Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Enviva Partners, LP | a15-23007_18k.htm |

Exhibit 99.1

Enviva Partners, LP Business Overview Last Updated:November 16, 2015

Forward-Looking Statements and Cautionary Statements Forward-Looking Statements This presentation contains “forward-looking statements” within the meaning of the securities laws. All statements, other than statements of historical fact, included in this presentation that address activities, events or developments that Enviva Partners, LP (NYSE: EVA) (“Enviva,” “we,” or “us”) expects, believes or anticipates will or may occur in the future are forward-looking statements. The words “believe,” “expect,” “may,” “estimates,” “will,” “anticipate,” “plan,” “intend,” “foresee,” “should,” “would,” “could,” or other similar expressions are intended to identify forward-looking statements, which are generally not historical in nature. However, the absence of these words does not mean that the statements are not forward-looking. These statements are based on certain assumptions made by Enviva based on management’s expectations and perception of historical trends, current conditions, anticipated future developments and other factors believed to be appropriate. Although Enviva believes that these assumptions were reasonable when made, because assumptions are inherently subject to significant uncertainties and contingencies that are difficult or impossible to predict and are beyond its control, Enviva cannot give assurance that it will achieve or accomplish these expectations, beliefs or intentions. A number of the assumptions on which these forward-looking statements are based are subject to risks and uncertainties, many of which are beyond the control of Enviva, and may cause actual results to differ materially from those implied or expressed by the forward-looking statements. These risks and uncertainties include the factors discussed or referenced in our filings with the Securities and Exchange Commission (the “SEC”), including the IPO prospectus filed on April 29, 2015 and the Quarterly Reports on Form 10-Q most recently filed with the SEC, including those risks relating to financial performance and results, economic conditions and resulting capital restraints, availability of sufficient capital to execute Enviva’s business plan, impact of compliance with legislation and regulations and other important factors that could cause actual results to differ materially from those projected. When considering the forward-looking statements, you should keep in mind the risk factors and other cautionary statements in such filings. You are cautioned not to place undue reliance on forward-looking statements, which speak only as of the date on which such statement is made, and Enviva undertakes no obligation to correct or update any forward-looking statement, whether as a result of new information, future events or otherwise, except as required by applicable law. All forward-looking statements attributable to Enviva are qualified in their entirety by this cautionary statement. Industry and Market Data This presentation has been prepared by Enviva and includes market data and other statistical information from third-party sources, including independent industry publications, government publications or other published independent sources. Although Enviva believes these third-party sources are reliable as of their respective dates, Enviva has not independently verified the accuracy or completeness of this information. Some data is also based on Enviva’s good faith estimates, which are derived from its review of internal sources as well as the third-party sources described above. 2

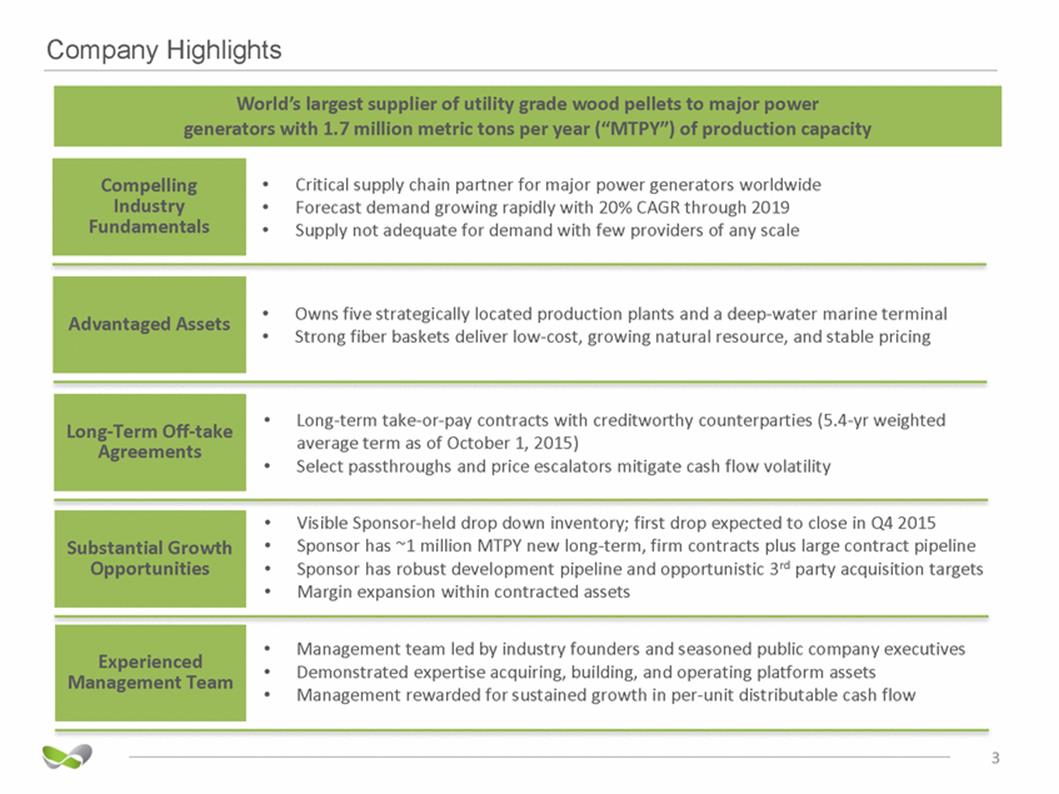

Company Highlights • • • Critical supply chain partner for major power generators worldwide Forecast demand growing rapidly with 20% CAGR through 2019 Supply not adequate for demand with few providers of any scale • • Owns five strategically located production plants and a deep-water marine terminal Strong fiber baskets deliver low-cost, growing natural resource, and stable pricing • Long-term take-or-pay contracts with creditworthy counterparties (5.4-yr weighted average term as of October 1, 2015) Select passthroughs and price escalators mitigate cash flow volatility • • • • • Visible Sponsor-held drop down inventory; first drop expected to close in Q4 2015 Sponsor has ~1 million MTPY new long-term, firm contracts plus large contract pipeline Sponsor has robust development pipeline and opportunistic 3rd party acquisition targets Margin expansion within contracted assets • • • Management team led by industry founders and seasoned public company executives Demonstrated expertise acquiring, building, and operating platform assets Management rewarded for sustained growth in per-unit distributable cash flow 3 Experienced Management Team Substantial Growth Opportunities Long-Term Off-take Agreements Advantaged Assets Compelling Industry Fundamentals World’s largest supplier of utility grade wood pellets to major power generators with 1.7 million metric tons per year (“MTPY”) of production capacity

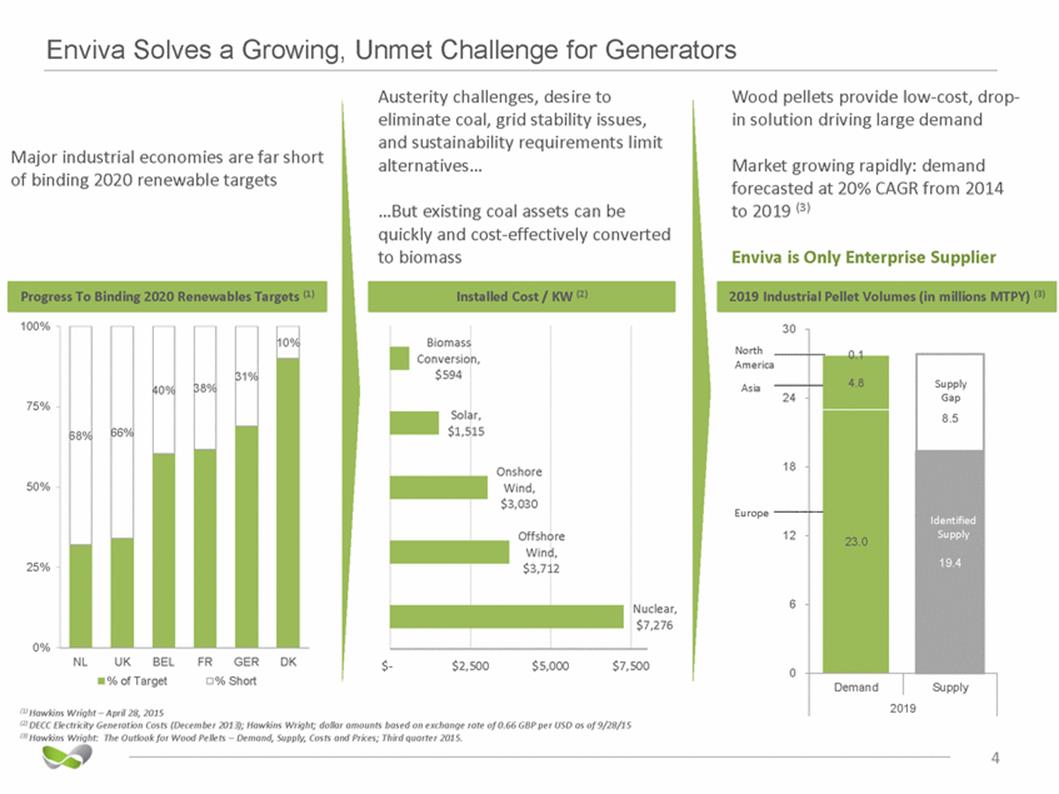

Enviva Solves a Growing, Unmet Challenge for Generators Austerity challenges, desire to eliminate coal, grid stability issues, and sustainability requirements limit alternatives… Wood pellets provide low-cost, drop-in solution driving large demand Major industrial economies are far short of binding 2020 renewable targets Market growing rapidly: demand forecasted at 20% CAGR from 2014 to 2019 (3) …But existing coal assets can be quickly and cost-effectively converted to biomass Enviva is Only Enterprise Supplier 2019 Industrial Pellet Volumes (in millions MTPY) (3) 100% 30 North America 0.1 Asia 75% ar, $1,515 50% Europe ore d, $3,712 25% clear, $7,276 0% NL UK BEL FR GER % Short DK $-$2,500 $5,000 $7,500 % of Target (1) Hawkins Wright – April 28, 2015 (2) DECC Electricity Generation Costs (December 2013); Hawkins Wright; dollar amounts based on exchange rate of 0.66 GBP per USD as of 9/28/15 (3) Hawkins Wright: The Outlook for Wood Pellets – Demand, Supply, Costs and Prices; Third quarter 2015. 4 Biomass n, Onshore Nu Conversio $594 Sol Wind, $3,030 Offsh Win 4.8 Supply Gap 8.5 24 18 23.0 Identified Supply 19.4 12 6 0 Demand Supply 2019 68% 66% 40% 38% 31% 10% Installed Cost / KW (2) Progress To Binding 2020 Renewables Targets (1)

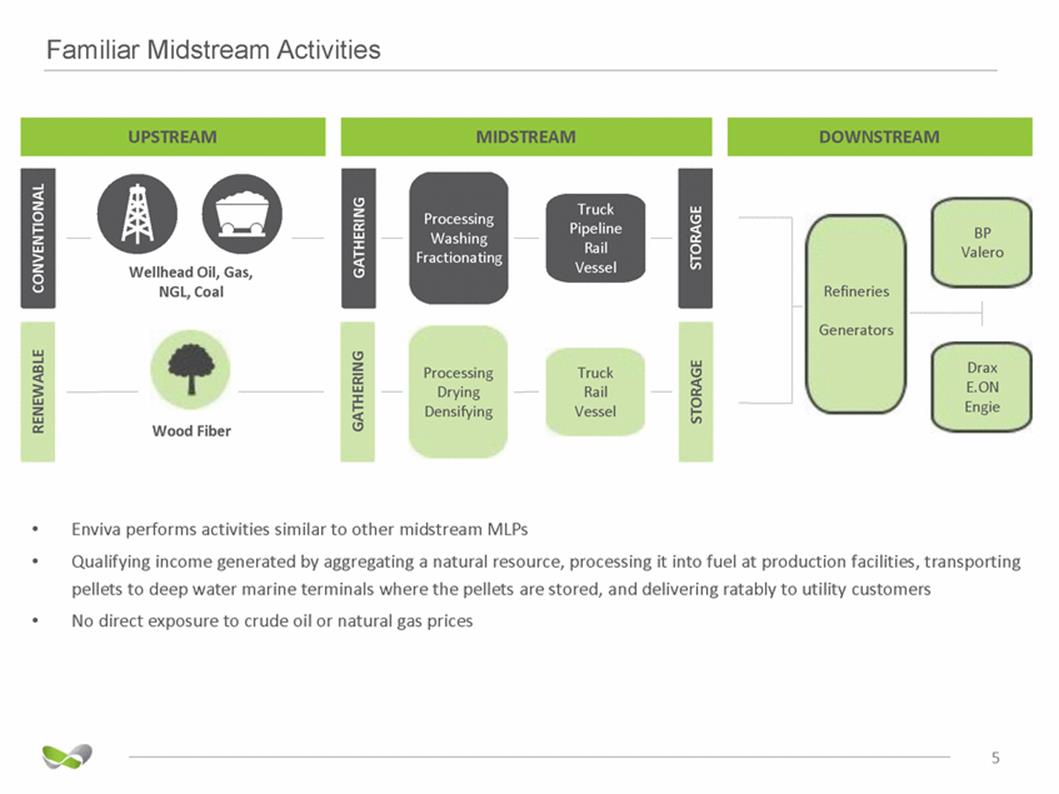

Familiar Midstream Activities Truck Pipeline Rail Vessel Processing Washing Fractionating BP Valero Wellhead Oil, Gas, NGL, Coal Refineries Generators Drax E.ON Engie Processing Drying Densifying Truck Rail Vessel Wood Fiber • • Enviva performs activities similar to other midstream MLPs Qualifying income generated by aggregating a natural resource, processing it into fuel at production facilities, transporting pellets to deep water marine terminals where the pellets are stored, and delivering ratably to utility customers No direct exposure to crude oil or natural gas prices • 5 RENEWABLE CONVENTIONAL GATHERING GATHERING STORAGE STORAGE DOWNSTREAM MIDSTREAM UPSTREAM

Enviva’s Port of Chesapeake Marine Terminal Compelling Industry Fundamentals

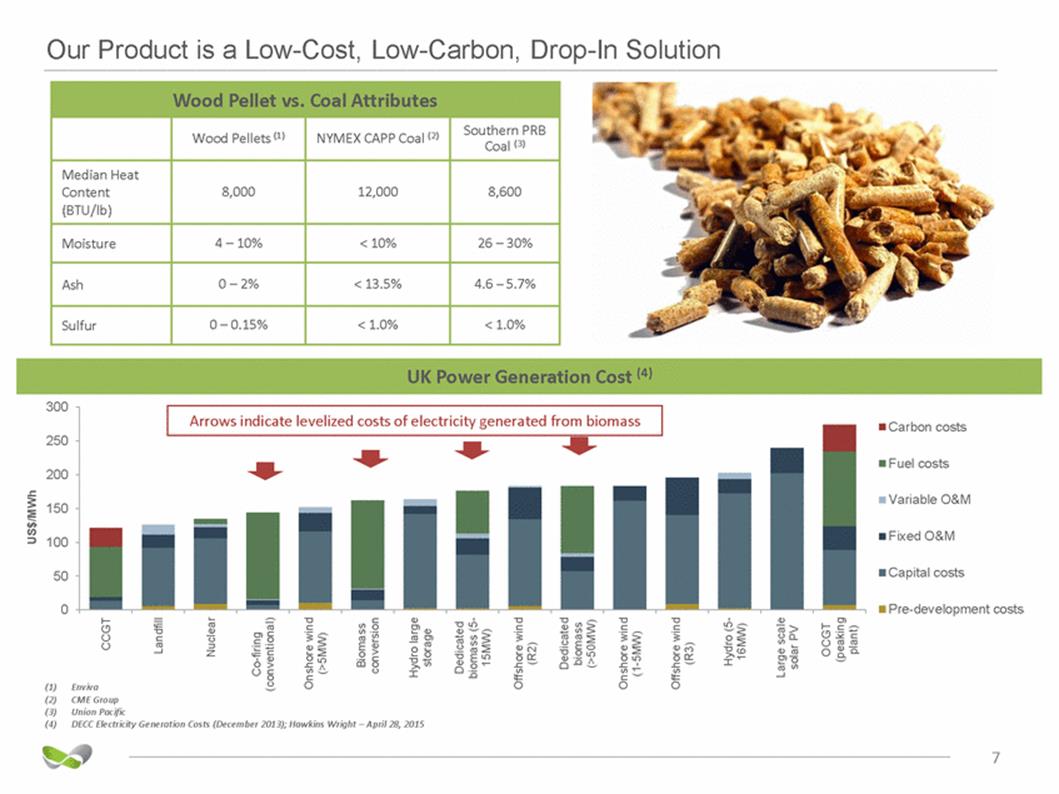

Our Product is a Low-Cost, Low-Carbon, Drop-In Solution Coal (3) 300 Carbon costs 250 Fuel costs 200 Variable O&M 150 Fixed O&M 100 Capital costs 50 0 Pre-development costs (1) (2) (3) (4) Enviva CME Group Union Pacific DECC Electricity Generation Costs (December 2013); Hawkins Wright – April 28, 2015 7 US$/MWh CCGT Landfill Nuclear Co-firing (conventional) Onshore wind (>5MW) Biomass conversion Hydro large storage Dedicated biomass (5-15MW) Offshore wind (R2) Dedicated biomass (>50MW) Onshore wind (1-5MW) Offshore wind (R3) Hydro (5-16MW) Large scale solar PV OCGT (peaking plant) Arrows indicate levelized costs of electricity generated from biomass UK Power Generation Cost (4) Wood Pellet vs. Coal Attributes Wood Pellets (1) NYMEX CAPP Coal (2) Southern PRB Median Heat Content (BTU/lb) 8,000 12,000 8,600 Moisture 4 – 10% < 10% 26 – 30% Ash 0 – 2% < 13.5% 4.6 – 5.7% Sulfur 0 – 0.15% < 1.0% < 1.0%

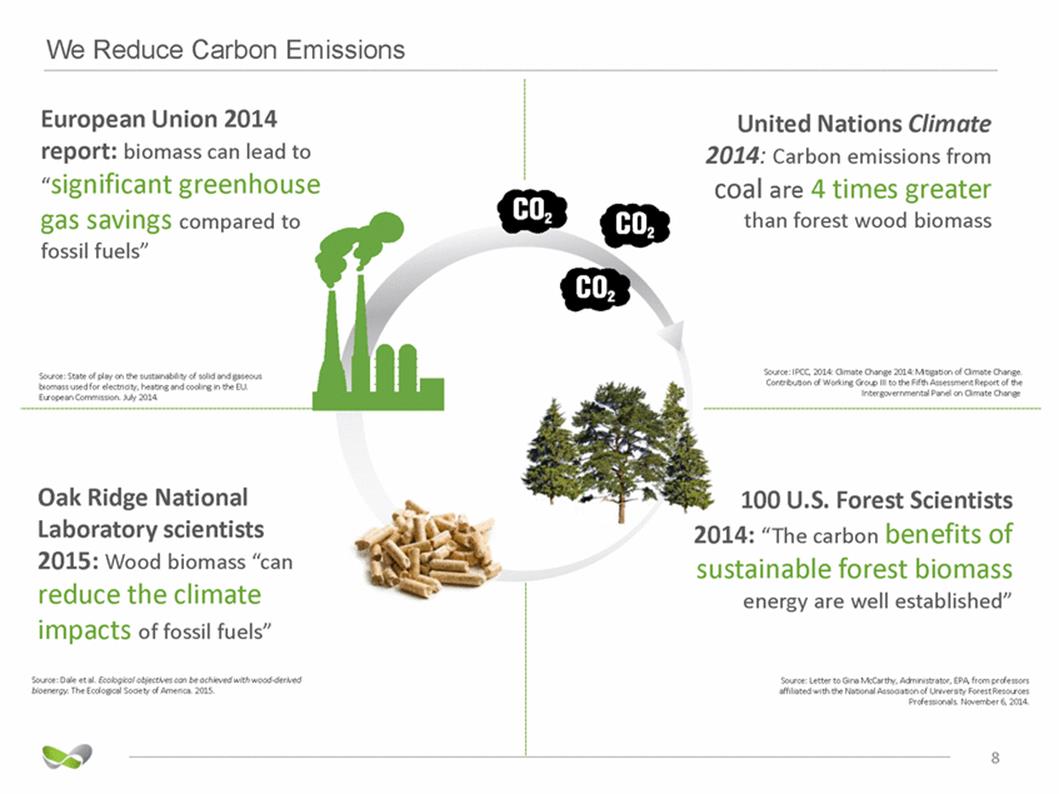

We Reduce Carbon Emissions European Union 2014 report: biomass can lead to “significant greenhouse gas savings compared to fossil fuels” United Nations Climate 2014: Carbon emissions from coal are 4 times greater than forest wood biomass Source: IPCC, 2014: Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change Source: State of play on the sustainability of solid and gaseous biomass used for electricity, heating and cooling in the EU. European Commission. July 2014. Oak Ridge National Laboratory scientists 2015: Wood biomass “can reduce the climate impacts of fossil fuels” Source: Dale et al. Ecological objectives can be achieved with wood-derived bioenergy. The Ecological Society of America. 2015. 100 U.S. Forest Scientists 2014: “The carbon benefits of sustainable forest biomass energy are well established” Source: Letter to Gina McCarthy, Administrator, EPA, from professors affiliated with the National Association of University Forest Resources Professionals. November 6, 2014. 8

Our Activities Sustain Thriving, Healthy Forests 1. 2. 3. Galik and Abt, Sustainability Guidelines and Forest Market Response: as assessment of European Union pellet demand in the Southeastern Unite d States. ECB Bioenergy. 2015 As cited in: United States Census Bureau. (2012). Statistical Abstract of the United States: 2012. USDA - http://blogs.usda.gov/2015/06/08/study-finds-increasing-wood-pellet-demand-boosts-forest-growth-reduces-greenhouse-gas-emissions-creates-jobs/ 9 “An industry that can reduce greenhouse gas emissions, increase forest growth, and create jobs sounds too good to be true. But that is the reality of the emerging wood pellet market in the Southern U.S.”3 -USDA Acting Chief Economist Robert Johansson, 2015 Pulpwood demand from pulp and paper industry down 100+ million tons annually since 1995 - U.S. Forest Service2 “We show a substantial increase in the area of all forest types in the presence of increased pellet demand.” - Duke University & NC State University1

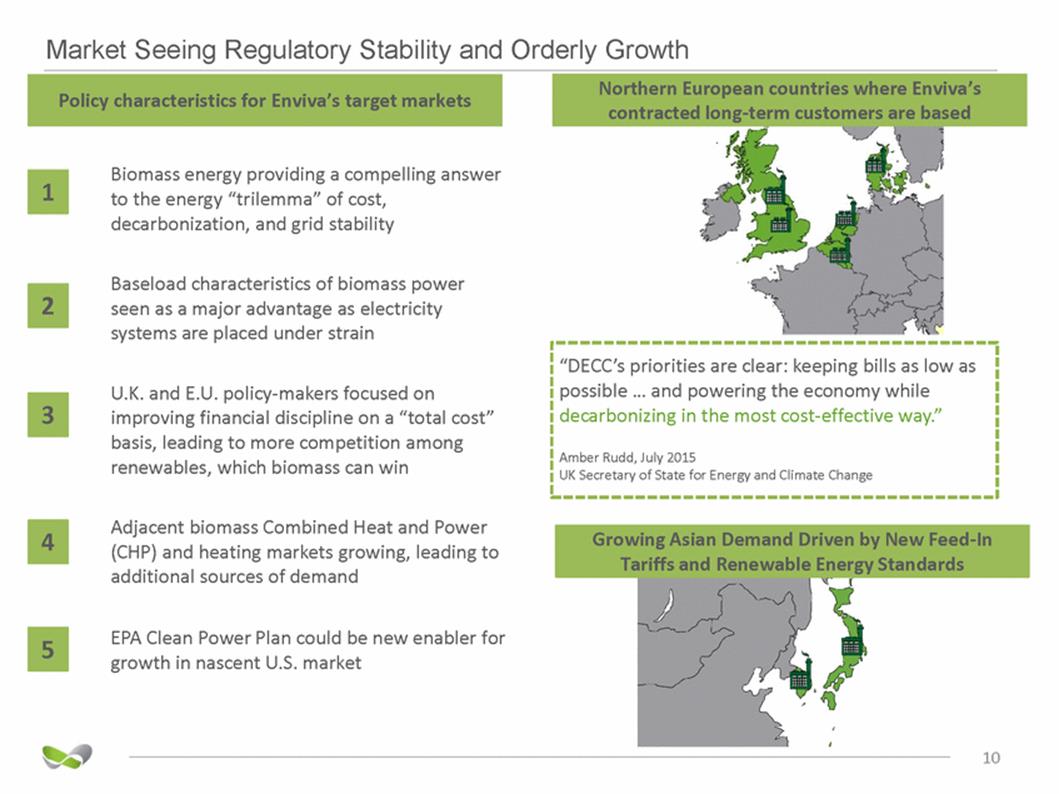

Market Seeing Regulatory Stability and Orderly Growth Biomass energy providing a compelling answer to the energy “trilemma” of cost, decarbonization, and grid stability Baseload characteristics of biomass power seen as a major advantage as electricity systems are placed under strain U.K. and E.U. policy-makers focused on improving financial discipline on a “total cost” basis, leading to more competition among renewables, which biomass can win Adjacent biomass Combined Heat and Power (CHP) and heating markets growing, leading to additional sources of demand EPA Clean Power Plan could be new enabler for growth in nascent U.S. market 10 5 Growing Asian Demand Driven by New Feed-In Tariffs and Renewable Energy Standards 4 3 “DECC’s priorities are clear: keeping bills as low as possible … and powering the economy while decarbonizing in the most cost-effective way.” Amber Rudd, July 2015 UK Secretary of State for Energy and Climate Change 2 1 Policy characteristics for Enviva’s target markets Northern European countries where Enviva’s contracted long-term customers are based

Supply Gap Created by Multiple Hurdles to Entry CAPITAL INVESTMENT REQUIRED IN: LIMITED SUPPLY CHAIN INFRASTRUCTURE Concentrated Customer Generation Set Fragmented Natural Resource Base Fiber Logistics Plant Ship Port Deep Process Capabilities Required Wood Aggregation Truck / Rail Loading Debarking & Chipping Size Reduction Wood Receiving & Storage Shipping Drying Port Storage Pelleting Commitment to Excellence in Safety, Sustainability & Reliability 11

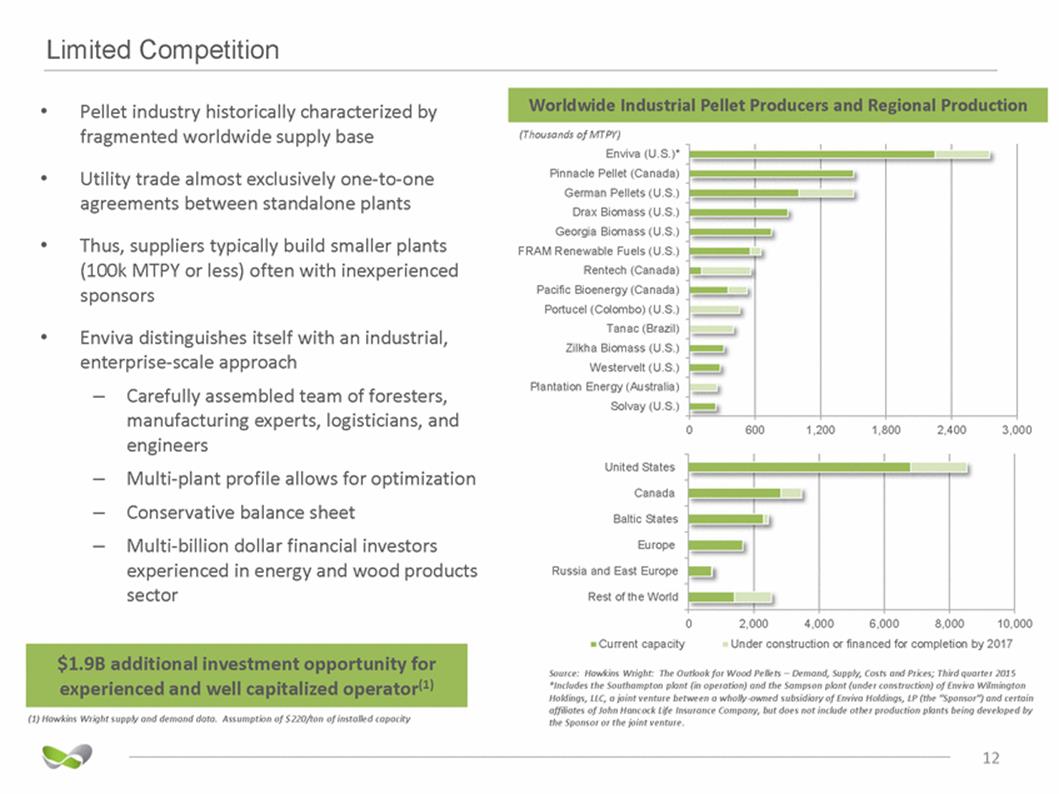

Limited Competition • Pellet industry historically characterized by fragmented worldwide supply base Utility trade almost exclusively one-to-one agreements between standalone plants (Thousands of MTPY) Enviva (U.S.)* Pinnacle Pellet (Canada) German Pellets (U.S.) Drax Biomass (U.S.) Georgia Biomass (U.S.) FRAM Renewable Fuels (U.S.) Rentech (Canada) Pacific Bioenergy (Canada) Portucel (Colombo) (U.S.) Tanac (Brazil) Zilkha Biomass (U.S.) Westervelt (U.S.) Plantation Energy (Australia) Solvay (U.S.) • • Thus, suppliers typically build smaller plants (100k MTPY or less) often with inexperienced sponsors Enviva distinguishes itself with an industrial, enterprise-scale approach • – Carefully assembled team of foresters, manufacturing experts, logisticians, and engineers Multi-plant profile allows for optimization Conservative balance sheet Multi-billion dollar financial investors experienced in energy and wood products sector 0 600 1,2001,800 2,400 3,000 United States – – – Canada Baltic States Europe Russia and East Europe Rest of the World 0 2,000 4,000 6,000 8,000 10,000 Current capacity Under construction or financed for completion by 2017 Source: Hawkins Wright: The Outlook for Wood Pellets – Demand, Supply, Costs and Prices; Third quarter 2015 *Includes the Southampton plant (in operation) and the Sampson plant (under construction) of Enviva Wilmington Holdings, LLC, a joint venture between a wholly-owned subsidiary of Enviva Holdings, LP (the “Sponsor”) and certain affiliates of John Hancock Life Insurance Company, but does not include other production plants being developed by the Sponsor or the joint venture. (1) Hawkins Wright supply and demand data. Assumption of $220/ton of installed capacity 12 $1.9B additional investment opportunity for experienced and well capitalized operator(1) Worldwide Industrial Pellet Producers and Regional Production

Enviva’s Production Facility in Northampton, NC Advantaged Assets

Assets at a Glance Bethesda, MD Port of Chesapeake, VA – 90K Northampton, NC – 500K Ahoskie, NC – 370K Amory, MS – 110K Wiggins, MS – 110K Cottondale, FL – 650K Port of Panama City, FL – 32K Port of Mobile, AL – 45K+ Startup: 3rd Party Agreement 14 Storage and Terminaling Assets Port of Mobile Location: Mobile, AL, Cooper Marine & Timberlands ChipCo Terminal Startup: 3rd Party Agreement Storage: Flex barge storage with 45K+ MT of capacity Port of Chesapeake Location: Chesapeake, VA, wholly owned by Enviva Startup: November 2011 Storage: Dome storage with 90K MT of capacity Port of Panama City Location: Panama City, FL, Port Panama City Storage: Flat warehouse storage with 32K MT of capacity Plants Port infrastructure Enviva Headquarters Current Production Plants Amory Location: Amory, MS Startup: August 2010 (acquired) Annual Production: 110K MTPY Wiggins Location: Wiggins, MS Startup: October 2010 (acquired) Annual Production: 110K MTPY Ahoskie Location: Ahoskie, NC Startup: November 2011 Annual Production: 370K MTPY Northampton Location: Northampton, NC Startup: April 2013 Annual Production: 500K MTPY Cottondale Location: Cottondale, FL Startup: May 2008 (acquired January 2015) Annual Production: 650K MTPY

Advantaged Assets Port of Chesapeake, VA Southampton, VA Northampton, NC Ahoskie, NC Hardwood Roundwood Pine Roundwood Open / Farmland 1MM tons annual facility demand 475MM+ tons inventory 8MM+ tons net annual fiber excess (1) 65,000+ private landowners 1.4MM MT+ consolidated annual throughput ~75mi average distance to port Dedicated, Low-Cost, Haul to Wholly Owned Terminal $15 $50 $12 $40 $9 $30 Enviva’s 1.4MM Tons $6 $20 $3 $10 $-$0 '00 '01 '02 '03 '04 '05 '06 '07 '08 '09 '10 '11 '12 '13 '14 250 500 750 1,0001,2501,5001,7502,000 MT/yr of Pellet Throughput 2,250 (1) FIA Data, Gross of 22MM+ tons annual growth (2) Timber Mart-South 1990-2014 (3) Source: Enviva 15 $ / MT Port Costs Stable Delivered Cost (2) North Carolina Pine Pulpwood 1990-2014 CAGR = 1.89% (2) North Carolina Hardwood Pulpwood 1990-2014 CAGR = 2.18% (2) Cost Advantage of Vertically Integrated Port (3) Operating Leverage of Northampton 7 mi. Robust Resource Availability Integrated Low-Cost Logistics

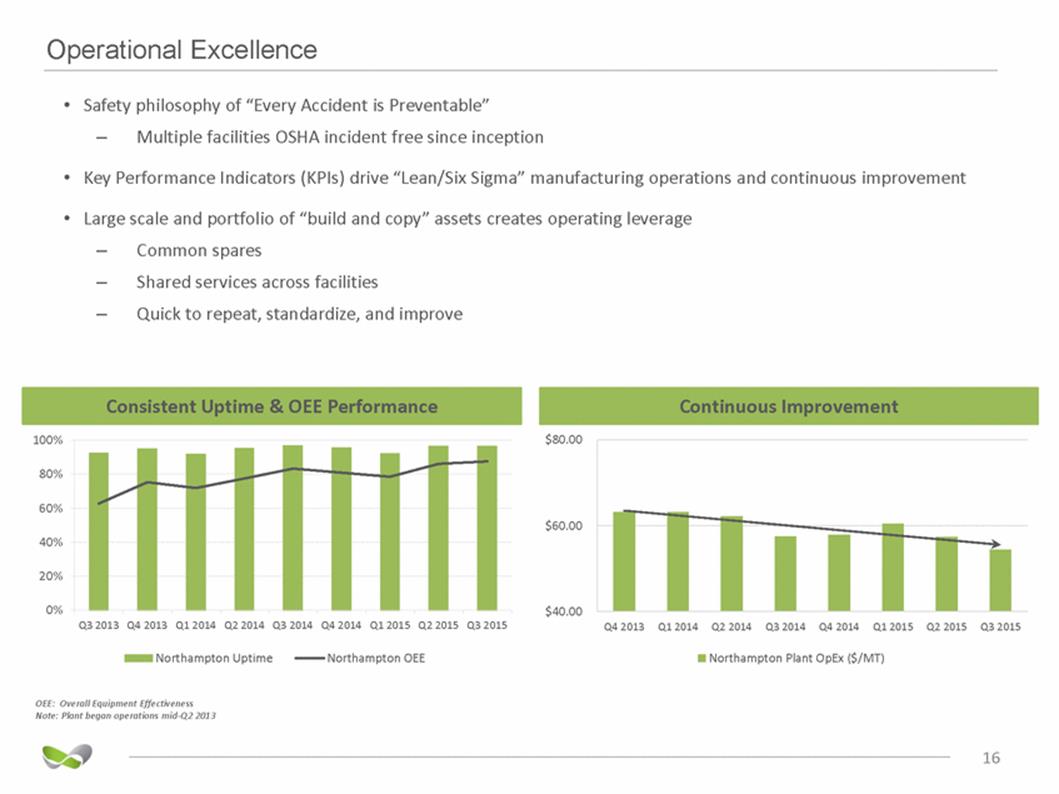

Operational Excellence • Safety philosophy of “Every Accident is Preventable” – Multiple facilities OSHA incident free since inception • Key Performance Indicators (KPIs) drive “Lean/Six Sigma” manufacturing operations and continuous improvement • Large scale and portfolio of “build and copy” assets creates operating leverage – – – Common spares Shared services across facilities Quick to repeat, standardize, and improve 100% $80.00 80% 60% $60.00 40% 20% 0% $40.00 Q3 2013 Q4 2013 Q1 2014 Q2 2014 Q3 2014 Q4 2014 Q1 2015 Q2 2015 Q3 2015 Q4 2013 Q1 2014 Q2 2014 Q3 2014 Q4 2014 Q1 2015 Q2 2015 Q3 2015 Northampton Uptime Northampton OEE Northampton Plant OpEx ($/MT) OEE: Overall Equipment Effectiveness Note: Plant began operations mid-Q2 2013 16 Consistent Uptime & OEE Performance Continuous Improvement

Barge-to-Ship Loading at Enviva’s Operations in Mobile, AL Long-Term Off-take Agreements

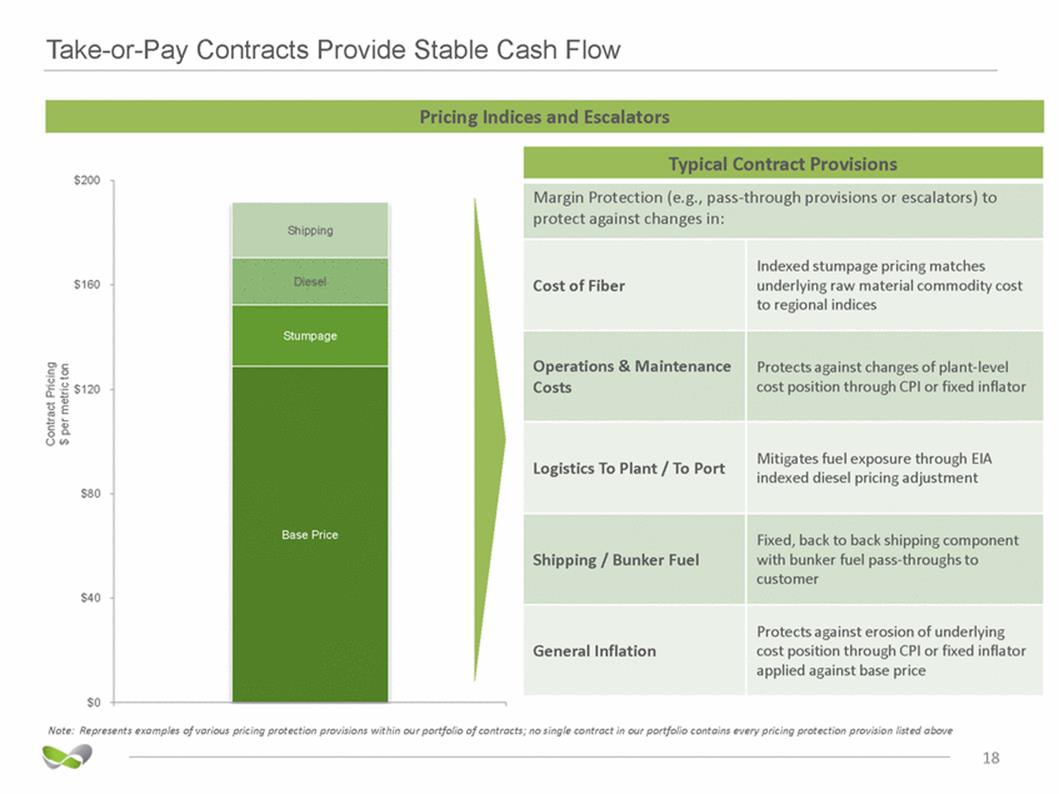

Take-or-Pay Contracts Provide Stable Cash Flow $200 $160 $120 indexed diesel pricing adjustment $80 $40 $0 Note: Represents examples of various pricing protection provisions within our portfolio of contracts; no single contract in our portfolio contains every pricing protection provision listed above 18 Contract Pricing $ per metric ton Shipping Diesel Stumpage Base Price Typical Contract Provisions Margin Protection (e.g., pass-through provisions or escalators) to protect against changes in: Cost of Fiber Indexed stumpage pricing matches underlying raw material commodity cost to regional indices Operations & Maintenance Costs Protects against changes of plant-level cost position through CPI or fixed inflator Logistics To Plant / To Port Mitigates fuel exposure through EIA Shipping / Bunker Fuel Fixed, back to back shipping component with bunker fuel pass-throughs to customer General Inflation Protects against erosion of underlying cost position through CPI or fixed inflator applied against base price Pricing Indices and Escalators

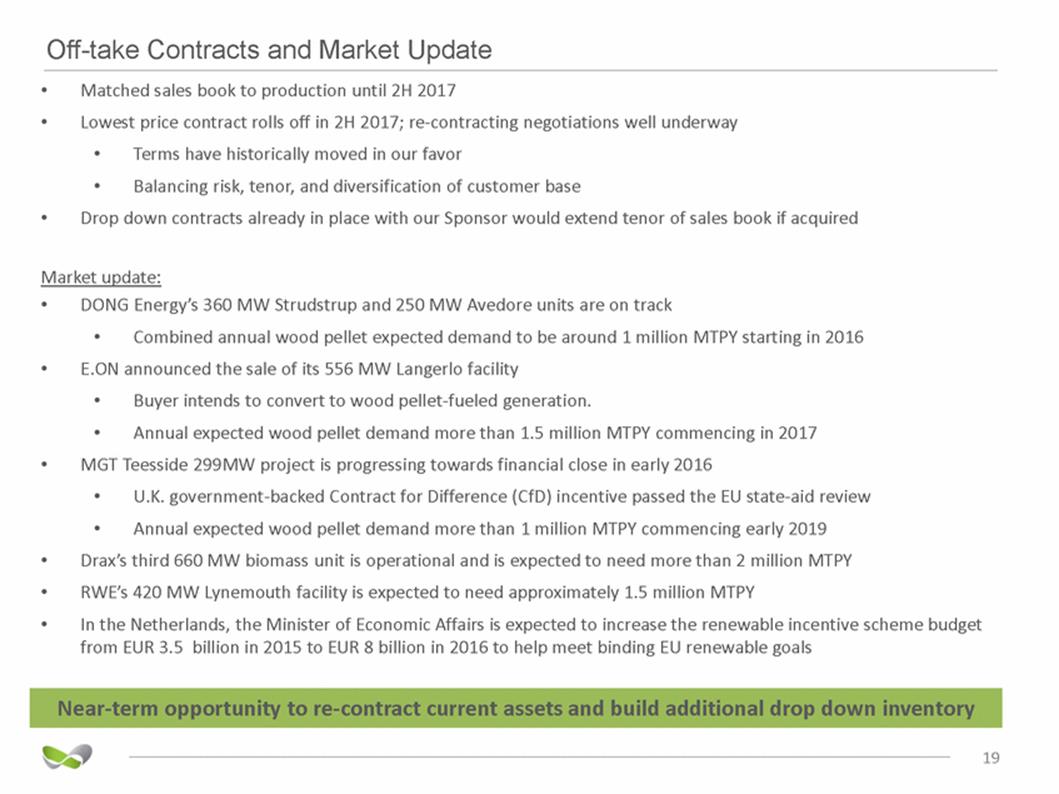

Off-take Contracts and Market Update • • Matched sales book to production until 2H 2017 Lowest price contract rolls off in 2H 2017; re-contracting negotiations well underway • • Terms have historically moved in our favor Balancing risk, tenor, and diversification of customer base • Drop down contracts already in place with our Sponsor would extend tenor of sales book if acquired Market update: • DONG Energy’s 360 MW Strudstrup and 250 MW Avedore units are on track • Combined annual wood pellet expected demand to be around 1 million MTPY starting in 2016 • E.ON announced the sale of its 556 MW Langerlo facility • • Buyer intends to convert to wood pellet-fueled generation. Annual expected wood pellet demand more than 1.5 million MTPY commencing in 2017 • MGT Teesside 299MW project is progressing towards financial close in early 2016 • • U.K. government-backed Contract for Difference (CfD) incentive passed the EU state-aid review Annual expected wood pellet demand more than 1 million MTPY commencing early 2019 • • • Drax’s third 660 MW biomass unit is operational and is expected to need more than 2 million MTPY RWE’s 420 MW Lynemouth facility is expected to need approximately 1.5 million MTPY In the Netherlands, the Minister of Economic Affairs is expected to increase the renewable incentive scheme budget from EUR 3.5 billion in 2015 to EUR 8 billion in 2016 to help meet binding EU renewable goals 19 Near-term opportunity to re-contract current assets and build additional drop down inventory

Enviva’s Port of Chesapeake Substantial Growth Opportunities

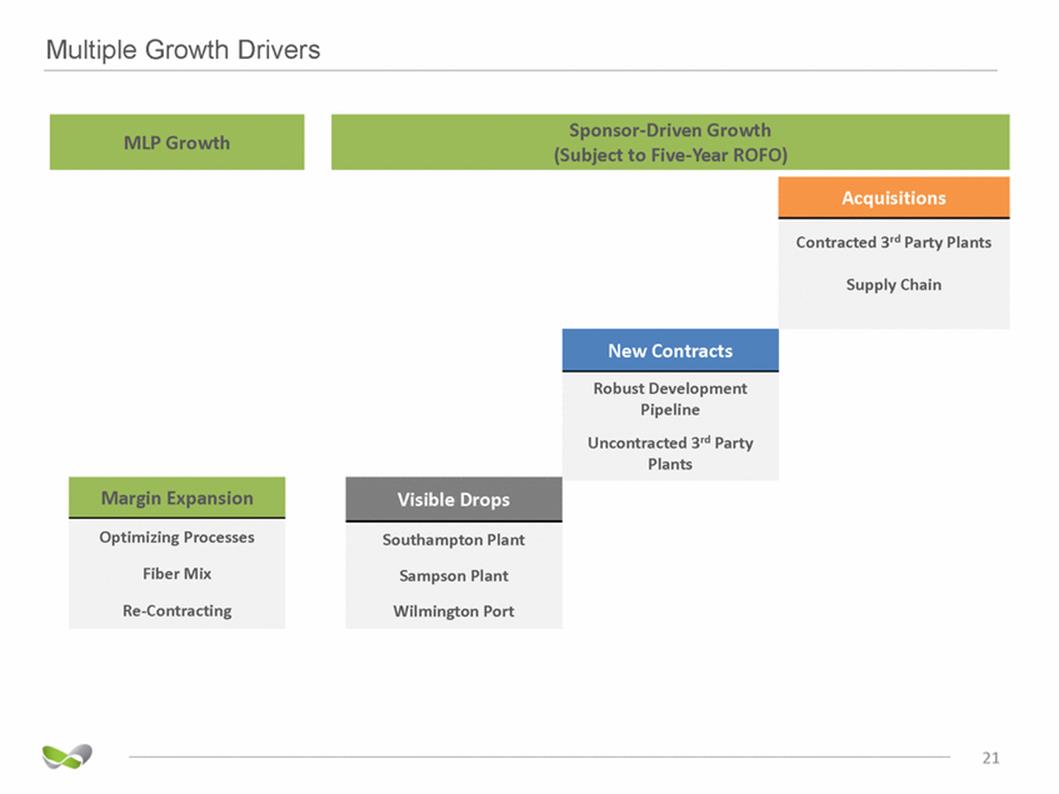

Multiple Growth Drivers (Subject to Five-Year ROFO) 21 Margin Expansion Optimizing Processes Fiber Mix Re-Contracting Acquisitions Contracted 3rd Party Plants Supply Chain New Contracts Robust Development Pipeline Uncontracted 3rd Party Plants Visible Drops Southampton Plant Sampson Plant Wilmington Port Sponsor-Driven Growth MLP Growth

Growth Supported by Committed Investors Invested • Principal owner of Enviva Holdings, LP Enviva Holdings, LP “Our Sponsor” Enviva Partners, LP NYSE: EVA for long-term and Sponsor Assets Development Finance, Construction, and Commissioning 22 Operations Attractive cost of capital with access to capital markets funding 5-year ROFO on JV $320 Million Joint Venture •Separate entity that finances, develops, constructs, and commissions projects from Sponsor pipeline •Currently developing the “Wilmington Projects,” consisting of three 500,000 MTPY wood pellet production plants and a deep-water marine terminal in Wilmington, NC region •Sponsor can compel sale of assets to EVA if certain investment returns are achieved •Capital can be recycled for future growth Strong Development Engine & Customer Contract Pipeline • John Hancock is the US unit of ManuLife Financial and the world’s largest timberland investment manager • $12.0 billion and 6.7 million acres of timberlands under management $550 Million • $27B energy/power private investment firm to Date

Southampton Drop Down Process • Sponsor has proposed sale of fully contracted and operational Southampton plant to EVA • 510K MTPY “build-and-copy” replica of Northampton plant that has been operational since Q4 2013 • Transaction comprised of sale of: – 100% equity interest in Enviva Pellets Southampton, LLC which owns the plant Enviva Pellets Southampton (VA) Production Plant – 10-year pellet off-take agreement commencing December 2015 – Shipping contract matched to the CIF obligations of the off-take agreement • Approximately $20 million estimated incremental Adjusted EBITDA1 • Independent Conflicts Committee of Board formed and process underway • Expect to complete the transaction in Q4 2015 subject to Conflicts Committee approval (1) See reconciliation on slide 42 23

Additional Sponsor Assets Contracted and in Construction • Fully financed 515K MTPY “Build and Copy” replica of Northampton/Southampton plants • Production will support new 10-year contract with DONG Energy commencing September 2016 • Expected commissioning in Q1 2016 • Approximately $20 million estimated incremental Adjusted EBITDA1 Enviva Pellets Sampson (NC) Construction • Fully financed “Build and Copy” replica of Enviva Port of Chesapeake • Port under construction, ~1 million MTPY throughput contracted with Sampson plant and 3rd party volumes • Expected commissioning in Q1 2016 • Approximately $7 million estimated incremental Adjusted EBITDA1 Enviva Port of Wilmington (NC) Construction (1) See reconciliation on slide 42 24 Enviva Port of Wilmington (NC) Enviva Pellets Sampson (NC)

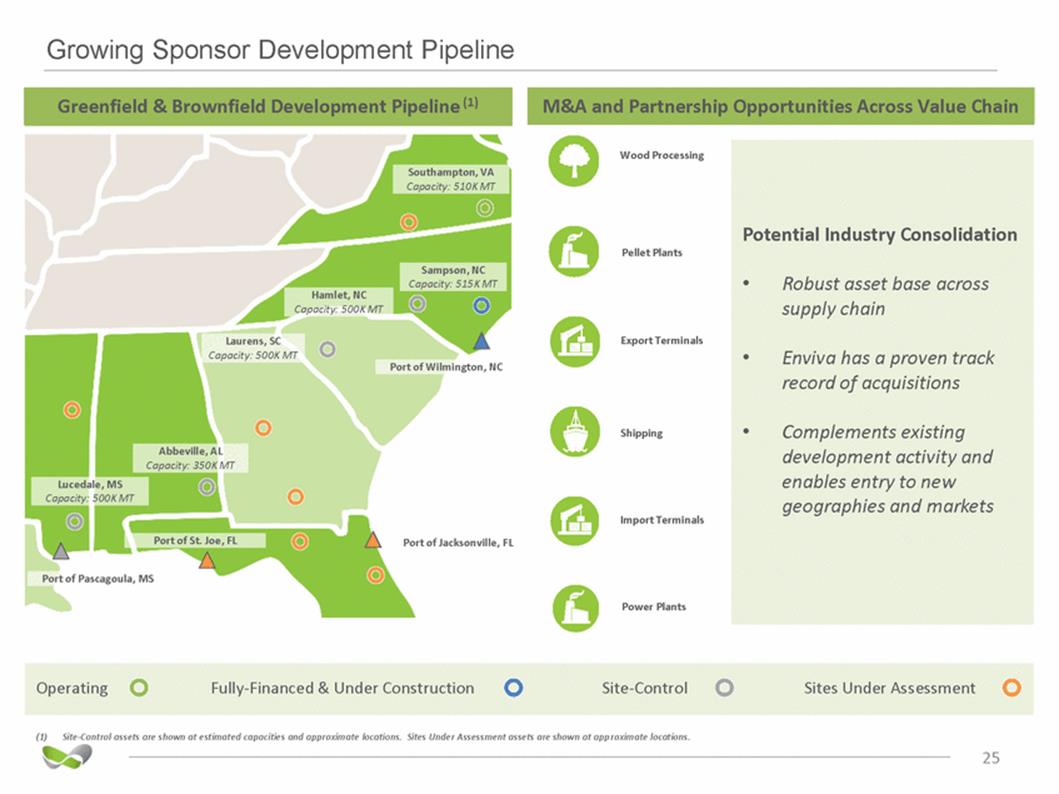

Growing Sponsor Development Pipeline Wood Processing Southampton, VA Capacity: 510K MT Pellet Plants Sampson, NC Capacity: 515K MT Hamlet, NC Capacity: 500K MT Laurens, SC Capacity: 500K MT Export Terminals Port of Wilmington, NC Shipping Abbeville, AL Capacity: 350K MT Lucedale, MS Capacity: 500K MT Import Terminals Port of St. Joe, FL Port of Jacksonville, FL Port of Pascagoula, MS Power Plants (1)Site-Control assets are shown at estimated capacities and approximate locations. Sites Under Assessment assets are shown at app roximate locations. 25 OperatingFully-Financed & Under ConstructionSite-ControlSites Under Assessment Potential Industry Consolidation •Robust asset base across supply chain •Enviva has a proven track record of acquisitions •Complements existing development activity and enables entry to new geographies and markets M&A and Partnership Opportunities Across Value Chain Greenfield & Brownfield Development Pipeline (1)

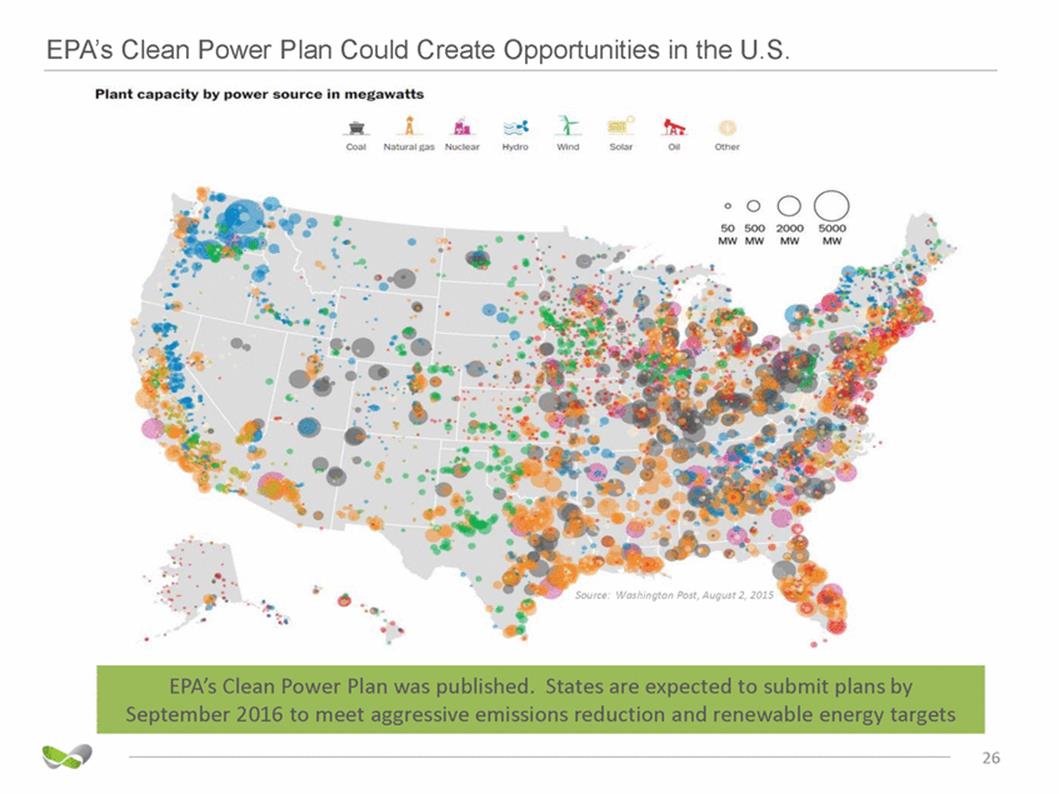

EPA’s Clean Power Plan Could Create Opportunities in the U.S. Source: Washington Post, August 2, 2015 26 EPA’s Clean Power Plan was published. States are expected to submit plans by September 2016 to meet aggressive emissions reduction and renewable energy targets

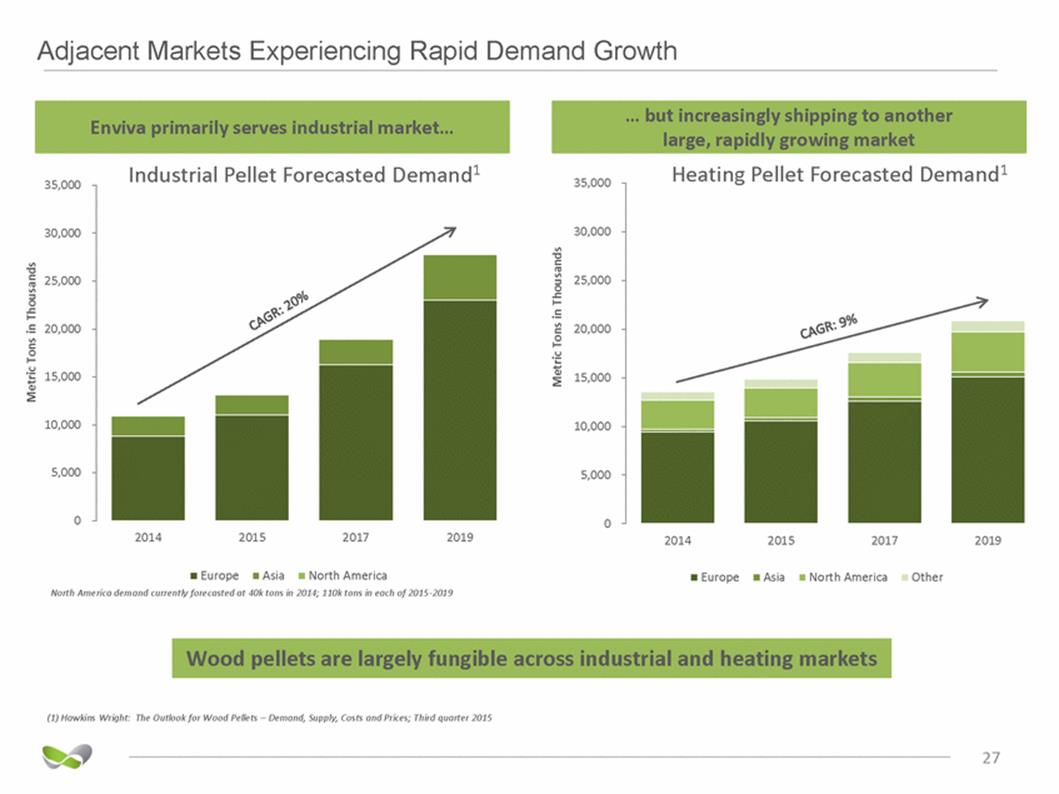

Adjacent Markets Experiencing Rapid Demand Growth large, rapidly growing market 1 1 Industrial Pellet Forecasted Demand Heating Pellet Forecasted Demand 35,000 35,000 30,000 30,000 25,000 25,000 20,000 20,000 15,000 15,000 10,000 10,000 5,000 5,000 0 0 2014 2015 2017 2019 2014 2015 2017 2019 Europe Asia North America Europe Asia North America Other North America demand currently forecasted at 40k tons in 2014; 110k tons in each of 2015-2019 (1) Hawkins Wright: The Outlook for Wood Pellets – Demand, Supply, Costs and Prices; Third quarter 2015 27 Metric Tons in Thousands Metric Tons in Thousands Wood pellets are largely fungible across industrial and heating markets … but increasingly shipping to another Enviva primarily serves industrial market…

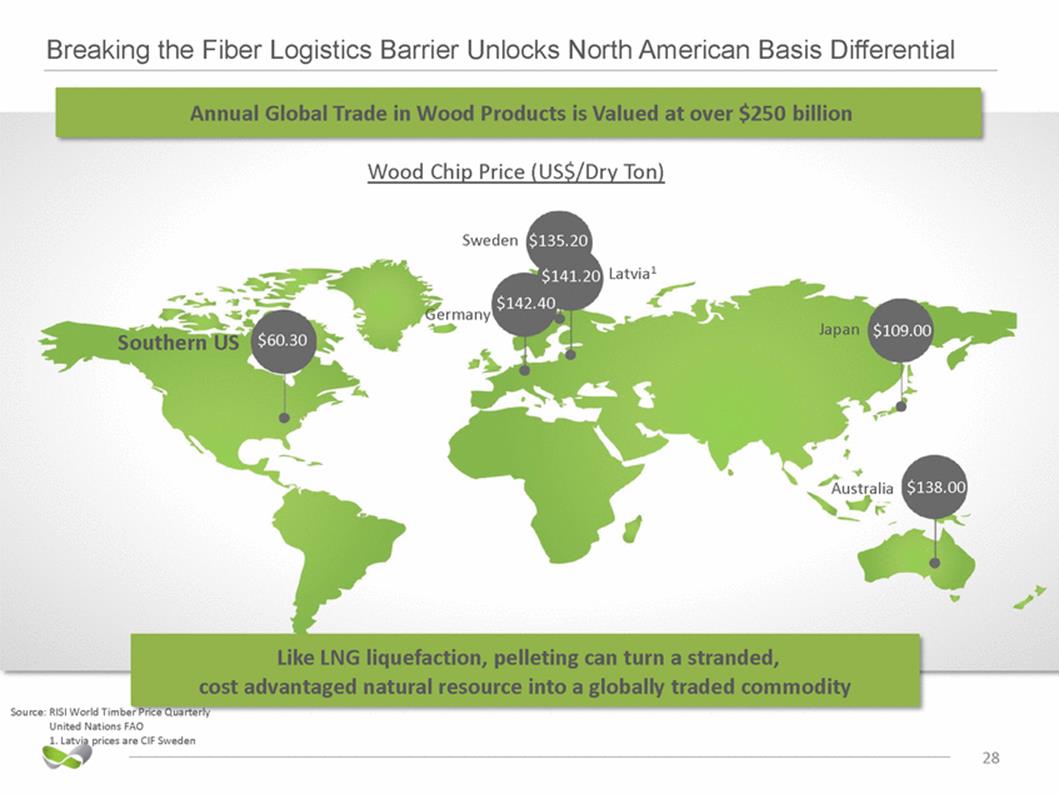

Breaking the Fiber Logistics Barrier Unlocks North American Basis Differential Wood Chip Price (US$/Dry Ton) Sweden $135.20 $141.20 Latvia1 Germany $142.40 Japan $109.00 Southern US $60.30 $138.00 Australia Source: RISI World Timber Price Quarterly United Nations FAO 1. Latvia prices are CIF Sweden 28 Like LNG liquefaction, pelleting can turn a stranded, cost advantaged natural resource into a globally traded commodity Annual Global Trade in Wood Products is Valued at over $250 billion

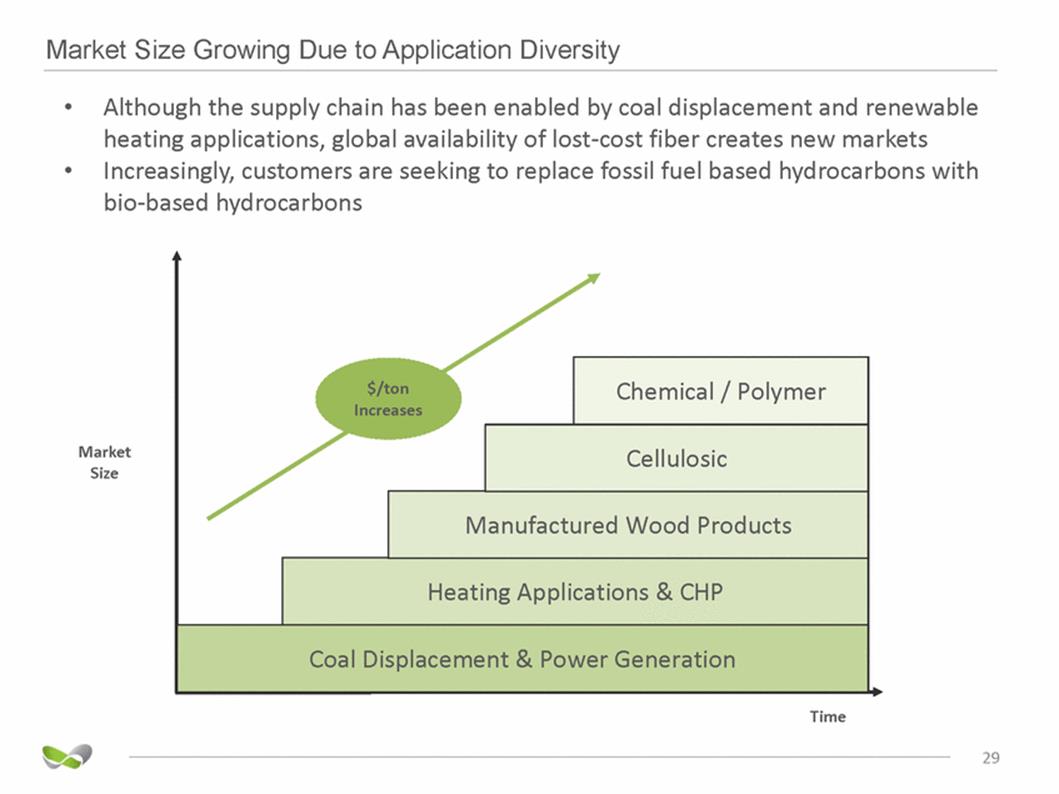

Market Size Growing Due to Application Diversity • Although the supply chain has been enabled by coal displacement and renewable heating applications, global availability of lost-cost fiber creates new markets Increasingly, customers are seeking to replace fossil fuel based hydrocarbons with bio-based hydrocarbons • Market Size Time 29 $/ton Increases Chemical / Polymer Cellulosic Manufactured Wood Products Heating Applications & CHP Coal Displacement & Power Generation

Night Shift at Enviva Pellets Northampton Financial Highlights

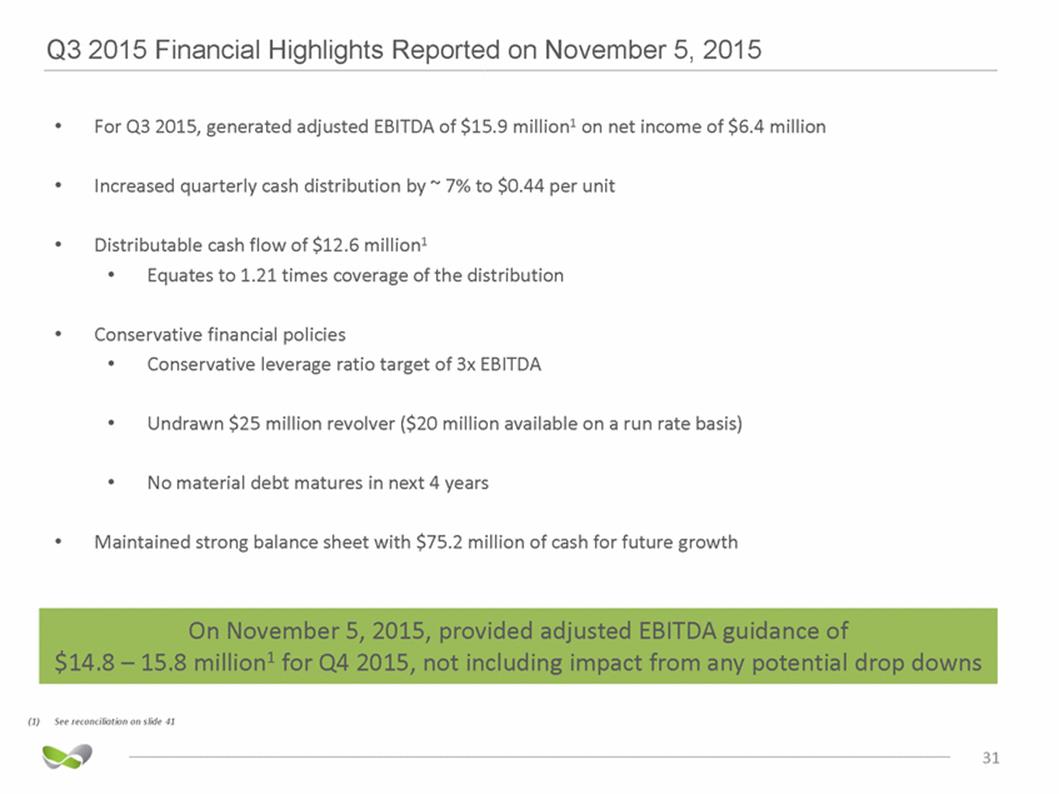

Q3 2015 Financial Highlights Reported on November 5, 2015 • For Q3 2015, generated adjusted EBITDA of $15.9 million1 on net income of $6.4 million • Increased quarterly cash distribution by ~ 7% to $0.44 per unit • Distributable cash flow of $12.6 million1 • Equates to 1.21 times coverage of the distribution • Conservative financial policies • Conservative leverage ratio target of 3x EBITDA • Undrawn $25 million revolver ($20 million available on a run rate basis) • No material debt matures in next 4 years • Maintained strong balance sheet with $75.2 million of cash for future growth (1)See reconciliation on slide 41 31 On November 5, 2015, provided adjusted EBITDA guidance of $14.8 – 15.8 million1 for Q4 2015, not including impact from any potential drop downs

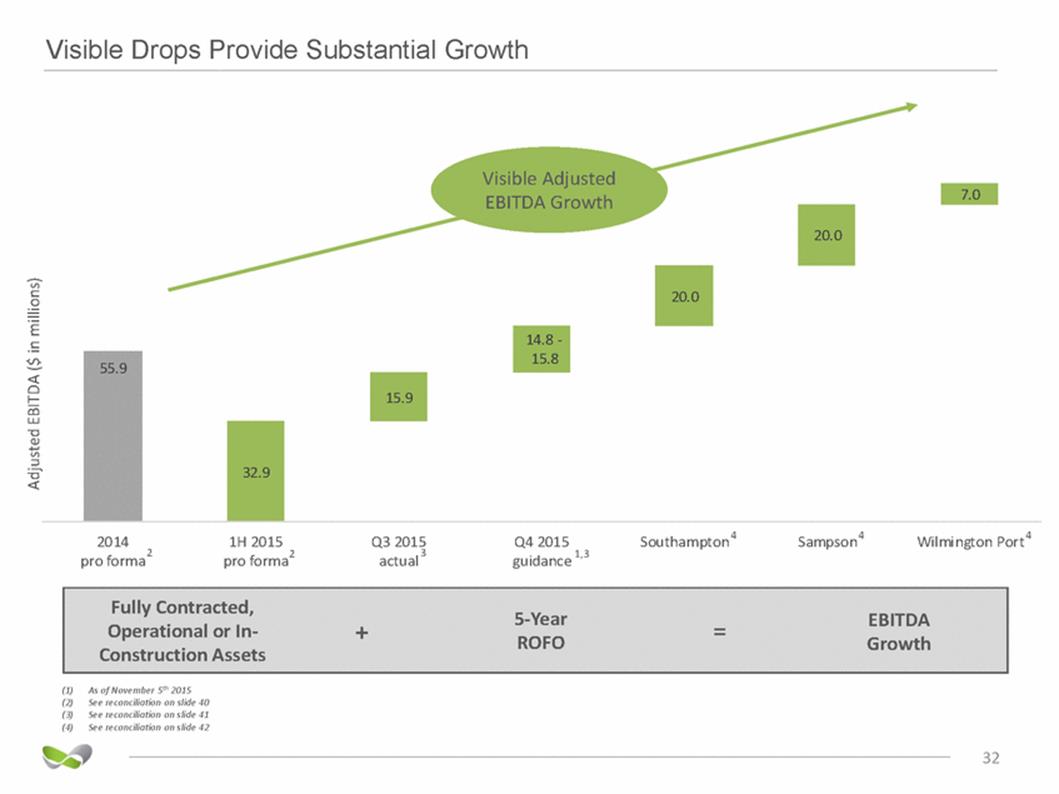

Visible Drops Provide Substantial Growth Visible Adjusted EBITDA Growth 15.3 Southampton4 Sampson4 Wilmington Port4 2014 2 pro forma 1H 2015 pro forma2 Q3 2015 3 actual Q4 2015 guidance 1,3 = + Operational or In-ROFO Growth (1) (2) (3) (4) As of November 5th 2015 See reconciliation on slide 40 See reconciliation on slide 41 See reconciliation on slide 42 32 Adjusted EBITDA ($ in millions) Fully Contracted, 5-Year EBITDA Construction Assets 55.9 32.9 15.9 14.8 - 15.8 20.0 20.0 7.0

Tool and Die Work at Enviva’s Production Plant in Ahoskie, NC Experienced Team

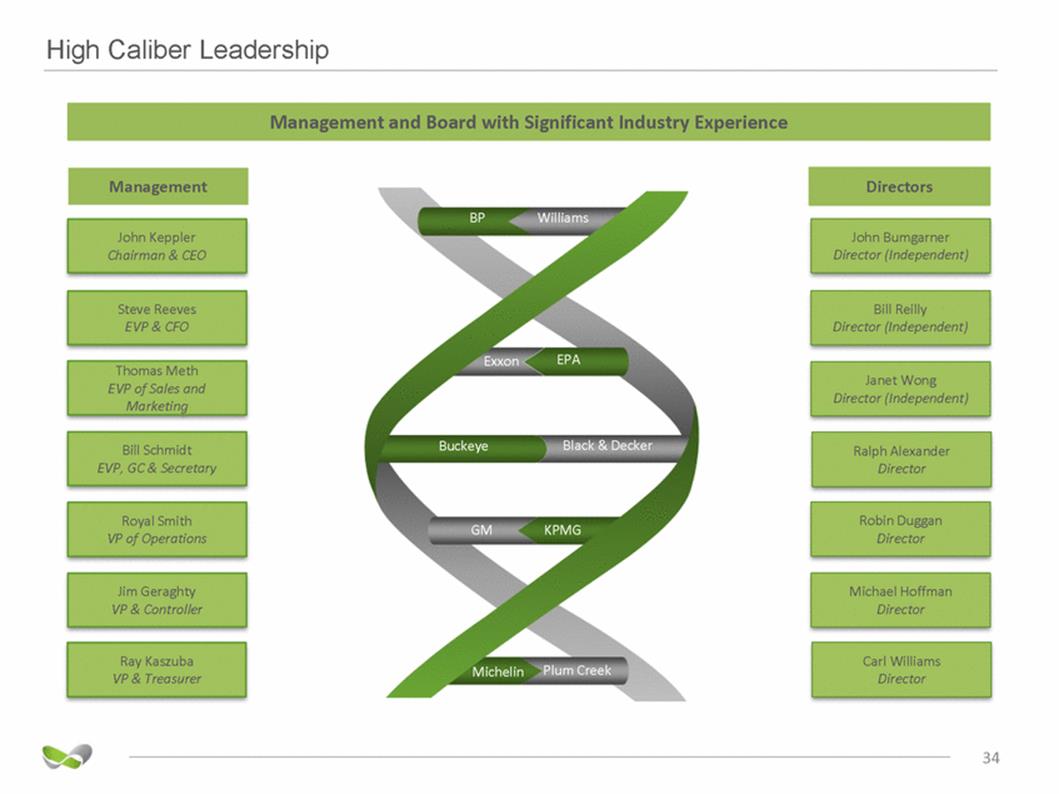

High Caliber Leadership BP Williams John Keppler Chairman & CEO John Bumgarner Director (Independent) Steve Reeves EVP & CFO Bill Reilly Director (Independent) EPA Exxon Thomas Meth EVP of Sales and Marketing Janet Wong Director (Independent) Buckeye Black & Decker Bill Schmidt EVP, GC & Secretary Ralph Alexander Director Royal Smith VP of Operations Robin Duggan Director GM KPMG Jim Geraghty VP & Controller Michael Hoffman Director Ray Kaszuba VP & Treasurer Carl Williams Director Michelin Plum Creek 34 Directors Management Management and Board with Significant Industry Experience

Enviva: A Compelling Story Compelling Industry Fundamentals Experienced Management Team Advantaged Assets Substantial Growth Opportunities Long-Term Off-take Agreements 35

Reg G Reconciliations

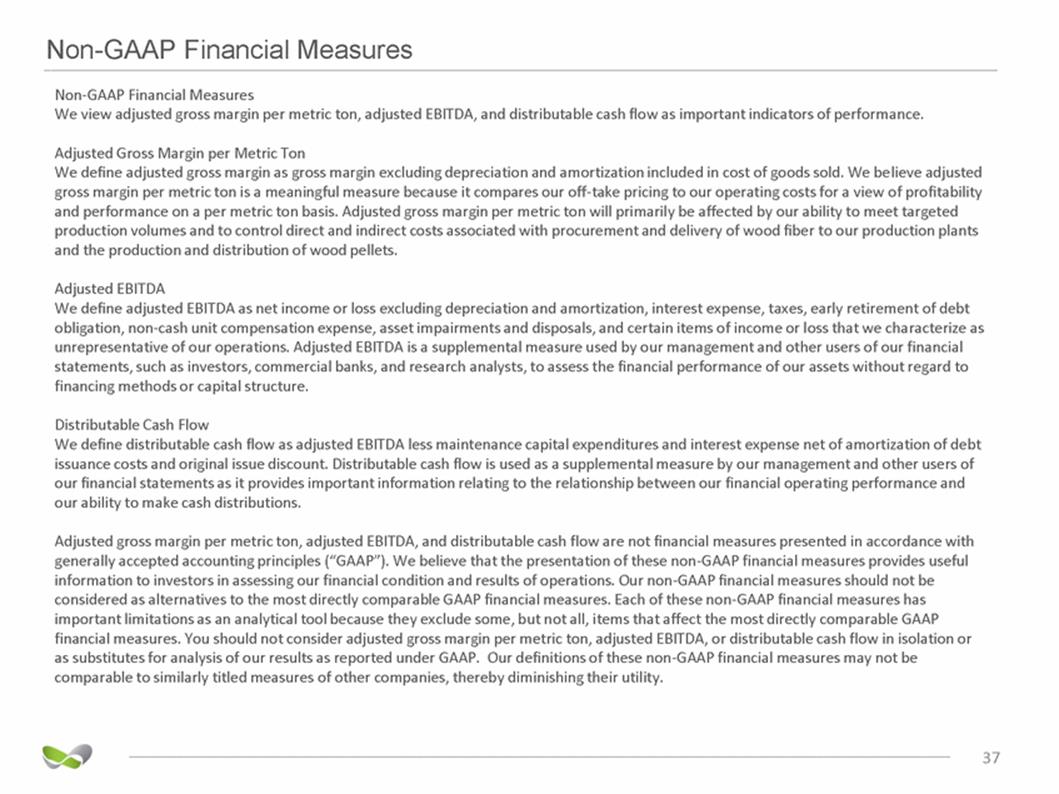

Non-GAAP Financial Measures Non-GAAP Financial Measures We view adjusted gross margin per metric ton, adjusted EBITDA, and distributable cash flow as important indicators of performance. Adjusted Gross Margin per Metric Ton We define adjusted gross margin as gross margin excluding depreciation and amortization included in cost of goods sold. We believe adjusted gross margin per metric ton is a meaningful measure because it compares our off-take pricing to our operating costs for a view of profitability and performance on a per metric ton basis. Adjusted gross margin per metric ton will primarily be affected by our ability to meet targeted production volumes and to control direct and indirect costs associated with procurement and delivery of wood fiber to our production plants and the production and distribution of wood pellets. Adjusted EBITDA We define adjusted EBITDA as net income or loss excluding depreciation and amortization, interest expense, taxes, early retirement of debt obligation, non-cash unit compensation expense, asset impairments and disposals, and certain items of income or loss that we characterize as unrepresentative of our operations. Adjusted EBITDA is a supplemental measure used by our management and other users of our financial statements, such as investors, commercial banks, and research analysts, to assess the financial performance of our assets without regard to financing methods or capital structure. Distributable Cash Flow We define distributable cash flow as adjusted EBITDA less maintenance capital expenditures and interest expense net of amortization of debt issuance costs and original issue discount. Distributable cash flow is used as a supplemental measure by our management and other users of our financial statements as it provides important information relating to the relationship between our financial operating performance and our ability to make cash distributions. Adjusted gross margin per metric ton, adjusted EBITDA, and distributable cash flow are not financial measures presented in accordance with generally accepted accounting principles (“GAAP”). We believe that the presentation of these non-GAAP financial measures provides useful information to investors in assessing our financial condition and results of operations. Our non-GAAP financial measures should not be considered as alternatives to the most directly comparable GAAP financial measures. Each of these non-GAAP financial measures has important limitations as an analytical tool because they exclude some, but not all, items that affect the most directly comparable GAAP financial measures. You should not consider adjusted gross margin per metric ton, adjusted EBITDA, or distributable cash flow in isolation or as substitutes for analysis of our results as reported under GAAP. Our definitions of these non-GAAP financial measures may not be comparable to similarly titled measures of other companies, thereby diminishing their utility. 37

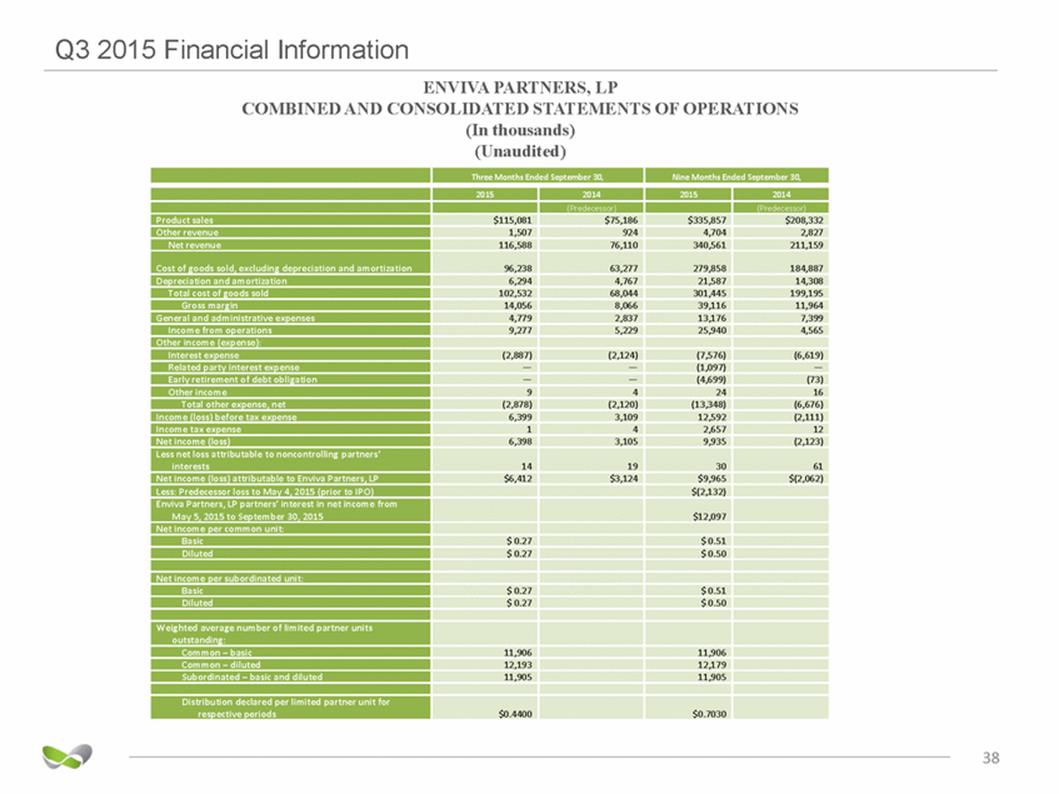

Q3 2015 Financial Information ENVIVA PARTNERS, LP COMBINED AND CONSOLIDATED STATEMENTS OF OPERATIONS (In thousands) (Unaudited) 38 Three Months Ended September 30, Nine Months Ended September 30, 2015 2014 2015 2014 (Predecessor) (Predecessor) Product sales $115,081 $75,186 $335,857 $208,332 Other revenue 1,507 924 4,704 2,827 Net revenue 116,588 76,110 340,561 211,159 Cost of goods sold, excluding depreciation and amortization 96,238 63,277 279,858 184,887 Depreciation and amortization 6,294 4,767 21,587 14,308 Total cost of goods sold 102,532 68,044 301,445 199,195 Gross margin 14,056 8,066 39,116 11,964 General and administrative expenses 4,779 2,837 13,176 7,399 Income from operations 9,277 5,229 25,940 4,565 Other income (expense): Interest expense (2,887) (2,124) (7,576) (6,619) Related party interest expense — — (1,097) — Early retirement of debt obligation — — (4,699) (73) Other income 9 4 24 16 Total other expense, net (2,878) (2,120) (13,348) (6,676) Income (loss) before tax expense 6,399 3,109 12,592 (2,111) Income tax expense 1 4 2,657 12 Net income (loss) 6,398 3,105 9,935 (2,123) Less net loss attributable to noncontrolling partners’ interests 14 19 30 61 Net income (loss) attributable to Enviva Partners, LP $6,412 $3,124 $9,965 $(2,062) Less: Predecessor loss to May 4, 2015 (prior to IPO) $(2,132) Enviva Partners, LP partners’ interest in net income from May 5, 2015 to September 30, 2015 $12,097 Net income per common unit: Basic $ 0.27 $ 0.51 Diluted $ 0.27 $ 0.50 Net income per subordinated unit: Basic $ 0.27 $ 0.51 Diluted $ 0.27 $ 0.50 Weighted average number of limited partner units outstanding: Common – basic 11,906 11,906 Common – diluted 12,193 12,179 Subordinated – basic and diluted 11,905 11,905 Distribution declared per limited partner unit for respective periods $0.4400 $0.7030

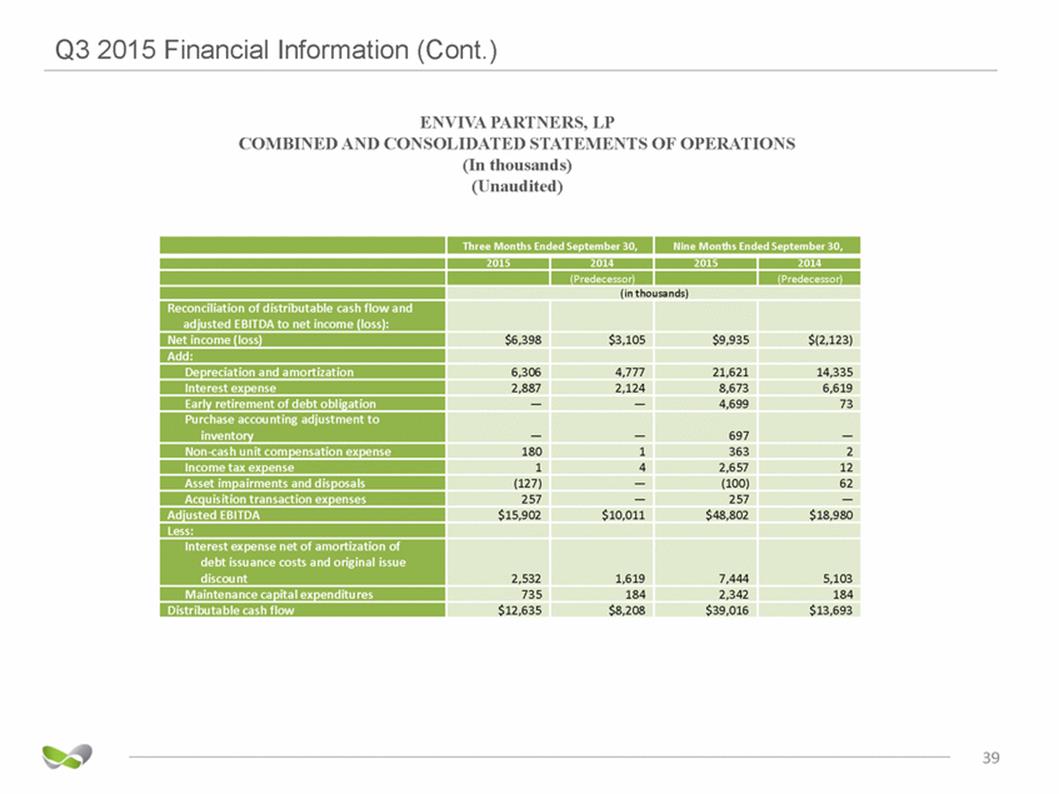

Q3 2015 Financial Information (Cont.) ENVIVA PARTNERS, LP COMBINED AND CONSOLIDATED STATEMENTS OF OPERATIONS (In thousands) (Unaudited) 39 Three Months Ended September 30, Nine Months Ended September 30, 2015 2014 2015 2014 (Predecessor) (Predecessor) (in thousands) Reconciliation of distributable cash flow and adjusted EBITDA to net income (loss): Net income (loss) $6,398 $3,105 $9,935 $(2,123) Add: Depreciation and amortization 6,306 4,777 21,621 14,335 Interest expense 2,887 2,124 8,673 6,619 Early retirement of debt obligation — — 4,699 73 Purchase accounting adjustment to inventory — — 697 — Non-cash unit compensation expense 180 1 363 2 Income tax expense 1 4 2,657 12 Asset impairments and disposals (127) — (100) 62 Acquisition transaction expenses 257 — 257 — Adjusted EBITDA $15,902 $10,011 $48,802 $18,980 Less: Interest expense net of amortization of debt issuance costs and original issue discount 2,532 1,619 7,444 5,103 Maintenance capital expenditures 735 184 2,342 184 Distributable cash flow $12,635 $8,208 $39,016 $13,693

Non-GAAP Financial Measures Reconciliation The following table provides, on a pro forma basis, a reconciliation of adjusted EBITDA to net income, in each case for the twelve months ending December 31, 2014 (in millions): The following table provides, on a pro forma basis, a reconciliation of adjusted EBITDA to net income, in each case for the six months ending June 30, 2015 (in millions): 40 Six Months Ended June 30, 2015 Net income (loss) $ 3.5 Add: Depreciation and amortization 15.3 Interest expense 5.8 Early retirement of debt obligation 4.7 Purchase accounting adjustment to inventory 0.7 Non-cash equity compensation 0.2 Income tax expense 2.7 Asset impairments and disposals — Acquisition transaction expenses — Adjusted EBITDA $32.9 Twelve Months Ended December 31, 2014 Net income (loss) $11.3 Add: Depreciation and amortization 26.1 Interest expense 10.9 Early retirement of debt obligation 7.2 Purchase accounting adjustment to inventory — Non-cash equity compensation — Income tax expense — Asset impairments and disposals 0.4 Acquisition transaction expenses — Adjusted EBITDA $55.9

Non-GAAP Financial Measures Reconciliation (Cont.) The following table provides a reconciliation of distributable cash flow and adjusted EBITDA to net income, in each case for the three months ending September 30, 2015 (in millions): The following table provides a reconciliation of the estimated range of adjusted EBITDA to the estimated range of net income, in each case for the three months ending December 31, 2015 (in millions): 41 Three Months Ending December 31, 2015 Estimated net income $5.6 – 6.6 Add: Depreciation and amortization 5.1 Interest expense 2.8 Non-cash unit compensation 0.4 Income tax expense 0.1 Asset impairments and disposals 0.3 Acquisition transaction expenses 0.5 Estimated adjusted EBITDA $14.8 – 15.8 Three Months Ended September 30, 2015 Net income (loss) $ 6.4 Add: Depreciation and amortization 6.3 Interest expense 2.9 Early retirement of debt obligation — Purchase accounting adjustment to inventory — Non-cash unit compensation expense 0.2 Income tax expense — Asset impairments and disposals (0.1) Acquisition transaction expenses 0.3 Adjusted EBITDA $15.9 Less: Interest expense net of amortization of debt issuance costs and original issue discount 2.5 Maintenance capital expenditures 0.7 Distributable cash flow $12.6

Non-GAAP Financial Measures Reconciliation (Cont.) The following table provides a reconciliation of the estimated annual Adjusted EBITDA to estimated net income associated with the Southampton plant and related contracts (in millions): Our sponsor’s estimates of annual adjusted EBITDA and maintenance capital expenditures for each of the Sampson plant and the Wilmington terminal are based on numerous assumptions that are subject to significant risks and uncertainties. The assumptions underlying our sponsor’s estimates of annual adjusted EBITDA and maintenance capital expenditures generated by certain of its assets are inherently uncertain and subject to significant business, economic, financial, regulatory, and competitive risks and uncertainties that could cause actual results and amounts to differ materially from those estimates. For more information about such significant risks and uncertainties, please see the risk factors discussed or referenced in our filings with the Securities and Exchange Commission (the “SEC”), including the IPO prospectus filed on April 29, 2015 and the Quarterly Reports on Form 10-Q most recently filed with the SEC. A reconciliation of estimated adjusted EBITDA to GAAP net income is not provided because forward-looking GAAP net income generated by each of the Sampson plant and the Wilmington terminal is not accessible and reconciling information is not available without unreasonable effort. The amount of interest expense and the amount of depreciation and amortization expense with respect to the Sampson plant and the Wilmington terminal, in each case, is not accessible or estimable at this time. The amount of actual interest expense or depreciation and amortization expense, as the case may be, incurred could be significant, such that the actual amount of net income generated by each of the Sampson plant and Wilmington terminal could vary substantially from the respective amounts of estimated annual adjusted EBITDA. 42 Estimated net income $10.7 Add: Depreciation and amortization 5.6 Interest expense 3.7 Non-cash unit compensation — Income tax expense — Asset impairments and disposals — Estimated adjusted EBITDA $20.0

env1va Contact: Ray Kaszuba Vice President and Treasurer +1240-482-3856 ir@envivapartners.com