Attached files

| file | filename |

|---|---|

| EX-23.2 - EX-23.2 - Summit Materials, Inc. | d45248dex232.htm |

| EX-23.3 - EX-23.3 - Summit Materials, Inc. | d45248dex233.htm |

| EX-23.1 - EX-23.1 - Summit Materials, Inc. | d45248dex231.htm |

Table of Contents

As filed with the Securities and Exchange Commission on July 31, 2015.

Registration No. 333-205561

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Amendment No. 2

to

FORM S-1

REGISTRATION STATEMENT

UNDER

THE SECURITIES ACT OF 1933

Summit Materials, Inc.

(Exact Name of Registrant as Specified in its Charter)

| Delaware | 1400 | 47-1984212 | ||

| (State or other jurisdiction of incorporation or organization) |

(Primary Standard Industrial Classification Code Number) |

(I.R.S. Employer Identification No.) |

1550 Wynkoop Street, 3rd Floor

Denver, Colorado 80202

(303) 893-0012

(Address, including zip code, and telephone number, including area code, of Registrant’s principal executive offices)

Anne Lee Benedict, Esq.

Chief Legal Officer

Summit Materials, Inc.

1550 Wynkoop Street, 3rd Floor

Denver, Colorado 80202

(303) 893-0012

(Name, address, including zip code, and telephone number, including area code, of agent for service)

Copies to:

| Edgar J. Lewandowski, Esq. Edward P. Tolley III, Esq. Simpson Thacher & Bartlett LLP 425 Lexington Avenue New York, New York 10017 (212) 455-2000 |

Michael P. Kaplan, Esq. Sophia Hudson, Esq. Davis Polk & Wardwell LLP 450 Lexington Avenue New York, New York 10017 (212) 450-4000 |

Approximate date of commencement of the proposed sale of the securities to the public: As soon as practicable after the Registration Statement is declared effective.

If any of the securities being registered on this form are to be offered on a delayed or continuous basis pursuant to Rule 415 under the Securities Act of 1933, check the following box. ¨

If this form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

If this form is a post-effective amendment filed pursuant to Rule 462(c) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

If this form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer | ¨ | Accelerated filer | ¨ | |||

| Non-accelerated filer | x (Do not check if a smaller reporting company) | Smaller reporting company | ¨ |

CALCULATION OF REGISTRATION FEE

|

| ||||

| Title of Each Class of Securities to be Registered |

Proposed Offering Price(1)(2) |

Amount of Registration Fee(3) | ||

| Class A common stock, par value $0.01 per share |

$100,000,001 | $11,620 | ||

|

| ||||

|

| ||||

| (1) | Estimated solely for the purpose of determining the amount of the registration fee in accordance with Rule 457(o) under the Securities Act of 1933, as amended |

| (2) | Includes shares of Class A common stock subject to the underwriters’ option to purchase additional shares of Class A common stock. |

| (3) | Previously paid. |

The Registrant hereby amends this Registration Statement on such date or dates as may be necessary to delay its effective date until the Registrant shall file a further amendment which specifically states that this Registration Statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933 or until the Registration Statement shall become effective on such date as the Commission, acting pursuant to said Section 8(a), may determine.

Table of Contents

Subject to completion, dated July 31, 2015

The information in this prospectus is not complete and may be changed. We may not sell these securities until the registration statement filed with the Securities and Exchange Commission is effective. This prospectus is not an offer to sell these securities and it is not soliciting an offer to buy these securities in any jurisdiction where the offer or sale is not permitted.

Preliminary Prospectus

Shares

Summit Materials, Inc.

Class A Common Stock

This is a public offering of shares of Class A common stock of Summit Materials, Inc.

We are offering shares of our Class A common stock. We intend to use all of the net proceeds from this offering to purchase newly-issued limited partnership units, or LP Units, from Summit Materials Holdings L.P., our direct subsidiary, and outstanding LP Units from certain holders, including affiliates of The Blackstone Group L.P. and certain of our directors and officers.

Our Class A common stock is listed on the New York Stock Exchange, or NYSE, under the symbol “SUM.” The last reported sale price of our common stock on the NYSE on July 30, 2015 was $25.62 per share.

Investing in shares of our Class A common stock involves risks. See “Risk Factors” beginning on page 24 to read about factors you should consider before buying shares of our Class A common stock.

| Per Share | Total | |||||||

| Public offering price |

$ | $ | ||||||

| Underwriting discounts and commissions |

$ | $ | ||||||

| Proceeds, before expenses, to us(1) |

$ | $ | ||||||

| (1) | See “Underwriting” for a description of compensation payable to the underwriters. |

To the extent that the underwriters sell more than shares of our Class A common stock, the underwriters have the option to purchase up to an additional shares of our Class A common stock from us at the public offering price less the underwriting discount, within 30 days from the date of this prospectus.

Neither the Securities and Exchange Commission nor any other regulatory body has approved or disapproved of these securities or passed upon the accuracy or adequacy of this prospectus. Any representation to the contrary is a criminal offense.

The underwriters expect to deliver the shares of our Class A common stock against payment in New York, New York on or about , 2015.

| Citigroup | Goldman, Sachs & Co. |

The date of this prospectus is , 2015.

Table of Contents

Table of Contents

Neither we nor the underwriters have authorized anyone to provide you with information different from that contained in this prospectus or any free writing prospectus prepared by us or on our behalf. Neither we nor the underwriters take any responsibility for, or can provide any assurance as to the reliability of, any information other than the information in this prospectus or any free writing prospectus prepared by us or on our behalf. We and the underwriters are offering to sell, and seeking offers to buy, shares of our Class A common stock only in jurisdictions where offers and sales are permitted.

Unless indicated otherwise, the information included in this prospectus assumes no exercise by the underwriters of the option to purchase up to an additional shares of Class A common stock from us.

ABOUT THIS PROSPECTUS

Financial Statement Presentation

This prospectus includes certain historical consolidated financial and other data for Summit Materials Holdings L.P. (“Summit Holdings”). Summit Holdings is considered our predecessor for financial reporting purposes. Summit Materials, Inc. is the financial reporting entity following the completion of our initial public offering of our Class A common stock (the “IPO”) on March 17, 2015, in which we issued and sold approximately 25.6 million shares of our Class A common stock at an IPO price of $18.00 per share. Summit Materials, LLC (“Summit LLC”), an indirect wholly-owned subsidiary of Summit Holdings, is the financial reporting entity with respect to our outstanding 10 1⁄2% senior notes due 2020 (the “2020 notes”) and the 6.125% senior notes due 2023 that we issued on July 8, 2015 (the “2023 notes” and together with the 2020 notes, the “senior notes”). The historical consolidated financial information of Summit Holdings as of December 27, 2014 and December 28, 2013 and for the three years ended December 27, 2014, December 28, 2013 and December 29, 2012 has been derived from the audited consolidated financial statements of Summit Holdings included elsewhere in this prospectus. We have derived the historical consolidated balance sheet data of Summit Holdings as of December 31, 2011 from Summit Holdings’ consolidated balance sheet as of December 31, 2011, which is not included in this prospectus. Our historical results are not necessarily indicative of the results

Table of Contents

expected for any future period. The historical consolidated financial information of Summit Materials as of March 28, 2015 and for the three months ended March 28, 2015 and March 29, 2014 was derived from the unaudited consolidated financial statements of Summit Materials included elsewhere in this prospectus. The unaudited consolidated financial statements of Summit Materials have been prepared on the same basis as the audited consolidated financial statements and, in our opinion, have included all adjustments, which include normal recurring adjustments necessary to present fairly in all material respects our financial position and results of operations. The results for any interim period are not necessarily indicative of the results that may be expected for any future period.

This prospectus also includes certain historical combined financial and other data for certain assets, including a cement plant and seven cement distribution terminals (collectively, the “Lafarge Target Business”) that we acquired from Lafarge North America Inc. (“Lafarge”) on July 17, 2015. See “Summary—The Davenport Acquisition.” The historical combined financial information of the Lafarge Target Business as of December 31, 2014 and December 31, 2013 and for the three years ended December 31, 2014, 2013 and 2012 has been derived from the audited combined financial statements of the Lafarge Target Business included elsewhere in this prospectus.

This prospectus also includes an unaudited pro forma condensed consolidated balance sheet as of March 28, 2015 and unaudited pro forma condensed consolidated statements of operations for the three months ended March 28, 2015 and the year ended December 27, 2014, which present our consolidated financial position and results of operations to give pro forma effect to this offering, the issuance and sale of the 2023 notes, the $650.0 million senior secured incremental term loan facility (the “New Term Loan Facility”) that was entered into in connection with the Davenport Acquisition (as defined herein), the redemption of $183.0 million of 2020 notes that is expected to occur on August 3, 2015, the Davenport Acquisition that was consummated on July 17, 2015 and the payment of related fees and expenses (collectively, the “Transactions”). The unaudited pro forma financial information is presented for illustrative purposes only and is not necessarily indicative of the operating results or financial position that would have occurred if the Transactions had been consummated on the date indicated, nor is it indicative of future operating results. In addition, the Lafarge Target Business’ results included in the pro forma financial information are presented based on Lafarge’s fiscal year, which is based on calendar period ends. Our fiscal year is based on a 52 to 53 week period, as applicable, commencing on the first day following the end of the prior fiscal year and ending on a Saturday. The resulting difference is not considered material to the pro forma condensed consolidated financial statements. See “Unaudited Pro Forma Condensed Consolidated Financial Information.”

You should read our selected historical consolidated financial data and unaudited pro forma condensed consolidated financial information and the accompanying notes in conjunction with, and each is qualified in its entirety by reference to, the consolidated historical financial statements and related notes included elsewhere in this prospectus and the financial and other information appearing elsewhere in this prospectus, including information contained in “Risk Factors,” “Use of Proceeds,” “Capitalization” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations.”

Certain Definitions

As used in this prospectus, unless otherwise noted or the context otherwise requires:

| • | “we,” “our,” “us,” the “Company” and “Summit Materials” refer (1) prior to the consummation of the IPO Transactions described under “Organizational Structure—IPO Transactions,” to Summit Materials Holdings L.P. and its consolidated subsidiaries and (2) after the consummation of the IPO Transactions described under “Organizational Structure—IPO Transactions,” to Summit Materials, Inc. and its consolidated subsidiaries. “Existing owners” and “pre-IPO owners” refer to the Sponsors and the other owners of Summit Holdings immediately prior to the IPO Transactions; |

| • | “Continental Cement” refers to Continental Cement Company, L.L.C.; |

ii

Table of Contents

| • | “Cornejo” refers collectively to Cornejo & Sons, L.L.C., C&S Group, Inc., Concrete Materials Company of Kansas, LLC and Cornejo Materials, Inc.; |

| • | “Harper Contracting” refers collectively to substantially all the assets of Harper Contracting, Inc., Harper Sand and Gravel, Inc., Harper Excavating, Inc., Harper Ready Mix Company, Inc. and Harper Investments, Inc.; |

| • | “Altaview Concrete” refers collectively to Altaview Concrete, LLC, Peak Construction Materials, LLC, Peak Management, L.C. and Wasatch Concrete Pumping, LLC; |

| • | “RK Hall” refers collectively to R.K. Hall Construction, Ltd., RHMB Capital, L.L.C., Hall Materials, Ltd., B&H Contracting, L.P. and RKH Capital, L.L.C.; |

| • | “B&B” refers collectively to B&B Resources, Inc., Valley Ready Mix, Inc. and Salt Lake Sand & Gravel, Inc.; |

| • | “Industrial Asphalt” refers collectively to Industrial Asphalt, LLC, Asphalt Paving Company of Austin, LLC, KBDJ, L.P. and all the assets of Apache Materials Transport, Inc.; |

| • | “Ramming Paving” refers collectively to J.D. Ramming Paving Co., LLC, RTI Hot Mix, LLC, RTI Equipment Co., LLC and Ramming Transportation Co., LLC; |

| • | “Lafarge” refers to Lafarge North America, Inc.; |

| • | “Westroc” refers to Westroc, LLC; |

| • | “Alleyton” refers collectively to Alleyton Resource Company, LLC, Alcomat, LLC and Alleyton Services Company, LLC, formerly known as Alleyton Resource Corporation, Colorado Gulf, LP and certain assets of Barten Shepard Investments, LP; |

| • | “Troy Vines” refers to Troy Vines, Incorporated; |

| • | “Buckhorn Materials” refers to Buckhorn Materials, LLC, which is the surviving entity from the acquisition of Buckhorn Materials, LLC and Construction Materials Group LLC; |

| • | “Canyon Redi-Mix” refers collectively to Canyon Redi-Mix, Inc. and CRM Mixers LP; |

| • | “Mainland” refers to Mainland Sand & Gravel ULC, which is the surviving entity from the acquisition of Rock Head Holdings Ltd., B.I.M Holdings Ltd., Carlson Ventures Ltd., Mainland Sand and Gravel Ltd. and Jamieson Quarries Ltd.; |

| • | “Southwest Ready Mix” refers to Southwest Ready Mix, LLC; |

| • | “Colorado County S&G” refers to Colorado County Sand & Gravel Co., L.L.C., which is the surviving entity from the acquisition of Colorado County Sand & Gravel Co., L.L.C, M & M Gravel Sales, Inc., Marek Materials Co. Operating, Ltd. and Marek Materials Co., L.L.C.; |

| • | “Concrete Supply” refers to Concrete Supply of Topeka, Inc., Penny’s Concrete and Ready Mix, L.L.C. and Builders Choice Concrete Company of Missouri, L.L.C.; |

| • | “Lewis & Lewis” refers to Lewis & Lewis, Inc.; |

| • | “Davenport Assets” and the “Lafarge Target Business” refer to Lafarge’s Davenport, Iowa cement plant (the “Davenport Plant”) and seven cement distribution terminals (the “Davenport Terminals”); |

| • | “Blackstone” refers to investment funds associated with or designated by The Blackstone Group L.P. and its affiliates; |

| • | “Silverhawk” refers to certain investment funds affiliated with Silverhawk Summit, L.P.; and |

| • | “Sponsors” refers to Blackstone and Silverhawk. |

Defined terms above that relate to our completed acquisitions are in chronological order. See “Business—Acquisition History” for a table of acquisitions we have completed since August 2009.

iii

Table of Contents

This summary highlights information contained elsewhere in this prospectus and does not contain all of the information you should consider before investing in shares of our Class A common stock. You should read this entire prospectus carefully, including the section entitled “Risk Factors” and the financial statements and the related notes thereto included elsewhere in this prospectus, before you decide to invest in shares of our Class A common stock.

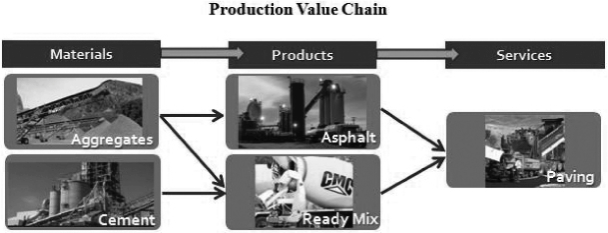

Our Company

We are one of the fastest growing construction materials companies in the United States, with a 197% increase in revenue between the year ended December 31, 2010 and the year ended December 27, 2014, as compared to an average increase of approximately 38% in revenue reported by our competitors over the same period. Our materials include aggregates, which we supply across the country, with a focus on Texas, Kansas, Kentucky, Utah and Missouri, and cement, which we supply primarily in Missouri, Iowa and along the Mississippi River. Within our markets, we offer customers a single-source provider for construction materials and related downstream products through our vertical integration. In addition to supplying aggregates to customers, we use our materials internally to produce ready-mixed concrete and asphalt paving mix, which may be sold externally or used in our paving and related services businesses. Our vertical integration creates opportunities to increase aggregates volumes, optimize margin at each stage of production and provide customers with efficiency gains, convenience and reliability, which we believe gives us a competitive advantage.

Since our first acquisition approximately six years ago, we have rapidly become a major participant in the U.S. construction materials industry. We believe that, by volume, we are a top 10 aggregates supplier, a top 20 cement producer and a major producer of ready-mixed concrete and asphalt paving mix. Our revenue in 2014 and the three months ended March 28, 2015 was $1.2 billion and $194.0 million, respectively, with net losses for the same periods of $6.3 million and $79.8 million, respectively. Our proven and probable aggregates reserves were 2.1 billion tons as of March 28, 2015. In the twelve months ended March 28, 2015, we sold 27.9 million tons of aggregates, 1.1 million tons of cement, 3.1 million cubic yards of ready-mixed concrete and 4.1 million tons of asphalt paving mix across our more than 200 sites and plants.

The rapid growth we have achieved over the last six years has been due in large part to our acquisitions, which we funded with equity and debt financing. During this period, we witnessed a cyclical decline and slow recovery in the private construction market and nominal growth in public infrastructure spending. However, the private construction market is beginning to rebound, which we believe signals the outset of a strong growth period in our industry and end markets. We believe we are well positioned to capitalize on this anticipated recovery to grow our business and reduce our leverage over time. As of March 28, 2015, our total indebtedness was approximately $1,062.7 million, or $1,486.5 million on a pro forma basis after giving effect to the Transactions.

The private construction market includes residential and nonresidential new construction and the repair and remodel market. According to the National Association of Home Builders, the number of total housing starts in the United States, a leading indicator for our residential business, is expected to grow 57% from 2013 to 2016. In addition, the Portland Cement Association (“PCA”) projects that spending in private nonresidential construction will grow 26% over the same period. The private construction market represented 69% and 56% of our revenue in the three months ended March 28, 2015 and the year ended December 27, 2014, respectively.

Public infrastructure, which includes spending by federal, state and local governments for roads, highways, bridges, airports and other public infrastructure projects, has been a relatively stable portion of government budgets providing consistent demand to our industry and is projected by the PCA to grow approximately 3% from 2013 to 2016. With the nation’s infrastructure aging, we expect U.S. infrastructure spending to grow over

1

Table of Contents

the long term, and we believe we are well positioned to capitalize on any such increase. Despite this projected growth, we do not believe it will be consistent across the United States, but will instead be concentrated in certain regions. The public infrastructure market represented 31% and 44% of our revenue in the three months ended March 28, 2015 and the year ended December 27, 2014, respectively.

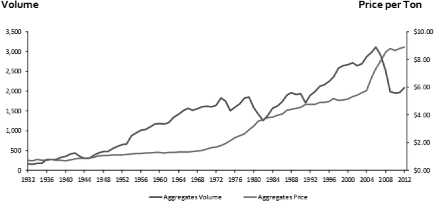

In addition to the anticipated growth in our end markets, we expect higher volume and pricing in our core product categories. Favorable market dynamics can be seen in aggregates, where volumes decreased from 3.1 billion tons in 2006 to an estimated 2.1 billion tons in 2013, a 34% decline that has been offset by growth in the average price per ton, which increased from $7.37 in 2006 to an estimated $8.94 in 2013, a 21% increase, according to the U.S. Geological Survey. In addition, the PCA estimates that cement consumption will increase approximately 30% from 2013 to 2016, reflecting rising demand in the major end markets. At the same time, we believe that cement pricing will be driven higher by tightening production capacity in the United States, where the PCA projects consumption will exceed domestic cement capacity by 2017 driven by both increasing demand and by capacity constraints arising from the U.S. Environmental Protection Agency’s (“EPA”) National Emission Standards for Hazardous Air Pollutants (“NESHAP”) regulation for Portland Cement Plants (“PC-MACT”), with which compliance is generally required in 2015.

Historically, we have sought to supplement organic growth potential with acquisitions, by strategically targeting attractive, new markets or expanding in existing markets. We consider population trends, employment rates, competitive landscape, private construction outlook, public funding and various other factors prior to entering a new market. In addition to analyzing macroeconomic data, we seek to establish a top position in our local markets, which we believe supports sustainable organic growth and attractive returns. This positioning provides local economies of scale and synergies, which benefit our pricing, costs and profitability. We believe that each of our operating companies has a top three market share position in its local market.

Our acquisition strategy, to date, has helped us to achieve scale and rapid growth, and we believe that significant opportunities remain for growth through acquisitions. We estimate that approximately 65% of the U.S. construction materials market is privately owned. From this group, our senior management team maintains contact with over 300 private companies. These long-standing relationships, cultivated over decades, have been the primary source for our past acquisitions and, we believe, will be a key driver of our future growth. We believe the value proposition we offer to potential sellers has made us a buyer of choice and has enabled us to largely avoid competitive auctions and instead negotiate directly with sellers at attractive valuations.

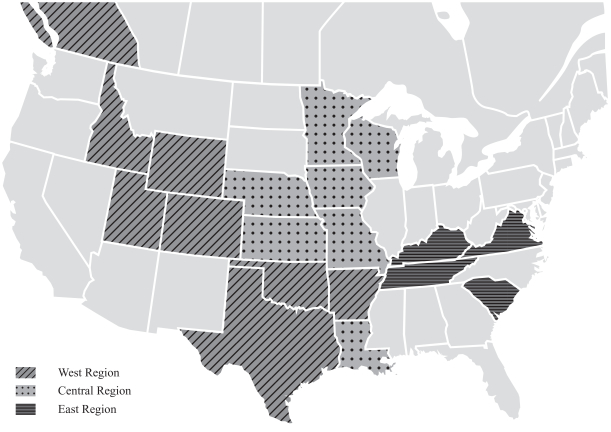

Our Regional Platforms

We currently operate across 18 U.S. states and in British Columbia, Canada through our three regional platforms that make up our operating segments: West; Central; and East. Each of our operating businesses has its own management team that, in turn, reports to a regional president who is responsible for overseeing the operating businesses, developing growth opportunities, implementing best practices and integrating acquired businesses. Acquisitions are an important element of our strategy, as we seek to enhance value through increased scale and cost savings within local markets.

| • | West Region: Our West region includes operations in Texas, the Mountain states of Utah, Colorado, Idaho and Wyoming and in British Columbia, Canada. We supply aggregates, ready-mixed concrete, asphalt paving mix and paving and related services in the West region. As of March 28, 2015, the West region controlled approximately 0.7 billion tons of proven and probable aggregates reserves and $365.8 million of net property, plant and equipment and inventories (“hard assets”). During the year ended December 27, 2014, approximately 55% of our revenue and approximately 49% of our Adjusted EBITDA, excluding corporate charges, were generated in the West region. In 2014, we expanded the West region’s operations with key acquisitions providing significant growth in Texas as well as the establishment of a new platform in British Columbia, Canada. |

2

Table of Contents

| • | Central Region: Our Central region extends across the Midwestern United States, most notably in Kansas, Missouri, Nebraska, Iowa and along the Mississippi River, where we supply aggregates, cement, ready-mixed concrete, asphalt paving mix and paving and related services. As of March 28, 2015, the Central region controlled approximately 0.5 billion tons of proven and probable aggregates reserves, approximately 0.4 billion of which serve its cement business, and $549.1 million of hard assets. During the year ended December 27, 2014, approximately 33% of our revenue and approximately 42% of our Adjusted EBITDA, excluding corporate charges, were generated in the Central region. |

Our Hannibal, Missouri cement plant, commissioned in 2008, is a highly efficient, technologically advanced, integrated manufacturing and distribution system strategically located 100 miles north of St. Louis along the Mississippi River. We utilize an on-site solid and liquid waste fuel processing facility, which can reduce the plant’s fuel costs by up to 50% and is one of only 12 facilities in the United States with such capabilities. This cement plant primarily serves markets in Missouri, Iowa and along the Mississippi River. The Davenport Acquisition expanded our cement operations on the Mississippi River with a plant in Davenport, Iowa and seven terminals on the Mississippi River from Minnesota to Louisiana. Our production capacity approximately doubled with the acquisition. See “—The Davenport Acquisition.”

| • | East Region: Our East region serves markets in Kentucky, South Carolina, North Carolina, Tennessee and Virginia, where we supply aggregates, asphalt paving mix and paving and related services. As of March 28, 2015, the East region controlled approximately 0.5 billion tons of proven and probable aggregates reserves and $159.1 million of hard assets. During the year ended December 27, 2014, approximately 12% of our revenue and approximately 9% of our Adjusted EBITDA, excluding corporate charges, were generated in the East region. |

Summary Regional Data(1)

(as of March 28, 2015)

| West | Central | East | Total | |||||||||||||

| Aggregates Details: |

||||||||||||||||

| Tonnage of Reserves (thousands of tons): |

||||||||||||||||

| Hard Rock |

333,236 | 874,458 | 458,409 | 1,666,103 | ||||||||||||

| Sand and Gravel |

346,083 | 77,596 | 7,143 | 430,822 | ||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

| Total Tonnage of Reserves (thousands of tons) |

679,319 | 952,054 | 465,552 | 2,096,925 | ||||||||||||

| Annual Production Capacity (thousands of tons) |

22,254 | 5,715 | 5,173 | 33,142 | ||||||||||||

| Average Years Until Depletion(2) |

31 | 167 | 90 | 63 | ||||||||||||

| Ownership Details: |

||||||||||||||||

| Owned |

33 | % | 67 | % | 39 | % | 50 | % | ||||||||

| Leased |

67 | % | 33 | % | 61 | % | 50 | % | ||||||||

| Aggregate Producing Sites |

51 | 62 | 24 | 137 | ||||||||||||

| Ready-Mix Plants |

41 | 23 | — | 69 | ||||||||||||

| Asphalt Plants |

21 | 5 | 14 | 40 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Primary States and Provinces: |

Texas | Kansas | Kentucky | |||||||||||||

| Utah | Missouri | South Carolina | ||||||||||||||

| Colorado | Nebraska | North Carolina | ||||||||||||||

| Idaho | Iowa | Tennessee | ||||||||||||||

| Wyoming | Illinois | Virginia | ||||||||||||||

| British Columbia | ||||||||||||||||

|

|

|

|

|

|

|

|||||||||||

3

Table of Contents

| West | Central | East | Total | |||||||||||||

| Primary Markets: |

Houston, TX | Wichita, KS | Lexington, KY | |||||||||||||

| Austin, TX | Kansas City, KS | Louisville, KY | ||||||||||||||

| San Antonio, TX | Topeka, KS | Bowling Green, KY | ||||||||||||||

| Midland, TX | Manhattan, KS | Elizabethtown, KY | ||||||||||||||

| Dallas, TX | Lawrence, KS | Charlotte, NC | ||||||||||||||

| Amarillo, TX | Columbia, MO | |||||||||||||||

| Longview, TX | St. Louis, MO | |||||||||||||||

| Texarkana, TX | ||||||||||||||||

| Denison, TX | ||||||||||||||||

| Salt Lake City, UT | ||||||||||||||||

| Grand Junction, CO | ||||||||||||||||

| British Columbia, Canada | ||||||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Products Produced: |

Aggregates | Aggregates | Aggregates | |||||||||||||

| Ready-Mixed concrete | Cement | Asphalt | ||||||||||||||

| Asphalt | |

Ready-Mixed concrete |

|

|||||||||||||

| Asphalt | ||||||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Revenue by End Market for Year ended December 27, 2014: |

||||||||||||||||

| Residential and Nonresidential |

67 | % | 55 | % | 10 | % | 56 | % | ||||||||

| Public |

33 | % | 45 | % | 90 | % | 44 | % | ||||||||

| (1) | Does not give effect to the consummation of the Davenport Acquisition. |

| (2) | Calculated based on total reserves divided by our average of 2013 and 2014 annual production. |

Our Competitive Strengths

Leading market positions. We believe each of our operating companies has a top three market share position in its local market area achieved through their respective, extensive operating histories, averaging over 35 years. We believe we are a top 10 supplier of aggregates, a top 20 producer of cement and a major producer of ready-mixed concrete and asphalt paving mix in the United States by volume. We focus on acquiring companies that have leading local market positions in aggregates, which we seek to enhance by building scale with other local aggregates and downstream products and services. The construction materials industry is highly local in nature due to transportation costs from the high weight-to-value ratio of the products. Given this dynamic, we believe achieving local market scale provides a competitive advantage that drives growth and profitability for our business. We believe that our ability to prudently acquire, improve and rapidly integrate multiple businesses has enabled, and will continue to enable, us to become market leaders.

Operations positioned to benefit from attractive industry fundamentals. We believe the construction materials industry has attractive fundamentals, characterized by high barriers to entry and a stable competitive environment in the majority of markets. Barriers to entry are created by scarcity of raw material resources, limited efficient distribution range, asset intensity of equipment, land required for quarry operations and a time-consuming and complex regulatory and permitting process. According to the April 2014 U.S. Geological Survey, aggregates pricing in the United States had increased in 65 of the previous 70 years, with growth accelerating since 2002 as continuing resource scarcity in the industry has led companies to focus increasingly on improved pricing strategies. While aggregates volumes decreased 19% from 2.6 billion tons in 2008 to 2.1 billion tons in 2013, average price per ton of aggregates in the United States during this same time period increased 4% from $8.57 in 2008 to $8.95 in 2013. Pricing growth remained strong in 2013, despite volume declines in certain key end markets.

4

Table of Contents

One significant factor that allows for pricing growth in periods of volume declines is that aggregates and asphalt paving mix have significant exposure to public road construction, which has demonstrated growth over the past 30 years, even during times of broader economic weakness. The majority of public road construction spending is funded at the state level through the states’ respective departments of transportation. The five key states in which we operate (Texas, Kansas, Kentucky, Utah and Missouri) have funds with certain constitutional protections for revenue sources dedicated for transportation projects. These dedicated, earmarked funding sources limit the negative effect current state deficits may have on public spending. As a result, we believe our business’ profitability is significantly more stable than most other building product subsectors.

Vertically-integrated business model. We generate revenue across a spectrum of related products and services. We internally supply approximately 80% of the aggregates used in the ready-mixed concrete and asphalt paving mixes that we produce and the asphalt paving mix that our paving crews lay. Our vertically-integrated business model enables us to operate as a single source provider of materials and paving and related services, creating cost, convenience and reliability advantages for our customers, while at the same time creating significant cross-marketing opportunities among our interrelated businesses. We believe this creates opportunities to increase aggregates volumes, optimize margin at each stage of production, foster more stable demand for aggregates through a captive demand outlet, create a competitive advantage through the efficiency gains, convenience and reliability provided to customers and enhance our acquisition strategy by allowing a greater range of target companies.

Attractive diversity, scale and product portfolio. Our three regional platforms operate across 18 U.S. states and British Columbia, Canada in 33 metropolitan statistical areas. Between the year ended December 31, 2010 and the twelve months ended March 28, 2015, we grew our revenue by 208% and brought substantial additional scale and geographic diversity to our operations. A combination of increased scale and vertical integration enabled us to improve profitability with Adjusted EBITDA margins increasing 180 basis points from the year ended December 31, 2010 to the twelve months ended March 28, 2015. In the twelve months ended March 28, 2015, 88% of EBITDA was derived from materials and products, with 51% coming from materials, 37% from products and the remaining 12% of EBITDA being derived from services. We have approximately 2.1 billion tons of proven and probable aggregates reserves serving our aggregates and cement business. Assuming production rates in future years are equal to those in 2014, we estimate that the useful life of our proven and probable reserves serving our aggregates and cement businesses are approximately 50 years and 200 years, respectively, and approximately 50 years at the Davenport, Iowa cement plant.

We own a dry process cement plant in Hannibal, Missouri that was commissioned in 2008 and one in Davenport, Iowa that was commissioned in 1981. These large capacity plants have technologically advanced manufacturing capabilities and favorable environmental performance compared to older facilities within the industry that will require upgrades to comply with stringent EPA standards coming into effect in the near term. According to PCA forecasts, consumption of cement in the United States is expected to exceed production capacity by the year 2017, creating opportunities for existing cement plants. In addition, our plants are strategically located on the Mississippi River and, consequently, in 2014, approximately 58% and 32% of cement sold from the Hannibal and Davenport plants, respectively, was shipped by barge, which is generally more cost-effective than truck transport.

Proven ability to incorporate new acquisitions and grow businesses. Since July 2009, we have acquired 36 companies, successfully integrating the businesses into three regions through the implementation of operational improvements, industry-proven information technology systems, a comprehensive safety program and best in class management programs. A typical acquisition generally involves retaining the local management team of the acquired business, maintaining operational decisions at the local level and providing strategic insights and leadership directed by Tom Hill, our President and Chief Executive Officer, a 30-year industry veteran. These acquisitions have helped us achieve significant revenue growth, from $405.3 million in 2010 to $1,204.2 million in 2014.

5

Table of Contents

Experienced and proven leadership driving organic growth and acquisition strategy. Our management team, led by Mr. Hill, has a proven track record of creating value. In addition to Mr. Hill, our management team, including corporate and regional operations managers, corporate development, finance executives and other heavy side industry operators, has extensive experience in the industry. Our management team has a track record of executing and successfully integrating acquisitions in the sector. Mr. Hill and his team successfully executed a similar consolidation strategy at another company in the industry, where Mr. Hill led the integration of 173 acquisitions worth, in the aggregate, approximately $6.3 billion, taking the business from less than $0.3 billion to $7.4 billion in sales from 1992 to 2008.

Our Business Strategy

Capitalize on expected recovery in U.S. economy and construction markets. The residential and nonresidential markets are starting to show positive growth signs in varying degrees across our markets. The National Association of Home Builders forecasts total housing starts to accelerate to 1.46 million in the United States by 2016, representing a compounded annual growth rate of 16.4% from 2013 to 2016. The American Institute of Architects’ Consensus Construction Forecast projects nonresidential construction to grow 8.1% in 2015. We believe that we have sufficient exposure to the residential and nonresidential end markets to benefit from a potential recovery in all of our markets. In 2014, approximately 83% of our revenue was derived from Texas, Kansas, Kentucky, Utah and Missouri. Across these states, Department of Transportation (“DOT”) budgets grew a combined 22.6% from 2013 to 2014. Given the nation’s aging infrastructure and considering longstanding historical spending trends, we expect U.S. infrastructure investment to grow over time. We believe we are well positioned to capitalize on any such increase in investment.

Expand local positions in the most attractive markets through targeted capital investments and bolt-on acquisitions. We plan to expand our business through organic growth and bolt-on acquisitions in each of our local markets. Our acquisition strategy involves acquiring platforms that serve as the foundation for continued incremental and complementary growth via locally situated bolt-on acquisitions to these platforms. We believe that increased local market scale will drive profitable growth. Our existing platform of operations is expected to enable us to grow significantly as we expand in our existing markets. In pursuing our growth strategy, we believe that our balance sheet and liquidity position will enable us to acquire most of the bolt-on acquisitions and platforms that we seek to purchase, but we may also pursue larger acquisition transactions, such as the Davenport Acquisition, that may require us to raise additional equity capital and indebtedness. Consistent with this strategy, we regularly evaluate potential acquisition opportunities, including ones that would be significant to us. We cannot predict the timing of any contemplated transactions.

Drive profitable growth through strategic acquisitions. Our goal is to become a top-five U.S. construction materials company through the successful execution of our acquisition strategy and implementation of best practices to drive organic growth. Based on aggregates sales, in volumes, we believe that we are currently a top-ten player, which we achieved within five years of our first acquisition. We believe that the relative fragmentation of our industry creates an environment in which we can continue to acquire companies at attractive valuations and increase scale and diversity over time through strategic acquisitions in markets adjacent to our existing markets within the states where we currently operate, as well as into additional states as market and competitive conditions support further growth.

Enhance margins and free cash flow generation through implementation of operational improvements. Our management team includes individuals with decades of experience in our industry and proven success in integrating acquired businesses and organically growing operations. This experience represents a significant source of value to us that has driven Adjusted EBITDA margins up 180 basis points from the year ended December 31, 2010 to the twelve months ended March 28, 2015. These margin improvements are

6

Table of Contents

accomplished through proven profit optimization plans, leveraging information technology and financial systems to control costs, managing working capital, achieving scale-driven purchasing synergies and fixed overhead control and reduction. Our regional presidents, supported by our central operations, risk management and finance and information technology teams, drive the implementation of detailed and thorough profit optimization plans for each acquisition post close, which typically includes, among other things, implementation of a systematic pricing strategy and an equipment utilization analysis that assesses repair and maintenance spending, the health of each piece of equipment and a utilization review to ensure we are maximizing productivity and selling any pieces of equipment that are not needed in the business.

Leverage vertically-integrated and strategically located operations for growth. We believe that our vertical integration of construction materials, products and services is a significant competitive advantage that we will leverage to grow share in our existing markets and enter into new markets. A significant portion of materials used to produce our products and provide services to our customers is internally supplied, which enables us to operate as a single source provider of materials, products and paving and related services, creating cost, convenience and reliability advantages for our customers and enabling us to capture additional value throughout the supply chain, while at the same time creating significant cross-marketing opportunities among our interrelated businesses.

Our Industry

The U.S. construction materials industry is composed of four primary sectors: aggregates; cement; ready-mixed concrete; and asphalt paving mix. Each of these materials is widely used in most forms of construction activity. Participants in these sectors typically range from small, privately-held companies focused on a single material, product or market to multinational companies that offer a wide array of construction materials, products and related services. Competition is limited in part by the distance materials can be transported efficiently, resulting in predominantly local or regional operations.

Transportation infrastructure projects, driven by both federal and state funding programs, represent a significant share of the U.S. construction materials market. In addition to federal funding, highway construction and maintenance funding is also available through state, county and local agencies. Our five largest states by revenue (Texas, Kansas, Kentucky, Utah and Missouri, which represented approximately 34%, 19%, 11%, 10% and 9%, respectively, of our total revenue in 2014) each have funds whose revenue sources have certain constitutional protections and may only be spent on transportation projects.

Aggregates. Aggregates are key material components used in the production of cement, ready-mixed concrete and asphalt paving mixes for the residential, nonresidential and public infrastructure markets and are also widely used for various applications and products, such as road and building foundations, railroad ballast, erosion control, filtration, roofing granules and in solutions for snow and ice control. Generally extracted from the earth using surface or underground mining methods, aggregates are produced from natural deposits of various materials such as limestone, sand and gravel, granite and trap rock.

Aggregates represent an attractive market with high profit margins, high barriers to entry and increasing resource scarcity, which, as compared to construction services, leads to relatively stable profitability through economic cycles. Production is moderately capital intensive and access to well-placed reserves is important given high transport costs and environmental permitting restrictions. Markets are typically local due to high transport costs and are generally fragmented, with numerous participants operating in localized markets. The top players controlled approximately 30% of the national market in 2013. According to the March 2015 U.S. Geological Survey, the U.S. market for these products was estimated at approximately 2.4 billion tons in 2014, at a total market value of $20.3 billion. Relative to other construction materials, such as cement, aggregates consumption

7

Table of Contents

is more heavily weighted towards public infrastructure and maintenance and repair. However, the mix of end uses can vary widely by geographic location, based on the nature of construction activity in each market. Typically, three to six competitors comprise the majority market share of each local market because of the constraints around the availability of natural resources and transportation. Vertically-integrated players can have a competitive advantage by leveraging their aggregates for downstream operations, such as ready-mixed concrete, asphalt paving mix and paving and related services.

Cement. Portland cement, an industry term for the common cement in general use around the world, is the basic ingredient of concrete and is made from a combination of limestone, shale, clay, silica and iron ore. Together with water, cement creates the paste that binds the aggregates together when making concrete. Cement is an input for ready-mixed concrete and concrete products and commands significantly higher prices relative to aggregates, reflecting the more intensive capital investment required. Cement production in the United States is distributed among 97 production facilities located across 34 states and is a capital-intensive business with variable costs dominated by raw materials and energy required to fuel the kiln. Building new plants is challenging given the extensive permitting requirements and capital investment requirements. We estimate new plant construction costs in the United States to be approximately $250-300 per ton, not including costs for property or securing raw materials and the required distribution network. Assuming construction costs of $275 per ton, a 1.25 million ton facility, comparable to our Hannibal, Missouri cement plant’s potential annual capacity, would cost approximately $343.8 million to construct. Establishing a distribution network, such as the seven terminals included in the Davenport Assets, would add significant cost to a cement plant investment.

Ready-mixed concrete. Ready-mixed concrete is one of the most versatile and widely used materials in construction today. It is created through the combination of coarse and fine aggregates, which make up approximately 60 to 75% of the mix by volume, with water, various chemical admixtures and cement making up the remainder. Given the high weight-to-value ratio, delivery of ready-mixed concrete is typically limited to a one-hour haul from a production plant and is further limited by a 90 minute window in which newly-mixed concrete must be poured to maintain quality and performance. As a result of the transportation constraints, the ready-mixed concrete market is highly localized, with an estimated 5,500 ready-mixed concrete plants in the United States, according to the National Ready Mixed Concrete Association (the “NRMCA”). We participate selectively in ready-mixed concrete markets where we provide our own aggregates for production, which we believe provides us a competitive advantage.

Asphalt paving mix. Asphalt paving mix is the most common roadway material used today, covering 93% of the more than 2.6 million miles of paved roadways in the United States, according to the National Asphalt Pavement Association (“NAPA”). Major inputs include aggregates and liquid asphalt (the refined residue from the distillation process of crude oils by refineries). Given the significant aggregates component in asphalt paving mix (up to 95% by weight), local aggregates producers often participate in the asphalt paving mix business to secure captive demand for aggregates. Asphalt and paving is highly fragmented in the United States, with end markets skewed towards new road construction and maintenance and repair of roads. Barriers to entry include permit requirements, access to aggregates (where possible, asphalt plants are typically located at quarries) and access to liquid asphalt.

8

Table of Contents

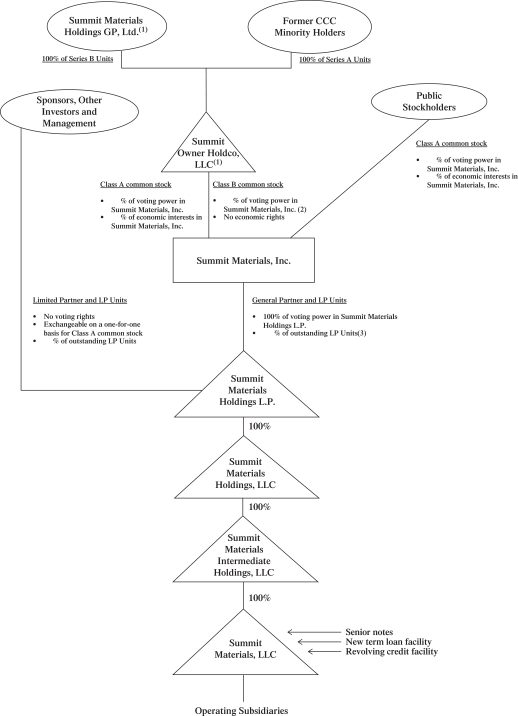

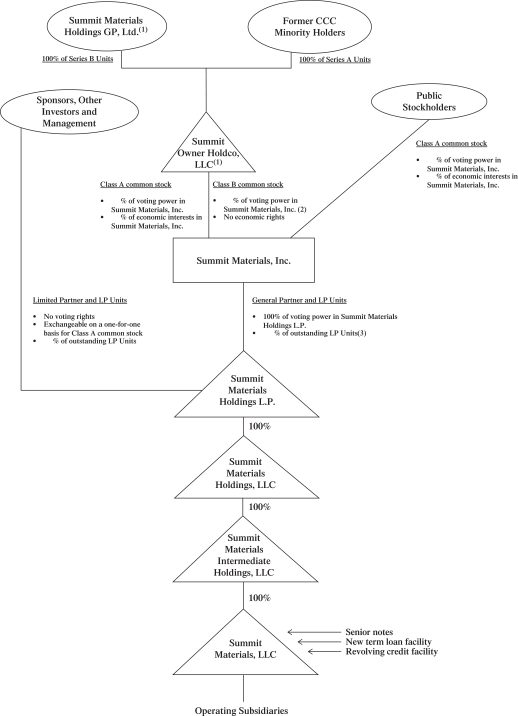

Our Structure

Summit Materials, Inc. is a holding company, and its sole material asset is a controlling equity interest in Summit Holdings. Summit Materials, Inc. operates and controls all of the business and affairs and consolidates the financial results of Summit Holdings and its subsidiaries. Prior to the completion of the IPO (the “IPO Date”), the partnership agreement of Summit Holdings was amended and restated to, among other things, modify its capital structure by reclassifying the interests held by our pre-IPO owners into a single new class of units that we refer to as “LP Units.” We and our pre-IPO owners have entered into an exchange agreement under which they (or certain permitted transferees) have the right, from and after the first anniversary of the IPO Date, or March 17, 2016, (subject to the terms of the exchange agreement), to exchange their LP Units for shares of our Class A common stock on a one-for-one basis, subject to customary conversion rate adjustments for stock splits, stock dividends and reclassifications. Notwithstanding the foregoing, Blackstone is generally permitted to exchange LP Units at any time. See “Certain Relationships and Related Person Transactions—Exchange Agreement.”

Summit Owner Holdco LLC (“Summit Owner Holdco”), a Delaware limited liability company that is owned by certain of our pre-IPO owners and the former holders of Class B Units of Continental Cement (the “Former CCC Minority Holders”), holds all of the shares of our outstanding Class B common stock. The Class B common stock entitles (x) Summit Owner Holdco, without regard to the number of shares of Class B common stock held by it, to a number of votes that is equal to the aggregate number of LP Units held by all limited partners of Summit Holdings (excluding Summit Materials, Inc.) as of the IPO Date and their respective successors and assigns on or after the IPO Date (the “Initial LP Units”) less the aggregate number of such Initial LP Units that, after the IPO Date, have been transferred to Summit Materials, Inc. in accordance with the exchange agreement, are forfeited in accordance with agreements governing unvested Initial LP Units or are held by a holder other than Summit Owner Holdco together with a share of Class B common stock (or fraction thereof) and (y) any other future holder of Class B common stock, without regard to the number of shares of Class B common stock held by such other holder, to a number of votes that is equal to the number of LP Units held by such holder. Currently, the limited partners of Summit Holdings consist solely of our pre-IPO owners. However, Summit Holdings may in the future admit additional limited partners, in connection with an acquisition or otherwise, that would not constitute pre-IPO owners. Limited partners of Summit Holdings are not entitled to shares of Class B common stock solely as a result of their admission as limited partners. However, we may in the future issue shares of Class B common stock to one or more limited partners to whom LP Units are also issued, for example in connection with the contribution of assets to us or Summit Holdings by such limited partner. Accordingly, as a holder of both LP Units and Class B common stock, any such holder of Class B common stock would be entitled to a number of votes equal to the number of LP Units held by it. If at any time the ratio at which LP Units are exchangeable for shares of our Class A common stock changes from one-for-one as described under “Certain Relationships and Related Person Transactions—Exchange Agreement,” for example, as a result of a conversion rate adjustment for stock splits, stock dividends or reclassifications, the number of votes to which Class B common stockholders are entitled will be adjusted accordingly. Holders of shares of our Class B common stock vote together with holders of our Class A common stock as a single class on all matters on which stockholders are entitled to vote generally, except as otherwise required by law.

9

Table of Contents

The diagram below depicts our organizational structure and equity ownership immediately following this offering. For additional detail, see “Organizational Structure.”

10

Table of Contents

| (1) | Affiliates of Blackstone have the right to appoint a majority of the board of directors of Summit Materials Holdings GP, Ltd. (“Summit GP”). |

| (2) | The Class B common stock entitles Summit Owner Holdco, without regard to the number of shares of Class B common stock held by it, to a number of votes that is equal to the aggregate number of Initial LP Units less the aggregate number of such Initial LP Units that, after the IPO Date, have been transferred to Summit Materials, Inc. in accordance with the exchange agreement, are forfeited in accordance with agreements governing unvested Initial LP Units or are held by a holder other than Summit Owner Holdco together with a share of Class B common stock (or fraction thereof) and entitle each other holder of Class B common stock, without regard to the number of shares of Class B common stock held by such other holder, to a number of votes that is equal to the number of LP Units held by such holder. If Summit Owner Holdco were to transfer shares of Class B common stock to a holder of Initial LP Units, such holder of Initial LP Units and shares of Class B common stock would be entitled to a number of votes equal to the number of Initial LP Units held and the number of votes available to Summit Owner Holdco would decrease commensurately. |

| (3) | As of March 28, 2015, 2,989,134 of the LP Units, or approximately 3.1% of the total LP Units outstanding, are unvested and are subject to certain time and performance vesting conditions. See “Executive and Director Compensation—Compensation Discussion and Analysis—Considerations Regarding 2014 NEO Compensation—Long-Term Incentives—Conversion of Class D Interests” on page 152. |

Corporate Information

Summit Materials, Inc. was formed under the laws of the State of Delaware on September 23, 2014. Our principal executive office is located at 1550 Wynkoop Street, 3rd Floor, Denver, Colorado 80202. Through our predecessors, we commenced operations in 2009 when Summit Holdings was formed as an exempted limited partnership in the Cayman Islands. In December 2013, Summit Holdings was domesticated as a limited partnership in Delaware. Our telephone number is (303) 893-0012.

Our Sponsors

Blackstone. The Blackstone Group L.P. is one of the world’s leading investment firms. Blackstone’s asset management businesses, with approximately $310.5 billion in assets under management as of March 31, 2015, include investment vehicles focused on private equity, real estate, public debt and equity, non-investment grade debt and secondary funds, all on a global basis. Blackstone also provides various financial advisory services, including financial and strategic advisory, restructuring and reorganization advisory and fund placement services.

Silverhawk. Silverhawk Capital Partners, LLC is a private equity firm with offices in Greenwich, Connecticut and Charlotte, North Carolina. The founding partners have invested as a team and operated businesses since 1989. Founded in 2005, Silverhawk’s investments are focused in the energy, manufacturing and business service sectors. As of March 31, 2015, Silverhawk had approximately $300.0 million of assets under management.

Investment Risks

An investment in shares of our Class A common stock involves substantial risks and uncertainties that may adversely affect our business, financial condition and results of operations and cash flows. Some of the more significant challenges and risks relating to an investment in our company include, among other things, the following:

| • | Our business depends on activity within the construction industry and the strength of the local economies in which we operate. |

11

Table of Contents

| • | Our business is cyclical and requires significant working capital to fund operations. |

| • | Weather can materially affect our business, and we are subject to seasonality. |

| • | Our industry is capital intensive and we have significant fixed and semi-fixed costs. Therefore, our earnings are sensitive to changes in volume. |

| • | Within our local markets, we operate in a highly competitive industry. |

| • | The success of our business depends, in part, on our ability to execute on our acquisition strategy, to successfully integrate acquisitions and to retain key employees of our acquired businesses. |

| • | A decline in public infrastructure construction and reductions in governmental funding could adversely affect our results. |

| • | Environmental, health and safety laws and regulations and any changes to, or liabilities arising under, such laws and regulations could have a material adverse effect on our financial condition, results of operations and liquidity. |

| • | If we are unable to accurately estimate the overall risks, requirements or costs when we bid on or negotiate contracts that are ultimately awarded to us, we may achieve lower than anticipated profits or incur contract losses. |

| • | The cancellation of a significant number of contracts or our disqualification from bidding for new contracts could have a material adverse effect on our financial position, results of operations and liquidity. |

| • | Our substantial leverage could adversely affect our financial condition, our ability to raise additional capital to fund our operations, our ability to operate our business, our ability to react to changes in the economy or our industry and pay our debts and could divert our cash flow from operations to debt payments. |

| • | Blackstone and its affiliates control us and their interests may conflict with ours or yours in the future. |

Please see “Risk Factors” for a discussion of these and other factors you should consider before making an investment in shares of our Class A common stock.

The Davenport Acquisition

Overview

On July 17, 2015, Continental Cement acquired the Davenport Assets for $450.0 million, subject to certain adjustments, plus certain assets, including Continental Cement’s Bettendorf, Iowa cement distribution terminal (the “Bettendorf Terminal”) (the “Davenport Acquisition”). Of the purchase price, $370.0 million was paid at closing and $80.0 million (the “Deferred Purchase Obligation”) is to be paid no later than December 31, 2015. The net proceeds from this offering that we use to purchase newly-issued LP Units from Summit Holdings are expected to be used to, among other things, finance all or a portion of the Deferred Purchase Obligation.

The combination of the Davenport Assets and Continental Cement is expected to create a strategically attractive and complementary multi-plant cement business. Synergy opportunities include distribution efficiencies, alternative fuels optimization and sharing of operational best practices. The acquisition expands our geographic footprint, provides new platforms for downstream growth and makes us the third largest cement producer by capacity on the Mississippi River as of the closing of the Davenport Acquisition.

12

Table of Contents

On a combined basis, after giving effect to the Davenport Acquisition, Continental Cement has 2.4 million short tons (“mt”) of cement capacity across the Davenport Plant and the cement plant in Hannibal, Missouri as well as eight cement distribution terminals along the Mississippi River from Minneapolis, Minnesota to New Orleans, Louisiana.

Premier assets. The Davenport Plant has been in operation since 1981 and, similar to Continental Cement’s Hannibal, Missouri cement plant, is served by barge, rail and truck distribution modes. It is a well-designed and well-run plant and has been a low-cost producer for the last decade. The Davenport Plant has 1.1mt of clinker and 1.2 mt of cement capacity and approximately 1.5 mt of cement was distributed through the Davenport Terminals in the twelve months ended December 31, 2014. Volume in excess of the Davenport Plant capacity is expected to be serviced with Continental Cement’s capacity. The Davenport Terminals have storage capacity of over 0.2 mt and annual throughput capacity of over 2.2 mt. Operations employ one vertical roller mill and one precalciner kiln along with a single classic ball mill for finish grinding. The Davenport Plant produces one clinker type and two cement types (Types I and II), both of which are low alkali and approved for use in all states in the Mississippi basin. At current production levels, we estimate that the Davenport Plant has approximately 50 years of quarry reserves.

The Davenport Terminals are well located to serve attractive markets. The cement distribution terminal in the New Orleans market can handle offshore cement imports, which favorably positions us to satisfy the gap between domestic consumption and capacity as supply tightens with recovering demand over the next two to three years.

Strategic fit with Continental Cement. The Davenport Plant together with the network of Davenport Terminals is a strategic fit with Continental Cement. The Davenport Plant and the Continental Cement plant in Hannibal, Missouri are the two most northern-located cement plants on the Mississippi River. Upon closing of the Davenport Acquisition, Continental Cement is the third largest cement producer on the Mississippi River, after Buzzi Unicem USA, Inc. (“Buzzi”) and Lafarge-Holcim. The Davenport Acquisition presents a compelling opportunity to develop a multi-plant cement business of scale, serving as a substantial platform for downstream growth over multiple new regional markets.

Operational fit with Continental Cement. The Davenport Plant is approximately 170 miles north of Continental Cement’s Hannibal, Missouri facility. Operationally, we have identified many opportunities for synergies, including distribution efficiencies, alternative fuels optimization (both plants use alternative fuels to replace coal) and other best practice transfers between the plants.

Improves our margin and earnings mix exposure. We believe the acquisition of the Davenport Assets, a 100% cement business, will significantly increase the proportion of our EBITDA that is derived from materials, improve our overall EBITDA margin by nearly 200 basis points (“bps”) and increase our materials-related earnings exposure by approximately 900 bps. Furthermore, the Davenport Assets increase our geographic diversity, expand exposure to higher-growth, privately-led construction materials demand and bring new platforms for downstream market growth.

Attractive markets present opportunity for volume growth. Cement production along the Mississippi River has remained relatively constant over the last 10 years. Cement capacity of 15 mt is split among six players (eight plants) along the Mississippi River. The Davenport Assets are well positioned in all up-river markets and have the lowest or second lowest delivered cost position in each. In most of the markets which the Davenport Assets supply, the primary competitors are Lafarge-Holcim and Buzzi. Lafarge-Holcim’s Ste. Genevieve site is the largest plant on the Mississippi River and competes with the Davenport Assets in more markets than any other competitor. The Davenport Terminals and Continental Cement’s St. Louis, Missouri terminal provide

13

Table of Contents

Continental Cement with coverage of many attractive markets along the Mississippi River via low-cost barge and rail distribution modes. Owning two strategically located plants and eight terminals covering the Mississippi River positions the business for expanded growth.

Attractive time to invest in the cement sector and the Mississippi River market. The U.S. cement industry is moving back towards its historical domestic cement supply-demand imbalance. Demand is expected to exceed U.S. domestic capacity by 2017. The developing domestic supply-demand imbalance is also attributable to tighter EPA NESHAP regulations for PC-MACT, compliance with which is generally required in 2015, as well as the closure in the past decade of a portion of the older and inefficient U.S. cement plants. This supply-demand imbalance has positive implications for industry pricing and the trend for real price increases are expected to continue. The Mississippi River market continues to experience a demand and pricing recovery since trough conditions in 2011-12. The Midwest economy is generally improving, driven by a rebound in industrial production and manufacturing. The unemployment rate in the Davenport Assets target market is well below that of the overall U.S. unemployment rate, and building permit growth is expected to grow at a faster rate than the U.S. over the next two years.

Recent Developments

Initial Public Offering

On March 17, 2015, we completed our IPO in which we sold 25,555,555 shares of our Class A common stock at a price to the public of $18.00 per share and received net proceeds of approximately $433.0 million, after deducting underwriting discounts and commissions. We used the net proceeds from the IPO to purchase newly-issued LP Units from Summit Holdings. Summit Holdings used these proceeds to, among other things, repay indebtedness and purchase the then-outstanding minority interest of Continental Cement. Upon consummation of the IPO, Continental Cement became our wholly-owned indirect subsidiary.

New Term Loan Facility

In connection with the Davenport Acquisition, Summit LLC entered into the New Term Loan Facility. The proceeds of the New Term Loan Facility were used to pay for a portion of the initial cash purchase price of $370.0 million for the Davenport Acquisition that was payable at closing and to refinance our existing $414.6 million term loan facility due 2019. See “Description of Certain Indebtedness—Senior Secured Credit Facilities.”

Release of Proceeds from Senior Notes Offering

In connection with the Davenport Acquisition and Summit LLC’s entry into the New Term Loan Facility, the gross proceeds from Summit LLC and its indirect wholly-owned subsidiary, Summit Materials Finance Corp.’s (together, the “Issuers”), private offering of the offering of the 2023 notes was released from the segregated account the Issuers established upon closing the offering of the 2023 notes on July 8, 2015. The net proceeds of the 2023 notes were used to finance a portion of the initial cash purchase price for the Davenport Acquisition and will be used along with other available cash to redeem $183.0 million in aggregate principal amount of the 2020 notes on or about August 3, 2015.

14

Table of Contents

Preliminary Consolidated Financial and Other Data for the Three and Six Months Ended June 27, 2015

The data presented below for the three and six months ended June 27, 2015 and June 28, 2014 and as of June 27, 2015 set forth preliminary financial results as of and for the three and six months ended June 27, 2015 based upon information available to us as of the date of this prospectus, is not a comprehensive statement of our financial results for such periods and has not been audited or reviewed by our independent registered public accounting firm. Our actual results as of and for the three and six months ended June 27, 2015 will not be available until after this offering is completed, and may differ materially from this preliminary data. During the course of the preparation of our financial statements and related notes, additional adjustments to the preliminary financial information presented below may be identified. Any such adjustments may be material. The preliminary results do not give effect to the Transactions. See “Unaudited Pro Forma Condensed Consolidated Financial Information.”

| Three Months Ended | Six Months Ended | |||||||||||||||

| June 27, 2015 | June 28, 2014 | June 27, 2015 | June 28, 2014 | |||||||||||||

| (in millions) | ||||||||||||||||

| Revenue(1) |

$ | $ | 324.3 | $ | $ | 475.4 | ||||||||||

| Cost of revenue(1) |

231.8 | 360.4 | ||||||||||||||

| General and administrative expenses(2) |

34.9 | 70.4 | ||||||||||||||

| Operating income (loss) |

33.9 | (1.1 | ) | |||||||||||||

| Cash |

24.1 | 24.1 | ||||||||||||||

| Long term debt current portion |

69.2 | 69.2 | ||||||||||||||

| (1) | Included in our estimated revenue for the three and six months ended June 27, 2015 is $ and $ , respectively, of delivery and subcontract revenue, which is recognized gross in revenue and cost of revenue. This amount compares to $31.9 million and $47.0 million in the three and six months ended June 28, 2014, respectively. Revenue for the three months ended June 27, 2015 was adversely affected by inclement weather, with asphalt and construction and paving services the most directly affected. |

| (2) | General and administrative expenses in the six months ended June 27, 2015 was affected by $28.3 million of one-time costs associated with our IPO. |

Based on our preliminary financial results, we expect our consolidated first lien net leverage ratio as of June 27, 2015 to be to 1.00. We calculate our consolidated first lien net leverage ratio, for purposes of confirming compliance with covenants in the agreements governing our senior secured credit facilities, by dividing our consolidated first lien net debt as of the end of the applicable quarterly period by our Further Adjusted EBITDA for the most recently ended four fiscal quarters for which internal financial statements are available. See “Management’s Discussion and Analysis of Financial Condition and Results of Operations—Liquidity and Capital Resources—Indebtedness” on pages 98 through 101 for more information.

15

Table of Contents

The Offering

| Class A common stock offered by Summit Materials, Inc. |

shares (plus up to an additional shares at the option of the underwriters). |

| Class A common stock outstanding after giving effect to this offering |

shares (or shares if all outstanding LP Units held by the limited partners of Summit Holdings were exchanged for newly-issued shares of Class A common stock on a one-for-one basis). |

| Voting power held by holders of Class A common stock after giving effect to this offering |

% (or 100% if all outstanding LP Units held by the limited partners of Summit Holdings were exchanged for newly-issued shares of Class A common stock on a one-for-one basis). |

| Voting power held by Summit Owner Holdco as a holder of all outstanding shares of Class B common stock after giving effect to this offering |

% (or 0.0% if all outstanding LP Units held by the limited partners of Summit Holdings were exchanged for newly-issued shares of Class A common stock on a one-for-one basis). If all outstanding LP Units held by the limited partners of Summit Holdings were exchanged for newly-issued shares of Class A common stock on a one-for-one basis and such shares continued to be held by such limited partners, our pre-IPO owners would hold % of the outstanding shares of Class A common stock and an equivalent percentage of the voting power of our common stock eligible to vote in the election of our directors, and, as a result, we would still be a “controlled company” if such limited partners formed a group. See “Organizational Structure” and “Management—Controlled Company Exception.” |

| Voting rights |

Each share of our Class A common stock entitles its holder to one vote on all matters to be voted on by stockholders generally. |

| Summit Owner Holdco, an entity that is owned by certain of our pre-IPO owners and the Former CCC Minority Holders, holds all of the outstanding shares of our Class B common stock. The Class B common stock entitles Summit Owner Holdco to a number of votes that is equal to the aggregate number of Initial LP Units less the aggregate number of such Initial LP Units that, after the IPO Date, have been transferred to Summit Materials, Inc. in accordance with the exchange agreement, are forfeited in accordance with agreements governing unvested Initial LP Units or are held by a holder other than Summit Owner Holdco together with shares of Class B common stock. See “Description of Capital Stock—Common Stock—Class B Common Stock.” |

16

Table of Contents

| Holders of shares of our Class B common stock vote together with holders of our Class A common stock as a single class on all matters on which stockholders are entitled to vote generally, except as otherwise required by law. |

| Use of proceeds |

We estimate that the net proceeds to Summit Materials, Inc. from this offering, after deducting estimated underwriting discounts, will be approximately $ million (or $ million if the underwriters exercise in full their option to purchase additional shares of Class A common stock). Summit Holdings will bear or reimburse Summit Materials, Inc. for all of the expenses payable by it in this offering, which we estimate will be approximately $ million. |

| We intend to use all of the net proceeds from this offering (including from any exercise by the underwriters of their option to purchase additional shares of Class A common stock) to purchase newly-issued LP Units from Summit Holdings and LP Units from certain of our pre-IPO owners, at a purchase price per LP Unit equal to the public offering price per share of Class A common stock, less underwriting discounts and commissions, with such LP Units in the aggregate equivalent to the number of shares of Class A common stock that we offer and sell in this offering. Summit Holdings will not receive any of the proceeds that we use to purchase LP Units from certain of our pre-IPO owners. See “Principal Stockholders” for information regarding the net proceeds of this offering that will be paid to affiliates of Blackstone and to certain of our directors and executive officers. |

| We intend to cause Summit Holdings to use a portion of the net proceeds from the offering to pay all or a portion of the deferred purchase price of $80.0 million for the Davenport Acquisition, with any remaining net proceeds to be used for general corporate purposes, which may include the repayment of existing indebtedness. See “Use of Proceeds.” |

| Dividend policy |

We have no current plans to pay cash dividends on our Class A common stock. The declaration, amount and payment of any future dividends on shares of Class A common stock will be at the sole discretion of our board of directors and we may reduce or discontinue entirely the payment of any such dividends at any time. |

| Summit Materials, Inc. is a holding company and has no material assets other than its ownership of Summit Holdings. Should we decide to pay a cash dividend on our Class A common stock in the future, we anticipate funding this cash dividend by causing Summit Holdings to make distributions to Summit Materials, Inc. in an amount sufficient to cover such cash dividend declared by us. If Summit Holdings makes such distributions to Summit Materials, Inc., the other holders of LP Units will be entitled to receive equivalent distributions. |

17

Table of Contents