Attached files

| file | filename |

|---|---|

| EX-32.2 - EXHIBIT 32.2 - QUANTUMSPHERE, INC. | s101863_ex32-2.htm |

| EX-32.1 - EXHIBIT 32.1 - QUANTUMSPHERE, INC. | s101863_ex32-1.htm |

| EX-31.2 - EXHIBIT 31.2 - QUANTUMSPHERE, INC. | s101863_ex31-2.htm |

| EX-31.1 - EXHIBIT 31.1 - QUANTUMSPHERE, INC. | s101863_ex31-1.htm |

UNITED

STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

| þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 | |

| For the fiscal year ended June 30, 2015 | ||

| ☐ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

QUANTUMSPHERE,

INC.

(Exact name of registrant as specified in its charter)

000-53913

(Commission File Number)

| Nevada | 20-3925307 | |

| (State or other jurisdiction of | (I.R.S. Employer Identification No.) | |

| Incorporation or organization) |

2905

Tech Center Drive, Santa Ana, CA 92705

(Address of principal executive offices, with zip code)

714-545-6266

(Registrant’s telephone number, including area code)

Securities Registered pursuant to Section 12(b) of the Act: None.

Securities Registered pursuant to Section 12(g) of the Exchange Act: Common Stock, $.001 par Value

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. YES ☐ NO þ

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. YES ☐ NO þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. YES þ NO ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). YES þ NO ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. þ

Indicate by check mark whether registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer ☐ | Accelerated filer ☐ | Non-accelerated filer ☐ | Smaller reporting company þ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). YES ☐ NO þ

The aggregate market value of the registrants common stock as of December 28, 2014, the last business day of the registrant’s most recently completed second fiscal quarter, held by non-affiliates of the registrant was approximately $36,346,376 (based on the last subscription price for our common stock of $2.00).

As of September 28, 2015, 22,511,884 shares of the registrant’s common stock were outstanding.

| -1- |

TABLE OF CONTENTS

| -2- |

Overview

QuantumSphere, Inc., formerly known as Way Cool Imports, Inc., was incorporated in the State of Nevada on December 1, 2005 (referred to as the “Registrant”). On April 22, 2014, we entered into an Agreement and Plan of Merger with QuantumSphere, Inc., a California corporation (“QSI”), whereby, among other things, QSI would merge with a wholly-owned subsidiary of the Registrant. On April 22, 2014, the parties consummated the merger and QSI became a wholly-owned subsidiary of the Registrant. Subsequently, on April 25, 2014, we filed Articles of Merger with the Nevada Secretary of State for the purposes of effecting a short-form merger of QSI with and into the Registrant. As part of the short-form merger, we amended our Articles of Incorporation to changes our name from “Way Cool Imports, Inc.” to “QuantumSphere, Inc.” The Articles of Merger were effective upon filing. In June 2014, the Company elected to change its year end from December 31 to June 30. As used in this Annual Report on Form 10-K, the references to “we” or “our” reflect the Registrant and its operations post-merger, i.e., inclusive of QSI and its operations.

We develop and manufacture proprietary high-performance catalysts, integrated components, and end-use products across a range of carefully selected chemicals markets, typically in conjunction with the sector’s larger participants. Our proprietary high-performance products can be utilized in thermo-chemical (chemical production) applications and have demonstrated the ability to reduce costs and increase efficiency in the generation, storage, and use of energy.

Platform Technology & Catalyst Market

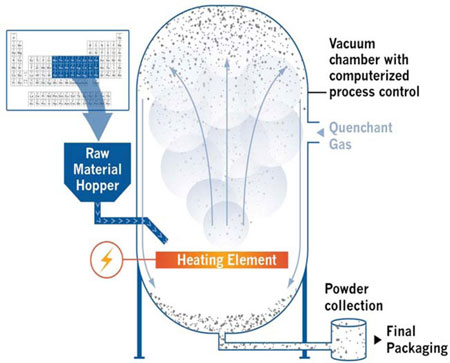

Our high value, end use applications in the chemicals sectors emanate from our award winning, patented, nanocatalyst manufacturing platform technology. Our platform technology allows us to manufacture, in an automated manner, highly uniform, 99.99% pure, narrowly distributed, nano-particles with high catalytic activity. We view ourselves as a products company, rather than an advanced materials company, with the products we distribute being made possible through our break-through platform technology.

We spent the first several years following our inception, designing, fabricating, testing, refining, improving, automating, and scaling our closed-loop, proprietary nanocatalyst manufacturing platform technology. In terms of the production of advanced nanocatalyst materials, we have progressed from a few grams per day to capacity of 300 kilograms per month in our existing manufacturing facility. This is essential as scale is required with each of the end use applications we are pursuing today and anticipate pursuing in the future.

Importantly, in 2007, we secured two broad patents on the QSI manufacturing technology process itself and, in 2010, we achieved ISO 9001:2008 certification for quality management systems related to our nanocatalyst manufacturing platform technology. With respect to our intellectual property relating to the platform technology, we have not disclosed our proprietary algorithms and software that are used in the manufacturing process. We treat the foregoing as our “Coca-Cola” trade secret that will remain proprietary. Other key features of our platform technology include the ability to rapidly scale the manufacturing process in a highly automated, modular fashion at low capital cost.

| -3- |

The following image depicts our nanocatalyst manufacturing platform technology and a portion of the periodic table of elements we convert and integrate into various commercial products.

By way of background, the catalyst market is a multi-billion dollar global industry. According to an industry study prepared by The Freedonia Group, the global catalyst markets exceeded $14 billion in 2013 with worldwide demand for catalysts to increase to $19.5 billion in 2016.1 Of this amount, nanocatalysts are expected to play a critical role in reducing costs and increasing efficiency in the generation, storage, and usage of energy with an estimated market of $6.6 billion by 2018.2

A nanometer (nm) is one billionth of a meter, or 1,000 times smaller than the diameter of a human hair, or roughly the size of a marble when compared to the earth. QSI catalysts typically measure 20-50 nm in size with a very narrow particle size distribution, and have surface area of up to 100 meters square per gram, roughly covering the size of a soccer field with just a small amount of material. A catalyst is a material that helps facilitate chemical reactions and can make chemical reactions happen more efficiently. The greater the surface area of the catalyst, the more efficient the chemical reaction, resulting in lower cost, higher performance end-use applications (e.g., chemical synthesis).

1 World Catalysts: Industry Study with Forecasts for 2016 & 2021, February 2013 (The Freedonia Group).

2 “Need to Curb Automobile & Industrial Emissions Drives the Global Nanocatalysts Market, According to New Report by Global Industry Analysts, Inc.”, PRWEB, November 23, 2013

(http://www.benzinga.com/pressreleases/13/11/p4106559/need-to-curb-automobile-industrial-emissions-drives-the-global-nanocata).

| -4- |

Our advanced catalysts have superior properties including their spherical shape, controlled oxide layer, narrow particle size distribution, high purity, low agglomeration, and large surface area. We believe these combined physical characteristics translate into greater efficiency in the generation, storage, and use of energy. Leveraging our patented, automated, highly scalable, and environmentally safe nanocatalyst manufacturing process, we manufacture a number of high-quality metals, bi-metallic alloys, and catalysts at the nano-scale including iron, silver, copper, nickel, manganese, and cobalt. We also offer custom dispersions and several specialty metals and catalysts including gold, palladium, aluminum, and tin.

Presently, we have sixteen dedicated gas phase condensation reactors which we utilize in the manufacture of nanocatalysts. With sixteen reactors, our capacity is approximately 300 kilograms per month (the foregoing is based on nano-iron production utilizing three production shifts, and the overall monthly kilogram production will depend on the catalysts being produced given varying production rates among catalysts we manufacture). Given the manner in which we have designed our production reactors, we are able to quickly scale and adjust production runs to satisfy our customers’ advanced material needs and delivery timelines. In addition, we leverage our technical knowledge and process chemistry expertise to offer custom dispersions, alloys and integrated catalytic solutions for the energy storage and chemical sectors. For example, we have a customer based in Israel that uses a highly active catalyst blend of nano-silver and nano-palladium to increase performance and lower cost in a platinum-free alkaline fuel cell, used for back-up power applications.

Chemicals Opportunity

QSI catalysts have the potential to benefit multiple, multi-billion dollar process applications in the refining, petrochemical, chemical, and pharmaceutical industries. Currently, the lead application and commercialization focus is in the global ammonia synthesis market. Ammonia production is a highly critical and energy-intensive process that occurs by combining hydrogen and nitrogen under high pressure and temperature in the presence of an iron catalyst. Though many incremental improvements have been achieved in both process and catalyst technology over the last 100 years, the industry is ripe for a paradigm shift in ammonia synthesis efficiency. Other applications of our nano catalysts in the chemicals industry, outside of the ammonia sector, are being pursued and are presently in the lab validation phase.

The Critical Role of Catalysts within the Chemicals Industry

A multi-billion dollar global industry, catalysts are essential to the world’s industrial production. As much as 90% of all chemical processes utilize catalysts (e.g., petroleum refining, pollution abatement, and production of fuels and chemicals) and 60% of all consumer and industrial products (e.g., fertilizers, plastics, pharmaceuticals, and batteries) are made using catalysts.3 Catalysts are now seen as a preferred way to improve process efficiency, lower costs, increase output, use less energy, and meet both performance and environmental standards. This is placing a strong emphasis on the development of new catalysts with higher activity, increased longevity, and reduced environmental and/or health impact. Our high surface area catalysts have demonstrated the ability to deliver much higher activity in multiple lab validations and, thus, greater efficiencies than existing commercial iron catalysts.

3 “Wide Participation in the 21st Annual Saudi-Japan Symposium “Catalysts in Petroleum Refining & Petrochemicals” at KFUPM”, King Fahd University of Petroleum & Minerals Press Release dated November 29, 2011 (http://web.kfupm.edu.sa/SitePages/en/UniversityNewsDetails.aspx?CUSTOMID=147).

| -5- |

Ammonia Market Overview

Globally, the amount of ammonia produced annually consumes more than 1% of the world’s energy supply.4 Nearly 80% of the global ammonia output is used as agricultural fertilizer for both food and non-food crops including biofuel feedstock.5 In addition, ammonia plants produce nearly 1% of the world’s total carbon dioxide emissions.6 Annual world production is heavily concentrated in China, accounting for more than 33% of ammonia produced today.7

Ammonia Market Status

On May 27, 2015, the Company entered into a multi-year Joint Development Agreement with Swiss-based Casale, S.A. (Casale), a global leader in production technologies for ammonia, urea, melamine, methanol, syngas, nitrates and phosphates. Casale’s reactor production technologies are utilized in approximately 38 percent of global ammonia production and 39 percent of global methanol production. Casale and QSI have agreed to collaborate on commercial technologies for ammonia, methanol, and other industrial chemicals, which collectively account for several hundred billion USD of production annually. Casale also agreed to utilize QSI as its exclusive provider of nanocatalysts for its chemical synthesis processes during the term of the agreement due to QSI’s demonstrated increase in catalytic activity and patented high-volume manufacturing process. The first objective of the Joint Development Agreement is to validate and optimize QSI-Nano catalysts with Casale production reactor technologies. Following a successful validation phase, the second objective is to enter into a long-term agreement with Casale for the joint global distribution and sale of QSI-Nano catalysts with Casale reactor technologies to chemical plant owners and operators.

To date, we have spent six years testing internally and externally validating the increased efficiencies of our QSI-Nano® iron catalysts, known as FeNix™, with several industry leaders in the UK, Switzerland, Germany, and more recently in China. In the last year, we were able to achieve a commercial validation of our FeNix™ catalyst in an ammonia plant owned and operated by the JH Group in China in May 2015. JH Group is the eleventh largest producer of ammonia in China. We are now in the process of arranging a second commercial validation of our FeNix™ catalyst in the western hemisphere in the first half of 2016. Upon achieving a second commercial validation, our objective is to achieve commercial purchase orders for our FeNix™ catalyst by the end of calendar 2016.

4 “New Revelations in Ammonia Synthesis,” University of Cambridge Press Release, November 17, 2000

(http://www.cam.ac.uk/news/new-revelations-in-ammonia-synthesis).

5 “Ammonia Production,” Encyclopedia of Earth, March 15, 2012 (http://www.eoearth.org/view/article/170573).

6 “Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2012 – Executive Summary,” U.S. EPA, 2014, (http://www.epa.gov/climatechange/Downloads/ghgemissions/US-GHG-Inventory-2014-Chapter-Executive-Summary.pdf).

7 “Biofuels Production, Improving Diets and Growing Economies in ‘BIC’ Countries Driving Global Demand for Ammonia, New IHS Study Says,” IHS, March 5, 2014 (http://press.ihs.com/press-release/ammonia/biofuels-production-improving-diets-and-growing-economies-bic-countries-drivin).

| -6- |

Our Competitive Advantage

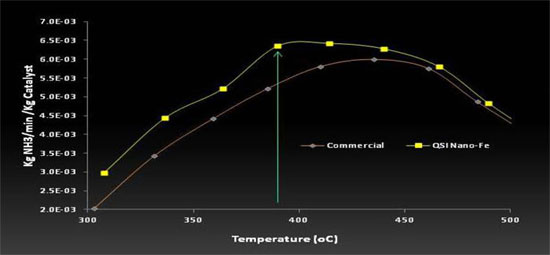

The figure below illustrates the performance difference between a FeNix™ coated and an uncoated commercial iron catalyst used in the production of ammonia. In sum, a 1.5% coating (by weight) of FeNix™ catalysts onto existing commercial iron catalysts produces up to a 20% increase in catalyst activity (per QSI in-house lab validation and thereafter confirmed in a China commercial validation completed in May 2015 where we realized 10% to 15% production increase). In addition, our research and development indicates an ammonia plant may alternatively choose to decrease the pressure and heat required for ammonia production, and achieve the same ammonia production (output), and in doing so save up to 5% in energy costs and reduce emissions.

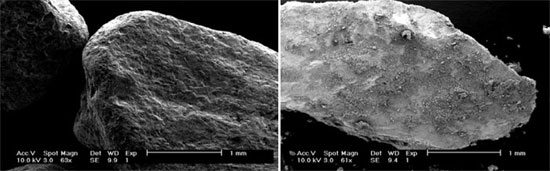

The TEM image on the left below represents a commercial iron catalyst (uncoated), while the TEM image on the right is the commercial iron catalyst coated with FeNix™ at a 1.5% loading.

| -7- |

Global Ammonia Market

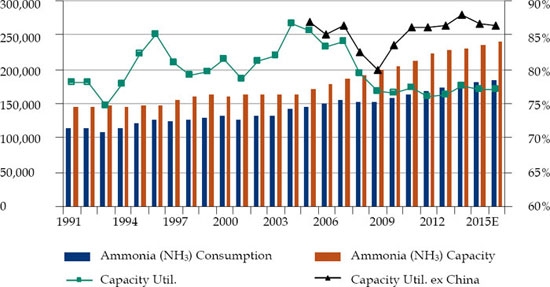

Ammonia is the building block of the global nitrogen industry. According to a January 9, 2014 research report by Bank of America Merrill Lynch,8 approximately 78% of ammonia is used in fertilizer where it is processed into downstream products like urea or direct-applied. Ammonia is produced in anhydrous form by catalytic reaction between nitrogen and hydrogen from natural gas or coal. The same report states that the demand for ammonia has grown 2% per year since 2000 and is expected to grow 2.5% per year through 2016 due to higher fertilizer demand in Asia and Latin America, where the capacity for ammonia has grown 2.5% per year since 2000 and is expected to maintain that annual rate of growth through 2016. The chart below shows the global ammonia supply and demand in 1,000 metric tons from 1991 to 2016.

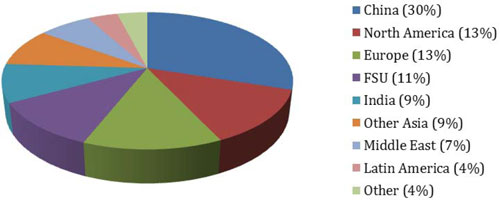

Ammonia Global Demand by Region – 2013E

In addition to the foregoing, Fertecon has estimated global ammonia production as follows for the period 2010 thru 2015, where the worldwide production capacity is estimated to increase from 177,230,000 metric tons in 2009/2010 to 310,542,000 metric tons in the foreseeable future.

8 Research report by Bank of America Merrill Lynch dated January 9, 2014 and entitled, “Move to Neutral from Buy; methanol surge priced in?” (citing Fertecon, Green Markets, FMC, CRU BofA Merrill Lynch Global Research estimates).

| -8- |

Ammonia Production Capacity by Region (in 1000 metric tons)9

| Region | 2009/10 | 2010/11 | 2011/12 | 2012/13 | 2013/14 | 2014/15 | 2015/16 | 2016/17 | Indefinite | |||||||||||||||||||||||||||

| North America | 16,425 | 16,737 | 17,013 | 17,603 | 17,807 | 17,886 | 19,146 | 19,146 | 26,461 | |||||||||||||||||||||||||||

| Latin America | 11,737 | 11,737 | 11,011 | 11,011 | 11,442 | 12,797 | 13,623 | 13,634 | 18,539 | |||||||||||||||||||||||||||

| Western Europe | 12,491 | 12,391 | 12,391 | 12,391 | 12,391 | 12,391 | 12,391 | 12,391 | 12,391 | |||||||||||||||||||||||||||

| Central Europe | 8,385 | 8,385 | 7,785 | 7,785 | 7,785 | 7,785 | 7,785 | 7,785 | 9,804 | |||||||||||||||||||||||||||

| Eurasia | 26,353 | 26,223 | 26,676 | 26,920 | 26,920 | 27,320 | 28,697 | 29,093 | 36,069 | |||||||||||||||||||||||||||

| Africa | 6,966 | 6,966 | 7,466 | 9,168 | 11,346 | 11,988 | 12,748 | 12,748 | 21,801 | |||||||||||||||||||||||||||

| West Asia | 15,407 | 16,496 | 17,596 | 17,596 | 19,827 | 21,247 | 21,632 | 21,632 | 25,993 | |||||||||||||||||||||||||||

| South Asia | 18,907 | 20,443 | 20,443 | 21,326 | 22,052 | 22,778 | 22,778 | 22,778 | 35,800 | |||||||||||||||||||||||||||

| East Asia | 58,534 | 61,946 | 68,903 | 73,762 | 88,235 | 95,487 | 98,005 | 98,005 | 119,550 | |||||||||||||||||||||||||||

| -- China | (47,327 | ) | (50,614 | ) | (57,571 | ) | (61,664 | ) | (76,137 | ) | (81,605 | ) | (83,463 | ) | (83,463 | ) | (101,326 | ) | ||||||||||||||||||

| Total Asia | 92,848 | 98,885 | 106,942 | 112,684 | 130,114 | 139,512 | 142,415 | 142,415 | 181,343 | |||||||||||||||||||||||||||

| Oceania | 2,025 | 2,025 | 2,110 | 2,110 | 2,259 | 2,259 | 2,259 | 2,259 | 4,133 | |||||||||||||||||||||||||||

| World Total | 177,230 | 183,349 | 191,394 | 199,672 | 220,064 | 231,938 | 239,064 | 239,471 | 310,541 | |||||||||||||||||||||||||||

Ammonia Production & Growth

Demand for fertilizer is escalating worldwide. Countries around the globe are aggressively increasing their agricultural output of both grains and livestock, and commodity crop prices are at record highs, encouraging farmers to fertilize heavily in search of higher yields. As fertilizer demand grows, supply is ramping up to meet it, and in the case of the U.S., it has benefited from the rapid expansion of the nation’s natural gas sector over the past several years given historically low prices.

But unlike many of the industries capitalizing on the low price of natural gas, ammonia producers outside of China and India do not typically use it as a fuel source. They use it as an ingredient—a source of abundant, accessible hydrogen. Ammonia production is, relatively speaking, fairly simple. The inputs are nitrogen, hydrogen and energy used to stimulate a reaction understood by first year chemistry students:

N2 + 3H2 => 2NH3

The nitrogen used in the process is taken from the air, but hydrogen sources vary depending on when and where ammonia production is happening. When ammonia plants first came online in the 1940s, most used water as their source of hydrogen; energy-intensive electrolysis decoupled the hydrogen and oxygen. By adding a catalyst, pressure and air, then a cooling phase, you can generate hydrogen with some oxygen. However, electrolysis is an expensive proposition, and ammonia plants today have a far cheaper source of hydrogen: hydrocarbons.

According to Scientific American, no ammonia plants have broken ground in the U.S. in more than 20 years.10 Despite the foregoing, in the next several years, there will be as many as 14 new ammonia plants in the U.S., with nearly 12 million tons of new capacity and $10 billion of expected investment. Several older plants are also being recommissioned and upgraded. Oklahoma, Louisiana, Iowa, North Dakota, Wyoming, Texas and Indiana are among the planned or proposed sites. This boom, driven by low natural gas prices, the main ingredient in ammonia production, will drive a corresponding surge in the industry’s already substantial carbon footprint.

9 See, Worldwide Ammonia Capacity Listing by Plant, International Fertilizer Development Center (June 2013).

10 “Fertilizer Plants Spring Up to Take Advantage of U.S.’s Cheap Natural Gas,” Scientific American, April 25, 2013 (http://www.scientificamerican.com/article/fertilizer-plants-grow-thanks-to-cheap-natural-gas).

| -9- |

Ammonia’s Greenhouse Impact

In 2011, U.S. ammonia-producing facilities released 25 million tons of greenhouse gases (nearly all of it CO2)—just under 14% of the chemical-manufacturing sector’s total carbon footprint (and about 0.1% of total U.S. emissions).11 Globally, ammonia production represents as much as 3% to 5% of carbon emissions, according to industry sources.12 These figures do not take into account the supply chain of natural gas production, energy-related emissions in the production process, fertilizer application (and misapplication) or industrial use of urea and other ammonia products.

This larger footprint is a concern, particularly as the industry expands. Glen Buckley, an industry consultant at NPK Fertilizer Advisory Services (and former chief economist at U.S. fertilizer giant CF Industries), estimates that only about six million tons of the proposed U.S. capacity will actually get funding and get built—still, that’s a more than 50% increase in total ammonia capacity nationwide.

Metal-Air Batteries

| Our battery technology consists of a high performance gas diffusion air electrode or cathode (i.e., the “engine inside” the battery) originally developed by QSI for Energizer and powered by high performance QSI-Nano® manganese catalyst material. In the past year, we have increased the manufacturing capacity of our battery electrode line to produce several hundred feet of our high rate air cathode material per shift. However, we have recently decided to discontinue our attempts to commercialize our Metal-Air batteries. We have determined that opportunities in the chemicals sector offer far greater gross margins and thus would be a better use of our financial and management resources. Therefore, we have decided to attempt to either sell or license our battery technology to another company. We are actively exploring opportunities in this regard, and we do not anticipate the writedown of any fixed assets. |  |

11 Ibid.

12 Ibid.

| -10- |

Raw Materials; Principal Suppliers

We engage a number of suppliers for our equipment and for our bulk raw materials and gases. In the manufacture of our nanocatalysts, we use a range of equipment from a number of suppliers in order to assemble our proprietary reactors. As for the bulk raw materials and gases used in our nanocatalyst manufacturing process, we contract with a number of companies and make our purchase decisions based on the prevailing market prices for such bulk raw materials and gases. We periodically audit these suppliers to ensure the quality of the bulk raw materials and gases provided. We have not entered into any long-term supply agreements for any of our equipment or our bulk raw materials and gases.

Competition and Differentiation

Our value discipline combines safety, quality, price, service and an approach to doing business that customers reward with loyalty and appreciation. This value discipline is designed to create a two-way street of value and profitability between QSI and our customers. Our strategy is built on three central tenets:

| · | Increasing revenue growth by improving market focus; |

| · | Enhancing profitability through process development and the efficient use of assets; and |

| · | Creating and enhancing customer value through continued innovation. |

Our nanocatalyst manufacturing process is capable of delivering high surface area nanocatalysts to a wide array of industries. Specifically, our advanced materials and integrated catalytic solutions empower the chemical synthesis industry sector with the potential to transform and revolutionize their product offerings. We believe that our proprietary manufacturing technology offers measurable improvement over existing manufacturing processes and has the potential to transform nanoscale catalysts applications from costly, inefficient processes to feasible, dynamic, and profitable assets.

We believe that our state-of-the-art technology will compete based on its:

| · | Industry-low manufacturing costs; |

| · | Highly scalable, fully automated manufacturing process; |

| · | Consistent particle size distribution; |

| · | Low levels of agglomeration and impurities; |

| · | Highly uniform dispersion; and |

| · | Environmentally friendly process. |

In terms of the catalyst market, we will face potential worldwide competition from advanced materials and chemical companies, and suppliers of traditional materials. The actual or potential competitors are larger, more established and more diversified than we are. Although we are focusing on specific market segments and opportunities where our nanocatalysts have demonstrated increased efficiencies and performance, we will compete against lower priced traditional materials for certain customer applications. In some product or process applications, the benefits of using nanomaterials may not be viewed as justifying a process change or outweigh the additional costs of such a process change.

| -11- |

Many of our competitors have greater market presence, longer operating histories, stronger name recognition, larger customer bases and significantly greater financial, technical, sales and marketing, research and development, manufacturing and other resources than we have. In addition, the number of start-up and development-stage companies involved in nanomaterials continues to grow on a global basis, posing increasing competitive risks. Although a number of these companies are associated with university or national laboratories and may be engaged primarily in funded research rather than commercial production, they may represent competitive risks in the future. Moreover, if one or more of our competitors were to merge or partner with another of our competitors or develop alternatives to our nanocatalysts or our manufacturing process, our ability to compete effectively will be adversely affected. We anticipate that foreign competition will play a greater role in the nanomaterials arena in the future.

Research and Development

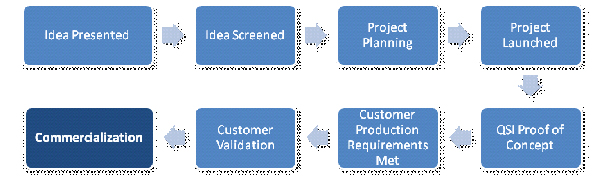

We maintain a disciplined approached to planning, tracking and conducting our research and development projects. Research and development ideas present themselves from both internal and external sources.

| -12- |

As depicted below, our science team meets frequently for brainstorming activities and maintains a master list of potential research and development ideas. In addition, our board of directors receives periodic briefings on all major research and development efforts and proposed initiatives.

To leverage our research and development capabilities, we have previously entered into and continue to discuss establishing research and development agreements with strategic parties in the chemical manufacturing industry.

Intellectual Property

Since our inception, our strategy has been to invest heavily in intellectual property protection and to build a strong IP portfolio around core nanocatalysts manufacturing, process integration technologies, as well as targeted end-use applications where our solutions add significant value and breakthrough results. This is done in such a way as to maximize the potential for prevailing in litigation and inhibiting competition from choosing to litigate. The QSI team includes an expert patent litigator with 20+ years of industry experience who has prevailed in multiple high profile patent cases, both in the U.S. and abroad. QSI maintains a patented production process and, as of September 28, 2015, has nine issued patents and three pending patent applications related to the manufacturing process and various end-use applications before the United States Patent and Trademark Office. In addition, we have three registered trademarks.

The patent for QSI’s platform gas phase condensation process was awarded on October 16, 2007, and includes broad claims on the manufacturing system that produces advanced metals and catalysts at the nano-scale. Additional patent applications have been filed covering QSI-Nano® catalysts in raw metal powder form, QSI-Nano® catalysts dispersed into custom liquid solutions / ink formulations used for coating various monolithic structures and membrane structures, QSI-Nano® catalysts integrated into physical electrode assemblies for other energy storage (battery) components, and QSI-Nano® iron catalysts used in the ammonia synthesis production process.

QSI’s patent portfolio protects the following principal areas:

| · | Advanced catalyst manufacturing; |

| · | Thermo-catalysis (highly efficient chemical production); and |

| · | Electro-catalysis (advanced metal-air battery electrodes, cells, portable power systems). |

Development results are formally vetted through a short list of criteria for assessing whether to seek to protect a “development” via a patent or whether to preserve it as a trade secret. This vetting process has produced a more efficient use of the capital QSI has allocated for its IP portfolio. Generally, if the development rests upon a methodology that is not likely to be either easily reverse engineered or invented independently by a competitor, then QSI elects to protect such methodology as a trade secret and preserve it with appropriate confidentiality procedures. QSI has relied on such confidentiality procedures for our software and algorithms that are associated with our nano-catalyst manufacturing process.

| -13- |

To the extent that the development has commercial value to QSI – either because it reflects a viable product in the future for QSI to manufacture and sell, or it reflects technology likely to be adopted by a competitor - then it is worthwhile to consider seeking patent protection. QSI believes that even in those cases where QSI is not going to market a product, it is wise to protect an invention that a competitor is likely to adopt. Thus far, this approach has resulted in nine high-value patents issued and three patent applications pending.

Depending upon the timeline for developing the technology at issue, or how well the development concept has been crystallized, it may be appropriate to simply file a provisional patent application rather than a non-provisional application. In the case where it is still early in development or concept, QSI will typically file what is essentially a white paper as a provisional application, which does not get examined, but secures an early priority date of invention. Where the technology at issue is fairly advanced in development, or the concept is sufficiently crystallized to know the full scope of the advantages over the prior art, QSI will typically file a non-provisional patent application. At that point, QSI develops a claim strategy that focuses on (1) highlighting the “gee whiz” that reflects the solution to the problem addressed while distinguishing the closest known prior art, and (2) addressing who the potential infringers might be (e.g., manufacturers, OEMs, distributors, customers, users, etc.). This claim strategy also takes into account the regions in which QSI intends to file for patent protection. All claims are formulated with an eye toward broad protection and litigation strategy. Active assessments are made as to how to prevail in cases in which QSI could choose to threaten potential infringers as well as to inhibit others from potentially challenging QSI.

Government Regulation

We are subject to federal, state and local laws and regulations applicable to businesses generally. Before we commercially introduce our products into certain markets, we may be required, or may voluntarily determine to obtain approval of our materials and/or products from one or more of the organizations engaged in regulating product safety. These approvals could require significant time and resources from our technical staff, and, if redesign were necessary, could result in a delay in the introduction of our products in those markets. Due to the continuous changes in the regulatory landscape, we cannot assure investors that federal, state or local laws, rules or regulations will not be amended or adopted in the future that could make compliance much more difficult or expensive.

The chemicals sector is governed by a variety of local, county, state, national and foreign rules and regulations. We are anticipating selling our nano-iron catalysts to ammonia plant operators for purposes of coating existing commercial iron catalysts to increase ammonia production yield and/or decrease energy consumption at these ammonia plants. Our ammonia plant customers will continue to handle all compliance with such laws, rules and regulations in their respective countries. With respect to the manufacture of the nano-iron catalysts, we have taken significant best practice measures in close coordination with various environmental agencies and advocate groups in relation to the manufacture and transport of catalysts. Despite the foregoing, there can be no assurance that additional or modified regulations relating to tariffs, as well as the transportation, importability, storage, use and disposal of nanomaterials, particularly nano-iron, will not be imposed by the U.S. or the countries into which our nano-iron catalysts may be shipped in the future.

| -14- |

Environmental, Health and Safety Policy

It is our environmental, health and safety, or EH&S, policy to ensure that our business practices continuously enhance the safety and health of all team members, the communities we operate in, and the environment. As a responsible corporate citizen, we observe strict compliance with all applicable laws, regulations, and responsible practices. In addition, we maintain an open partnership approach with regulatory agencies to develop guidance, regulations, and best practices for safely working with nanomaterials. We have a “Vision of Zero” – zero incidents, zero injuries and illnesses, zero accidents and zero environmental harm. Our EH&S policy is guided by our safety values of:

Leadership. We take an active leadership role in understanding and managing potential risks and hazards arising from working with nanomaterials. Our management provides the vision, the driving force, and resources needed to involve all employees in establishing a safe and healthy workplace environment.

Knowledge. As nanomaterials pose new challenges to understanding, predicting, and managing potential hazards and risks, we conduct periodic worksite analyses that study all working conditions to identify, prevent, and eliminate existing or potential hazards. The results of these studies are shared with all employees under a comprehensive EH&S training program as well as posted in product Material Safety Data Sheets (“MSDS”). We have also participated in various government-funded university research studies dealing with environmental safety and handling concerns. In addition, pertinent data is made available to customers, partners, industry groups, regulatory agencies, universities and community first responders.

Prevention. To prevent any harmful impact to the safety and health of the employees, the community, and the environment, we employ established safety systems in our operations, including, without limitation, administrative and engineering controls, personal protective equipment, safe work practices, preventive maintenance, and emergency preparedness programs.

Sustainability. We actively work to conserve resources and minimize or eliminate adverse EH&S effects and risks that may be associated with our products, services and operations. In addition, we will strive towards a “green supply chain” by the choice of suppliers, materials, services, and process and plant designs to ensure sustainability of operations and lifecycle product stewardship.

Continuous Improvement. We manages our business and operations with the goal of continuously upgrading our understanding of the EH&S impact of nanomaterials and systematically adapting our mode of operations to reach and maintain our policy of “Vision of Zero.”

Employees

As of September 28, 2015, we have 9 employees and 1 independent contractor. None of our employees are represented under a collective bargaining agreement.

Properties

We lease our principal offices located at 2905 Tech Center Dr., Santa Ana, California, consisting of 7,357 square feet of offices, laboratory and manufacturing space. Effective March 1, 2014, we entered into a new lease of our current facilities for a period of three years and concluding on February 28, 2017. The lease rate for the period March 1, 2015 through February 29, 2016 is $8,336 per month. The lease rate for the period March 1, 2016 through February 28, 2017 is $8,586 per month.

| -15- |

The investment in our common stock involves a number of significant risks. You should consider carefully the following information about these risks before investing in our common stock. If any of the following risk events actually occur, the business, our results of operations, and our financial condition would likely suffer, and investors could lose part or all of their investment. It is impossible to accurately predict the results to investors, as we have limited operating history as a public company. Prior to purchasing any of our common stock, you should carefully consider the following risks.

Risks Related to Our Business

We have a limited operating history and have experienced operating losses since our inception and may incur additional operating losses in the future. If we fail to generate significant revenue from the sale of our products, we may be unable to continue operations.

From inception through June 30, 2015, we have generated losses in excess of $42.1 million on revenues of approximately $2.2 million. As we have not yet generated substantive revenues, we will not be profitable until we establish a significant customer base and realize several million dollars in annual revenues. We expect to continue to lose money unless we are able to generate sufficient revenues and cash flows. If we are unable to generate sufficient revenues and cash flows to meet our costs of operations, we may be forced to cease our business. Our continued operations are dependent upon our ability to generate revenues from operations and obtain further financing. If we are unable to generate sufficient revenues and obtain sufficient financing, our current business plans could fail and we may be forced to close our business.

Our capitalization is limited and we will need additional funds to sustain our operations. If we are unable to raise additional capital, as needed, the future growth of our business and operations will be severely limited.

A limiting factor on our growth, including our ability to penetrate new markets such as the chemicals sector, attract new customers and deliver new products in a timely matter, is our limited capitalization compared to other companies in the industry. Our currently available capital resources are limited, and are only adequate to fund our operations and business objectives until November 30, 2015, assuming no revenues are realized from our current business plan, no equity or debt financing is procured, and no exercise of derivative securities (i.e., expiring options and warrants with a low exercise price per share) occurs. We will require additional financing in the form of debt or equity securities, or a combination thereof, and we are presently working with multiple interested prospective and existing investors in this regard. If additional financing is not procured, we will not achieve our revenue and profit objectives and may be forced to cease some or all of our operations. There can be no assurance that future debt or equity financing will be available to us on a timely basis, on acceptable terms, or at all. If we are unable to raise additional funds on acceptable terms, our business operations and business prospects will be adversely affected.

We have not generated significant revenue and may never be profitable.

Our ability to generate significant revenue and achieve profitability depends on our ability to complete additional commercial validations of our nanocatalysts in chemical production and receive significant purchase orders. We do not anticipate generating measurable revenues from sales of our nanocatalysts in chemical production until calendar Q1 of 2017 at the earliest, following an anticipated second commercial validation in a commercial ammonia plant located in the western hemisphere.

Because of the numerous risks and uncertainties associated with our additional commercial validations and obtaining significant purchase orders, we are unable to predict the timing or amount of increased expenses, and when, or if, we will be able to achieve or maintain profitability. Even if we are able to generate significant revenues from the sale of our products, we may not become profitable and may need to obtain additional funding to continue operations.

| -16- |

We have not generated gross profit and may never generate gross profit.

Our ability to generate gross profit depends on our ability to achieve significant revenue to cover our fixed costs of goods sold and our variable costs of goods sold related to materials production. We do not anticipate generating gross profit until calendar Q1 2017 at the earliest, and if at all, as we do not anticipate generating significant revenue until calendar Q1 2017 at the earliest. If we do not generate significant revenues, we may need to obtain additional funding to continue our operations.

We are dependent on our key personnel to operate our business, which could adversely affect our ability to operate if we are unable to retain or replace these persons. We may also require additional personnel, however, there can be no assurance that we will be able to hire or retain qualified personnel.

Our future performance will be substantially dependent on the continued services and on the performance of our senior management and other key personnel, particularly, Kevin D. Maloney, our Chief Executive Officer and President and Gregory L. Hrncir, our Chief Strategy Officer, among others. Our performance also depends on our ability to attract, retain and motivate other officers and key employees. The loss of the services of Messrs. Maloney and Hrncir, or any other key personnel could have a material adverse effect on our business, prospects, financial condition and results of operations. Our success will also depend upon our ability to recruit and retain additional qualified personnel.

There can be no assurance that sales, if any, of our nanocatalysts for use in the chemicals sector will result in profitability.

We have developed and patented a process to manufacture a variety of nanocatalysts, and have used these nanocatalysts to augment chemical production in an ammonia plant in China that resulted in commercial validation in May 2015. However, there is no guarantee that the use of nanocatalysts in chemicals applications will result in profitability or long-term viability. Our future success is a function of use of our nanocatalysts in the chemicals sector. There are no guarantees that use of one or more of our catalysts for one or more applications in the chemicals sector will occur. In the event this does not occur, our results of operations would be adversely affected and we may be forced to cease our business.

We only have one manufacturing facility

We manufacture all of our nano-catalysts at our Santa Ana, California facility. In the event of a fire, flood, tornado, earthquake or other form of a catastrophic event, we would be unable to fulfill any then existing demand for our products, if any, and would not be able to do so for several quarters, depending upon the severity of the event. While we carry what we believe to be sufficient property and casualty insurance, given the nature of our operations and our manufacturing equipment being of a bespoke nature, we will not be able to quickly replace our manufacturing and other equipment in a rapid fashion. As a result, should a catastrophic event occur which results in the loss of all or a measurable portion of our manufacturing equipment, our financial condition and results of operation would be materially adversely affected.

| -17- |

Our operations may expose us to litigation, tax, environmental and other legal compliance risks.

We are subject to a variety of litigation, tax, environmental, health and safety, and other legal compliance risks. These risks include, among other things, possible liability relating to product liability matters, personal injuries, intellectual property rights, contract-related claims, government contracts, taxes, tariffs, health and safety liabilities, environmental matters and compliance with U.S. and foreign laws, competition laws and laws governing improper business practices. We or one of our business units could be charged with wrongdoing as a result of such matters. If convicted or found liable, we could be subject to significant fines, penalties, repayments or other damages (in certain cases, treble damages). As a global business, we are subject to complex laws and regulations in the U.S. and other countries in which we intend to operate. Those laws and regulations may be interpreted in different ways. They may also change from time to time, subject to related interpretations and other guidance. Changes in laws or regulations could result in higher expenses, payments, tariffs and taxes, and uncertainty relating to laws or regulations may also affect how we conduct our operations and structure our investments and could limit our ability to enforce our rights.

In the area of taxes, changes in tax laws and regulations in the U.S. and other countries, as well as changes in related interpretations and other tax guidance could materially impact our tax receivables and liabilities and our deferred tax assets and tax liabilities. Additionally, in the ordinary course of business, we are subject to examinations by various authorities, including tax authorities. Although we are not subject to any current investigations, there could be additional investigations launched in the future by governmental authorities in various jurisdictions and existing investigations could be expanded. The global and diverse nature of our operations means that these risks will continue to exist and legal proceedings and contingencies may arise from time to time. Our results may be affected by the outcome of legal proceedings and other contingencies that cannot be predicted with certainty.

We face competition from companies that have substantially greater capital resources, research and development, manufacturing and marketing resources than we have in the chemicals sector.

While we believe that we have significant competitive benefits offered by our proprietary platform technology for use in the chemicals sector, there are competitors with much longer operating histories, greater name recognition, larger customer bases and significantly greater financial, technical and marketing resources than we do. Such competition could materially adversely affect our business, operating results or financial condition.

Our future revenues are very difficult to predict with any accuracy.

It is not feasible to predict with accuracy or assurance the timing or the amount of revenues that we will receive from the sale, or license, of our products. Any delay in the integration of one or more of our nanocatalysts in the chemicals sector, could result in significant delays in the realization of revenues, the need to raise additional capital through the issuance of additional equity or debt securities sooner than we intend, and may allow competitors to reach certain of such markets with products before we do. In view of the emerging nature of the technology involved in certain of these markets, and the attendant uncertainty as to whether our products will achieve meaningful commercial acceptance, if at all, there can be no assurance that we will realize revenues sufficient to achieve profitability.

We will have to establish distribution channels in the chemicals sector.

We have no experience in the license or sale of nanocatalysts in the chemicals sector. While we have retained the services of individuals with experience and relationships in the chemicals industry, we lack deep domain expertise in the chemicals sector. Further, should we be unsuccessful in establishing such distribution channels as well as recruiting, managing and retaining additional internal and external sales and business development personnel, our business, operating results and financial condition could be adversely affected.

| -18- |

We may face increased pricing pressures from current and future competitors and, accordingly, there can be no assurance that competitive pressures will not require us to reduce our prices on our nanocatalysts.

It is likely that we will experience significant competitive pressure over time. Accordingly, the use and pricing of our nanocatalysts in the chemicals sector may decline as the market becomes more competitive. Any material reduction in the price of our nanocatalysts will negatively affect our gross margin and results of operations.

We rely heavily on collaborative partners such as distributors, manufacturers and vendors and our relationships with such parties may restrict or limit our business operations.

We are currently working with several third party entities in the validation and optimization of our nanocatalysts for use in the chemicals sector. Our current and future collaborations and joint ventures are important as they allow greater access to funds, to research, development and testing resources, validation, and to manufacturing, sales and distribution resources that we would otherwise not have. We intend to continue to significantly rely on such collaborative and joint venture arrangements. Some of the risks and uncertainties related to the reliance on such collaborations and joint ventures in the chemicals sector include the fact that such relationships could actually serve to limit or restrict us, while our partners are free to pursue other catalyst solutions either on their own or with others. Further, our partners may terminate a collaborative technology relationship and such termination may require us to seek other partners, or expend substantial resources to pursue these activities independently.

We may be subject to product liability claims, which could damage our reputation, cause us to lose customers, and expose us to liabilities in excess of our product liability insurance coverage to cover any claims.

Our nanocatalysts proposed to be used in the chemicals sector must be handled according to strict guidelines to ensure safety. We have obtained product liability insurance, but we can make no assurance that the product liability insurance we have procured will be sufficient to cover any potential product liability claim. Failure to maintain sufficient insurance coverage could have a material adverse effect on our business, prospects and results of operations if claims are made that exceed the coverage we have obtained.

The anticipated growth of our business will result in a corresponding growth in the demands on our management and our operating systems and internal controls.

Any future growth may strain existing management resources and operational, financial, human and management information systems and controls, which may not be adequate to support our operations and will require us to develop further financial and management controls, reporting systems and procedures. There can be no assurance that we will be able to develop such controls, systems or procedures effectively, or on a timely basis. Our failure to do so could have a material adverse effect on our business, operating results and financial condition.

Although we have entered into confidentiality and non-compete agreements with all of our employees and consultants, if we are unable to protect our proprietary information against unauthorized use by others, our competitive position could be harmed.

Our proprietary information is critically important to our competitive position and is a significant aspect of the products we provide. If we are unable to protect our proprietary information against unauthorized use by others, our competitive position could be harmed. We enter into confidentiality and noncompete agreements with our employees and consultants, and control access to, and distribution of, our documentation and other proprietary information. Despite these precautions, we cannot assure you that these strategies will be adequate to prevent misappropriation of our proprietary information. Therefore, we could be required to expend significant amounts to defend our rights to proprietary information in the future if a breach were to occur.

| -19- |

Risks Related to the Chemicals Production Industry

If we fail to obtain strategic partnerships with key players in the chemicals sector, our results of operation will be adversely affected.

If we are unsuccessful in creating long-term strategic partnerships with ammonia catalyst providers, ammonia plant owners and operators, and ammonia reactor engineering and design firms in the chemicals sector, our overall business, financial condition and results of operations could be materially adversely affected.

We have no experience operating in the multi-billion global chemicals industry.

While we have significant experience in the manufacturing of nanocatalysts over the last 12 years, we have no experience working with conglomerates in the chemicals industry. We are operating without the assistance of experienced agents at this time; provided, however, we are in discussions with several global players in the ammonia industry, but there is no assurance that we will reach a definitive agreement with them, or an agreement which is on favorable terms. Our lack of experience could prove to be detrimental to our operating results and overall business prospects and condition.

As part of the sale of our QSI-Nano® iron catalysts, we will be required to coat these catalysts onto existing commercial iron catalysts used by ammonia producers and we have no commercial experience in doing so.

As part of the sale of QSI-Nano® iron catalysts to ammonia producers we will be required to coat our catalysts onto commercial iron substrates and we have very limited lab experience in doing so. Although we have developed our own coating machine that has demonstrated favorable early test results, we will need significantly more testing and development before our coating machine is fully proven, if at all. In sum, the coating process has many risks, we have very limited experience, it requires significant capital expenditure, and is a critical part of our overall value proposition. If we are not successful in implementing the coating process on a timely basis in each geographic region in which we anticipate operating, then our business condition and results of operation will be adversely affected.

Doing business in China has inherent risks and the ammonia plants in China use less pure hydrogen and nitrogen gases in the production of ammonia than that which has been used by QSI and is typically used in ammonia production in other regions around the world.

Doing business in China is fraught with risks, including but not limited to, theft of intellectual property, failure to make timely or full payment on goods delivered, major cultural and language differences and barriers, an economy in China that seems to have hit its peak and may be on the decline, currency risk, legal and tax issues, tariffs, etc. Each of the foregoing risks are real and we take them seriously, not the least of which is theft of intellectual property which we have addressed solidly by taking the firm position that the manufacture of our QSI-Nano® iron will never be undertaken in China. In addition, Chinese ammonia producers use “medium-dirty” nitrogen and hydrogen gas in the production of ammonia as opposed to the 99.9%+ pure gas utilized by QSI in our five years of QSI-Nano® iron testing. We do not know what effect the “less pure” gases used by the Chinese ammonia operators will have on our operating results in a commercial plant. Both the risks of doing business in China as well as the “medium dirty” gas utilized by ammonia operators in China could have a materially adverse effect on our business operations and financial condition.

| -20- |

We presently have sixteen gas-phase condensation reactors in our prototype facility in Santa Ana, California and will require significant scale-up should significant purchase orders be received.

If we are successful in achieving significant purchase orders for our QSI-Nano® iron catalysts, we will likely be required to significantly expand our base of reactors in a relatively short period of time. We have no experience in large-scale manufacturing, including the planning, design, permitting, build-out, and operation phases. Further, if we are required to expand we would likely need to do so in a state other than California, such as southern Nevada or Utah, given the extremely high electricity costs in California, and electricity being the largest component of our cost of goods. In sum, there is a host of issues surrounding a major manufacturing expansion, which will place significant burden on our management, financial, and other resources, all of which could have an effect on our overall business.

Warranty claims and product liability claims could harm our business, results of operations and financial condition.

Through the introduction of our nanocatalysts for use in the chemicals sector (with ammonia being the lead application), we will be exposed to potential warranty and product liability claims in the event that our products fail to perform as expected or such failure of our products results, or is alleged to result, in bodily injury or property damage (or both). Although we do not anticipate any claims, such claims may arise despite our quality controls and proper testing, either due to a defect during manufacturing or due to any individual or enterprise’s improper use of our products. In addition, if any of our products are or are alleged to be defective, then we may be required to participate in a recall of them. If a warranty or product liability claim is brought against us, regardless of merit or eventual outcome, such claim or recall may result in damage to our reputation, breach of contracts with our customers, decreased demand for our products, costly litigation, loss of revenue, and the inability to commercialize some products.

Risks Related to our Common Stock

You may find it difficult to sell our common stock.

There has been a limited trading market in our common stock. While we expect that this will change in the future, we cannot assure you that an active trading market for our common stock will develop or be sustained. Regardless of whether an active and liquid public market exists, negative fluctuations in our actual or anticipated operating results will likely cause the market price of our common stock to fall, making it more difficult for you to sell our common stock at a favorable price, or at all.

We intend to issue additional stock options to employees and consultants in the future, which will result in dilution to existing and new investors.

In the future, we will provide additional compensation to our employees, officers, directors, consultants and independent contractors through an equity incentive plan. Our equity incentive plan permits the issuance of options to purchase shares of common stock and restricted shares of our common stock. Because stock options granted under the plan will generally only be exercised when the exercise price for such option is below the then market value of the common stock, the exercise of such options will cause dilution to the book value per share of our common stock and to existing and new investors.

| -21- |

We do not intend to pay dividends on our common stock in the foreseeable future.

You should not rely on an investment in our common stock to provide dividend income. It is our present intention that all future earnings, if applicable, will be reinvested and used for ongoing product development as well as working capital. Any determination to pay dividends in the future will be made at the discretion of our board of directors and will depend on our results of operations, financial conditions, contractual restrictions, restrictions imposed by applicable laws and other factors that our board of directors deems relevant. In addition, our ability to pay dividends may be limited or prohibited by the terms of future financings and/or credit facilities. Accordingly, investors in our common stock should not expect dividends to be paid on their shares of common stock in the foreseeable future. Further, investors must rely on sales of their common stock after price appreciation, which may never occur, as the only way to realize any return on their investment. As a result, investors seeking cash dividends should not purchase our common stock.

Anti-takeover provisions in our Articles of Incorporation and Bylaws or provisions of Nevada law could prevent or delay a change in control, even if a change of control would benefit our stockholders.

Provisions of our Articles of Incorporation and Bylaws, as well as provisions of Nevada law, could discourage, delay or prevent a merger, acquisition or other change in control, even if a change in control would benefit our stockholders. These provisions:

| · | Establish advance notice requirements for nominations for election to the board of directors or for proposing matters that can be acted upon by stockholders at stockholder meetings; |

| · | Authorize our board of directors to issue “blank check” preferred stock to increase the number of outstanding shares and thwart a takeover attempt; |

| · | Require the written request of at least 75% of the voting power of our capital stock in order to compel management to call a special meeting of the stockholders; and |

| · | Prohibit stockholder action by written consent and require that all stockholder actions be taken at a meeting of our stockholders, unless otherwise specifically required by our Articles of Incorporation or the Nevada Revised Statutes. |

In addition, the Nevada Revised Statutes contain provisions governing the acquisition of a controlling interest in certain Nevada corporations. These laws provide generally that any person that acquires 20% or more of the outstanding voting shares of certain Nevada corporations in the secondary public or private market must follow certain formalities before such acquisition or they may be denied voting rights, unless a majority of the disinterested stockholders of the corporation elects to restore such voting rights in whole or in part. These laws will apply to us if we have 200 or more stockholders of record, at least 100 of whom have addresses in Nevada, unless our Articles of Incorporation or Bylaws in effect on the tenth day after the acquisition of a controlling interest provide otherwise. These laws provide that a person acquires a “controlling interest” whenever a person acquires shares of a subject corporation that, but for the application of these provisions of the Nevada Revised Statutes, would enable that person to exercise

| · | One-fifth or more, but less than one-third; |

| · | One-third or more, but less than a majority; or |

| · | A majority or more, of all of the voting power of the corporation in the election of directors. |

Once an acquirer crosses one of these thresholds, shares, which it acquired in the transaction taking it over the threshold and within the 90 days immediately preceding the date when the acquiring person acquired or offered to acquire a controlling interest, become “control shares.” These laws may have a chilling effect on certain transactions if our Articles of Incorporation or Bylaws are not amended to provide that these provisions do not apply to us or to an acquisition of a controlling interest, or if our disinterested stockholders do not confer voting rights in the control shares.

| -22- |

Nevada law also provides that if a person is the “beneficial owner” of 10% or more of the voting power of certain Nevada corporations, such person is an “interested stockholder” and may not engage in any “combination” with the corporation for a period of two years from the date such person first became an interested stockholder, unless the combination or the transaction by which the person first became an interested stockholder is approved by the board of directors of the corporation before the person first became an interested stockholder. Another exception to this prohibition is if the combination is approved by the affirmative vote of the holders of stock representing a majority of the outstanding voting power not beneficially owned by the interested stockholder at a meeting, no earlier than two years after the date that the person first became an interested stockholder. These laws generally apply to Nevada corporations with 200 or more stockholders of record, but a Nevada corporation may elect in its Articles of Incorporation not to be governed by these particular laws.

Nevada law also provides that directors may resist a change or potential change in control if the directors determine that the change is opposed to, or not in the best interest of, the corporation.

Risks Related to Our Securities, Tax Concerns And Reporting Requirements

There is a limited market for our common stock.

Only a very limited trading market currently exists for our common stock. As a result, any broker/dealer that makes a market in our common stock or other person that buys or sells our common stock could have a significant influence over our common stock price at any given time. We cannot assure our stockholders that a market for our common stock will be sustained. There is no assurance that our shares will have any greater liquidity than shares which do not trade on a public market, particularly given recent changes in legislation related to shell companies which will further restrict the ability of our stockholders to sell their shares in the public market.

Our stock price is likely to be volatile.

There is generally significant volatility in the market prices and limited liquidity of securities of companies at our stage. Contributing to this volatility are various events that can affect our stock price in a positive or negative manner. These events include, but are not limited to: governmental regulations or actions; market acceptance and sales growth of our products; litigation involving our industry; developments or disputes concerning our patents or other proprietary rights; departure of key personnel; future sales of our securities; fluctuations in our financial results or those of companies that are perceived to be similar to us; investors’ general perception of us; announcements by us of significant contracts, acquisitions, strategic partnerships, joint ventures or capital commitments, and general economic, industry and market conditions. If any of these events occur, it could cause our stock price to fall.

The price of our common stock may be adversely affected by the future issuance and sale of shares of our common stock or other equity securities.

We cannot predict the size of future issuances or sales of our common stock or other equity securities future acquisitions or capital raising activities, or the effect, if any, that such issuances or sales may have on the market price of our common stock. The issuance and sale of substantial amounts of common stock or other equity securities or announcement that such issuances and sales may occur, could adversely affect the market price of our common stock. As of September 28, 2015, we had 22,511,884 shares of common stock issued and outstanding, and an additional 477,488,116 shares of common stock and 10,000,000 shares of preferred stock authorized for issuance. Any decline in the price of our common stock may encourage short sales, which could place further downward pressure on the price of our common stock and may impair our ability to raise additional capital through the sale of equity securities.

| -23- |

Our reduced stock price may adversely affect our liquidity.

Our common stock has limited trading history. Many market makers are reluctant to make a market in stock with a trading price of less than $5.00 per share, as well as shares quoted on the OTCBB. To the extent that we have fewer market makers for our common stock, our volume and liquidity will likely decline, which could further depress our stock price.

Additional risks may exist since we became public through a “reverse merger.”

Because we became public by means of a “reverse merger,” we may not be able to attract the attention of major brokerage firms. Securities analysts of major brokerage firms may not provide coverage of us since there is little incentive to brokerage firms to recommend the purchase of our common stock. We cannot assure you that brokerage firms will want to conduct any secondary offerings on our behalf in the future.

Our reporting obligations as a public company are costly.

Operating a public company involves substantial costs to comply with reporting obligations under federal securities laws, which are continuing to increase as provisions of the Sarbanes-Oxley Act of 2002 are implemented. We may not reach sufficient size to justify our public reporting status. If we were forced to become a private company following the Merger, then our stockholders may lose their ability to sell their shares and there would be substantial costs associated with becoming a private company.

Our shares are “penny stock”.

In general, “penny stock” includes securities of companies which are not listed on the principal stock exchanges and have a bid price in the market of less than $5.00; and companies with net tangible assets of less than $2 million ($5 million if the issuer has been in continuous operation for less than three years), or which have recorded revenues of less than $6 million in the last three years. As “penny stock,” our stock therefore is subject to Rule 15g-9, which imposes additional sales practice requirements on broker-dealers which sell such securities to persons other than established customers and “accredited investors” (generally, individuals with net worth in excess of $1 million or annual incomes exceeding $200,000, or $300,000 together with their spouses, or individuals who are the officers or directors of the issuer of the securities). For transactions covered by Rule 15g-9, a broker-dealer must make a special suitability determination for the purchaser and have received the purchaser’s written consent to the transaction prior to sale. Consequently, this rule may adversely affect the ability of broker-dealers to sell our stock, and therefore may adversely affect stockholders’ ability to sell the stock in the public market.

The requirements of being a public company may strain our resources, divert management’s attention and affect our ability to attract and retain qualified members of the board of directors.

As a public company, we are subject to the reporting requirements of the Securities Exchange Act of 1934, as amended, or the Exchange Act, the Sarbanes-Oxley Act, the Dodd-Frank Act, the listing requirements of the OTCBB and other applicable securities rules and regulations. Compliance with these rules and regulations requires significant legal and financial compliance costs, makes some activities more difficult, time-consuming or costly and increases demand on our systems and resources. The Exchange Act requires, among other things, that we file annual, quarterly and current reports with respect to our business and operating results. The Sarbanes-Oxley Act requires, among other things, that we maintain effective disclosure controls and procedures and internal control over financial reporting. In order to maintain and, if required, improve our disclosure controls and procedures and internal control over financial reporting to meet this standard, significant resources and management oversight may be required. As a result, management’s attention may be diverted from other business concerns, which could harm our business and operating results. Although we have already hired additional employees to comply with these requirements, we may need to hire more employees in the future, which will increase our costs and expenses.

| -24- |

In addition, changing laws, regulations and standards relating to corporate governance and public disclosure are creating uncertainty for public companies, increasing legal and financial compliance costs and making some activities more time consuming. These laws, regulations and standards are subject to varying interpretations, in many cases due to their lack of specificity, and, as a result, their application in practice may evolve over time as new guidance is provided by regulatory and governing bodies. This could result in continuing uncertainty regarding compliance matters and higher costs necessitated by ongoing revisions to disclosure and governance practices. We intend to invest resources to comply with evolving laws, regulations and standards, and this investment may result in increased general and administrative expenses and a diversion of management’s time and attention from revenue-generating activities to compliance activities. If our efforts to comply with new laws, regulations and standards differ from the activities intended by regulatory or governing bodies due to ambiguities related to practice, regulatory authorities may initiate legal proceedings against us and our business may be harmed.

We also expect that being a public company with these new rules and regulations will make it more expensive for us to obtain director and officer liability insurance, and we may be required to accept reduced coverage or incur substantially higher costs to obtain coverage. These factors could also make it more difficult for us to attract and retain qualified members for our board of directors, particularly to serve any committees, and qualified executive officers.

As a result of disclosure of information in filings required of a public company, our business and financial condition will become more visible, which we believe may result in threatened or actual litigation, including by competitors and other third parties. If such claims are successful, our business and operating results could be harmed, and even if the claims do not result in litigation or are resolved in our favor, these claims, and the time and resources necessary to resolve them, could divert the resources of our management and harm our business and operating results.

We will be obligated to develop and maintain proper and effective internal controls over financial reporting.

We are required, pursuant to Section 404 of the Sarbanes-Oxley Act, to furnish a report by management on, among other things, the effectiveness of our internal control over financial reporting annually. This assessment will need to include disclosure of any material weaknesses identified by our management in our internal control over financial reporting.

We may not be able to complete our evaluation, testing and any required remediation in a timely fashion. During the evaluation and testing process, if we identify one or more material weaknesses in our internal control over financial reporting, we will be unable to assert that our internal controls are effective.