Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - GYROTRON TECHNOLOGY INC | gyti_8k.htm |

EXHIBIT 99.1

These materials contain forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended and Section 21E of the Securities Exchange Act of 1934, as amended.

All forward-looking statements are inherently uncertain as they are based on current expectations and assumptions concerning future events or future performance of GYTI. Readers are cautioned

not to place undue reliance on these forward-looking statements, which are only predictions and speak only as of the date hereof. In evaluating such statements, prospective investors should review

carefully various risks and uncertainties inherent herein and in publically available information on GYTI, including information filed with the SEC. These risks and uncertainties could cause actual results

to differ materially from those indicated in the forward-looking statements. GYTI is under no obligation to update this presentation.

All forward-looking statements are inherently uncertain as they are based on current expectations and assumptions concerning future events or future performance of GYTI. Readers are cautioned

not to place undue reliance on these forward-looking statements, which are only predictions and speak only as of the date hereof. In evaluating such statements, prospective investors should review

carefully various risks and uncertainties inherent herein and in publically available information on GYTI, including information filed with the SEC. These risks and uncertainties could cause actual results

to differ materially from those indicated in the forward-looking statements. GYTI is under no obligation to update this presentation.

GYROTRON TECHNOLOGY INC.. ♦ 3412 PROGRESS DRIVE BENSALEM, PA 19020 ♦ 215-244-4740 ♦ WWW.GYROTRONTECH.COM

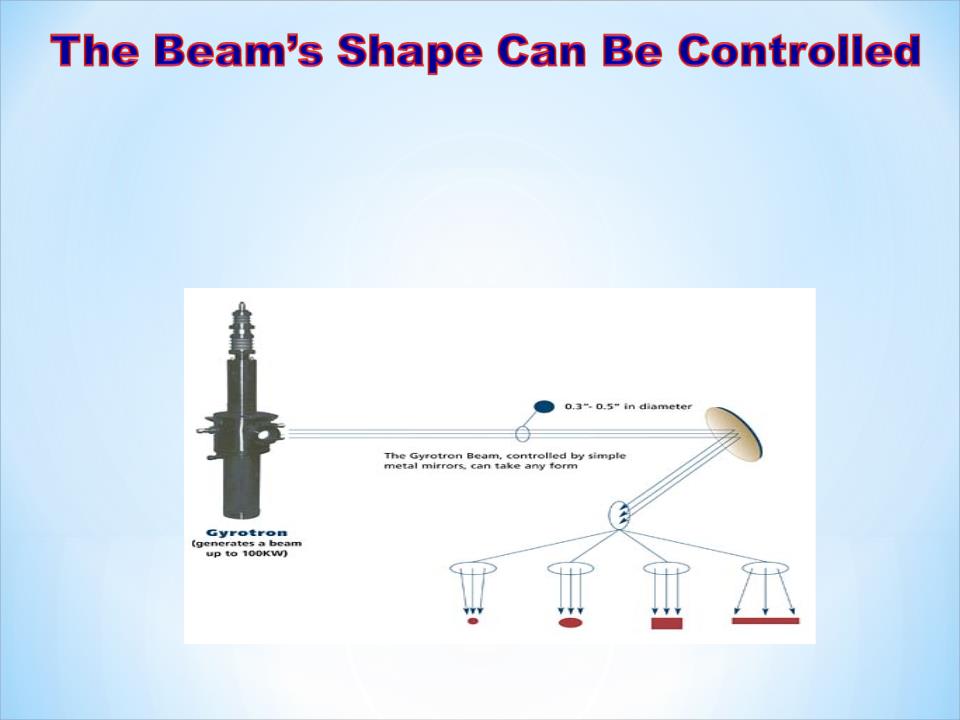

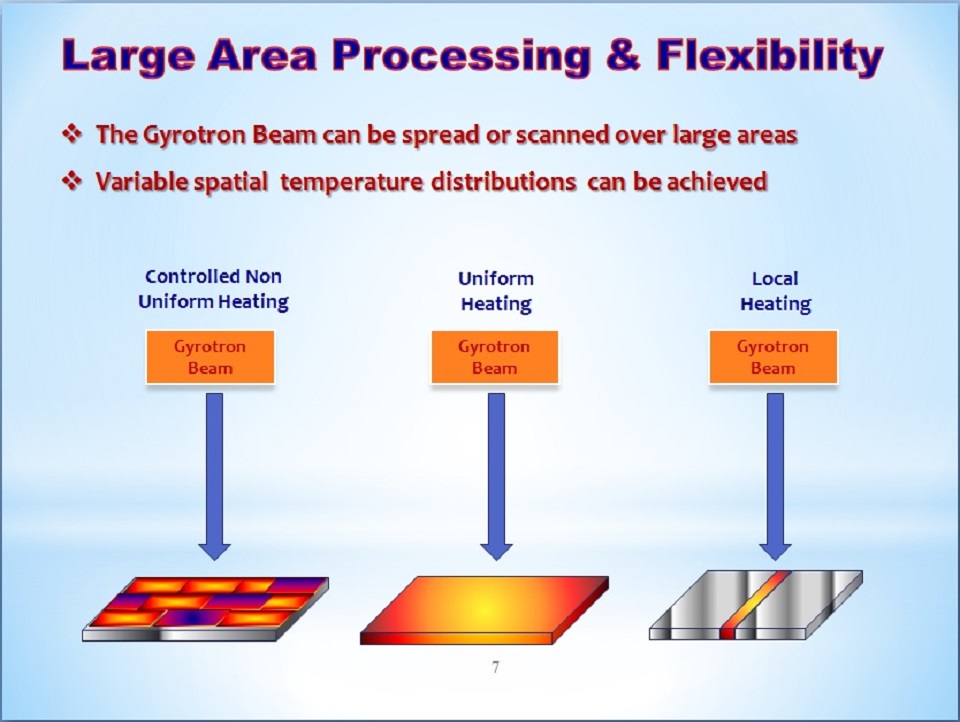

v The Gyrotron’s beam can be shaped into any form, such as a circle, strip, square, etc.

… by using simple metal mirrors

… by using simple metal mirrors

v This shaping feature greatly expands the Gyrotron’s processing possibilities

5

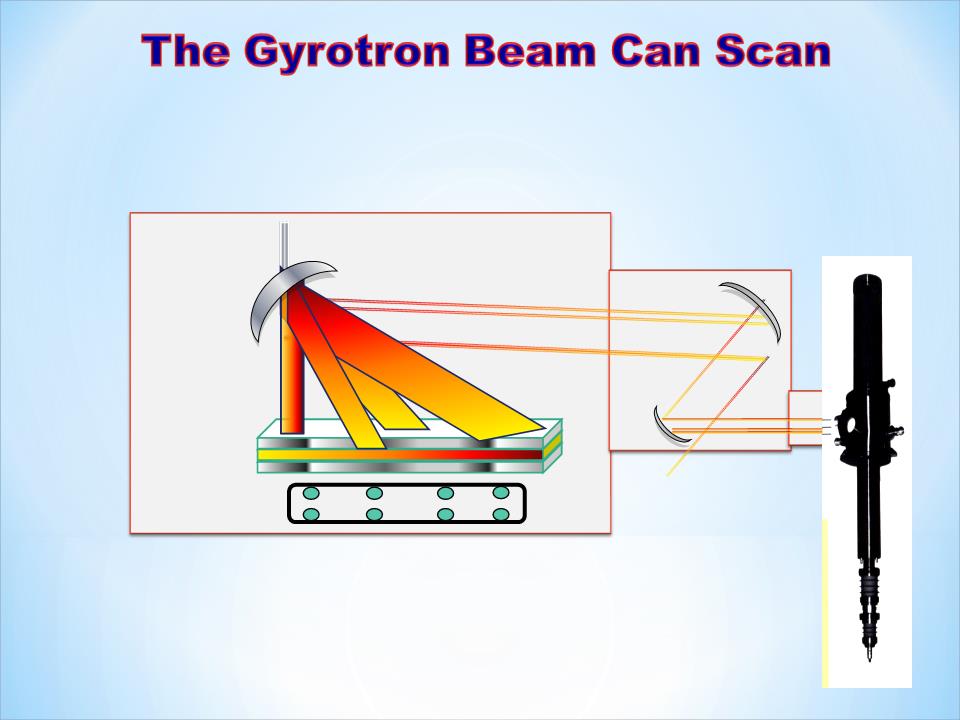

The Gyrotron Beam can be scanned to heat selected areas, at varying

temperatures, using a configuration of moving mirrors

temperatures, using a configuration of moving mirrors

6

SEMICONDUCTOR APPLICATIONS

§Annealing wafers

§Photovoltaic thin films (solar)

§Protective coatings

§Silicon carbide semiconductors

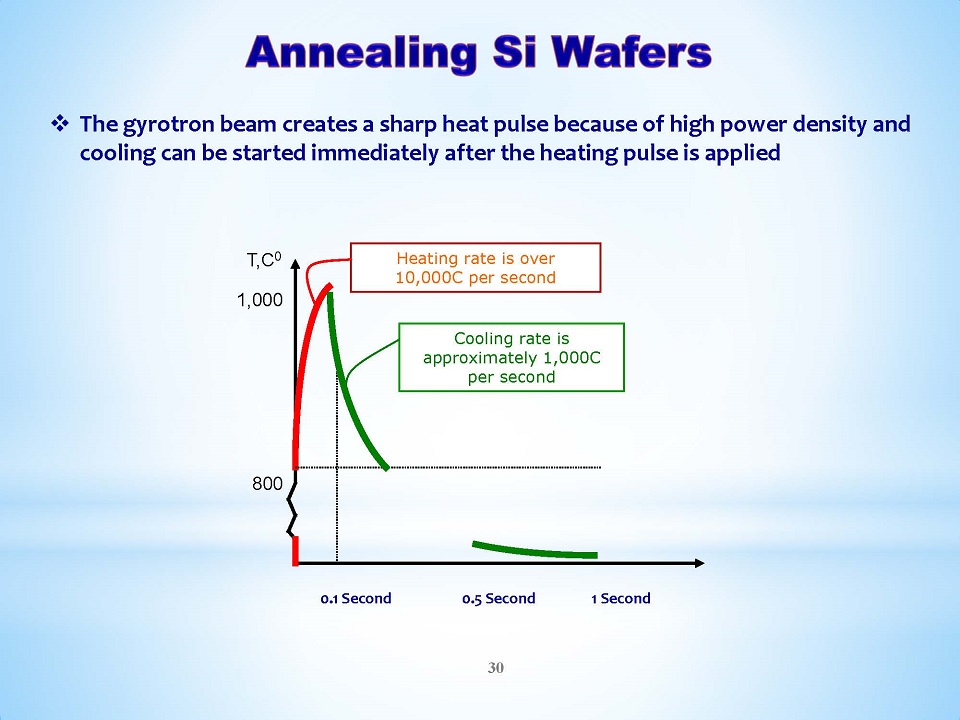

v GYTI solutions can activate boron in silicon crystals, achieving high conductivity

and ultra-shallow junctions, which allows for more complex chip designs

and ultra-shallow junctions, which allows for more complex chip designs

v GYTI believes its gyrotron-based process should dramatically accelerate silicon-

carbide activation, & significantly improve efficiency

carbide activation, & significantly improve efficiency

10

KEY APPLICATIONS

vCuring plastics and coatings

vCuring composite pipes

vCuring construction panels

vCuring car parts

vDrying paper

vDrying tiles

GYTI is engaged with a Tier-One consumer product market leader, who is looking to

deploy gyrotron-based solutions to more efficiently & cost-effectively cure plastic

foam.

deploy gyrotron-based solutions to more efficiently & cost-effectively cure plastic

foam.

11

DECONTAMINATION APPLICATIONS

•Beef, Pork, and Poultry

•Solid and semisolid produce

• GYTI ‘s technologies possess attractive prospects in the massive food

decontamination and safety space

decontamination and safety space

• For example, meat processing plants typically deploy labor-intensive chemical

decontamination methods with sub-optimal results.

decontamination methods with sub-optimal results.

• Gyrotron-based systems can achieve record decontamination (99.999%) levels &

process efficiency - improves shelf life, safety & economics

process efficiency - improves shelf life, safety & economics

12

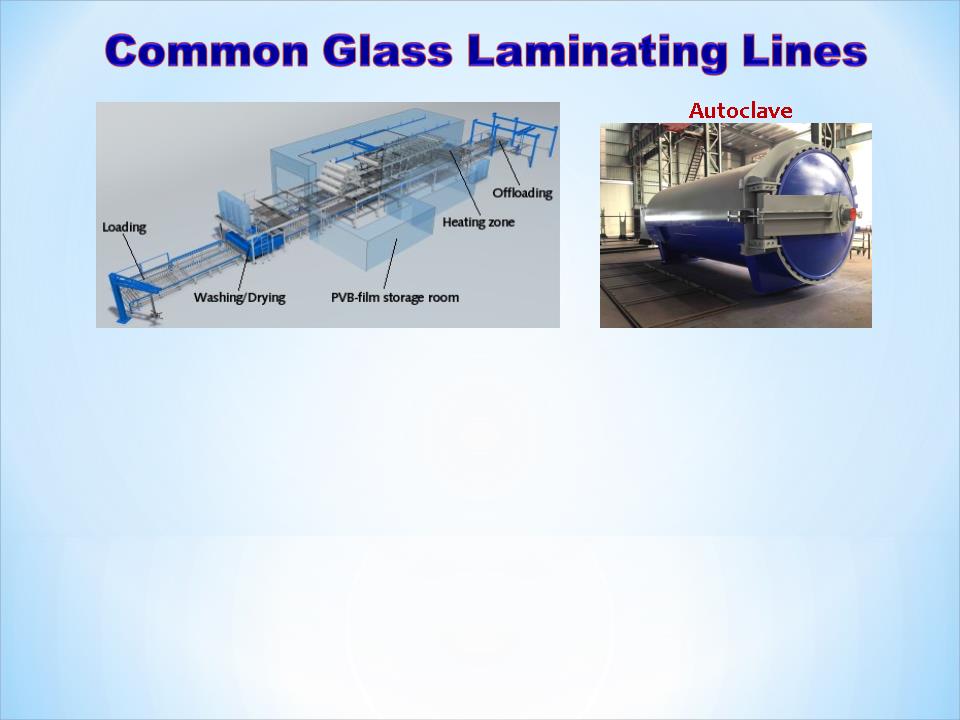

LAMINATION APPLICATIONS

•Windows, doors, floors,

•Auto windshields, side windows

•Facades & decorative panels

•Bullet proof glass

•Solar panels

• GYTI markets its “Gyrotron Laminating System” (GLS), a patented, continuous

in-line process and equipment architecture for:

in-line process and equipment architecture for:

1. lamination of architectural flat glass

2. encapsulation of solar modules

• The GLS has major advantages over conventional laminating systems:

1. Conventional systems require an autoclave for finishing

2. the GLS reduces capital intensity and improves efficiency

13

14

In the following slides, we discuss global market size in terms of quantity, aggregate $

value and/or $ value per item.

value and/or $ value per item.

In addition we discuss annual capacity per gyrotron installation.

Each of these numbers are Company estimates, and should be treated as such.

In addition, we speak of installation fees and royalty rates. These are targets that may

or may not be achieved.

or may not be achieved.

The reader is reminded of the cautionary language regarding forward looking

statements contained on the cover page of this presentation and the risks inherent in

an investment in the Company.

statements contained on the cover page of this presentation and the risks inherent in

an investment in the Company.

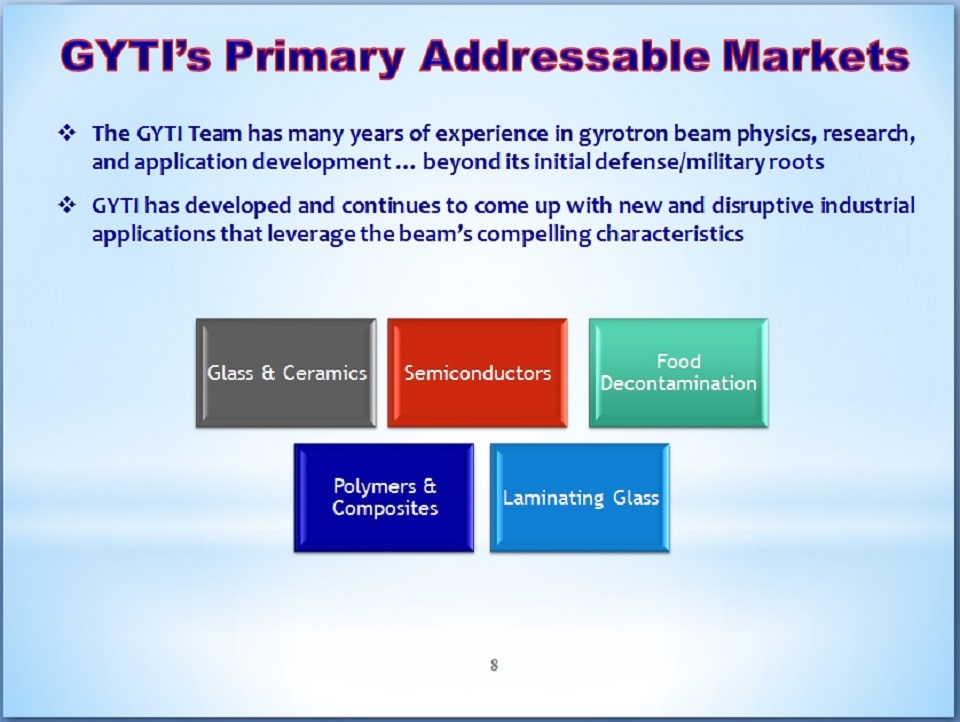

GYTI solutions target a broad range of industrial heating applications, such as:

A. Glass Shaping & Bending

v Estimated Annual Global Market for Shaped Windshields is $4.5B

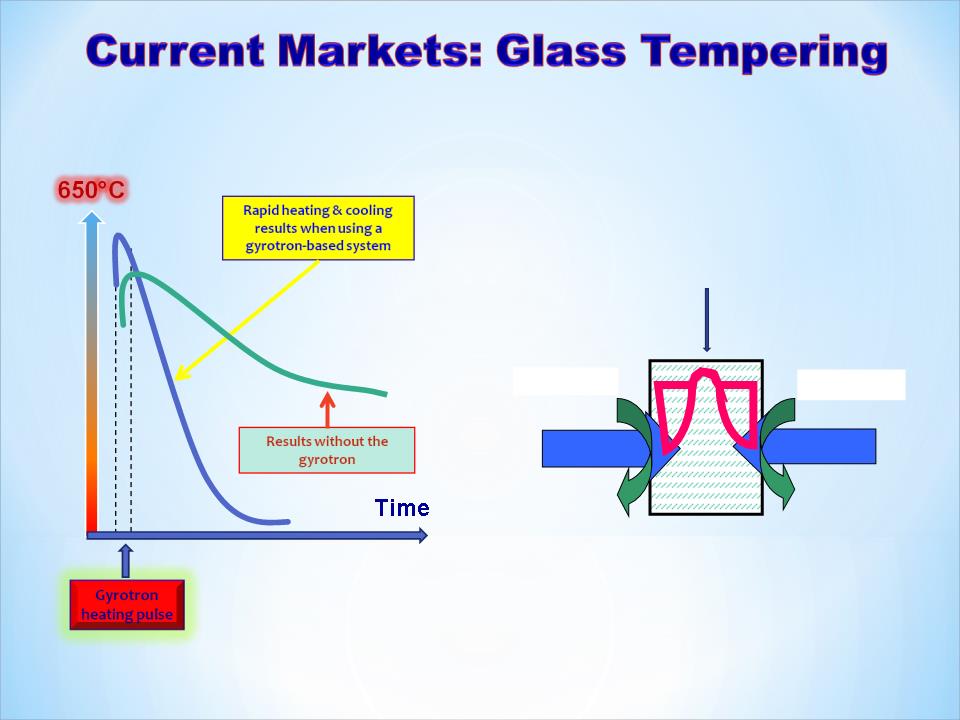

B. Glass Tempering

v Estimated Annual Global Market for Tempered Glass is $11B

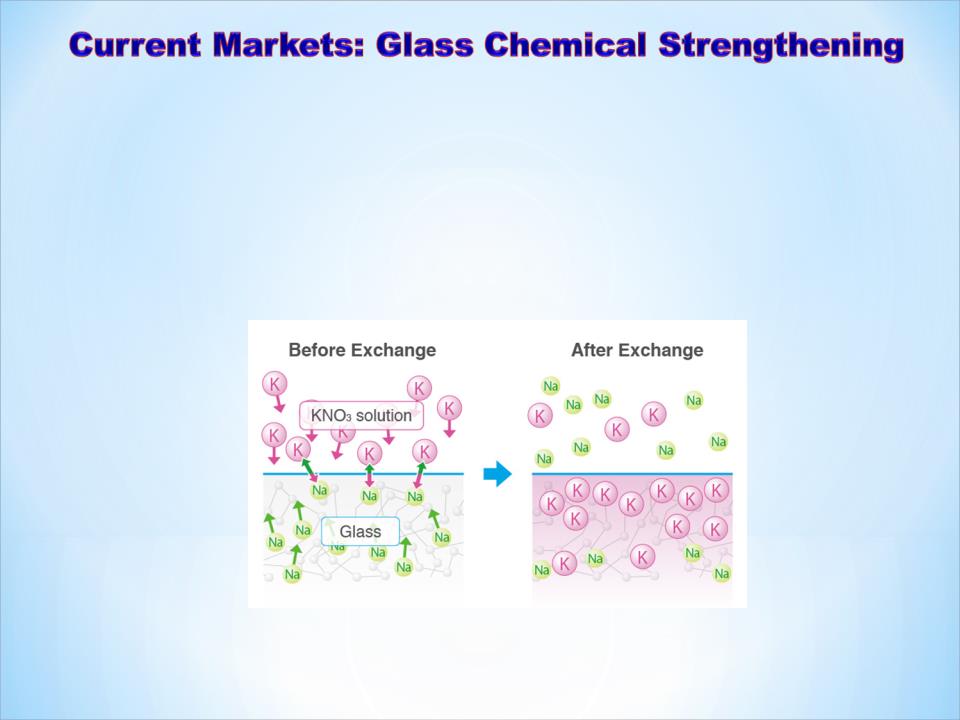

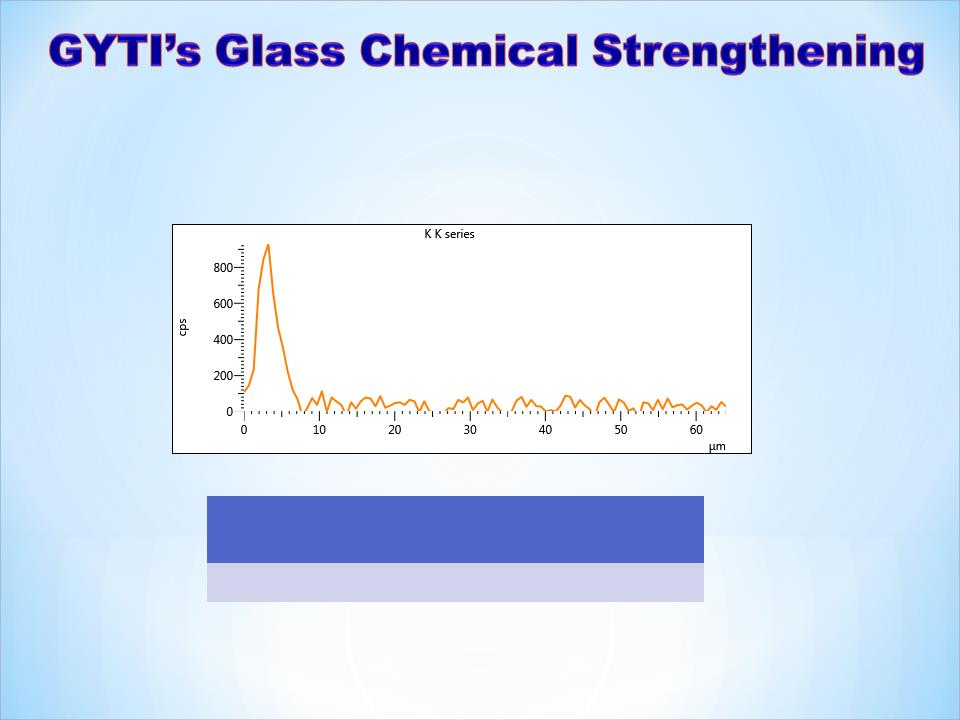

C. Glass Chemical Strengthening

v Estimated Annual Global Market for Chemically-Strengthened Glass

is $2B

is $2B

D. Lamination

v Estimated Annual Global Market for Laminated Glass is $10B

• Silicon Wafer Diffusion

v Estimated Annual Global Silicon Wafer Annealing Market is $8B

• Food Decontamination

v Estimated Annual Global Beef Decontamination Costs are $28.5B

A. Curing of Plastics

B. Silicon Carbide Wafer Processing

15

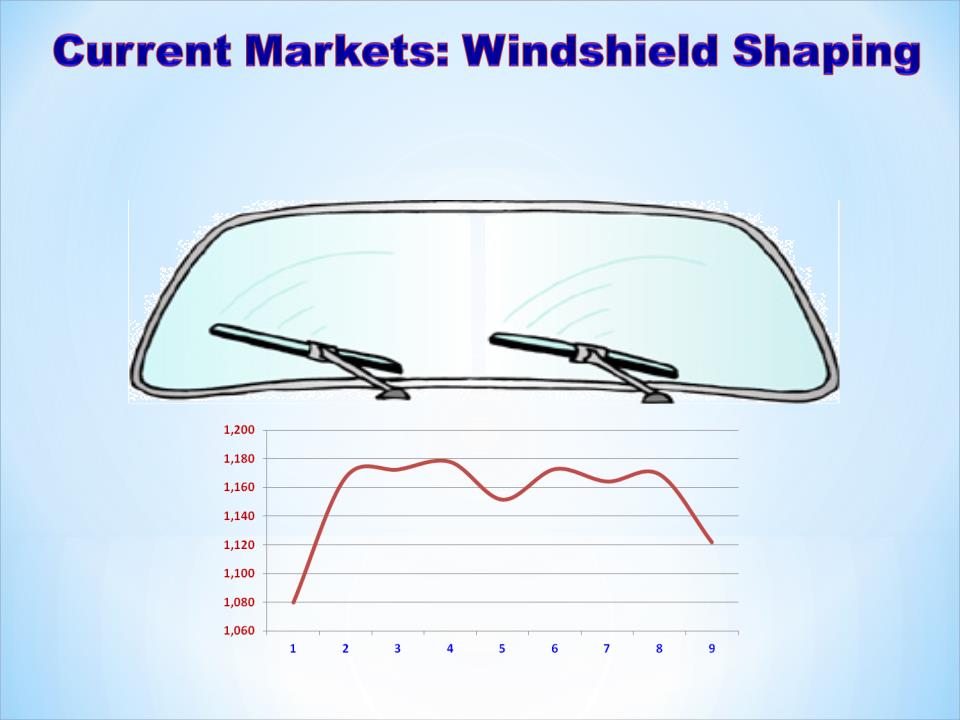

Any temperature distribution over the glass sheet (i.e. different curvatures

require different heat levels) can be utilized by gyrotron beam scanning

require different heat levels) can be utilized by gyrotron beam scanning

|

ZONE

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

ZONE

|

|

A

|

1060°C

|

1167°C

|

1142°C

|

1130°C

|

1155°C

|

1205°C

|

1183°C

|

1190°C

|

1164°C

|

A

|

|

B

|

1120°C

|

1160°C

|

1184°C

|

1202°C

|

1160°C

|

1130°C

|

1120°C

|

1140°C

|

1060°C

|

B

|

|

C

|

1060°C

|

1175°C

|

1192°C

|

1202°C

|

1140°C

|

1184°C

|

1190°C

|

1178°C

|

1142°C

|

C

|

16

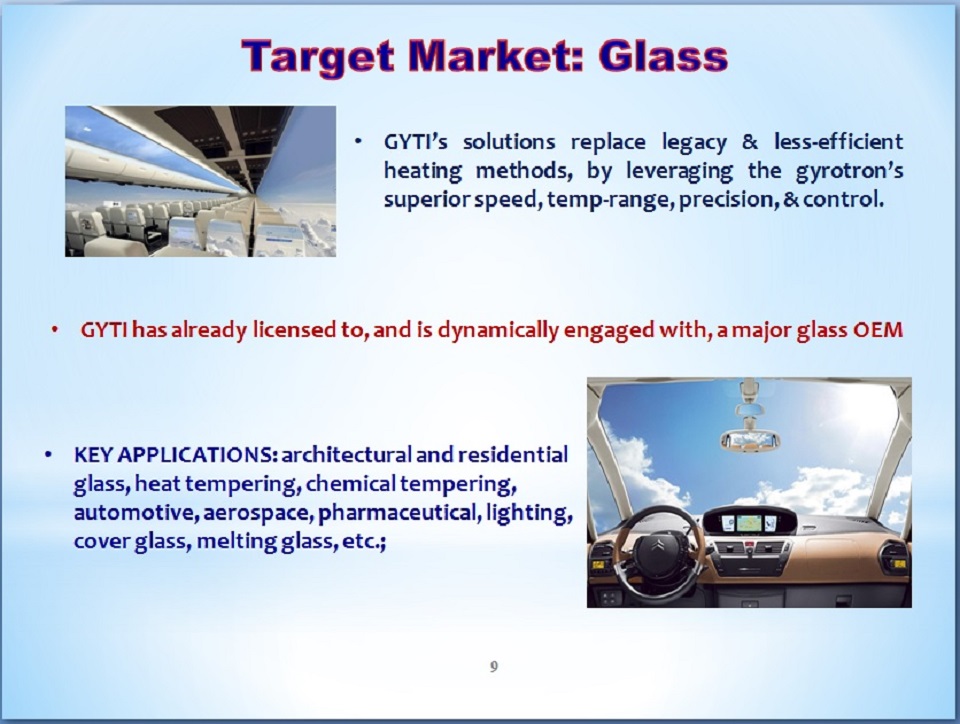

Benefits of GYTI’s glass shaping system VS. incumbent lamp heater arrays

GYTI’s gyrotron-based system enables OEMs to:

•Substantially lower production costs

•Improve automation and process efficiency

•Yield superior end-product, with wider shape varieties

•Improve compliance with new national distortion-testing standards

Market Opportunity for GYTI

•Approximately 100 million windshields need to be shaped annually.

•Average cost per finished windshield unit is $45

•Capacity per GYTI gyrotron-system installation = 120K units per year

•GYTI’s upfront licensing fee = $150K per installation

Accordingly, each 1% of market share, is targeted to yield upfront

licensing of $1.2M, & annual royalties of ~$450K, based on a $0.45 per

unit target royalty, i.e. a 1% rate.

licensing of $1.2M, & annual royalties of ~$450K, based on a $0.45 per

unit target royalty, i.e. a 1% rate.

17

Beam

Beam

Glass

Cooling

Cooling

Glass

Temperature distribution inside

glass

glass

A gyrotron beam can focus on the glass-sheet mid-plane, keeping its temperature high

18

GYTI’s gyrotron-based tempering solutions enable OEMs to manufacture:

•Glass & low-E coated product without roller marks and waviness

•Tempered product with significantly less distortion

•With substantially reduced (up to 40%) energy requirements

•With lower production costs, better quality & wider shape variety

•Automotive glazing that can be tempered

Market Opportunity for GYTI

•~200M square meters (SM) of automotive glass, plus 300M SM of other glass types,

require tempering on an annual basis

require tempering on an annual basis

•Average tempered product costs are $22 per square meter

•Annual capacity per gyrotron installation = 380K square meters

•Upfront licensing fee = $100K per installation

Accordingly, each 1% of market share is targeted to yield upfront

licensing fees of $1.3M, and recurring annual royalties of $1.1M, at a 1%

rate.

licensing fees of $1.3M, and recurring annual royalties of $1.1M, at a 1%

rate.

19

• To strengthen glass, OEMs replace smaller sodium ions with larger potassium ions

• The ion size difference creates “compression stress”, which strengthens the glass

• This chemical process is very slow (hours) and requires expensive specialty glass

• Thus, chemically-strengthened glass is costly & is not used as widely as it could be

20

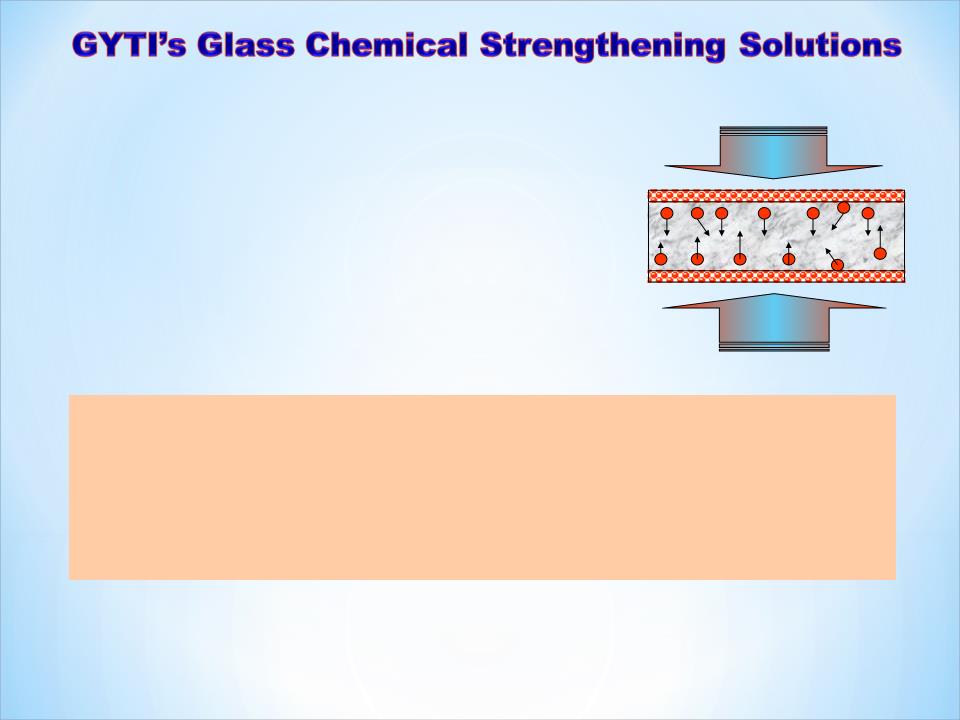

Radiation

Radiation

|

Glass

OEM

|

STRESS

In Megapascals

(MPa) |

DEPTH

In Term of

Microns |

GYTI’s Processing

Duration Time |

PROCESSING TIME for Incumbent

Chemical Strengthening Solutions |

|

Company A

|

420

|

|

55 seconds

|

9K seconds or 2.5 hours

|

|

Company B

|

650

|

14

|

100 seconds

|

12.6K sec. or 3.5 hours

|

|

Company C

|

500

|

18

|

75 seconds

|

16.2K sec. or 4.5 hours

|

• A gyrotron’s radiation can specifically heat

both soda and potassium ions

both soda and potassium ions

• This accelerates the ion exchange process

• Thus, glass can be strengthened in a few

minutes not in hours.

minutes not in hours.

21

v Our tests indicate ordinary/cheap soda lime glass can also be chemically tempered

v This has never been economically feasible with conventional technology

|

Glass

|

Stress

(MPa)

|

Depth

(microns)

|

Time

(sec)

|

|

Soda Lime

|

-

|

8

|

240

|

22

GYTI’s glass chemical-strengthening solutions enable OEMs to:

•Strengthen glass in a few minutes, versus hours using current methods

•Significantly lower production costs, and improve process efficiency

•Thus, any glass can be now be cost-effectively strengthened

•GYTI’s disruptive solutions could significantly drive market growth

Market Opportunity for GYTI

•The chemically-strengthened glass market is ~$2B per annum

•Average cost of ~$80 per SM, equates to an annual size of 25M SMs

•Capacity per gyrotron installation is ~6 Square Meters per hour = 50K SM per year

•Upfront licensing fee is $250K per installation

Accordingly, each 1% of market share is targeted to yield upfront

licensing fees of $1.25M & annual recurring royalties of $600K

(expected royalty rate is 3%).

licensing fees of $1.25M & annual recurring royalties of $600K

(expected royalty rate is 3%).

23

Laminated glass consists of a tough

protective interlayer made of an

adhesive polymer film such as PVB

bonded together between two

panes of glass under heat and

pressure.

protective interlayer made of an

adhesive polymer film such as PVB

bonded together between two

panes of glass under heat and

pressure.

• The standard two-ply construction

provides resistance to penetration when

subjected to attempted force entry.

provides resistance to penetration when

subjected to attempted force entry.

• In multi-ply configurations, laminated

glass can even resist hurricanes and

heavy objects, or small explosions.

glass can even resist hurricanes and

heavy objects, or small explosions.

24

Issues with conventional/incumbent glass lamination processes

vHigh operating costs: Labor intensity and high energy losses

vSpoilage: Autoclave breakage & batch processing delays are costly

vTime-consuming: Autoclave heating & cooling takes many hours

vCostly space requirements: single line = thousands of SF

vLimitations: difficult to laminate tempered/thin glass and mirrors

25

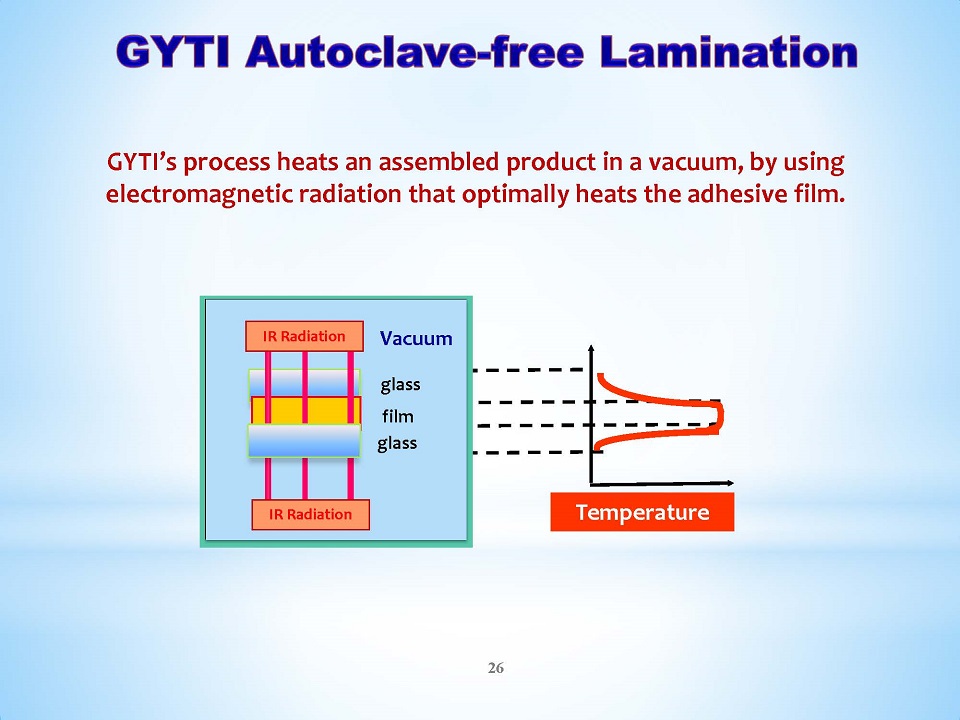

Vacuum

IR Radiation

IR Radiation

Pumping and Heating

Sandwich is heated to 220F. Trapped air and

moisture, as well as, intrinsic film moisture is

completely pumped off.

moisture, as well as, intrinsic film moisture is

completely pumped off.

Sandwich is then heated to the required

temperature (approx. 270 - 300F) for selected

adhesion level

temperature (approx. 270 - 300F) for selected

adhesion level

Final Curing

27

28

GYTI’s Lamination solutions enable OEMs to:

•Lower operating costs due to reduced labor, energy and maintenance

•Substantially augment productivity

•Upgrade at a comparable equipment price

•Deal with films, as GYTI’s process is less sensitive to moisture control

•Laminating both glass and solar modules

Market Opportunity for GYTI

•Flat laminated glass production is ~300M square meters annually

•Average cost is approximately $30- $50 per square meter

•Annual capacity per gyrotron installation = 250K SM

•Upfront license fee = $50K per installation

Accordingly each 1% of market share is targeted to generate upfront

fees of $600K and recurring annual royalties of $2.3M (target rate is

$0.75 per SM)

fees of $600K and recurring annual royalties of $2.3M (target rate is

$0.75 per SM)

29

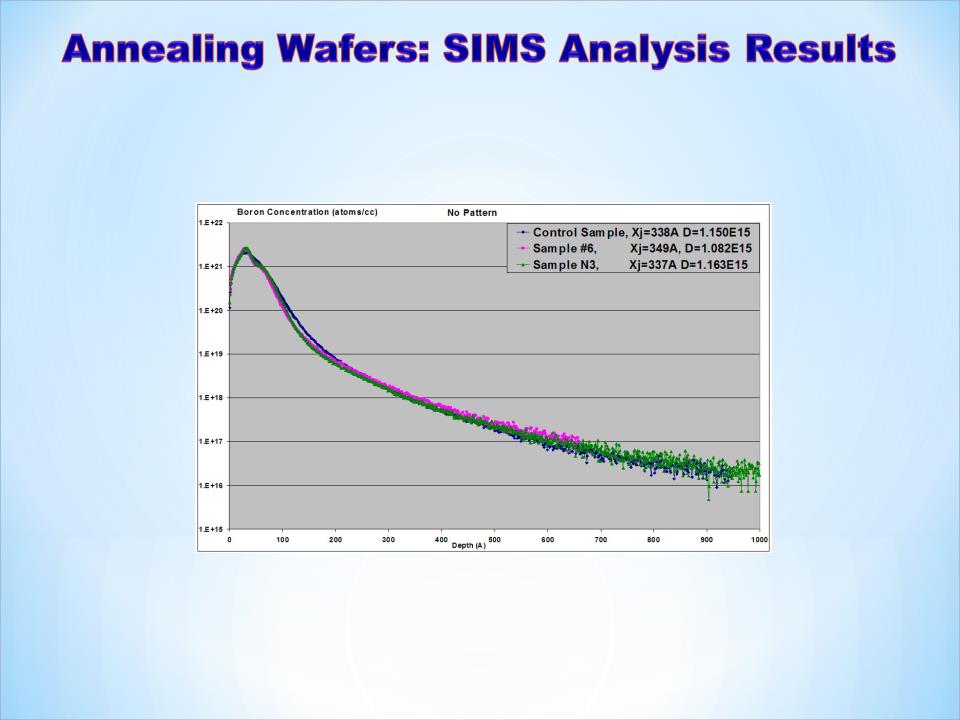

v Boron distribution remains the same after the gyrotron processing

v This allows for the creation of ultra-shallow junctions

SHEET RESISTANCES: Sample #6 = 180 Ohms; Sample# 3 = 200 Ohms

31

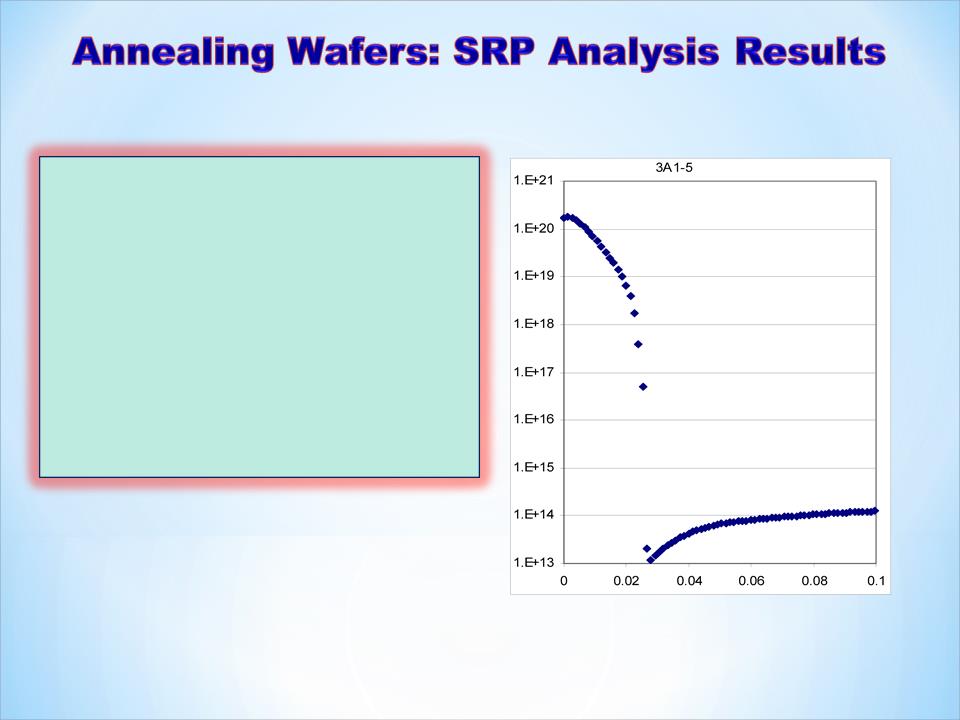

Conditions:

Processing time: 0.15 seconds

Temperature: 1,050°C

Resistance: 710 Ohms

Peak concentration: 3.7 E 20

The peak concentration is unusual high

This process paves the way for creation of

semiconductors with ultra shallow junctions

and low-resistance.

semiconductors with ultra shallow junctions

and low-resistance.

32

GYTI’s gyrotron-based wafer annealing solutions:

•Can creates ultra shallow junctions of less than 70 Angstroms

•Feature ultra rapid heating, which provides low diffusion of dopants

•Yield high conductivity due to high concentration of activated dopants

•Creates precondition for next-gen PCs & electronics devices

Market Opportunity for GYTI

•There are ~160M wafers require activation on an annual basis

•Average cost per activated wafer is ~$50

•Annual capacity per gyrotron installation = 1M wafers

•Upfront license fee = $300K per installation

Accordingly each 1% of market is targeted to yield upfront licensing

fees of $500K and recurring annual royalties of $1.6M (expected

royalty rate is 2%).

fees of $500K and recurring annual royalties of $1.6M (expected

royalty rate is 2%).

33

• The USDA estimates foodborne pathogens are responsible for ~48M illnesses annually

• These ~48M food-contamination incidents lead to ~8,000 deaths per annum

• The estimated annual healthcare costs resulting from these cases are $152 billion

• Thus, the ability to improve on incumbent decontamination processes, which are labor

intensive and nowhere close to perfection, presents an huge opportunity for GYTI

intensive and nowhere close to perfection, presents an huge opportunity for GYTI

• GYTI’s target decontaminating opportunities relate to cleaning:

v Beef, Pork, and Poultry

v Solid and semisolid produce

34

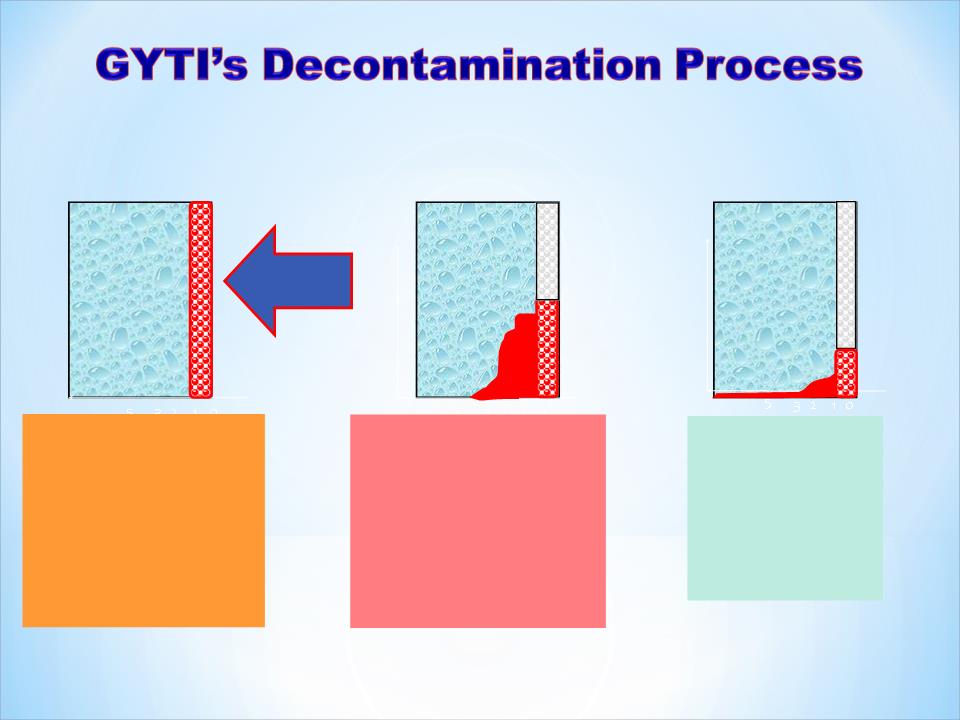

Gyrotron

Beam

Beam

100°C

Meat,

produce,

etc

produce,

etc

Heating for LESS than

0.1 second

0.1 second

0.3 seconds after

heating

heating

After 0.6

seconds

temperature

everywhere will

be not higher

than ambient.

seconds

temperature

everywhere will

be not higher

than ambient.

A thin layer (around

0.1 mm) will be

heated by the

Gyrotron Beam to a

temperature over

100°C, in

milliseconds.

0.1 mm) will be

heated by the

Gyrotron Beam to a

temperature over

100°C, in

milliseconds.

Within 0.3 sec after

heating stops, heat

will migrate into the

meat to around 0.3

mm & temperature

will drop to less than

60C.

heating stops, heat

will migrate into the

meat to around 0.3

mm & temperature

will drop to less than

60C.

0.6 seconds after

heating

heating

50°C

100°C

50°C

100°C

50°C

35

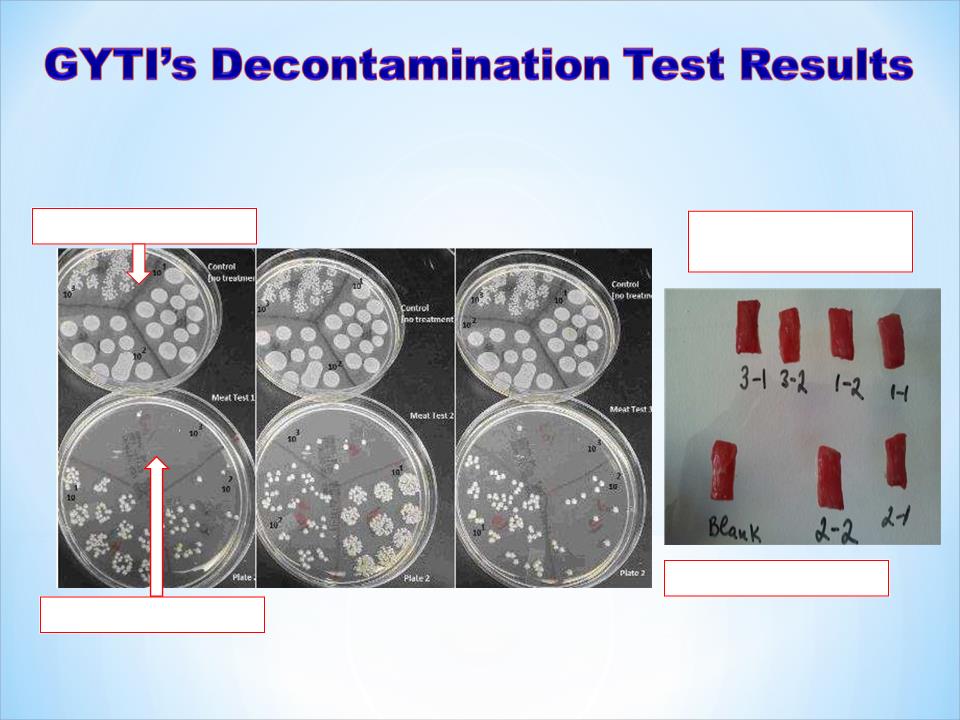

v Meat surfaces inoculated with ~1x107 cells/surface

v Reduction of inoculated bacteria from surfaces was over 300K times

Before processing

After processing

Meat appearance

after processing

after processing

Not processed meat

36

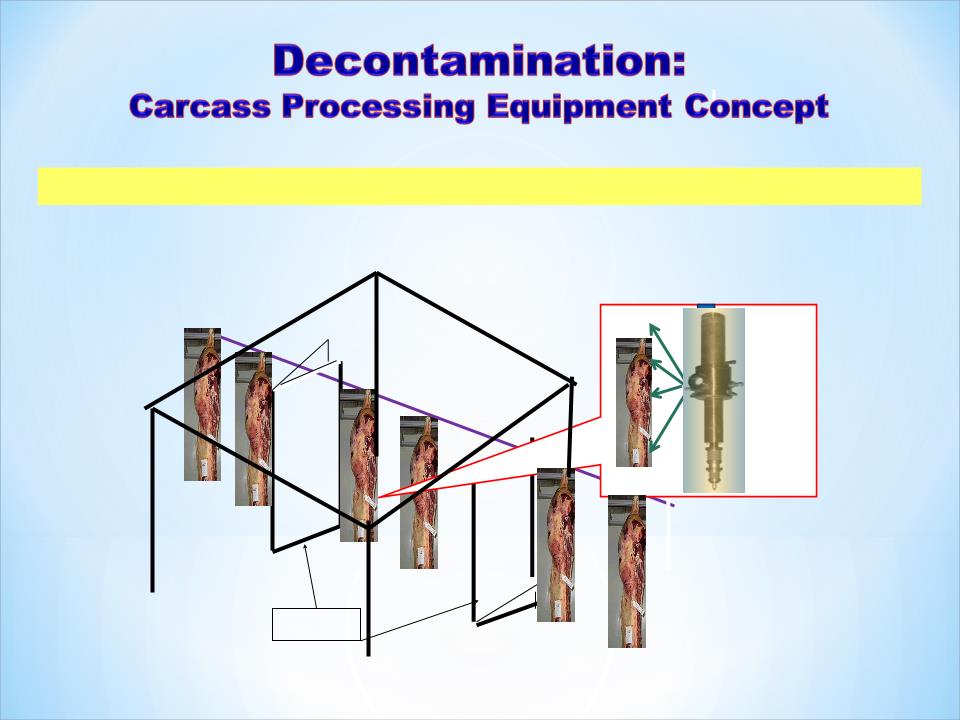

~3.6K carcasses can be cleaned daily (20 seconds per) = the capacity of a large packaging plant

Gyrotron

Doors

37

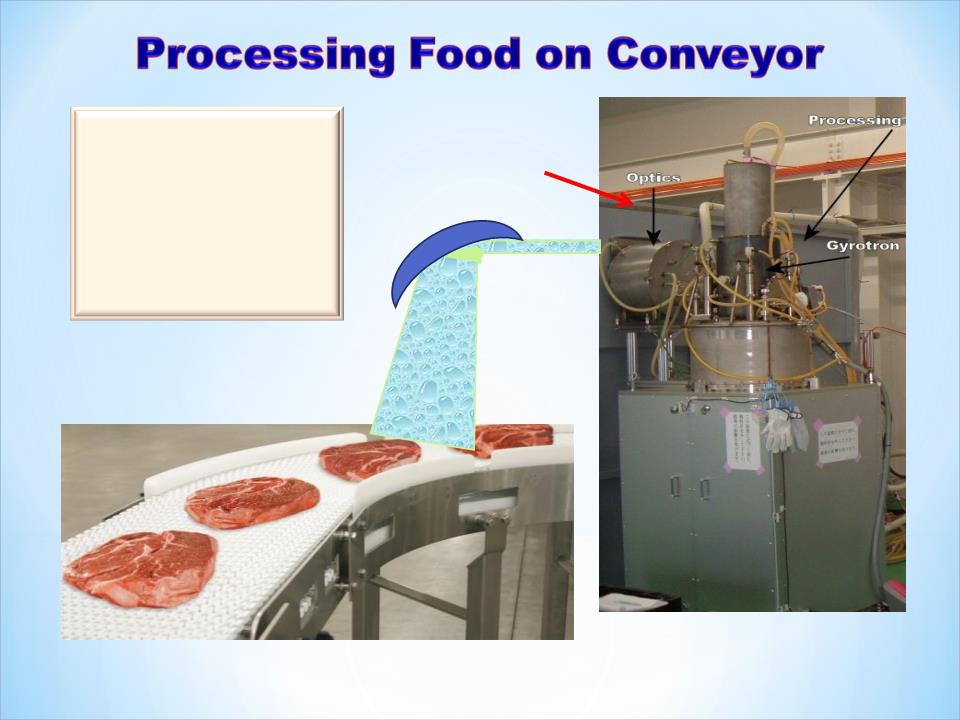

Food (meat, fruits,

vegetables, etc) can be

processed on the

moving conveyer with a

speed up to 100m/min

(350’/min) using a single

200 kW gyrotron.

vegetables, etc) can be

processed on the

moving conveyer with a

speed up to 100m/min

(350’/min) using a single

200 kW gyrotron.

38

Metal

processing

chamber

processing

chamber

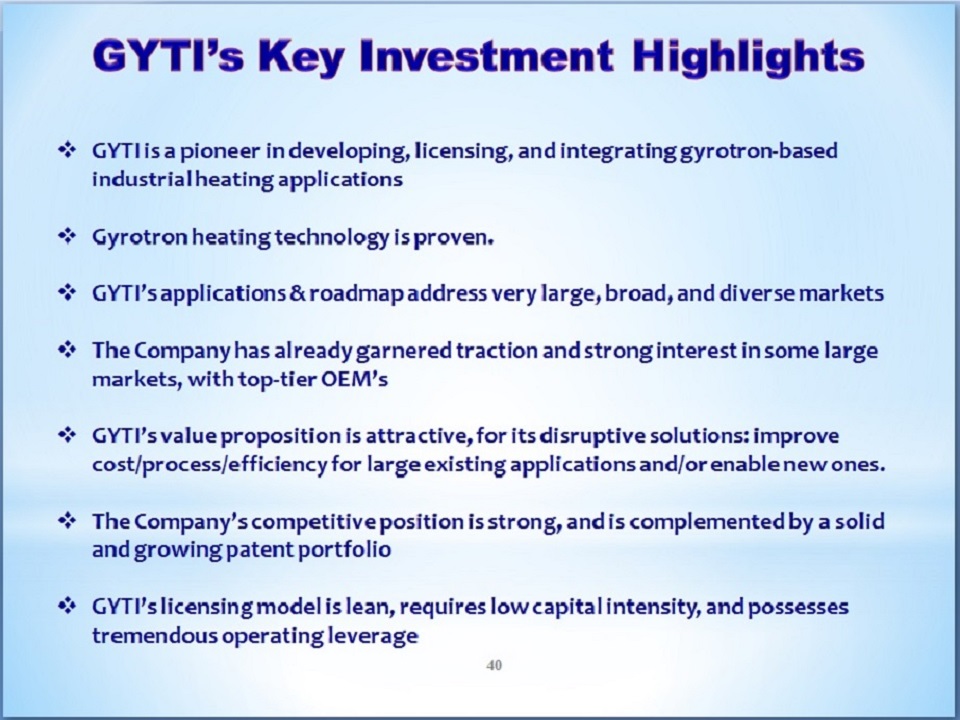

GYTI’s gyrotron-based food decontamination solutions can:

•Eradicate 99.999% of bacteria on meat surfaces

•This level is orders of magnitude better than any competitive process

Market Opportunity for GYTI

•~190M beef carcasses need to be decontaminated annually

•Average cost of processing (cleaning) is approximately $15

•The total market for carcass cleaning is $2.9 billion.

•The targeted royalty is $1 per carcass

•Capacity per gyrotron installation = 1M carcasses/year

•Upfront license fee = $400K per installation

Accordingly each 1% of market share is targeted to generate upfront

licensing fees of $800K, and a recurring annual royalty of $2M.

licensing fees of $800K, and a recurring annual royalty of $2M.

39

41

|

GYTI CAPITALIZATION

|

|

|

1/1/15

|

|

|

|

|

|

strike/

|

|

|

|

Shares

|

Liq preference

|

Conversion

|

F/D Shares

|

|

common

|

14,388,454

|

|

|

14,388,454

|

|

Pfd A and A1

|

498,951

|

$ 2,993,706

|

$1.60

|

1,871,066

|

|

Pfd B

|

39,981

|

$ 1,199,430

|

$0.85

|

1,199,430

|

|

Pfd B1

|

40,650

|

$ 1,422,748

|

$0.70

|

2,032,497

|

|

Warrants Exp 10/1/18

|

60,000

|

|

$0.75

|

60,000

|

|

Warrants Exp 3/31/15

|

1,044,864

|

|

$1.00

|

1,044,864

|

|

Warrants Exp 3/31/16 *

|

1,938,950

|

|

$1.00

|

1,938,950

|

|

Options

|

60,000

|

|

$0.725

|

60,000

|

|

Total

|

|

|

|

22,805,145

|

|

*may expire earlier in

certain circumstances |

|

|

|

|