Attached files

| file | filename |

|---|---|

| 8-K - 8-K - ENPRO INDUSTRIES, INC | d785397d8k.htm |

| EX-99.2 - EX-99.2 - ENPRO INDUSTRIES, INC | d785397dex992.htm |

Exhibit 99.1

Information Excerpted from

Preliminary Offering Memorandum dated September 8, 2014

This summary highlights significant aspects of our business and this offering, but it is not complete and may not contain all of the information that may be important to you. You should read this entire offering memorandum carefully, including the historical financial statements and their related notes included elsewhere or incorporated by reference in this offering memorandum. Investing in the notes involves significant risks, as described in the “Risk Factors” section. In this offering memorandum, unless otherwise indicated or the context otherwise requires, references to the terms “we,” “us,” “our,” the “Issuer,” “EnPro” or the “Company” refer to EnPro Industries, Inc. and its subsidiaries. All financial data presented in this offering memorandum is the financial data of EnPro Industries, Inc. and its consolidated subsidiaries unless otherwise indicated.

Company Overview

We are a leader in the design, development, manufacture and marketing of proprietary engineered industrial products that primarily include: sealing products; heavy-duty truck wheel-end component systems; self-lubricating non-rolling bearing products; precision engineered components and lubrication systems for reciprocating compressors; and heavy-duty, medium-speed diesel, natural gas and dual fuel reciprocating engines, including parts and services. We serve a diverse set of end markets and customers with leading brands, including Garlock®, STEMCO®, GGB® and Fairbanks Morse Engine™. We believe our products are considered by our customers to be best-in-class due to a history of performance in critical and demanding applications where there is a high cost for failure. We manufacture our products at 63 manufacturing facilities in 13 countries. For the twelve months ended June 30, 2014 we generated $1,152 million of consolidated net sales and $142 million of Adjusted EBITDA, see “—Summary Historical Consolidated Financial Information and Other Data.”

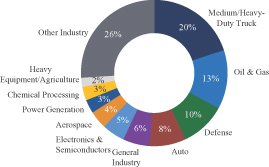

The charts below highlight our diversity of net sales by end market and geography:

| 2013 Consolidated Sales by End Use Market | 2013 Consolidated Sales by Geography | |

|

|

| |

2

Consolidated Operations

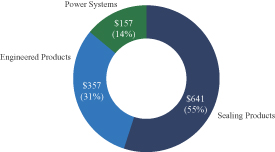

We manage our business as three segments: Sealing Products, Engineered Products, and Power Systems. Our reportable segments are managed separately based on differences in their products and services and their end-customers. Segment EBITDA is segment profit (which is the total segment revenue reduced by operating expenses and restructuring and other costs identifiable with the segment) before depreciation and amortization expense, see “—Summary Historical Consolidated Financial Information and Other Data.”

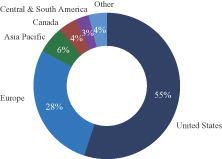

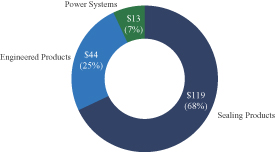

The following charts set forth the sales and Segment EBITDA of each of our segments for the last twelve months ended June 30, 2014.

LTM June 30, 2014

(dollars in millions)

| Segment Sales | Segment EBITDA | |

|

|

|

3

Segment Overview of EnPro Industries

| Segments |

Sealing Products |

Engineered Products |

Power Systems | |||||||||

| LTM June 30, 2014 |

Sales(1): $641 million Segment EBITDA(2): $119 million Segment EBITDA Margin(3): 19% |

Sales(1): $357 million Segment EBITDA(2): $44 million Segment EBITDA Margin(3): 12% |

Sales(1): $157 million Segment EBITDA(2): $13 million Segment EBITDA Margin(3): 8% | |||||||||

|

|

|

|

|

|

| |||||||

| Products |

• Gaskets & Packing • Oil Seals • Bearing Isolators • Expansion Joints • Flange Isolation Seal • Pipeline Products |

• Polymer Products • High Performance Metal Seals • Bellows • Brush Seals • Acoustic Media |

• Wheel End • Suspension • Brake Products • Intelligent Transportation Systems |

• Metal-polymer Plain Bearings • Bushing Blocks • Solid Polymer Bearings • Bearing Assemblies • Filament Wound Plain Bearings |

• Core Compressor Products • Sealing Components • Lubrication Systems • Reciprocating Compressor Reconditioning and Field Service |

• Medium-speed Diesel, Natural Gas and Dual Fuel Engines to 24MW • Parts & Service • Systems Packager | ||||||

| End Markets |

• General Industry • Oil & Gas • Basic Materials • Chemical Processing • Power Generation • Water/Wastewater • Pulp and Paper • Other Industries |

• Electronics & Semiconductors • Aerospace • Power Generation • General Industry • Oil & Gas • Food & Beverage |

• Medium/Heavy Duty Truck • Other Industries |

• Auto • General Industry • Agriculture Equipment • Fluid Power • Primary Metals • Other Industries |

• Oil & Gas • PET Bottle Manufacturing • Chemical Processing • Other Industries |

• Marine Power & Propulsion • Utility Standby Power Generation • Oil & Gas • Engine and Auxiliary Equipment Engineering | ||||||

| Representative |

• BASF • Chevron • Daewoo E&C • Dow • GE • Saudi Aramco • ThyssenKrupp |

• AREVA • Applied Materials • Cameron • Exelon • Honeywell • Schlumberger • Siemens |

• FedEx • H-E-B • Utility • Mack • UPS • Volvo • Wal-Mart |

• Alstom • Bosch • Caterpillar • Casappa • Emerson • United Technologies • John Deere |

• Apache • Air Products • Dow • GE • Graham Packaging • Shell • Tesoro |

• U.S. Navy • U.S. Coast Guard • Naval Shipyards • Ecopetrol • General Dynamics NASSCO • Petroecuador | ||||||

| (1) | Sales for each segment include intersegment sales. Intersegment sales for the twelve months ended June 30, 2014 were $3.1 million. |

| (2) | Segment EBITDA is segment profit before depreciation and amortization. Segment profit does not include an allocation of corporate expenses. For a presentation of segment profit and the calculation of segment EBITDA, see “—Summary Historical Consolidated Financial Information and Other Data.” |

| (3) | Segment EBITDA Margin is Segment EBITDA divided by segment sales. |

| (4) | The Garlock column, and the discussion of the Sealing Products segment below, includes products, customers, competition, and raw materials for Garlock Sealing Technologies, LLC which is one of the three of our subsidiaries that filed voluntary petitions for reorganization under Chapter 11 of the United States Bankruptcy Code on June 4, 2010. The financial results of GST and subsidiaries are not included in our consolidated results after June 4, 2010 and are not included in the sales, Segment EBITDA, Segment EBITDA Margin or other financial measures of the Sealing Products segment for periods after June 4, 2010 included above or elsewhere in this offering memorandum. |

4

Sealing Products Segment

Our Sealing Products segment includes three operating divisions, Garlock, Technetics and Stemco, that serve a wide variety of industries where performance and durability are vital for safety and environmental protection. Our products are used in many demanding environments such as those characterized by high pressure, high temperature and chemical corrosion, and many of our products support critical applications with a low tolerance for failure.

The Garlock family of companies designs, manufactures and sells sealing products including: metallic, non-metallic and composite material gaskets; dynamic seals; compression packing; hydraulic components; expansion joints; flange sealing and isolation products; pipeline casing spacers/isolators; casing end seals; modular sealing systems for sealing pipeline penetrations; safety-related signage for pipelines; conveyor belting; and sheet rubber products. These products are used in a variety of industries, including chemical and petrochemical processing, petroleum extraction and refining, pulp and paper processing, power generation, food and pharmaceutical processing, primary metal manufacturing, mining, and water and waste treatment. Among the well-known brand names are Garlock®, Gylon®, Klozure®, Lubrikup®, Pikotek®, PSITM, and Gar-Seal®.

Technetics Group designs, manufactures and sells high performance metal seals; elastomeric seals; bellows and bellows assemblies; pedestals for semiconductor manufacturing; and a wide range of polytetrafluoroethylene (“PTFE”) products. These products are used in a variety of industries, including electronics and semiconductor, aerospace, power generation, oil and gas, food and beverage and other industries. Brands include Helicoflex®, Belfab®, Feltmetal®, PlastomerTM, and Bio-GuardianTM and Origraf®.

Stemco designs, manufactures and sells heavy-duty truck wheel-end component systems including: seals; hubcaps; mileage counters; bearings; locking nuts; brake products; suspension components; and RF-based tire pressure monitoring and inflation systems and automated mileage collection devices. Its products primarily serve the medium and heavy-duty truck market. Product brands include STEMCO®, STEMCO Kaiser®, STEMCO Duroline®, STEMCO Crewson®, STEMCO Motor Wheel®, Grit Guard®, Guardian HP®, Voyager®, Discover®, Endeavor®, Pro-Torq®, Sentinel®, Data Trac®, DataTrac®, QwikKit®, Centrifuse® and AerisTM.

Customers

Our Sealing Products segment sells products to industrial agents and distributors, original equipment manufacturers (“OEMs”), engineering and construction firms and end users worldwide. Sealing products are offered to global customers, with approximately 40% of sales delivered to customers outside the United States in 2013. Representative customers are shown in the segment overview table above. In 2013, no single customer accounted for more than 7% of segment revenues.

Raw Materials and Components

Our Sealing Products segment uses PTFE resins, aramid fibers, specialty elastomers, elastomeric compounds, graphite and carbon, common and exotic metals, cold-rolled steel, leather, aluminum die castings, nitrile rubber, powdered metal components, and various fibers and resins. We believe all of these raw materials and components are readily available from various suppliers.

Engineered Products Segment

Our Engineered Products segment includes two high performance industrial products businesses: GGB and Compressor Products International (CPI).

5

GGB designs, manufactures and sells self-lubricating, non-rolling, metal polymer, solid polymer, and filament wound bearing products, as well as aluminum bushing blocks for hydraulic applications. The bearing surfaces are made of PTFE or a mixture that includes PTFE to provide maintenance-free performance and reduced friction. GGB’s bearing products typically perform as sleeve bearings or thrust washers under conditions of no lubrication, minimal lubrication or pre-lubrication and are used in a wide variety of markets such as the automotive, pump and compressor, construction, power generation and general industrial markets. GGB has approximately 20,000 bearing part numbers of different designs and physical dimensions. GGB® is a leading and well recognized brand name and sells products under the DU®, DP®, DX®, DS™, HX™, EP™, SY™ and GAR-MAX™ names.

CPI designs, manufactures sells and services components for reciprocating compressors and engines. These components, which include, packing and wiper rings, piston and rider rings, compressor valve assemblies, divider block valves, compressor monitoring systems, lubrication systems and related components, are utilized primarily in the refining, petrochemical, natural gas gathering, storage and transmission, and general industrial markets. Brand names for our products include Hi-Flo™, Valvealert™, Mentor™, Triple Circle™, CPI Special Polymer Alloys™, Twin Ring™, Liard™, Pro Flo™, Neomag™, CVP™, XDC™, POPR™ and Protecting Compressor World Wide™.

Customers

The Engineered Products segment sells its products to a diverse customer base using a combination of direct sales and independent distribution networks worldwide, with approximately 73% of sales delivered to customers outside the United States in 2013. GGB has customers worldwide in all major industrial sectors, and supplies products directly to customers through GGB’s own local distribution system and indirectly to the market through independent agents and distributors with their own local networks. CPI sells its products and services globally through its internal salesforce, independent sales representatives, distributors and service centers. Representative customers are shown in the segment overview table above. In 2013, no single customer accounted for more than 3% of segment revenues.

Raw Materials

GGB’s major raw material purchases include steel coil, bronze powder, bronze coil, PTFE and aluminum. GGB sources components from a number of external suppliers. CPI’s major raw material purchases include PTFE, polyetheretherketone (“PEEK”), compound additives, bronze, steel, and stainless steel bar stock. We believe all of these raw materials and components are readily available from various suppliers.

Power Systems Segment

Our Power Systems segment designs, manufactures, sells and services heavy-duty, medium-speed diesel, natural gas and dual-fuel reciprocating engines. We market these products and services under the Fairbanks Morse Engine™ brand name. Products in this segment include licensed heavy-duty, medium-speed diesel, natural gas and dual fuel reciprocating engines, in addition to our own designs. The reciprocating engines range in size from 700 to 31,970 horsepower and from five to 20 cylinders. The government and the general industrial market for marine propulsion, power generation, and pump and compressor applications use these products. We have been building engines for over 115 years under the Fairbanks Morse Engine™ brand name and we have a large installed base of engines for which we supply aftermarket parts and service. Fairbanks Morse Engine has been a key supplier to the U.S. Navy for medium-speed diesel engines and has supplied engines to the U.S. Navy for over 70 years.

6

Customers

Our Power Systems segment sells its products and services to customers worldwide, including major shipyards, municipal utilities, institutional and industrial organizations, sewage treatment plants, nuclear power plants and offshore oil and gas platforms, with approximately 4% of sales delivered to customers outside the United States in 2013. We market our products through a direct sales force of engineers in North America and through independent agents worldwide. Representative customers are shown in the segment overview table above. In 2013, the largest customer accounted for approximately 21% of segment revenues.

Raw Materials and Components

The Power Systems segment purchases multiple ferrous and non-ferrous castings, forgings, plate stock and bar stock for fabrication and machining into engines. In addition, we buy a considerable amount of precision-machined engine components. We believe all of these raw materials and components are readily available from various suppliers, but may be subject to long and variable lead times.

Garlock Sealing Technologies

On June 5, 2010 (the “Petition Date”), three of our subsidiaries, GST LLC, Anchor and Garrison, filed voluntary petitions for reorganization under Chapter 11 of the United States Bankruptcy Code in the Bankruptcy Court. The filings were the initial step in an asbestos claims resolution process. The filings did not include EnPro Industries, Inc., or any other EnPro Industries, Inc. operating subsidiary. GST LLC now operates in the ordinary course under court protection from asbestos claims. All pending litigation against GST is stayed during the bankruptcy process. For the last twelve months ended June 30, 2014, GST generated $238 million in net sales and $58 million in Adjusted EBITDA, and at June 30, 2014 its aggregate cash and cash equivalents and investments in marketable securities were $216 million.

The financial results of GST and subsidiaries are included in our consolidated results through June 4, 2010, the day prior to the Petition Date. However, GAAP requires an entity that files for protection under the U.S. Bankruptcy Code, whether solvent or insolvent, whose financial statements were previously consolidated with those of its parent, as GST’s and its subsidiaries’ were with ours, generally must be prospectively deconsolidated from the parent and the resulting investment to be accounted for using the cost method. Prior to its deconsolidation effective on the Petition Date, GST LLC and its subsidiaries operated as part of the Garlock group of companies within EnPro’s Sealing Products segment. GST LLC designs, manufactures and sells sealing products, including metallic, non-metallic and composite material gaskets, rotary seals, compression packing, resilient metal seals, elastomeric seals, hydraulic components, and expansion joints. GST LLC and its subsidiaries operate five primary manufacturing facilities, including GST LLC’s operations in Palmyra, New York and Houston, Texas.

On May 29, 2014, GST filed an amended proposed plan of reorganization that provides $275 million in total funding for (a) the treatment of present and future asbestos claims against GST that have not been resolved by settlement or verdict prior to the Petition Date, and (b) administrative and litigation costs. The $275 million is to be funded by GST ($245 million) and Coltec ($30 million), through two facilities—a settlement facility (which would receive $245 million) and a litigation facility (which would receive $30 million). If the proposed plan is confirmed and consummated, funds contained in the settlement facility and the litigation facility would provide the exclusive remedies for current and future GST asbestos claimants other than claimants whose claims had been resolved by settlement or verdict prior to the Petition Date and were not paid prior to the Petition Date. The plan provides that GST will pay in full claims that had been resolved by settlement or verdict prior to the Petition Date that were not paid prior to the Petition Date (with respect to claims resolved by verdict, such payment will be made only to the extent the verdict becomes final). The amount of such claims resolved by verdict is $2.4 million. GST estimates the range of its aggregate liability for such unpaid settled asbestos claims

7

to be from $3.1 million to $16.4 million. The plan incorporates the Bankruptcy Court’s determination in January 2014 that $125 million is sufficient to satisfy GST’s aggregate liability for present and future mesothelioma claims (although such determination is currently the subject of the motion by the Official Committee of Asbestos Personal Injury Claimants representing current asbestos personal injury claimants in the bankruptcy proceeding to reopen the record); however, it also provides additional funds to provide full payment for non-mesothelioma claims and to support a feasibility determination. Under the terms of the plan, we would retain 100% of the equity interests of GST LLC.

If the plan is confirmed by the Bankruptcy Court and is consummated, GST will be re-consolidated with our results for financial reporting purposes. The plan is subject to confirmation by the Bankruptcy Court and we cannot assure you that GST will be able to obtain necessary Bankruptcy Court approval of the plan, including the settlement of asbestos claims and related releases of claims against us included therein, and that the plan will become effective or that the asbestos claimants will not be successful in their attempt to have the record on the Bankruptcy Court’s determination reopened or what the final terms of the plan will be at consummation. See “Risk Factors—We cannot assure you that GST will be able to obtain Bankruptcy Court approval of its amended plan of reorganization and the settlement and resolution of claims and related releases of liability embodied therein or what the final terms of such plan will be at consummation, and the time period for the resolution of the bankruptcy proceedings is not presently determinable.”

Competition

We compete with a number of competitors in each of our segments. Although it varies by products, competition is based primarily on performance of the product for specific applications, product reliability, availability and price. Our leading brand names, including Garlock® and STEMCO®, have been built upon long-standing reputations for reliability and durability. In addition, we believe the breadth, performance and quality of our product offerings allow us to achieve premium pricing and have made us a preferred supplier among our agents and distributors in many of our businesses. Key competitors for the Sealing Products segment include Federal-Mogul Corporation, A.W. Chesterton Company and SKF USA Inc. Key competitors for the Engineered Products segment include Federal-Mogul Corporation and Saint-Gobain’s Norglide division. Key competitors for the Power Systems segment include MTU, Caterpillar Inc., and Wartsila Corporation.

Competitive Strengths

We believe the following strengths provide us with significant competitive advantages as we execute our business strategy:

Our Brands Set Industry Standards and Drive a Portfolio of Highly Repeatable, Stable Businesses

Our leading brands, including Garlock®, STEMCO®, GGB® and Fairbanks Morse Engine™, have legacies ranging from 60 to 125 years. We believe that the products sold under these leading brands are well established and highly recognized in their respective markets, and, in our flagship product lines, we hold leading market positions. In many cases, we expect our products are the products of choice for our customers given our long-standing histories of reliable performance in demanding and critical applications. We believe many of our products set industry standards around safety, emissions control, reliability, and performance. And we were among the first to market with a number of products, including opposed piston engines, non-asbestos sealing products, high-performance PTFE gaskets, metal-polymer bearings, and zero-PFOA (perfluorooctanoic acid) bearings. A meaningful percentage of our sales is generated by products that are either sole-sourced or customer-specified. The focus of our brand and business model has been, and continues to be, developing premium quality products that meet demanding performance standards, providing customers with focused service and support, and developing and nurturing enduring customer relationships.

8

Many of Our Products Perform in Demanding Environments and Serve Critical Applications

Many of our products support critical applications in demanding environments such as those characterized by high pressure, high temperature, chemical corrosion and demand for zero failure. Notable examples include sealing products for nuclear reactor pressure vessels; seals, bearings and related products for aircraft engines and landing gear; wheel-end and brake products for Class 8 trucks; and engines that provide propulsion or auxiliary power for U.S. Navy vessels. We believe many of our products’ long-standing histories of performance reliability in demanding environments and for critical applications provide significant commercial advantages, leading to value-based pricing opportunities that drive premium margins and capital returns. In addition, some applications in which our products serve are characterized by high customer switching costs, due to both the critical nature of the application and the specification process.

Our Highly Diversified Business Portfolio Leads to Stable Cash Flows

Our sales are generated across a broad range of industries and geographies. We serve more than 30 end markets, and approximately 45% of our 2013 net sales were from sales of our products outside of the United States. A slowdown in a specific industry or economy can be offset by an uptick in other markets, providing confidence in our ability to sustain profitability and stable cash flows over time. We also have a strong mix of aftermarket and OEM customers. In 2013, approximately 48% of our net sales were to aftermarket customers and 52% to OEM customers. Much of our OEM business is platform-based and sole-sourced, resulting in very low product displacement. Additionally, our large installed base of products generates a steady recurring aftermarket revenue stream.

We Have Positioned Our Company for Growth and Continuous Improvement

Since our spin-off from Goodrich Corporation (“Goodrich”) in 2002, we have systematically refined our business mix and model, and we are well positioned for future growth and continuous operational improvement. Initiatives undertaken include the following:

| • | We have streamlined our mix of businesses, divesting a large division (Quincy Compressor) and several small, non-strategic business units. We have reinvested fully the proceeds of those divestitures into businesses that fit strategically with our operating divisions and that provide new products, new technologies and new or expanded geographic reach. In the process, we have refined our acquisition processes and developed a formal playbook for a strategy-driven conservative approach to managing our portfolio. We have expanded globally through both acquisitions and organic initiatives, particularly in Asia, South America and the Middle East. |

| • | We have developed a comprehensive supply chain management process and currently have 38 category teams managing 85% of our total spend, targeting annual savings of 3% through the business cycle. |

| • | We have developed a world-class safety program and culture and are one of only three companies to be recognized on two separate occasions by EHS Today as America’s Safest Company. |

| • | We have invested heavily in our infrastructure with major facility upgrades and ERP implementations in all of our operating divisions. And we have developed an EnPro global manufacturing and commercial business model through cross-division collaboration and external benchmarking. |

| • | On the commercial front, we recently added the roles of Chief Innovation Officer and Chief Customer Officer to the responsibilities of two of our senior executives. |

9

The EnPro Senior Executive Team is Composed of Members with Diverse Educational and Functional Backgrounds and Demonstrated Track Records of Success

Our executive management team is led by Steve Macadam, President and Chief Executive Officer, who has served in this capacity for the past six years. Prior to joining EnPro, Mr. Macadam was CEO of two other industrial companies and a senior operating executive at a third manufacturer, all following an earlier career as Principal with McKinsey & Company. Others on the EnPro senior team bring a diverse mix of educational and functional backgrounds and demonstrated records of success at both EnPro and in their roles prior to joining EnPro. The varied backgrounds include experience with companies such as W.L. Gore, General Electric, General Motors, Federal-Mogul and with professional consulting and accounting firms such as McKinsey and Ernst & Young. Dale Herold, President of the Garlock family of companies and Chief Customer Officer, and Ken Walker, Engineered Products Segment President, both have strong technical commercial backgrounds. Jon Cox, Stemco Group President and Chief Innovation and Information Officer, has deep experience in new product development. Marvin Riley, President of Fairbanks Morse Engine (the Power Systems segment), held senior manufacturing positions prior to his current role.

Business Strategy

We seek to take advantage of our competitive strengths to execute our growth and cost reduction strategies and, as a result, to maximize our free cash flow. Examples include:

Capitalize on Secular Growth Trends in Core Lines of Business

We serve a diverse group of markets and geographies and seek to invest in, and capture the benefits of, positive secular trends.

In our Sealing Products segment, our Garlock business has benefitted recently from its significant presence in domestic and international hydrocarbon processing markets and from market demands for products that protect the environment from leaks and emissions. Garlock is also focusing on expansion into less cyclical end markets such as food and pharmaceutical markets. Stemco is currently experiencing growth in its core trailer market as trailer build rates and truck loadings have been strong. Stemco is also capitalizing on its products that enhance highway safety and on regulatory trends addressing stopping distance, brake quality and fuel efficiency. At Technetics Group, we are benefitting from strength in the semiconductor and aerospace markets.

In our Engineered Products segment, we believe growth at GGB will be driven by more favorable conditions in the European automotive market and more generally as a result of economic strengthening in both North America and Europe. GGB will continue to pursue incremental growth through efforts to convert legacy roller bearing applications in the U.S. to high performing and less costly plain bearings. We also seek to gain share in China as premium quality auto production develops to serve a rising middle class. At CPI, we have grown historically through acquisition-driven geographic expansion and adjacent product line additions and are currently undergoing a broad-based business transformation to realize the full value of these prior strategic moves. We anticipate future benefits with positive secular trends in the hydrocarbon processing and natural gas markets.

In our Power Systems segment, Fairbanks Morse Engine is a significant supplier to the U.S. Navy and has a leading market share in the U.S. nuclear market. Future growth is anticipated to come primarily from new initiatives underway to expand in commercial markets. Currently, we are developing a next generation opposed piston engine (OP 2.0) that, if successful, will provide increased opportunities in commercial markets. In addition, Fairbanks Morse Engine recently announced a new agreement with MAN Diesel that will provide Fairbanks Morse Engine with additional products for sale to the U.S. power generation market. Fairbanks Morse Engine has entered into other agreements that provide access to products for sale to its core marine and power generation markets.

10

Drive Growth through Product Innovation

We seek to drive growth by enhancing our product and technology offerings. Within our Sealing Products segment, we are working to adapt the Garlock family of products to meet the needs of the food and pharmaceutical markets. At Stemco, we have an established track record of new product development and a number of product innovation initiatives underway in its wheel-end, brake and suspension components groups. At Technetics, we are expanding our product offerings for the aerospace, semiconductor, nuclear and oil & gas markets through close customer collaboration and active partnerships with companies like Airbus, Applied Materials, and the French nuclear agency (CEA). In our Power Systems segment, we are working to develop and commercialize the next generation opposed piston engine (OP 2.0). We plan to continue the development of proprietary products as a means to differentiate ourselves from our competitors and grow our business. These efforts are supported by an enterprise-wide focus on innovation led by our recently appointed Chief Innovation Officer.

Capture Growth via Geographic Expansion

While our primary markets are the developed economies of North America and Europe, we have expanded selectively in Eastern Europe, Asia, South America, the Middle East and Africa since the 2002 spin-off from Goodrich. All of our operating divisions other than Fairbanks Morse Engine now have a presence in Asia where our focus, with the exception of Stemco, is serving the local market. In the case of Stemco, we established a facility in China to produce wheel-end bearings for export to the U.S. We will continue to expand geographically in areas, and with customers, that value our high-performance products and service capabilities.

Supplement Organic Growth with Strategic Acquisitions

In addition to new product development and geographic expansion, acquisitions provide a means for expanding our addressable market through adding new products and technologies and helping us enter new markets. We maintain a disciplined and conservative acquisition approach that is grounded in business strategy and that incorporates all aspects of the acquisition process, including target identification, valuation and negotiation, due diligence, integration and post-closing business planning and execution. Our acquisition focus has led to a ten-fold increase in Stemco’s addressable market over the past five years, establishment of the Technetics Group to focus on high-performance sealing and related products, expansion of Garlock’s pipeline products business and expansion of Compressor Product International’s service capability and geographic reach. At Stemco, we have significant room to capture share in our expanded addressable market based on brand strength, channel strategy and sales excellence. Since the spinoff from Goodrich in 2002, we have invested approximately $580 million in acquisitions at an average price to EBITDA multiple of 7.1x before consideration of synergies.

Ongoing Focus on Cost Containment and Continuous Improvement

We continue to seek opportunities to lower manufacturing costs by optimizing our production footprint, implementing new manufacturing practices and processes and investing in capital equipment to increase manufacturing efficiencies and improve product quality. We will continue to manage our total supply spend through the work of our 38 category teams with the goal of realizing annual savings of 3% through the business cycle. In addition, we expect to benefit from the investments made in new ERP systems.

Recent Developments

Although we do not routinely report financial information other than with respect to our annual and quarterly fiscal periods, our preliminary unaudited net sales, income before income taxes and segment profit for the two-month period ended August 31, 2014 were approximately $188.3 million, $6.0 million and $20.4 million, respectively, compared to unaudited net sales, income before income taxes and segment profit for the two-month period ended August 31, 2013 of approximately $166.0 million, $0.9 million and $15.4 million, respectively.

11

Segment profit is the total of the segment revenue of each of our reportable segments reduced by operating, restructuring and other expenses identifiable with the segment. Expenses not directly attributable to the segments, corporate expenses (which include general corporate administrative costs), net interest expense, gains/losses related to the sale of assets, and income taxes are not included in the computation of segment profit. The accounting policies of our reportable segments are the same as those for EnPro.

The following table sets forth a reconciliation of segment profit to income before income taxes for the two-month periods ended August 31, 2014 and 2013.

| Two Months Ended August 31, | ||||||||

| 2013 | 2014 | |||||||

| (unaudited) | ||||||||

| (in millions) | ||||||||

| Segment profit |

$ | 15.4 | $ | 20.4 | ||||

| Corporate expenses |

(5.4 | ) | (7.5 | ) | ||||

| Other items |

(1.7 | ) | (0.8 | ) | ||||

| Interest expense |

(7.4 | ) | (6.1 | ) | ||||

|

|

|

|

|

|||||

| Income before income taxes |

$ | 0.9 | $ | 6.0 | ||||

|

|

|

|

|

|||||

We do not intend to provide future financial information for any period other than with respect to our annual and quarterly fiscal periods.

The preliminary unaudited financial information presented above for the two-month period ended August 31, 2014 reflects estimates based only upon preliminary information available to us as of the date of this offering memorandum, is subject to change pending finalization and is not a comprehensive statement of our financial results or position as of or for the two-months ended August 31, 2014. During the course of our financial statement closing process, we may identify items that would require us to make adjustments to our preliminary operating results described above. As a result, the foregoing discussion constitutes forward-looking statements and, therefore, we caution you that these statements are subject to risks and uncertainties, including possible adjustments to our preliminary operating results. The financial data for the two-month periods ended August 31, 2014 and 2013 included in this offering memorandum have been prepared by and is the responsibility of EnPro’s management. PricewaterhouseCoopers LLP has not audited, reviewed, compiled or performed any procedures with respect to such financial data. Accordingly, PricewaterhouseCoopers LLP does not express an opinion or any other form of assurance with respect thereto.

Refinancing Transactions

Cash Tender Offer for Convertible Debentures

On August 11, 2014, we commenced a cash tender offer (the “Tender Offer”) to purchase any and all of our outstanding $74.78 million in aggregate principal amount Convertible Debentures. In the Tender Offer, we are offering to purchase the Convertible Debentures at a cash purchase price, for each $1,000 principal amount of such Convertible Notes, equal to the sum of (i) the average volume-weighted-average price of our common stock over the 20 consecutive trading days beginning on August 13, 2014 in the manner described in the documents governing the terms of the Tender Offer multiplied by 29.5972 plus (ii) a fixed cash amount of $52.50, provided that in no event will the purchase price be less than $ 1,650.75 or more than $2,301.89 per $1,000 principal amount of the Convertible Debentures. In addition, we will pay all accrued and unpaid interest, to but not including the settlement date of the Tender Offer, on all Convertible Debentures purchased in the Tender Offer. The Tender Offer expires at midnight at the end of September 12, 2014, unless we extend the expiration to a later date and time (the “Expiration Date”).

12

There can be no assurance as to how many, if any, Convertible Debentures will be tendered in the Tender Offer. The Convertible Debentures are not redeemable at the option of the Company and, therefore, we anticipate that any Convertible Debentures that remain outstanding after the consummation of the Tender Offer will continue to be outstanding under the terms of the indenture governing the Convertible Debentures (and subject to any conversion rights set forth therein). See “Description of Other Indebtedness—Convertible Debentures” and “Capitalization.” To the extent that any Convertible Debentures remain outstanding following consummation of the Tender Offer, we currently intend to seek to retire such Convertible Debentures on acceptable terms, including through open market purchases, privately negotiated transactions or another tender offer.

Revolving Credit Facility

On August 28, 2014, we entered into an amendment and restatement (the “Credit Facility Amendment”) to the credit agreement governing our credit facility. The Credit Facility Amendment provides for a five year, $300.0 million senior secured revolving credit facility. Unlike our prior credit facility, borrowing availability under the amended credit facility is not limited by reference to a borrowing base. See “Description of Other Indebtedness—Senior Secured Revolving Credit Facility” for a more detailed description of our senior secured revolving credit facility as amended and restated by the Credit Facility Amendment. Unless otherwise noted, the term “Revolving Credit Facility” refers to the senior secured revolving credit facility as amended and restated by the Credit Facility Amendment.

Use of Proceeds

We intend to use the net proceeds from this offering: (i) to repay outstanding borrowings under the Revolving Credit Facility made to fund the purchase of any and all of our Convertible Debentures in the Tender Offer and related fees and expenses; (ii) to repay all remaining borrowings and accrued interest outstanding under the Revolving Credit Facility; and (iii) for other general corporate purposes. We currently intend to seek to retire any Convertible Debentures that remain outstanding after completion of the Tender Offer on acceptable terms, including through open market purchases, privately negotiated transactions or another tender offer.

We collectively refer to this offering and the use of proceeds therefrom, including the purchase of any and all of the Convertible Debentures in the Tender Offer and the entering into the Credit Facility Amendment, as the “Refinancing Transactions,” and information included in this offering memorandum after giving effect to the Refinancing Transactions assumes that all of the outstanding Convertible Debentures are tendered and purchased in the Tender Offer at the $2,301.89 maximum purchase price per $1,000 principal amount of the Convertible Debentures. See “Use of Proceeds” and “Capitalization.”

13

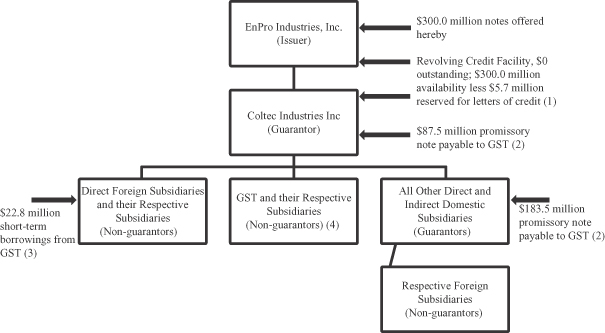

Ownership and Corporate Structure

The following chart summarizes our organizational structure and our principal outstanding debt obligations at June 30, 2014 on an as adjusted basis after giving effect to this offering and the application of the net proceeds as described in “Use of Proceeds” and the effectiveness of our Revolving Credit Facility. The notes will initially be guaranteed by all of our existing and future direct and indirect domestic subsidiaries that guarantee our indebtedness under the Revolving Credit Facility. Accordingly, the notes will initially be guaranteed by all of our direct and indirect domestic subsidiaries, other than GST and the respective subsidiaries of GST which do not initially guarantee indebtedness under the Revolving Credit Facility. This chart also shows the entities that are obligors with respect to promissory notes payable to GST LLC.

| (1) | As of June 30, 2014, after giving effect to the Refinancing Transactions, $300.0 million, representing the full amount of the Revolving Credit Facility, less $5.7 million reserved for outstanding letters of credit, would have been available for borrowing under the Revolving Credit Facility. Borrowers under the Revolving Credit Facility are EnPro Industries, Inc. and Coltec Industries Inc (“Coltec”), and the Revolving Credit Facility is guaranteed by all of our direct and indirect domestic subsidiaries, other than GST and the respective subsidiaries of GST. For a description of the material terms of the Revolving Credit Facility, see “Description of Other Indebtedness—Revolving Credit Facility.” |

| (2) | Respectively, includes approximately $87.5 million under a promissory note made by Coltec payable to GST LLC (the “Coltec Note”) and approximately $183.5 million under a promissory note made by Stemco LP , an indirect subsidiary of Coltec, payable to GST LLC (the “Stemco Note,” and together with the Coltec Note, the “Intercompany Notes”). The Coltec Note is secured by Coltec’s pledge of certain of its equity ownership in specified U.S. subsidiaries. The Stemco Note is guaranteed by Coltec and secured by Coltec’s pledge of its interest in Stemco LP and Stemco Holdings, Inc. The principal amount of each of these Intercompany Notes is subject to increase over time as a portion of the interest on these notes is added to the principal amount of the Intercompany Notes as payment-in-kind interest. The Intercompany Notes are subordinated to any obligations under the Revolving Credit Facility, pursuant to existing subordination |

14

| agreements which subordinate GST LLC’s right to receive payment of principal of the Intercompany Notes to the prior payment in full of all obligations under the Revolving Credit Facility but permit the payment of interest on the Intercompany Notes in the ordinary course of business so long as no event of default exists, or would occur as a result of any such payment, under the Revolving Credit Facility and there is availability of at least $20.0 million under the Revolving Credit Facility. In addition, under these subordination agreements GST LLC is prohibited from exercising any rights and remedies it may have against Coltec and Stemco LP with respect to the Intercompany Notes except for purposes of filing a claim during an insolvency proceeding. It will not be a default under the Revolving Credit Facility and the notes offered hereby if the Intercompany Notes are not repaid on their stated maturity date, January 1, 2017, to the extent such payment is prohibited by these subordination agreements. See “Other Indebtedness—Intercompany Notes.” |

| (3) | As of June 30, 2014, Coltec Finance Company Ltd., a wholly-owned foreign subsidiary of Coltec, had aggregate, short-term borrowings of $22.8 million from GST LLC’s subsidiaries in Mexico and Australia. These unsecured obligations were denominated in the currency of the lending party. |

| (4) | As described more fully in “Description of the Notes—Defaults,” it will be an event of default under the indenture that will govern the notes if, following notice and the expiration of a cure period, any of GST or their respective subsidiaries fails to execute and deliver a supplemental indenture pursuant to which it guarantees payment of the notes within ten Business Days (as defined) after it guarantees or becomes a borrower under the Revolving Credit Agreement or guarantees any other of our Capital Markets Indebtedness (as defined). It is an event of default under the Credit Facility Amendment governing the Revolving Credit Facility if the domestic entities of GST fail to become guarantors within 60 days after reconsolidation with EnPro Industries, Inc. for financial reporting purposes following GST’s exit from bankruptcy. See “Description of Other Indebtedness—Revolving Credit Facility—Events of Default.” |

Corporate Information

We were incorporated under the laws of the State of North Carolina on January 11, 2002, as a wholly owned subsidiary of Goodrich Corporation. The incorporation was in anticipation of Goodrich’s announced distribution of its Engineered Industrial Products segment to existing Goodrich shareholders. The distribution took place on May 31, 2002. Our principal executive offices are located at 5605 Carnegie Boulevard, Suite 500, Charlotte, North Carolina 28209 and our telephone number is (704) 731-1500. Our common stock is listed on the New York Stock Exchange under the symbol “NPO.” We maintain an Internet website at www.enproindustries.com; however, the information on our website is not part of this offering memorandum, and you should rely only on the information contained in this offering memorandum and in the documents incorporated by reference into this offering memorandum when making a decision whether to invest in the notes.

15

Summary Historical Consolidated Financial Information and Other Data

The following summary historical consolidated financial information and other data as of December 31, 2013 and 2012 and for the years ended December 31, 2013, 2012 and 2011 have been derived from and should be read together with the Audited Consolidated Financial Statements and related notes included elsewhere in this offering memorandum. The following summary historical consolidated financial information and other data as of December 31, 2011 have been derived from our audited consolidated financial statements which are not included or incorporated by reference in this offering memorandum. The following summary historical consolidated financial information and other data for the six months ended June 30, 2014 and 2013 and as of June 30, 2014 have been derived from and should be read together with the Unaudited Consolidated Financial Statements and related notes included elsewhere in this offering memorandum. The following summary historical consolidated financial information and other data as of June 30, 2013 have been derived from our unaudited consolidated financial statements as of June 30, 2013 which are not included or incorporated by reference in this offering memorandum. The following summary historical consolidated financial information and other data presented for the twelve months ended June 30, 2014 has been derived by taking the amounts from the historical Audited Consolidated Financial Statements for the year ended December 31, 2013, less the amounts from the historical Unaudited Consolidated Financial Statements for the six months ended June 30, 2013, plus the amounts from the historical Unaudited Consolidated Financial Statements for the six months ended June 30, 2014.

Our summary historical consolidated financial information and other data are not necessarily indicative of our future performance. The financial information and data provided in this table are only summary, do not provide all of the information or data contained in our financial statements, and should also be read in conjunction with the sections of this offering memorandum entitled “Use of Proceeds,” “Capitalization” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations.”

16

| Year Ended December 31, |

Six Months Ended June 30, (unaudited) |

Twelve June 30, |

||||||||||||||||||||||

| 2011(1) |

2012(2) |

2013 |

2013 |

2014 |

2014 |

|||||||||||||||||||

| (dollars in millions) | ||||||||||||||||||||||||

| Statement of Operations Data: |

||||||||||||||||||||||||

| Net Sales |

$ | 1,105.5 | $ | 1,184.2 | $ | 1,144.2 | $ | 592.7 | $ | 600.3 | $ | 1,151.8 | ||||||||||||

| Cost of sales |

726.5 | 784.1 | 762.9 | 389.3 | 395.7 | 769.3 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Gross profit |

379.0 | 400.1 | 381.3 | 203.4 | 204.6 | 382.5 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Operating expenses: |

||||||||||||||||||||||||

| Selling, general and administrative |

275.0 | 286.1 | 285.8 | 148.2 | 162.4 | 300.0 | ||||||||||||||||||

| Other |

2.3 | 6.5 | 9.1 | 3.7 | 0.7 | 6.1 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Total operating expenses |

277.3 | 292.6 | 294.9 | 151.9 | 163.1 | 306.1 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Operating income (loss) |

101.7 | 107.5 | 86.4 | 51.5 | 41.5 | 76.4 | ||||||||||||||||||

| Interest expense |

(40.8 | ) | (43.2 | ) | (45.1 | ) | (22.4 | ) | (21.5 | ) | (44.2 | ) | ||||||||||||

| Interest income |

1.2 | 0.4 | 0.8 | 0.4 | 0.5 | 0.9 | ||||||||||||||||||

| Other income (expense) |

2.9 | (1.2 | ) | (6.3 | ) | (6.3 | ) | (6.7 | ) | (6.7 | ) | |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Income before income taxes |

65.0 | 63.5 | 35.8 | 23.2 | 13.8 | 26.4 | ||||||||||||||||||

| Income tax expense |

(20.8 | ) | (22.5 | ) | (8.4 | ) | (6.6 | ) | (4.2 | ) | (6.0 | ) | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Net income |

$ | 44.2 | $ | 41.0 | $ | 27.4 | $ | 16.6 | $ | 9.6 | $ | 20.4 | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Balance Sheet Data: |

||||||||||||||||||||||||

| Cash and cash equivalents |

$ | 30.7 | $ | 53.9 | $ | 64.4 | $ | 58.2 | $ | 64.9 | $ | 64.9 | ||||||||||||

| Total current assets |

$ | 382.7 | $ | 394.2 | $ | 447.6 | $ | 427.7 | $ | 523.9 | $ | 523.9 | ||||||||||||

| Property, plant and equipment |

$ | 164.2 | $ | 185.5 | $ | 187.5 | $ | 185.7 | $ | 185.6 | $ | 185.6 | ||||||||||||

| Total assets |

$ | 1,252.1 | $ | 1,370.9 | $ | 1,392.7 | $ | 1,400.8 | $ | 1,466.2 | $ | 1,466.2 | ||||||||||||

| Total current liabilities |

$ | 225.1 | $ | 227.5 | $ | 417.5 | $ | 381.9 | $ | 333.6 | $ | 333.6 | ||||||||||||

| Long-term debt (including current portion) |

$ | 150.2 | $ | 185.3 | $ | 165.1 | $ | 201.3 | $ | 119.2 | $ | 119.2 | ||||||||||||

| Notes payable to GST (including current portion) |

$ | 237.4 | $ | 248.1 | $ | 259.3 | $ | 259.3 | $ | 271.0 | $ | 271.0 | ||||||||||||

| Total shareholders’ equity |

$ | 494.1 | $ | 547.1 | $ | 597.5 | $ | 536.6 | $ | 716.8 | $ | 716.8 | ||||||||||||

| Other Financial Data: |

||||||||||||||||||||||||

| EBITDA(3) |

$ | 153.0 | $ | 161.8 | $ | 136.7 | $ | 73.6 | $ | 63.7 | $ | 126.8 | ||||||||||||

| Adjusted EBITDA(3) |

$ | 155.2 | $ | 172.2 | $ | 154.8 | $ | 84.6 | $ | 71.5 | $ | 141.7 | ||||||||||||

| Ratio of total net debt, as adjusted, to Adjusted EBITDA(3)(4) |

3.2x | |||||||||||||||||||||||

| Percentage of total debt to total capitalization(5) |

19.2 | % | ||||||||||||||||||||||

| Net cash provided by operating activities |

$ | 81.4 | $ | 118.2 | $ | 69.9 | $ | 5.5 | $ | (13.8 | ) | $ | 50.6 | |||||||||||

| Net cash used in investing activities |

$ | (260.7 | ) | $ | (125.6 | ) | $ | (41.5 | ) | $ | (22.1 | ) | $ | (23.2 | ) | $ | (42.6 | ) | ||||||

| Net cash provided by (used in) financing activities |

$ | (9.4 | ) | $ | 29.5 | $ | (19.5 | ) | $ | 23.0 | $ | 36.4 | $ | (6.1 | ) | |||||||||

| Capital expenditures |

$ | 34.3 | $ | 40.9 | $ | 39.9 | $ | 20.3 | $ | 19.0 | $ | 38.6 | ||||||||||||

| Segment Data: |

||||||||||||||||||||||||

| Sales |

||||||||||||||||||||||||

| Sealing Products |

$ | 534.9 | $ | 609.1 | $ | 622.9 | $ | 312.5 | $ | 330.4 | $ | 640.8 | ||||||||||||

| Engineered Products |

386.7 | 363.0 | 356.4 | 186.9 | 187.3 | 356.8 | ||||||||||||||||||

| Power Systems(6) |

185.8 | 214.6 | 167.6 | 94.4 | 84.1 | 157.3 | ||||||||||||||||||

| Segment Profit |

||||||||||||||||||||||||

| Sealing Products |

81.2 | 88.8 | 97.1 | 49.0 | 39.9 | 88.0 | ||||||||||||||||||

| Engineered Products |

29.2 | 20.5 | 17.6 | 14.4 | 17.6 | 20.8 | ||||||||||||||||||

| Power Systems(6) |

30.6 | 39.2 | 14.0 | 11.2 | 6.7 | 9.5 | ||||||||||||||||||

| Segment EBITDA(3) |

||||||||||||||||||||||||

| Sealing Products |

104.1 | 119.1 | 127.5 | 64.3 | 55.3 | 118.5 | ||||||||||||||||||

| Engineered Products |

50.7 | 42.3 | 40.0 | 25.6 | 29.1 | 43.5 | ||||||||||||||||||

| Power Systems(6) |

34.2 | 42.3 | 17.6 | 13.0 | 8.5 | 13.1 | ||||||||||||||||||

17

| (1) | In August 2011, we acquired certain assets and assumed certain liabilities of PI Bearing Technologies, a privately held manufacturer of bearing blocks and other bearing products used in fluid power applications, and a distributor of high performance plain bearing products used in industrial applications. The business is part of our Engineered Products segment. In July 2011, we acquired Tara Technologies Corporation (“Tara”), a privately-held company that offers highly engineered products and solutions to the semiconductor, aerospace, energy and medical markets. The business is part of our Sealing Products segment. In February 2011, we acquired the Mid Western group of companies, a privately-owned business primarily serving the oil and gas drilling, production and processing industries of western Canada. Mid Western services and rebuilds reciprocating compressors, designs and installs lubrication systems, and services and repairs a variety of other equipment used in the oil and gas industry. The business is part of our Engineered Products segment. In February 2011, we acquired the business of Pipeline Seal and Insulator, Inc. and its affiliates (“PSI”), a privately-owned group of companies that manufacture products for the safe flow of fluids through pipeline transmission and distribution systems worldwide. The PSI business primarily serves the global oil and gas industry and water and wastewater infrastructure markets. The business’s products include flange sealing and flange isolation products; pipeline casing spacers/isolators; casing end seals; the original Link-Seal® modular sealing system for sealing pipeline penetrations into walls, floors, ceilings and bulkheads; hole forming products; manhole infiltration sealing systems; and safety-related signage for pipelines. The business is part of our Sealing Products segment. In January 2011, we acquired certain assets and assumed certain liabilities of Rome Tool & Die, Inc., a leading supplier of steel brake shoes to the North American heavy-duty truck market. The business is part of our Sealing Products segment. We paid for the acquisitions completed during 2011 with $228.2 million in cash, which included $99.2 million for the purchase of PSI. Additionally, there were approximately $2.2 million of acquisition-related costs recorded during 2011. We allocated the purchase prices of the acquired businesses to the assets acquired and liabilities assumed based on their estimated fair values. The excess of the purchase prices over the identifiable assets acquired less the liabilities assumed was reflected as goodwill. |

| (2) | In April 2012, we acquired Motorwheel Commercial Vehicle Systems, Inc. (“Motorwheel”). Motorwheel is a leading U.S. manufacturer of lightweight brake drums for heavy-duty trucks and other commercial vehicles. Motorwheel also sells wheel-end component assemblies for the heavy-duty market, sells fasteners for wheel-end applications and provides related services to its customers, including product development, testing and certification. The business is managed as part of the Stemco operations in the Sealing Products segment. We paid for the Motorwheel acquisition with approximately $85 million of cash, which was funded by additional borrowings from our revolving credit facility. We allocated the purchase price of the business to the assets acquired and liabilities assumed based on their estimated fair values. The excess of the purchase price over the identifiable assets acquired less the liabilities assumed was reflected as goodwill. |

| (3) | We define “EBITDA” for the periods presented above as net income before interest expense (net of interest income), income tax expense, and depreciation and amortization expense. EBITDA does not represent, and should not be considered as, an alternative to net income or cash flows from operating activities, each as determined in accordance with GAAP. We define “Adjusted EBITDA” for the periods presented above as net income before interest expense (net of interest income), income tax expense, depreciation and amortization expense, restructuring costs, environmental reserve adjustment, loss on debt exchange and other selected items. We define Segment EBITDA as segment profit before depreciation and amortization expense. We have presented EBITDA, Adjusted EBITDA and Segment EBITDA in this offering memorandum because we believe they are useful financial measurements for assessing operating performance as they provide investors with additional bases to evaluate our performance. In addition, we use these metrics to further our understanding of our historical and prospective consolidated operating performance and, with respect to Segment EBITDA, the operating performance of our segments before expenses incurred by our corporate activities. In addition, we use Adjusted EBITDA to evaluate the ordinary course of our operations, before certain selected items, even though those items may be recurring, because we believe to effectively compare our core operating performance from period to period on a historical and prospective basis, this metric should exclude items relating to restructuring costs, environmental reserve adjustment, loss on debt exchange and other selected items incurred outside the ordinary course of our operations. Other companies may calculate EBITDA, Adjusted EBITDA and Segment EBITDA differently than we do. EBITDA, Adjusted EBITDA and Segment EBITDA are not measures of performance under GAAP and should not be considered as a substitute for our net income, or the segment profit of our reporting segments, respectively, prepared in accordance with GAAP. Each of EBITDA, Adjusted EBITDA and Segment EBITDA has limitations as an analytical tool, and you should not consider it in isolation or as a substitute for analysis of our results as reported under GAAP. Some of these limitations are: EBITDA, Adjusted EBITDA and Segment EBITDA do not reflect our cash expenditures, |

18

| or future requirements, for capital expenditures or contractual commitments; EBITDA, Adjusted EBITDA and Segment EBITDA do not reflect interest expense or the cash requirements necessary to service interest or principal payments on our debt; EBITDA, Adjusted EBITDA and Segment EBITDA do not reflect income tax expense or the cash requirements necessary to pay for income tax obligations; and although depreciation and amortization are non-cash charges, the assets being depreciated and amortized will often have to be replaced in the future, and EBITDA, Adjusted EBITDA and Segment EBITDA do not reflect any cash requirements for such replacements. In addition, in evaluating Adjusted EBITDA you should be aware that in the future we may incur expenses that are the same as or similar to some of the adjustments in this presentation. Our presentation of Adjusted EBITDA should not be construed as an inference that our future results will not be unaffected by unusual or non-recurring items. |

The following table sets forth the reconciliation of net income to EBITDA and Adjusted EBITDA for the periods indicated:

| Year Ended December 31, |

Six Months Ended June 30, (unaudited) |

Twelve June 30, (unaudited) |

||||||||||||||||||||||

| 2011 |

2012 |

2013 |

2013 |

2014 |

2014 |

|||||||||||||||||||

| (in millions) | ||||||||||||||||||||||||

| Net income |

$ | 44.2 | $ | 41.0 | $ | 27.4 | $ | 16.6 | $ | 9.6 | $ | 20.4 | ||||||||||||

| Interest expense |

40.8 | 43.2 | 45.1 | 22.4 | 21.5 | 44.2 | ||||||||||||||||||

| Interest income |

(1.2 | ) | (0.4 | ) | (0.8 | ) | (0.4 | ) | (0.5 | ) | (0.9 | ) | ||||||||||||

| Income tax expense |

20.8 | 22.5 | 8.4 | 6.6 | 4.2 | 6.0 | ||||||||||||||||||

| Depreciation |

25.3 | 28.8 | 29.6 | 14.8 | 14.9 | 29.7 | ||||||||||||||||||

| Amortization |

23.1 | 26.7 | 27.0 | 13.6 | 14.0 | 27.4 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| EBITDA |

153.0 | 161.8 | 136.7 | 73.6 | 63.7 | 126.8 | ||||||||||||||||||

| Restructuring costs |

1.4 | 5.0 | 6.7 | 2.9 | 0.6 | 4.4 | ||||||||||||||||||

| Environmental reserve adjustment |

— | 1.2 | 6.3 | 6.3 | 0.7 | 0.7 | ||||||||||||||||||

| Loss on debt exchange |

— | — | — | — | 6.0 | 6.0 | ||||||||||||||||||

| Other(a) |

0.8 | 4.2 | 5.1 | 1.8 | 0.5 | 3.8 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Adjusted EBITDA |

$ | 155.2 | $ | 172.2 | $ | 154.8 | $ | 84.6 | $ | 71.5 | $ | 141.7 | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| (a) | “Other” represents intercompany managements fees and legal fees related to the GST bankruptcy. For the years ended December 31, 2013, 2012 and 2011 and the twelve months ended June 30, 2014, it includes $0.4 million, $1.2 million, $1.9 million and $0.4 million, respectively, of inventory adjustments primarily related to acquisition date fair value adjustments. For the year ended December 31, 2011, “Other” includes an adjustment to exclude a $2.9 million gain for a guaranteed investment contract, which is described in Note 19 to our Audited Consolidated Financial Statements included elsewhere in this offering memorandum. |

19

The following table sets forth the reconciliation of segment profit of each of our reporting segments to Segment EBITDA for the periods indicated:

| Year Ended December 31, |

Six Months Ended June 30, (unaudited) |

Twelve June 30, |

||||||||||||||||||||||

| 2011 |

2012 |

2013 |

2013 |

2014 |

2014 |

|||||||||||||||||||

| (in millions) | ||||||||||||||||||||||||

| Sealing Products |

||||||||||||||||||||||||

| Segment profit |

$ | 81.2 | $ | 88.8 | $ | 97.1 | $ | 49.0 | $ | 39.9 | $ | 88.0 | ||||||||||||

| Depreciation and amortization expense |

22.9 | 30.3 | 30.4 | 15.3 | 15.4 | 30.5 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Segment EBITDA |

$ | 104.1 | $ | 119.1 | $ | 127.5 | $ | 64.3 | $ | 55.3 | $ | 118.5 | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Engineered Products |

||||||||||||||||||||||||

| Segment profit |

$ | 29.2 | $ | 20.5 | $ | 17.6 | $ | 14.4 | $ | 17.6 | $ | 20.8 | ||||||||||||

| Depreciation and amortization expense |

21.5 | 21.8 | 22.4 | 11.2 | 11.5 | 22.7 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Segment EBITDA |

$ | 50.7 | $ | 42.3 | $ | 40.0 | $ | 25.6 | $ | 29.1 | $ | 43.5 | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Power Systems |

||||||||||||||||||||||||

| Segment profit |

$ | 30.6 | $ | 39.2 | $ | 14.0 | $ | 11.2 | $ | 6.7 | $ | 9.5 | ||||||||||||

| Depreciation and amortization expense |

3.6 | 3.1 | 3.6 | 1.8 | 1.8 | 3.6 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| Segment EBITDA |

$ | 34.2 | $ | 42.3 | $ | 17.6 | $ | 13.0 | $ | 8.5 | $ | 13.1 | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

| (4) | Ratio of total net debt, as adjusted, to Adjusted EBITDA is calculated as the ratio of our total debt less cash and cash equivalents at June 30, 2014, in each case as adjusted to give effect to the Refinancing Transactions, to Adjusted EBITDA for the twelve months ended June 30, 2014. See “Capitalization” for a presentation of our total debt and cash and cash equivalents as adjusted to give effect to the Refinancing Transactions. |

| (5) | Ratio of total debt to total capitalization is our total debt at June 30, 2014 divided by the product of the number of shares of our common stock outstanding on June 30, 2014 (less treasury shares) multiplied by the closing price per share of our common on the New York Stock Exchange on June 30, 2014 ($73.16). |

| (6) | Effective the first quarter of 2014, we changed the name of what had previously been called the Engine Products and Services segment to the Power Systems segment to more accurately reflect that the segment’s products are the principal components of systems that generate electrical power and other types of energy. There was no change to the composition of this segment and there is no impact on the sales, segment profit or Segment EBITDA of the previously reported segment. |

20

The table below sets forth, as of June 30, 2014, (i) our actual historical cash and capitalization, (ii) our cash and capitalization as adjusted to give effect to the Refinancing Transactions other than the offering of notes and the application of the net proceeds therefrom as contemplated hereby, as if such events occurred on June 30, 2014 and (iii) our cash and cash capitalization as further adjusted to give effect to the Refinancing Transactions, including the offering of the notes and the application of the net proceeds therefrom as contemplated hereby, as if such events occurred on June 30, 2014. See “Use of Proceeds” for additional detail on the use of net proceeds from the issuance of the notes.

You should read this table along with our audited and unaudited consolidated financial statements and related notes and other financial information included in this offering memorandum.

| As of June 30, 2014 |

||||||||||||

| Actual |

As |

As Further Adjusted(2) |

||||||||||

| (unaudited) | ||||||||||||

| (in millions) | ||||||||||||

| Cash and cash equivalents |

$ | 64.9 | $ | 64.9 | $ | 136.8 | ||||||

|

|

|

|

|

|

|

|||||||

| Short-term debt: |

||||||||||||

| Short-term borrowings from GST |

$ | 22.8 | $ | 22.8 | $ | 22.8 | ||||||

| 3.9375% Convertible Senior Debentures due 2015 |

74.8 | (3) | — | — | ||||||||

| Notes payable to GST(4) |

11.7 | 11.7 | 11.7 | |||||||||

| Long-term debt: |

||||||||||||

| Senior secured revolving credit facility |

$ | 48.7 | 222.1 | — | (5) | |||||||

| Notes payable to GST(4) |

259.3 | 259.3 | 259.3 | |||||||||

| Senior Notes due 2022 offered hereby |

— | — | 300.0 | |||||||||

| Other long-term debt |

0.8 | 0.8 | 0.8 | |||||||||

|

|

|

|

|

|

|

|||||||

| Total debt |

418.1 | 516.7 | 594.6 | |||||||||

| Total shareholders’ equity |

716.8 | 613.7 | (6) | 613.7 | (6) | |||||||

|

|

|

|

|

|

|

|||||||

| Total capitalization |

$ | 1,134.9 | $ | 1,130.4 | $ | 1,208.3 | ||||||

|

|

|

|

|

|

|

|||||||

| (1) | The “As Adjusted” column gives effect to the effectiveness of the Credit Facility Amendment, the purchase of all of our outstanding Convertible Debentures in the Tender Offer at a price per $1,000 principal amount of the Convertible Debentures equal to the maximum $2,301.89 purchase price, plus payment of accrued and unpaid interest, for an aggregate amount of $173.4 million (assuming a payment date of September 15, 2014), and borrowings under the Revolving Credit Facility to fully fund such purchase of the Convertible Debentures. In the event that less than all of the Convertible Debentures are purchased in the Tender Offer, the “As Adjusted” amount of Convertible Debentures would be the aggregate principal amount of the Convertible Debentures not purchased in the Tender Offer and the amount of cash and cash equivalents would be increased by $2,318.30 (which reflects accrued interest assuming a payment date of September 15, 2014) per $1,000 principal amount of the Convertible Debentures not purchased in the Tender Offer. |

| (2) | The “As Further Adjusted” column gives effect to the Refinancing Transactions after the payment of the initial purchasers’ commissions and estimated fees and expenses payable by us and reflects the purchase of all of our outstanding Convertible Debentures in the Tender Offer at a price per $1,000 principal amount of the Convertible Debentures equal to the maximum $2,301.89 purchase price, plus payment of accrued and unpaid interest, for an aggregate amount $173.4 million (assuming a payment date of September 15, 2014). In the event that less than all of the Convertible Debentures are purchased in the Tender Offer, the “As Further Adjusted” amount of Convertible Debentures would be the aggregate principal amount of the Convertible Debentures not purchased in the Tender Offer and the amount of cash and cash equivalents |

21

| would be increased by $2,318.30 (which reflects accrued interest assuming a payment date of September 15, 2014) per $1,000 principal amount of the Convertible Debentures not purchased in the Tender Offer. |

| (3) | The amount shown is equal to the $69.7 million debt associated with the liability component of the Convertible Debentures plus the $5.1 million unamortized debt discount associated with the equity component of the Convertible Debentures. Because the Convertible Debentures were convertible at June 30, 2014, the amount is reflected in current maturities as of June 30, 2014. |

| (4) | Includes indebtedness under an a promissory note made by Coltec payable to GST LLC with an aggregate principal balance of $87.5 million at June 30, 2014 and under a promissory note made by Stemco LP , an indirect subsidiary of Coltec, payable to GST LLC with an aggregate principal balance of $183.5 million at June 30, 2014. The Coltec Note is secured by Coltec’s pledge of certain of its equity ownership in specified U.S. subsidiaries. The Stemco Note is guaranteed by Coltec and secured by Coltec’s pledge of its interest in Stemco LP and Stemco Holdings, Inc. The principal amount of each of these Intercompany Notes is subject to increase over time as a portion of the interest on these notes is added to the principal amount of the Intercompany Notes as payment-in-kind (PIK) interest. The Intercompany Notes provide that if GST LLC is unable to pay ordinary course operating expenses, under certain conditions, GST LLC can require Coltec and Stemco to pay the accrued and unpaid PIK interest in cash to the extent necessary to meet such ordinary course operating expenses, subject to certain caps. The PIK interest is payable on January 31 of each year. Accordingly, such amount of accrued and unpaid PIK interest on the Intercompany Notes is reflected as short-term debt. The Intercompany Notes are subordinated to any obligations under the Revolving Credit Facility, pursuant to existing subordination agreements which subordinate GST LLC’s right to receive payment of principal of the Intercompany Notes to the prior payment in full of all obligations under the Revolving Credit Facility but permit the payment of interest on the Intercompany Notes in the ordinary course of business so long as no event of default exists, or would occur as a result of any such payment, under the Revolving Credit Facility and there is availability of at least $20.0 million under the Revolving Credit Facility. In addition, under these subordination agreements GST LLC is prohibited from exercising any rights and remedies it may have against Coltec and Stemco LP with respect to the Intercompany Notes except for purposes of filing a claim during an insolvency proceeding. It will not be an event of default under the Revolving Credit Facility and the notes offered hereby if, as required by the subordination agreements, the Intercompany Notes are not repaid on their stated maturity date, January 1, 2017. See “Other Indebtedness—Intercompany Notes.” |

| (5) | As of June 30, 2014, after giving effect to the Refinancing Transactions, an additional $300.0 million, representing the full amount of the Revolving Credit Facility, less $5.7 million reserved for outstanding letters of credit would have been available for borrowing under the Revolving Credit Facility. For a description of the material terms of the Revolving Credit Facility, see “Description of Other Indebtedness—Revolving Credit Facility.” |

| (6) | The premium included in the assumed purchase price for all of the Convertible Debentures in the Tender Offer of $3.9 million would be charged to expense and the remaining excess of the purchase price over the premium and the debt component of the Convertible Debentures, or $97.5 million, would reduce additional paid in capital included in shareholders’ equity. Unamortized debt issuance costs of $0.6 million and the excess of the amount paid for the debt component over the carrying value of such Convertible Debentures would be charged to expense. Shareholders’ equity has not been adjusted for fees paid in connection with the Credit Facility Amendment as such fees are capitalized and will reduce shareholders’ equity as the fees are expensed over the life of the Revolving Credit Facility. |

22

MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

The following is management’s discussion and analysis of certain significant factors that have affected our consolidated financial condition and operating results during the periods included in the accompanying audited Consolidated Financial Statements and the related notes. You should read the following discussion in conjunction with our audited Consolidated Financial Statements and the related notes, included elsewhere in this offering memorandum.

Forward-Looking Statements