Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Hi-Crush Inc. | q42015-earningsrelease8xk.htm |

| EX-99.1 - EXHIBIT 99.1 - Hi-Crush Inc. | exhibit991-earningsrelease.htm |

INVESTOR PRESENTATION FEBRUARY 2016

Forward Looking Statements Some of the information included herein may contain forward-looking statements within the meaning of the federal securities laws. Forward- looking statements give our current expectations and may contain projections of results of operations or of financial condition, or forecasts of future events. Words such as “may,” “assume,” “forecast,” “position,” “predict,” “strategy,” “expect,” “intend,” “plan,” “estimate,” “anticipate,” “could,” “believe,” “project,” “budget,” “potential,” or “continue,” and similar expressions are used to identify forward-looking statements. They can be affected by assumptions used or by known or unknown risks or uncertainties. Consequently, no expected results of operations or financial condition or other forward-looking statements can be guaranteed. When considering these forward-looking statements, you should keep in mind the risk factors and other cautionary statements in Hi-Crush Partners LP’s (“Hi-Crush”) reports filed with the Securities and Exchange Commission (“SEC”), including those described under Item 1A, “Risk Factors” of Hi-Crush’s Annual Report on Form 10-K for the fiscal year ended December 31, 2015 and any subsequently filed Quarterly Report on Form 10-Q. Actual results may vary materially. You are cautioned not to place undue reliance on any forward-looking statements. You should also understand that it is not possible to predict or identify all such factors and should not consider the risk factors in our reports filed with the SEC or the following list to be a complete statement of all potential risks and uncertainties. Factors that could cause our actual results to differ materially from the results contemplated by such forward-looking statements include: the volume of frac sand we are able to sell; the price at which we are able to sell frac sand; the outcome of any pending litigation; changes in the price and availability of natural gas or electricity; changes in prevailing economic conditions; and difficulty collecting receivables. All forward-looking statements are expressly qualified in their entirety by the foregoing cautionary statements. Hi-Crush’s forward-looking statements speak only as of the date made and Hi-Crush undertakes no obligation to update or revise its forward-looking statements, whether as a result of new information, future events or otherwise. 2

A Challenging Market with Partial Offsets 3 Partia l O ff s et s C h a lle n g e s • Lower completion activity as E&Ps reduce capex budgets and delay well completions • Decline in frac sand pricing as demand adjusts to lower overall activity • Highly competitive environment with a significant customer focus on cost reductions • Low visibility in near-term demand due to general market uncertainty generated from low commodity prices • Increasing sand intensity as companies pump more sand to generate best well economics in a stressed price environment • HCLP’s market leading low-cost structure and vendor relationships offers flexibility in an increasingly cost-focused industry • Trend of in-basin purchases benefits HCLP’s strategic network of distribution terminals • Vendor rationalization as customers partner with leading sand companies capable of delivering efficiently and reliably

Taking Steps to Effectively Manage the Downturn 4 Focusing on Internal Cost Reductions • Temporarily idled Augusta facility to maximize production from our lowest cost plants • Optimizing origin / destination pairings, to minimize freight costs and efficiently managing our railcar fleet • Taking action to ensure a lean cost structure Partnering with Long Term Customers Maintaining Liquidity & Capital Flexibility • Extend previous pricing discounts to contract customers in 2016 as market uncertainty persists • Working with customers to reduce costs along the entire sand supply chain • Building upon our long-term customer relationships to best position HCLP for the eventual market recovery • Temporarily suspended distribution to conserve cash flow • Executed revolver amendment to improve and extend flexibility • Announced capex budget of $15-25 million for highly strategic investments remains flexible based on market conditions

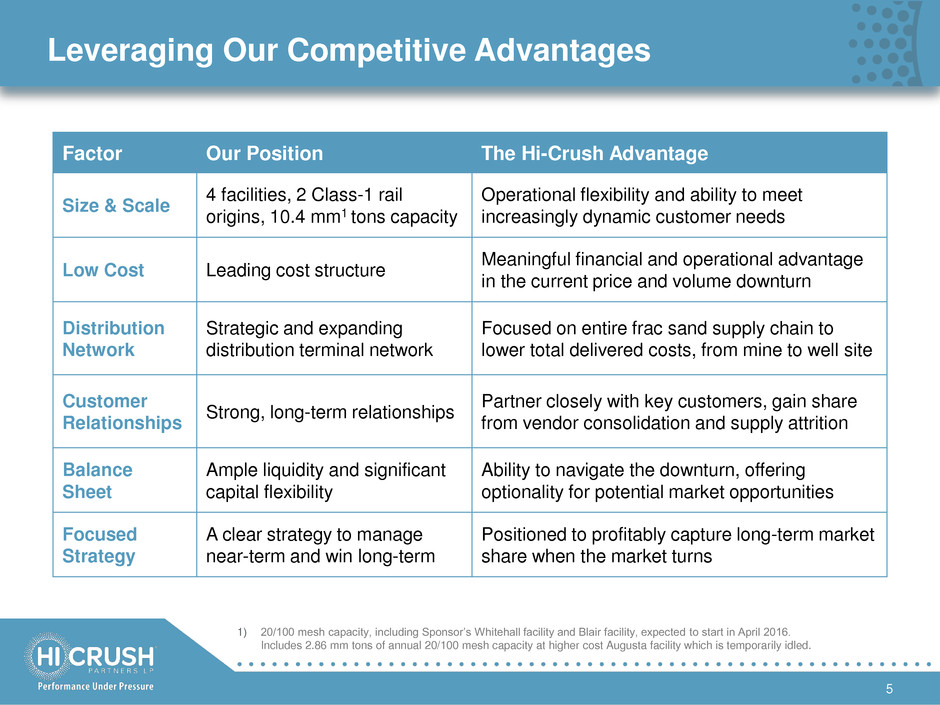

Leveraging Our Competitive Advantages 5 1) 20/100 mesh capacity, including Sponsor’s Whitehall facility and Blair facility, expected to start in April 2016. Includes 2.86 mm tons of annual 20/100 mesh capacity at higher cost Augusta facility which is temporarily idled. Factor Our Position The Hi-Crush Advantage Size & Scale 4 facilities, 2 Class-1 rail origins, 10.4 mm1 tons capacity Operational flexibility and ability to meet increasingly dynamic customer needs Low Cost Leading cost structure Meaningful financial and operational advantage in the current price and volume downturn Distribution Network Strategic and expanding distribution terminal network Focused on entire frac sand supply chain to lower total delivered costs, from mine to well site Customer Relationships Strong, long-term relationships Partner closely with key customers, gain share from vendor consolidation and supply attrition Balance Sheet Ample liquidity and significant capital flexibility Ability to navigate the downturn, offering optionality for potential market opportunities Focused Strategy A clear strategy to manage near-term and win long-term Positioned to profitably capture long-term market share when the market turns

Credit Facility Amendment Adds Flexibility 6 Metric Amendment Details Commitment Total commitment available of $100 million Covenants Replaces leverage covenant with EBITDA minimum through 3/31/17 (details above) Interest Coverage Minimum of 2.50x beginning 6/30/17 Capex Maximum of $28 million for FY 2016 Distribution 50% of DCF less principal payments available for distribution during the Effective Period1 Asset Coverage2 Minimum of 1.0x as a condition precedent to draw funds during Effective Period1 1) Effective Period commencing December 31, 2015 through June 29, 2017 2) Calculated as: (Fixed assets book value + eligible accounts receivable and inventory) / total funded debt Trailing 6 Month EBITDA Minimum Leverage Ratio Maximum 2.0 5.0 8.0 12.0 12.0 5.0x 4.5x 4.0x 3.5x 0.0x 1.0x 2.0x 3.0x 4.0x 5.0x 6.0x 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 1Q16 2Q16 3Q16 4Q16 1Q17 2Q17 3Q17 4Q17 1Q18+ Multip le X ( gray bar) $mm (blue bars)

1,20 9 TBD TBD TB D 300 600 900 1,200 1,500 1,800 2,100 HCLP FMSA EMES SLCA 3Q14 4Q14 1Q15 2Q15 3Q15 4Q15 Gaining Market Share and Outperforming 7 HCLP, 21% FMSA, 28% EMES, 20% SLCA, 31% HCLP, 25% FMSA, 27% EMES, 18% SLCA, 30% Quarterly Sand Tons Sold (000s) YTD ‘15 vs. YTD ‘14 % Change2 Quarterly Sand Tons Sold Comparison1 Volume Splits of Public Peers2 22% 0% -9% -4% -20% -10% 0% 10% 20% 30% HCLP FMSA EMES SLCA 9 mos. YTD ‘14 9 mos. YTD ‘15 19% -15% -30% -15% 18% -6% -7% 32% -40% -30% -20% -10% 0% 10% 20% 30% 40% HCLP FMSA EMES SLCA YoY% QoQ% Source: Company filings. 1 YoY%: 3Q15 vs. 3Q14; QoQ%: 3Q15 vs. 2Q15. 2 YTD sand volumes sold through 3Q15 by large public peers; excludes private company sand sales and is not directly indicative of total market share.

Strong Frac Sand Fundamentals Unchanged 8 Factors Supporting an Eventual Recovery • Supply reduced as producers idle or shut down operations • Net new sand supply pushed out to 2017 as projects are delayed or cancelled • Sand intensity trends support demand; “super fracs” growing to 15,000+ tons per well • Drilled but uncompleted well (“DUC”) backlog could represent significant pent- up demand Targeting of Shale & Unconventional Increased Horizontal Drilling Longer Laterals Lengths More Stages per Foot More Sand per Stage More Wells Drilled per Rig GREATER FRAC SAND INTENSITY

Rig / Completion Rate Impact on Sand Demand1 9 10 rigs 20 days 18 wells 18 wells 180 wells 2,500 tons 450,000 tons Rig Count # of rigs Rig Efficiency Days/Well Drilled Rig Productivity Wells drilled/year/rig Completions Well completions/year/rig Wells Completed Well completions/year Sand Usage Tons/well Company XYZ Demand Tons/year 5 rigs 16 days 22 wells 17 wells 85 wells 4,500 tons 382,500 tons -50% +20% Calculated -25% Calculated +80% -15% Before After Company XYZ 1) Hypothetical example for illustrative purposes only; some results rounded

Hi-Crush Operations

Our Model – Q4 and FY 2015 Operating Results 11 Sold FOB plant direct to customer Sand delivered to terminal via rail Customer truck delivers to well site Sold at terminal to customer Freight costs Class-1 and short-line rail Tons Sold Q415: 1,209,171 Tons Sold FY15: 5,003,702 Terminal locations Q4 2015 FY 2015 48% 52% FOB Plant In-Basin 49% 51% FOB Plant In-Basin

Hi-Crush Ranks Among Largest in Industry 12 #1 in Wisconsin #2 in World Largest production capacity of frac sand in Wisconsin Second largest production capacity of frac sand in the world 10.4 million1 tons capacity 1) 20/100 mesh capacity, including Sponsor’s Whitehall facility and Blair facility, expected to start in April 2016. Includes 2.86 mm tons of annual 20/100 mesh capacity at higher cost Augusta facility which is temporarily idled. Source: Internal estimates

Logistics Flexibility Critical 13 Sandstone Formations Sponsor’s Whitehall Facility • Access to all major U.S. oil and gas basins • Direct loading and unloading of unit trains • Multiple in-basin terminals across Marcellus and Utica shales and one located in Permian Basin • Expanding our terminal network in the Permian and DJ Basins for more efficient in-basin deliveries • Strong relationships with multiple Class-1 and short- line railroads HCLP Sand Facilities Sponsor Sand Facility Existing Distribution Terminals Basin Play Terminals Under Development1 1) New Permian Basin and DJ Basin terminals expected to be operational in 2016 Sponsor Sand Facility Under Development

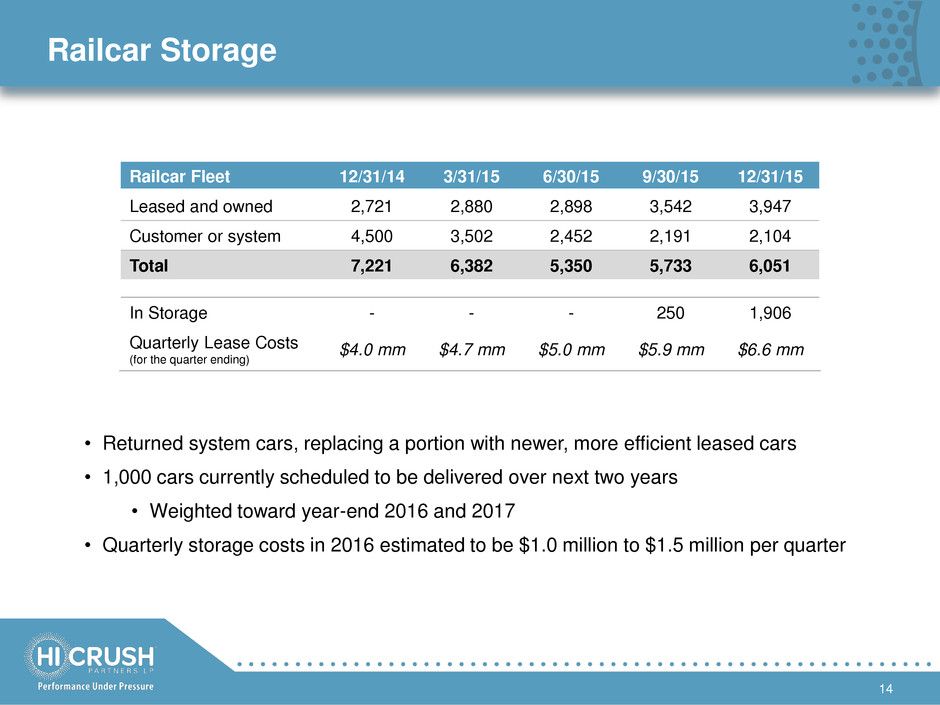

Railcar Storage 14 Railcar Fleet 12/31/14 3/31/15 6/30/15 9/30/15 12/31/15 Leased and owned 2,721 2,880 2,898 3,542 3,947 Customer or system 4,500 3,502 2,452 2,191 2,104 Total 7,221 6,382 5,350 5,733 6,051 In Storage - - - 250 1,906 Quarterly Lease Costs (for the quarter ending) $4.0 mm $4.7 mm $5.0 mm $5.9 mm $6.6 mm • Returned system cars, replacing a portion with newer, more efficient leased cars • 1,000 cars currently scheduled to be delivered over next two years • Weighted toward year-end 2016 and 2017 • Quarterly storage costs in 2016 estimated to be $1.0 million to $1.5 million per quarter

Financial Results

Comparison to Prior Quarters and Prior Year 16 $ in 000s Q4 2015 Q3 2015 Q2 2015 FY 2015 FY 2014 Revenues $72,077 $81,494 $83,958 $339,640 $386,547 Adjusted EBITDA1 $19,699 $13,426 $19,195 $81,901 $148,015 Adjusted EPU (basic)1 $0.36 $0.15 $0.31 $1.42 $3.09 Adjusted EPU (diluted)1 $0.35 $0.15 $0.31 $1.42 $3.00 Sales volumes (tons) 1,209,171 1,409,032 1,190,156 5,003,702 4,584,811 Contribution margin ($/ton)2 $9.66 $14.00 $20.67 $18.28 $37.34 Distributions per unit3 – – $0.475 $1.15 $2.40 1) Adjusted EBITDA and adjusted earnings per unit for Q4 2015, Q3 2015 and FY 2015 include add-backs for one-time expenses related to impairments and restructuring. 2) Contribution margin is defined as total revenues less costs of goods sold excluding depreciation, depletion and amortization. Contribution margin excludes other operating expenses and income, including costs not directly associated with the operations of our business such as accounting, human resources, information technology, legal, sales and other administrative activities. 3) Represents distributions declared for the quarter. • Increasing sand intensity more than offset by lower well completions • Working with customers and vendors to lower delivered cost at terminal locations • Preserving capital and protecting our strong balance sheet for an eventual recovery

4th Quarter 2015 Summary 17

4th Quarter 2015 Summary – EBITDA & DCF 18 a) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital.

Full-Year 2015 Summary 19 a) Financial information has been recast to include the financial position and results attributable to Hi-Crush Augusta LLC.

Full-Year 2015 Summary – EBITDA & DCF 20 a) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long- term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital. b) The Partnership's historical financial information has been recast to consolidate Augusta for all periods presented. For purposes of calculating distributable cash flow attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recasted distributable cash flow earned during the periods prior to the acquisition by the Partnership on April 28, 2014 of substantially all of the remaining equity interests in Hi-Crush Augusta LLC (the "Augusta Contribution").

Reconciliation of Adjusted Net Income & EPU 21

Balance Sheet Remains Strong 22 $ in 000s As of December 31, 2015 Cash $ 10,414 Revolver1 $ 52,500 Term loan2 194,971 Other notes payable 6,924 Total debt $ 254,395 Net debt $ 243,981 Net debt / LTM Adj. EBITDA 2.98x Revolver availability (as amended)1 $ 39.8 million 1) Revolving credit agreement: $39.8 mm available at L+4.50% ($100 mm capacity less $52.5 mm of borrowings and $7.7 mm of LCs); includes accordion feature to increase capacity to $150 mm 2) Senior secured term loan: $200 mm original face value at L+3.75%; rated B3 and BB- by Moody’s and Standard & Poor’s, respectively; includes accordion feature to increase capacity to $300 mm Strong liquidity Financial flexibility