Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Hi-Crush Inc. | a123114-earningsrelease8xk.htm |

| EX-99.1 - EXHIBIT 99.1 - Hi-Crush Inc. | exhibit991-earningsrelease.htm |

4TH QUARTER & FULL-YEAR 2014 RESULTS FEBRUARY 3, 2015

Forward Looking Statements Some of the information included herein may contain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements give our current expectations and may contain projections of results of operations or of financial condition, or forecasts of future events. Words such as “may,” “assume,” “forecast,” “position,” “predict,” “strategy,” “expect,” “intend,” “plan,” “estimate,” “anticipate,” “could,” “believe,” “project,” “budget,” “potential,” or “continue,” and similar expressions are used to identify forward-looking statements. They can be affected by assumptions used or by known or unknown risks or uncertainties. Consequently, no expected results of operations or financial condition or other forward-looking statements can be guaranteed. When considering these forward-looking statements, you should keep in mind the risk factors and other cautionary statements in Hi-Crush Partners LP’s (“Hi-Crush”) reports filed with the Securities and Exchange Commission (“SEC”), including those described under Item 1A, “Risk Factors” of Hi-Crush’s Annual Report on Form 10-K for the fiscal year ended December 31, 2013 and any subsequently filed Quarterly Report on Form 10-Q. Actual results may vary materially. You are cautioned not to place undue reliance on any forward-looking statements. You should also understand that it is not possible to predict or identify all such factors and should not consider the risk factors in our reports filed with the SEC or the following list to be a complete statement of all potential risks and uncertainties. Factors that could cause our actual results to differ materially from the results contemplated by such forward-looking statements include: the volume of frac sand we are able to sell; the price at which we are able to sell frac sand; the outcome of any pending litigation; changes in the price and availability of natural gas or electricity; changes in prevailing economic conditions; and difficulty collecting receivables. All forward-looking statements are expressly qualified in their entirety by the foregoing cautionary statements. Hi-Crush’s forward-looking statements speak only as of the date made and Hi-Crush undertakes no obligation to update or revise its forward-looking statements, whether as a result of new information, future events or otherwise. 2

2014: A Record Year 3 (1) Full year – paid in 2015/2014 for distributions declared for 2014, paid in 2014/2013 for distributions declared for 2013; Quarter – paid in Q1 for distribution declared in Q4. 2014 2013 Q4 2014 Q4 2013 ($ in 000s) Revenues $386,547 $178,970 $130,929 $63,975 EBITDA $148,015 $73,534 $44,567 $24,418 Sales volumes 4,584,811 2,520,119 1,481,914 814,094 Production costs per ton $15.78 $18.74 $15.72 $17.08 Earnings per unit Basic $3.09 $2.08 $0.85 $0.63 Diluted $3.00 $2.08 $0.85 $0.63 Distributions per unit 1 $2.400 $1.950 $0.675 $0.510

Balance Sheet is Strong 4 (1) Revolving credit facility: $143.8mm available at L+2.75% ($150mm capacity less $6.2mm of LCs); includes accordion feature to increase to $200mm (2) Senior secured term loan: $200mm face value at L+3.75%; rated B2 and B+ by Moody's and Standard & Poor's, respectively Leverage (as of December 31, 2014) ($ in 000s) Cash 4,646$ Revolver -$ 1 Term loan 196,688 2 Other notes payable 3,676 Total debt 200,364$ Net debt 195,718$ Net debt / EBITDA 1.32x

Committed to Growing Distribution Long-Term 5 • Pattern of raising distribution with quarterly increases — 32% increase from distribution paid Q1 2014 vs paid Q1 2015 • Delivered on guidance of $2.30-$2.50 per unit distribution range in 2014 • Focused on generating increases in our distribution each quarter for unit holders Declared Distributions Per Unit (Annualized) * * $1.90 represents the Minimum Quarterly Distribution per unit at IPO $1.90 $1.96 $2.04 $2.10 $2.30 $2.50 $2.70 Q3 '13 Q4 '13 Q1 '14 Q2 '14 Q3 '14 Q4 '14 Q1 '15

Strong Coverage Provides Flexibility for Growth 6 • Strong coverage ratio averaging above target coverage of 1.20x — Average since Q1 2013 of 1.26x • Coverage provides flexibility in volatile market conditions and supports organic growth (1) Actual coverage ratio was 1.0x including $0.525 per unit distribution paid on 4.25 million units issued in April 2014 (2) Excludes impact of the August 15, 2014 conversion of Class B units to common units and related distribution paid upon conversion (3) Excludes the portion of DCF allocable to the Incentive Distribution Rights held by our Sponsor (1) (2) (3) (3) (3) 1.12x 1.14x 1.24x 1.38x 1.15x 1.35x 1.40x 1.31x – 0.20x 0.40x 0.60x 0.80x 1.00x 1.20x 1.40x $0 $5 $10 $15 $20 $25 $30 $35 Q1 '13 Q2 '13 Q3 '13 Q4 '13 Q1 '14 Q2 '14 Q3 '14 Q4 '15 $ in M ill io n s Distributions (Total $/Q) - LHS Coverage Ratio - RHS

Industry Backdrop

Oil Prices Adding Uncertainty to Market Conditions 8 $0 $20 $40 $60 $80 $100 $120 $140 $160

Historical Sand Demand Growth 9 Source: 2013 Proppant Market Report, PropTester, Inc./KELRIK LLC; internal estimates 0 20 40 60 80 100 120 140 Ra w F ra c S a n d De m a n d (B ill io n s o f P o u n d s )

Drilling Activity Supported by Low Breakeven Prices 10 (1) Source: Credit Suisse Research (October 2014) WTI Oil Breakeven Prices ($/bbl) (1) $36.01 $39.30 $42.77 $50.41 $51.64 $53.71 $53.84 $63.04 $0 $20 $40 $60 $80 $100

Frac Sand Demand Commentary “Wells aren't getting shorter, and stage density is not getting less, and our customers are not going to pump less sand per stage. We were up 22% or so sequentially in pounds per stage.” Q3 2014 Earnings Call “We are achieving excellent initial results on our wells with sand concentrations ranging from 1,750 to 2,250 pounds per foot.” Q4 2014 Earnings Call • E&P operators are using fracture stimulation techniques, such as longer laterals, increased frac stages per well, and increased proppant per stage to drive well performance • These activities are driving premium Northern White frac sand demand growth 11 “We actually saw in Q4 a year-on-year increase of about 46% sand on a per well basis, so that was up sequentially another 5% or 6% again on a per well basis.” Q4 2014 Earnings Call

Hi-Crush Operations

Hi-Crush’s Competitive Advantages • Long-Term Contracted Cash Flow • Low-Cost Producer • Long-Lived, High Quality Reserves • Prime Portfolio of Assets • Focused Strategy • Visible Avenues to Growth 13 6.6 mm Take-or-Pay Tons in 2015, 4.2 yrs Remaining 88% of Production Capacity Contracted Strong Northern White Frac Sand Demand Key Strategic Network in Marcellus/Utica Strong Balance Sheet Future Whitehall Drop-down, Plant #4, Expansion of Terminal Facilities

Hi-Crush Ranks Among Largest in Industry 14 • With 7.5 million tons current capacity, Hi-Crush is estimated to have: — The largest production capacity of frac sand in Wisconsin. — The fourth largest production capacity of frac sand worldwide. Source: Internal estimates

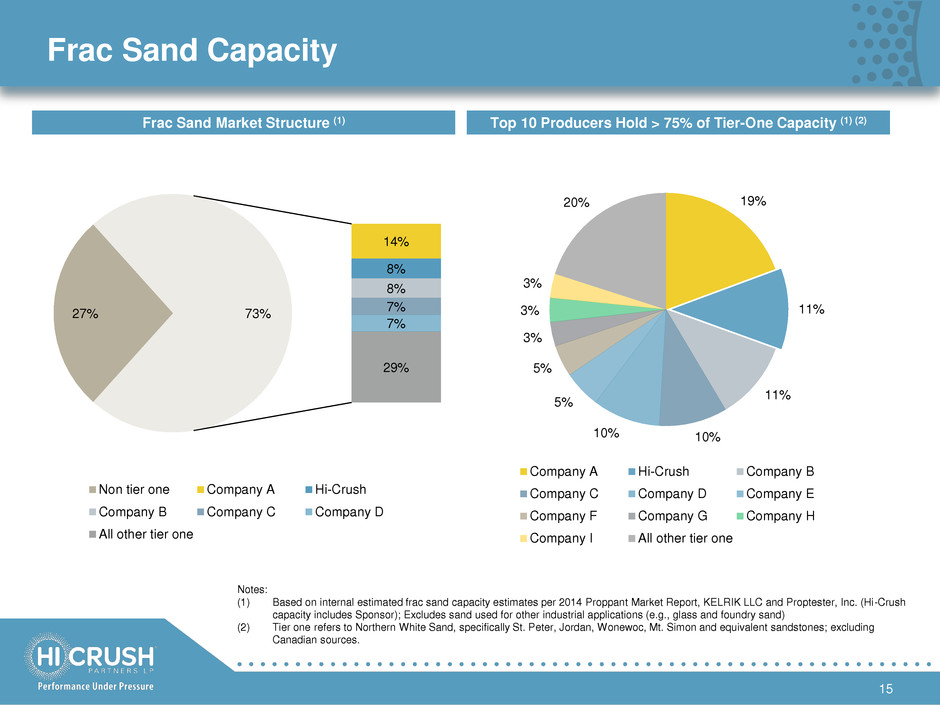

Frac Sand Capacity 15 Frac Sand Market Structure (1) Top 10 Producers Hold > 75% of Tier-One Capacity (1) (2) Notes: (1) Based on internal estimated frac sand capacity estimates per 2014 Proppant Market Report, KELRIK LLC and Proptester, Inc. (Hi-Crush capacity includes Sponsor); Excludes sand used for other industrial applications (e.g., glass and foundry sand) (2) Tier one refers to Northern White Sand, specifically St. Peter, Jordan, Wonewoc, Mt. Simon and equivalent sandstones; excluding Canadian sources. 27% 14% 8% 8% 7% 7% 29% 73% Non tier one Company A Hi-Crush Company B Company C Company D All other tier one 19% 11% 11% 10% 10% 5% 5% 3% 3% 3% 20% Company A Hi-Crush Company B Company C Company D Company E Company F Company G Company H Company I All other tier one

Contracts Indicative of Partnership with Customers YE 2012 YE 2013 16 1.2 MM Tons Under Contract 2.4 MM Tons Under Contract 6.6 MM Tons Under Contract 2.8 Year Average Life 2.5 Year Average Life 4.2 Year Average Life YE 2014 • 8 Contract Customers — Nearest maturity is 12/31/16 — Remainder mature at the end of 2018 through 2019

Low Cost Structure Essential 17 Hi-Crush Partners Production Costs per Ton Produced and Delivered Note: Recasted to include Augusta facility tons produced and delivered – 200,000 400,000 600,000 800,000 1,000,000 1,200,000 $0.00 $5.00 $10.00 $15.00 $20.00 $25.00 1Q 2013 2Q 2013 3Q 2013 4Q 2013 1Q 2014 2Q 2014 3Q 2014 4Q 2014 Quarterly Productions Costs / Ton Quarterly Tons Produced & Delivered

Logistics Flexibility Critical Sandstone Formations • Access to all major U.S. oil and gas basins • Direct loading and unloading of unit trains • Multiple in-basin terminals across Marcellus and Utica shales and one located in Permian Basin • 7,200 railcars under management • Strong relationships with multiple Class-1 and short-line railroads Sponsor’s Whitehall Facility 18 Sponsor Sand Facilities Existing Distribution Terminals Basin Play HCLP Sand Facilities

Positioned to Meet Challenges & Opportunities 19 • Northern White in highest demand relative to other proppant types • 6.6 million contracted take-or-pay tons in 2015: • 88% of production capacity • All contracts held by HCLP • Lowest cost frac sand producer • Logistics capabilities are key distinguishing factors • Financial strength and flexibility • Positioned for growth • Future dropdown of Sponsor’s Whitehall facility • Sponsor currently permitting fourth facility in Wisconsin • Organic growth of terminal network

Levers for Further Performance 20

Financial Results

4th Quarter 2014 Summary 22 Three Months Ended December 31, (in thousands, except per unit) 2014 2013(a) Revenues $ 130,929 $ 63,975 Cost of goods sold (including depreciation, depletion and amortization) 82,319 37,271 Gross profit 48,610 26,704 Operating costs and expenses: General and administrative expenses 7,059 5,774 Exploration expense — (9 ) Accretion of asset retirement obligation 62 56 Income from operations 41,489 20,883 Other income (expense): Interest expense (3,110 ) (1,370 ) Net income 38,379 19,513 Income attributable to non-controlling interest (251 ) (124 ) Net income attributable to Hi-Crush Partners LP $ 38,128 $ 19,389 Earnings per unit: Common and subordinated units - basic $ 0.85 $ 0.63 Common and subordinated units - diluted $ 0.85 $ 0.63 (a) Financial information has been recast to include the financial position and results attributable to Hi -Crush Augusta LLC.

Full-Year 2014 Summary 23 Year Ended December 31, (in thousands, except per unit) 2014(a) 2013(a) Revenues $ 386,547 $ 178,970 Cost of goods sold (including depreciation, depletion and amortization) 225,984 95,884 Gross profit 160,563 83,086 Operating costs and expenses: General and administrative expenses 26,346 19,096 Exploration expense — 47 Accretion of asset retirement obligation 246 228 Income from operations 133,971 63,715 Other income (expense): Interest expense (9,946 ) (3,671 ) Net income 124,025 60,044 Income attributable to non-controlling interest (955 ) (274 ) Net income attributable to Hi-Crush Partners LP $ 123,070 $ 59,770 Earnings per unit: Common and subordinated units - basic $ 3.09 $ 2.08 Common and subordinated units - diluted $ 3.00 $ 2.08 (a) Financial information has been recast to include the financial position and results attributable to Hi -Crush Augusta LLC.

4th Quarter 2014 Summary (1) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long-term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital. (2) The Partnership's historical financial information has been recast to consolidate Augusta for all periods presented. For purposes of calculating distributable cash flow attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recasted distributable cash flow earned during the periods prior to the acquisition by the Partnership on April 28, 2014 of substantially all of the remaining equity interests in Hi-Crush Augusta LLC (the "Augusta Contribution"). 24 Three Months Ended December 31, (in thousands) 2014 2013 Reconciliation of distributable cash flow to net income: Net income $ 38,379 $ 19,513 Depreciation and depletion expense 2,277 1,873 Amortization expense 801 1,662 Interest expense 3,110 1,370 EBITDA $ 44,567 $ 24,418 Less: Cash interest paid (2,698 ) (1,269 ) Less: Income attributable to non-controlling interest (251 ) (124 ) Less: Maintenance and replacement capital expenditures, including accrual for reserve replacement (1) (1,357 ) (909 ) Add: Accretion of asset retirement obligation 62 56 Add: Unit based compensation 548 — Distributable cash flow $ 40,871 $ 22,172 Adjusted for: Distributable cash flow attributable to Hi-Crush Augusta LLC, net of intercompany eliminations, prior to the Augusta Contribution (2) — (1,815 ) Distributable cash flow attributable to Hi-Crush Partners LP 40,871 20,357 Less: Distributable cash flow attributable to holders of incentive distribution rights (8,157 ) — Distributable cash flow attributable to common and subordinated unitholders $ 32,714 $ 20,357

Full-Year 2014 Summary (1) Maintenance and replacement capital expenditures, including accrual for reserve replacement, were determined based on an estimated reserve replacement cost of $1.35 per ton produced and delivered during the period. Such expenditures include those associated with the replacement of equipment and sand reserves, to the extent that such expenditures are made to maintain our long-term operating capacity. The amount presented does not represent an actual reserve account or requirement to spend the capital. (2) The Partnership's historical financial information has been recast to consolidate Augusta for all periods presented. For purposes of calculating distributable cash flow attributable to Hi-Crush Partners LP, the Partnership excludes the incremental amount of recasted distributable cash flow earned during the periods prior to the Augusta Contribution. 25 Year Ended December 31, (in thousands) 2014 2013 Reconciliation of distributable cash flow to net income: Net income $ 124,025 $ 60,044 Depreciation and depletion expense 8,858 6,132 Amortization expense 5,186 3,687 Interest expense 9,946 3,671 EBITDA $ 148,015 $ 73,534 Less: Cash interest paid (8,682 ) (3,123 ) Less: Income attributable to non-controlling interest (955 ) (274 ) Less: Maintenance and replacement capital expenditures, including accrual for reserve replacement (1) (5,001 ) (3,026 ) Add: Accretion of asset retirement obligation 246 228 Add: Unit based compensation 1,470 — Distributable cash flow $ 135,093 $ 67,339 Adjusted for: Distributable cash flow attributable to Hi-Crush Augusta LLC, net of intercompany eliminations, prior to the Augusta Contribution (2) (7,199 ) 696 Distributable cash flow attributable to Hi-Crush Partners LP 127,894 68,035 Less: Distributable cash flow attributable to holders of incentive distribution rights (18,401 ) — Distributable cash flow attributable to common and subordinated unitholders $ 109,493 $ 68,035

Production Costs per Ton Produced and Sold 26 (1) Recasted to include Augusta facility tons produced and sold Hi-Crush Partners LP (Wyeville & Augusta) (1) Production Cost per Ton Fiscal Quarter 1Q 2013 2Q 2013 3Q 2013 4Q 2013 1Q 2014 2Q 2014 3Q 2014 4Q 2014 Tons produced and delivered 382,607 557,457 597,659 703,481 718,166 953,361 1,027,611 1,005,492 Production costs ($ in thousands) 8,355 10,214 11,411 12,017 14,836 13,534 14,274 15,808 Production costs per ton $21.84 $18.32 $19.09 $17.08 $20.66 $14.20 $13.89 $15.72 12 months ended 12 months ended 12 months ended 12 months ended 12 months ended Trailing Twelve Months 12/31/2013 3/31/2014 6/30/2014 9/30/2014 12/31/2014 Tons produced and delivered 2,241,204 2,576,763 2,972,667 3,402,619 3,704,630 Production costs ($ in thousands) 41,998 48,479 51,799 54,661 58,452 Production costs per ton $18.74 $18.81 $17.43 $16.06 $15.78

Appendix

A Portfolio of Opportunity Sandstone Formations Sponsor’s Whitehall Facility 28 Sponsor Sand Facilities Existing Distribution Terminals Basin Play HCLP Sand Facilities Wisconsin • 7.5 million tons of annual production capacity, including 100 mesh • Over 30 years of reserves Marcellus & Utica • Exclusive rail access • Largest distribution network • Further expanding storage capabilities Permian • Facility in Big Spring, TX fully operational Growth • Permitting underway by our Sponsor for fourth Wisconsin production facility • Expanding distribution network through additional destination terminals and increased silo storage capacity

Our Business Model – Q4 2014 Operating Results 29 Sold FOB plant direct to customer (67%) Hi-Crush terminal Freight costs Hi-Crush plants Tons produced and delivered – 1,005,492 Production cost/ton – $15.72 Sold at the terminal to customer (33%) Sand delivered to Hi-Crush terminal via rail Tons sold – 1,481,914 Class-1 and short-line rail Customer truck delivers to well site

67% 33% Tons Sold FOB Mine During the Quarter 30 FOB Mine Volume (1) Primarily sold in Marcellus and Utica shales (2) Tons sold FOB mine primarily comprised of volumes sold under contract to long-term, take or pay customers (3) FOB mine sales shipped to Marcellus and Utica exclude volumes sold FOB destination at Hi-Crush terminal locations (2) Q4 2014 – FOB Mine Sales Volume Sold at Terminals (1) (3) 51% 22% 13% 11% 3% Permian / Eagle Ford Marcellus / Utica Colorado Oklahoma Other

67% 33% Hi-Crush Terminals Addressing Customer Needs 31 Hi-Crush terminal Freight costs Sand delivered to Hi-Crush terminal via rail Class-1 and short-line rail Customer truck delivers to well site Volume Sold at Terminals Sand sourced from mine 1 1 2 3 4 Sand transported by rail to destination terminal 2 In-basin terminal locations provide convenient customer services 3 Customer trucks deliver sand to well site for completion 4 • Ability to source from Hi-Crush mines, the Sponsor’s Whitehall facility, and 3rd party suppliers • On-site rail access is significant logistical advantage; rail fleet creates flexibility • Hi-Crush earns margin for alleviating customers’ logistical challenges • Additional revenue generated via storage and transload services • Unit train capabilities key for asset utilization and inventory management • Mix of contract and spot sales • Terminals transfer product to customer or 3rd party trucking service via silo or portable conveyor Q4 2014 FOB Mine Volume

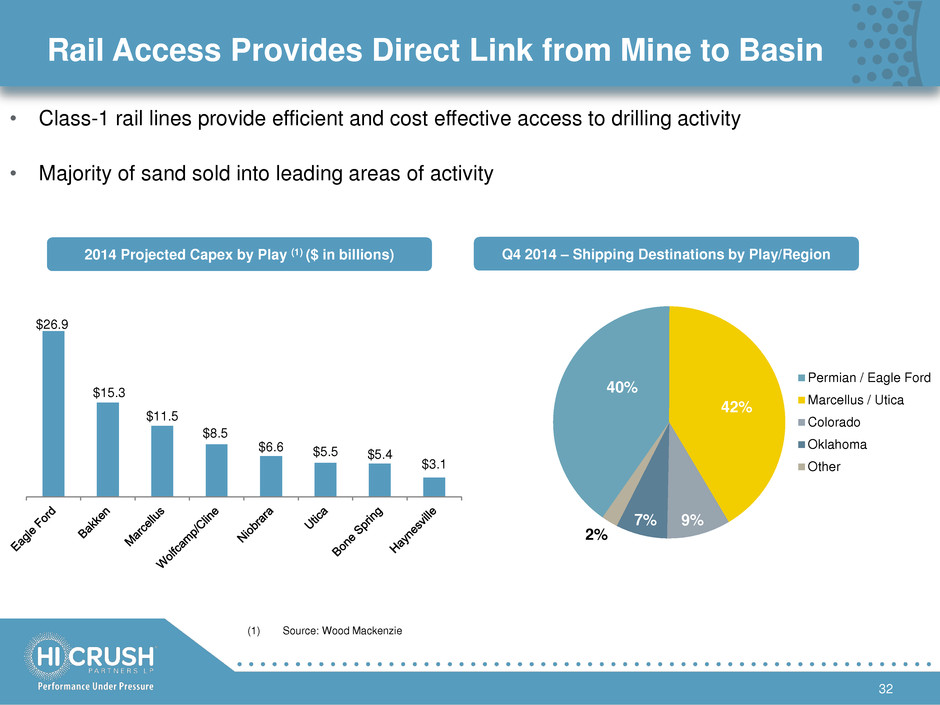

Rail Access Provides Direct Link from Mine to Basin 32 • Class-1 rail lines provide efficient and cost effective access to drilling activity • Majority of sand sold into leading areas of activity Q4 2014 – Shipping Destinations by Play/Region $26.9 $15.3 $11.5 $8.5 $6.6 $5.5 $5.4 $3.1 2014 Projected Capex by Play (1) ($ in billions) (1) Source: Wood Mackenzie 40% 42% 9% 7% 2% Permian / Eagle Ford Marcellus / Utica Colorado Oklahoma Other

Proven Production Execution * Includes Augusta 1.0 million ton annual 20/70 capacity expansion completed in 2014 ** Whitehall 2.6 million ton annual 20/70 capacity facility held at Sponsor level completed in third quarter 2014 January 2014 April 2014 3rd Quarter 2014 End of Year 2014 33 Wyeville Wyeville + Augusta Wyeville + Augusta + Augusta Expansion* Wyeville + Augusta + Augusta Expansion* + Whitehall** 3.2 MM tons/yr 4.2 MM tons/yr 6.8 MM tons/yr 1.6 MM tons/yr 3.6 MM tons/yr 4.6 MM tons/yr 7.5 MM tons/yr Nameplate capacity of 20/70 sand 100 mesh