providing a significant gain in performance. The HXI machine has a load path rating of 150 to 250 tons and is driven by a 700 horsepower self-contained diesel-driven hydraulic power unit.

In addition to our top drive sales, we maintain a fleet of 124 top drives and four catwalks deployed strategically throughout the world that we rent on a day-rate basis for land and offshore drilling rigs. Our rental fleet is highly transportable, offers a range of systems that can be installed in practically any mast configuration, including workover rigs, and are mobilized to meet the needs of our customers. Our rental fleet is composed principally of hydraulically powered top drive systems, with power ratings of 475 to 1,205 horsepower and load path ratings of 150 to 650 tons, each equipped with its own independent diesel engine driven hydraulic power unit. This unique combination permits a high level of portability and installation flexibility. We currently maintain top drive rental units in Latin America, the United States, Canada, Russia, Asia-Pacific, Europe and the Middle East. In 2014, we added catwalk rental units to our offering.

We also provide after-market sales and services to our installed customer base through our facilities around the globe. Our service offerings include initial rig up and training for our sold units and recertification and repair of our units. In 2014, we extended our after-market support beyond our own equipment to service competitor brand top drives and other automated pipe handling equipment. Entry into this market was primarily at the request of our current customer base with mixed fleets and represents a significant growth opportunity for us. We maintain regional stocks of high-demand parts in order to expedite top quality, original replacement parts for top drive systems. Our highly experienced field personnel are responsible for the rig up and installation of most units, which includes both rental units and customer-owned units. Our personnel also provide onsite training and top drive supervision. In addition, our technicians are available to perform work under ongoing maintenance and fleet management contracts.

Markets and Competition

Demand for our top drive products and rental services depends primarily upon the level of drilling activity and capital spending of drilling contractors and oil and natural gas companies. Our customers for top drive sales and after-market sales and service primarily consist of drilling contractors, rig builders and equipment brokers. Occasionally, we may also sell top drives and provide after-market sales and services to major and independent oil and natural gas companies and national oil companies who wish to own and manage their own top drive systems. Our customers for our rental fleet include drilling contractors, major and independent exploration and production companies.

We estimate that approximately 60% to 70% of land drilling rigs drilling deviated and horizontal wells are currently equipped with top drive systems, including Russia, China and India, where a lower number of rigs operate with top drives today. By contrast, we estimate that approximately 95% of offshore rigs are equipped with top drives. We were the first top drive manufacturer to provide portable top drives for land drilling rigs. We believe that significant land-based market potential exists for our top drive

2

drilling system technology, including both portable and permanently installed applications. Further, when many top drive systems approach the end of their useful lives and are inefficient or may not have legacy parts available, we see the development of a conversion market, which provides an important opportunity for us. In addition, the current technology demand associated with complex drilling is driving the demand for newer more capable Top Drives to replace older existing equipment.

Our primary competitors in the sale of top drive systems are National Oilwell Varco, Inc. ("NOV") and Canrig Drilling Technology Ltd., a subsidiary of Nabors Industries Ltd. In addition, low-cost manufacturers, notably from China, have entered the market in recent years. We believe that we have the second largest installed base and are the number two global provider of top drives, following NOV. Of the three major top drive system providers, we believe that we maintain the largest fleet of assets solely for rental purposes. Competition in our industry in the sale of top drive systems takes place primarily on the basis of the features and capacities of the equipment, the quality of the services and technical support offered, delivery lead time, and price.

Backlog

Historically we have reported top drive sales backlog as a fair indicator of how our business is impacted by the global macro-economic environment. In the current environment, however, we are experiencing top drive sales that were not previously part of reported backlog as customer’s willingness to commit to long lead time purchases diminishes. For that reason, we maintain a supply of finished goods top drives to rapidly satisfy top drive demand.

We consider a product sales order as backlog when the customer has signed a purchase contract, submitted the purchase order and, if required by the purchase agreement, paid a deposit. Revenue from services is recognized as the services are rendered, based upon agreed daily, hourly, or job rates. Accordingly, we have no backlog for services.

Our top drive sales backlog at December 31, 2015 was eight units with a total potential revenue value of $7.2 million, compared to 33 units with a total potential revenue value of $35.5 million at December 31, 2014. The backlog revenue varies depending on the product mix and the scope of the equipment supplied.

We have the ability to expand or contract our top drive assembly capacity to meet current and expected customer demand. In the past, we contracted our assembly operations substantially in response to market conditions and later, when conditions improved, we expanded them to meet demand.

In 2014, we initiated the sale of automated Catwalks. Catwalks are used to deliver pipe from the pipe racking systems at ground level into the rig floor in an automated manner. Catwalks work in conjunction with the Top Drives and our CDSTM to automate the pipe movement around the rig floor, minimizing the risks and eliminating the need for pipe manipulation by people. Our primary competitors for the sale of our Catwalks product line are Forum Energy Technologies, Canrig Drilling Technology Ltd. and NOV.

Tubular Services segment

Our Tubular Services segment includes a suite of automated offerings, as well as conventional casing and tubing running services for both onshore and offshore markets. These services are typically contracted on a call-out basis. Casing is steel pipe that is installed in oil, natural gas, or geothermal wells to maintain the pressure and structural integrity of the well bore, isolate water bearing surface sands, prevent communication between subsurface strata and provide structural support of the wellhead and other casing and tubing strings in the well. Most operators and drilling contractors install casing and tubing using service companies, like ours, that use specialized equipment and personnel trained for this purpose. Wells can have from two to ten casing strings of various sizes installed. These jobs encompass wells from vertical holes to high angle extended reach wells and include both onshore and offshore applications.

Our patented Casing Drive System ("CDSTM") is a tool which facilitates running, reaming and drilling casing into a well bore on most rigs equipped with a top drive. This tool offers improved safety and efficiency over traditional methods by eliminating operations that are associated with high risk of personal injury. It also increases the likelihood that the casing can be run to casing point on the first attempt, offers the ability to simultaneously rotate and reciprocate the casing string as required while circulating drilling fluid and requires fewer people on the rig for casing running operations than traditional methods.

The Company also supplies a rotating Side Entry Swivel Sub ("SESS"). This tool works in conjunction with the CDS tool to allow rotation and reciprocation of the casing string during cementing operations. Reciprocation and rotation is recognized by the industry as greatly improving the uniformity and quality of the cement around the casing, in turn helping to reduce the potential of environmental incidents and future intervention costs.

3

We offer a full range of offshore casing and tubing running services, in both deep water and shelf applications. As part of our suite of equipment, we also offer installation services of deep water completion equipment using our Multiple Control Line Running System ("MCLRS") which is a proprietary and patented technology. We believe that this technology substantially improves the quality of the installation of high-end well completions by eliminating damage and the need to splice or replace control and injection lines. We also believe that this technology improves the speed and safety of the completion process by splitting the work area between personnel making up the tubing and personnel installing completion equipment.

Our conventional service offerings provide automated and manual equipment and personnel for the installation of tubing and casing, including power tongs, pick-up/lay-down units, torque monitoring services and connection testing services for new well construction and in work-over and re-entry operations.

Markets and Competition

Our Tubular Services customers primarily consist of oil and natural gas operating companies, including major and independent companies, national oil companies and, on occasion, other service companies, particularly those providing integrated project management services to operating companies that under these projects have contractual obligations to provide tubular running and handling services. Demand for our tubular services strongly depends upon capital spending of oil and natural gas companies, the actual number of wells drilled by these companies and the complexity of the wells drilled.

The tubular services market consists generally of very few large, global operators and a large number of small and medium-sized operators that typically operate in limited geographic areas where the market is highly fragmented. The largest global competitors in this market are Weatherford International, Ltd., Franks International, Inc. and Baker Hughes Incorporated. Competition takes place primarily on the basis of safety, service quality, utility and quality of the equipment provided, the proximity of the service provider and equipment to the work site and price. We leverage our existing global infrastructure to maintain a competitive tubular service business that is able to respond to customer needs in most regions of the world. We believe that the demand for our proprietary automated tubular services will increase as non-conventional drilling technologies such as directional and horizontal drilling are more frequently implemented in new wells being drilled.

While we are aware of competitive technology similar to our CDSTM tool, we believe that we continue to be a market leader in this technology. Our CDSTM system is easily and quickly installed on any top drive system and we offer skilled and trained personnel at the field level who have specialized knowledge of top drive drilling system operations.

Casing Drilling segment

On June 4, 2012, we completed the sale of substantially all of the assets of the Casing Drilling segment to subsidiaries of Schlumberger Ltd. For detailed discussion of this matter, see Part II, Item 8, "Financial Statements and Supplementary Data, Note 2" included in this Report.

The Casing Drilling segment was based on our proprietary casing drilling technology, which used patented equipment and processes to allow an oil or gas well to be simultaneously drilled and cased using standard well casing pipe. In contrast, conventional or straight practice rotary drilling requires the use of drill pipe and drill string components. The demonstrated benefits of using well casing to drill the well compared to conventional drilling include, among other benefits, a reduction in the risk of unscheduled downhole events that typically result in non-productive time and additional cost and operational risk to the drilling contractor and well operator. In addition, it avoided well bore exposure during tripping and mitigated associated risks such as borehole collapse, lost circulation problems and stuck tools or pipe.

Research and Engineering segment

As a technology-driven company, we continue to invest significantly in research and development activities, primarily related to the further development and enhancement of our automated product offerings. We hold rights, through patents and patent license agreements, to patented and/or patent pending technologies for certain innovations that we believe will have application to our core businesses. We pursue patent protection in appropriate jurisdictions including, but not limited to, the United States, Canada and Europe, where we believe our innovations could have significant potential application to our core businesses. Our patent portfolio currently includes 146 issued patents, comprised of 64 U.S. and 82 foreign patents, and 125 pending patent applications, comprised of 39 U.S. and 86 foreign patent applications. We generally retain all intellectual property rights to our technology through non-disclosure and technology ownership agreements with our employees, suppliers, consultants and other third parties with whom we do business.

4

We hold patents for various specific aspects of the design of our portable top drive and related equipment. Our CDS is protected by patents on some of the gripping tools and on the "link tilt" system, which is a method used to handle casing. We hold numerous patents related to the installation and utilization of certain accessories for casing for purposes of casing rotation. Various other related methods and tools are patent protected as well.

We historically invest the equivalent to 1.5% to 2.0% of our revenue in research and engineering activities annually. We expect to continue to invest in the development, commercialization and enhancements of proprietary technologies.

Corporate and Other

The Corporate and Other segment consists of expense at the corporate level, which includes executive management, general and administrative costs, selling, marketing and other expenses that are not directly related to or allocated down to other segments in our internal reporting.

Financial Information About Geographic Areas

Our Top Drive and Tubular Services businesses are distributed globally. For the information of our property, plant and equipment by business segment and geographic area at December 31, 2015, see Part II, Item 8, "Financial Statements and Supplementary Data, Note 15" included in this Report. The following table presents our revenue by segment and geographic areas for the years ended December 31, 2015, 2014 and 2013 (in thousands):

United States and Canada | International | Total | ||||||||||||||

Revenue | % | Revenue | % | |||||||||||||

Top Drive | ||||||||||||||||

2015 | $ | 45,791 | 31% | $ | 99,917 | 69% | $ | 145,708 | ||||||||

2014 | 139,100 | 44% | 179,686 | 56% | 318,786 | |||||||||||

2013 | 88,128 | 28% | 223,442 | 72% | 311,570 | |||||||||||

Tubular Services | ||||||||||||||||

2015 | $ | 54,723 | 41% | $ | 79,307 | 59% | $ | 134,030 | ||||||||

2014 | 106,600 | 48% | 117,542 | 52% | 224,142 | |||||||||||

2013 | 109,004 | 51% | 103,667 | 49% | 212,671 | |||||||||||

Casing Drilling(1) | ||||||||||||||||

2014 | $ | 63 | 100% | $ | — | —% | $ | 63 | ||||||||

2013 | 624 | 100% | — | —% | 624 | |||||||||||

__________________________________

(1) | On June 4, 2012, we completed the sale of substantially all of the assets of the Casing Drilling segment to the Schlumberger Group. For detailed discussion of this matter, see Part II, Item 8, "Financial Statements and Supplementary Data, Note 3" included in this Report. |

Procurement of Materials and Supplies

We believe that materials and components used in our servicing and assembly operations and purchased for sales are generally available from multiple sources. The prices paid by us for our raw materials may be affected by, among other things, energy, steel and other commodity prices; tariffs and duties on imported materials; foreign currency exchange rates and the general level of activity within the industry. For a discussion of the procurement of materials and supplies, see Part II, Item 8, "Financial Statements and Supplementary Data, Note 15" included in this Report.

Seasonality

Our business is subject to seasonal cycles associated with winter-only, summer-only, dry-season, or regulatory-based access to drilling locations. The most significant of these occur in Canada and Russia. Traditionally, the first and fourth calendar quarters of each year are the busiest, as the contractor fleet can access drilling locations that are only accessible when frozen. As of December 31, 2015, approximately 16% of our top drive rental fleet was located in Canada and Russia.

5

In certain regions in Asia Pacific and South America, we are subject to a decline in activities due to seasonal rains. Further, seasonal variations in the demand for hydrocarbons and accessibility of certain drilling locations in North America can affect our business as our activity follows the active drilling rig count. We actively manage our asset base around the world to minimize the impact of geographically specific seasonality.

Customers

Our accounts receivable are principally with major international and national oil and natural gas service and exploration and production companies and are subject to normal industry credit risks. We perform ongoing credit evaluations of customers and grant credit based upon past payment history, financial condition and anticipated industry conditions. Customer payments are regularly monitored and a provision for doubtful accounts is established based upon specific situations and overall industry conditions. Many of our customers are located in international areas that are inherently subject to risks of economic, political and civil instabilities, including the effects of currency fluctuations and exchange controls, such as devaluation of foreign currencies and other economic problems, which may impact our ability to collect those accounts receivable. We monitor customers who are at risk for non-payment and will, if warranted by the set of circumstances, lower available credit extended to those customers or establish alternative arrangements, including increased deposit requirements or payment schedules.

No single customer accounted for 10% or more of our consolidated revenue in the years ended December 31, 2015 and 2014. However, one customer accounted for approximately 10% of our consolidated revenue during the year ended December 31, 2013.

Employees

As of December 31, 2015, the total number of our employees worldwide was 1,594. We believe that we have a good relationship with our employees. We seek to maintain a high level of employee satisfaction and we believe our employee compensation systems are competitive. Approximately 11% of our employees are subject to union contracts, primarily where required by local regulations. As of February 29, 2016 the total number of our employees worldwide is approximately 1,416.

Trademarks

We own various trademarks that are important to our business. Depending upon the jurisdiction, trademarks are valid as long as they are in use and/or their registrations are properly maintained. A list of our trademarks and the countries in which they are registered is presented below:

Trademark | Country of Registration | |

TESCO® | United States, Canada, European Union, China, Ukraine, Kazakhstan | |

Casing Drive System™ | United States, Canada | |

CDS™ | United States, Canada | |

Multiple Control Line Running System™ | United States, Canada | |

MCLRS™ | United States, Canada | |

OCSET™ | Ukraine, Kazakhstan | |

MLT™ | United States | |

TESCO DESIGN™ | United States | |

Tescosity™ | United States | |

TescoCorp | China | |

Item 1A. Risk Factors

Cautionary Statement for Purposes of the "Safe Harbor" Provisions of the Private Securities Litigation Reform Act of 1995

We operate in an environment that involves a number of significant risks and uncertainties. We caution you to read the following risk factors, which have affected, and/or in the future could affect, our business, prospects, operating results and financial condition. The risks described below include forward-looking statements, and actual events and our actual results may differ materially from these forward-looking statements. Additional risks and uncertainties not currently known to us or that we currently deem immaterial

6

may also impair our business, prospects, operating results and financial condition. Furthermore, additional risks and uncertainties are described under other captions in this Report and should also be considered by our investors.

Risks associated with the oil and natural gas industry

The decline of the price of oil has negatively impacted our business and continued depressed prices of oil and natural gas would continue to negatively impact our business.

Reduction in the prices of oil and natural gas impact the level of drilling activity by our customers and potential customers. The prices are primarily determined by supply, demand, government regulations relating to oil and natural gas production and processing and international political events, none of which can be accurately predicted. In times of declining activity, not only is there less opportunity for us to sell our products and services but there is increased competitive pressure that tends to reduce our prices and, therefore, our margins.

Beginning in the second half of 2014 and continuing through 2015 crude oil prices declined significantly. Moreover, 2016 began with another sharp decline in prices, with West Texas Intermediate ("WTI") dropping as low as $26.19 per barrel before recovering slightly. Commodity prices are expected to remain depressed for the foreseeable future. Accordingly, we anticipate 2016 will be a challenging year for us, as many of our customers reduce their operating budgets beyond reductions experienced in 2015. We expect limited activity in 2016 coupled with pricing pressures that will impact our revenue and operating margins. A continuing environment of depressed oil and natural gas prices would reduce the immediate levels of exploration, development and production activity which would have a material adverse effect on our business, consolidated results of operations and consolidated financial condition. An extended reduction in oil and natural gas prices or continued trends of drilling activity as seen today would require us to record asset impairments. Such a potential impairment charge may have a material adverse impact on our operating results. For more information, see “Management’s Discussion and Analysis of Financial Condition and Results of Operations.”

We face risks due to the cyclical nature of the energy industry and the corresponding credit risk of our customers.

Changing political, economic, or military circumstances throughout the energy-producing regions of the world can impact the market price of oil and natural gas for extended periods of time. As most of our accounts receivable are with customers involved in the oil and natural gas industry, any significant change in such circumstances could result in financial exposure in relation to affected customers.

Our revenue and earnings are subject to fluctuations period over period and are difficult to forecast.

Our revenue and earnings may vary significantly from quarter to quarter depending upon:

• | the level of drilling activity worldwide, as well as the particular geographic focus of the activity; |

• | the variability of customer orders or a reduction in customer orders, which are particularly unpredictable in international markets and which may leave us with excess or obsolete inventories; |

• | the levels of inventories of our products held by end-users and distributors; |

• | the mix of our products sold or leased and the margins on those products; |

• | new products offered and sold or leased by us or our competitors; |

• | weather conditions or other natural disasters that can affect our operations or our customers’ operations; |

• | changes in oil and natural gas prices and currency exchange rates, which in some cases affect the costs and prices for our products; |

• | the level of capital equipment project orders, which may vary with the level of new rig construction and refurbishment activity in the industry; |

• | changes in drilling and exploration plans, which can be particularly volatile in international markets; |

• | the ability of our vendors to timely supply necessary component parts used for the manufacturing of our products; and |

• | the ability to manufacture and timely deliver customer orders, particularly in the top drive segment due to the increasing size and complexity of our models. |

7

In addition, our fixed costs cause our margins to decrease when demand is low and service capacity is underutilized.

We could be subject to substantial liability claims, which would adversely affect our financial condition, results of operations and cash flows.

Certain equipment and processes are used by us and other companies in the oil and natural gas industry during the delivery of oilfield services in hostile environments, such as exploration, development and production applications. An accident or a failure of a product or process could cause personal injury, loss of life, damage to property, equipment, or the environment and suspension of operations. Our insurance may not protect us against liability for some kinds of events, including events involving pollution, or against losses resulting from business interruption. Moreover, in the future we may not be able to maintain insurance at levels of risk coverage or policy limits that we deem adequate. Substantial claims made under our policies could cause our premiums to increase. Any future damages caused by our products that are not covered by insurance, or are in excess of policy limits or are subject to substantial deductibles, could adversely affect our financial condition, results of operations and cash flows.

Possible legislation and regulations related to global warming and climate change could have an adverse effect on our operations and the demand for oil and natural gas.

Foreign, federal, state and local authorities and agencies are currently evaluating and promulgating climate-related legislation and regulations that are focused on restricting greenhouse gas ("GHG") emissions. In addition, climate change legislation is periodically considered in the United States Congress, and foreign jurisdictions are also considering the need to address climate changes by legislation or regulation. Several regional GHG initiatives have formed which may require reporting or development of cap and trade programs. These developments may curtail production and demand for fossil fuels such as oil and natural gas in areas of the world where our customers operate and thus adversely affect future demand for our services, which may in turn adversely affect future results of operations. Additionally, federal and/or state legislation to reduce the effects of GHG may potentially have a direct or indirect adverse effect on our operations, including the possible imposition on us and/or our customers of additional operational costs due to carbon emissions generated by oil and natural gas related activities. Finally, our business could be negatively affected by climate change-related physical changes or changes in weather patterns, which could result in damages to or loss of our physical assets, impacts on our ability to conduct operations and/or disruption of our customers’ operations.

Onshore oil and natural gas operations could be adversely impacted by changes in, and compliance with, restrictions or regulations on onshore drilling in the United States and in other areas around the world which may adversely affect our business and operating results.

New federal and state legislation regulating hydraulic fracturing may result in increased costs to drill, complete and operate wells, as well as delays in obtaining permits to drill wells all of which could negatively impact our clients and thereby our business and operating results. If legislation is passed to ban hydraulic fracturing, the number of wells drilled in the future could drop dramatically and the economic performance of those drilled would be negatively affected. Local authorities have also instituted restrictions to hydraulic fracturing operations which could result in negative impacts to our business.

Any significant consolidation or loss of end-user customers could have an impact on our business.

Exploration and production company operators and drilling contractors have undergone substantial consolidation in recent years and additional consolidation is probable. Also, many oil and natural gas properties could be transferred over time to different potential customers.

Consolidation of drilling contractors would result in fewer end-users for our products and could result in the combined contractor standardizing its equipment preferences in favor of a competitor’s products.

Merger activity among both major and independent oil and natural gas companies also affects exploration, development and production activity, as these consolidated companies attempt to increase efficiency and reduce costs. Generally, only the more promising exploration and development projects from each merged entity are likely to be pursued, which may result in overall lower post-merger exploration and development budgets. Moreover, some end-users prefer not to use relatively new products or premium products in their drilling operations.

We operate in an intensively competitive industry, and if we fail to compete effectively, our business will suffer.

The drilling industry is driven primarily by cost minimization. Our strategy is aimed at reducing drilling costs through the application of new technologies. Our competitors, many of whom have a more diverse product line and access to greater amounts of capital

8

than we do, have the ability to compete against the cost savings generated by our technology by reducing prices and by introducing competing technologies. Our competitors may also have the ability to offer bundles of products and services to customers that we do not offer. We have limited resources to sustain prolonged price competition and maintain the level of investment required to continue the commercialization and development of our new technologies.

To compete in our industry, we must continue to develop new technologies and products.

The markets for our products and services are characterized by continual technological developments and we have identified our products as providing technological advantages over other competitive products. As a result, substantial improvements in the scope and quality of product function and performance can occur over a short period of time. If we are not able to develop commercially competitive products in a timely manner in response to changes in technology, our business may be adversely affected. Our future ability to develop new products depends on our ability to:

• | design and commercially produce products that meet the needs of our customers; |

• | successfully market new products; and |

• | obtain and maintain patent protection. |

We may encounter resource constraints, cash and credit constraints, technical barriers, or other difficulties that would delay introduction of new products and services in the future. Our competitors may introduce new products or obtain patents before we do and achieve a competitive advantage. Additionally, the time and expense invested in product development may not result in commercial applications.

For example, from time to time, we have incurred significant losses in the development of new technologies which were not successful for various commercial or technical reasons. If we are unable to successfully implement technological or research and engineering type activities, our growth prospects may be reduced and our future revenue may be materially and adversely affected. Moreover, we may experience operating losses after new products are introduced and commercialized because of high start-up costs, unexpected manufacturing costs or problems, or lack of demand.

Risks associated with the global economy

The current global economic and political environment may negatively impact industry fundamentals, and the related decrease in demand for drilling rigs could cause a downturn in the oil and natural gas industry. Such a condition could have a material adverse impact on our business.

An extended deterioration in the global economic environment may impact fundamentals that are critical to our industry, such as the global demand for, and consumption of, oil and natural gas. Reduced demand for oil and natural gas generally results in lower oil and natural gas prices and prolonged weakness in the economy could impact the economics of planned drilling projects, resulting in curtailment, reduction, delay or postponement for an indeterminate period of time. Furthermore, an extended deterioration in the political environment in countries where we operate or that produce significant supply of the world’s demand for oil may also impact fundamentals that are critical to our industry, such as the global supply of oil and natural gas. Constraints in the global supply of oil caused by political turmoil in any of the large oil-producing countries of the world could significantly increase oil and natural gas prices while the removal of such constraints could significantly decrease oil and natural gas prices for an indeterminate period of time. Such volatility in oil and natural gas prices could negatively impact the world economy and our industry. Any long-term reduction in oil and natural gas prices will reduce oil and natural gas drilling and production activity and result in a corresponding decline in the demand for our products and services, which could adversely affect the demand for sales, rentals or services of our top drive units and for our tubular services. These reductions could adversely affect the future net realizability of assets, including inventory, fixed assets and other intangible assets.

We are exposed to risks associated with the financial markets.

While we intend to finance our operations with existing cash and cash flow from operations, we may require additional financing to support our operations and fund our growth. If any of the significant lenders, insurance companies, or other financial institutions are unable to perform their obligations under our credit agreements, insurance policies, or other contracts, and we are unable to find suitable replacements on acceptable terms as a result of recent credit disruptions or otherwise, our results of operations, liquidity and cash flows could be adversely affected.

9

Many of our customers access the credit markets to finance their oil and natural gas drilling and production activity. The inability of these parties to obtain financing on acceptable terms, due to credit disruptions or otherwise, could impair their ability to perform under their agreements with us and lead to various negative effects on us, including business disruption, decreased revenue and increases in bad debt write-offs. A sustained decline in the financial stability of our customers would have a material adverse impact on our business and results of operations.

The occurrence or threat of terrorist attacks could materially impact our business.

The occurrence or threat of terrorist attacks could adversely affect the economies of countries where we operate. A lower level of economic activity could result in a decline in energy consumption, which could cause a decrease in spending by oil and natural gas companies for exploration and development. In addition, these risks could trigger increased volatility in prices for crude oil and natural gas which could also adversely affect spending by oil and natural gas companies. A decrease in spending for any reason could adversely affect the markets for our products and thereby adversely affect our revenue and margins and limit our future growth prospects. Moreover, these risks could cause increased instability in the financial and insurance markets and adversely affect our ability to access capital and to obtain insurance coverage that we consider adequate or are required to obtain by our contracts with third parties.

We face risks related to natural disasters and pandemic diseases, which could materially and adversely disrupt our operations and affect travel required for our worldwide operations.

A portion of our business involves the movement of people, parts and supplies to or from foreign locations. Any restrictions on travel or shipments to and from foreign locations, due to the occurrence of natural disasters such as earthquakes, floods, or hurricanes; or an epidemic or outbreak of diseases, in these locations, could significantly disrupt our operations and decrease our ability to provide services to our customers. In addition, our local workforce could be affected by such an occurrence or outbreak which could also significantly disrupt our operations and decrease our ability to provide services to our customers.

Our operations are subject to political and economic instability and risk of government action that could have a material adverse effect on our business, consolidated results of operations and consolidated financial condition.

We are exposed to risks inherent in doing business in each of the countries in which we operate. In places like Russia, Latin America, the Middle East and Asia Pacific, we may have difficulty or extra expense in navigating the local bureaucracies and legal systems. We may face challenges in enforcing contracts in local courts or be at a disadvantage when we have a dispute with a customer that is an agency of the state. We may be at a disadvantage to competitors that are not subject to the same international trade and business practice restrictions that U.S. and Canadian laws impose on us.

While diversification is desirable, it can expose us to risks related to cultural, political and economic factors of foreign jurisdictions which are beyond our control. As a general rule, we have elected not to carry political risk insurance against these risks. Such risks include the following:

• | loss of revenue, property and equipment as a result of hazards such as wars, insurrection and other instances of political and economic instability; |

• | the effects of currency fluctuations and exchange controls, such as devaluation of foreign currencies and other economic problems; |

• | changes or interpretations in laws, regulations and policies of foreign governments, including those associated with changes in the governing parties, nationalization and expropriation; |

• | protracted delays in securing government consents, permits, licenses, or other regulatory approvals necessary to conduct our operations; and |

• | protracted delays in the collection of accounts receivable due to economic, political and civil instabilities. |

We are subject to foreign governmental regulations in some jurisdictions in which we operate that favor or require awarding contracts to local contractors or require foreign contractors to employ citizens of, or purchase supplies from, a certain jurisdiction. Such regulations may adversely affect our ability to compete in that jurisdiction. Our operations in some jurisdictions may be significantly affected by union activity and general labor unrest. In Argentina and Mexico, particularly, where we have significant operations, labor organizations have substantial support and have considerable political influence. In Argentina, the demands of labor organizations have increased in recent years and seem likely to continue as a result of the general labor unrest and dissatisfaction resulting from the disparity between the cost of living and salaries in Argentina exacerbated by the devaluation of the Argentine

10

Peso. There can be no assurance that our operations in Argentina or Mexico will not face labor disruptions in the future or that any such disruptions will not have a material adverse effect on our financial condition or results of operations. Further, unionization efforts have been made from time to time in other jurisdictions in which we operate with varying degrees of success. Any such unionization could increase our costs or limit the flexibility in that market.

Due to unsettled political conditions in many oil-producing countries, our operations, revenue and profits are subject to adverse consequences of war, the effects of terrorism, civil unrest, strikes, currency controls and governmental actions. These and other risks described above could result in the loss of our personnel or assets, cause us to evacuate our personnel from certain countries, cause us to increase spending on security worldwide, disrupt financial and commercial markets, including the supply of and pricing for oil and natural gas and generate greater political and economic instability in some of the geographic areas in which we operate. Areas where we operate that have significant risk include, but are not limited to: Argentina, Colombia, Egypt, Indonesia, Iraq, Mexico and Russia. In addition, any possible reprisals as a consequence of military or other action, such as acts of terrorism in the United States or elsewhere, could have a material adverse effect on our business, consolidated results of operations and consolidated financial condition. The continuance of our sales to customers, and our operations, in Russia and the region are uncertain if existing sanctions are amended or otherwise expanded. Continued political instability, deteriorating macroeconomic conditions, the implementation of additional economic sanctions that restrict our ability to do business and actual or threatened military action in the region could have a material adverse effect on our operations in the region and on the result of operations of our Top Drive segment.

Cybersecurity incidents could have a material adverse effect on our business, consolidated results of operations and consolidated financial condition.

Our operations are also subject to the risk of information technology disruptions. Cybersecurity incidents, in particular, are evolving and include, but are not limited to, malicious software, attempts to gain unauthorized access to data and other electronic security breaches that could lead to disruptions in systems, unauthorized release of confidential or otherwise protected information and the corruption of data. We believe that we have implemented appropriate measures to mitigate potential risks to our technology and our operations from these information technology disruptions. However, given the unpredictability of the timing, nature and scope of information technology disruptions, we could potentially be subject to production downtimes, operational delays, the compromising of confidential or otherwise protected information, destruction or corruption of data, security breaches, other manipulation or improper use of our systems and networks or financial losses from remedial actions, any of which could have a material adverse effect on our cash flows, competitive position, financial condition or results of operations.

Risks associated with our business

We have been party to patent infringement claims and we may not be able to protect or enforce our intellectual property rights.

Some of our products and the processes used to produce them have been granted U.S. and international patent protection, or have patent applications pending. Nevertheless, patents may not be granted for our applications and, if patents are issued, the claims allowed may not be sufficient to protect our technology. Changes in U.S. patent law may have the effect of making certain of our patents more likely to be the subject of claims for invalidation.

Our competitors may be able to independently develop technology that is similar to ours without infringing on our patents. This is especially true internationally where the protection of intellectual property rights may not be as effective. In addition, obtaining and maintaining intellectual property protection internationally may be significantly more expensive than doing so domestically. We may have to spend substantial time and money defending our patents. After our patents expire, our competitors will not be legally constrained from marketing products substantially similar to ours.

We are subject to legal proceedings and may, in the future, be subject to additional legal proceedings.

In the normal course of our business, we are subject to legal proceedings brought by or against us and our subsidiaries. We are currently involved in legal proceedings described in Part II, Item 8, "Financial Statements and Supplementary Data, Note 14" included in this Report. From time to time, we may become subject to additional legal proceedings which may include contract, tort, intellectual property, tax, regulatory compliance and other claims.

We are also subject to complaints or allegations from former, current, or prospective employees from time to time, alleging violations of employment-related laws. Lawsuits or claims could result in decisions against us which could have a material adverse effect on our financial condition, results of operations, or cash flows.

11

Our products and services are used in hazardous conditions and we are subject to risks relating to potential liability claims.

Most of our products are used in hazardous drilling and production applications where an accident or a failure of a product can have catastrophic consequences. While we attempt to limit our exposure to such risks through contracts with our customers, these measures may not protect us against liability for certain kinds of events, including blowouts, cratering, explosions, fires, loss of well control, loss of hole, damaged or lost drilling equipment, damage or loss from inclement weather or natural disasters and losses resulting from business interruption. Our insurance coverage generally provides that we assume a portion of the risk in the form of a self-insured retention, and may not be adequate in risk coverage or policy limits to cover all losses or liabilities that we may incur. The occurrence of an event not fully insured or indemnified against, or the failure of a customer or insurer to meet its indemnification or insurance obligations, could result in substantial losses. Moreover, we may not be able in the future to maintain insurance at levels of risk coverage or policy limits that we deem adequate. Any significant claims made under our policies will likely cause our premiums to increase. Any future damages caused by our products or services that are not covered by insurance, are in excess of policy limits or are subject to substantial deductibles, could materially reduce our earnings and cash available for operations.

Environmental compliance and remediation costs and the costs of environmental liabilities could exceed our estimates.

The energy industry is affected by changes in public policy, federal, state, local and foreign laws and regulations. The adoption of laws and regulations curtailing exploration and development drilling for oil and natural gas for economic, environmental and other policy reasons may adversely affect our operations due to our customers having limited drilling and other opportunities in the oil and natural gas exploration and production industry. The operations of our customers, as well as our properties, are subject to increasingly stringent laws and regulations relating to environmental protection, including laws and regulations governing air emissions, water discharges, waste management and workplace safety.

Our credit facility contains restrictions that may limit our ability to finance future operations or capital needs and could accelerate debt payments.

Our credit facility contains covenants which limit the amount of borrowings available by the maintenance of certain financial ratios. Decreases in our financial performance could prohibit us from borrowing amounts under our credit facility, force us to make repayments of outstanding debt in order to remain in compliance with these restrictive covenants, or accelerate our debt payments and other financing obligations and those of our subsidiaries. Additionally, our credit agreements are collateralized by equity interests in certain of our subsidiaries. A breach of the covenants under these agreements could permit the lenders to exercise their rights to foreclose on these collateral interests. If this were to occur, we might not be able to repay such debt and other financing obligations. These restrictions may negatively impact our ability to finance future operations, implement our business strategy or fund our capital needs. Compliance with these financial ratios may be affected by events beyond our control, including the risks and uncertainties described in the other risk factors discussed elsewhere in this report. At the time of this Report, the Company is in compliance with it covenants but is prohibited from borrowing per the terms of the Waiver described in Part II, Item 7, "Liquidity and Capital Resources" included in this Report and Part II, Item 8, "Financial Statements and Supplementary Data, Note 9" included in this Report.

We have a revolving credit facility that is not contracted at current market rates.

In April 2012, we amended our credit agreement to provide a revolving line of credit of $125.0 million including up to $20.0 million of swing line loans, (collectively, the "Revolver"). In February 2016, we reduced the line of credit by $65 million to $60 million. The credit facility has a term of five years and all outstanding borrowings on the credit agreement are due and payable on April 27, 2017. As of December 31, 2015, we had $1.3 million in letters of credit outstanding under this credit facility.

At this time it is difficult to forecast the future state of the bank loan market. As a result of the uncertain state of various financial institutions and the credit markets generally, we may be unable to maintain our current borrowing capacity in the event of bank or banks failure to fund any commitments under the current credit facility, and we may not be able to refinance or replace our bank facility. Likewise, as we seek to replace the current credit facility, we are unlikely to secure a new facility in the same amount and on the same terms as we currently hold, which could negatively impact our liquidity and results of operations.

We provide warranties on our products and if our products fail to operate properly our business will suffer.

We provide warranties as to the proper operation and conformance to specifications of the equipment we manufacture. Our products are often deployed in harsh environments including subsea applications. The failure of these products to operate properly or to meet specifications may increase our costs by requiring additional engineering resources and services, replacement of parts and

12

equipment or monetary reimbursement to a customer. We have experienced quality problems with raw material vendors, which required us to recall and replace certain equipment and components. We have also received warranty claims and we expect to continue to receive them in the future. Such claims may exceed the reserve we have set aside for them. To the extent that we incur substantial warranty claims in any period because of quality issues with our products, our reputation, ability to obtain future business and earnings could be materially and adversely affected.

Our profitability is driven to a large extent by our ability to deliver the products we manufacture in a timely manner.

Disruptions to our production schedule may adversely impact our ability to meet delivery commitments. If we fail to deliver products according to contract terms, we may suffer material financial penalties and a diminution of our commercial reputation and future product orders.

We rely on the availability of raw materials, component parts and finished products to produce our products.

We buy raw materials, components and precision machining or sub-assembly services from many different vendors located in Canada, the U.S., Europe, South East Asia and the Middle East. The price and lead times for some products have fluctuated along with the general changes of steel prices around the world. We also source a substantial amount of electrical components, including permanent magnet motors and drives as well as a substantial amount of hydraulic components, including hydraulic motors, from suppliers located in the U.S. and abroad. The inability of suppliers to meet performance, quality specifications and delivery schedules could cause delays in manufacturing and make it difficult or impossible for us to meet outstanding orders or accept new orders for the manufacture of the affected equipment. In addition, the lack of an efficient supply chain could cause us to hold higher levels of inventory.

The design of some of our equipment is based on components provided by specific sole source manufacturers.

Some of our products have been designed around components which are only available from one source of supply. In some cases, a manufacturer has developed or modified the design of a component at our request, and consequently we are the only purchaser of such items. If the manufacturer of such an item should go out of business or cease or refuse to manufacture the component in question, or raise the price of such components unduly, we may have to identify alternative components and redesign portions of our equipment. This could cause delays in manufacturing and make it difficult or impossible for us to meet outstanding orders or accept new orders for the manufacture of the affected equipment.

Our business requires the retention and recruitment of a skilled workforce and key employees, and the loss of such employees could result in the failure to implement our business plans.

As a technology-based company, we depend upon skilled engineering and other professionals in order to engage in product innovation and ensure the effective implementation of our innovative technology. We compete for these professionals, not only with other companies in the same industry, but with oil and natural gas service companies generally and other industries. In periods of high energy and industrial manufacturing activity, demand for the skills and expertise of these professionals increases, which can make the hiring and retention of these individuals more difficult and expensive. Failure to recruit and retain such individuals may result in our inability to maintain a competitive advantage over other companies and loss of customer satisfaction. The loss or incapacity of certain key employees for any reason, including our President and Chief Executive Officer, Fernando R. Assing, and Senior Vice President and Chief Financial Officer, Christopher L. Boone, could have a negative impact on our ability to implement our business plan due to the specialized knowledge these individuals possess. We do not maintain key man insurance on any of our personnel.

Our business relies on the skills and availability of trained and experienced trades and technicians to provide efficient and necessary services to us and our customers. Hiring and retaining such individuals are critical to the success of our business plan. Retention of staff and the prevention of injury to staff are essential in order to provide a high level of service.

We may be unable to identify or complete acquisitions.

Acquisitions have been and may continue to be an element of our business strategy. We can give no assurance that we will be able to secure, close, or integrate successfully the assets and operations of acquired businesses with our own business. Any inability on our part to integrate and manage the growth of acquired businesses may have a material adverse effect on our results of operations and financial condition. We can give no assurance that we will be able to identify and acquire additional businesses in the future on terms favorable to us.

13

Item 1B. Unresolved Staff Comments.

None.

14

Item 2. Properties.

The following table details our principal facilities, including all properties that we own and those leased properties that serve as corporate or regional headquarters as of December 31, 2015.

Location | Approximate Square Footage (Buildings) | Owned or Leased | Description | |||

Houston, Texas, United States of America | 27,225 | Leased | Corporate headquarters. | |||

Houston, Texas, United States of America | 89,893 | Owned | Regional headquarters for North American operations in Top Drive and Tubular Services and our U.S. regional operations base which also provides equipment repair and maintenance for U.S. and certain overseas operations. | |||

Kilgore, Texas, United States of America | 20,536 | Owned | Regional operations base for the Tubular Services segment in east Texas and northern Louisiana. | |||

Lafayette, Louisiana, United States of America | 43,300 | Owned | Regional operations base for the Tubular Services segment in southern Louisiana and the Gulf of Mexico. | |||

Calgary, Alberta, Canada | 90,592 | Owned | Assembly of top drives and other equipment. | |||

Moscow, Russia | 4,080 | Leased | Regional headquarters for Russia. | |||

Dubai, United Arab Emirates | 30,526 | Leased | Regional headquarters for the Middle East, North Africa and East Africa. | |||

Cairo, Egypt | 78,819 | Owned | Regional operations base for the Tubular Services segment in Egypt. | |||

Kuala Lumpur, Malaysia | 4,950 | Leased | Regional headquarters for the Asia Pacific region. | |||

In addition, we lease operational facilities at locations in Oklahoma, New Mexico, Pennsylvania, Texas and Wyoming. Each of these locations supports operations in its local area, primarily for the Tubular Services segment.

Outside the U.S., some of our additional leased operating facilities are in Argentina, Australia, Canada, China, Colombia, Dubai, Egypt, Indonesia, Malaysia, Mexico, Russia, Republic of Singapore and the United Kingdom. The majority of these facilities support the Top Drive and Tubular Services segments.

We believe our existing equipment and facilities to be adequate to support our operations.

Item 3. Legal Proceedings.

In the normal course of our business, we are subject to legal proceedings brought by or against us and our subsidiaries. None of these proceedings involves a claim for damages exceeding ten percent of our current assets on a consolidated basis. See Part II, Item 8, "Financial Statements and Supplementary Data, Note 14" included in this Report for a summary of certain closed and ongoing legal proceedings. Such information is incorporated into this Part I, Item 3, "Legal Proceedings" in this Report by reference.

Item 4. Mine Safety Disclosures.

None.

15

PART II

Item 5. Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities.

Market Information

Our outstanding shares of common stock are traded on the Nasdaq Stock Market ("NASDAQ") under the symbol "TESO." The following table outlines the share price trading range by quarter for 2015 and 2014.

Share Price Trading Range | |||||||

High | Low | ||||||

2015 | ($ per share) | ||||||

1st Quarter | $ | 13.12 | $ | 9.53 | |||

2nd Quarter | 13.28 | 10.86 | |||||

3rd Quarter | 10.96 | 7.01 | |||||

4th Quarter | 9.00 | 6.63 | |||||

2014 | |||||||

1st Quarter | $ | 21.55 | $ | 16.30 | |||

2nd Quarter | 22.50 | 17.74 | |||||

3rd Quarter | 22.30 | 18.92 | |||||

4th Quarter | 19.99 | 11.53 | |||||

As of February 29, 2016, there were approximately 218 holders of record of our common stock, including brokers and other nominees.

Dividend Policy

On May 5, 2014 the Company's Board of Directors (the "Board") approved the initiation of a quarterly cash dividend. Cash dividends aggregated $7.8 million and $6.0 million for the years ended December 31, 2015 and 2014, respectively.

In February 2016, the Board suspended payment of the Company’s quarterly dividend as part of a broader plan of reducing costs, working capital, and capital expenditures in order to preserve liquidity. Moreover, the Waiver we received under our Credit Facility prohibits the Company from declaring or paying any dividends. For detailed discussion of this matter, see Part II, Item 7, "Liquidity and Capital Resources" included in this Report. The Board will continue to evaluate the Company’s ability to reinstate the dividend on an ongoing basis.

Stock Repurchase Program

On May 2, 2014, the Board authorized a common stock repurchase program (the "Program"), which permits us to repurchase up to $100,000,000 USD of our current shares outstanding. The repurchase of the common shares was conducted as a normal course issuer bid ("NCIB"). This Board authorization expires June 30, 2016. We did not repurchase any shares during the year ended December 31, 2015.

16

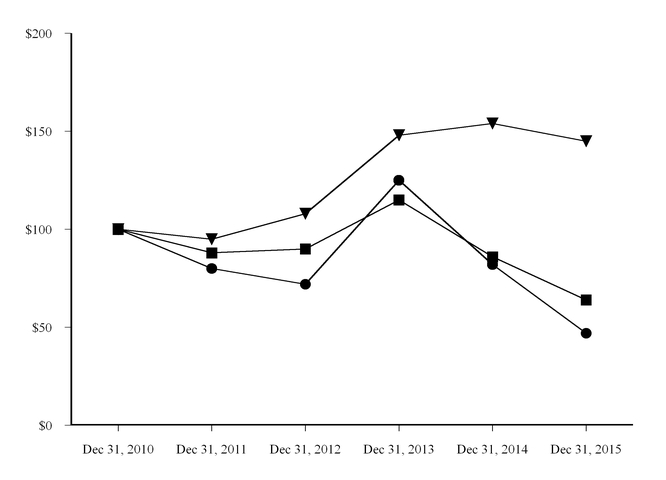

Performance Graph

The following performance graph and table compares the yearly percentage change in the cumulative shareholder return for the five year period commencing on December 31, 2010 and ending on December 31, 2015 on our common shares (assuming a $100 investment was made on December 31, 2010) with the total cumulative return of the Russell 2000 Index and the Philadelphia Oil Service Sector Index ("OSX"), assuming reinvestment of dividends.

Dec 31, 2010 | Dec 31, 2011 | Dec 31, 2012 | Dec 31, 2013 | Dec 31, 2014 | Dec 31, 2015 | |||||||||||||||||||

● Tesco Corp. | $ | 100 | $ | 80 | $ | 72 | $ | 125 | $ | 82 | $ | 47 | ||||||||||||

■ OSX | $ | 100 | $ | 88 | $ | 90 | $ | 115 | $ | 86 | $ | 64 | ||||||||||||

q Russell 2000 | $ | 100 | $ | 95 | $ | 108 | $ | 148 | $ | 154 | $ | 145 | ||||||||||||

17

Item 6. Selected Financial Data.

The following selected financial data should be read in conjunction with "Item 7, Management’s Discussion and Analysis of Financial Condition and Results of Operations" and "Item 8, Financial Statements and Supplementary Data" of this report.

Years Ended December 31, | |||||||||||||||||||

2015 | 2014 | 2013 | 2012 | 2011 | |||||||||||||||

(in millions, except per share data) | |||||||||||||||||||

Summary of operations | |||||||||||||||||||

Operating revenues | $ | 279.7 | $ | 543.0 | $ | 524.9 | $ | 553.2 | $ | 513.1 | |||||||||

Net income (loss) from continuing operations | (133.8 | ) | 21.4 | 35.3 | 50.2 | 25.8 | |||||||||||||

Per share data | |||||||||||||||||||

Basic earnings (loss) per share | $ | (3.43 | ) | $ | 0.54 | $ | 0.90 | $ | 1.30 | $ | 0.68 | ||||||||

Diluted earnings (loss) per share | (3.43 | ) | 0.53 | 0.89 | 1.28 | 0.66 | |||||||||||||

Dividends declared | 0.20 | 0.15 | — | — | — | ||||||||||||||

Balance sheet data | |||||||||||||||||||

Total assets | $ | 421.7 | $ | 619.3 | $ | 634.7 | $ | 585.6 | $ | 546.6 | |||||||||

Long term obligations (including capital leases) | — | — | 0.5 | 0.3 | 6.6 | ||||||||||||||

Factors affecting comparability

• | In 2015, due to declines in the market value of our stock, oil and natural gas prices and utilization, we recognized a goodwill impairment of $34.4 million. |

• | In 2015, we recorded valuation allowances against deferred tax assets in certain jurisdictions of $41.1 million compared to valuation allowances of $0.9 million recorded in 2014. |

• | In 2015, due to currency reforms in Argentina that resulted in a 32% devaluation in the Argentine Peso against the U.S. Dollar, we recorded a $6.1 million foreign exchange charge. |

• | In 2015, due to the decline in the upstream energy industry and its corresponding impact on our business outlook, we initiated a company-wide reduction in workforce and other cost rationalization efforts which was intended to reduce costs and better align our workforce with anticipated activity levels in the current market. Accordingly, we recorded a charge related to restructuring costs of $10.9 million for the year. |

• | In 2015 we recorded an inventory obsolescence reserve and inventory cost adjustments of $13.5 million. |

• | In 2014, we recorded a selling, general and administrative expense of $1.5 million related to a dispute with a third party in Asia Pacific. |

• | On May 5, 2014, we approved our initiation of a quarterly cash dividend of $0.05 per share to our common shareholders. The first quarterly dividend was declared in the second quarter of 2014 and has been approved and paid each successive quarter through 2015. |

• | On May 2, 2014, the Board authorized a common stock repurchase program, under which we repurchased over 1.6 million shares for total cash value of approximately $27.3 million in 2014. No shares were repurchased during 2015. |

• | In 2015, we recorded additional warranty expense of $1.5 million related to operational issues related to our catwalk units. In 2014, we recorded additional warranty expense of $1.5 million for quills installed on specific top drive units. In 2013, we recorded a $1.1 million warranty expense in regards to the torque arrest systems. In 2012, we recorded additional warranty expense of $4.4 million for ESI gear box issues. |

• | In 2013 and 2012, we recorded a $1.4 million and $12.4 million pre-tax gain on the sale of the Casing Drilling business, respectively. For detailed discussion of this matter, see Part II, Item 8, "Financial Statements and Supplementary Data, Note 3" included in this Report. |

• | In 2011, we saw a significant increase in revenues due to increased demand, both domestically and internationally for top drives and our proprietary tubular services that approached the pre-recession levels. |

18

• | In 2011, we assumed $7.4 million of outstanding debt as part of the acquisition of Premiere Casing Services - Egypt S.A.E. ("Premiere"). At December 31, 2011, the balance of this debt was $5.6 million related to capital leases and $1.1 million related to notes payable. In 2012, we paid off all of the outstanding balances related to Premiere's notes payable and a significant amount of the outstanding balances related to Premiere's capital leases. |