Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - FMC CORP | d885276d8k.htm |

Exhibit 99.1

Excerpts from the Evolution Escrow Issuer LLC

Confidential Preliminary Offering Memorandum dated March 9, 2015

The inclusion of the information presented below (including the risk factors and the financial statements) should not be viewed as a determination that such information is material to FMC Corporation. As used in these excerpts, except where otherwise specified or unless the context otherwise requires, the term “Alkali Chemicals” refers to the Alkali Chemicals division of FMC Corporation, a Delaware corporation, including Alkali Holdings Corporation, a Delaware corporation, and its direct and indirect subsidiaries.

Risks Related to the Alkali Chemicals Business

Soda ash prices have been and in the future may be volatile, and lower soda ash prices will negatively affect our financial position and results of operations.

The market price of soda ash directly affects the profitability of the Alkali Chemicals business. If the market price for soda ash declines, our revenue from the Alkali Chemicals business may decrease. Historically, the global market and, to a lesser extent, the domestic market for soda ash have been volatile, and those markets are likely to remain volatile in the future. Volatility in soda ash prices can make it difficult to predict the cash we may have on hand at any given time, and a prolonged period of low soda ash prices may materially and adversely affect our financial position, liquidity, ability to finance planned capital expenditures and results of operations.

Prices for soda ash may fluctuate in response to relatively minor changes in the supply of and demand for soda ash, market uncertainty and other factors beyond our control. These factors include, among other things:

| • | overall economic conditions; |

| • | the level of customer demand, including in the glassmaking industry; |

| • | the level of production and exports of soda ash globally; |

| • | the level of production and cost of materials used to produce soda ash, including trona ore or synthetic materials, globally; |

| • | the cost of energy consumed in the production of soda ash, including the price of natural gas, electricity and coal; |

| • | the impact of competitors increasing their capacity and exports; |

| • | domestic and foreign governmental relations, regulations and taxes; and |

| • | political conditions or hostilities and unrest in regions where we export soda ash. |

A significant portion of the demand for soda ash comes from glass manufacturers and other industrial end users whose businesses can be adversely affected by economic downturns.

A significant portion of the demand for soda ash comes from glass manufacturers and other industrial customers. Companies that operate in the industries that glass manufacturers serve, including the automotive, construction and glass container industries, may experience significant fluctuations in demand for their own end products because of economic conditions, changes in consumer demand, or increases in raw material and energy costs. In addition, many large end users of soda ash depend upon the availability of credit on favorable terms to make purchases of raw materials such as soda ash. As interest rates increase or if our customers’ creditworthiness deteriorates, this credit

1

may be expensive or difficult to obtain. If these customers cannot obtain credit on favorable terms, they may be forced to reduce their purchases of soda ash. These and other factors may lead some customers to seek renegotiation or cancellation of their arrangements with the Alkali Chemicals business, which could have a material adverse effect on our results of operations.

Increased use of glass substitutes and recycled glass may affect demand for soda ash, which could adversely affect our result of operations.

Increased use of glass substitutes or recycled glass in the container industry could have a material adverse effect on our results of operations and financial condition. Container glass production is one of the principal end markets for soda ash. Competition from increased use of glass substitutes, such as plastic and recycled glass, has had a negative effect on demand for soda ash. We believe that the use of containers containing alternative materials such as plastic and aluminum could negatively affect the growth in demand for soda ash.

Violations or noncompliance with the extensive environmental, health and safety laws and regulations to which we are subject or changes in laws or regulations governing our operations could result in additional cost, unanticipated loss or liability.

Our operations and production facilities are subject to extensive, and frequently changing, federal and State environmental and health and safety laws and regulations governing environmental protection, occupational health and safety and the release or discharge of materials into the environment, including air emissions, wastewater discharges, water usage, mine safety, soil and groundwater remediation, and protection of endangered or threatened species. Any failure to comply with such laws and regulations may result in the assessment of administrative, civil and criminal penalties, injunctive orders, or the imposition of investigatory and remedial obligations. Although we believe that we are in substantial compliance with existing environmental laws and regulations and that continued compliance with existing requirements will not materially affect us, there is no assurance that the current level of regulation will continue in the future. The costs of compliance with these laws and regulations or the inability to obtain, update or renew permits required for operation or expansion of our business could reduce our profitability or otherwise adversely affect our business.

Moreover, certain environmental laws impose joint and several, strict liability for costs to clean up and restore sites where pollutants have been disposed or otherwise spilled or released. We are currently addressing certain areas of known contamination on our own properties, none of which we presently anticipate will result in any material costs or adverse impacts on our business or operations. However, we cannot assure you that we will not incur significant costs and liabilities for remediation or damage to property, natural resources or persons as a result of spills or releases from our operations or those of a third party.

Our dependence on burning coal to generate electrical energy and steam could mean that governmental initiatives to limit the emission of greenhouse gas (‘‘GHG’’) could have an adverse effect in the future on our costs and therefore our results of operations.

Our operations are also subject to EPA’s regulations regarding greenhouse gas (‘‘GHG’’) emissions and, depending upon the nature and scope of any future regulations, could become subject to additional costs or limitations. Current requirements include an obligation to monitor and report the GHG emissions from our facilities and to comply with the Clean Air Act’s Prevention of Significant Deterioration requirements in connection with any new or modified major sources of GHG emissions. Although we believe our operations are currently in compliance with these obligations, EPA has continued to pursue additional GHG regulations, including the currently proposed Clean Power Plan for existing sources of GHGs in the power generating sector. In addition, several states have taken legal measures to reduce emissions of GHGs, including through the planned development of GHG emission inventories and/or regional GHG ‘‘cap and trade’’ programs. Although our facilities are not currently subject to any such program, the expansion or further adoption of such programs in jurisdictions where we operate could impose additional compliance obligations on our facilities. As a result, such programs could result in an increase in fuel or energy costs for our businesses or, if we are directly regulated, an additional cost to acquire necessary allowances. We cannot assure you that the costs of compliance with either the existing or future federal or State regulations will not materially and adversely affect our business, operating results and financial condition.

2

A substantial portion of the Alkali Chemicals business’ costs are attributable to transportation and freight costs. Increases in freight costs could increase our costs significantly and adversely affect our results of operations.

Most soda ash is sold inclusive of transportation costs, which make up a substantial portion of the total delivered cost to the customer. The Alkali Chemicals business transports its soda ash by rail or truck and ocean vessel. As a result, our business and financial results are sensitive to increases in rail freight, trucking and ocean vessel rates. Increases in transportation costs, including increases resulting from emission control requirements, port taxes and fluctuations in the price of fuel, could make soda ash a less competitive product for glass manufacturers when compared to glass substitutes or recycled glass, or could make the Alkali Chemicals business’ soda ash less competitive than soda ash produced by competitors that have other means of transportation or are located closer to their customers. We may be unable to pass on its freight and other transportation costs in full because market prices for soda ash are generally determined by supply and demand forces.

An increase in energy prices, or an interruption in our coal or natural gas supply, would negatively impact our competitive cost position when compared to other foreign and domestic soda ash producers.

The Alkali Chemicals business relies on two fuel sources as the main energy source in its soda ash production process: coal and natural gas. Natural gas prices, and to a lesser extent, coal prices have historically been volatile. The coal industry is under regulatory pressure in the United States, which depending on the direction of such regulations could affect the future availability and cost of coal used in our operations. We receive coal by rail and truck from a single mine in Western Wyoming under a long term contract. Any disruption at this coal mine or an unexpected increase in the costs of transporting coal to our facility could adversely affect our future results of operations. Furthermore, the price of natural gas could increase as a result of reduced domestic drilling and production activity. Drilling and production operations are subject to extensive federal, state, local and foreign laws and government regulations concerning, among other things, emissions of pollutants and greenhouse gases, hydraulic fracturing, and the handling of natural gas and other substances used in connection with natural gas operations, such as drilling fluids and wastewater. In addition, natural gas operations are subject to extensive federal, state and local taxation. More stringent legislation, regulation or taxation of natural gas drilling activity in the United States could directly curtail such activity or increase the cost of drilling, resulting in reduced levels of drilling activity and therefore increased natural gas prices.

Any material increase in energy prices could adversely impact our operations by making us less competitive with other soda ash producers. If U.S. energy prices were to increase to a level where foreign soda ash producers were able to improve their competitive position on a unit cost basis, this would negatively affect our competitive cost position.

Adverse developments in the end markets of the soda ash industry would adversely affect Alkali Chemicals results of operations.

The Alkali Chemicals business relies exclusively on the revenues generated from the production and sale of soda ash products. An adverse development in the market for soda ash in U.S. or foreign markets could have a significant adverse impact on the operations of the Alkali Chemicals business.

For the year ended December 31, 2014, approximately 90% of the Alkali Chemicals business’ soda ash was shipped via rail. Interruptions of service on this rail line could adversely affect the results of operations of Alkali Chemicals business.

For the year ended December 31, 2014, the Alkali Chemicals business shipped over 90% of its soda ash from its facility on a single rail line. Rail operations are subject to various risks that may result in a delay or lack of service at the Alkali Chemicals business facility, including mechanical problems, extreme weather conditions, work stoppages, labor strikes, terrorist attacks and operating hazards. Moreover, if our railcar provider’s financial condition was adversely affected, it could decide to cease or suspend service to the Alkali Chemicals business facility. If we are unable to ship soda ash by rail, it would be impracticable to ship all of our soda ash by truck and it would be cost-prohibitive to construct a rail connection to the closest alternative rail line. Any delay or failure in the rail services on which we rely could have a material adverse effect on our financial condition and results of operations.

A significant portion of the Alkali Chemicals business’ international sales of soda ash are to ANSAC, a U.S. export trade association, and therefore adverse developments at ANSAC or its customers, or in any of the markets in which the Alkali Chemicals business makes direct international sales, could adversely affect its ability to compete in certain international markets.

The Alkali Chemicals business, along with two other U.S. trona-based soda ash producers, utilizes ANSAC as its exclusive export vehicle for sales to customers in all countries excluding Canada, South Africa and members of the

3

European Community and European Free Trade Area, which provides us with the benefits of large purchases of soda ash and significant economies of scale in managing international sales and logistics. Because ANSAC makes sales to its end customers directly and then allocates a portion of such sales to each member, we do not have direct access to ANSAC’s customers and we have no direct control over the credit or other terms ANSAC extends to its customers. As a result, we are indirectly vulnerable to ANSAC’s customer relationships and the credit and other terms ANSAC extends to its customers. Any adverse change in ANSAC’s customer relationships could have a direct impact on ANSAC’s ability to make sales and our ability to make sales to ANSAC. In addition, to the extent ANSAC extends credit or other favorable terms to its end customers and those customers subsequently default under sales contracts or otherwise fail to perform, we would have no direct recourse against them.

Furthermore, from time to time international competition authorities have conducted inquiries into the potentially anticompetitive nature of ANSAC’s activities. In 2010, the Secretariat of Economic Law of the Ministry Justice of Brazil commenced an investigation into ANSAC’s activities in Brazil. Alkali Chemicals business and the two other members of ANSAC have been named in these investigations. An unfavorable outcome in any such investigation could result in our having to pay fines or penalties, either on behalf of Alkali Chemicals or through ANSAC, or otherwise adversely affect the ability of ANSAC to continue serving export markets. In the event of an unfavorable outcome in any such investigation, the withdrawal of one of the other two members of ANSAC or the dissolution of ANSAC, we would be forced to use alternative methods to facilitate additional direct export sales of soda ash, resulting in less favorable arrangements in respect of logistics or sales. Any of these developments could lead us to incur significant additional costs and may result in lower pricing for its export sales, which could have a negative impact on our results of operations and financial condition.

Unfavorable economic conditions may reduce demand for the products of the Alkali Chemicals business, which could adversely affect our results of operations.

Worldwide soda ash demand generally correlates to global economic growth generally. The U.S. economy and global capital and credit markets remain volatile. Worsening economic conditions or factors that negatively affect the economic health of the United States and other parts of the world into which the Alkali Chemicals business or ANSAC sells soda ash could reduce our revenues and adversely affect our results of operations. The lingering effects of the 2008-2009 global financial crisis and sovereign debt crises in Europe have led to a global economic slowdown, with the economies of those regions showing significant signs of weakness, resulting in greater volatility in the U.S. economy and in the global capital and credit markets. These markets have been experiencing disruption, including volatility in securities markets, diminished liquidity and credit availability, credit ratings downgrades, failure and potential failures of major financial institutions, unprecedented government support of financial institutions and high unemployment rates. Instability in consumer confidence and increased unemployment has increased concerns of prolonged economic weakness. These developments may adversely affect the ability of the Alkali Chemicals business’ customers to obtain financing to perform their obligations to the Alkali Chemicals business. In addition, the recent slowdown in the growth of China’s economy, if it persists, could have an adverse impact on the market conditions for U.S. soda ash. We believe that further deterioration of economic conditions or a prolonged period of economic weakness will have an adverse impact on our results of operations, business and financial condition.

Mining development, exploration and processing operations pose numerous hazards and uncertainties that may negatively affect our business.

Mining and processing operations involve many hazards and uncertainties, including, among other things:

| • | seismic activity; |

| • | ground failures; |

| • | industrial accidents; |

| • | environmental contamination or leakage; |

| • | fires and explosions; |

4

| • | unusual or unexpected rock formations or water conditions; |

| • | periodic interruptions due to inclement or hazardous weather conditions, floods or other acts of nature; and |

| • | mechanical equipment failure. |

These occurrences could damage or destroy our properties or production facilities, or result in personal injury or wrongful death claims, environmental damage to our properties or the properties of others, delays in, or prohibitions on, mining or processing, increased production costs, asset write downs, monetary losses and legal liability, which could have an adverse effect on our results of operations and financial condition. In particular, underground mining and related processing activities present inherent risks of injury to persons and damage to equipment. Our insurance policies provide limited coverage for some of these risks but will not fully cover these risks. Significant mine accidents could occur, potentially resulting in a mine shutdown or leading to liabilities, which could have a material adverse effect on our results of operations, financial condition and cash flows.

We may be unable to obtain, maintain or renew leases and permits necessary for our mining operations, which could adversely affect our results of operations.

Our facility and operations require us to obtain a number of permits that impose strict regulations on various environmental and operational matters in connection with mining trona ore and producing soda ash products. These include permits issued by various federal, state and local agencies and regulatory bodies. The permitting rules, and the interpretations of these rules, are complex, change frequently and are subject to discretionary interpretations by our regulators, all of which may make compliance difficult or impractical and may impair our existing operations or the development of future facilities. The public, including non-governmental organizations, environmental groups and individuals, have certain statutory rights to comment upon and submit objections to requested permits and environmental impact statements prepared in connection with applicable regulations and otherwise engage in the permitting process, including bringing citizen’s lawsuits to challenge the issuance or renewal of permits, the validity of environmental impact statements or the performance of mining activities. If permits are not issued or renewed in a timely fashion or at all or are conditioned in a manner that restricts our ability to conduct our operations economically, our cash flows may decline.

All of the Alkali Chemicals business’ reserves are held under leases with the State of Wyoming and the U.S. Bureau of Land Management and Anadarko Petroleum or its affiliates. As of December 31, 2014, leases covering more than 40% of the Alkali Chemicals business’ acreage were scheduled to expire in the next six years. If we are not able to renew such leases, it will have a material adverse effect on our results of operations.

Equipment upgrades, equipment failures and deterioration of assets may lead to production curtailments, shutdowns or additional expenditures.

Our operations depend upon critical equipment that require scheduled upgrades and maintenance and may suffer unanticipated breakdowns or failures. As a result, our mining operations and processing may be interrupted or curtailed, which could have a material adverse effect on our results of operations.

In addition, assets critical to our trona ore mining and soda ash production operations may deteriorate due to wear and tear or otherwise sooner than we currently estimate. Such deterioration may result in additional maintenance spending and additional capital expenditures. If these assets do not generate the amount of future cash flows that we expect, and we are not able to procure replacement assets in an economically feasible manner, our future results of operations may be materially and adversely affected.

If any of the equipment on which we depend were severely damaged or were destroyed by fire, abnormal wear and tear, flooding, or otherwise, we may be unable to replace or repair it in a timely manner or at a reasonable cost, which would impact our ability to produce and ship soda ash, which would have a material adverse effect our results of operations and financial condition.

5

|

KPMG LLP 1601 Market Street Philadelphia, PA 19103-2499 |

Independent Auditors’ Report

To the Management of FMC Corporation:

Report on the Financial Statements

We have audited the accompanying combined financial statements of the Alkali Chemicals Division of FMC Corporation, which comprise the combined balance sheets as of December 31, 2014 and 2013, and the related combined statements of operations, cash flows, and changes in divisional equity for each of the years in the three-year period ended December 31, 2014, and the related notes to the combined financial statements.

Management’s Responsibility for the Financial Statements

Management is responsible for the preparation and fair presentation of these combined financial statements in accordance with U.S. generally accepted accounting principles; this includes the design, implementation, and maintenance of internal control relevant to the preparation and fair presentation of combined financial statements that are free from material misstatement, whether due to fraud or error.

Auditors’ Responsibility

Our responsibility is to express an opinion on these combined financial statements based on our audits. We conducted our audits in accordance with auditing standards generally accepted in the United States of America and in accordance with the auditing standards of the Public Company Accounting Oversight Board (United States). Those standards require that we plan and perform the audit to obtain reasonable assurance about whether the combined financial statements are free from material misstatement.

An audit involves performing procedures to obtain audit evidence about the amounts and disclosures in the combined financial statements. The procedures selected depend on the auditors’ judgment, including the assessment of the risks of material misstatement of the combined financial statements, whether due to fraud or error. In making those risk assessments, the auditor considers internal control relevant to the entity’s preparation and fair presentation of the combined financial statements in order to design audit procedures that are appropriate in the circumstances, but not for the purpose of expressing an opinion on the effectiveness of the entity’s internal control. Accordingly, we express no such opinion. An audit also includes evaluating the appropriateness of accounting policies used and the reasonableness of significant accounting estimates made by management, as well as evaluating the overall presentation of the combined financial statements.

We believe that the audit evidence we have obtained is sufficient and appropriate to provide a basis for our audit opinion.

Opinion

In our opinion, the combined financial statements referred to above present fairly, in all material respects, the financial position of the Alkali Chemicals Division of FMC Corporation as of December 31, 2014 and 2013, and the results of its operations and its cash flows for each of the years in the three-year period ended December 31, 2014 in accordance with U.S. generally accepted accounting principles.

| KPMG LLP is a Delaware limited liability partnership, the U.S. member firm of KPMG International Cooperative (“KPMG International”), a Swiss entity. |

6

Other Matter

Our audits were conducted for the purpose of forming an opinion on the combined financial statements as a whole. The Schedule of Valuation and Qualifying Accounts and Reserves is presented for purposes of additional analysis and is not a required part of the combined financial statements. Such information is the responsibility of management and was derived from and relates directly to the underlying accounting and other records used to prepare the combined financial statements. The information has been subjected to the auditing procedures applied in the audit of the combined financial statements and certain additional procedures, including comparing and reconciling such information directly to the underlying accounting and other records used to prepare the combined financial statements or to the combined financial statements themselves, and other additional procedures in accordance with auditing standards generally accepted in the United States of America and in accordance with the auditing standards of the Public Company Accounting Oversight Board (United States). In our opinion, the information is fairly stated in all material respects in relation to the combined financial statements as a whole.

Philadelphia, Pennsylvania

February 26, 2015

7

Alkali Chemicals Division

(A Division of FMC Corporation)

Combined Statements of Operations

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| Revenue |

$ | 782.8 | $ | 751.3 | $ | 738.1 | ||||||

|

|

|

|

|

|

|

|||||||

| Costs and Expenses |

||||||||||||

| Costs of sales |

(619.6 | ) | (611.0 | ) | (565.1 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Gross Margin |

163.2 | 140.3 | 173.0 | |||||||||

|

|

|

|

|

|

|

|||||||

| Selling, general and administrative expenses |

(37.5 | ) | (36.9 | ) | (38.3 | ) | ||||||

| Research and development expenses |

(2.0 | ) | (2.1 | ) | (1.6 | ) | ||||||

| Restructuring (expense) income |

(0.8 | ) | 2.6 | — | ||||||||

|

|

|

|

|

|

|

|||||||

| Total costs and expenses |

(659.9 | ) | (647.4 | ) | (605.0 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Income from operations before equity in loss of affiliate, interest expense and income taxes |

122.9 | 103.9 | 133.1 | |||||||||

| Equity in loss of affiliate |

(1.1 | ) | (1.7 | ) | (1.5 | ) | ||||||

| Interest expense |

(4.8 | ) | (4.8 | ) | (4.8 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Income from operations before income taxes |

117.0 | 97.4 | 126.8 | |||||||||

| Provision for income taxes |

(24.2 | ) | (18.9 | ) | (27.4 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Net income |

92.8 | 78.5 | 99.4 | |||||||||

|

|

|

|

|

|

|

|||||||

| Less: Net income attributable to noncontrolling interests |

(5.2 | ) | (7.6 | ) | (15.0 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Net income attributable to division |

$ | 87.6 | $ | 70.9 | $ | 84.4 | ||||||

|

|

|

|

|

|

|

|||||||

The accompanying notes are an integral part of these combined financial statements.

8

Alkali Chemicals Division

(A Division of FMC Corporation)

Combined Balance Sheets

| December 31, | ||||||||

| (in Millions) |

2014 | 2013 | ||||||

| ASSETS |

||||||||

| Current assets |

||||||||

| Cash and cash equivalents |

$ | — | $ | — | ||||

| Trade receivables, net of allowance of $0.4 in 2014 and $0.1 in 2013 |

84.9 | 89.1 | ||||||

| Receivables from related parties and affiliates, net |

71.2 | 60.1 | ||||||

| Inventories |

26.5 | 23.3 | ||||||

| Prepaid and other current assets |

20.9 | 20.8 | ||||||

| Deferred income taxes |

0.6 | 0.4 | ||||||

|

|

|

|

|

|||||

| Total current assets |

204.1 | 193.7 | ||||||

| Equity method investment |

19.6 | 19.5 | ||||||

| Property, plant and equipment, net |

374.2 | 361.9 | ||||||

| Other assets |

3.4 | 4.2 | ||||||

|

|

|

|

|

|||||

| Total assets |

$ | 601.3 | $ | 579.3 | ||||

|

|

|

|

|

|||||

| LIABILITIES AND DIVISIONAL EQUITY |

||||||||

| Current liabilities |

||||||||

| Accounts payable, trade and other |

$ | 58.3 | $ | 50.1 | ||||

| Accrued and other current liabilities |

32.5 | 27.3 | ||||||

| Accrued customer rebates |

1.6 | 2.3 | ||||||

|

|

|

|

|

|||||

| Total current liabilities |

92.4 | 79.7 | ||||||

| Long-term debt |

90.0 | 90.0 | ||||||

| Deferred income taxes |

36.1 | 31.5 | ||||||

| Other long-term liabilities |

1.3 | 1.3 | ||||||

| Commitments and contingent liabilities (Note 14) |

||||||||

| Divisional equity |

||||||||

| Net investment of parent |

381.5 | 352.4 | ||||||

| Noncontrolling interests |

— | 24.4 | ||||||

|

|

|

|

|

|||||

| Total divisional equity |

381.5 | 376.8 | ||||||

|

|

|

|

|

|||||

| Total liabilities and net divisional equity |

$ | 601.3 | $ | 579.3 | ||||

|

|

|

|

|

|||||

The accompanying notes are an integral part of these combined financial statements.

9

Alkali Chemicals Division

(A Division of FMC Corporation)

Combined Statements Of Cash Flows

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| Cash provided by operating activities: |

||||||||||||

| Net income |

$ | 92.8 | $ | 78.5 | $ | 99.4 | ||||||

| Adjustments from net income to cash provided (required) by operating activities: |

||||||||||||

| Depreciation and amortization |

37.7 | 39.2 | 38.3 | |||||||||

| Equity in loss of affiliates |

1.1 | 1.7 | 1.5 | |||||||||

| Restructuring expense (income) |

0.8 | (2.6 | ) | — | ||||||||

| Deferred income taxes |

4.4 | (0.4 | ) | 5.2 | ||||||||

| Share-based compensation |

1.1 | 1.0 | 1.3 | |||||||||

| Net (gain)/loss from disposals and impairment of property, plant and equipment |

0.5 | (0.2 | ) | 2.1 | ||||||||

| Changes in operating assets and liabilities: |

||||||||||||

| Trade receivables, net |

4.2 | (16.0 | ) | 1.8 | ||||||||

| Receivables from related parties and affiliates, net |

(11.1 | ) | 7.9 | (15.1 | ) | |||||||

| Inventories |

(3.2 | ) | 3.2 | (6.9 | ) | |||||||

| Prepaid and other assets |

(0.1 | ) | (2.9 | ) | 3.0 | |||||||

| Accounts payable |

4.5 | (3.1 | ) | (4.3 | ) | |||||||

| Accrued and other liabilities |

4.2 | (2.2 | ) | (7.7 | ) | |||||||

| Accrued customer rebates |

(0.7 | ) | 0.4 | (0.7 | ) | |||||||

|

|

|

|

|

|

|

|||||||

| Cash provided by operating activities |

136.2 | 104.5 | 117.9 | |||||||||

|

|

|

|

|

|

|

|||||||

| Cash required by investing activities: |

||||||||||||

| Capital expenditures |

$ | (45.8 | ) | $ | (57.2 | ) | $ | (55.9 | ) | |||

| Proceeds from disposal of property, plant and equipment |

— | 3.2 | 0.5 | |||||||||

| Investments in nonconsolidated affiliate |

(1.2 | ) | (6.4 | ) | (13.8 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Cash required by investing activities |

(47.0 | ) | (60.4 | ) | (69.2 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Cash required by financing activities: |

||||||||||||

| Acquisitions of noncontrolling interests(1) |

(95.7 | ) | (80.0 | ) | — | |||||||

| Dividends paid to noncontrolling interests |

(3.0 | ) | (9.9 | ) | (15.4 | ) | ||||||

| Net change in net investment of parent(2) |

9.5 | 45.8 | (33.3 | ) | ||||||||

|

|

|

|

|

|

|

|||||||

| Cash required by financing activities |

(89.2 | ) | (44.1 | ) | (48.7 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Increase (decrease) in cash and cash equivalents |

— | — | — | |||||||||

| Cash and cash equivalents, beginning of period |

— | — | — | |||||||||

|

|

|

|

|

|

|

|||||||

| Cash and cash equivalents, end of period |

$ | — | $ | — | $ | — | ||||||

|

|

|

|

|

|

|

|||||||

| (1) | See the Combined Statements of Changes in Divisional Equity for more information. |

| (2) | Net change in net investment of parent excludes non-cash transactions associated with share-based compensation totaling $1.1 million, $1.0 million and $1.3 million for the years ended December 31, 2014, 2013 and 2012, respectively. |

Accrued additions to property, plant and equipment, net at December 31, 2014, 2013 and 2012 were $11.8 million, $8.1 million and $14.5 million, respectively.

The accompanying notes are an integral part of these combined financial statements.

10

Alkali Chemicals Division

(A Division of FMC Corporation)

Combined Statements of Changes in Divisional Equity

| (in Millions) |

Net Investment of Parent |

Non-controlling Interest |

Total | |||||||||

| Balance, January 1, 2012 |

$ | 237.5 | $ | 51.9 | $ | 289.4 | ||||||

| Net income |

84.4 | 15.0 | 99.4 | |||||||||

| Dividends declared and paid |

— | (15.4 | ) | (15.4 | ) | |||||||

| Net change in net investment of parent |

(32.0 | ) | — | (32.0 | ) | |||||||

|

|

|

|

|

|

|

|||||||

| Balance, December 31, 2012 |

$ | 289.9 | $ | 51.5 | $ | 341.4 | ||||||

| Net income |

70.9 | 7.6 | 78.5 | |||||||||

| Dividends declared and paid |

— | (9.9 | ) | (9.9 | ) | |||||||

| Acquisition noncontrolling interest(1) |

(55.2 | ) | (24.8 | ) | (80.0 | ) | ||||||

| Net change in net investment of parent |

46.8 | — | 46.8 | |||||||||

|

|

|

|

|

|

|

|||||||

| Balance, December 31, 2013 |

$ | 352.4 | $ | 24.4 | $ | 376.8 | ||||||

| Net income |

87.6 | 5.2 | 92.8 | |||||||||

| Dividends declared and paid |

— | (3.0 | ) | (3.0 | ) | |||||||

| Acquisition noncontrolling interest(2) |

(69.1 | ) | (26.6 | ) | (95.7 | ) | ||||||

| Net change in net investment of parent |

10.6 | — | 10.6 | |||||||||

|

|

|

|

|

|

|

|||||||

| Balance, December 31, 2014 |

$ | 381.5 | $ | — | $ | 381.5 | ||||||

|

|

|

|

|

|

|

|||||||

| (1) | Represents the purchase of Nippon Sheet Glass’s (“NSG”) 6.25 percent equity in FMC Wyoming Corporation (“FMC WY”) for $80.0 million, which increased our ownership in FMC WY from 87.50 percent to 93.75 percent. |

| (2) | Represents the purchase of the remaining 6.25 percent equity in FMC WY for $95.7 million, which increased our ownership in FMC WY from 93.75 percent to 100 percent. |

The accompanying notes are an integral part of these combined financial statements.

11

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

| Note 1: | Description of the Business |

The accompanying combined financial statements include the historical accounts of Alkali Chemicals Division (“Alkali”, “We”, “Us”, or “Our”) of FMC Corporation (the “Parent” or “FMC”), a publicly traded company incorporated in Delaware (United States). On September 8, 2014, FMC publicly announced a plan to divest of Alkali (the “Transaction”).

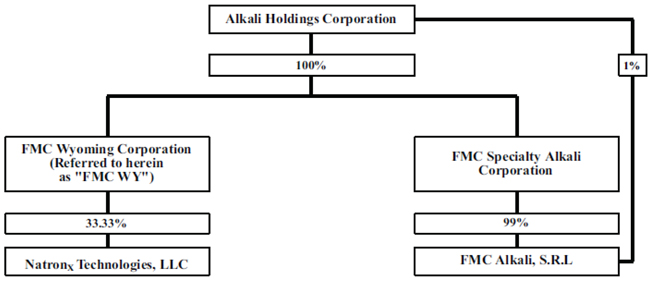

In preparation for the Transaction, effective January 1, 2015, FMC reorganized the legal entities comprising Alkali under a holding company named Alkali Holdings Corporation (“AHC”) and transferred certain liabilities and the employees of Alkali to AHC. Subsequently, certain assets of Alkali were also transferred to AHC. AHC, a wholly-owned subsidiary of FMC, was incorporated under Delaware law on October 21, 2014. AHC did not own the legal entities comprising Alkali during the periods presented in the accompanying combined financial statements.

The chart below shows the legal structure of Alkali subsequent to January 1, 2015:

On February 3, 2015, FMC entered into a definitive agreement to sell AHC to a wholly owned subsidiary of Tronox Limited for $1.64 billion. The Transaction is expected to close in the first quarter of 2015. See Note 16 within these combined financial statements for additional information related to the sale of AHC.

Nature of Operations

Our operations include the mining of trona for the production of natural soda ash and its derivatives: sodium bicarbonate, sodium sesquicarbonate and caustic soda (collectively referred to as “alkali-products”). We provide our alkali-products to a variety of industries such as glass manufacturing, water treatment, pulp and paper, textiles, food and pharmaceutical and cosmetics. We also sell our alkali-products to various domestic and international customers and to the American Natural Soda Ash Corporation (“ANSAC”) which is our primary export customer. ANSAC is a third-party nonprofit corporation whose purpose is to promote export sales of U.S. produced soda ash in conformity with the Webb-Pomerene Act. All mining and processing activities take place in our facility located in the Green River Basin of Wyoming, United States. See Note 5 within these combined financial statements for additional information related to ANSAC.

12

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

| Note 2: | Basis of Presentation |

The accompanying combined financial statements have been prepared in accordance with accounting principles generally accepted in the United States (“U.S. GAAP”). The accompanying combined financial statements include the net assets, liabilities, revenues and expenses of the entities that comprise Alkali, as carved out from the historical results of operations, cost basis of the assets and liabilities, costs incurred by and cash flows of FMC for these entities using both specific identification and the allocation methodologies described below.

As the separate legal entities that comprise Alkali were not historically held by a single legal entity, net investment of parent is shown in lieu of shareholders’ equity in these combined financial statements. With the exception of certain sales and receivables, intercompany balances and transactions between Alkali and FMC have been eliminated and included in net investment of parent. Intracompany balances and accounts within Alkali have been eliminated. Net investment of parent represents FMC’s interest in the recorded net assets of Alkali.

During the periods presented, Alkali functioned as part of the larger group of companies controlled by FMC, and accordingly, FMC performed certain corporate overhead functions for Alkali. Therefore, certain costs related to Alkali have been allocated from the Parent. These allocated costs are primarily related to certain governance and corporate functions such as legal, investor relations, communications and corporate facilities and administration. The costs associated with these services and support functions have been allocated to Alkali primarily based on a general shared services methodology, which was calculated based on a blend of personnel count, net property, plant and equipment, and cost of sales. The net costs allocated for these functions are included in selling, general and administrative expenses within the combined statements of operations.

In addition to allocated costs, balances related to industrial revenue bonds have been assigned and certain assets have been allocated to Alkali from FMC based on methodologies suited to the nature of the specific assets and liabilities.

We believe the assumptions and allocations are reasonable. The expense and cost allocations have been determined on a basis considered to be a reasonable reflection of the utilization of services provided to or the benefit received by Alkali during the periods relative to the total costs incurred by FMC. Additionally, the assets and liabilities assigned from FMC have been deemed attributable to, and reflective of the historical operations of, Alkali; however, the amounts recorded may not be representative of the amounts that would have been incurred had Alkali been an entity that operated independently of FMC. Consequently, these combined financial statements may not be indicative of Alkali’s future performance and do not necessarily reflect what its results of operations, financial position and cash flows would have been had Alkali operated as a separate entity apart from FMC during the periods presented. See Note 5 within these combined financial statements for more information.

| Note 3: | Summary of Significant Accounting Policies |

Estimates and assumptions. In preparing the combined financial statements in conformity with U.S. GAAP we are required to make estimates and assumptions that affect the reported amounts of assets and liabilities and disclosures of contingent assets and liabilities at the date of the combined financial statements and the reported amounts of revenue and expenses during the reporting period. Actual results are likely to differ from those estimates, but we do not believe such differences will materially affect our financial position, results of operations, or cash flows.

Cash and cash equivalents. We consider investments in all liquid debt instruments with original maturities of three months or less to be cash equivalents. Historically we have participated in and relied upon FMC’s cash management systems to manage working capital and investing activities such as capital expenditures.

Trade receivables, net of allowance. Trade receivables consist of amounts owed to us from customer sales and are recorded when revenue is recognized. The allowance for trade receivables represents our best estimate of the probable losses associated with potential customer defaults. In developing our allowance for trade receivables, we utilize a two stage process which includes calculating a general formula to develop an allowance to appropriately

13

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

address the uncertainty surrounding collection risk of our entire portfolio and specific allowances for customers where the risk of collection has been reasonably identified either due to liquidity constraints or disputes over contractual terms and conditions.

Our method of calculating the general formula consists of estimating the recoverability of trade receivables based on historical experience, current collection trends, and external business factors such as economic factors, including regional bankruptcy rates, and political factors. Our analysis of trade receivable collection risk is performed quarterly, and the allowance is adjusted accordingly. The allowance for trade receivables was $0.4 million at December 31, 2014 and $0.1 million at December 31, 2013, respectively. The provision to the allowance for trade receivables charged against operations was $0.7 million, $0.6 million, and zero for the years ended December 31, 2014, 2013, and 2012 respectively.

Inventories. Inventories are stated at the lower of cost or market value. Inventory costs include those costs directly attributable to products before sale, including all manufacturing overhead but excluding distribution costs. All inventories, excluding materials and supplies, are determined on a last-in, first-out (“LIFO”) basis and our remaining inventories are recorded on a first-in, first-out (“FIFO”) basis.

Prepaid and other current assets. Prepaid expenses and other current assets primarily consist of prepaid freight and transportation credits.

Equity method investment. Our investment of 33 1/3 percent in NatronX Technologies, LLC (“NatronX”) is accounted for using the equity method. Under the equity method, the original investment in NatronX was recorded at cost and is adjusted by our share of undistributed earnings and losses. The fair value of our investment in NatronX exceeds its carrying value at December 31, 2014 and 2013.

Property, plant and equipment. We record property, plant and equipment at cost. Depreciation is provided principally on the straight-line basis over the estimated useful lives of the assets (land improvements—20 years, mineral rights—40 years, buildings—20 to 40 years, mine and development costs— three to 15 years, and machinery and equipment—three to 15 years). Gains and losses are reflected in income upon sale or retirement of assets. Expenditures that extend the useful lives of property, plant and equipment or increase productivity are capitalized. Ordinary repairs and maintenance are expensed as incurred through operating expense.

Capitalized interest. Capitalized interest balances as of December 31, 2014 and 2013 of $18.6 million and $17.8 million, respectively, have been assigned to us by the Parent. These balances have been included with our machinery and equipment fixed assets within our property, plant and equipment, net balance on our combined balance sheets. These assigned balances were associated with the construction of certain long-lived assets, which were funded by the Parent, and have been capitalized as part of the cost of those assets. During the years ended December 31, 2014, 2013, and 2012 we capitalized interest costs of $2.2 million, $1.1 million, and $2.4 million, respectively. Capitalized interest is amortized over the assets’ estimated useful lives.

Impairments of long-lived assets. We review the recovery of the net book value of long-lived assets whenever events and circumstances indicate that the net book value of an asset may not be recoverable from the estimated undiscounted future cash flows expected to result from its use and eventual disposition. In cases where undiscounted expected future cash flows are less than the net book value, we recognize an impairment loss equal to an amount by which the net book value exceeds the fair value of the asset. Long-lived assets to be disposed of are reported at the lower of carrying amount or fair value less cost to sell. There were no impairments during 2014 and 2013. During the year ended December 31, 2012, we recorded a charge of $1.6 million to write down, to fair value, decommissioned mining equipment.

Asset retirement obligations. We record asset retirement obligations (“AROs”) at fair value from the time the original assets were placed into service. The associated AROs are capitalized as part of the carrying amount of related long-lived assets. In future periods, the liability is accreted to its present value and the capitalized cost is depreciated over the useful life of the related asset. We also adjust the liability for changes resulting from the passage of time and/or revisions to the timing or the amount of the original estimate. Upon retirement of the long-lived asset, we either settle the obligation for its recorded amount or incur a gain or loss.

14

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

Financial instruments. Our financial instruments are trade receivables, affiliate receivables, net and trade payables. These financial instruments are recorded at cost, which approximates fair value due to the short-term nature of the instruments. Alkali does not have any off-balance sheet financing arrangements.

Restructuring income and expense. We continually perform strategic reviews and assess the return on our business. This sometimes results in a plan to restructure the operations of our business. We record an accrual for severance and other exit costs under the provisions of the relevant accounting guidance. During the years ended December 31, 2014, 2013 and 2012 we recognized restructuring expense of $0.8 million, a gain of $2.6 million, and zero, respectively. The recognized gain during the year ended December 31, 2013 was due to the sale of a fully depreciated facility that was included in an earlier business restructuring. We expect no further material cash outflows regarding this transaction.

Revenue recognition. We recognize revenue when the earnings process is complete, which is generally upon transfer of title. This transfer typically occurs either upon shipment to the customer or upon receipt by the customer. In all cases, we apply the following criteria in recognizing revenue: persuasive evidence of an arrangement exists, delivery has occurred, the selling price is fixed or determinable and collection is reasonably assured. Rebates due to customers are accrued as a reduction of revenue in the same period that the related sales are recorded based on the contract terms.

We record amounts billed for shipping and handling fees as revenue. Costs incurred for shipping and handling are recorded as costs of sales on the combined statements of operations.

Research and development. Research and development costs are expensed as incurred.

Income and other taxes. For purposes of the combined financial statements, the income tax expense and deferred tax balances have been estimated as if we filed income tax returns on a basis separate from FMC. Allocations of current income taxes are payable to FMC in the period the related income taxes were recorded. Uncertain tax positions are accounted for in accordance with U.S. GAAP accounting guidance for uncertainty in income taxes.

We recognize deferred tax assets and deferred liabilities for deductible temporary differences as well as deferred tax assets for operating loss carry forwards, and tax credit carry forwards. Deferred tax assets are reduced by a valuation allowance if it is more likely than not that some portion, or all, of the deferred tax assets will not be realized.

Segment information. We operate as one reportable segment based on the commonalities among our products and services and the manner in which we review and evaluate operating performance. Segment disclosures and geographical information are included in Note 15 within these combined financial statements. Geographic segment revenue is based on the location of our customers.

Stock-based compensation. We do not currently sponsor any stock compensation plans. Instead, our eligible employees participated in the Parent’s sponsored stock-based compensation plans. Prior to the consummation of the Transaction, our employees will continue to participate in the Parent’s stock-based compensation plans and we will recognize stock-based compensation expense based on the awards granted to our employees. Stock-based compensation expense for the years ended December 31, 2014, 2013 and 2012 has been recognized for all share options and other equity-based arrangements. Share-based compensation cost is measured at the date of grant, based on the fair value of the award, and is recognized over the employee’s requisite service period.

Pension and other postretirement benefits. FMC provides a range of benefits, including pensions, postretirement and postemployment benefits to eligible current and former employees, of which certain of our employees participate. Expenses associated with our employees’ participation in these plans for the years ended December 31, 2014, 2013 and 2012 have been allocated to us and included within the combined statement of operations.

15

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

| Note 4: | Recently Issued and Adopted Accounting Pronouncements and Regulatory Items |

New accounting guidance and regulatory items

In February 2015, the Financial Accounting Standards Board (“FASB”) issued ASU 2015-02, Consolidation: Amendments to the Consolidation Analysis. This new standard changes the consolidation evaluation for entities that are required to evaluate whether they should consolidate certain legal entities. We are required to adopt this standard in the first quarter of 2016. Early adoption is permitted. The standard permits the use of a modified retrospective approach by recording a cumulative-effect adjustment to equity as of the beginning of the fiscal year of adoption, or a reporting entity may also apply the amendments retrospectively. We are evaluating the effect that ASU 2015-02 will have on our consolidated financial statements. We have not yet completed the assessment to determine the effect of the standard on our ongoing financial reporting.

Revenue from Contracts with Customers

In May 2014, the Financial Accounting Standards Board (“FASB”) issued ASU 2014-09, Revenue from Contracts with Customers, which requires an entity to recognize the amount of revenue to which it expects to be entitled for the transfer of promised goods or services to customers. This new guidance will replace most existing revenue recognition guidance in U.S. GAAP when it becomes effective. We are required to adopt this standard on January 1, 2017. Early application is not permitted. The standard permits the use of either the retrospective or cumulative effect transition method. We are evaluating the effect that ASU 2014-09 will have on our combined financial statements and related disclosures. We have not yet selected a transition method nor have we determined the effect of the standard on our ongoing financial reporting.

| Note 5: | Agreements and Transactions with Related Parties and Affiliates |

Shared Services and Corporate Costs

During the periods presented, we benefited from certain governance and corporate functions provided by Parent as discussed in Note 2. The combined statements of operations include allocations for such services of $16.2 million, $18.2 million and $17.1 million for the years ended December 31, 2014, 2013 and 2012, respectively. These allocations are included within selling, general and administrative expenses within the combined financial statements.

All of our accounts payable processing is handled by FMC and we are charged the costs of these services through our affiliate accounts. Trade payables represent accounts payable that have not been paid by FMC as of December 31, 2014 and 2013.

Cash Management, Financing and Financial Instruments

The structure of our Parent’s risk management strategy is managed on a FMC consolidated basis. Realized gains and losses associated with derivative contracts entered into on our behalf are allocated to us by our Parent. As of December 31, 2014, our Parent had entered into natural gas contacts through December 31, 2015 with a fair market value of approximately $4.3 million asset on our behalf. For the years ended December 31, 2014, 2013, and 2012 our Parent allocated approximately $1.3 million gain, zero, and $7.0 million loss, respectively, related to natural gas contracts. These amounts have been included within cost of sales in the accompanying combined financial statements. There were no foreign exchange contracts outstanding as of December 31, 2014 entered into by our Parent on our behalf. For the years ended December 31, 2014, 2013, and 2012 our Parent allocated losses of approximately $0.1 million, $0.2 million, and $0.5 million, respectively, related to foreign exchange contracts. These amounts are included within cost of sales or selling, general, and administrative depending on the nature of the contract.

16

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

FMC uses a centralized approach to cash management and financing of operations. Our cash was available for use and was regularly “swept” by FMC at its discretion. FMC also funds our operating and investing activities as needed. Transfers of cash both to and from FMC are included within net investment of parent on the combined balance sheets. Included as part of the centralized cash management services are risk management strategies, which minimize the exposure to our cash flow over time, caused by changes in commodity and currency exchange rates.

With the exception of $90.0 million of Sweetwater County, Wyoming industrial revenue bonds issued specifically for the use of Alkali, FMC has issued debt for general corporate purposes and acquisitions. In no instance is this debt guaranteed by, or will be assumed by Alkali. Additionally, none of this debt has been secured by the assets of Alkali. With the exception of the aforementioned $90.0 million industrial revenue bonds, none of FMC’s debt is directly attributable to us, and, therefore, no such amount has been assigned to and recognized in these combined financial statements.

Contractual Agreements of the Parent

We benefit from certain contractual agreements of FMC, or with other businesses of FMC, to utilize certain services and assets, such as railcars for the distribution of finished goods throughout the U.S. The contract prices associated with these services and assets may not be transferable to another party. The costs associated with these contractual agreements have been included within the combined financial statements.

Agreements and Transactions with Affiliates

We had a soda ash supply agreement with Nippon Sheet Glass Co. Ltd (“NSG”) and its approved affiliates, which was renewed on June 30, 2005 for the first of two successive automatic ten-year renewal periods. This soda ash agreement was terminated by NSG subsequent to FMC’s purchase of NSG’s ownership in FMC WY in 2013.

We also have a soda ash supply agreement with FMC. Under this agreement, we have committed to supply soda ash to FMC and its approved affiliates. The agreement was renewed on June 30, 2005 for the first of two successive automatic ten-year renewal periods. FMC also has the ability to renew in ten-year increments thereafter. There were also other affiliate receivables from related parties and affiliates related to the transactions with FMC in the normal course of business exclusive of soda ash sales. Revenue from the sale of soda ash to FMC and its affiliates is provided in the table below. Sales to affiliates are at a market-based price, which is reset at least annually.

We hold a membership in ANSAC, which is responsible for promoting and increasing the use and sale of soda ash and other refined or processed sodium products produced. Certain sales and marketing costs incurred by ANSAC are charged directly to us. Selling, general and administrative expenses also include amounts charged to us by ANSAC principally consisting of salaries, benefits, office supplies, professional fees, travel, rent and certain other costs. These transactions do not necessarily represent arm’s length transactions and may not represent all costs if we operated on a stand-alone basis. The total costs charged to us for the years ended December 31, 2014, 2013 and 2012 are as follows:

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| FMC – shared services and corporate costs |

$ | 16.2 | $ | 18.2 | $ | 17.1 | ||||||

| ANSAC |

3.3 | 2.8 | 2.0 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total related parties and affiliates selling, general and administrative expenses(1) |

$ | 19.5 | $ | 21.0 | $ | 19.1 | ||||||

|

|

|

|

|

|

|

|||||||

| (1) | Amounts included in selling, general and administrative expenses within the combined statements of operations. |

17

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

Net revenue from related parties and affiliates for the years ended December 31, 2014, 2013 and 2012 are as follows:

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| FMC |

$ | 3.8 | $ | 7.2 | $ | 5.8 | ||||||

| NatronX Technologies LLC |

1.6 | 4.3 | 5.2 | |||||||||

| Nippon Sheet Glass Co. Ltd(1) |

— | 5.2 | 9.9 | |||||||||

| ANSAC |

260.0 | 210.9 | 227.5 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total related parties and affiliates net sales(2) |

$ | 265.4 | $ | 227.6 | $ | 248.4 | ||||||

|

|

|

|

|

|

|

|||||||

| (1) | During the first quarter of 2013, we purchased all of NSG’s shares in FMC WY. |

| (2) | Amounts included in revenue within our combined statements of operations. |

Net receivables from related parties and affiliates, net as of December 31, 2014 and 2013 are as follows:

| December 31, | ||||||||

| (in Millions) |

2014 | 2013 | ||||||

| FMC |

$ | 2.5 | $ | 2.4 | ||||

| NatronX Technologies LLC |

1.0 | 0.8 | ||||||

| ANSAC(1) |

67.7 | 56.9 | ||||||

|

|

|

|

|

|||||

| Total receivables from related parties and affiliates, net |

$ | 71.2 | $ | 60.1 | ||||

|

|

|

|

|

|||||

| (1) | Includes $0.3 million and $0.4 million of payables due to ANSAC as of December 31, 2014 and 2013, respectively. |

| Note 6: | Equity Method Investments |

In 2011 we, in conjunction with Church & Dwight and TATA Chemicals (Soda Ash) Partners, formed NatronX. We hold a 33 1/3 percent ownership interest in NatronX. The joint venture engages in the manufacturing and marketing of sodium-based, dry absorbents for air pollution control in electric utility and industrial boiler operations. NatronX is currently in the process of completing a major plant construction project to build a beneficiated milled trona facility. The facility’s expected total cost is approximately $60 million and is projected to be completed by mid-2015.

We contributed $1.2 million, $6.4 million and $13.8 million during the years ended December 31, 2014, 2013 and 2012, respectively, to NatronX. During the years ended December 31, 2014, 2013 and 2012 we recognized $1.1 million, $1.7 million and $1.5 million in losses associated with NatronX. NatronX is still in its development stage and as a result since its formation has incurred losses associated with its start-up. Although NatronX is operating at a cumulative net loss, we performed an impairment analysis at December 31, 2014 and 2013 for which we have concluded that our investment in NatronX is still recoverable. As a result we do not believe that any impairment of our investment is deemed necessary. Our investment balance at December 31, 2014 and 2013 of $19.6 million and $19.5 million, respectively, is included within equity method investments in the combined balance sheets.

18

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

| Note 7: | Inventories |

| December 31, | ||||||||

| (in Millions) |

2014 | 2013 | ||||||

| Finished goods |

$ | 14.5 | $ | 13.9 | ||||

| Materials and supplies |

13.4 | 13.6 | ||||||

| Stockpiled ore |

10.3 | 6.9 | ||||||

|

|

|

|

|

|||||

| FIFO inventory |

38.2 | 34.4 | ||||||

| Less: Excess of FIFO cost over LIFO cost(1) |

(11.7 | ) | (11.1 | ) | ||||

|

|

|

|

|

|||||

| Net inventories |

$ | 26.5 | $ | 23.3 | ||||

|

|

|

|

|

|||||

| (1) | Inventories determined on a LIFO basis of accounting are finished goods and stockpiled ore. |

| Note 8: | Property, Plant and Equipment, Net |

| Year Ended December 31, |

||||||||

| (in Millions) |

2014 | 2013 | ||||||

| Land and land improvements |

$ | 80.2 | $ | 74.2 | ||||

| Mineral rights |

31.4 | 31.4 | ||||||

| Buildings |

89.0 | 88.4 | ||||||

| Mine and development costs |

29.0 | 27.3 | ||||||

| Machinery and equipment |

825.7 | 801.2 | ||||||

|

|

|

|

|

|||||

| Total cost |

$ | 1,055.3 | $ | 1,022.5 | ||||

|

|

|

|

|

|||||

| Accumulated depreciation(1) |

(743.9 | ) | (725.5 | ) | ||||

| Construction in progress |

62.8 | 64.9 | ||||||

|

|

|

|

|

|||||

| Property, plant and equipment, net |

$ | 374.2 | $ | 361.9 | ||||

|

|

|

|

|

|||||

| (1) | Depreciation expense was $36.8 million, $38.0 million and $35.5 million for the years ended December 31, 2014, 2013 and 2012, respectively. |

| Note 9: | Asset Retirement Obligations |

Our AROs primarily consist of our mine reclamation obligations. Our obligations under the mine reclamation obligation, among other things, is to return the surface of the mine in the Green River Basin in Wyoming back to its original state before mining operations began. As a result, we are required by the Wyoming Department of Environmental Quality (“WyDEQ”) to provide financial security associated with the cost to satisfy our obligations pertaining to our mining operations in the Green River Basin.

We provide this financial security via a “self-bond” the value of which at December 31, 2014 was approximately $73 million. The self-bond value is based on the amount we would need to pay the State of Wyoming for

19

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

reclamation costs if we ceased mining operations currently. The amount of this self-bond is subject to change upon periodic re-evaluation by the Land Quality Division. Under the “self-bonding” program, we or our Parent are entitled to guarantee our obligation as long as either party meets the WyDEQ’s requirements for the financial strength and ability to pay. In 2013, our Parent, began to guarantee these obligations on our behalf to meet the WyDEQ’s financial strength requirements. During the years ended December 31, 2014 and 2013, we paid $0.8 million and $0.7 million to our Parent for this guarantee.

We have recognized the present value of our mine reclamation obligation as well as other AROs associated with our operations on our combined balance sheets. The balance of these AROs was $1.1 million at both December 31, 2014 and 2013. Accretion expense associated with our AROs was not considered material in the periods presented.

| Note 10: | Income Taxes |

Taxable income and/or loss generated by us have been included in the consolidated federal income tax returns of FMC with all income tax payments made by the Parent to the taxing authorities. FMC has allocated income taxes to us in the accompanying combined financial statements as if we were held in a separate corporation which filed separate income tax returns. FMC believes the assumptions underlying the allocation of income taxes on a separate return basis are reasonable. However, the amounts allocated for income taxes in the accompanying combined financial statements are not necessarily indicative of the actual amount of income taxes that would have been recorded had we been held within a separate stand-alone entity.

The provision (benefit) for income taxes attributable to income consisted of:

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| Current |

$ | 19.8 | $ | 19.3 | $ | 22.2 | ||||||

| Deferred |

4.4 | (0.4 | ) | 5.2 | ||||||||

|

|

|

|

|

|

|

|||||||

| Total |

$ | 24.2 | $ | 18.9 | $ | 27.4 | ||||||

|

|

|

|

|

|

|

|||||||

Total income tax provisions (benefits) were allocated as follows:

Significant components of the deferred income tax provision (benefit) attributable to income before income taxes are as follows:

| Year Ended December 31, | ||||||||||||

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| Deferred tax (exclusive of valuation allowance) |

$ | (2.8 | ) | $ | (7.1 | ) | $ | 1.0 | ||||

| Net increase in the valuation allowance for deferred tax assets |

7.2 | 6.7 | 4.2 | |||||||||

|

|

|

|

|

|

|

|||||||

| Deferred income tax provision |

$ | 4.4 | $ | (0.4 | ) | $ | 5.2 | |||||

|

|

|

|

|

|

|

|||||||

We have recognized that it is more likely than not that certain future tax benefits may not be realized through future taxable income. The valuation allowance increased $7.2 million and $6.7 million for the years ended December 31, 2014 and 2013, respectively. These increases were primarily due to U.S. federal alternative minimum tax credits generated during the year that are not expected to be recoverable.

20

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

Significant components of our deferred tax assets and liabilities were attributable to:

| December 31, | ||||||||

| (in Millions) |

2014 | 2013 | ||||||

| Alternative minimum, and other credit carryforwards |

68.3 | 61.1 | ||||||

| Deferred expenditures capitalized for tax |

— | 1.0 | ||||||

| Other assets and reserves |

9.1 | 8.2 | ||||||

|

|

|

|

|

|||||

| Deferred tax assets |

$ | 77.4 | $ | 70.3 | ||||

| Valuation allowance |

(68.3 | ) | (61.1 | ) | ||||

|

|

|

|

|

|||||

| Deferred tax assets, net of valuation allowance |

$ | 9.1 | $ | 9.2 | ||||

|

|

|

|

|

|||||

| Property, plant and equipment, net |

(44.6 | ) | (40.3 | ) | ||||

|

|

|

|

|

|||||

| Deferred tax liabilities |

$ | (44.6 | ) | $ | (40.3 | ) | ||

|

|

|

|

|

|||||

| Net deferred tax liabilities |

$ | (35.5 | ) | $ | (31.1 | ) | ||

|

|

|

|

|

|||||

We evaluate our deferred income taxes each reporting period to determine if valuation allowances are required or should be adjusted. U.S. GAAP accounting guidance requires that companies assess whether valuation allowances should be established against their deferred tax assets based on all available evidence, both positive and negative, using a “more likely than not” standard. In assessing the need for a valuation allowance, appropriate consideration is given to all positive and negative evidence related to the realization of the deferred tax assets. This assessment considers, among other matters, the nature and severity of current and cumulative losses, forecasts of future profitability, the duration of statutory carryforward periods, and tax planning alternatives.

At December 31, 2014, we had tax credit carryforwards primarily related to U.S. federal alternative minimum tax credits with an indefinite expiration period. These credits were allocated to Alkali based on its contribution to the FMC consolidated alternative minimum tax credit under a separate return methodology.

The effective income tax rate applicable to income from operations before income taxes was different from the statutory U.S. federal income tax rate due to the factors listed in the following table:

| Year Ended December 31, | ||||||||||||

| 2014 | 2013 | 2012 | ||||||||||

| Statutory U.S. tax rate |

35.0 | % | 35.0 | % | 35.0 | % | ||||||

| Net difference: |

||||||||||||

| Percentage depletion |

(19.2 | ) | (21.4 | ) | (16.6 | ) | ||||||

| Manufacturer’s production deduction and miscellaneous tax credits |

(1.0 | ) | (1.1 | ) | (1.3 | ) | ||||||

| Change in valuation allowance |

6.1 | 6.9 | 3.3 | |||||||||

| Other |

(0.2 | ) | — | 1.2 | ||||||||

|

|

|

|

|

|

|

|||||||

| Total difference |

(14.3 | ) | (15.6 | ) | (13.4 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Effective tax rate |

20.7 | % | 19.4 | % | 21.6 | % | ||||||

|

|

|

|

|

|

|

|||||||

21

Alkali Chemicals Division

(A Division of FMC Corporation)

Notes to Combined Financial Statements

Uncertain Income Tax Positions

U.S. GAAP accounting guidance for uncertainty in income taxes prescribes a model for the recognition and measurement of a tax position taken or expected to be taken in a tax return, and provides guidance on derecognition, classification, interest and penalties, disclosure and transition.

Our financial results are included in our Parent’s consolidated income tax returns in the U.S. federal jurisdiction. As of December 31, 2014, the U.S. federal income tax returns are open for examination and adjustment for the years 2011-2014. We recognize accrued interest and penalties related to unrecognized tax benefits as a component of income tax expense in the financial statements. The amount accrued for interest and penalties is not significant to the financial statements as of December 31, 2014.

The total amount of unrecognized tax benefits that, if recognized, would impact the effective tax rate was $1.2 million and $1.8 million as of December 31, 2014 and 2013, respectively. See the reconciliation of the total amounts of unrecognized tax benefits below.

We do not expect that our liability for gross unrecognized tax benefits will significantly change within the next 12 months.

A reconciliation of the beginning and ending amount of unrecognized tax benefits is as follows:

| (in Millions) |

2014 | 2013 | 2012 | |||||||||

| Balance at beginning of year |

$ | 1.8 | $ | 1.5 | $ | 1.1 | ||||||

| Additions for positions of the current year |

0.3 | 0.3 | 0.3 | |||||||||

| Additions for positions of the prior year |

— | — | 0.1 | |||||||||

| Reductions due to expiration of statutes of limitations |

(0.9 | ) | — | — | ||||||||

|

|

|

|

|

|

|

|||||||

| Balance at end of year |

$ | 1.2 | $ | 1.8 | $ | 1.5 | ||||||

|

|

|

|

|

|

|

|||||||

| Note 11: | Debt |

Industrial revenue bonds

Industrial revenue bonds bearing fixed rate interest of 5.60 percent annually were issued in December 2005 with a 30 year maturity date and the ability of the Parent to call the bonds at face value beginning December 2015. Interest payments of $5.0 million for 2014, 2013 and 2012 have been paid by the Parent. The industrial revenue bonds are recorded at cost of $90.0 million as of December 31, 2014 and 2013. The fair market value of the bonds approximated $91 million at both December 31, 2014 and 2013.

| Note 12: | Pension and Other Postretirement Benefits |