Attached files

| file | filename |

|---|---|

| EX-99.1 - EXHIBIT 99.1 - FINDEX COM INC | exhibit99_1.htm |

| EX-4.1 - EXHIBIT 4.1 - FINDEX COM INC | exhibit4_1.htm |

| EX-10.3 - EXHIBIT 10.3 - FINDEX COM INC | exhibit10_3.htm |

| EX-10.2 - EXHIBIT 10.2 - FINDEX COM INC | exhibit10_2.htm |

| EX-2.1 - EXHIBIT 2.1 - FINDEX COM INC | exhibit2_1.htm |

| EX-10.4 - EXHIBIT 10.4 - FINDEX COM INC | exhibit10_4.htm |

| EX-10.1 - EXHIBIT 10.1 - FINDEX COM INC | exhibit10_1.htm |

| EX-99.3 - EXHIBIT 99.3 - FINDEX COM INC | exhibit99_3.htm |

| EX-99.2 - EXHIBIT 99.2 - FINDEX COM INC | exhibit99_2.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 8-K

CURRENT REPORT

Pursuant to Section 13 OR 15(d) of the Securities Exchange Act of 1934

Date of Current Report on Form 8-K (Date of earliest event reported): July 23, 2014

FINDEX.COM, INC.

(Exact name of registrant as specified in its charter)

|

Nevada

|

000-29963

|

88-0379462

|

||

|

(State or other jurisdiction of incorporation)

|

(Commission File Number)

|

(IRS Employer Identification No.)

|

1313 South Killian Drive

Lake Park, FL 33403

(Address of principal executive offices) (Zip Code)

Registrant’s telephone number, including area code: (561) 328-6488

18151 Lafayette Avenue

Elkhorn, Nebraska 68022

(402) 333-1900

(Former name or former address, if changed since last report.)

Check the appropriate box below if the Form 8-K filing is intended to simultaneously satisfy the filing obligation of the registrant under any of the following provisions (see General Instruction A.2. below):

Written communications pursuant to Rule 425 under the Securities Act (17 CFR 230.425)

Soliciting material pursuant to Rule 14a-12 under the Exchange Act (17 CFR 240.14a-12)

Pre-commencement communications pursuant to Rule 14d-2(b) under the Exchange Act (17 CFR 240.14d-2(b))

Pre-commencement communications pursuant to Rule 13e-4(c) under the Exchange Act (17 CFR 240.13e-4(c)

SPECIAL NOTE REGARDING FORWARD LOOKING STATEMENTS

This Current Report on Form 8-K (this “Current Report on Form 8-K”) contains forward-looking statements. The forward-looking statements are contained principally in the sections entitled “Description of Business,” “Risk Factors,” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations.” These statements involve known and unknown risks, uncertainties and other factors which may cause our actual results, performance or achievements to be materially different from any future results, performances or achievements expressed or implied by the forward-looking statements. In some cases, you can identify forward-looking statements by terms such as “anticipates,” “believes,” “seeks,” “could,” “estimates,” “expects,” “intends,” “may,” “plans,” “potential,” “predicts,” “projects,” “should,” “would” and similar expressions intended to identify forward-looking statements. Forward-looking statements reflect our current views with respect to future events and are based on assumptions and subject to risks and uncertainties. These risks and uncertainties include, but are not limited to, the factors described in the section captioned “Risk Factors” below. Given these uncertainties, you should not place undue reliance on these forward-looking statements. Such statements may include, but are not limited to, information related to: anticipated operating results; relationships with our customers; consumer demand; financial resources and condition; changes in revenues; cost of sales; selling, general and administrative expenses; interest expense; legal proceedings and claims.

Also, forward-looking statements represent our estimates and assumptions only as of the date of this Current Report on Form 8-K. You should read this Current Report on Form 8-K, and the documents that we reference and filed as exhibits to this Current Report on Form 8-K, completely and with the understanding that our actual future results may be materially different from what we expect. Except as required by law, we assume no obligation to update any forward-looking statements publicly, or to update the reasons actual results could differ materially from those anticipated in any forward-looking statements, even if new information becomes available in the future.

ITEM 1.01 ENTRY INTO A MATERIAL DEFINITIVE AGREEMENT

Agreement and Plan of Merger

On July 23, 2014, we, Findex.com, Inc. (the “Company”), entered into an agreement and plan of merger (the “Merger Agreement”), with each of EcoSmart Acquisition Corp., a Delaware corporation and a wholly-owned special-purpose acquisition subsidiary of ours (“Merger-Sub”), EcoSmart Surface & Coating Technologies, Inc., a Florida Corporation (“EcoSmart”), and The Renewable Corporation, a Washington corporation and the majority-controlling stockholder of EcoSmart (“TRC”), pursuant to which Merger-Sub acquired all of the outstanding capital stock of EcoSmart in exchange for 111,193 shares of our Series MX convertible preferred stock, par value $0.001 per share (the “Series MX Convertible Preferred Stock”), which shares of Series MX Convertible Preferred Stock will automatically convert, on a combined basis, into a total of 277,981,807 shares of our common stock, par value $0.001 (our “Common Stock”) upon the effectiveness of any amendment to our articles of incorporation increasing the number of authorized shares of our Common Stock to 900,000,000 or more (currently fixed at 120,000,000). On July 23, 2014, we completed the filings of the corresponding certificate of merger in each of the States of Delaware and Florida, thereby consummating a statutory merger (the “Merger”). In effect, the Merger involved our issuing new shares amounting to 70% of our Common Stock in order to acquire the business of EcoSmart.

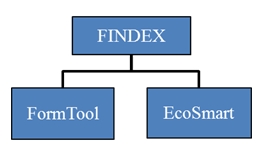

As a result of the Merger, in addition to our pre-Merger FormTool consumer software business, we are now the holding company of EcoSmart, which is an operating business centered around the development of a proprietary line of state-of-the-art specialty materials coatings that have a broad range of value-adding industrial, commercial, and residential applications.

The Merger Agreement contains certain detailed information regarding the terms of the Merger, which, in general, govern the contractual rights and relationships, and allocate certain risks, between and among the parties in relation to the Merger. The Merger Agreement additionally sets out the legal effects and procedural mechanics surrounding the conversion and exchange of the EcoSmart common stock and other securities into FIND securities, including how and when the EcoSmart securityholders will receive new certificates reflecting the FIND securities to which they became entitled as a result of the Merger.

-1-

The Merger Agreement provides that, as of the consummation of the Merger (the “Closing”), which occurred on July 23, 2014 contemporaneously with the signing of the Merger Agreement, EcoSmart merged with and into Merger-Sub, a wholly-owned subsidiary of FIND recently formed under the laws of the State of Delaware for the specific purpose of effecting the Merger, and as a result, the entity that was EcoSmart prior to the Merger has now been merged out of existence while the business of EcoSmart has, as a result of the Merger, effectively become a wholly-owned subsidiary of FIND, albeit now held in the form of the recently-formed Delaware corporation.

Also as a result of the Merger:

|

▪

|

our existing articles of incorporation and bylaws, and the certificate of incorporation and bylaws of Merger-Sub, remain unaffected by the Merger, but the certificate of incorporation and bylaws of Merger-Sub have become the certificate of incorporation and bylaws of EcoSmart, as our wholly-owned subsidiary;

|

|

|

▪

|

in addition to the existing members of our board of directors, Steven Malone and John Kuehne, one new director, Donald Schoenfeld, has been added, and, collectively, these three individuals now also serve as the members of the board of directors of Merger-Sub;

|

|

|

▪

|

Steven Malone, as both president and chief executive officer, remains our only incumbent officer of each of FIND and Merger-Sub, though he now serves pursuant to an employment agreement;

|

|

|

▪

|

the liabilities and obligations of EcoSmart became the liabilities and obligations of Merger-Sub;

|

|

|

▪

|

each share of issued and outstanding FIND common stock and other securities issued and outstanding immediately prior to the Closing remain unaffected; and

|

|

|

▪

|

all of the issued and outstanding shares of common stock of EcoSmart were converted into a number of shares of FIND common stock such that all EcoSmart securityholders immediately prior to the Merger owned, in the aggregate immediately following the Merger, approximately 70% of our Common Stock on a fully-diluted basis, and all other issued and outstanding securities of EcoSmart convertible into or exchangeable for shares of EcoSmart common stock prior to the Merger, including any debentures, purchase warrants and stock options, were converted into equivalent securities of FIND convertible into shares of FIND common stock on a pro-rata basis.

|

The Merger Agreement contains certain representations and warranties of FIND and Merger-Sub, on the one hand, and TRC, on the other, most but not necessarily all of which are customarily found in similar agreements between comparable, similarly situated entities. These representations and warranties were negotiated between the parties with the principal purpose of setting forth their respective rights with respect to the representations and warranties they have made regarding their respective operational, financial, and other business characteristics, which in many cases are subject to material limitations and/or qualifications as specifically set forth in the corresponding provisions of the Merger Agreement.

Any right to pursue claims for breach of any of the representations, warranties, and/or other agreements arising under the Merger Agreement exist until July 23, 2015, which will be the one year anniversary of the consummation of the Merger. Any breaching party shall, jointly and severally, indemnify, defend and hold harmless the non-breaching party for and against all damages and liabilities or amounts that are incurred or paid in settlement of or in connection with any such qualifying claim or proceeding arising out of any such breach.

The foregoing description of the Merger Agreement is merely a brief summary of certain of the agreement’s key terms and is qualified in its entirety by reference to the specific provisions of the Merger Agreement itself which is filed as Exhibit 2.1 to this Current Report on Form 8-K and incorporated by reference herein.

-2-

Malone Employment Agreement

Contemporaneous with consummation of the Merger on July 23, 2014, and viewed by the parties as a related aspect thereof, FIND and Merger-Sub entered into an employment agreement with Steven Malone to serve as our president and chief executive officer. Since April 2010, when the last employment agreement between Mr. Malone and the Company expired, Mr. Malone, who has served in these positions for the past 14 years in total, has been doing so on an employment-at-will basis. Among other terms and provisions, the employment agreement entered into as of Closing of the Merger provides that Mr. Malone will be employed by FIND and Merger-Sub with specific executive-level responsibilities for a term of 3 years, unless the term is either extended or the agreement is terminated at some time prior to the duration of the term by either party, either for cause, without cause, due to disability or death, or voluntarily. During the term of the employment agreement, and in addition to certain benefits, expense coverage and severance compensation, Mr. Malone is entitled to a base annual salary of not less than $150,000, as well as an annual cash bonus equal to 1% of FIND free cash flow, as such term is specifically defined therein.

The foregoing description of Mr. Malone’s employment agreement is merely a brief summary of certain of its key terms and is qualified in its entirety by reference to the specific provisions of such agreement, a copy of which is filed as Exhibit 10.1 to this Current Report on Form 8-K and incorporated by reference herein.

ITEM 1.02 TERMINATION OF A MATERIAL DEFINITIVE AGREEMENT

As disclosed in a current report on Form 8-K filed by us on January 29, 2014, we entered into a definitive Agreement and Plan of Merger on January 23, 2014 with Merger-Sub, TRC, and EcoSmart, as well as certain of our affiliated stockholders (the “Original Merger Agreement”). Pursuant to the Original Merger Agreement, we had agreed to enter into a series of transactions centered around a statutory merger, pursuant to which we would issue what would have amounted to approximately 70% of our Common Stock in exchange for all of the issued and outstanding capital stock of EcoSmart. The basic economic and other terms of the Original Merger Agreement were very similar to the Merger Agreement, but, among other differences, the Original Merger Agreement contemplated a period between its execution and its closing, something not contemplated by the Merger Agreement. For a variety of reasons centered around transactional mechanics for the most part, a restructuring of the Original Merger Agreement resulted in what became the Merger Agreement.

Pursuant to Section 6.10 of the Merger Agreement, the Original Merger Agreement was terminated as of July 23, 2014, effectively superceded by the Merger Agreement, and is of no further force or effect.

ITEM 2.01 COMPLETION OF ACQUISITION OR DISPOSITION OF ASSETS

As disclosed above under Item 1.01, as of the Closing, and pursuant to the Merger Agreement, the shareholders of EcoSmart effectively exchanged all of their shares of EcoSmart common stock for 111,193 newly issued shares Series MX Convertible Preferred Stock which, upon issuance at Closing and as of the date hereof, represents 70% of our total issued and outstanding Common Stock on an as-converted, fully diluted basis.

As more fully described in Item 5.02 below, as of the Closing, we appointed one new member to our board of directors, which now consists of three members, each of whom are expected to serve until their death, incapacitation, resignation, removal, or until their successor has been duly elected by our stockholders and assumed such role.

FORM 10 DISCLOSURE

As disclosed elsewhere in this Current Report on Form 8-K, on July 23, 2014, the Company acquired the business of EcoSmart pursuant to the Merger Agreement. Item 2.01(f) of Form 8-K provides that if a registrant is a shell company, other than a business combination related shell company, as those terms are defined in Rule 12b-2 under the Securities Exchange Act of 1934, as amended, (“Exchange Act”), immediately before a transaction such as the Merger, then, upon consummation of the transaction, such registrant must disclose the information that would be required if it were filing a general form for registration of securities on SEC Form 10 under the Exchange Act reflecting all classes of it’s securities subject to the reporting requirements of Section 13 of the Exchange Act.

-3-

Although we do not believe that we meet the definition of a shell company for purposes of the additional disclosure required by Item 2.01(f) of Form 8-K, because we recognize that the extent of our assets and operations, coupled with the relative extent of EcoSmart’s assets and operations and the change in our overall strategic direction expected to result from the Merger, render the transaction one otherwise apparently contemplated by the mandate of Item 2.01(f) of Form 8-K, we have elected to voluntarily comply with the mandate of Item 2.01(f) of Form 8-K as if we did meet the definition of a shell company. In this regard, we are providing below the information that we would be required to disclose on Form 10 under the Exchange Act if we were to be filing such form. Please note that the information provided below relates to the combined enterprises of the Company and EcoSmart, after consummation of the Merger, except that information relating to periods prior to the date of the Merger relate to either FIND or EcoSmart, as applicable, depending on the particular context.

Information in response to this Item 2.01 below is based generally on the format of Form 10.

BUSINESS

Our headquarters and operations are based in Lake Park, Florida. Our business is comprised of two distinct operating divisions. One of these divisions, EcoSmart, which we acquired as a result of the Merger, centers around the development of a proprietary line of specialty materials coatings that have a broad range of value-adding industrial, commercial, and residential applications. The other division, FormTool, which we acquired in February 2008, is focused upon the production, marketing and distribution of a line of consumer software products that offer quality, professionally designed forms for business, accounting, construction, sales, real estate, human resources and personal organization needs.

History and Background

Prior to the Merger, and since 1999, our business had been developing, publishing, marketing, distributing and direct-selling off-the-shelf consumer and organizational software products for the Windows platform. Following divestitures of two software titles which had consistently accounted for the overwhelming majority of our revenues while owned by us, including our Membership Plus product line, which we sold in late 2007, and our flagship QuickVerse product line, which we sold during 2011, and title acquisitions during the same period that, in the aggregate, have been relatively insignificant in offsetting the loss of revenues associated with those divestitures, our continuing operations, while not nominal, have been very limited and insubstantial in terms of revenue, both relative to what they had been prior thereto and by any appropriate standalone measure. Specifically, our operations immediately prior to the Merger consisted exclusively of those relating to the FormTool line of products which we acquired in February 2008, as well as two language tutorial products, which were retained after the sale of the QuickVerse product line. Due to a continuing lack of capital over a number of years, we were unable to meaningfully grow the FormTool line and develop related products, and our business and financial prospects became increasingly challenged.

As a result of the Merger, and although it is our current intention to continue to operate and further develop our FormTool product line and business, it is expected that our primary focus will shift going forward in the direction of the business of EcoSmart, where we believe the opportunities for our future growth are greater and have significantly more to offer economically.

-4-

Corporate Formation and Legacy

We were incorporated in the State of Nevada on November 7, 1997 as EJH Entertainment, Inc. On December 4, 1997, a predecessor corporation with the same name as our own but domiciled in Idaho was merged with and into us. Although the predecessor Idaho corporation was without material assets or operations as of the time of the merger, since being organized in 1968, it had historically been involved in mining and entertainment businesses unrelated to our current business.

Beginning in 1997, and although we were not then a reporting company under the Securities Exchange Act, our common stock was quoted on the OTC Bulletin Board (originally under the symbol “TIXX”, which was later changed to “TIXXD”). On May 13, 1999, we changed our name to FINdex.com, Inc. On March 7, 2000, in an effort to satisfy a newly imposed NASD Rule eligibility requirement that companies quoted on the OTC Bulletin Board be fully reporting under the Securities Exchange Act (thereby requiring recently audited financial statements) and current in their filing obligations, we acquired, as part of a share exchange in which we issued 150,000 shares of our common stock, all of the outstanding capital stock of Reagan Holdings, Inc., a Delaware corporation. At the time of this transaction, Reagan Holdings was subject to the requirements of having to file reports pursuant to Section 13 of the Securities Exchange Act, had recently audited financial statements and was current in its reporting obligations. Having no operations, employees, revenues or other business plan at the time, however, it was a public shell company. As a result of this transaction, Reagan Holdings, Inc. became our wholly owned subsidiary and we became the successor issuer to Reagan Holdings for reporting purposes pursuant to Rule 12g-3 of the Securities Exchange Act. Shortly thereafter, we changed our stock symbol to “FIND”. Though it does not currently have any operations, employees, or revenues, Reagan Holdings remains our wholly owned subsidiary.

In addition to Reagan Holdings, we also have one other wholly owned subsidiary, Findex.com, Inc. (i.e. the same name as our own), a Delaware corporation. Like Reagan Holdings, this entity, too, does not currently have any operations, employees, or revenues. This subsidiary resulted from an acquisition on April 30, 1999 pursuant to which we acquired all of the issued and outstanding capital stock of FINdex Acquisition Corp., a Delaware corporation, from its then stockholders in exchange for 4,700,000 shares of our common stock, which, immediately following the transaction, represented 55% of our total outstanding common stock. Our purpose for this acquisition was to broaden our then-existing stockholder base, an important factor in our effort to develop a strong market for our common stock. On May 12, 1999, in exchange for the issuance of 457,625 shares of FINdex Acquisition Corp. common stock, FINdex.com, Inc., another Delaware corporation (originally incorporated in December 1995 as FinSource, Ltd.), was merged with and into FINdex Acquisition Corp., with FINdex Acquisition Corp. remaining as the surviving entity. Our purpose for this merger was to acquire a proprietary financial information search engine for the Internet which was to serve as the cornerstone for a Web-based development-stage business, but which has since been abandoned. As part of the certificate of merger relating to this transaction, FINdex Acquisition Corp. changed its name to FINdex.com, Inc. We currently own 4,700,000 shares of FINdex.com, Inc. (the Delaware corporation), representing 100% of its total outstanding common stock.

EcoSmart

In its most recent corporate form, EcoSmart was organized in 2012. The patents and other intellectual property forming the foundation of the EcoSmart business were originally developed during a preceding period dating back to 2003 in which it was operated by the developers of the Company’s technologies as Surface Modification Technologies, Inc. (“SMT”), a Florida corporation, and EcoSmart, LLC, a Florida limited liability company, which were sold together to TRC in 2012. On January 20, 2012, EcoSmart Coating Technologies, Inc., a Florida corporation, was organized as a wholly-owned subsidiary of TRC. Simultaneously, EcoSmart Surface Technologies, Inc., also a Florida corporation, was formed as a wholly-owned subsidiary of TRC. With common ownership by TRC, the assets of each of SMT and EcoSmart, LLC were thereafter transferred in part to EcoSmart Coating Technologies, Inc. with the remainder to EcoSmart Surface Technologies, Inc. On September 18, 2012, EcoSmart Surface Technologies, Inc. changed its name to EcoSmart Surface & Coating Technologies, Inc. On October 19, 2012, EcoSmart Coating Technologies, Inc. was merged with and into EcoSmart Surface & Coating Technologies, Inc., leaving EcoSmart Surface & Coating Technologies, Inc. (“EcoSmart”) as the surviving corporation.

-5-

EcoSmart is divided into two basic product areas. One product area is currently centered around a line of specialty industrial glass-based “smart surface” coatings that have a wide range of uses across each of the industrial, commercial, and household market segments and that are centered around a U.S. patented technology that, either on its own or when coupled with any of an array of available proprietary formula additives, offers a unique combination of beneficial surface properties that allow for a broad array of multi-surface and end-product applications. The other product area involves a proprietary surfacing process – for which a U.S. patent is currently pending – to treat and cover existing floors, walls, counter-tops and table-tops, that offers property owners and occupants of all types a cost-effective means of enjoying a virtually limitless array of very lightweight, aesthetically desirable and high-demand decorative options, coupled with a variety of meaningfully beneficial surface-layer properties, without the necessity for having to remove and dispose of the floors, walls, counter-tops and table-tops already in place, and which process affords a uniquely attractive solution to those property owners and occupants otherwise facing the very costly, time-consuming and administratively burdensome challenges of having to remove and dispose of existing legacy-laden, chemically contaminated and/or vinyl asbestos tile (so-called “VAT”).

Over time, EcoSmart intends to develop itself in the strategic direction of becoming a leading research-oriented high-tech specialty “smart-surface” materials development and licensing company centered around a highly qualified research team and state-of-the-art research lab and applying a combination of organic and inorganic chemistries, materials science engineering, and nanotechnology. EcoSmart currently has expertise and capabilities in each of these areas.

Organic chemistry is a chemistry sub-discipline involving the scientific study of the structure, properties, and reactions of organic compounds and organic materials (i.e., matter in its various forms that contain carbon atoms). Inorganic chemistry, by contrast, refers to the chemistry sub-discipline aimed at understanding the synthesis and behavior of inorganic and organometallic compounds, generally focused on the silicon atom. Nanotechnology is the creation of functional materials, devices and systems through control of matter (atoms and molecules) on the nanometer length scale (1-100 nanometers), and exploitation of novel phenomena and properties (physical, chemical, biological, mechanical, electrical) at that length scale. Materials science engineering has as its focus the development of new products based on materials whose properties and behavior are controlled at the micrometer and nanometer scales, and through microfabrication technologies.

Currently, and as is expected to remain true in the near term, EcoSmart consists solely of the specialty coatings business and the specialty surfacing businesses, which, while possessing certain overlap in terms of underlying technology and product development, are operated by EcoSmart as separate divisions, chiefly because of certain differences in their respective business models and marketing strategies.

During the year ended December 31, 2013, EcoSmart revenues were approximately 70% attributable to sales within the specialty coatings division and approximately 30% attributable to sales within the specialty surfacing division. For the year ended December 31, 2012, these revenue percentages were approximately 63% and 37%, respectively.

-6-

Specialty Coatings Division

The surface is an integral aspect of virtually every physical object and often plays a fundamental role in many of the processes, beyond mere connectivity and structural support, that govern chemical and biological interactions involving the product. In some instances, the surface serves to protect the internal elements of the object that it surrounds; in others, it provides an entry point into those chemical or biological systems. In most, combinations of these attributes are present, and the potential variations are both vast in number and complex in structure.

The EcoSmart specialty coatings division produces, markets, and distributes a line of effectively invisible glass-based specialty coatings – “smart surfaces” – that have a wide range of industrial, commercial, and household applications that add a competitive advantage to a given product or surface through a variety of protective and other features. With an addition of only 50 millionths to 2 thousandths of an inch in surface thickness (depending on which product is used), no loss of either hardness, on the one hand, or pliability, on the other, and no reduction in photon (light) penetration, the patented platform technology, either on its own or when coupled with any of an array of available proprietary formula additives, offers the following unique combination of beneficial protective, maintenance-reducing, performance-enhancing and cosmetically-enhancing properties to most surfaces, including metals, plastics, paints, fabrics, vinyl, wood, masonry, or concrete, in each case without regard to temperature, climate or most other environmental conditions, without hazard to either human, animal or plant health/life, and for a period of up to as many as approximately 15-20 years:

|

Protective Benefits

|

|||||

|

Against Physical Surface Damage

|

Against Surface Appearance / Cosmetic Degradation

|

||||

|

▪

|

Resistant to Abrasion / Scratching

|

▪

|

Resistant to Dust / Dirt / Grime

|

||

|

▪

|

Resistance to Corrosion

|

▪

|

Resistant to Staining

|

||

|

▪

|

Resistant to Oxidation

|

▪

|

Resistant to Color Fading

|

||

|

▪

|

Resistant to (Effects of) Weather / Elements

|

▪

|

Resistant to Fingerprints

|

||

|

▪

|

Resistant to (Effects of) UV

|

▪

|

Resistant to Marking / Graffiti

|

||

|

▪

|

Resistant to (Effects of) All But Most Extreme Alkaline or Acidic Chemicals

|

▪

|

Oleophobic (Oil-Repellent)

|

||

|

▪

|

Resistance to (Effects of) Acid Rain

|

||||

|

▪

|

Resistance to (Effects of) Guano (excrement of birds, bats, seals, etc.)

|

||||

|

▪

|

Resistance to Termite Infestation

|

||||

|

Against Human Health Risks / Contagion

|

Against Human Physical / Safety Risks

|

||||

|

▪

|

Resistant to Bacterial Growth / Germs (sometimes referred to as “Self-Sterilizing”)

|

▪

|

Slip-Resistant When Wet

|

||

|

▪

|

Resistant to Mold / Fungal Spore Growth

|

||||

|

▪

|

Resistant to Small and Large Viruses

|

||||

Maintenance-Reducing Benefits (sometimes referred to as “Self-Cleaning” attributes)

|

▪

|

Hydrophobic (Water-Repellent

|

|

|

▪

|

Oleophobic (Oil-Repellent)

|

|

|

▪

|

Resistant to Dust / Dirt / Grime

|

|

|

▪

|

Rinses Cleans with Only Water and/or Mild Detergent

|

Performance-Enhancing Benefits

|

▪

|

Improved Hydrodynamics / Drag Reduction / Fuel Efficiency

|

|

|

▪

|

Improved Aerodynamics / Drag Reduction / Fuel Efficiency

|

|

|

▪

|

Energy Efficiency

|

-7-

Cosmetically-Enhancing Benefits

|

▪

|

Enhanced Color Clarity

|

|

|

▪

|

Enhanced Gloss / Sheen

|

|

|

▪

|

Enhanced Reflection

|

With the extraordinary array of beneficial properties identified above, certain but not all of which have been independently lab-tested and verified, the range of potential applications of EcoSmart’s specialty coatings is notably far-reaching, spanning across numerous industrial, commercial, and household segments. While the Company is currently focusing its pursuit on only several of these potential applications, and there can be no assurance that it will ever pursue any one or more of the others, it has identified the following as potential markets, among others, to be explored and possibly pursued over time:

|

▪

|

residential, commercial, and industrial building / construction

|

▪

|

automotive / auto body

|

||

|

▪

|

interior and exterior flooring and tiling / pavers

|

▪

|

motorcycles and ATVs

|

||

|

▪

|

sewage infrastructure, highways, bridges

|

▪

|

boats, jet-skis and snowmobiles

|

||

|

▪

|

oil & gas drilling / production equipment

|

▪

|

windshields

|

||

|

▪

|

solar panels, reflectors and heliostats

|

▪

|

bathroom fixtures

|

||

|

▪

|

wind turbines

|

▪

|

kitchen countertops and cabinetry

|

||

|

▪

|

HVAC / commercial refrigeration systems

|

▪

|

swimming pools and hot-tubs / jacuzzis

|

||

|

▪

|

desalination and potable water systems

|

▪

|

outdoor home decking

|

||

|

▪

|

aircraft / drones

|

▪

|

patio furnishings

|

||

|

▪

|

military equipment and weapons systems

|

▪

|

outdoor cooking hardware

|

||

|

▪

|

spacecraft / satellites / space-stations

|

▪

|

outdoor lighting systems

|

||

|

▪

|

passenger cruise ships

|

▪

|

kitchen and other household appliances

|

||

|

▪

|

railroad / monorail

|

▪

|

telescopic equipment

|

||

|

▪

|

medical equipment, operating environments and implant devices

|

▪

|

sunglasses

|

||

|

▪

|

biometric and other security devices

|

▪

|

water/snow skis, surf boards, and other sporting goods

|

||

|

▪

|

industrial machinery and robotics

|

▪

|

protective helmets and sporting gear

|

||

|

▪

|

telecommunications hardware

|

▪

|

playground equipment / apparatus

|

||

|

▪

|

textiles

|

▪

|

camping equipment

|

||

|

▪

|

smart-phones and tablets

|

▪

|

home furnishings, picture frames and decorative items

|

To date, the Company has not commissioned or otherwise undertaken or obtained any comprehensive market study in respect of any one or more of the above-listed potential product applications. The immediate-term focus of the Company is on the following five, unrelated applications, each of which has been selected based on management’s combined assessment of (i) the relative size, age and projected growth trend of the subject market, (ii) experience, observational/anecdotal intelligence, and testing results previously obtained in relation to the application, (iii) the relative strength of the value proposition to prospective customers, (iv) the comparative time-to-market, (v) the comparative cost-to-market coupled with existing industry relationships and available resources, (vi) the relative geographic accessibility of the market, (vii) the seasonality of the market, if any, (viii) the relative barriers-to-entry within the market, (ix) the relative, projected length of the particular sales cycle, (x) the projected gross profit margins, (xi) both the presence within the subject market, together with the relative quality, of competitive products, and (xii) the relative size and strength of the individual competitors:

-8-

|

▪

|

Hardscape. This is the market segment defined by EcoSmart to include applications involving surfaces consisting of pavers, poured and stamped concrete, natural stone, brick, and ceramic tile. It has been targeted based on a combination of all of the factors identified above, with a particular emphasis on (i) geographic accessibility to the regional market of South Florida, in which the Company maintains its executive offices and principal operations, and (ii) relative ease of installation. At a competitive price point, the Company’s products offer this market a high-grade, functional alternative to comparatively under-performing water-based hardscape sealants, and one with numerous unique, secondary benefits. The marketing and sales strategy being applied by EcoSmart is a dual-pronged approach aimed at manufacturers of primary materials, on the one hand, and contractor-installers, on the other. Able to rely for showcasing purposes on a recent major installation involving 310,000 square feet of pavers at the newly-opened Palm Beach Outlet Mall in West Palm Beach, Florida, the Company believes it is poised for an aggressive roll-out in the hardscape arena.

|

|

|

▪

|

Solar Panels, Reflectors and Heliostats. This is the alternative energy production and related hardware application market segment consisting of photovoltaic (PV) solar panel modules, reflectors, and heliostats (computer-controlled, curved mirrors which concentrate the sun’s rays and keep them reflected on a target as the sun moves across the sky) in relation to which the value-proposition associated with EcoSmart’s product offerings arise out of the “self-cleaning” attributes they afford. Because of the economic importance in maximizing the capture of incoming photons for energy conversion output, insuring the consistent cleanliness of solar panels has become an increasingly high priority and a continuing challenge throughout the industry, and the worldwide demand for coatings with efficiently “self-cleaning” properties – such as those produced by EcoSmart, which do not come at the expense of the optical properties of high transmission (in the PV modules) or high reflectance (in the heliostats) – is growing rapidly. In its earliest stages of market entrance, but driving the forefront, EcoSmart is currently targeting both domestic and foreign PV panel manufacturers as well as operators of distributed solar energy farms. In respect of both groups, and though there can be no assurance, the Company seeks to build its business through the securing of long-term, ongoing supply contracts. EcoSmart is aggressively targeting this application based on a combination of all of the factors identified above, including most notably the relative newness and projected growth rate of the developing market. Recently conducted initial field tests utilizing EcoSmart product, moreover, have been promising, showing in excess of a 30% increase in efficiency over uncoated PV array panels due primarily to increased cleanliness.

|

|

|

▪

|

Oil & Gas Drilling / Production Equipment. This is the market segment application surrounding the opportunity to sell certain EcoSmart coatings to be used as protective pipe linings for use in the oil-drilling and fracking industries, and as a protective coating on micro-turbines, hydraulic systems, and related heavy equipment used in the industry. According to recent industry reports, and with industrial coatings generally comprising more than approximately a third of the worldwide aggregate coatings market, the oil and gas segment is one seen as holding the greatest growth potential. Based on the preliminary results of early-stage field and lab tests being conducted by prospective customers, and though there can be no assurance, management believes the effectiveness of its products for this purpose is already higher than many competing products with the potential for material refinement in the near-term with only minor modification, and that the market and demand for these products is potentially very significant. EcoSmart is aggressively targeting this application based on a combination of all of the factors identified above, and, to date, it has been pursuing potential distribution opportunities through select industry operators.

|

|

|

▪

|

HVAC / Commercial Refrigeration Systems. This is the market segment application consisting of coatings for HVAC and commercial refrigeration systems intended to serve as protection from corrosion, including in salt water, acid, alkaline and chemical environments, and from clogging by particles of mold, pollen, dust, and soot. Testing in this area has shown that there is a significant efficiency loss factor on HVAC units due to natural oxidation and the restricted airflow caused by dirt that collects on the condenser coils. With a product that repels moisture and contaminants, offers increased operating/energy efficiency of 12-15% over the life of a subject condensing unit, and substantially reduced cleaning requirements generally, management believes a significant opportunity exists for the Company within this market. Accordingly, EcoSmart has targeted this application based on a combination of all of the factors identified above and is currently in the process of developing a strategic marketing plan aimed at this segment.

|

|

|

▪

|

Potable Water Systems. This is the market segment application for coatings to be applied in the manufacture of drinkable water systems used in remote workplaces where the environmental conditions are unusually harsh, and potable water is otherwise unavailable, including, for example, offshore and desert oil rigs, and naval ships. Based on the preliminary results of prospective customer field and lab tests, and though there can be no assurance, management believes the quality of its products for this purpose is better than many alternatives already widely available, and that the market and demand for these products is potentially material. EcoSmart is targeting this application based on a combination of all of the factors identified above, though, to date, it has not determined the distribution strategy it intends to pursue. It is expected, however, that such strategy will be built principally on a licensing model.

|

-9-

In general, though not necessarily across all segments, EcoSmart intends to pursue a strategic approach to identified market opportunities that relies on master distribution arrangements within individual product/application industry verticals. An emphasis is being made in the immediate-term on the establishment of such master distribution relationships holding what management believes to be an industrial customer-base with the greatest potential likelihood of benefitting without a significant lag-time by incorporating the specialty smart coatings as a product upgrade to their respective current offerings.

For purposes of development, competitive analysis, and prioritizing sales initiatives and resource deployment, EcoSmart views its specialty coatings business in terms of numerous individual markets identified in each case by reference to the particular combination of Company product, on the one hand, and targeted surface and application, on the other. While the Company’s complete line of individual specialty coatings products includes more than fifteen separate formulations, the following list identifies the Company’s principal five products, by name, together with their respective primary targeted surfaces and application categories, as well certain information in each case relating to their unique benefits in relation to the target application:

|

Product Name:

|

ECT-1 General Purpose Surface Treatment

|

|

|

Primary Targeted Surfaces:

|

tile, masonry, paint, cement, stucco, metals, plastics, fabric, flame-exposed, cryogenic

|

|

|

Primary Target Application Categories:

|

interior and exterior flooring and tiling / pavers

|

|

|

Featured Properties For Target Application:

|

hydrophobic (water-repellent) and oleophobic (oil-repellent); slip-resistant when wet; protective barrier at all temperatures resistant to abrasion/scratching, corrosion, oxidation, microbials, (effects of) weather/elements, UV, guano, acid rain, staining, color fading, mold/fungal spore growth

|

* * *

|

Product Name:

|

ECT-2 General Purpose Polyurethane Coating

|

|

|

Primary Targeted Surfaces:

|

ceramic floor tile, terrazzo, granite

|

|

|

Primary Target Application Categories:

|

interior and exterior flooring and tiling / pavers

|

|

|

Featured Properties For Target Application:

|

water-based low VOC (volatile organic compound); extreme chemical-resistance; available with anti-slip additives; single coat potentially equivalent to three coats of competitive product in terms of physical performance.

|

* * *

-10-

|

Product Name:

|

ECT-5 HVAC Corrosion Energy Coating

|

|

|

Primary Targeted Surfaces:

|

all surfaces of condensing unit, including coils, copper lines, compressor and cabinet

|

|

|

Primary Target Application Categories:

|

HVAC and refrigeration condensing units, micro turbines and other equipment on oil rigs

|

|

|

Featured Properties For Target Application:

|

“glassifying surface treatment”; condensing unit protection from corrosion, including in salt water, acid, alkaline and chemical environments; protection from clogging by particles of mold, pollen, dust, and soot; increased operating/energy efficiency of 12-15% over life of condensing unit; reduced cleaning requirements generally, and condensing units easily cleaned with only water and/or mild soap eliminating need for caustic coil cleaners; reduced maintenance for cooling towers and chiller barrels

|

* * *

|

Product Name:

|

ECT-10 Universal Micro-Coating

|

|

|

Primary Targeted Surfaces:

|

glass, mirrors, fiberglass, paints, plastics, metals, fabrics, granites

|

|

|

Primary Target Application Categories:

|

automotive/motorcycle/marine interior and exteriors, countertops, sunglasses, surfboards, water and snow skis

|

|

|

Featured Properties For Target Application:

|

ultra-thin (50 millionths of an inch) gasified glass layer version of ECT-1 that be easily applied directly by consumers and last for 6-8 months; hydrophobic (water-repellent) and oleophobic (oil-repellent); repels dirt and dust, including brake dust; exceptional clarity on glass and mirrors by filling in microscopic voids in the surface (tests conducted by the Ford Motor Company showed improvement in the “Distinction of Image” measurement (clarity of a glossy surface) of 10% on new, and 20% on old, automotive paint); protective barrier at all temperatures resistant to abrasion/scratching, corrosion, oxidation, microbials, (effects of) weather/elements, UV, guano, acid rain, acid damage from insects, staining, color fading, mold/fungal spore growth

|

* * *

|

Product Name:

|

ECT-775

|

|

|

Primary Targeted Surfaces:

|

pavers, concrete, roofing tile, ceramic tile, and other porous surfaces

|

|

|

Primary Target Application Categories:

|

floors, walls, decorative panels, swimming pools, solar panels, reflectors

|

|

|

Featured Properties For Target Application:

|

able to be applied in heavy coats; protective against staining, chemicals, UV fading, slipping; “self-cleaning”

|

The most unique feature shared by the EcoSmart coatings, and the specific focal point of a patent held by the Company considered by it to be the centerpiece of its smart surface technology, is the positive surface charge they possess once applied. It is this positive surface charge that is responsible for their most unique and valuable properties identified above, including the hydrophobicity, oleophobicity, microbial and fungal resistance, dust-repellance, and the enhanced aerodynamics and hydrodynamics.

Hydrophibicity is a term largely unfamiliar to many outside scientific circles, but that describes a quality with which most everybody has a basic familiarity. Surfaces may be characterized as either hydrophilic or hydrophobic depending on whether or not they attract or repel water or other water-based liquids. Hydrophilic and hydrophobic surfaces are abundant in both nature as well as in synthetic materials, and they exist both organically and inorganically in terms of chemical composition. A hydrophilic surface can be wet and may adsorb water; a hydrophobic surface cannot and will not – it is compositionally incapable of becoming wet. An example of a hydrophilic surface encountered routinely in daily life are sponges, which, of course, readily soak up whatever water with which they come into contact, at least to the point of saturation. Hydrophobic materials and coatings, by contrast, prevent water from pooling on their surfaces. In scientific terms, hybrophobicity is caused by surfaces that disrupt the hydrogen bonding in water; so as to minimize the disruption in its molecular makeup, the water droplet pushes itself away from the surface to minimize its contact area, thus becoming very tightly bound. Hydrophobic materials are generally easy to identify because water forms into droplets upon contact with them after which they tend to roll around freely, like marbles on a flat Formica countertop, as occurs commonly on the freshly waxed exterior of a car or recently cleaned windshield with new wiper blades. The more hydrophobic the material (all the way up to and including so-called “superhydrophobic” surfaces), the stronger this effect, until the water effectively floats or skims across the surface with what amounts to very low friction. Naturally occurring hydrophobic surfaces include many species of plant leaves and flower petals, as well as many types of bird feathers and the outer body parts of a variety of insects; the lotus leaf is among the most hydrophobic of naturally occurring hydrophobic surfaces. Synthetic hydrophobic surfaces include such household-name brands as Scotchgard™ treated fabric, Teflon® coated metal, or Rain-X® coated glass.

-11-

Oleophobicity is a property very comparable to hydrophobicity, but it relates to oil-repellancy, not water-repellancy. There are important technical differences, but, for practical and basic observational purposes, they are very similar.

In terms of chemistry, EcoSmart’s platform smart surface, and the coating variations identified above that it serves as a basis for, are inorganic, formed as they are of chemically “grown” glass. The process by which they form upon application can be likened to the process, witnessed by many daily in science classrooms, labs, or at home with popular science kits, whereby quartz crystals are effectively “grown” in a solution. This is important because it results in the establishment of a uniquely firm chemical bond between the coating and the surface, far stronger than would exist through either a mechanical or light bonding (the traditional alternatives), fundamentally setting the coatings apart from most others. When coupled with the unusually thin layer they inhabit – approximately 50 millionths to 1-2 thousandths of an inch – the combination of properties leaves them notably flexible, permitting their use in connection with such items as fabrics, plastics, and pliable floor-boards, yet hard, durable, and resilient, particularly when refined with select additives.

The additives used in the various EcoSmart coating formulations available to customers fall into three basic categories. In the first category are color tints, which, in recent years, have seen major technology advancements in terms of durability, variety and depth of color, reflectivity, and fade-resistance. Through developing strategic relationships, EcoSmart has available to it a wide range of the most advanced offerings in this regard. In the second category are additives intended to provide increased hardness and wear-resistance. Here, too, EcoSmart has access to what it believes are some of the most superior materials available. In the third category is a single additive, ConShield™, an EPA approved “on-contact” mechanical microbial germ and virus so-called “quat” (industrial and commercial quaternary ammonium) killer – that works in such a way as to prohibit the mutation of microbials which can otherwise become resistant over time to chemical kill mechanisms, such as antibiotics – capable of fortifying any EcoSmart coating with additional protection against bacteria and relatively large viruses/microbials, including, for example, Methicillin-resistant Staphylococcus Aureus (more commonly known as “MRSA), Clostridium difficile bacterial infection (more commonly known as “C-diff”), and Influenza A virus subtype H1N1 (more commonly known as “H1N1” or “Swine Flu”). By combining the EcoSmart coatings – which, based on their positive surface charge, already powerfully discourage the growth of many of the smaller, more common viruses which can exist between active elements of existing “on-contact” killers (such as the Norovirus, for example, a concern long plaguing the vacation cruise ship industry) – with ConShield™, available to EcoSmart through an informal, strategic joint-marketing arrangement with its manufacturer, a unique, broader spectrum of microbial protection is afforded, un-matched, in the belief of EcoSmart management, by any other product in anti-microbial effectiveness.

Competition

Product performance, technology, cost effectiveness, quality and technical and customer service are major competitive factors in the industrial coatings businesses. EcoSmart management is unaware of any one or more products possessing the same combination of physical properties, and that, on the whole, offers the same array of benefits, as its proprietary line of specialty smart surface coatings. There can be no assurance, however, that there not products under development or already in existence and in the early stages of market introduction of which management is not yet aware. The market for industrial and product performance coatings is extremely large, broad in scope, and consists of many different segments and sub-segments, each of which involves a range of product applications. It is also increasingly characterized by rapidly evolving technology. Precisely because of the wide array of beneficial properties they possess, and notwithstanding the U.S. patent held by us on our platform smart surface technology, the specialty coatings produced and distributed by EcoSmart should be viewed as competing with other coatings products across a wide variety of the various existing market segments and sub-segments. Hydrophobic and antimicrobial coatings, for example, are each segments in which numerous companies are aggressively competing with one another worldwide, both in terms of technology and market share, but that, combined, represent only a minor portion of the aggregate competition that EcoSmart should be viewed as meaningfully confronting.

-12-

The competition faced by EcoSmart in relation to its proprietary line of specialty smart surface coatings includes both public and private organizations and collaborations among academic institutions and large companies, both domestic and foreign, most of which have significantly greater experience and financial resources than EcoSmart. Management expects that EcoSmart’s most significant competitors in its specialty coatings business will tend to be larger, more established companies, including many major multinational corporations such as Akzo Nobel N.V., PPG Industries, Inc., Axalta Coating Systems, BASF Corporation, and Valspar Corporation. In general, these companies are all developing products that, at some level or in one or more ways, compete with those of EcoSmart and, in addition to many existing issued and pending patents, they have significantly greater capital and other resources available to them for research and development, testing, seeking and obtaining any required regulatory approvals, marketing and distribution. In addition, many smaller coatings and related nanotechnology companies have formed strategic alliances or collaborative arrangements, partnerships, and other types of joint ventures with larger, well-established industry competitors that afford these companies’ potential research and development and commercialization advantages, and may be aided in becoming significant competitors through rapid evolution of new technologies. Academic institutions, governmental agencies, and other public and private dedicated research organizations are also financing and conducting research and development activities that could result in the introduction of products directly competitive to those of EcoSmart.

Specialty Surfacing Division

The EcoSmart specialty surfacing division produces, markets, and installs, directly and through third-party contractors, a proprietary system to treat and cover existing floors, walls, counter-tops and table-tops, providing property owners and occupants of all types with a cost-effective solution that affords a virtually limitless array of very lightweight, aesthetically desirable and high-demand decorative choices, coupled with a variety of meaningfully beneficial surface-layer properties. Through a combination of advancements in applied chemical engineering, enhanced digital imaging and printing technologies, as well as EcoSmart’s own specialty coatings, the system, marketed under the brand name EcoSmart Digital Flooring™, is able to generate a safe, rugged, durable, maintenance-friendly, and monolithic flooring alternative containing the sharp, color-rich visual imagery of virtually any desired pattern, design, photo, graphic, logo, or inlaid artwork, on the one hand, or, alternatively, carrying the textured, virtually indistinguishable appearance of natural, solid materials traditionally associated with both classic and contemporary flooring applications, such as hardwood, marbles, and granites, but at a fraction of the weight, on the other.

Developed over recent years in cooperation with Bayer Material Sciences, one of the largest resin suppliers worldwide, EcoSmart Digital Flooring system centers around a unique compound – for which a U.S. patent is currently pending – which chemically activates any unclean surface (including a floor), allowing a clear resin/polymer base floor-coating to be integrally – chemically – bonded to it. The process further encompasses the integral high-definition digital printing component, effected vis-a-vis a porous media embedded in the clear resin base floor-coating, as well as a surface preparatory agent and a topcoat drawn from products belonging to EcoSmart’s family of specialty coating formulations, all of which combine to deliver not only a visually appealing, premium quality end-product reasonably expected to meet and exceed the most demanding commercial grade standards for any indoor and/or outdoor application, but one that also features enhanced protection, stability, durability and slip-resistance.

Taken as a whole, and depending in each case on the particular starting surface involved, on the one hand, and desired end-product, on the other, the system involves either a two, three, or five step procedure, with each step corresponding to an additional layer/coating of a particular proprietary EcoSmart formulation:

-13-

|

Two-Step Procedure:

|

(1) ECT 110 – Surface Preparatory Agent

|

|

(2) ECT 210 – Encapsulating Base Coat

|

|

|

Three-Step Procedure:

|

(1) ECT 110 – Surface Preparatory Agent

|

|

(2) ECT 210 – Encapsulating Base Coat

|

|

|

(3) ECT 310 – Color Polyaspartic Top Coat

|

|

|

Five-Step Procedure:

|

(1) ECT 110 – Surface Preparatory Agent

|

|

(2) ECT 210 – Encapsulating Base Coat

|

|

|

(3) ECT Surfaces Digital Design/Image

|

|

|

(4) ECT 310 – Color Polyaspartic Mid Coat

|

|

|

(5) ECT 775 – Top Coat

|

A notably unique aspect of the EcoSmart Digital Flooring system is that, because of the end-result both enabled and facilitated by the underlying chemical technology, the necessity for having to remove and dispose of existing flooring and baseboards, or wall tiling, and, in many cases, to purchase replacement flooring or surfacing, is entirely eliminated. This feature is attributable to the fundamental nature of the final product made possible by the system, which, as applied, resides directly over an existing floor – be it wood, wood laminate, engineered wood flooring, ceramic tile, concrete slabs, and including formerly carpeted areas – with as little as 1/16th of an inch in additional, even surface thickness, devoid of irregularities. The resultant negation of any need for demolition and clean-up afforded by the system, and the avoidance this leads to in associated dust-up and diminution in air-quality that would otherwise follow, is not insignificant, particularly when occurring in homes or small business; it is not uncommon for such clean-up to otherwise have to include the air-handling system, and for the subject premises to have to be vacated in the meantime. A complete install utilizing the EcoSmart Digital Flooring system, by contrast, requires only minor preparation and typically takes – for a residential floor, for example – approximately two days, during which occupants can remain on the premises because there is neither dust nor other particulates, nor anything more than a minor odor, released into the immediately surrounding environment.

While an attractive option both aesthetically and economically for most any application, EcoSmart Digital Flooring presents EcoSmart with one of its most compelling, immediate-term to long-term market opportunities because it has proven particularly well-suited for those faced – increasingly through federal and state level regulatory mandates coupled with substantial monetary fines for non-compliance – with the unique and daunting challenges of having to work with legacy-laden, chemically contaminated (with, for example, asbestos, fossil fuel residues, or other potentially hazardous substances), and/or, most notably, vinyl asbestos tile (so-called “VAT”), floors and walls. This is because of the heightened importance in such situations of having to undertake the intensely regulated, administratively burdensome, highly dangerous, and very costly processes of specialized demolition, removal, and disposal of the contaminated substrates, which are inherently hazardous to human health in most cases, and often lethally carcinogenic, and the comparatively low-cost avoidance of all that made possible through use of the EcoSmart Digital Flooring system rather than abatement or other officially EPA sanctioned forms of remediation. Applying the technology, old asbestos-based tile, for example, can be chemically bonded and very effectively encapsulated for all purposes – including those arising under applicable EPA guidelines – without the need for any of the machine abrasion and otherwise highly-intensive cleaning processes traditionally associated with the handling of friable, asbestos-fibre-laden materials, and without the need for specialized and expensive hazmat materials treatment and disposal. Consisting of a highly durable coating with resultant flexibility properties such that it can tolerate elongation of up to approximately 100% once installed, the containment provided by this encapsulation is not jeopardized by potential cracking and future instability in the composition of the asbestos materials, thereby effectively eliminating the risk of future liberation and exposure of the hazardous substances.

Although there can be no assurance as to which markets will be targeted by EcoSmart over time, or in what order they may be targeted, the potential markets for the EcoSmart Digital Flooring system include owners or operators of essentially all types of premises:

|

▪

|

residential properties, including all single and multi-family homes, apartments, condominiums, cooperatives

|

|

|

▪

|

commercial properties, including retail spaces, office complexes and buildings, restaurants, and gas stations

|

|

|

▪

|

hospitals, medical centers and research laboratories

|

|

|

▪

|

private and public schools and universities

|

|

|

▪

|

churches, synagogues, temples and other places of worship

|

|

|

▪

|

federal, state and local government occupied buildings and properties

|

|

|

▪

|

factories, storage facilities, and related industrial buildings and complexes

|

-14-

To date, the EcoSmart Digital Flooring system has been used with favorable results, through installations conducted by EcoSmart, in more than twelve U.S. Veteran’s Administration (VA) facilities, six Wal-Mart stores, and four Bed, Bath and Beyond retail outlets, and through installations conducted by approved distributor-contractors, an additional 150 Bed, Bath and Beyond outlets. In each of these cases, the installations principally involved restrooms, kitchens and other tiled areas.

Competition

EcoSmart management is unaware of any one or more products possessing the same combination of physical properties, and that, on the whole, offers the same array of benefits, as the EcoSmart Digital Flooring system. There can be no assurance, however, that there not products under development or already in existence and in the early stages of market introduction of which management is not yet aware. The market for comparable floor, wall, tabletop and countertop surfacing products and systems is extremely large, broad in scope, and consists of many different participants. It is also increasingly characterized by rapidly evolving technology. Notwithstanding the unique attributes of the EcoSmart Digital Flooring system, or the U.S. patent-pending on it, it should be viewed as competing with all other products in the market vying for differentiation and customers.

The competition faced by EcoSmart in relation to the EcoSmart Digital Flooring system includes both public and private organizations and collaborations among academic institutions and large companies, both domestic and foreign, most of which have significantly greater experience and financial resources than EcoSmart. Management expects that EcoSmart’s most significant competitors in its specialty surfacing business will tend to be larger, more established companies, including many major multinational corporations such as Akzo Nobel N.V., PPG Industries, Inc., Axalta Coating Systems, BASF Corporation, Valspar Corporation, Dupont, and Sherwin-Williams. In general, these companies are all developing products that, at some level or in one or more ways, compete with those of EcoSmart and, in addition to many existing issued and pending patents, they have significantly greater capital and other resources available to them for research and development, testing, seeking and obtaining any required regulatory approvals, marketing and distribution. In addition, many smaller surfacing product/system companies have formed strategic alliances or collaborative arrangements, partnerships, and other types of joint ventures with larger, well-established industry competitors that afford these companies’ potential research and development and commercialization advantages, and may be aided in becoming significant competitors through rapid evolution of new technologies. Academic institutions, governmental agencies, and other public and private dedicated research organizations are also financing and conducting research and development activities that could result in the introduction of products and systems directly competitive to those of EcoSmart.

EcoSmart-Related Intellectual Property

Patents and Licenses

The competitive environment in which EcoSmart operates is largely driven by technology, proprietary or otherwise. In general, companies in this environment seek to develop competitive advantages – both offensive and defensive –through the obtaining and maintaining of relevant patents relating to their respective technological advancements. As a science and technology based company, EcoSmart believes that securing intellectual property is an important part of protecting its research, and that, in particular, patent, as well as related trade secret – protection, is critical for the new specialty coatings and surfacing technologies it develops, as well as any products and processes derived through them.

By way of assignment, EcoSmart currently holds one United States patent relating to our smart surface specialty coatings technology and one United States patent pending relating to our EcoSmart Digital Flooring system:

|

Title

|

Awarded

|

Pending

|

Expiration

|

|||

|

Method of Treating Surfaces For Self-Sterilization and Microbial Growth Resistance

|

X

|

2025

|

||||

|

Decorative Monolithic, Functionally Bonded Composite Surface Overlayment System and Application Process

|

X

|

-15-

Over time, EcoSmart intends to apply for additional patents relating to advancements it achieves through its research and development initiatives. There can be no assurance however, that any of the patents currently held, or any obtained in the future, will prove adequate to protect its technologies or that it will have sufficient financial and resources to keep others from infringing the exclusive rights it possesses in relation to its technologies. The fields in which EcoSmart operates have been characterized by significant efforts by competitors to establish dominant or blocking patent rights to gain a competitive advantage, and by considerable differences of opinion as to the value and legal legitimacy of competitors’ purported patent rights and the technologies they actually utilize in their businesses.

Because we may license our technology and products in foreign markets, we may also seek foreign patent protection for some specific patents. With respect to foreign patents, the patent laws of other countries may differ significantly from those of the United States as to the patentability of our products or technology.

It is possible that competitors in both the United States and foreign countries, many of which have substantially greater resources and have made substantial investments in competing technologies, may have applied for, or may in the future apply for and obtain, patents, which will have an adverse impact on our ability to make and sell our products. There can also be no assurance that competitors will not infringe on our patents or will not claim that we are infringing on their patents. Defense and prosecution of patent infringement suits, even if successful, are both costly and time consuming. An adverse outcome in the defense of a patent infringement suit could subject us to significant liabilities to third parties, require disputed rights to be licensed from third parties or potentially even require us to cease our operations.

Certain aspects of EcoSmart’s know-how and technology are not patentable, or, for strategic reasons, are best protected in the determination of management by leaving them unpatented. In this regard, trade secrets play an important part in the Company’s intellectual property strategy, and EcoSmart vigilantly seeks to protect them. To protect our proprietary position in trade secrets, we require all employees, consultants, advisors and collaborators with access to our technology to enter into confidentiality and invention ownership agreements with us. There can be no assurance, however, that these agreements will provide meaningful protection for our trade secrets, know-how or other proprietary information in the event of any unauthorized use or disclosure. Further, in the absence of patent protection, competitors who independently develop substantially equivalent technology, or otherwise acquire it, may adversely impact our business. If and when we discover that any trade secrets have been misappropriated, it is expected that we will, unless we otherwise determine for strategic or similar reasons, report the matter to governmental authorities for investigation and potential criminal action, as appropriate. In addition, and to the extent that we have the available financial resources, we intend to take all reasonably required measures in an effort to mitigate any potential adverse economic impact, which may include civil actions seeking redress, restitution and/or damages based on loss to the Company and/or unjust enrichment.

EcoSmart owns the rights to two unique registered trademarks for its proprietary digital flooring system. One of these is for the name “EcoSmart Digital Flooring” system itself, and the other is for a name the use of which the Company has abandoned and has no present intention of using or otherwise benefitting from in the future. The Company is in the process of evaluating its options in connection with the registering of other trademarks, both for its specialty coatings business and its specialty surfacing business, and this process is expected to be ongoing. Unlike patent rights, ownership rights in trademarks do not expire if the trademarks are continued in use and properly protected.

EcoSmart Product Returns Policies and Warranties

EcoSmart’s product returns policies and warranties do not differ materially as between the specialty coatings and specialty surfacing divisions. Within the divisions, however, these policies and warranties do differ materially based on the type of surface to which the product is being applied as well as the anticipated performance life of the particular product.

-16-

In general, EcoSmart maintains a consistent return policy relative to any products in relation to which there is either no associated installation or, if there is an installation involved, it is one that EcoSmart has no participation in or responsibility for (as may be the case in relation to the EcoSmart Digital Flooring system, for example, as well as the Company’s paver application specialty coating products). The policy under such circumstances requires that the subject products be returned unopened within no more than 30 days of purchase, and that all shipping charges associated with the return be borne by the customer, together with a re-stocking fee equal to 10% of the corresponding purchase price unless the return is received in the form of purchase credit. For a period of up to 10 years from purchase, a warranty is extended in such cases to customers relative to both the chemical integrity (as represented upon sale) and the performance integrity of the coatings based on the specific characteristics of the subject product and application, and the corresponding representations made by the Company in relation thereto.

In general, EcoSmart does not maintain a separate return policy in relation to specialty surfacing products sold as part of the EcoSmart Digital Flooring system, distinct from the one maintained in relation to the system taken as a whole, inclusive of the installation, except as it relates to product purchased by contract installers, in relation to which the policy is consistent with the one for EcoSmart specialty coatings. In these cases, the contract installer bears exclusive responsibility for all of the preparatory site work associated with the application (including, e.g. cleaning and insuring that the surface subject to treatment has acceptable PH readings and moisture levels). Where the installation is additionally covered and the warranty extends directly to the property owner, which is only the case when EcoSmart itself, or an EcoSmart approved contract installer, performs the application, the EcoSmart warranty extends for a number of years from the date of installation, determined in each case based on a variety of case-specific situational factors and relates to the performance integrity of the surfacing product based on the characteristics claimed by EcoSmart in relation to the EcoSmart Digital Flooring system generally. The warranty in these cases guarantees coverage of not only the cost for new product but also the associated labor for re-application in the event that that is necessary.

In connection with the sale of specialty coatings products in relation to which EcoSmart is involved in the corresponding installation (e.g. pavers), the product returns policies and warranties are similar to those that apply to sales and installations of the EcoSmart Digital Flooring system.

EcoSmart’s returns policies and product warranties relative to both divisions are general policies and warranties and are subject to change in relation to any particular sale. Further, the general policies and warranties themselves are subject to change from time to time and are likely to evolve as EcoSmart’s operations and revenues develop.

EcoSmart Manufacturing and Fulfillment