Attached files

| file | filename |

|---|---|

| 8-K - 8-K - MERCURY SYSTEMS INC | a8-k2015investordaypresent.htm |

© 2015 Mercury Systems, Inc. Mercury Systems FY16 Investor Day Presentation December 2, 2015 Nasdaq MarketSite New York, NY

2 © 2015 Mercury Systems, Inc. Forward-looking safe harbor statement This presentation contains certain forward-looking statements, as that term is defined in the Private Securities Litigation Reform Act of 1995, including those relating to the products and services described herein. You can identify these statements by the use of the words “may,” “will,” “could,” “should,” “would,” “plans,” “expects,” “anticipates,” “continue,” “estimate,” “project,” “intend,” “likely,” “forecast,” “probable,” “potential,” and similar expressions. These forward-looking statements involve risks and uncertainties that could cause actual results to differ materially from those projected or anticipated. Such risks and uncertainties include, but are not limited to, continued funding of defense programs, the timing and amounts of such funding, general economic and business conditions, including unforeseen weakness in the Company’s markets, effects of continued geopolitical unrest and regional conflicts, competition, changes in technology and methods of marketing, delays in completing engineering and manufacturing programs, changes in customer order patterns, changes in product mix, continued success in technological advances and delivering technological innovations, changes in, or in the U.S. Government’s interpretation of, federal export control or procurement rules and regulations, market acceptance of the Company's products, shortages in components, production delays or unanticipated expenses due to performance quality issues with outsourced components, inability to fully realize the expected benefits from acquisitions and restructurings, or delays in realizing such benefits, challenges in integrating acquired businesses and achieving anticipated synergies, changes to export regulations, increases in tax rates, changes to generally accepted accounting principles, difficulties in retaining key employees and customers, unanticipated costs under fixed-price service and system integration engagements, and various other factors beyond our control. These risks and uncertainties also include such additional risk factors as are discussed in the Company's filings with the U.S. Securities and Exchange Commission, including its Annual Report on Form 10-K for the fiscal year ended June 30, 2015. The Company cautions readers not to place undue reliance upon any such forward-looking statements, which speak only as of the date made. The Company undertakes no obligation to update any forward-looking statement to reflect events or circumstances after the date on which such statement is made. Use of Non-GAAP (Generally Accepted Accounting Principles) Financial Measures In addition to reporting financial results in accordance with generally accepted accounting principles, or GAAP, the Company provides adjusted EBITDA, adjusted income from continuing operations, and adjusted EPS which are non-GAAP financial measures. Adjusted EBITDA, adjusted income from continuing operations, and adjusted EPS exclude certain non-cash and other specified charges. The Company believes these non-GAAP financial measures are useful to help investors better understand its past financial performance and prospects for the future. However, the presentation of adjusted EBITDA, adjusted income from continuing operations and adjusted EPS is not meant to be considered in isolation or as a substitute for financial information provided in accordance with GAAP. Management believes the adjusted EBITDA, adjusted income from continuing operations, and adjusted EPS financial measures assist in providing a more complete understanding of the Company’s underlying operational results and trends, and management uses these measures along with the corresponding GAAP financial measures to manage the Company’s business, to evaluate its performance compared to prior periods and the marketplace, and to establish operational goals. A reconciliation of GAAP to non-GAAP financial results discussed in this presentation is contained in the Appendix hereto.

3 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Agenda • Strategy & Business Update – Mark Aslett President & CEO • Program Update • Financial Update • Q&A

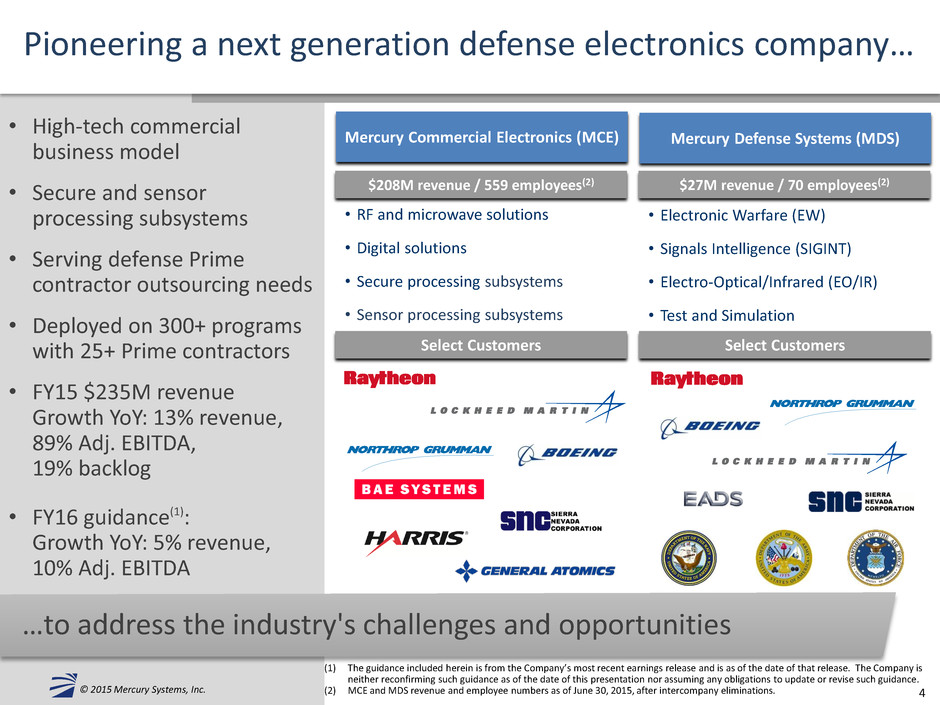

4 © 2015 Mercury Systems, Inc. …to address the industry's challenges and opportunities Pioneering a next generation defense electronics company… • High-tech commercial business model • Secure and sensor processing subsystems • Serving defense Prime contractor outsourcing needs • Deployed on 300+ programs with 25+ Prime contractors • FY15 $235M revenue Growth YoY: 13% revenue, 89% Adj. EBITDA, 19% backlog • FY16 guidance(1): Growth YoY: 5% revenue, 10% Adj. EBITDA Mercury Commercial Electronics (MCE) • RF and microwave solutions • Digital solutions • Secure processing subsystems • Sensor processing subsystems Select Customers $208M revenue / 559 employees(2) Mercury Defense Systems (MDS) • Electronic Warfare (EW) • Signals Intelligence (SIGINT) • Electro-Optical/Infrared (EO/IR) • Test and Simulation Select Customers $27M revenue / 70 employees(2) (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance. (2) MCE and MDS revenue and employee numbers as of June 30, 2015, after intercompany eliminations.

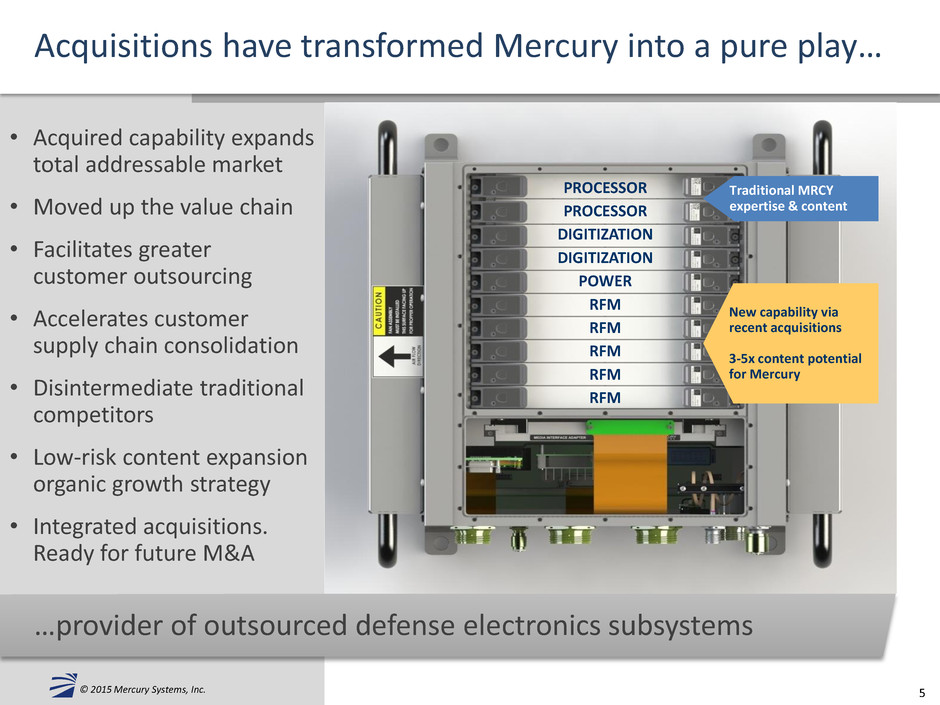

5 © 2015 Mercury Systems, Inc. …provider of outsourced defense electronics subsystems Acquisitions have transformed Mercury into a pure play… • Acquired capability expands total addressable market • Moved up the value chain • Facilitates greater customer outsourcing • Accelerates customer supply chain consolidation • Disintermediate traditional competitors • Low-risk content expansion organic growth strategy • Integrated acquisitions. Ready for future M&A PROCESSOR PROCESSOR DIGITIZATION DIGITIZATION POWER RFM RFM RFM RFM RFM Traditional MRCY expertise & content New capability via recent acquisitions 3-5x content potential for Mercury

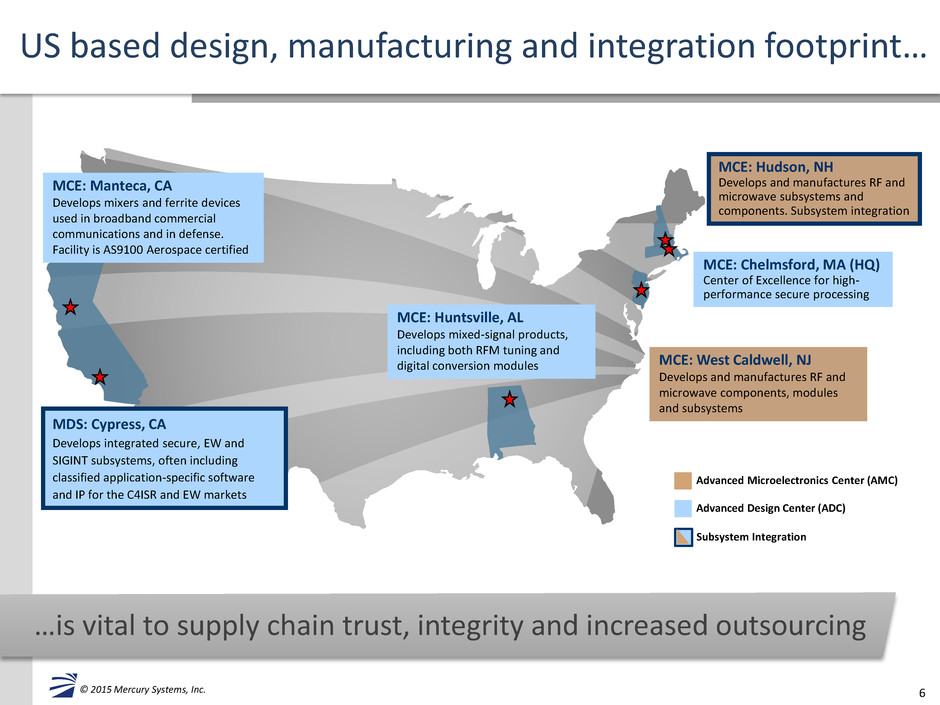

6 © 2015 Mercury Systems, Inc. US based design, manufacturing and integration footprint… …is vital to supply chain trust, integrity and increased outsourcing MDS: Cypress, CA Develops integrated secure, EW and SIGINT subsystems, often including classified application-specific software and IP for the C4ISR and EW markets MCE: Manteca, CA Develops mixers and ferrite devices used in broadband commercial communications and in defense. Facility is AS9100 Aerospace certified MCE: West Caldwell, NJ Develops and manufactures RF and microwave components, modules and subsystems MCE: Chelmsford, MA (HQ) Center of Excellence for high- performance secure processing MCE: Huntsville, AL Develops mixed-signal products, including both RFM tuning and digital conversion modules MCE: Hudson, NH Develops and manufactures RF and microwave subsystems and components. Subsystem integration Advanced Microelectronics Center (AMC) Advanced Design Center (ADC) Subsystem Integration

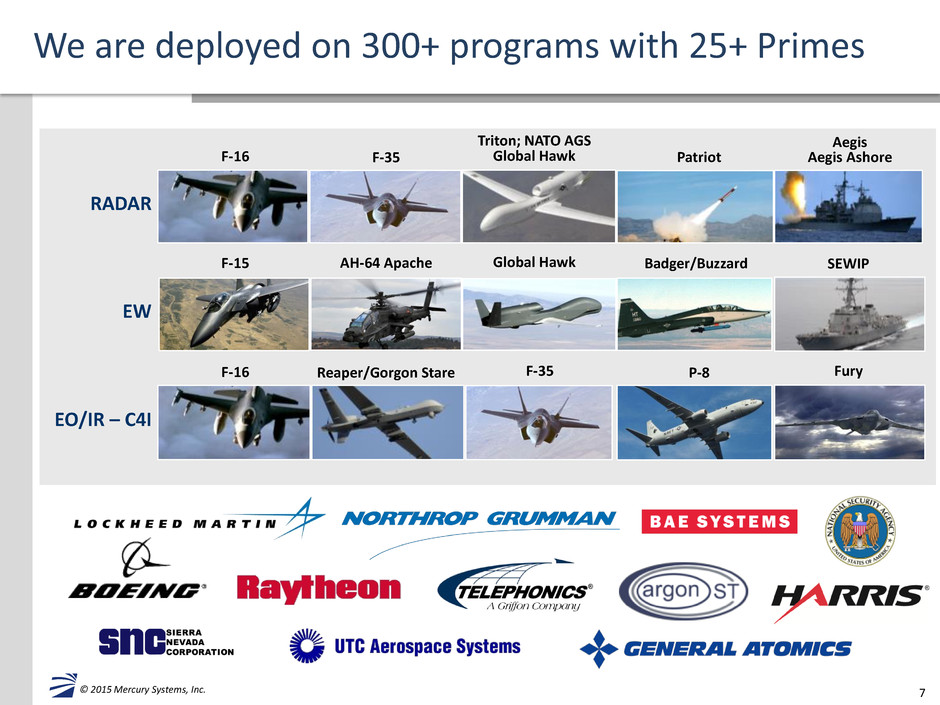

7 © 2015 Mercury Systems, Inc. We are deployed on 300+ programs with 25+ Primes RADAR EW EO/IR – C4I Triton; NATO AGS Global Hawk Aegis Aegis Ashore Patriot F-16 F-35 Global Hawk SEWIP Badger/Buzzard F-15 AH-64 Apache F-35 Fury P-8 F-16 Reaper/Gorgon Stare

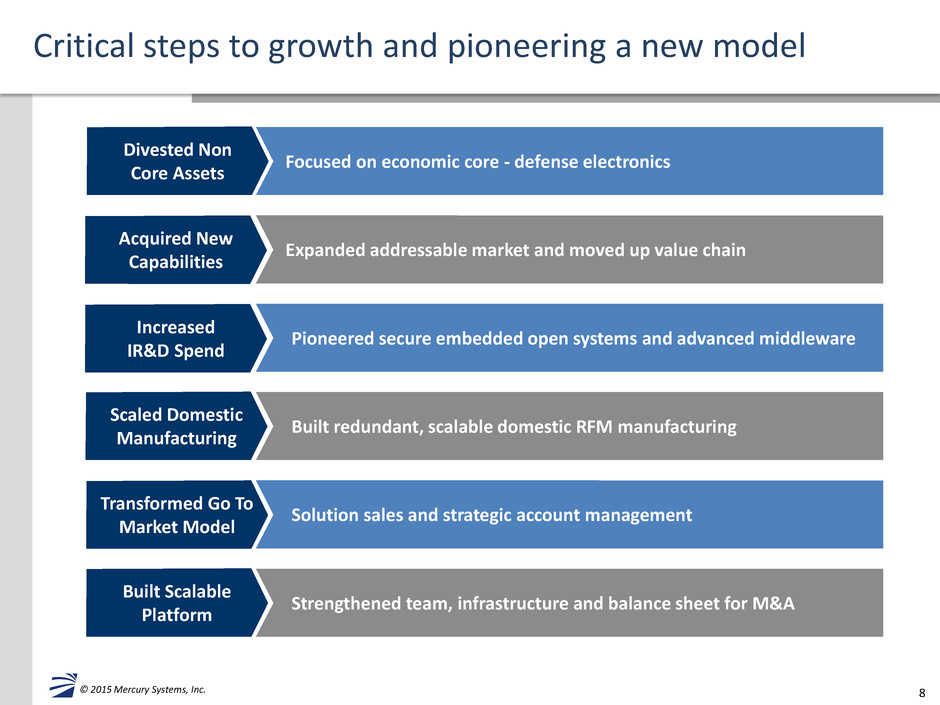

8 © 2015 Mercury Systems, Inc. Critical steps to growth and pioneering a new model Focused on economic core - defense electronics Divested Non Core Assets Expanded addressable market and moved up value chain Pioneered secure embedded open systems and advanced middleware Built redundant, scalable domestic RFM manufacturing Solution sales and strategic account management Strengthened team, infrastructure and balance sheet for M&A Acquired New Capabilities Increased IR&D Spend Scaled Domestic Manufacturing Transformed Go To Market Model Built Scalable Platform

9 © 2015 Mercury Systems, Inc. Defense will likely remain a $500B+ industry… …despite the ongoing political and budget uncertainty Crowding Out of Defense Spending and Investment: Rising interest rates, healthcare and social spending; MilPer expense growth, aging military platforms’ O&M costs rising Defense Procurement Reform 3.0: Firm-fixed-price contracts and less government-funded R&D changing economics and competitive dynamics of defense industry Political Dysfunction: Sequestration-driven cuts and repeated Continuing Resolutions disrupting DoD budget process and spending Industry Has Cut Capacity to Innovate: Reduced headcount, fewer engineers and aging workforce; Less IR&D and growth investments, increased dividends and buybacks

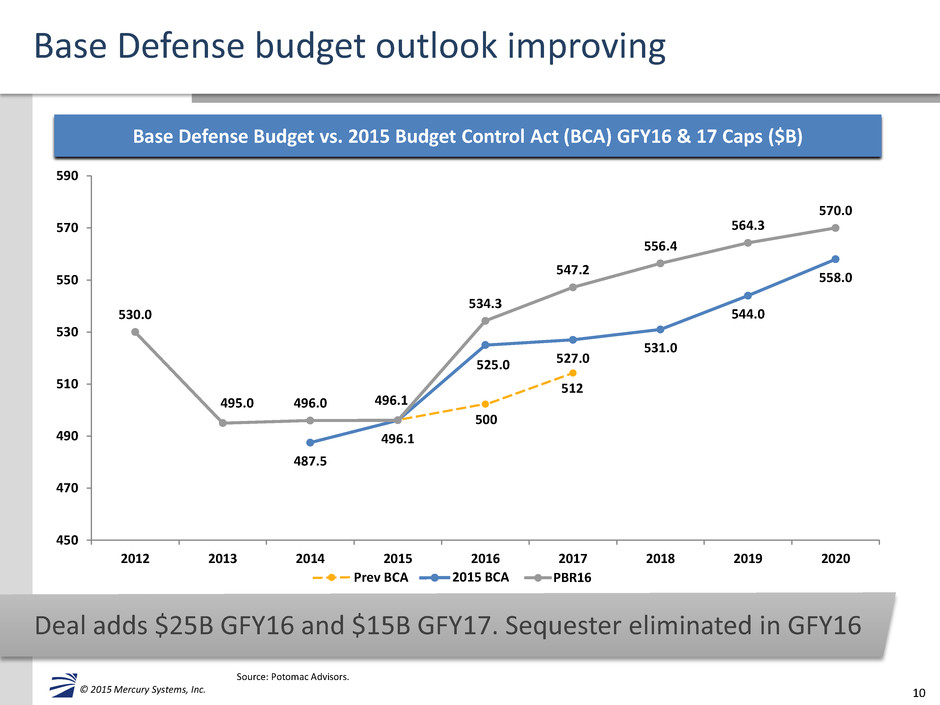

10 © 2015 Mercury Systems, Inc. 487.5 496.1 525.0 527.0 531.0 544.0 558.0 530.0 495.0 496.0 496.1 534.3 547.2 556.4 564.3 570.0 450 470 490 510 530 550 570 590 2012 2013 2014 2015 2016 2017 2018 2019 2020 PBR16 500 512 Prev BCA 2015 BCA Base Defense budget outlook improving Deal adds $25B GFY16 and $15B GFY17. Sequester eliminated in GFY16 Source: Potomac Advisors. Base Defense Budget vs. 2015 Budget Control Act (BCA) GFY16 & 17 Caps ($B)

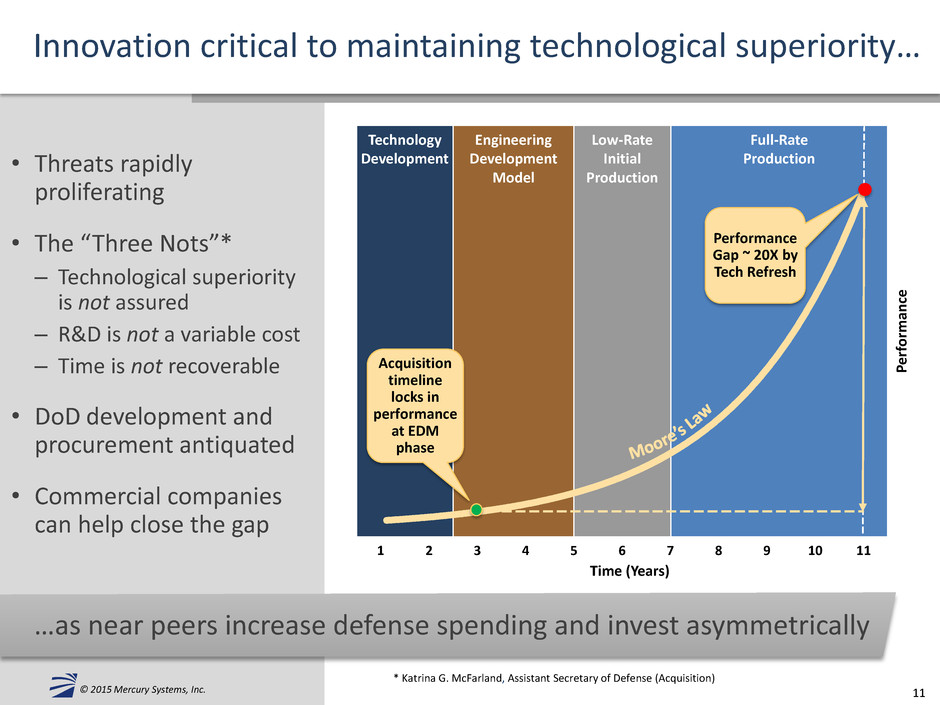

11 © 2015 Mercury Systems, Inc. …as near peers increase defense spending and invest asymmetrically Innovation critical to maintaining technological superiority… • Threats rapidly proliferating • The “Three Nots”* – Technological superiority is not assured – R&D is not a variable cost – Time is not recoverable • DoD development and procurement antiquated • Commercial companies can help close the gap Time (Years) Full-Rate Production Technology Development Engineering Development Model Low-Rate Initial Production 1 2 3 4 5 6 7 8 9 10 11 P er fo rm an ce Acquisition timeline locks in performance at EDM phase Performance Gap ~ 20X by Tech Refresh * Katrina G. McFarland, Assistant Secretary of Defense (Acquisition)

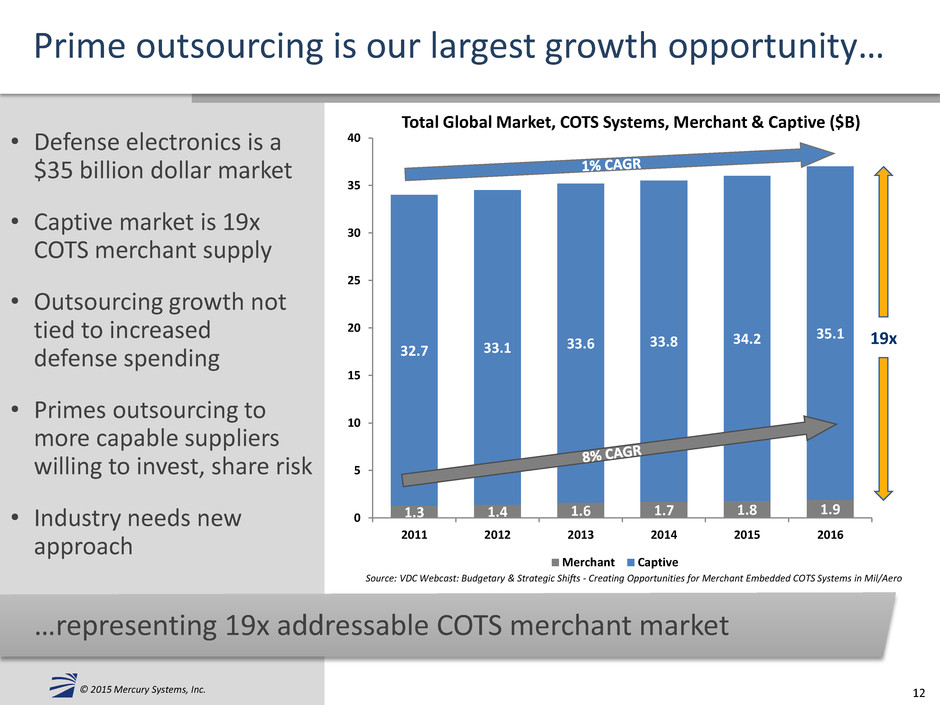

12 © 2015 Mercury Systems, Inc. …representing 19x addressable COTS merchant market Prime outsourcing is our largest growth opportunity… • Defense electronics is a $35 billion dollar market • Captive market is 19x COTS merchant supply • Outsourcing growth not tied to increased defense spending • Primes outsourcing to more capable suppliers willing to invest, share risk • Industry needs new approach Source: VDC Webcast: Budgetary & Strategic Shifts - Creating Opportunities for Merchant Embedded COTS Systems in Mil/Aero 1.3 1.4 1.6 1.7 1.8 1.9 32.7 33.1 33.6 33.8 34.2 35.1 0 5 10 15 20 25 30 35 40 2011 2012 2013 2014 2015 2016 Merchant Captive 19x Total Global Market, COTS Systems, Merchant & Captive ($B)

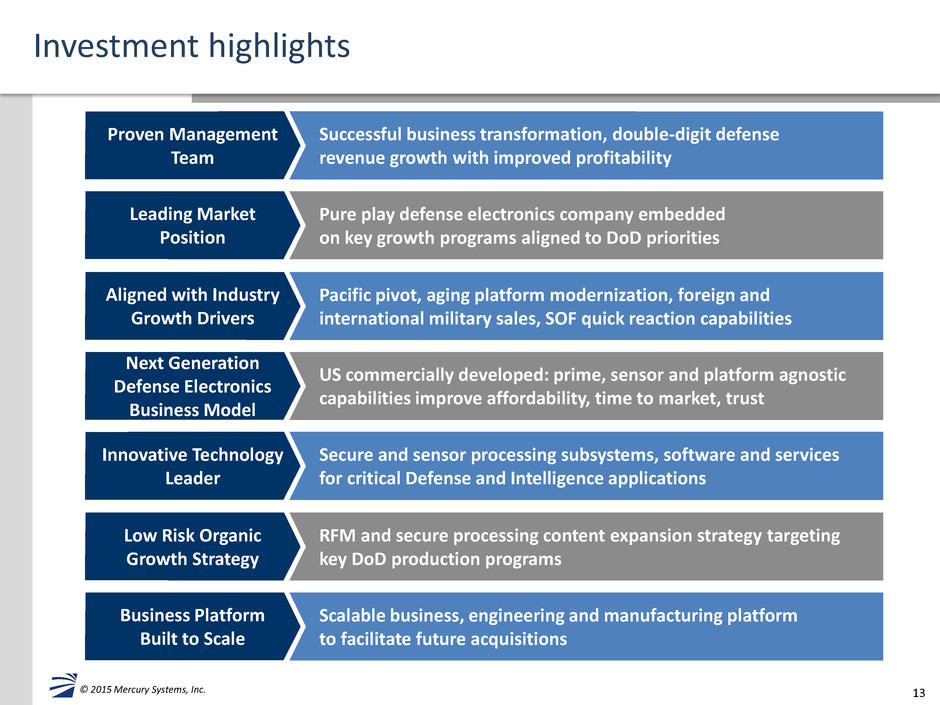

13 © 2015 Mercury Systems, Inc. Investment highlights Successful business transformation, double-digit defense revenue growth with improved profitability Proven Management Team Pure play defense electronics company embedded on key growth programs aligned to DoD priorities Leading Market Position Pacific pivot, aging platform modernization, foreign and international military sales, SOF quick reaction capabilities Aligned with Industry Growth Drivers US commercially developed: prime, sensor and platform agnostic capabilities improve affordability, time to market, trust Next Generation Defense Electronics Business Model Secure and sensor processing subsystems, software and services for critical Defense and Intelligence applications Innovative Technology Leader RFM and secure processing content expansion strategy targeting key DoD production programs Low Risk Organic Growth Strategy Scalable business, engineering and manufacturing platform to facilitate future acquisitions Business Platform Built to Scale

14 © 2015 Mercury Systems, Inc. Mercury’s vision is to be the… Leading high-tech commercial provider of affordable secure and sensor processing subsystems designed and made in the USA

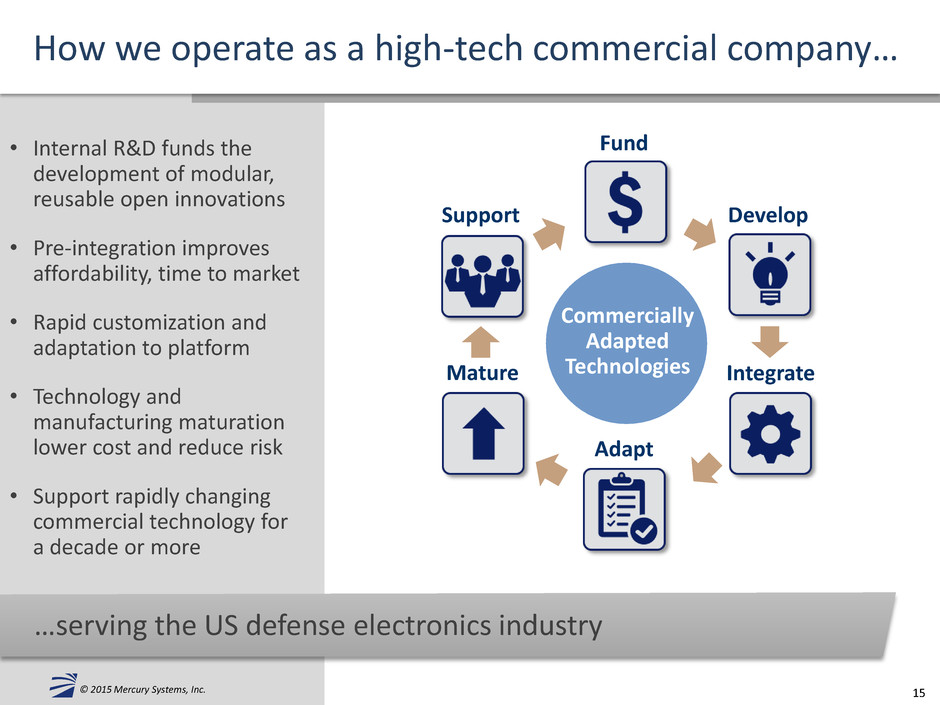

15 © 2015 Mercury Systems, Inc. …serving the US defense electronics industry How we operate as a high-tech commercial company… • Internal R&D funds the development of modular, reusable open innovations • Pre-integration improves affordability, time to market • Rapid customization and adaptation to platform • Technology and manufacturing maturation lower cost and reduce risk • Support rapidly changing commercial technology for a decade or more Fund Develop Integrate Mature Support Adapt Commercially Adapted Technologies

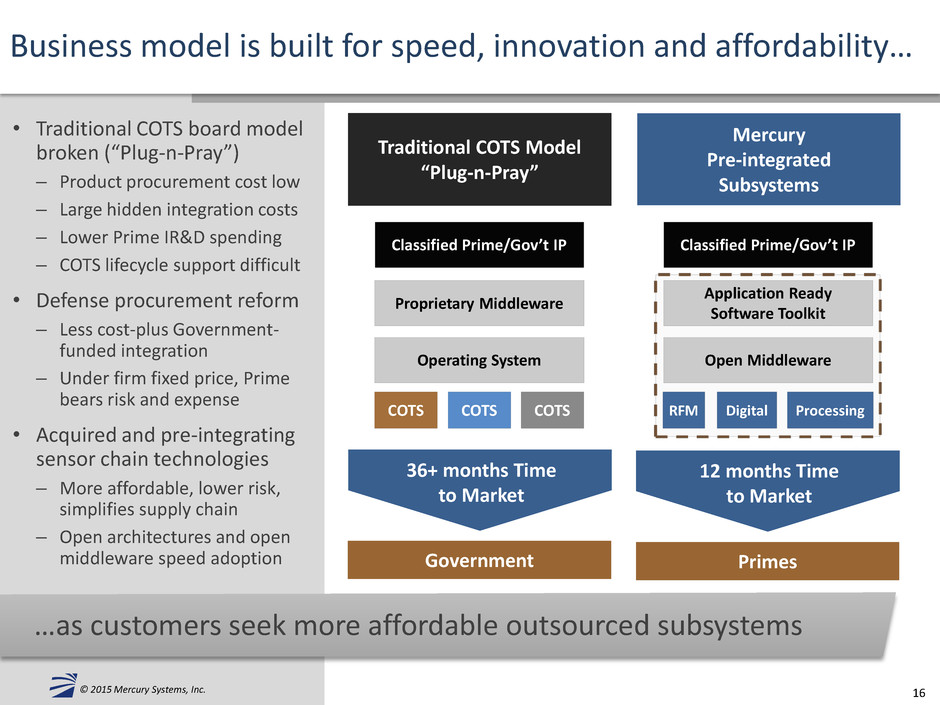

16 © 2015 Mercury Systems, Inc. …as customers seek more affordable outsourced subsystems Business model is built for speed, innovation and affordability… • Traditional COTS board model broken (“Plug-n-Pray”) – Product procurement cost low – Large hidden integration costs – Lower Prime IR&D spending – COTS lifecycle support difficult • Defense procurement reform – Less cost-plus Government- funded integration – Under firm fixed price, Prime bears risk and expense • Acquired and pre-integrating sensor chain technologies – More affordable, lower risk, simplifies supply chain – Open architectures and open middleware speed adoption Primes RFM Digital Processing Mercury Pre-integrated Subsystems Government Traditional COTS Model “Plug-n-Pray” Operating System COTS COTS COTS Proprietary Middleware Classified Prime/Gov’t IP 36+ months Time to Market 12 months Time to Market Open Middleware Application Ready Software Toolkit Classified Prime/Gov’t IP

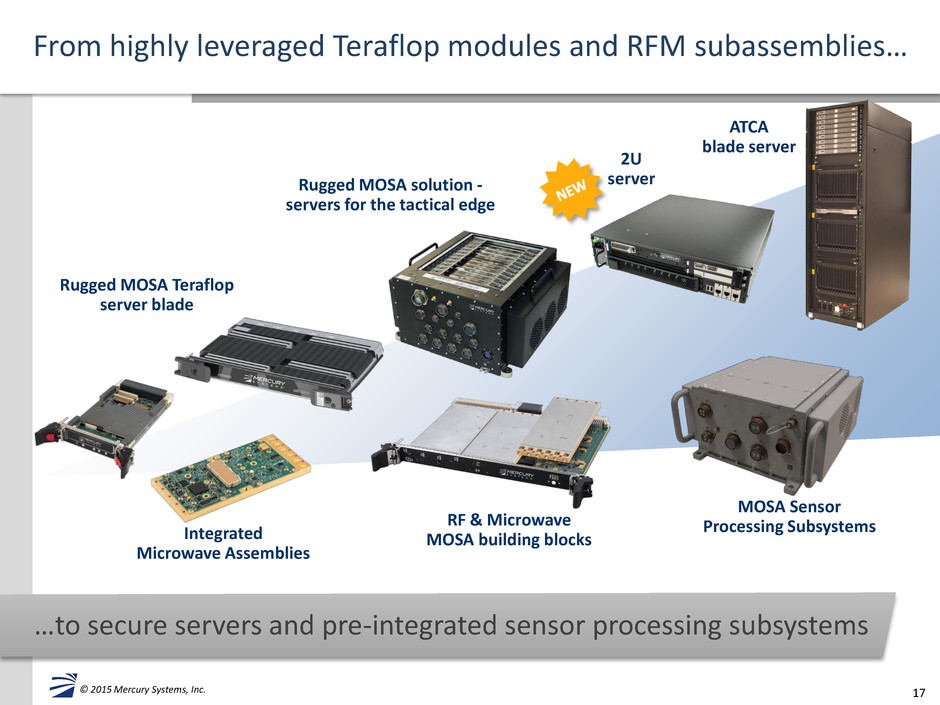

17 © 2015 Mercury Systems, Inc. From highly leveraged Teraflop modules and RFM subassemblies… …to secure servers and pre-integrated sensor processing subsystems Rugged MOSA Teraflop server blade Rugged MOSA solution - servers for the tactical edge ATCA blade server Integrated Microwave Assemblies MOSA Sensor Processing Subsystems RF & Microwave MOSA building blocks 2U server

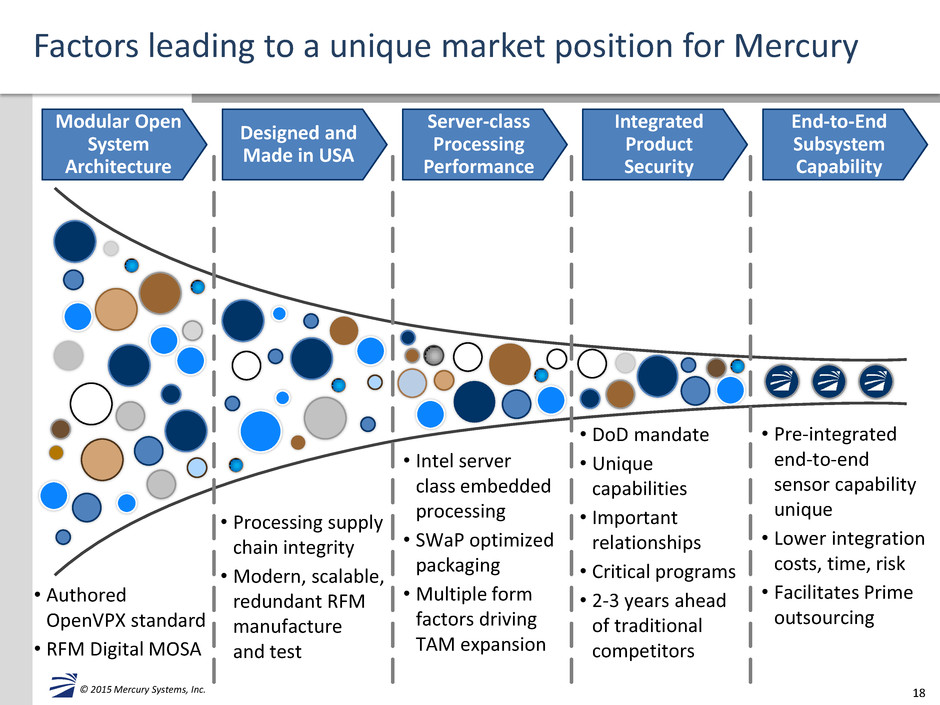

18 © 2015 Mercury Systems, Inc. • Pre-integrated end-to-end sensor capability unique • Lower integration costs, time, risk • Facilitates Prime outsourcing • DoD mandate • Unique capabilities • Important relationships • Critical programs • 2-3 years ahead of traditional competitors • Intel server class embedded processing • SWaP optimized packaging •Multiple form factors driving TAM expansion Factors leading to a unique market position for Mercury • Processing supply chain integrity • Modern, scalable, redundant RFM manufacture and test • Authored OpenVPX standard • RFM Digital MOSA Modular Open System Architecture Designed and Made in USA Server-class Processing Performance Integrated Product Security End-to-End Subsystem Capability

19 © 2015 Mercury Systems, Inc. Mercury’s capabilities and opportunity for growth… …are aligned to DoD investment priorities Pacific Pivot: Platforms need improved sensors, autonomy, electronic protection and attack, on-board exploitation. Greater demand for onboard processing Aging Platform Modernization: Port customer software to available state-of-the-art open architectures to rapidly and affordably upgrade electronics on aging military platforms International and Foreign Military Sales: Upgrade subsystems with security for export to expand addressable market, grow revenues and access international customer R&D funding Special Operations Forces Quick Reaction Capability: Provide rapid reaction and affordable new capabilities to support anti-terror and other special forces missions globally

20 © 2015 Mercury Systems, Inc. Defense industry growth drivers translate into specific… …company growth drivers that we are pursuing Outsourced Secure Processing Subsystems: Grow blade-server processing applications. Expand into other mission- critical secure compute applications beyond the sensor Outsourced Pre-Integrated Sensor Processing Subsystems: Provide more affordable pre-integrated MOSA sensor processing subsystems that preserves customer software value-add RF and Microwave Outsourcing: Grow share in integrated RF and microwave assemblies and MOSA RF subsystems by providing customers a better alternative

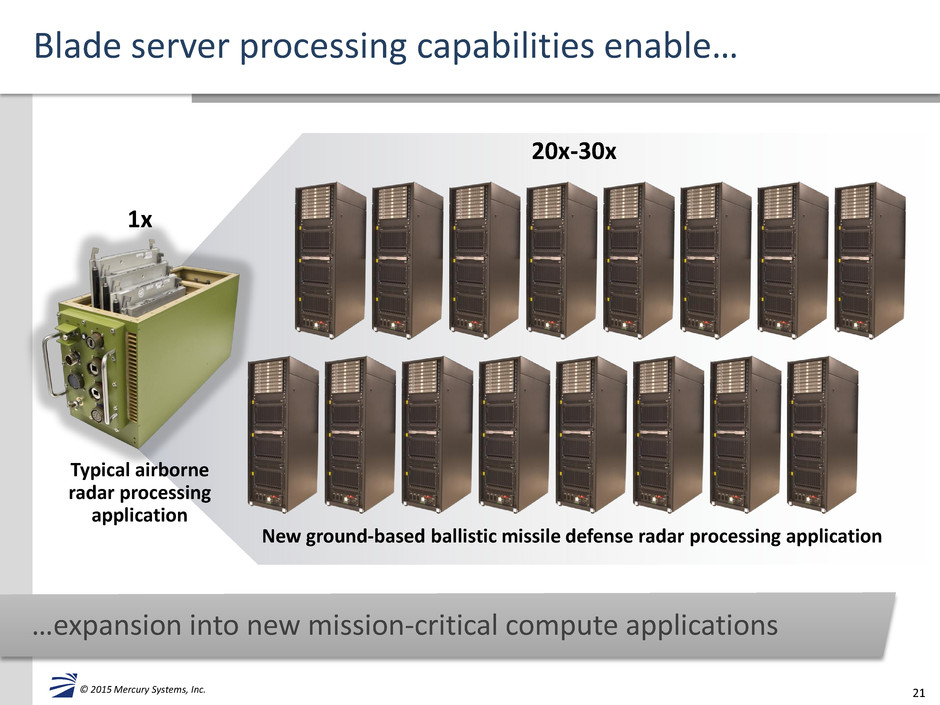

21 © 2015 Mercury Systems, Inc. Blade server processing capabilities enable… …expansion into new mission-critical compute applications 1x 20x-30x Typical airborne radar processing application New ground-based ballistic missile defense radar processing application

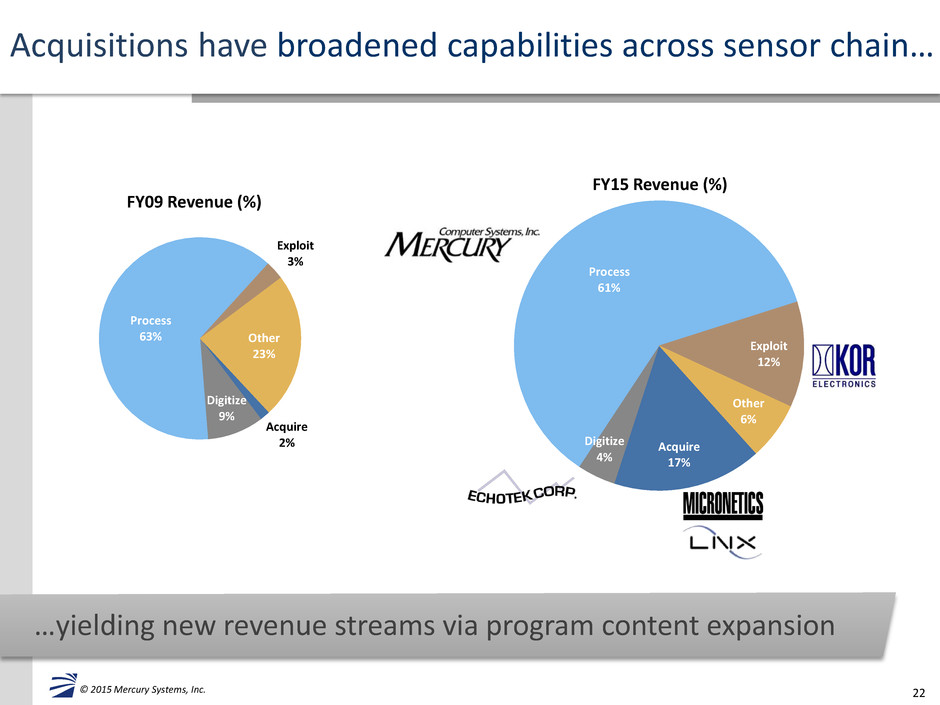

22 © 2015 Mercury Systems, Inc. Acquisitions have broadened capabilities across sensor chain… …yielding new revenue streams via program content expansion Acquire 17% Digitize 4% Process 61% Exploit 12% Other 6% FY15 Revenue (%) Acquire 2% Digitize 9% Process 63% Exploit 3% Other 23% FY09 Revenue (%)

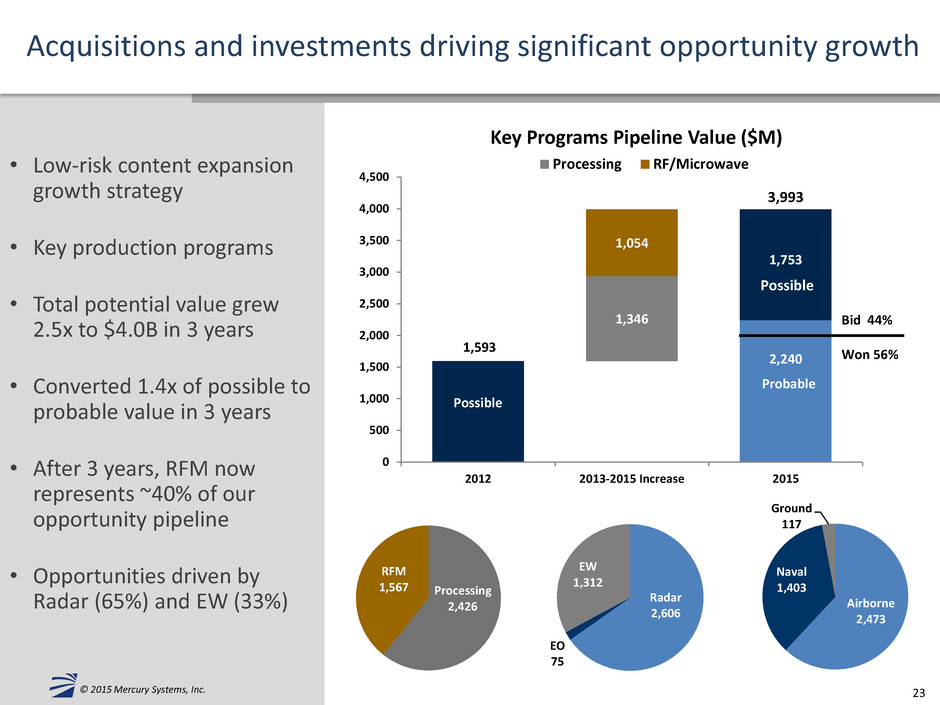

23 © 2015 Mercury Systems, Inc. Acquisitions and investments driving significant opportunity growth • Low-risk content expansion growth strategy • Key production programs • Total potential value grew 2.5x to $4.0B in 3 years • Converted 1.4x of possible to probable value in 3 years • After 3 years, RFM now represents ~40% of our opportunity pipeline • Opportunities driven by Radar (65%) and EW (33%) Processing 2,426 RFM 1,567 Radar 2,606 EO 75 EW 1,312 Airborne 2,473 Naval 1,403 Ground 117 2,240 1,593 1,753 1,346 1,054 0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 2012 2013-2015 Increase 2015 Key Programs Pipeline Value ($M) Processing RF/Microwave 3,993 Probable Possible Possible Bid 44% Won 56%

24 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Strategy and investments have positioned Mercury well • Pioneering a next-generation defense electronics business model • Unique technology and capabilities on key production programs • Low-risk content expansion growth strategy with demonstrable progress • Largest secular growth opportunity captive Prime outsourcing • Above industry-average growth; dramatic improvement in profitability • Business platform built to grow and scale through future acquisitions

25 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Agenda • Strategy & Business Update • Program Update – Didier Thibaud President, Mercury Commercial Electronics (MCE) • Financial Update • Q&A

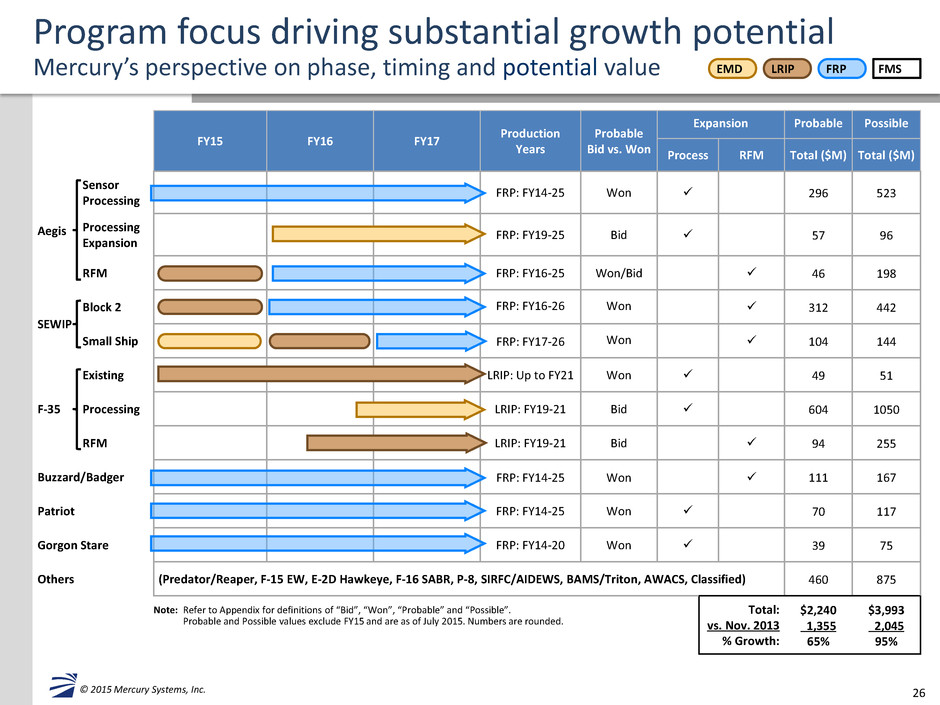

26 © 2015 Mercury Systems, Inc. FY15 FY16 FY17 Production Years Probable Bid vs. Won Expansion Probable Possible Process RFM Total ($M) Total ($M) Aegis Sensor Processing FRP: FY14-25 Won 296 523 Processing Expansion FRP: FY19-25 Bid 57 96 RFM FRP: FY16-25 Won/Bid 46 198 SEWIP Block 2 FRP: FY16-26 Won 312 442 Small Ship FRP: FY17-26 Won 104 144 F-35 Existing LRIP: Up to FY21 Won 49 51 Processing LRIP: FY19-21 Bid 604 1050 RFM LRIP: FY19-21 Bid 94 255 Buzzard/Badger FRP: FY14-25 Won 111 167 Patriot FRP: FY14-25 Won 70 117 Gorgon Stare FRP: FY14-20 Won 39 75 Others (Predator/Reaper, F-15 EW, E-2D Hawkeye, F-16 SABR, P-8, SIRFC/AIDEWS, BAMS/Triton, AWACS, Classified) 460 875 Total: vs. Nov. 2013 % Growth: $2,240 1,355 65% $3,993 2,045 95% Program focus driving substantial growth potential Mercury’s perspective on phase, timing and potential value EMD LRIP FRP FMS Note: Refer to Appendix for definitions of “Bid”, “Won”, “Probable” and “Possible”. Probable and Possible values exclude FY15 and are as of July 2015. Numbers are rounded.

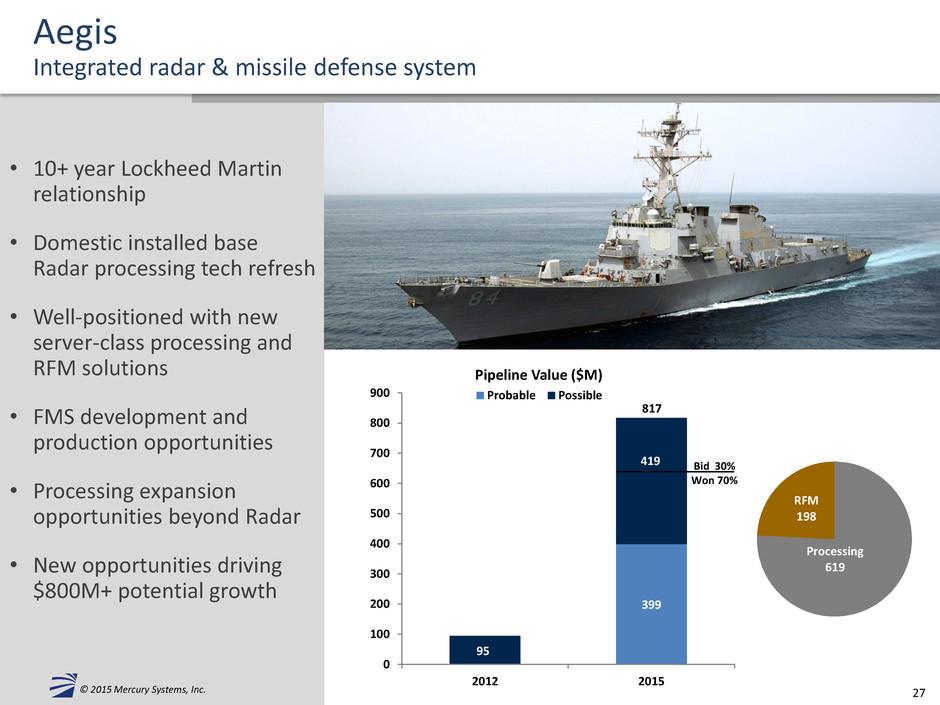

27 © 2015 Mercury Systems, Inc. Processing 619 RFM 198 Aegis Integrated radar & missile defense system • 10+ year Lockheed Martin relationship • Domestic installed base Radar processing tech refresh • Well-positioned with new server-class processing and RFM solutions • FMS development and production opportunities • Processing expansion opportunities beyond Radar • New opportunities driving $800M+ potential growth 399 95 419 0 100 200 300 400 500 600 700 800 900 2012 2015 Probable Possible 817 Bid 30% Won 70% Pipeline Value ($M)

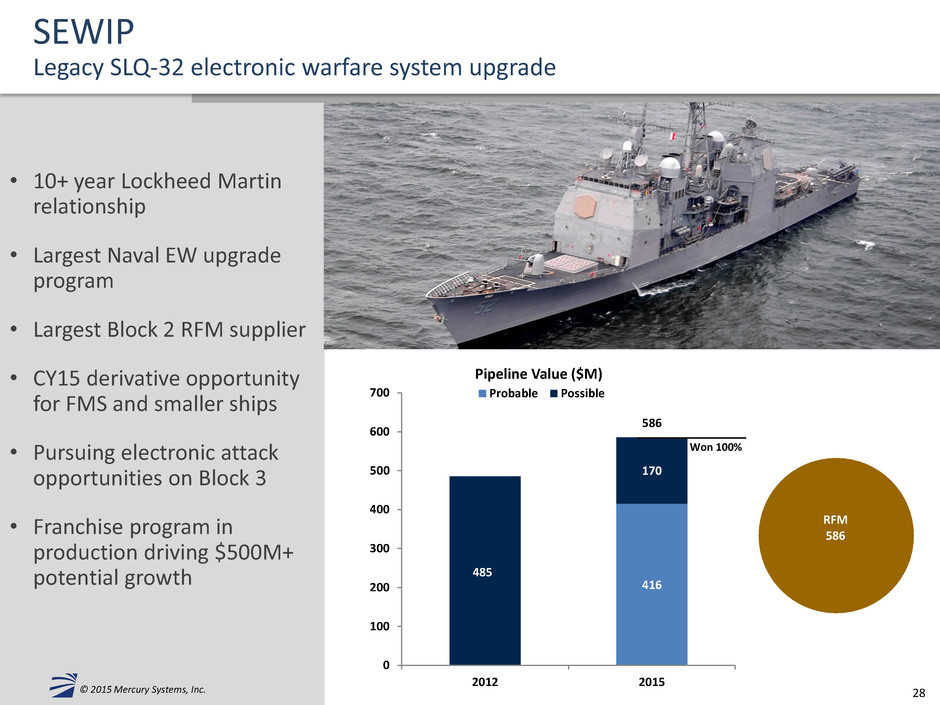

28 © 2015 Mercury Systems, Inc. RFM 586 SEWIP Legacy SLQ-32 electronic warfare system upgrade • 10+ year Lockheed Martin relationship • Largest Naval EW upgrade program • Largest Block 2 RFM supplier • CY15 derivative opportunity for FMS and smaller ships • Pursuing electronic attack opportunities on Block 3 • Franchise program in production driving $500M+ potential growth 416 485 170 0 100 200 300 400 500 600 700 2012 2015 Probable Possible 586 Won 100% Pipeline Value ($M)

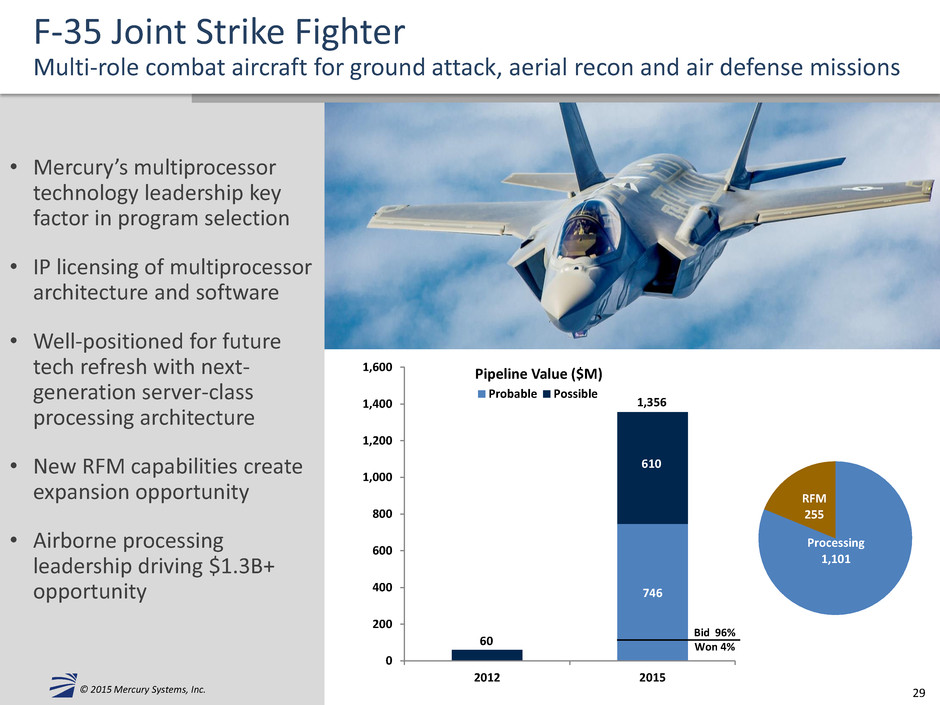

29 © 2015 Mercury Systems, Inc. Processing 1,101 RFM 255 F-35 Joint Strike Fighter Multi-role combat aircraft for ground attack, aerial recon and air defense missions • Mercury’s multiprocessor technology leadership key factor in program selection • IP licensing of multiprocessor architecture and software • Well-positioned for future tech refresh with next- generation server-class processing architecture • New RFM capabilities create expansion opportunity • Airborne processing leadership driving $1.3B+ opportunity 746 60 610 0 200 400 600 800 1,000 1,200 1,400 1,600 2012 2015 Probable Possible 1,356 Bid 96% Won 4% Pipeline Value ($M)

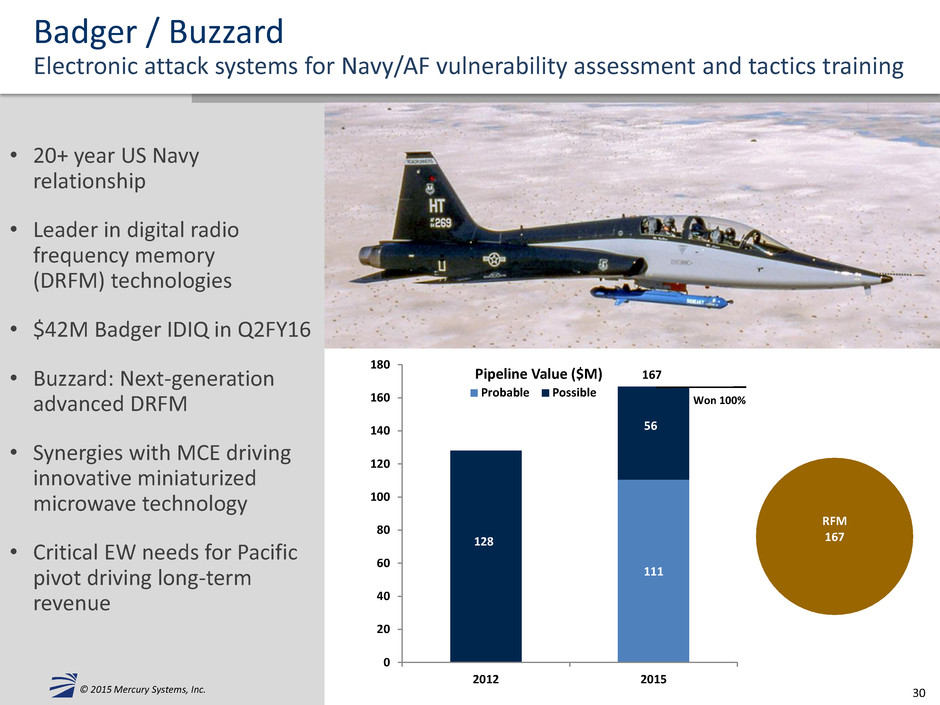

30 © 2015 Mercury Systems, Inc. Badger / Buzzard Electronic attack systems for Navy/AF vulnerability assessment and tactics training • 20+ year US Navy relationship • Leader in digital radio frequency memory (DRFM) technologies • $42M Badger IDIQ in Q2FY16 • Buzzard: Next-generation advanced DRFM • Synergies with MCE driving innovative miniaturized microwave technology • Critical EW needs for Pacific pivot driving long-term revenue 111 128 56 0 20 40 60 80 100 120 140 160 180 2012 2015 Probable Possible 167 Won 100% RFM 167 Pipeline Value ($M)

31 © 2015 Mercury Systems, Inc. Mercury’s technology leadership driving design win E-2D Advanced Hawkeye Navy’s new carrier-based tactical battle management aircraft • Upgrades Radar system, missile defense capabilities, multi-sensor integration • 75 aircraft Navy program; in FRP • Developed prototypes with LM for several years • Providing Radar processing subsystem using advanced packaging technology • Design win in Q4FY15 • $15M award in Q1FY16

32 © 2015 Mercury Systems, Inc. Strategic partnership and technology leadership fueling growth Long Range Discrimination Radar (LRDR) New ground-based ballistic missile defense Radar • Long-standing relationship with LM based on Aegis • Designed to protect U.S. from ballistic missile threats • Enhances target discrimination capability • Providing full server-class Radar processing subsystem • Leadership in server-class open architecture • Potential expansion to RFM

33 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Stable base of programs driving long-term visibility • Designed in on well-funded, long-standing programs of record • Aligned with DoD strategy and in growing areas of the budget • Leveraging long-standing relationships with key strategic accounts • Internal investment in innovation builds annuity revenue streams • Driving content and market expansion through RFM acquisitions

34 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Agenda • Strategy & Business Update • Program Update • Financial Update – Gerry Haines CFO • Q&A

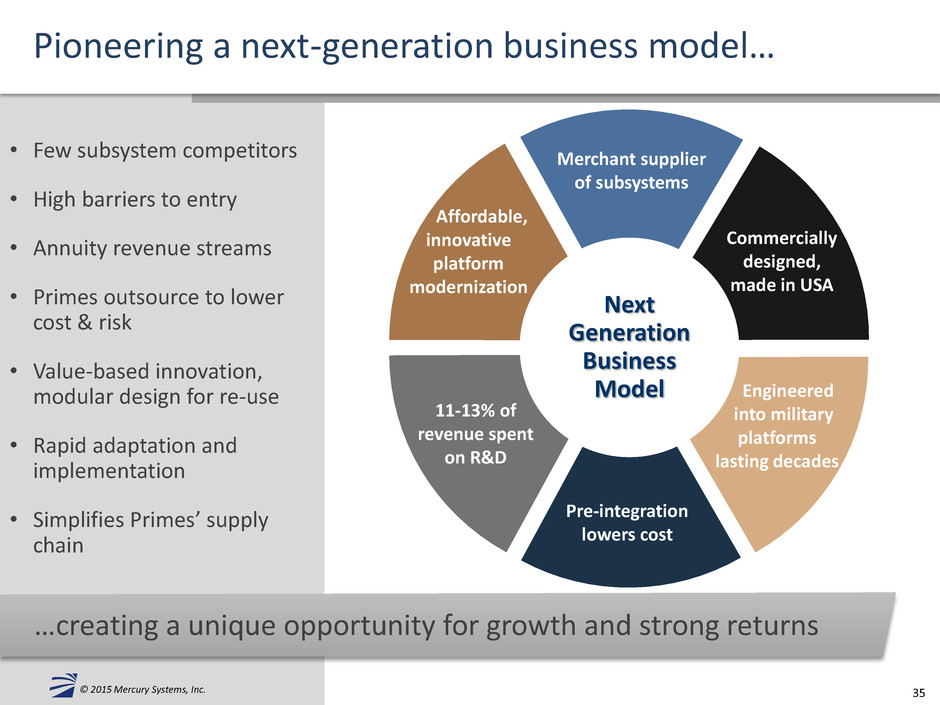

35 © 2015 Mercury Systems, Inc. …creating a unique opportunity for growth and strong returns Pioneering a next-generation business model… • Few subsystem competitors • High barriers to entry • Annuity revenue streams • Primes outsource to lower cost & risk • Value-based innovation, modular design for re-use • Rapid adaptation and implementation • Simplifies Primes’ supply chain Merchant supplier of subsystems Commercially designed, made in USA Engineered into military platforms lasting decades Pre-integration lowers cost Affordable, innovative platform modernization 11-13% of revenue spent on R&D Next Generation Business Model

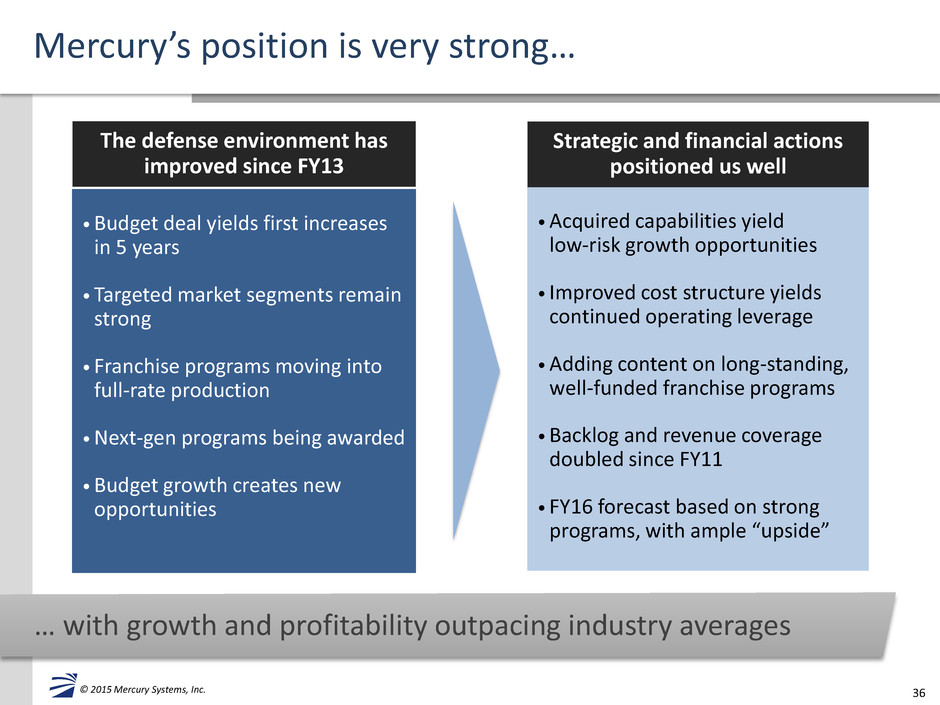

36 © 2015 Mercury Systems, Inc. Mercury’s position is very strong… … with growth and profitability outpacing industry averages •Budget deal yields first increases in 5 years •Targeted market segments remain strong • Franchise programs moving into full-rate production •Next-gen programs being awarded •Budget growth creates new opportunities The defense environment has improved since FY13 •Acquired capabilities yield low-risk growth opportunities •Improved cost structure yields continued operating leverage •Adding content on long-standing, well-funded franchise programs • Backlog and revenue coverage doubled since FY11 •FY16 forecast based on strong programs, with ample “upside” Strategic and financial actions positioned us well

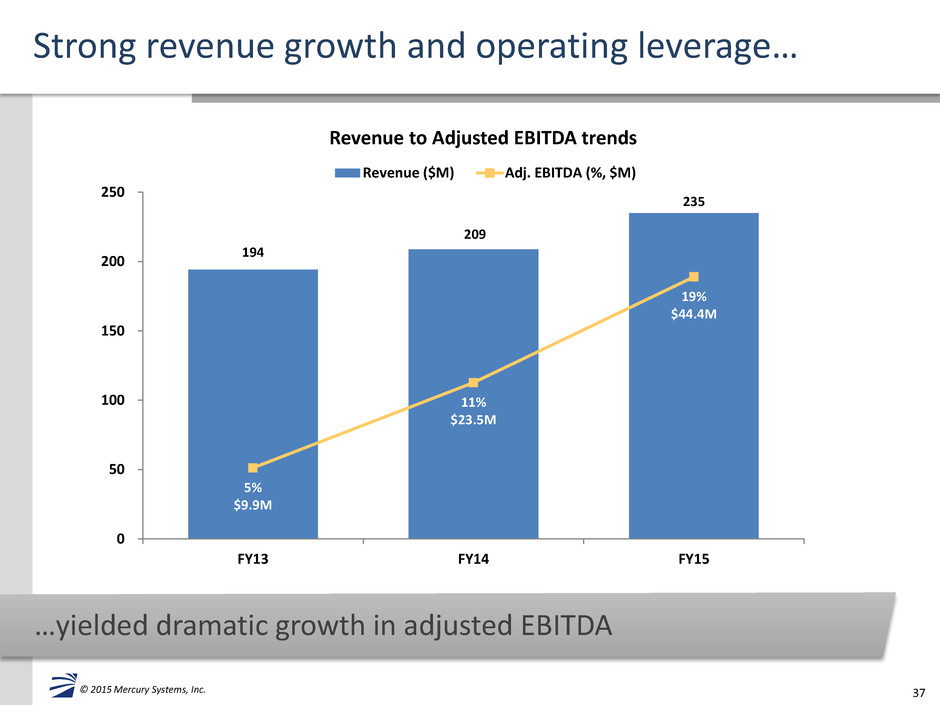

37 © 2015 Mercury Systems, Inc. Strong revenue growth and operating leverage… …yielded dramatic growth in adjusted EBITDA 194 209 235 5% $9.9M 11% $23.5M 19% $44.4M 0 50 100 150 200 250 FY13 FY14 FY15 Revenue to Adjusted EBITDA trends Revenue ($M) Adj. EBITDA (%, $M)

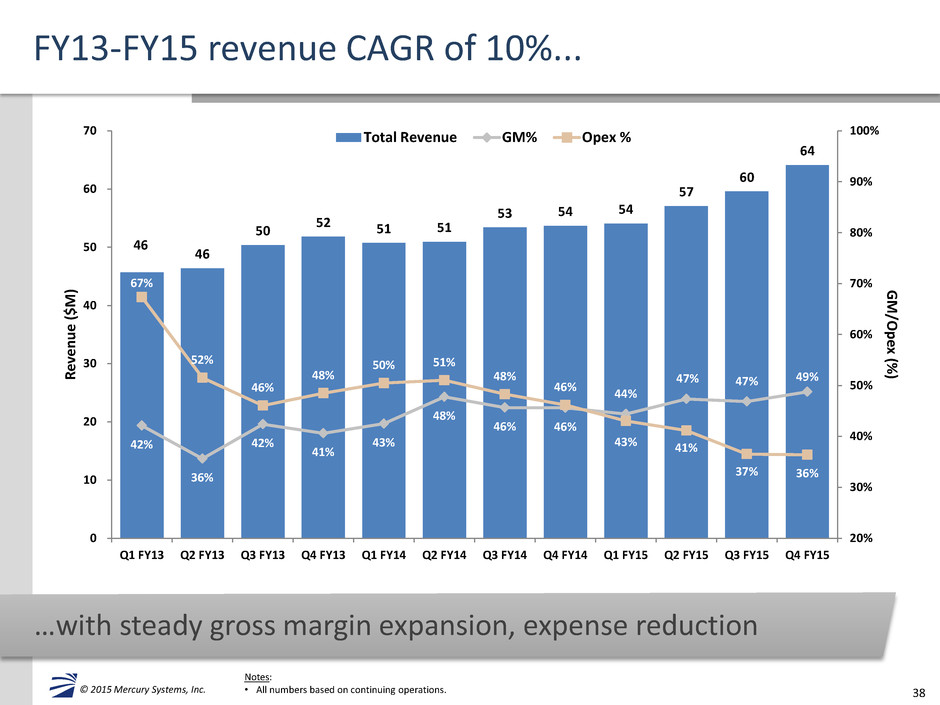

38 © 2015 Mercury Systems, Inc. FY13-FY15 revenue CAGR of 10%... …with steady gross margin expansion, expense reduction Notes: • All numbers based on continuing operations. 46 46 50 52 51 51 53 54 54 57 60 64 42% 36% 42% 41% 43% 48% 46% 46% 44% 47% 47% 49% 67% 52% 46% 48% 50% 51% 48% 46% 43% 41% 37% 36% 20% 30% 40% 50% 60% 70% 80% 90% 100% 0 10 20 30 40 50 60 70 Q1 FY13 Q2 FY13 Q3 FY13 Q4 FY13 Q1 FY14 Q2 FY14 Q3 FY14 Q4 FY14 Q1 FY15 Q2 FY15 Q3 FY15 Q4 FY15 GM/O p ex (% ) R ev en u e ($ M ) Total Revenue GM% Opex %

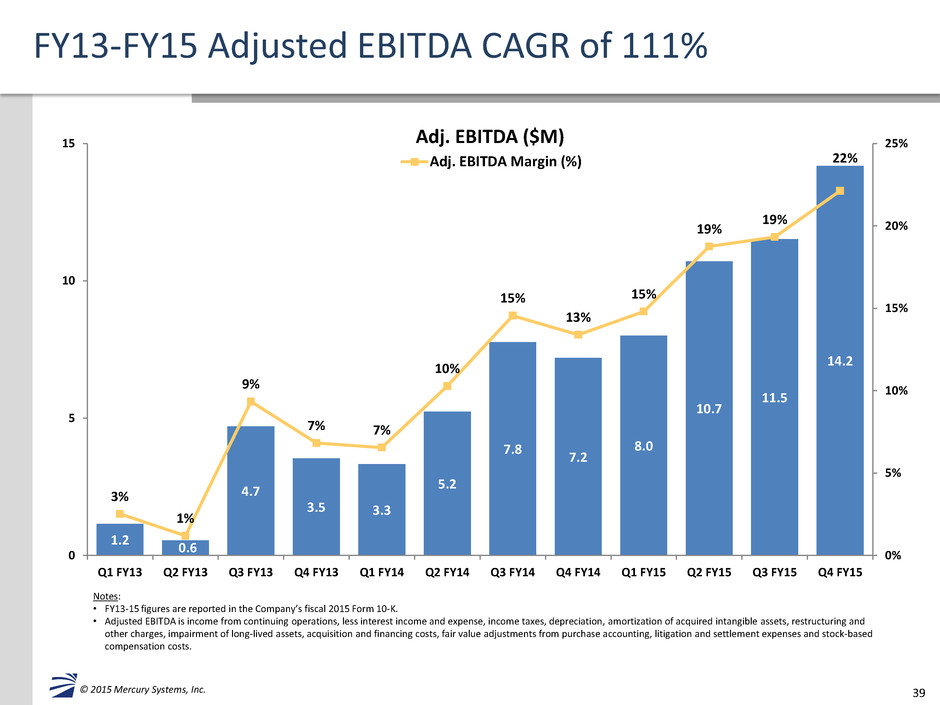

39 © 2015 Mercury Systems, Inc. FY13-FY15 Adjusted EBITDA CAGR of 111% Notes: • FY13-15 figures are reported in the Company’s fiscal 2015 Form 10-K. • Adjusted EBITDA is income from continuing operations, less interest income and expense, income taxes, depreciation, amortization of acquired intangible assets, restructuring and other charges, impairment of long-lived assets, acquisition and financing costs, fair value adjustments from purchase accounting, litigation and settlement expenses and stock-based compensation costs. 1.2 0.6 4.7 3.5 3.3 5.2 7.8 7.2 8.0 10.7 11.5 14.2 3% 1% 9% 7% 7% 10% 15% 13% 15% 19% 19% 22% 0% 5% 10% 15% 20% 25% 0 5 10 15 Q1 FY13 Q2 FY13 Q3 FY13 Q4 FY13 Q1 FY14 Q2 FY14 Q3 FY14 Q4 FY14 Q1 FY15 Q2 FY15 Q3 FY15 Q4 FY15 Adj. EBITDA ($M) Adj. EBITDA Margin (%)

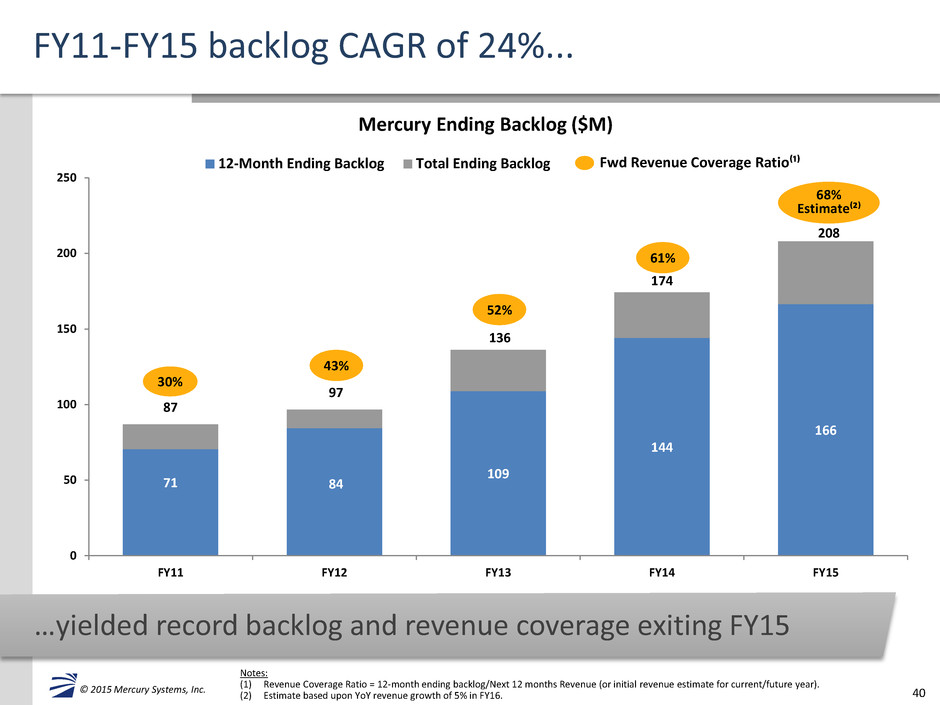

40 © 2015 Mercury Systems, Inc. FY11-FY15 backlog CAGR of 24%... …yielded record backlog and revenue coverage exiting FY15 Notes: (1) Revenue Coverage Ratio = 12-month ending backlog/Next 12 months Revenue (or initial revenue estimate for current/future year). (2) Estimate based upon YoY revenue growth of 5% in FY16. 71 84 109 144 166 87 97 136 174 208 0 50 100 150 200 250 FY11 FY12 FY13 FY14 FY15 Mercury Ending Backlog ($M) 12-Month Ending Backlog Total Ending Backlog 61% 30% 43% 52% 68% Estimate⁽²⁾ Fwd Revenue Coverage Ratio⁽¹⁾

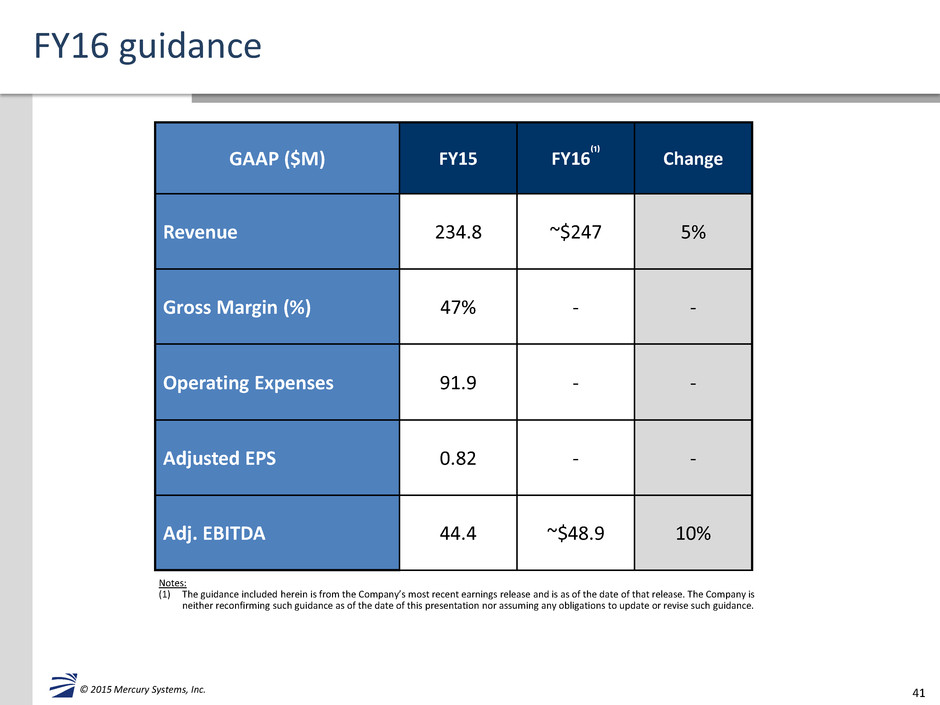

41 © 2015 Mercury Systems, Inc. FY16 guidance Notes: (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance. GAAP ($M) FY15 FY16⁽¹⁾ Change Revenue 234.8 ~$247 5% Gross Margin (%) 47% - - Operating Expenses 91.9 - - Adjusted EPS 0.82 - - Adj. EBITDA 44.4 ~$48.9 10%

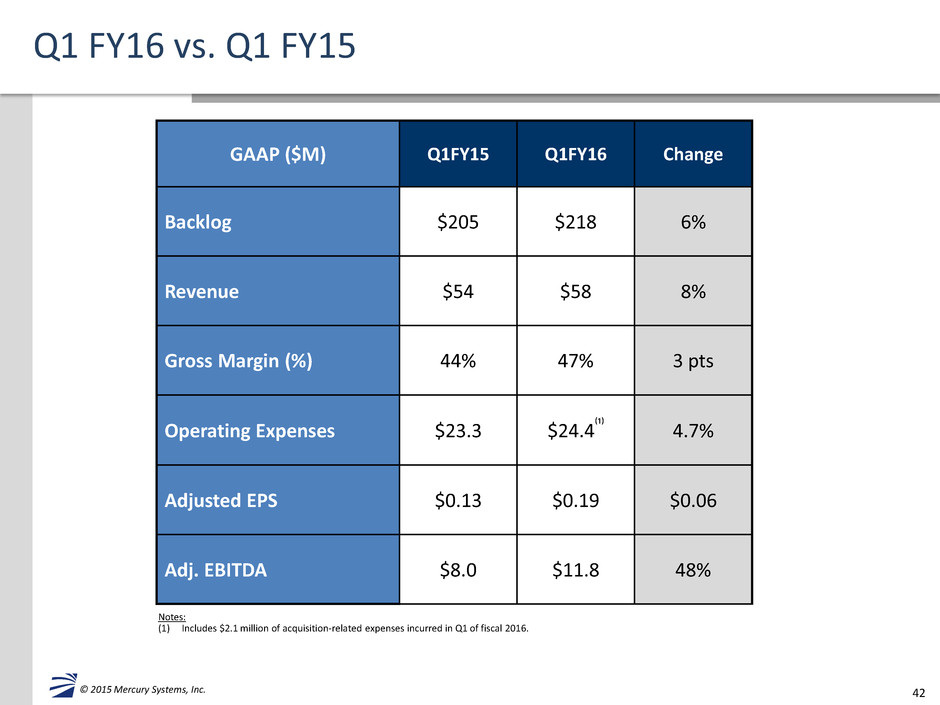

42 © 2015 Mercury Systems, Inc. Q1 FY16 vs. Q1 FY15 GAAP ($M) Q1FY15 Q1FY16 Change Backlog $205 $218 6% Revenue $54 $58 8% Gross Margin (%) 44% 47% 3 pts Operating Expenses $23.3 $24.4⁽¹⁾ 4.7% Adjusted EPS $0.13 $0.19 $0.06 Adj. EBITDA $8.0 $11.8 48% Notes: (1) Includes $2.1 million of acquisition-related expenses incurred in Q1 of fiscal 2016.

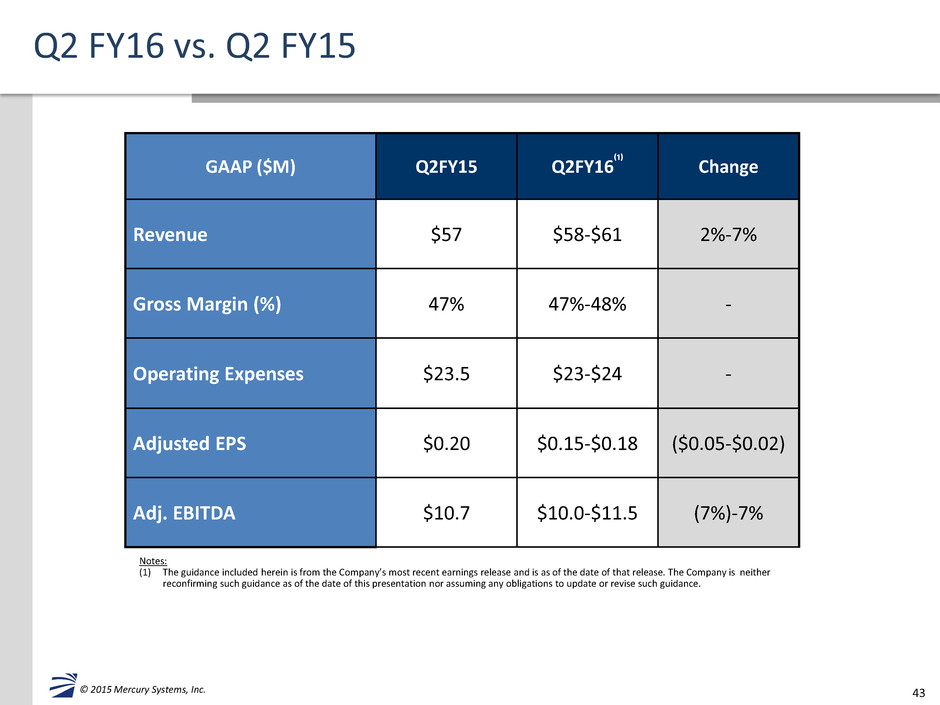

43 © 2015 Mercury Systems, Inc. Q2 FY16 vs. Q2 FY15 GAAP ($M) Q2FY15 Q2FY16⁽¹⁾ Change Revenue $57 $58-$61 2%-7% Gross Margin (%) 47% 47%-48% - Operating Expenses $23.5 $23-$24 - Adjusted EPS $0.20 $0.15-$0.18 ($0.05-$0.02) Adj. EBITDA $10.7 $10.0-$11.5 (7%)-7% Notes: (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance.

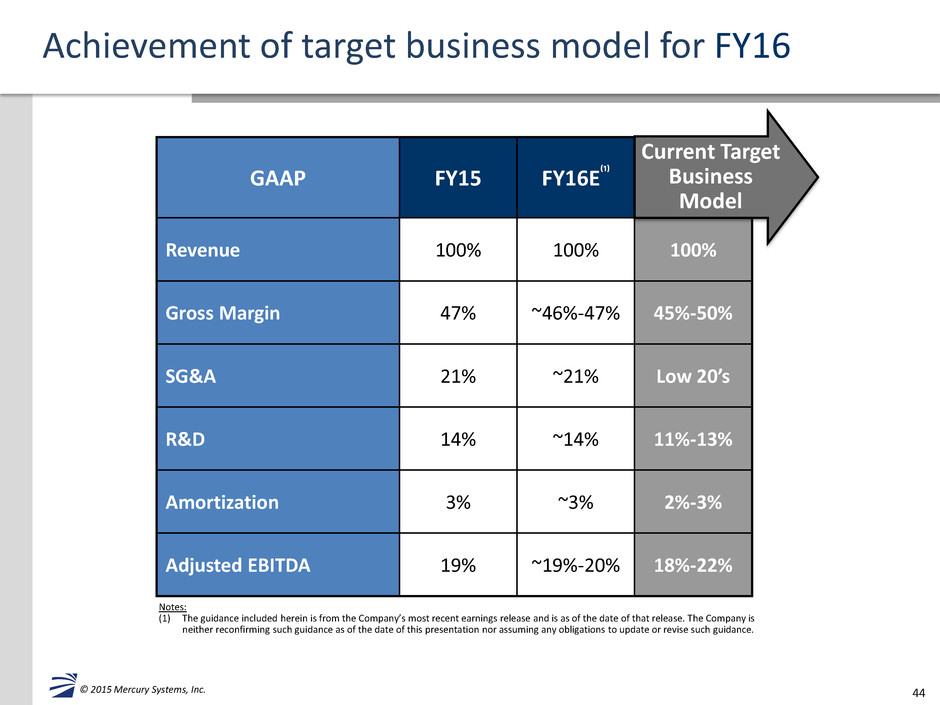

44 © 2015 Mercury Systems, Inc. Achievement of target business model for FY16 GAAP FY15 FY16E⁽¹⁾ Revenue 100% 100% 100% Gross Margin 47% ~46%-47% 45%-50% SG&A 21% ~21% Low 20’s R&D 14% ~14% 11%-13% Amortization 3% ~3% 2%-3% Adjusted EBITDA 19% ~19%-20% 18%-22% Current Target Business Model Notes: (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance.

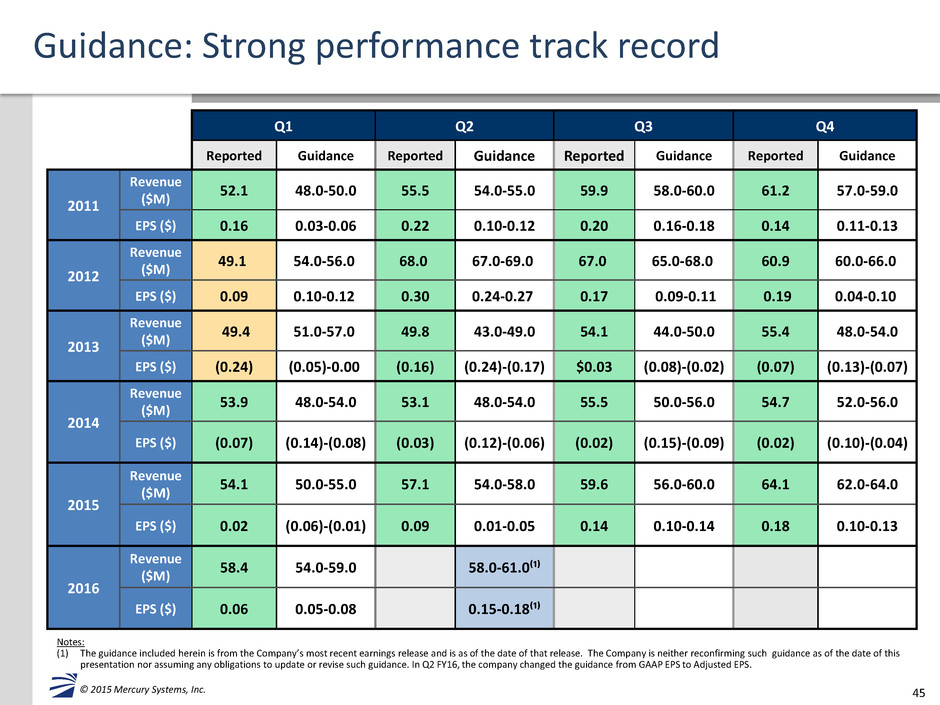

45 © 2015 Mercury Systems, Inc. Guidance: Strong performance track record Q1 Q2 Q3 Q4 Reported Guidance Reported Guidance Reported Guidance Reported Guidance 2011 Revenue ($M) 52.1 48.0-50.0 55.5 54.0-55.0 59.9 58.0-60.0 61.2 57.0-59.0 EPS ($) 0.16 0.03-0.06 0.22 0.10-0.12 0.20 0.16-0.18 0.14 0.11-0.13 2012 Revenue ($M) 49.1 54.0-56.0 68.0 67.0-69.0 67.0 65.0-68.0 60.9 60.0-66.0 EPS ($) 0.09 0.10-0.12 0.30 0.24-0.27 0.17 0.09-0.11 0.19 0.04-0.10 2013 Revenue ($M) 49.4 51.0-57.0 49.8 43.0-49.0 54.1 44.0-50.0 55.4 48.0-54.0 EPS ($) (0.24) (0.05)-0.00 (0.16) (0.24)-(0.17) $0.03 (0.08)-(0.02) (0.07) (0.13)-(0.07) 2014 Revenue ($M) 53.9 48.0-54.0 53.1 48.0-54.0 55.5 50.0-56.0 54.7 52.0-56.0 EPS ($) (0.07) (0.14)-(0.08) (0.03) (0.12)-(0.06) (0.02) (0.15)-(0.09) (0.02) (0.10)-(0.04) 2015 Revenue ($M) 54.1 50.0-55.0 57.1 54.0-58.0 59.6 56.0-60.0 64.1 62.0-64.0 EPS ($) 0.02 (0.06)-(0.01) 0.09 0.01-0.05 0.14 0.10-0.14 0.18 0.10-0.13 2016 Revenue ($M) 58.4 54.0-59.0 58.0-61.0⁽¹⁾ EPS ($) 0.06 0.05-0.08 0.15-0.18⁽¹⁾ Notes: (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance. In Q2 FY16, the company changed the guidance from GAAP EPS to Adjusted EPS.

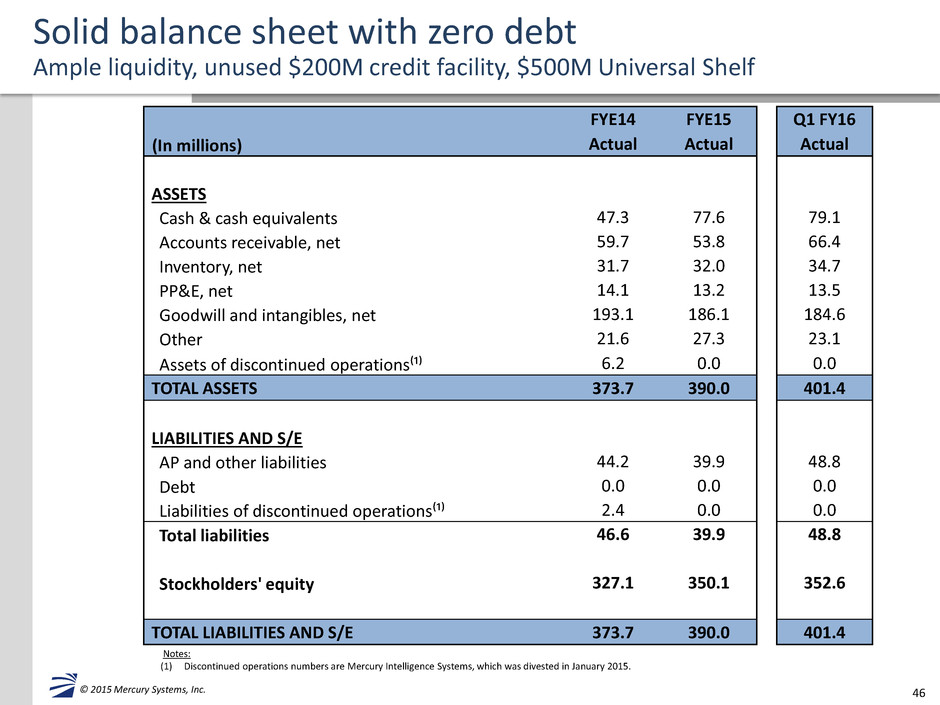

46 © 2015 Mercury Systems, Inc. Solid balance sheet with zero debt Ample liquidity, unused $200M credit facility, $500M Universal Shelf Notes: (1) Discontinued operations numbers are Mercury Intelligence Systems, which was divested in January 2015. FYE14 FYE15 Q1 FY16 (In millions) Actual Actual Actual ASSETS Cash & cash equivalents 47.3 77.6 79.1 Accounts receivable, net 59.7 53.8 66.4 Inventory, net 31.7 32.0 34.7 PP&E, net 14.1 13.2 13.5 Goodwill and intangibles, net 193.1 186.1 184.6 Other 21.6 27.3 23.1 Assets of discontinued operations⁽¹⁾ 6.2 0.0 0.0 TOTAL ASSETS 373.7 390.0 401.4 LIABILITIES AND S/E AP and other liabilities 44.2 39.9 48.8 Debt 0.0 0.0 0.0 Liabilities of discontinued operations⁽¹⁾ 2.4 0.0 0.0 Total liabilities 46.6 39.9 48.8 Stockholders' equity 327.1 350.1 352.6 TOTAL LIABILITIES AND S/E 373.7 390.0 401.4

47 © 2015 Mercury Systems, Inc. © 2015 Mercury Systems, Inc. Poised for continued, profitable growth • Strategy, operational discipline, integration, yielded significant operating leverage • Growth and profitability above industry averages • Record backlog enhances forward visibility, facilitates operational execution • Strong, established, well-funded programs drive growth potential • Improving defense environment enhances opportunity set • Very strong balance sheet with zero debt supports future M&A

© 2015 Mercury Systems, Inc. Q & A

© 2015 Mercury Systems, Inc. Appendix

50 © 2015 Mercury Systems, Inc. Management team Since 2007, Mercury management has successfully grown the Company’s defense business, returned the Company to profitability, acquired and integrated three companies, and positioned Mercury as a leading pure-play defense electronics company. • Mark joined Mercury in 2007 as President and CEO • In-depth experience that spans the technology industry, across a variety of markets including telecommunications, data networking, security, defense and life sciences • Prior to joining Mercury, Mark was President and Chief Executive Officer of Enterasys Networks and held various positions with Marconi plc and its affiliated companies Mark Aslett President, Chief Executive Officer and Director • Michael is responsible for Mercury’s corporate development activities, including strategy, planning and mergers and acquisitions • Fifteen years of investment banking experience spanning mergers and acquisitions, capital formation, strategy development and execution in aerospace and defense markets • Prior to joining Mercury, Michael was Co-Founder and Managing Partner of RSPartners, LLC and has held various positions with UBS Securities, Lehman Brothers and Lazard Michael Ruppert Senior Vice President, Strategy and Corporate Development • Gerry joined Mercury in 2010 and is responsible for Mercury’s financial and treasury functions, as well as the Company’s legal, security, and compliance and risk management functions • Executive experience spanning defense, high-tech, biotech, alternative energy and manufacturing • Prior to joining Mercury, Gerry was Executive Vice President at Verenium Corporation and held various positions with Enterasys Networks, Cabletron Systems, and Applied Extrusion Technologies • Didier has served as President of MCE since 2012; prior positions include managing the Company’s Advanced Computing Solutions group and heading international subsidiaries • Before joining Mercury in 1995, Didier was Technical Director and Account Manager for Horizon Technologies, where he specialized in the development of Services and System Integrations for European Defense and Commercial businesses Didier Thibaud President, Mercury Commercial Electronics Demonstrated track record of double-digit defense revenue growth and improved profitability Gerry Haines Executive Vice President, Chief Financial Officer and Treasurer

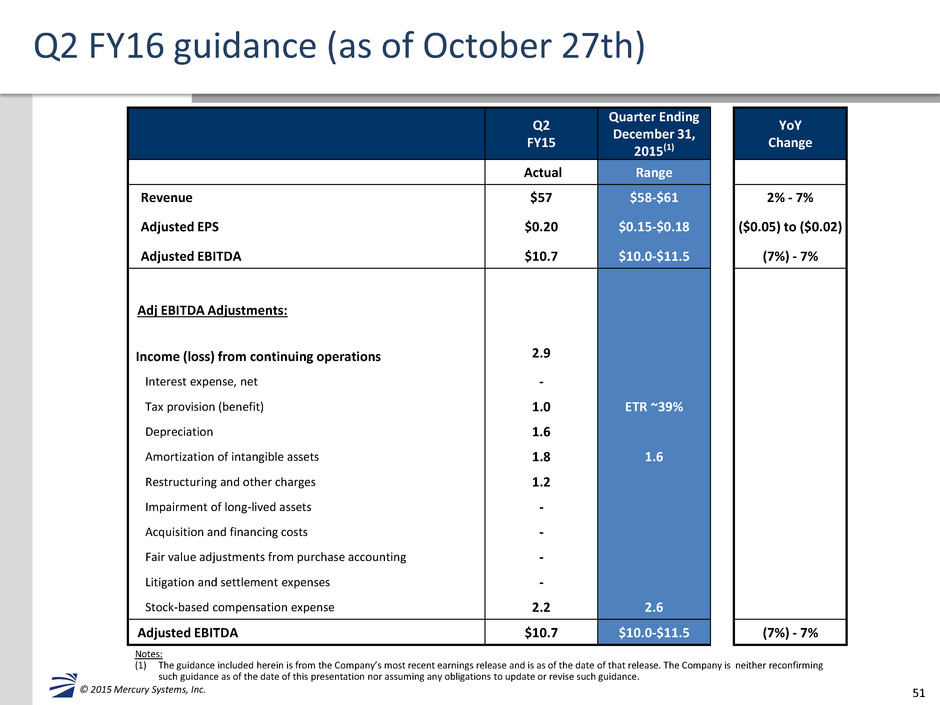

51 © 2015 Mercury Systems, Inc. Q2 FY16 guidance (as of October 27th) Q2 FY15 Quarter Ending YoY Change December 31, 2015(1) Actual Range Revenue $57 $58-$61 2% - 7% Adjusted EPS $0.20 $0.15-$0.18 ($0.05) to ($0.02) Adjusted EBITDA $10.7 $10.0-$11.5 (7%) - 7% Adj EBITDA Adjustments: Income (loss) from continuing operations 2.9 Interest expense, net - Tax provision (benefit) 1.0 ETR ~39% Depreciation 1.6 Amortization of intangible assets 1.8 1.6 Restructuring and other charges 1.2 Impairment of long-lived assets - Acquisition and financing costs - Fair value adjustments from purchase accounting - Litigation and settlement expenses - Stock-based compensation expense 2.2 2.6 Adjusted EBITDA $10.7 $10.0-$11.5 (7%) - 7% Notes: (1) The guidance included herein is from the Company’s most recent earnings release and is as of the date of that release. The Company is neither reconfirming such guidance as of the date of this presentation nor assuming any obligations to update or revise such guidance.

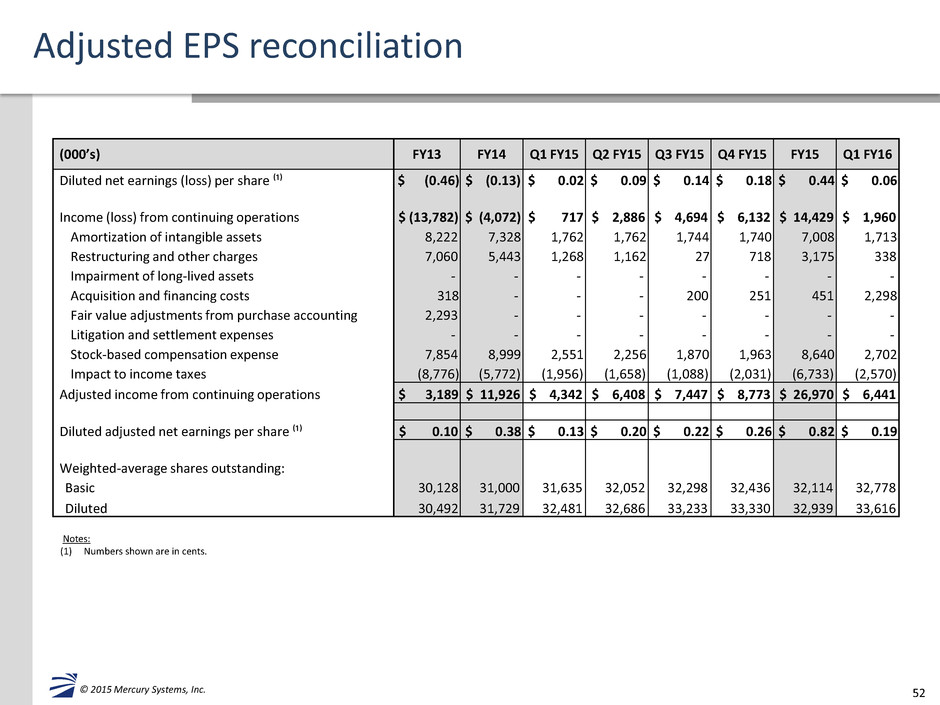

52 © 2015 Mercury Systems, Inc. Adjusted EPS reconciliation (000’s) FY13 FY14 Q1 FY15 Q2 FY15 Q3 FY15 Q4 FY15 FY15 Q1 FY16 Diluted net earnings (loss) per share ⁽¹⁾ $ (0.46) $ (0.13) $ 0.02 $ 0.09 $ 0.14 $ 0.18 $ 0.44 $ 0.06 Income (loss) from continuing operations $ (13,782) $ (4,072) $ 717 $ 2,886 $ 4,694 $ 6,132 $ 14,429 $ 1,960 Amortization of intangible assets 8,222 7,328 1,762 1,762 1,744 1,740 7,008 1,713 Restructuring and other charges 7,060 5,443 1,268 1,162 27 718 3,175 338 Impairment of long-lived assets - - - - - - - - Acquisition and financing costs 318 - - - 200 251 451 2,298 Fair value adjustments from purchase accounting 2,293 - - - - - - - Litigation and settlement expenses - - - - - - - - Stock-based compensation expense 7,854 8,999 2,551 2,256 1,870 1,963 8,640 2,702 Impact to income taxes (8,776) (5,772) (1,956) (1,658) (1,088) (2,031) (6,733) (2,570) Adjusted income from continuing operations $ 3,189 $ 11,926 $ 4,342 $ 6,408 $ 7,447 $ 8,773 $ 26,970 $ 6,441 Diluted adjusted net earnings per share ⁽¹⁾ $ 0.10 $ 0.38 $ 0.13 $ 0.20 $ 0.22 $ 0.26 $ 0.82 $ 0.19 Weighted-average shares outstanding: Basic 30,128 31,000 31,635 32,052 32,298 32,436 32,114 32,778 Diluted 30,492 31,729 32,481 32,686 33,233 33,330 32,939 33,616 Notes: (1) Numbers shown are in cents.

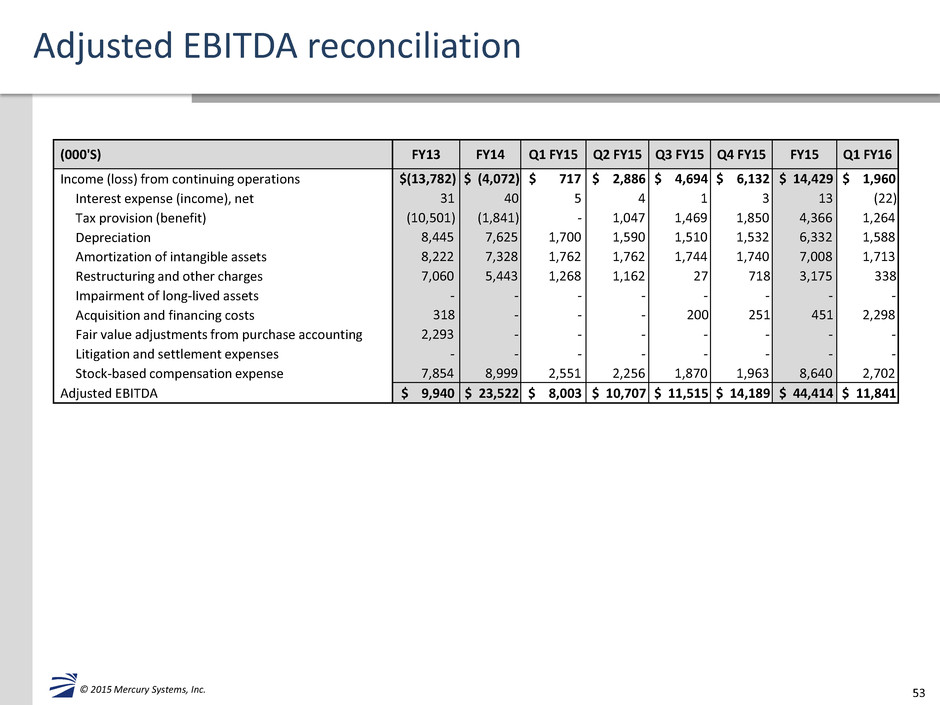

53 © 2015 Mercury Systems, Inc. Adjusted EBITDA reconciliation (000'S) FY13 FY14 Q1 FY15 Q2 FY15 Q3 FY15 Q4 FY15 FY15 Q1 FY16 Income (loss) from continuing operations $(13,782) $ (4,072) $ 717 $ 2,886 $ 4,694 $ 6,132 $ 14,429 $ 1,960 Interest expense (income), net 31 40 5 4 1 3 13 (22) Tax provision (benefit) (10,501) (1,841) - 1,047 1,469 1,850 4,366 1,264 Depreciation 8,445 7,625 1,700 1,590 1,510 1,532 6,332 1,588 Amortization of intangible assets 8,222 7,328 1,762 1,762 1,744 1,740 7,008 1,713 Restructuring and other charges 7,060 5,443 1,268 1,162 27 718 3,175 338 Impairment of long-lived assets - - - - - - - - Acquisition and financing costs 318 - - - 200 251 451 2,298 Fair value adjustments from purchase accounting 2,293 - - - - - - - Litigation and settlement expenses - - - - - - - - Stock-based compensation expense 7,854 8,999 2,551 2,256 1,870 1,963 8,640 2,702 Adjusted EBITDA $ 9,940 $ 23,522 $ 8,003 $ 10,707 $ 11,515 $ 14,189 $ 44,414 $ 11,841

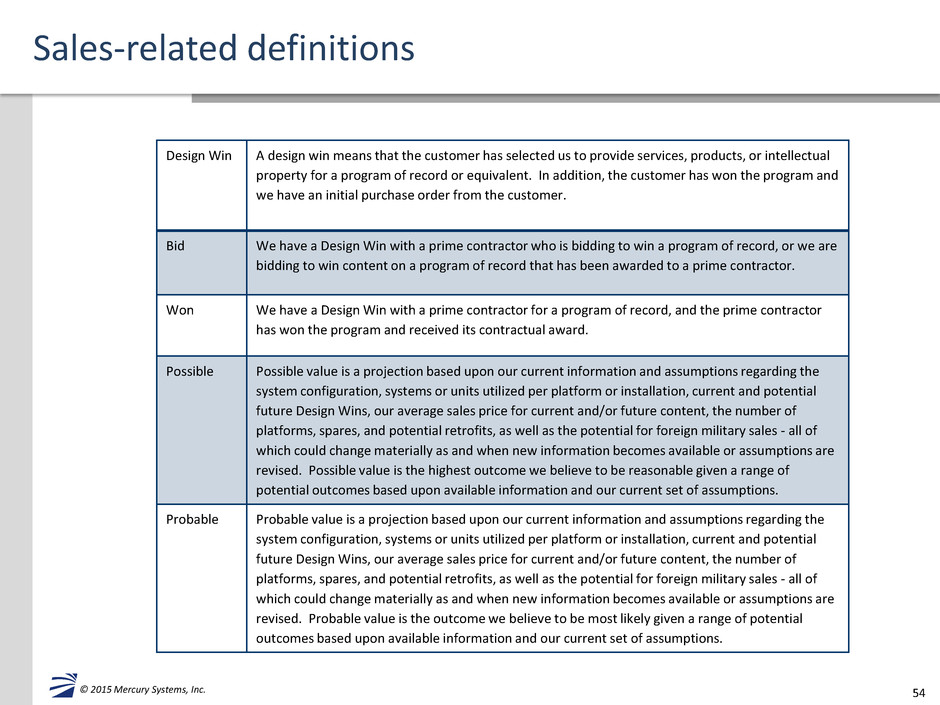

54 © 2015 Mercury Systems, Inc. Sales-related definitions Design Win A design win means that the customer has selected us to provide services, products, or intellectual property for a program of record or equivalent. In addition, the customer has won the program and we have an initial purchase order from the customer. Bid We have a Design Win with a prime contractor who is bidding to win a program of record, or we are bidding to win content on a program of record that has been awarded to a prime contractor. Won We have a Design Win with a prime contractor for a program of record, and the prime contractor has won the program and received its contractual award. Possible Possible value is a projection based upon our current information and assumptions regarding the system configuration, systems or units utilized per platform or installation, current and potential future Design Wins, our average sales price for current and/or future content, the number of platforms, spares, and potential retrofits, as well as the potential for foreign military sales - all of which could change materially as and when new information becomes available or assumptions are revised. Possible value is the highest outcome we believe to be reasonable given a range of potential outcomes based upon available information and our current set of assumptions. Probable Probable value is a projection based upon our current information and assumptions regarding the system configuration, systems or units utilized per platform or installation, current and potential future Design Wins, our average sales price for current and/or future content, the number of platforms, spares, and potential retrofits, as well as the potential for foreign military sales - all of which could change materially as and when new information becomes available or assumptions are revised. Probable value is the outcome we believe to be most likely given a range of potential outcomes based upon available information and our current set of assumptions.

55 © 2015 Mercury Systems, Inc. Glossary AEGIS Aegis Ballistic Missile Defense System EDM Engineering Development Model MOSA Modular Open Systems Architecture AESA Active Electronically Scanned Array EMD Engineering and Manufacturing Development O&M Operations & Maintenance AGS Alliance Ground Surveillance EO/IR Electro-optical / Infrared OpenVPX System-level specification for VPX, initiated by Mercury AIDEWS Advanced Integrated Defensive Electronic Warfare Suite EW Electronic Warfare PoR Program of Record AMC Advanced Microelectronics Center FAR Federal Acquisition Regulation RFM Radio Frequency / Microwave AS9100 Widely adopted and standardized quality management system for aerospace industry FMS Foreign Military Sales SABR Scalable Agile Beam Radar ATCA Advanced Telecommunications Architecture FRP Full Rate Production SEWIP Surface Electronic Warfare Improvement Program AWACS Airborne Warning and Control System IDIQ Indefinite Quantity / Indefinite Delivery SIGINT Signals Intelligence BAMS Broad Area Maritime Surveillance IMA Integrated Microwave Assembly SIRFC Suite of Integrated RF Countermeasures BCA Budget Control Act LRIP Low-Rate Initial Production SOF Special Operations Forces C4ISR Command, Control, Communications, Computers, Intelligence, Surveillance, Reconnaissance MCE Mercury Commercial Electronics SWaP Size Weight and Power COTS Commercial off-the Shelf MDS Mercury Defense Systems TAM Total Addressable Market DRFM Digital Radio Frequency Memory MILPER Military Personnel