Attached files

| file | filename |

|---|---|

| EX-21 - EX-21 - WORTHINGTON INDUSTRIES INC | d943911dex21.htm |

| EX-24 - EX-24 - WORTHINGTON INDUSTRIES INC | d943911dex24.htm |

| EX-4.9 - EX-4.9 - WORTHINGTON INDUSTRIES INC | d943911dex49.htm |

| EX-31.1 - EX-31.1 - WORTHINGTON INDUSTRIES INC | d943911dex311.htm |

| EX-31.2 - EX-31.2 - WORTHINGTON INDUSTRIES INC | d943911dex312.htm |

| EX-99.1 - EX-99.1 - WORTHINGTON INDUSTRIES INC | d943911dex991.htm |

| EX-23.1 - EX-23.1 - WORTHINGTON INDUSTRIES INC | d943911dex231.htm |

| EX-32.1 - EX-32.1 - WORTHINGTON INDUSTRIES INC | d943911dex321.htm |

| EX-23.2 - EX-23.2 - WORTHINGTON INDUSTRIES INC | d943911dex232.htm |

| EX-32.2 - EX-32.2 - WORTHINGTON INDUSTRIES INC | d943911dex322.htm |

| EX-4.10 - EX-4.10 - WORTHINGTON INDUSTRIES INC | d943911dex410.htm |

| EX-10.74 - EX-10.74 - WORTHINGTON INDUSTRIES INC | d943911dex1074.htm |

| EX-10.58 - EX-10.58 - WORTHINGTON INDUSTRIES INC | d943911dex1058.htm |

| EX-10.69 - EX-10.69 - WORTHINGTON INDUSTRIES INC | d943911dex1069.htm |

| EX-10.57 - EX-10.57 - WORTHINGTON INDUSTRIES INC | d943911dex1057.htm |

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

(Mark One)

| þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended May 31, 2015

or

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 1-8399

WORTHINGTON INDUSTRIES, INC.

(Exact Name of Registrant as Specified in its Charter)

| Ohio |

31-1189815 | |

| (State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification No.) | |

| 200 Old Wilson Bridge Road, Columbus, Ohio |

43085 | |

| (Address of Principal Executive Offices) | (Zip Code) | |

| Registrant’s telephone number, including area code: |

(614) 438-3210 | |

Securities registered pursuant to Section 12(b) of the Act:

| Title of Each Class |

Name of Each Exchange on Which Registered | |

| Common Shares, Without Par Value |

New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the Registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities

| Act. |

Yes þ No ¨ |

| Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. |

Yes ¨ No þ |

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes þ No ¨

Indicate by check mark whether the Registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the Registrant was required to submit and post such files). Yes þ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer þ Accelerated filer ¨ Non-accelerated filer ¨ Smaller reporting company ¨

(Do not check if a smaller reporting company)

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No þ

The aggregate market value of the Common Shares (the only common equity of the Registrant) held by non-affiliates computed by reference to the closing price on the New York Stock Exchange on November 28, 2014, the last business day of the Registrant’s most recently completed second fiscal quarter, was approximately $1,784,231,417. For this purpose, executive officers and directors of the Registrant are considered affiliates.

Indicate the number of shares outstanding of each of the Registrant’s classes of common stock, as of the latest practicable date. On July 24, 2015, the number of Common Shares issued and outstanding was 65,408,865.

DOCUMENT INCORPORATED BY REFERENCE:

Selected portions of the Registrant’s definitive Proxy Statement to be furnished to shareholders of the Registrant in connection with the Annual Meeting of Shareholders to be held on September 24, 2015, are incorporated by reference into Part III of this Annual Report on Form 10-K to the extent provided herein.

Table of Contents

| ii | ||||||

| PART I |

||||||

| Item 1. |

1 | |||||

| Item 1A. |

11 | |||||

| Item 1B. |

22 | |||||

| Item 2. |

22 | |||||

| Item 3. |

24 | |||||

| Item 4. |

24 | |||||

| Supplemental Item. |

24 | |||||

| PART II |

||||||

| Item 5. |

27 | |||||

| Item 6. |

30 | |||||

| Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

32 | ||||

| Item 7A. |

56 | |||||

| Item 8. |

59 | |||||

| Item 9. |

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure |

117 | ||||

| Item 9A. |

117 | |||||

| Item 9B. |

120 | |||||

| PART III |

||||||

| Item 10. |

121 | |||||

| Item 11. |

122 | |||||

| Item 12. |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

122 | ||||

| Item 13. |

Certain Relationships and Related Transactions, and Director Independence |

123 | ||||

| Item 14. |

123 | |||||

| PART IV |

||||||

| Item 15. |

124 | |||||

| 125 | ||||||

| E-1 | ||||||

i

Table of Contents

Selected statements contained in this Annual Report on Form 10-K, including, without limitation, in “PART I –Item 1. – Business” and “PART II – Item 7. – Management’s Discussion and Analysis of Financial Condition and Results of Operations,” constitute “forward-looking statements” as that term is used in the Private Securities Litigation Reform Act of 1995 (the “Act”). Forward-looking statements reflect our current expectations, estimates or projections concerning future results or events. These statements are often identified by the use of forward-looking words or phrases such as “believe,” “expect,” “anticipate,” “may,” “could,” “intend,” “estimate,” “plan,” “foresee,” “likely,” “will,” “should” or other similar words or phrases. These forward-looking statements include, without limitation, statements relating to:

| • | outlook, strategy or business plans; |

| • | the ability to correct performance issues at operations; |

| • | future or expected growth, forward momentum, performance, sales, volumes, cash flows, earnings, balance sheet strengths, debt, financial condition or other financial measures; |

| • | projected profitability potential, capacity, and working capital needs; |

| • | demand trends for us or our markets; |

| • | additions to product lines and opportunities to participate in new markets; |

| • | pricing trends for raw materials and finished goods and the impact of pricing changes; |

| • | anticipated capital expenditures and asset sales; |

| • | anticipated improvements and efficiencies in costs, operations, sales, inventory management, sourcing and the supply chain and the results thereof; |

| • | the ability to make acquisitions and the projected timing, results, benefits, costs, charges and expenditures related to acquisitions, newly-created joint ventures, headcount reductions and facility dispositions, shutdowns and consolidations; |

| • | the alignment of operations with demand; |

| • | the ability to operate profitably and generate cash in down markets; |

| • | the ability to maintain margins and capture and maintain market share and to develop or take advantage of future opportunities, customer initiatives, new businesses, new products and new markets; |

| • | expectations for our and our customers’ inventories, jobs and orders; |

| • | expectations for the economy and markets or improvements therein; |

| • | expected benefits from transformation plans, cost reduction efforts and other new initiatives; |

| • | expectations for increasing volatility or improving and sustaining earnings, earnings potential, margins or shareholder value; |

| • | effects of judicial rulings; and |

| • | other non-historical matters. |

Because they are based on beliefs, estimates and assumptions, forward-looking statements are inherently subject to risks and uncertainties that could cause actual results to differ materially from those projected. Any number of factors could affect actual results, including, without limitation, those that follow:

| • | the effect of national, regional and worldwide economic conditions generally and within major product markets, including a recurrent slowing economy; |

| • | the effect of conditions in national and worldwide financial markets; |

| • | product demand and pricing; |

| • | changes in product mix, product substitution and market acceptance of our products; |

| • | fluctuations in the pricing, quality or availability of raw materials (particularly steel), supplies, transportation, utilities and other items required by operations; |

| • | effects of facility closures and the consolidation of operations; |

| • | the effect of financial difficulties, consolidation and other changes within the steel, automotive, oil and gas, construction and other industries in which we participate; |

| • | failure to maintain appropriate levels of inventories; |

ii

Table of Contents

| • | financial difficulties (including bankruptcy filings) of original equipment manufacturers, end-users and customers, suppliers, joint venture partners and others with whom we do business; |

| • | the ability to realize targeted expense reductions from headcount reductions, facility closures and other cost reduction efforts; |

| • | the ability to realize other cost savings and operational, sales and sourcing improvements and efficiencies, and other expected benefits from transformation initiatives, on a timely basis; |

| • | the overall success of, and the ability to integrate, newly-acquired businesses and joint ventures, maintain and develop their customers, and achieve synergies and other expected benefits and cost savings therefrom; |

| • | capacity levels and efficiencies, within facilities, within major product markets and within the industry as a whole; |

| • | the effect of disruption in the business of suppliers, customers, facilities and shipping operations due to adverse weather, casualty events, equipment breakdowns, acts of war or terrorist activities or other causes; |

| • | changes in customer demand, inventories, spending patterns, product choices, and supplier choices; |

| • | risks associated with doing business internationally, including economic, political and social instability, foreign currency exposure and the acceptance of our products in markets; |

| • | the ability to improve and maintain processes and business practices to keep pace with the economic, competitive and technological environment; |

| • | the outcome of adverse claims experience with respect to workers’ compensation, product recalls or product liability, casualty events or other matters; |

| • | deviation of actual results from estimates and/or assumptions used by us in the application of our significant accounting policies; |

| • | level of imports and import prices in our markets; |

| • | the impact of judicial and governmental agency rulings as well as the impact of governmental regulations, both in the United States and abroad, including those adopted by the United States Securities and Exchange Commission and other governmental agencies as contemplated by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010; |

| • | the effect of changes to healthcare laws in the United States, which may increase our healthcare and other costs and negatively impact our financial results and operations; and |

| • | other risks described from time to time in the filings of Worthington Industries, Inc. with the United States Securities and Exchange Commission, including those described in “PART I – Item 1A. – Risk Factors” of this Annual Report on Form 10-K. |

We note these factors for investors as contemplated by the Act. It is impossible to predict or identify all potential risk factors. Consequently, you should not consider the foregoing list to be a complete set of all potential risks and uncertainties. Any forward-looking statements in this Annual Report on Form 10-K are based on current information as of the date of this Annual Report on Form 10-K, and we assume no obligation to correct or update any such statements in the future, except as required by applicable law.

iii

Table of Contents

PART I

General Overview

Worthington Industries, Inc. is a corporation formed under the laws of the State of Ohio (individually, the “Registrant” or “Worthington Industries” or, collectively with the subsidiaries of Worthington Industries, Inc., “we,” “our,” “Worthington” or the “Company”). Founded in 1955, Worthington is primarily a diversified metals manufacturing company, focused on value-added steel processing and manufactured metal products. Our manufactured metal products include: pressure cylinders for liquefied petroleum gas (“LPG”), compressed natural gas (“CNG”), oxygen, refrigerant and other industrial gas storage; hand torches and filled hand torch cylinders; propane-filled camping cylinders; helium-filled balloon kits; steel and fiberglass tanks and processing equipment primarily for the oil and gas industry; cryogenic pressure vessels for liquefied natural gas (“LNG”) and other gas storage applications; engineered cabs and operator stations and cab components; steel pallets and racks; and, through joint ventures, suspension grid systems for concealed and lay-in panel ceilings; laser welded blanks; light gauge steel framing for commercial and residential construction; and current and past model automotive service stampings.

Worthington is headquartered at 200 Old Wilson Bridge Road, Columbus, Ohio 43085, telephone (614) 438-3210. The common shares of Worthington Industries are traded on the New York Stock Exchange under the symbol WOR.

Worthington Industries maintains an Internet web site at www.worthingtonindustries.com. This uniform resource locator, or URL, is an inactive textual reference only and is not intended to incorporate Worthington Industries’ web site into this Annual Report on Form 10-K. Worthington Industries’ Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and amendments to those reports, filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), as well as Worthington Industries’ definitive annual meeting proxy materials filed pursuant to Section 14 of the Exchange Act, are available free of charge, on or through the Worthington Industries web site, as soon as reasonably practicable after such material is electronically filed with, or furnished to, the Securities and Exchange Commission (the “SEC”).

Segments

As of May 31, 2015, we, together with our unconsolidated affiliates, operated 83 manufacturing facilities in 26 states and 11 countries. A total of 33 of these facilities are operated by wholly-owned and consolidated subsidiaries of the Company. The remaining facilities are operated by our consolidated and unconsolidated joint ventures.

Our operations are managed principally on a products and services basis and are comprised of three primary operating segments which correspond with our reportable business segments: Steel Processing, Pressure Cylinders and Engineered Cabs. The Steel Processing operating segment consists of the Worthington Steel business unit (“Worthington Steel”) which operates 12 main facilities; Precision Specialty Metals, Inc. (“PSM”), a specialty stainless processor located in Los Angeles, California; and Worthington Steelpac Systems, LLC (“SteelPac”), which designs and manufactures recyclable steel packaging solutions for the movement of products; and also includes two consolidated joint ventures: Spartan Steel Coating, LLC (“Spartan”), which operates a cold-rolled hot dipped galvanizing line in Monroe, Michigan; and TWB Company, L.L.C. (“TWB”), which operates a laser welded blank business headquartered in Monroe, Michigan. The Pressure Cylinders operating segment consists of the Worthington Cylinders business unit (“Worthington Cylinders”) which operates 17 main facilities, and also includes three consolidated joint ventures: India-based Worthington Nitin Cylinders Limited (“Worthington Nitin Cylinders”), a manufacturer of high-pressure, seamless steel cylinders; Turkey-based Worthington Aritaş Basinçli Kaplar Sanayi (“Worthington Aritas,”), a manufacturer of cryogenic

1

Table of Contents

pressure vessels for LNG and other gas storage applications; and Utah-based dHybrid Systems, LLC (“dHybrid”), a manufacturer of CNG fuel systems for large trucks. The Engineered Cabs operating segment consists of the Worthington Industries Engineered Cabs business unit (“Engineered Cabs”), formerly Angus Industries, Inc. Engineered Cabs operates 3 main facilities.

Our remaining operating segments include Construction Services and Worthington Energy Innovations (“WEI”), which are disclosed in the Other category for segment reporting purposes, as they do not meet the quantitative thresholds for separate disclosure. Certain income and expense items not allocated to our operating segments are also included in the Other category as is the activity related to the wind down of Construction Services.

We hold equity positions in 13 active joint ventures, which are further discussed in the Joint Ventures section below. Of these, six are consolidated with their operating results reported within our reportable business segments as follows: Spartan and TWB in Steel Processing; dHybrid, Worthington Aritas and Worthington Nitin Cylinders in Pressure Cylinders; and WEI in Other.

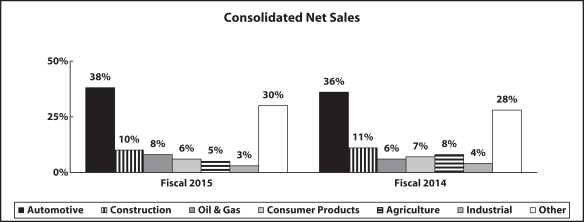

During the fiscal year ended May 31, 2015 (“fiscal 2015”), the Steel Processing, Pressure Cylinders and Engineered Cabs operating segments served approximately 1,000, 4,500, and 100 customers, respectively, located primarily in the United States. Foreign operations accounted for approximately 6% of consolidated net sales during fiscal 2015 and were comprised primarily of sales to customers in Europe. No single customer accounted for over 10% of consolidated net sales in fiscal 2015.

Refer to “Item 8. – Financial Statements and Supplementary Data – Notes to Consolidated Financial Statements – Note N – Segment Data” of this Annual Report on Form 10-K for a full description of our reportable business segments.

Recent Developments

On July 31, 2014, the Company acquired the assets of James Russell Engineering Works, Inc. (“JRE”) for cash consideration of $1.6 million. The JRE business manufactures aluminum and stainless steel cryogenic transport trailers used for hauling liquid oxygen, nitrogen, argon, hydrogen and LNG for producers and distributors of industrial gases and LNG. The acquired assets became part of our Pressure Cylinder operating segment upon closing.

On August 1, 2014, the Company acquired the assets of Midstream Equipment Fabrication LLC (“MEF”) for cash consideration of $38.4 million and the assumption of certain liabilities. The MEF business manufactures patented horizontal heated and high pressure separators used to separate oilfield fluids and gas. The acquired assets became part of our Pressure Cylinder operating segment upon closing.

On October 20, 2014, we acquired a 79.59% ownership interest in dHybrid, a manufacturer of CNG systems for large trucks, for total consideration of $15.9 million, including contingent consideration with an estimated fair value of $4.0 million, and the assumption of certain liabilities. The remaining 20.41% was retained by a founding member. The acquired business became part of our Pressure Cylinders operating segment upon closing.

On November 13, 2014, the Company’s consolidated laser welded blank joint venture, TWB, opened a new facility in Cambridge, Ontario. The facility will initially operate one laser welding line with the capacity to produce two million tailor welded blanks per year.

On January 16, 2015, the Company acquired the assets of Rome Strip Steel Company, Inc. (“Rome Strip Steel”) for cash consideration of $54.5 million after an adjustment for estimated working capital. Located in Rome, New York, the Rome Strip Steel business manufactures cold rolled steel to extremely tight tolerances. The acquired assets became part of our Steel Processing operating segment upon closing.

2

Table of Contents

On January 30, 2015, the Company sold the Advanced Component Technologies, Inc. (“ACT”) business within Engineered Cabs located in Northwood, Iowa.

On March 6, 2015, WAVE, Worthington’s joint venture with Armstrong World Industries, Inc., acquired the Axiom® and Serpentina® ceiling system manufacturing capabilities from Fry Reglet Corporation.

On March 24, 2015, the Company announced its decision to close its Engineered Cabs facility in Florence, South Carolina, and a workforce reduction in several oil and gas equipment locations due to slowing demand. These decisions led to non-cash impairment charges of $81.6 million for goodwill and other long-lived assets in Engineered Cabs and a restructuring charge of $2.2 million for the estimated severance expense covering those affected by the workforce reductions within Pressure Cylinders.

On April 23, 2015, the Company amended its five-year, revolving credit facility, increasing commitments under the facility by $75.0 million, to a total of $500.0 million, and extending the maturity by three years to April 2020.

On May 1, 2015, the Company sold the operating assets and real property related to its Pressure Cylinders facility in New Albany, Mississippi, which manufactures impact extruded steel and aluminum components and high pressure aluminum cylinders. These assets were sold to companies affiliated with Thunderbird LLC, for an aggregate sale price of approximately $8.4 million.

On June 26, 2015, the Company announced the closure of its stainless steel business, PSM. The Company is in the process of winding down operations and expects to complete the exit of the facility by December 2015. The Company estimates that the closure will result in restructuring charges in the range of $1.0 million to $1.5 million, primarily due to severance costs.

Steel Processing

Our Steel Processing operating segment consists of the Worthington Steel business unit, which includes PSM and SteelPac and our consolidated joint ventures, Spartan and TWB. For fiscal 2015, fiscal 2014, and fiscal 2013, the percentage of consolidated net sales generated by Steel Processing was approximately 63%, 62%, and 61%, respectively.

Worthington Steel is one of the largest independent intermediate processors of flat-rolled steel in the United States. It occupies a niche in the steel industry by focusing on products requiring exact specifications. These products cannot typically be supplied as efficiently by steel mills to the end-users of these products.

The Steel Processing operating segment, including Spartan and TWB, operates 21 manufacturing facilities located in Ohio (6), Mexico (4), Alabama (2), Indiana (2), Michigan (2), and one each in California, New York, Pennsylvania, Tennessee and Canada.

Our Steel Processing operating segment serves approximately 1,000 customers, principally in the agricultural, appliance, automotive, construction, hardware, HVAC, lawn and garden, leisure and recreation, office furniture, office equipment, container, and aerospace markets. Automotive-related customers have historically represented approximately half of Steel Processing’s net sales. No single customer represented greater than 10% of Steel Processing’s net sales during fiscal 2015.

Our Steel Processing operating segment buys coils of steel from integrated steel mills and mini-mills and processes them to the precise type, thickness, length, width, shape and surface quality required by customer specifications. Computer-aided processing capabilities include, among others:

| • | cold reducing, which achieves close tolerances of thickness; |

| • | configured blanking, which stamps steel into specific shapes; |

3

Table of Contents

| • | cutting-to-length, which cuts flattened steel sheets to exact lengths; |

| • | dry-lubing, the process of coating steel with a dry, soap-based lubricant; |

| • | edging, which conditions the edges of the steel by imparting round, smooth or knurled edges; |

| • | hot-dipped galvanizing, which coats steel with zinc and zinc alloys through a hot-dip process; |

| • | hydrogen annealing, a thermal process that changes the hardness and certain metallurgical characteristics of steel; |

| • | laser welding, which joins metal blanks and coils with different thicknesses, coatings or material strength; |

| • | pickling, a chemical process using an acidic solution to remove surface oxide which develops on hot-rolled steel; |

| • | primacoat, which is a high-lubricity, acrylic-based coating; |

| • | slitting, which cuts steel coils or steel sheets to specific widths; |

| • | oscillate slitting, a slitting process that spools together several narrow coils welded end to end into one larger coil; |

| • | temper rolling, which is the process of light cold-rolling sheet steel; |

| • | tension leveling, a method of applying pressure to achieve precise flatness tolerances; and |

| • | non-metallic coating, including acrylic and paint coating. |

Our Steel Processing operating segment also toll processes steel for steel mills, large end-users, service centers and other processors. Toll processing is different from typical steel processing in that the mill, end-user or other party retains title to the steel and has the responsibility for selling the end product. Toll processing enhances Worthington Steel’s participation in the market for wide sheet steel and large standard orders, which is a market generally served by steel mills rather than by intermediate steel processors.

The steel processing industry is fragmented and highly competitive. There are many competitors, including other independent intermediate processors. Competition is primarily on the basis of price, product quality and the ability to meet delivery requirements. Technical service and support for material testing and customer-specific applications enhance the quality of products (see “Business – Technical Services”). However, the extent to which technical service capability has improved Worthington Steel’s competitive position has not been quantified. Worthington Steel’s ability to meet tight delivery schedules is, in part, based on the proximity of our facilities to customers, suppliers and one another. The extent to which plant location has impacted Worthington Steel’s competitive position has not been quantified. Processed steel products are priced competitively, primarily based on market factors, including, among other things, market pricing, the cost and availability of raw materials, transportation and shipping costs, and overall economic conditions in the United States and abroad.

On July 31, 2013, we purchased an additional 10% interest in TWB, increasing our ownership to a 55% controlling interest. As a result, TWB’s results have been consolidated within Steel Processing since the acquisition date. TWB operates three facilities in the United States, with one facility in each of Alabama, Michigan and Tennessee, and four facilities in Mexico.

During the first quarter of fiscal 2014, we made certain organizational changes impacting the internal reporting and management structure of SteelPac. As a result of these organizational changes, management responsibilities and internal reporting were realigned under Steel Processing. SteelPac designs and manufactures reusable custom steel platforms, racks and pallets for supporting, protecting and handling products throughout the shipping process for customers in industries such as automotive, lawn and garden and recreational vehicles. SteelPac operates three facilities, with one facility in each of Indiana, Ohio and Pennsylvania.

4

Table of Contents

Pressure Cylinders

The Pressure Cylinders operating segment consists of the Worthington Cylinders business unit and three consolidated joint ventures: India-based Worthington Nitin Cylinders, a manufacturer of high-pressure, seamless steel cylinders for CNG and other industrial gas storage applications; Worthington Aritas, one of Europe’s leading cryogenic technology companies for LNG and other gas storage applications; and dHybrid, which manufactures CNG fuel systems for large trucks out of a facility in Salt Lake City, Utah. The percentage of consolidated net sales generated by Pressure Cylinders was approximately 30% in each of fiscal 2015, fiscal 2014 and fiscal 2013.

Our Pressure Cylinders operating segment manufactures and sells filled and unfilled pressure cylinders, tanks, hand torches, and oil and gas equipment along with various accessories and related products for diversified end-use market applications. The following is a description of these markets:

| • | Industrial Products: This market sector includes high pressure and acetylene cylinders for industrial gases, refrigerant and certain propane gas cylinders, hand torch cylinders and joining products such as solder and brazing rods and other specialty products. Cylinders in these markets are generally sold to gas producers, cylinder exchangers and industrial distributors. Industrial cylinders hold fuel for uses such as cutting, brazing and soldering, semiconductor production, and beverage delivery. Refrigerant gas cylinders are used to hold refrigerant gases for commercial, residential and automotive air conditioning and refrigeration systems. LPG cylinders hold fuel for barbeque grills, recreational vehicle equipment, residential and light commercial heating systems, industrial forklifts and commercial/residential cooking (the latter, generally outside North America). Specialty products include a variety of fire suppression and chemical tanks. |

| • | Consumer Products: This market sector includes propane-filled cylinders for torches, camping stoves and other applications, hand held torches and accessories, and Balloon Time® helium-filled balloon kits. These products are sold primarily to mass merchandisers and distributors. |

| • | Alternative Fuels: This market sector includes composite and steel cylinders for containment of CNG and hydrogen for automobiles, buses, and light-duty trucks, propane/autogas cylinders for automobiles and light- and medium-duty trucks, as well as CNG fuel systems for buses, refuse and heavy-duty trucks. |

| • | Oil and Gas Equipment: This market sector includes steel and fiberglass storage tanks, separation equipment, controls and other products primarily used in the energy markets, including oil and gas and nuclear. This sector also includes hoists and other marine products which are used principally in shipyard lift systems. This sector also leverages its manufacturing competencies to produce pressure vessels, atmospheric tanks, controls and various custom machined components for other industrial and agricultural end markets. This market sector was formed in fiscal 2013 as a result of the acquisition of Westerman, Inc. on September 17, 2012, and also include the assets acquired from Palmer Mfg. & Tank, Inc, Steffes Corporation and MEF. |

| • | Cryogenics: This market sector includes cryogenic equipment systems, and service for the transportation, storage and use of liquefied gases such as LNG and industrial gases such as liquid nitrogen, oxygen, argon, and hydrogen. Key end markets include LNG storage and transportation, LNG onboard fueling for marine applications, and storage and transportation of industrial gases for manufacturing and healthcare. Pressure Cylinders entered this sector through new product development of industrial gas cryogenic cylinders, its joint venture with Aritas in Istanbul, Turkey which focuses on highly engineered tanks and systems, and the acquisition of cryogenic trailer manufacturer, JRE, based in Boston. |

While a large percentage of Pressure Cylinders sales are made to major accounts, this operating segment serves approximately 4,500 customers. No single customer represented greater than 10% of net sales for the Pressure Cylinders operating segment during fiscal 2015.

5

Table of Contents

The Pressure Cylinders operating segment, including the Worthington Nitin Cylinders, Worthington Aritas and dHybrid consolidated joint ventures, operates 20 manufacturing facilities located in California, Kansas (2), Massachusetts, North Carolina, North Dakota, Ohio (5), Oklahoma, Utah, Wisconsin, Austria, India, Poland (2), Portugal and Turkey.

For sales in the United States and Canada, high-pressure and low-pressure cylinders, are primarily manufactured in accordance with United States Department of Transportation and Transport Canada specifications. Outside the United States and Canada, cylinders are manufactured according to European norm specifications, as well as various other international standards. Other products are produced to applicable industry standards including, as applicable, those standards issued by the American Petroleum Institute, ASME and UL.

Worthington Cylinders has one principal domestic competitor in the low-pressure non-refillable refrigerant market and one principal domestic competitor in the low-pressure LPG cylinder market. There are also several foreign competitors in these markets. We believe that Worthington Cylinders has the largest market share in its domestic low-pressure cylinder markets. In the other cylinder markets, there are several competitors. We believe that Worthington Cylinders is a leading supplier to the European markets for LNG vessels and for both the high-pressure cylinders and the low-pressure non-refillable cylinders. Worthington Cylinders generally has a strong competitive position for its industrial, energy, retail and specialty products, but competition varies on a product-by-product basis, and geographically for energy products. As with our other operating segments, competition is based upon price, service and quality.

The Pressure Cylinders operating segment uses the trade name “Worthington Cylinders” to conduct business and the registered trademark “Balloon Time®” to market helium-filled balloon kits; the registered trademark “Bernzomatic®” to market certain fuel cylinders and hand held torches; the trademark “WORTHINGTON PRO-GRADE” to market certain LPG cylinders, hand torches and camping fuel cylinders; and the registered trademarks “MAP-PRO®” and “Pro-Max®” to market certain hand torch cylinders. During the second quarter of fiscal 2014, the Company committed to a re-branding initiative to brand substantially all of our businesses under the Worthington Industries name. In connection with the branding strategy, the Company discontinued the use of non-Worthington trade names except for retail brand names such as those referenced above and those related to our joint ventures.

In connection with the acquisition of the propane fuel cylinders business of The Coleman Company, Inc. (“Coleman Cylinders”) in fiscal 2012, we executed a trademark license agreement whereby we are required to make minimum annual royalty payments of approximately $2.0 million in exchange for the exclusive right to use certain Coleman trademarks within the United States and Canada in connection with our operation of the acquired business.

Engineered Cabs

The Engineered Cabs operating segment consists of the Worthington Industries Engineered Cabs business unit, formerly Angus Industries, Inc., which was acquired on December 29, 2011. For fiscal 2015, fiscal 2014, and fiscal 2013, the percentage of consolidated net sales generated by Engineered Cabs was approximately 6%, 7%, and 9%, respectively.

Engineered Cabs is headquartered in Columbus, Ohio and operates three primary manufacturing facilities, one in each South Carolina, South Dakota and Tennessee, which are located near key assembly locations of original equipment manufacturers. The Company is in the process of closing its facility in Florence, South Carolina. The majority of the business will be moved to the facility in Greeneville, Tennessee.

Engineered Cabs is a non-captive designer and manufacturer of high-quality, custom-engineered open and enclosed cabs and operator stations and custom fabrications for heavy mobile equipment used primarily

6

Table of Contents

in the agricultural, construction, forestry, mining, military, and various other industries. Engineered Cabs’ product design, engineering support and broad manufacturing capabilities enable it to produce cabs and structures used in products ranging from small utility equipment to the large earthmovers.

In addition to its engineered cab products, this operating segment has the capability to provide a full suite of complementary products such as machined structural components, complex and painted weldments, engine doors, boom components and complete frames. Engineered Cabs has the manufacturing capability for:

| • | Steel laser cutting; |

| • | Steel bending and forming; |

| • | Roll-form tube curving and bending; |

| • | Machining; |

| • | Welding – robotic and manual; |

| • | Automated steel product cleaning and E-coating; |

| • | Top coat painting; and |

| • | Assembly. |

Engineered Cabs produces products for over 150 different equipment platforms for approximately 100 customers. For fiscal 2015, Engineered Cabs’ top three customers represented approximately 78% of the operating segment’s total net sales. Its production levels can run from small and medium production volumes through high volume productions.

Engineered Cabs competes primarily with a handful of primary non-captive producers of engineered cabs in the United States, although there are numerous other suppliers who can perform some of the functions supplied by the Company. Some customers can also produce operator cabs in-house. The Company believes its competitive strengths include its design and engineering capabilities and its broad manufacturing capabilities, which allow it to provide a fully-integrated complete cab, and its ability to provide cabs at a more effective cost than customers can produce in-house. Competition is based on price, quality, delivery and service.

Key supplies for this operating segment include steel sheet and plate, stampings, steel tubing, hardware, controls, wiper systems, glazing materials (glass, polycarbonate), perishables (paint, urethane, caulk), electrical materials, HVAC systems and aesthetic materials (acoustical trim, plastics, foam), which are available from a variety of sources.

Other

The Other category includes the Construction Services and WEI operating segments, which do not meet the quantitative thresholds for separate disclosure, as well as other corporate-related entities.

Construction Services. The Company is in the process of winding down its Military Construction business unit, whose operations involve the supply and construction of single family housing, with a focus on military housing.

Worthington Energy Innovations. This operating segment is comprised of our 75%-owned and consolidated joint venture, WEI, which is described in more detail in the Joint Ventures section below.

7

Table of Contents

Segment Financial Data

Financial information for the reportable business segments is provided in “Item 8. – Financial Statements and Supplementary Data – Notes to Consolidated Financial Statements – Note N – Segment Data”.

Financial Information About Geographic Areas

For fiscal 2015, our foreign operations represented 6% of consolidated net sales, (2)% of pre-tax earnings attributable to controlling interest and 14% of consolidated net assets. During fiscal 2015, fiscal 2014 and fiscal 2013, we had consolidated operations in Austria, Canada (through February 2014), the Czech Republic (through October 2012), India, Mexico (beginning July 2013), Poland, Portugal, Turkey (beginning January 2014) and the United States. During these same three fiscal years, our unconsolidated joint ventures had operations in China, France, Mexico, Spain (through December 2013), the United Kingdom and the United States. Summary information about our foreign operations, including net sales and fixed assets by geographic region, is provided in “Item 8. – Financial Statements and Supplementary Data – Notes to Consolidated Financial Statements – Note A – Summary of Significant Accounting Policies – Risks and Uncertainties” and “Note N – Segment Data” of this Annual Report on Form 10-K.

Suppliers

The primary raw material purchased by Worthington is steel. We purchase steel in large quantities at regular intervals from major primary producers of steel, both domestic and foreign. The amount purchased from any particular supplier varies from year to year depending on a number of factors including market conditions, then current relationships and prices and terms offered. In nearly all market conditions, steel is available from a number of suppliers and generally any supplier relationship or contract can and has been replaced with little or no significant interruption to our business. During fiscal 2015, we purchased approximately 2.2 million tons of steel (83% hot-rolled, 13% cold-rolled and 4% galvanized) on a consolidated basis. In the Steel Processing operating segment, steel is primarily purchased and processed based on specific customer orders. The Pressure Cylinders and Engineering Cabs operating segments purchase steel to meet production schedules. For certain raw materials, there are more limited suppliers – for example, helium and zinc, which are generally purchased at market prices. Since there are a limited number of suppliers in the helium and zinc markets, if delivery from a major supplier is disrupted due to a force majeure type occurrence, it may be difficult to obtain an alternative supply. Raw materials are generally purchased in the open market on a negotiated spot-market basis at prevailing market prices. Supply contracts are also entered into, some of which have fixed pricing and some of which are indexed (monthly or quarterly). During fiscal 2015, we purchased steel from the following major suppliers, in alphabetical order: AK Steel Corporation; ArcelorMittal; Essar Steel Algoma Inc.; NLMK USA; North Star BlueScope Steel, LLC; Nucor Corporation; Steel Dynamics, Inc.; and United States Steel Corporation (“U.S. Steel”). Major suppliers of aluminum to the Pressure Cylinders operating segment in fiscal 2015 were, in alphabetical order: Alcoa; DK Tech Co; Rio Tinto Alcan; and Sapa Group. Major suppliers of zinc to the Steel Processing operating segment were, in alphabetical order: Considar Metal Marketing Inc. (a/k/a HudBay); Glencore Ltd; Teck Cominco Limited; and U.S. Zinc. Approximately 34 million pounds of zinc were purchased in fiscal 2015. We believe our supplier relationships are good.

Technical Services

We employ a staff of engineers and other technical personnel and maintain fully equipped laboratories to support operations. These facilities enable verification, analysis and documentation of the physical, chemical, metallurgical and mechanical properties of raw materials and products. Technical service personnel also work in conjunction with the sales force to determine the types of flat-rolled steel required for customer needs. Engineers at Engineered Cabs design cabs and cab manufacturing processes. To provide these services, we maintain a continuing program of developmental engineering with respect to product characteristics and performance under varying conditions. Laboratory facilities also perform metallurgical and

8

Table of Contents

chemical testing as dictated by the regulations of the United States Department of Transportation, Transport Canada, and other associated agencies, along with International Organization for Standardization (ISO) and customer requirements. An IASI (International Accreditations Service, Incorporated) accredited product testing laboratory supports these efforts.

Seasonality and Backlog

Sales are generally strongest in the fourth quarter of our fiscal year as our operating segments are generally operating at seasonal peaks. Historically, sales have generally been weaker in the third quarter of our fiscal year, primarily due to reduced activity in the building and construction industry as a result of inclement weather, as well as customer plant shutdowns in the automotive industry due to holidays. We do not believe backlog is a significant indicator of our business.

Employees

As of May 31, 2015, we had approximately 10,500 employees, including those employed by our unconsolidated joint ventures. Approximately 6% of these employees are represented by collective bargaining units. Worthington believes it has good relationships with its employees, including those covered by collective bargaining units.

Joint Ventures

As part of our strategy to selectively develop new products, markets and technological capabilities and to expand our international presence, while mitigating the risks and costs associated with those activities, we participate in six consolidated and seven unconsolidated joint ventures.

Consolidated

The results of the following six consolidated joint ventures have been consolidated with the financial results of the Company since the respective dates on which the Company acquired majority ownership. The equity owned by the minority members is shown as noncontrolling interests on our consolidated balance sheets and their portions of net earnings are included as net earnings attributable to noncontrolling interests in our consolidated statements of earnings.

| • | dHybrid is a 79.59%-owned consolidated joint venture with M&M Residual, LLC that manufactures CNG fuel systems for large trucks out of a facility in Salt Lake City, Utah. dHybrid’s financial results are consolidated within Pressure Cylinders. |

| • | Spartan is a 52%-owned consolidated joint venture with AK Steel Corporation (as successor to Severstal Dearborn LLC), located in Monroe, Michigan. It operates a cold-rolled, hot-dipped galvanizing line for toll processing steel coils into galvanized and galvannealed products intended primarily for the automotive industry. Spartan’s financial results are consolidated within Steel Processing. |

| • | TWB is a 55%-owned consolidated joint venture with a subsidiary of Wuhan Iron and Steel Company (“WISCO”). It is a leading North American supplier of laser welded blanks, laser welded coils and other laser welded products for use primarily in the automotive industry for products such as inner-door panels, body sides, rails and pillars. TWB operates facilities in Monroe, Michigan; Prattville, Alabama; and Smyrna, Tennessee as well as in Puebla, Ramos Arizpe (Saltillo), Hermosillo and Silao, Mexico; and Cambridge, Ontario, Canada. TWB’s financial results have been consolidated within Steel Processing since July 31, 2013, when we increased our ownership interest from 45% to 55%. For periods prior to the acquisition date, our portion of the equity in the net income of TWB was included within equity in the net income of unconsolidated affiliates. |

9

Table of Contents

| • | WEI is a 75%-owned consolidated joint venture with Tom E. Kiser (20%) and Stonehenge Structured Finance Partners, LLC (5%) (together referred to as “WEI Partners”), with offices in Fremont and Columbus, Ohio. WEI is an Energy Services Company that develops cost-effective energy solutions for entities in North America and Asia. Once these solutions are implemented, WEI monitors, verifies and guarantees these energy saving solutions. WEI’s financial results are reported within the Other category for segment reporting purposes. |

| • | Worthington Nitin Cylinders is a 60%-owned consolidated joint venture based in Visakhapatnam, India with Nitin Fire Protection Industries Limited (“Nitin Fire”). Worthington Nitin Cylinders manufactures high-pressure, seamless steel cylinders for CNG and other industrial gas storage applications. Worthington Nitin Cylinders’ financial results are consolidated within Pressure Cylinders. During the fourth quarter of fiscal 2014, management committed to plans to sell its interest in Worthington Nitin Cylinders and actions to locate a buyer are ongoing. However, the joint venture is no longer manufacturing cylinders and the investment has been entirely written off. |

| • | Worthington Aritas is a 75%-owned consolidated joint venture based in Turkey. Worthington Aritas is one of Europe’s leading cryogenic technology companies for LNG and other gas storage applications. Its financial results have been consolidated within Pressure Cylinders since January 24, 2014. |

Unconsolidated

| • | ArtiFlex Manufacturing, LLC (“ArtiFlex”), a 50%-owned joint venture with International Tooling Solutions, LLC, provides an integrated solution for engineering, tooling, stamping, assembly and other services to customers primarily in the automotive industry. ArtiFlex operates six manufacturing facilities: three in Michigan, two in Ohio and one in Kentucky. |

| • | ClarkDietrich, a 25%-owned joint venture with Clarkwestern Building Systems, Inc., is the industry leader in the manufacture and supply of light gauge steel framing products in the United States. ClarkDietrich manufactures a full line of drywall studs and accessories, structural studs and joists, metal lath and accessories, shaft wall studs and track, and vinyl products used primarily in residential and commercial construction. This joint venture operates 13 manufacturing facilities, one each in Connecticut, Georgia, Hawaii, Illinois, and Maryland and two each in California, Ohio, Florida and Texas. |

| • | Samuel Steel Pickling Company (“Samuel”), a 31.25%-owned joint venture with Samuel Manu-Tech Pickling, Inc. operates one steel pickling facility in Twinsburg, Ohio, and another in Cleveland, Ohio. Samuel also performs in-line slitting, side trimming, pickle dry, under winding and the application of dry lube coatings during the pickling process. |

| • | Serviacero Planos, S. de R.L. de C.V. (“Serviacero Worthington”), a 50%-owned joint venture with Inverzer, S.A. de C.V., operates three facilities in Mexico, one each in Leon, Queretaro and Monterrey. Serviacero Worthington provides steel processing services, such as pickling, slitting, multi-blanking and cutting-to-length, to customers in a variety of industries including automotive, appliance, electronics and heavy equipment. |

| • | Worthington Armstrong Venture (“WAVE”), a 50%-owned joint venture with Armstrong Ventures, Inc., a subsidiary of Armstrong World Industries, Inc., is one of the three largest global manufacturers of ceiling suspension systems for concealed and lay-in panel ceilings used in commercial and residential ceiling markets. It competes with the two other global manufacturers and numerous smaller manufacturers. WAVE operates ten facilities in five countries: Santa Fe Springs, California; Alpharetta, Georgia; Aberdeen, Maryland; Benton Harbor, Michigan; North Las Vegas, Nevada; Qingpu, Shanghai, China; Sittingbourne and Team Valley, United Kingdom; Prouvy, France; and Marval, Pune, India. |

| • | Worthington Specialty Processing (“WSP”), a 51%-owned joint venture with a subsidiary of U. S. Steel, operates three steel processing facilities located in Canton, Jackson and Taylor, Michigan, |

10

Table of Contents

| which are managed by Steel Processing. WSP serves primarily as a toll processor for U.S. Steel and others. Its services include slitting, blanking, cutting-to-length, laser welding, tension leveling and warehousing. WSP is considered to be jointly controlled and not consolidated due to substantive participating rights of the minority partner. |

| • | Zhejiang Nisshin Worthington Precision Specialty Steel Co., Ltd, a 10%-owned unconsolidated joint venture with Nisshin Steel Co., Ltd. and Marubeni-Itochu Steel Inc., is based in Pinghu City, Zhejiang, China. The joint venture is constructing a facility that will produce cold-rolled strip steel, primarily for the automotive industry. |

See “Item 8. – Financial Statements and Supplementary Data – Notes to Consolidated Financial Statements – Note B – Investments in Unconsolidated Affiliates” of this Annual Report on Form 10-K for additional information about our unconsolidated joint ventures.

Environmental Regulation

Our manufacturing facilities, generally in common with those of similar industries making similar products, are subject to many federal, state, local and foreign laws and regulations relating to the protection of the environment. We examine ways to reduce emissions and waste and to decrease costs related to environmental compliance. The cost of compliance or capital expenditures for environmental control facilities required to meet environmental requirements are not anticipated to be material when compared with overall costs and capital expenditures and, accordingly, are not anticipated to have a material effect on our financial position, results of operations, cash flows, or the competitive position of Worthington or any particular business segment.

Future results and the market price for Worthington Industries’ common shares are subject to numerous risks, many of which are driven by factors that cannot be controlled or predicted. The following discussion, as well as other sections of this Annual Report on Form 10-K, including “PART II – Item 7.– Management’s Discussion and Analysis of Financial Condition and Results of Operations,” describe certain business risks. Consideration should be given to the risk factors described below as well as those in the Safe Harbor Statement at the beginning of this Annual Report on Form 10-K, in conjunction with reviewing the forward-looking statements and other information contained in this Annual Report on Form 10-K. These risks are not the only risks we face. Our business operations could also be affected by additional factors that are not presently known to us or that we currently consider to be immaterial in our operations.

Risks Related to Our Business

Economic or Industry Downturns and Weakness

Our industries are cyclical and weakness or downturns in the economy or certain industries could have an adverse effect on our business. The overall general economic conditions, both domestically and globally, have improved from the lows reached during the recession, but they are not strong. The automotive market has rebounded, and the construction market is improving. However, global economic conditions, particularly in Europe, remain fragile, and the possibility remains that the domestic or global economies, or certain industry sectors of those economies that are key to our sales, could deteriorate, which could result in a corresponding decrease in demand for our products and negatively impact our results of operations and financial condition.

If the price of natural gas and/or oil prices remain low or decline further, the demand for products in our oil and gas equipment business could be adversely affected. Volatility or weakness in oil prices or natural gas prices, or the perception of future price weakness, affects the spending patterns of our customers within the

11

Table of Contents

oil and gas equipment business. This has resulted and may continue to result in the drilling of fewer wells or lower production spending on existing wells, lowering demand for our oil and gas equipment products and negatively impacting our results of operations and financial condition.

The automotive and construction industries account for a significant portion of our net sales, and reduced demand from these industries could adversely affect our business. An overall downturn in the economy, a disruption in capital and credit markets, high unemployment, reduced consumer confidence or other factors could cause reductions in demand from our end markets in general and, in particular, the automotive and construction end markets. If demand for the products we sell to the automotive, construction or other end markets which we supply were to be reduced, this could negatively affect our sales, financial results and cash flows.

Financial difficulties and bankruptcy filings by our customers could have an adverse impact on our business. In past years, some customers have experienced and some continue to experience challenging financial conditions. The financial difficulties of certain customers and/or their failure to obtain credit or otherwise improve their overall financial condition could result in changes within the markets we serve, including plant closings, decreased production, reduced demand, changes in product mix, unfavorable changes in the prices, terms or conditions we are able to obtain and other changes that may result in decreased purchases from us and otherwise negatively impact our business. These conditions also increase the risk that these customers may delay or default on their payment obligations to us. Should the economy or any of our markets decline, the risk of bankruptcy filings by and financial difficulties of our customers may increase. While we have taken and will continue to take steps intended to mitigate the impact of financial difficulties and potential bankruptcy filings by our customers, these matters could have a negative impact on our business.

Volatility in the United States and worldwide capital and credit markets could impact our end markets and result in negative impacts on demand, increased credit and collection risks and other adverse effects on our business. The domestic and worldwide capital and credit markets have experienced significant volatility, disruptions and dislocations with respect to price and credit availability. These factors caused diminished availability of credit and other capital in our end markets, and for participants in, and the customers of, those markets. Although domestic credit markets have largely stabilized from the height of the financial crisis, the effects of the financial crisis continue to present additional risks to us, our customers and suppliers. In particular, there is no guarantee that the credit markets or liquidity will not once again be restricted. Additionally, stricter lending standards may make it more difficult and costly for some firms to access the credit markets. In addition, uncertainties in Europe regarding the financial sector and sovereign debt and the potential impact on banks in other regions of the world will continue to weigh on global and domestic growth. Although we believe we have adequate access to several sources of contractually committed borrowings and other available credit facilities, these risks could temporarily restrict our ability to borrow money on acceptable terms in the credit markets and potentially could affect our ability to draw on our credit facilities. In addition, restricted access to the credit markets could make it difficult, or in some cases, impossible for customers to borrow money to fund their operations. Lack of, or limited access to, capital would adversely affect our customers’ ability to purchase our products or, in some cases, to pay for our products on a timely basis.

Raw Material Pricing and Availability

Our operating results may be adversely affected by declining steel prices. If steel prices or other raw material prices decrease, competitive conditions may impact how quickly we must reduce our prices to our customers, and we could be forced to use higher-priced raw materials then on hand to complete orders for which the selling prices have decreased. Decreasing steel prices could also require us to write-down the value of our inventory to reflect current market pricing.

Our operating results may be affected by fluctuations in raw material prices, and we may be unable to pass on increases in raw material costs to our customers. Our principal raw material is flat-rolled steel, which we

12

Table of Contents

purchase from multiple primary steel producers. The steel industry as a whole has been cyclical, and at times availability and pricing can be volatile due to a number of factors beyond our control. These factors include general economic conditions, domestic and worldwide demand, the influence of hedge funds and other investment funds participating in commodity markets, curtailed production from major suppliers due to factors such as the closing or idling of facilities, accidents or equipment breakdowns, repairs or catastrophic events, labor costs or problems, competition, new laws and regulations, import duties, tariffs, energy costs, availability and cost of steel inputs (e.g., ore, scrap, coke and energy), currency exchange rates and other factors described in the immediately preceding paragraph. This volatility, as well as any increases in raw material costs, could significantly affect our steel costs and adversely impact our financial results. If our suppliers increase the prices of our critical raw materials, we may not have alternative sources of supply. In addition, in an environment of increasing prices for steel and other raw materials, competitive conditions may impact how much of the price increases we can pass on to our customers. To the extent we are unable to pass on future price increases in our raw materials to our customers, our financial results could be adversely affected.

The costs of manufacturing our products and our ability to supply our customers could be negatively impacted if we experience interruptions in deliveries of needed raw materials or supplies. If, for any reason, our supply of flat-rolled steel or other key raw materials, such as aluminum, zinc or helium, or other supplies is curtailed or we are otherwise unable to obtain the quantities we need at competitive prices, our business could suffer and our financial results could be adversely affected. Such interruptions could result from a number of factors, including a shortage of capacity in the supplier base of raw materials, energy or the inputs needed to make steel or other supplies, a failure of suppliers to fulfill their supply or delivery obligations, financial difficulties of suppliers resulting in the closing or idling of supplier facilities, other significant events affecting supplier facilities, significant weather events, those factors listed in the immediately following paragraph or other factors beyond our control. Further, the number of suppliers has decreased in recent years due to industry consolidation and the financial difficulties of certain suppliers, and this consolidation may continue.

Inventories

Our business could be harmed if we fail to maintain proper inventory levels. We are required to maintain sufficient inventories to accommodate the needs of our customers including, in many cases, short lead times and just-in-time delivery requirements. Although we typically have customer orders in hand prior to placement of our raw material orders for Steel Processing, we anticipate and forecast customer demand for each of our operating segments. We purchase raw materials on a regular basis in an effort to maintain our inventory at levels that we believe are sufficient to satisfy the anticipated needs of our customers based upon orders, customer volume expectations, historic buying practices and market conditions. Inventory levels in excess of customer demand may result in the use of higher-priced inventory to fill orders reflecting lower selling prices, if raw material prices have significantly decreased. These events could adversely affect our financial results. Conversely, if we underestimate demand for our products or if our suppliers fail to supply quality products in a timely manner, we may experience inventory shortages. Inventory shortages could result in unfilled orders, negatively impacting our customer relationships and resulting in lost revenues, which could harm our business and adversely affect our financial results.

Suppliers and Customers

The loss of significant volume from our key customers could adversely affect us. A significant loss of, or decrease in, business from any of our key customers could have an adverse effect on our sales and financial results if we cannot obtain replacement business. Also, due to consolidation in the industries we serve, including the construction, automotive, and retail industries, our sales may be increasingly sensitive to deterioration in the financial condition of, or other adverse developments with respect to, one or more of our top customers. In addition, certain of our top customers may be able to exert pricing and other influences on

13

Table of Contents

us, requiring us to market, deliver and promote our products in a manner that may be more costly to us. Moreover, we generally do not have long-term contracts with our customers. As a result, although our customers periodically provide indications of their product needs and purchases, they generally purchase our products on an order-by-order basis, and the relationship, as well as particular orders, can be terminated at any time.

Many of our key industries, such as automotive, construction and heavy mobile equipment, are cyclical in nature. Many of our key industries, such as automotive, oil and gas, construction and heavy mobile equipment, are cyclical and can be impacted by both market demand and raw material supply, particularly with respect to steel. The demand for our products is directly related to, and quickly impacted by, customer demand in our industries, which can change as the result of changes in the general United States or worldwide economy and other factors beyond our control. Adverse changes in demand or pricing can have a negative effect on our business.

Significant reductions in sales to any of the Detroit Three automakers could have a negative impact on our business. More than half of the net sales of our Steel Processing operating segment and a significant amount of the net sales of certain joint ventures are to automotive-related customers. Although we do sell to the domestic operations of foreign automakers and their suppliers, a significant portion of our automotive sales are to Ford, General Motors, and FCA US LLC (the “Detroit Three automakers”) and their suppliers. A reduction in sales for any of the Detroit Three automakers could negatively impact our business. Since 2011, automobile producers have begun taking steps toward complying with new Corporate Average Fuel Economy mileage requirements for new cars and light trucks that they produce. As automobile producers work to produce vehicles in compliance with these standards, they may reduce the amount of steel or begin utilizing alternative materials in cars and trucks to improve fuel economy, thereby reducing demand for steel and resulting in further over-supply of steel in North America. Certain automakers have announced that they will use greater amounts of aluminum and smaller proportions of steel in some new models.

A significant reduction in sales to any of our large heavy mobile equipment customers could have a negative impact on our business. Substantially all of the sales of our Engineered Cabs operating segment are to customers who manufacture heavy mobile equipment. A reduction in sales to any of our major customers in this market could negatively impact our business. A reduction in demand could result from numerous causes including a reduction in overall market demand for heavy mobile equipment, in-sourcing of engineered cabs by our customers, or increased competition.

The closing or relocation of customer facilities could adversely affect us. Our ability to meet delivery requirements and the overall cost of our products as delivered to customer facilities are important competitive factors. If customers close or move their production facilities further away from our manufacturing facilities which can supply them, it could have an adverse effect on our ability to meet competitive conditions, which could result in the loss of sales. Likewise, if customers move their production facilities overseas, it could result in the loss of potential sales for us.

Sales conflicts with our customers and/or suppliers may adversely impact us. In some instances, we may compete with one or more of our customers and/or suppliers in pursuing the same business. In addition, in the Engineered Cabs business, our customers often have the option of producing certain cabs in-house instead of having them supplied by us or our competition. To the extent they elect to produce such cabs in-house, it could adversely affect our sales. Such conflicts may strain our relationships with those parties, which could adversely affect our future business with them.

The closing or idling of steel manufacturing facilities could have a negative impact on us. As steel makers have reduced their production capacities by closing or idling production lines in light of the challenging economic conditions, the number of facilities from which we can purchase steel, in particular certain specialty steels, has decreased. Accordingly, if delivery from a supplier is disrupted, particularly with respect to certain

14

Table of Contents

types of specialty steel, it may be more difficult to obtain an alternate supply than in the past. These closures and disruptions could also have an adverse effect on our suppliers’ on-time delivery performance, which could have an adverse effect on our ability to meet our own delivery commitments and may have other adverse effects on our business.

The loss of key supplier relationships could adversely affect us. Over the years, our various manufacturing operations have developed relationships with certain steel and other suppliers which have been beneficial to us by providing more assured delivery and a more favorable all-in cost, which includes price and shipping costs. If any of those relationships were disrupted, it could have an adverse effect on delivery times and the overall cost and quality of our raw materials, which could have a negative impact on our business. In addition, we do not have long-term contracts with any of our suppliers. If, in the future, we are unable to obtain sufficient amounts of steel and other products at competitive prices and on a timely basis from our traditional suppliers, we may be unable to obtain these products from alternative sources at competitive prices to meet our delivery schedules, which could have a material adverse impact on our results of operations.

Competition

Our business is highly competitive, and increased competition could negatively impact our financial results. Generally, the markets in which we conduct business are highly competitive. Our competitors include a variety of both domestic and foreign companies in all major markets. Competition for most of our products is primarily on the basis of price, product quality and our ability to meet delivery requirements. Depending on a variety of factors, including raw material, energy, labor and capital costs, government control of currency exchange rates and government subsidies of foreign steel producers, our business may be materially adversely affected by competitive forces. Competition may also increase if suppliers to or customers of our industries begin to more directly compete with our businesses through new facilities, acquisitions or otherwise. As noted above, we can have conflicts with our customers or suppliers who, in some cases, supply the same products and services as we do. Increased competition could cause us to lose market share, increase expenditures, lower our margins or offer additional services at a higher cost to us, which could adversely impact our financial results.

Material Substitution

If steel prices increase compared to certain substitute materials, the demand for our products could be negatively impacted, which could have an adverse effect on our financial results. In certain applications, steel competes with other materials, such as aluminum (particularly in the automobile industry), cement and wood (particularly in the construction industry), composites, glass and plastic. Prices of all of these materials fluctuate widely, and differences between the prices of these materials and the price of steel may adversely affect demand for our products and/or encourage material substitution, which could adversely affect prices and demand for steel products. The high cost of steel relative to other materials may make material substitution more attractive for certain uses.

If increased government mileage standards for automobiles result in the substitution of other materials for steel, demand for our products could be negatively impacted, which could have an adverse effect on our financial results. Due to government requirements that manufacturers increase the fuel efficiency of automobiles, the automobile industry is exploring alternative materials to steel to decrease weight. The substitution of lighter weight material for steel in automobiles could adversely affect prices and demand for our steel products.

Freight and Energy

Increasing freight and energy costs could increase our operating costs, which could have an adverse effect on our financial results. The availability and cost of freight and energy, such as electricity, natural gas and diesel fuel, is important in the manufacture and transport of our products. Our operations consume substantial

15

Table of Contents

amounts of energy, and our operating costs generally increase when energy costs rise. Factors that may affect our energy costs include significant increases in fuel, oil or natural gas prices, unavailability of electrical power or other energy sources due to droughts, hurricanes or other natural causes or due to shortages resulting from insufficient supplies to serve customers, or interruptions in energy supplies due to equipment failure or other causes. During periods of increasing energy and freight costs, we may be unable to fully recover our operating cost increases through price increases without reducing demand for our products. Our financial results could be adversely affected if we are unable to pass all of the increases on to our customers or if we are unable to obtain the necessary freight and energy. Also, increasing energy costs could put a strain on the transportation of our materials and products if the increased costs force certain transporters to close.

We depend on third parties for freight services, and increases in costs or the lack of availability of freight services can adversely affect our operations. We rely primarily on third parties for transportation of our products as well as delivery of our raw materials, primarily by truck. If, due to lack of freight services, raw materials are not delivered to us in a timely manner, we may be unable to manufacture and deliver our products to meet customer demand. Likewise, if due to lack of freight service, we cannot deliver our products in a timely manner, it could harm our reputation, negatively affect our customer relationships and have a material adverse effect on our results of operations.

Information Systems

We are subject to information system security risks and systems integration issues that could disrupt our internal operations. We are dependent upon information technology for the distribution of information internally and also to our customers and suppliers. This information technology is subject to damage or interruption from a variety of sources, including, without limitation, computer viruses, security breaches and defects in design. We could also be adversely affected by system or network disruptions if new or upgraded business management systems are defective, not installed properly or not properly integrated into operations. Various measures have been implemented to manage our risks related to information system and network disruptions and to prevent attempts to gain unauthorized access through the Internet to our information systems. However, a system failure could negatively impact our operations and financial results. In addition, cyber attacks could threaten the integrity of our trade secrets and sensitive intellectual property.

Business Disruptions