Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - Trilogy Metals Inc. | form8k.htm |

NovaCopper Inc.

NI 43-101 Technical

Report

on the Bornite Project,

Northwest Alaska, USA

| Report Prepared For: | NovaCopper Inc. |

| Suite 1950 – 777 Dunsmuir Street, Vancouver, BC V7Y 1K4 Canada | |

| Tel: 604-638-8088 Fax: 604-638-0644 www.novacopper.com | |

| Report Prepared By: | BD Resource Consulting, Inc. |

| 4253 Cheyenne Drive, Larkspur, CO 80118 USA | |

| Tel: 303-694-6546, Email: bdavis@simgeological | |

| SIM Geological Inc. | |

| 6810 Cedarbrook Place, Delta, BC Canada V4E 3C5 | |

| Tel: 604-596-6339, Email: rsim@simgeological | |

| International Metallurgical & Environmental Inc. | |

| #13-2550 Acland Road, Kelowna, BC Canada V1X 7L4 | |

| Tel: 250-317-3739, Email: austin@internationalmet.com | |

| Signed by Qualified Persons: | Bruce Davis, FAusIMM, BD Resource Consulting, Inc. |

| Robert Sim, P.Geo., SIM Geological Inc. | |

| Jeff Austin, P.Eng., International Metallurgical & Environmental Inc. | |

| Effective Date: | March 18, 2014 |

| Release Date: | April 1, 2014 |

NovaCopper Inc.

NI 43-101 Technical Report on the

Bornite Project,

Northwest Alaska

| T A B L E O F C O N T E N T S |

| LIST OF TABLES | VI | |||

| LIST OF FIGURES | VI | |||

| GLOSSARY | VIII | |||

| 1.0 | SUMMARY | 1-1 | ||

| 1.1 | Introduction | 1-1 | ||

| 1.2 | Property Description and Location | 1-2 | ||

| 1.3 | Geology and Mineralization | 1-2 | ||

| 1.4 | Metallurgical Testting | 1-3 | ||

| 1.5 | Resource Estimate | 1-4 | ||

| 1.6 | Interpretations and Conclusions | |||

| 1.7 | Opportunities and Recommendations | 1-4 | ||

| 2.0 | INTRODUCTION | 2-5 | ||

| 2.1 | Terms of Reference | 2-5 | ||

| 2.2 | Units of Measurement | 2-5 | ||

| 2.3 | Qualified Persons | 2-5 | ||

| 2.4 | Site Visit | 2-6 | ||

| 2.5 | Information Sources | 2-6 | ||

| 3.0 | RELIANCE ON OTHER EXPERTS | 3-7 | ||

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 4-8 | ||

| 4.1 | Location | 4-8 | ||

| 4.2 | Mineral Tenure | 4-8 | ||

| 4.3 | Royalties, Agreements and Encumbrances | 4-11 | ||

| 4.3.1 | Kennecott Agreements | 4-11 | ||

| 4.3.2 | NANA Agreement | 4-11 | ||

| 4.4 | Environmental Liabilities | 4-13 | ||

| 4.5 | Permits | 4-13 | ||

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-14 | ||

| 5.1 | Accessibility | 5-14 | ||

| 5.1.1 | AIR | 5-14 | ||

| 5.1.2 | WATER | 5-14 | ||

| 5.1.3 | ROAD | 5-14 | ||

| 5.2 | Climate | 5-14 | ||

| 5.3 | Local Resources | 5-15 | ||

| 5.4 | Infrastructure | 5-16 | ||

| NovaCopper Inc. | i | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 5.5 | Physiography | 5-16 | ||

| 5.6 | Sufficiency of Surface Rights | 5-17 | ||

| 6.0 | HISTORY | 6-18 | ||

| 6.1 | Geochemistry | 6-18 | ||

| 6.2 | Geophysics | 6-18 | ||

| 6.3 | Drilling and Underground Workings | 6-20 | ||

| 6.4 | Petrology, Mineralogy, and Research Studies | 6-22 | ||

| 6.5 | Geotechnical and Hydrological Studies | 6-22 | ||

| 6.6 | Metallurgical Studies | 6-22 | ||

| 6.7 | Historical Mineral Resource Estimates | 6-22 | ||

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 7-25 | ||

| 7.1 | Regional Geology | 7-25 | ||

| 7.2 | Tectonic and Metamorphic History | 7-25 | ||

| 7.2.1 | Regional Stratigraphy | 7-26 | ||

| 7.2.2 | Igneous Rocks | 7-27 | ||

| 7.2.3 | Timing of Mineralization in the District | 7-28 | ||

| 7.3 | Deposit Geology | 7-28 | ||

| 7.3.1 | Lithology Units | 7-28 | ||

| 7.3.2 | Structure | 7-30 | ||

| 7.4 | Mineral Deposits | 7-31 | ||

| 7.4.1 | Mineralization | 7-32 | ||

| 7.4.2 | Alteration | 7-33 | ||

| 7.5 | Prospects/Exploration Targets | 7-36 | ||

| 8.0 | DEPOSIT TYPES | 8-37 | ||

| 9.0 | EXPLORATION | 9-38 | ||

| 9.1 | Introduction | 9-38 | ||

| 9.2 | NovaGold Exploration - 2006 | 9-38 | ||

| 9.3 | NovaGold Exploration - 2010 | 9-39 | ||

| 9.4 | NovaGold Exploration - 2011 | 9-41 | ||

| 9.5 | NovaCopper Exploration - 2012 | 9-42 | ||

| 9.6 | NovaCopper Exploration - 2013 | 9-44 | ||

| 9.7 | Exploration Potential | 9-44 | ||

| 10.0 | DRILLING | 10-46 | ||

| 10.1 | Introduction | 10-46 | ||

| 10.2 | Drill Core Procedures | 10-49 | ||

| 10.2.1 | BCMC/Kennecott Procedures | 10-50 | ||

| 10.2.2 | NovaGold/NovaCopper Procedures | 10-50 | ||

| NovaCopper Inc. | ii | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 10.3 | Drill Core Recovery | 10-52 | ||

| 10.4 | Collar Surveys | 10-53 | ||

| 10.4.1 | Kennecott Tenure | 10-53 | ||

| 10.4.2 | NovaCopper Tenure | 10-54 | ||

| 10.5 | Down-Hole Surveys | 10-54 | ||

| 11.0 | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 11-56 | ||

| 11.1 | Sample Preparation | 11-56 | ||

| 11.1.1 | Density Determinations | 11-57 | ||

| 11.2 | Security | 11-57 | ||

| 11.3 | Assaying and Analytical Procedures | 11-58 | ||

| 11.4 | Quality Assurance/Quality Control | 11-59 | ||

| 11.4.1 | Core Drilling Sampling QA/QC | 11-59 | ||

| 11.4.2 | Density Determinations QA/QC | 11-60 | ||

| 11.5 | Author’s Opinion | 11-61 | ||

| 12.0 | DATA VERIFICATION | 12-62 | ||

| 12.1 | Verifications By BD Resource Consulting, Inc. and SIM Geological Inc. (2011-2013) | 12-62 | ||

| 12.2 | Conclusions | 12-62 | ||

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 13-63 | ||

| 13.1 | Metallurgical Test Work Review | 13-63 | ||

| 13.1.1 | Introduction | 13-63 | ||

| 13.1.2 | Historical Test Work Review | 13-63 | ||

| 13.1.3 | Mineralogical and Metallurgical Test Work - NovaCopper | 13-63 | ||

| 13.2 | Recommended Test Work | 13-69 | ||

| 14.0 | MINERAL RESOURCE ESTIMATE | 14-70 | ||

| 14.1 | Introduction | 14-70 | ||

| 14.2 | Sample Database and other available data | 14-70 | ||

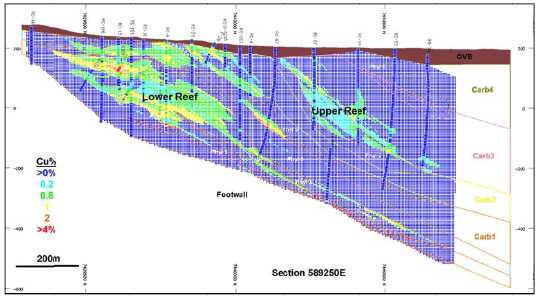

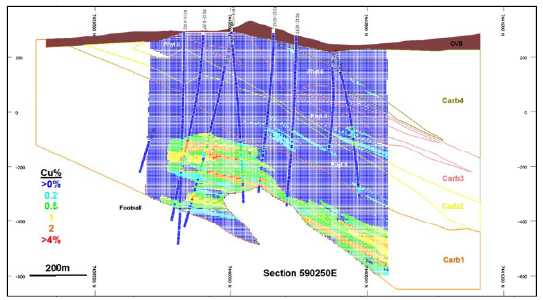

| 14.2.1 | Geologic Model | 14-73 | ||

| 14.2.2 | Summary of Geologic Domains | 14-77 | ||

| 14.3 | Compositing | 14-78 | ||

| 14.4 | Exploratory Data Analysis | 14-78 | ||

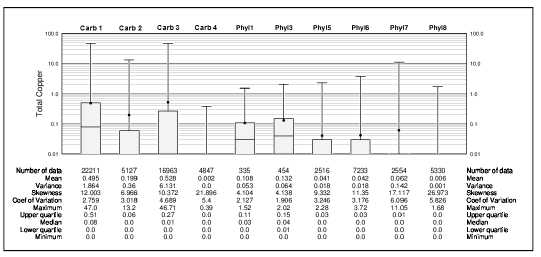

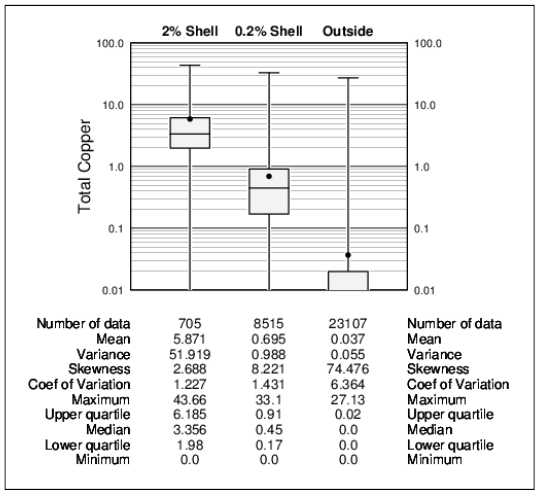

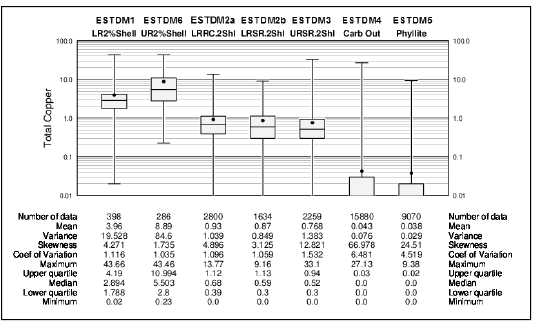

| 14.4.1 | Boxplots | 14-78 | ||

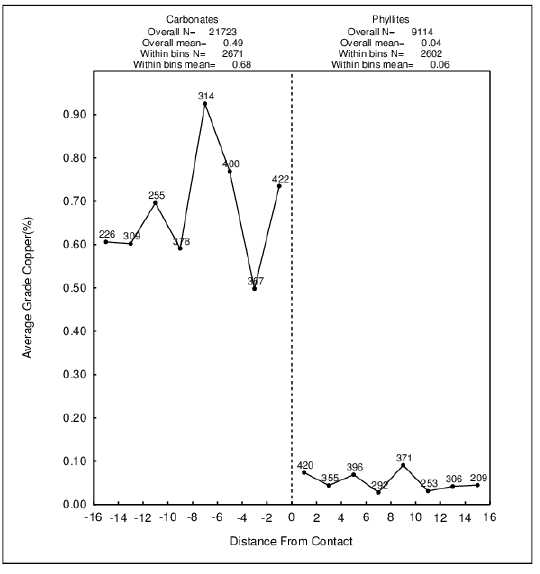

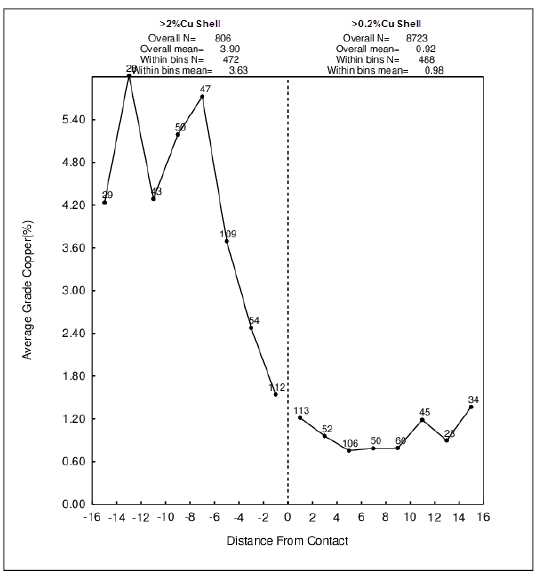

| 14.4.2 | Contact Profiles | 14-80 | ||

| 14.4.3 | Modelling Implications | 14-83 | ||

| 14.5 | Treatment of Outlier Grades | 14-85 | ||

| 14.6 | Specific Gravity Data | 14-86 | ||

| 14.7 | Variography | 14-87 | ||

| 14.8 | Model Setup and Limits | 14-88 | ||

| NovaCopper Inc. | iii | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 14.9 | Interpolation Parameters | 14-89 | ||

| 14.10 | Block Model Validation | 14-90 | ||

| 14.10.1 | Visual Inspection | 14-90 | ||

| 14.10.2 | Model Checks for Change of Support | 14-92 | ||

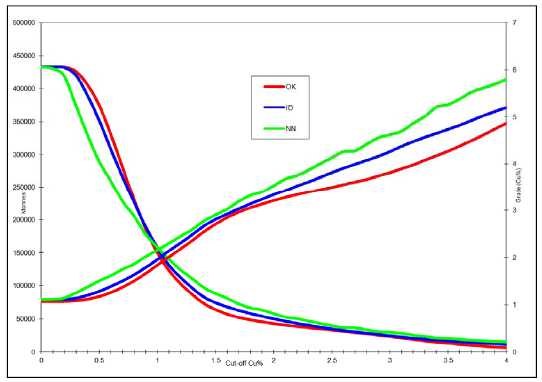

| 14.10.3 | Comparison of Interpolation Methods | 14-93 | ||

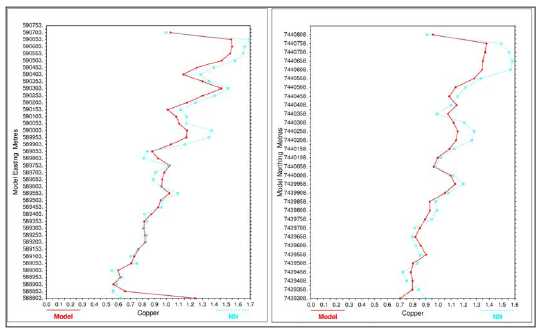

| 14.10.4 | Swath Plots (Drift Analysis) | 14-94 | ||

| 14.11 | Resource Classification | 14-95 | ||

| 14.12 | Mineral Resource Estimate | 14-96 | ||

| 14.13 | Grade Sensitivity Analysis | 14-99 | ||

| 14.14 | Comparison with the Previous Resource Estimate | 14-100 | ||

| 15.0 | MINERAL RESERVE ESTIMATES | 15-102 | ||

| 16.0 | MINING METHODS | 16-103 | ||

| 17.0 | RECOVERY METHODS | 17-104 | ||

| 18.0 | PROJECT INFRASTRCTURE | 18-105 | ||

| 18.1 | Road | 18-105 | ||

| 18.2 | Power | 18-105 | ||

| 19.0 | MARKET STUDIES AND CONTRACTS | 19-108 | ||

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | 20-109 | ||

| 20.1 | Environmental Studies | 20-109 | ||

| 20.1.1 | Archaeology | 20-109 | ||

| 20.1.2 | Aquatic Life and Fisheries | 20-109 | ||

| 20.1.3 | Ecosystem and Soils | 20-109 | ||

| 20.1.4 | Hydrology | 20-110 | ||

| 20.1.5 | Meteorology, Air Quality, and Noise | 20-110 | ||

| 20.1.6 | Subsistence | 20-110 | ||

| 20.1.7 | Additional Baseline Data Requirements | 20-112 | ||

| 20.2 | Permitting | 20-113 | ||

| 20.3 | Social or Community Considerations | 20-115 | ||

| 20.4 | Reclamation | 20-117 | ||

| 20.4.1 | Bornite Mine Legacy Cleanup | 20-117 | ||

| 20.4.2 | Reclamation of Exploration Activities | 20-117 | ||

| 21.0 | CAPITAL AND OPERATING COSTS | 21-119 | ||

| 22.0 | ECONOMIC ANALYSIS | 22-120 | ||

| 23.0 | ADJACENT PROPERTIES | 23-121 | ||

| 23.1 | Sun Deposit | 23-122 | ||

| 23.2 | Smucker Deposit | 23-123 | ||

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 24-124 | ||

| NovaCopper Inc. | iv | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 24.1 | Arctic Deposit | 24-124 | |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 25-128 | |

| 26.0 | RECOMMENDATIONS | 26-130 | |

| 27.0 | REFERENCES | 27-131 | |

| 28.0 | CERTIFICATES OF QUALIFIED PERSONS | 28-136 | |

| 28.1 | Bruce M. Davis, FAusIMM | 28-137 | |

| 28.2 | Robert Sim, P.Geo. | 28-138 | |

| 28.3 | Jeff Austin, P.Eng | 28-139 | |

| NovaCopper Inc. | v | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| LIST OF TABLES |

| Table 1.1: Mineral Resource Estimate for the Bornite Project | 1-3 |

| Table 4.1: Summary of UKMP Lands Status | 4-8 |

| Table 6.1: Bornite (Ruby Creek) Historical Resource (Kennecott, 1997) | 6-23 |

| Table 7.1: Stratigraphic Units of the Cosmos Hills Area (modified from Hitzman et al., 1986) | 7-27 |

| Table 7.2: Lithology Units on the Bornite Property | 7-29 |

| Table 10.1: Summary Bornite Drill Hole Campaigns by Operator | 10-47 |

| Table 10.2: Summary of Bornite Drill Hole Campaigns by Drill Contractor | 10-48 |

| Table 10.3: BCMC/Kennecott era Drill Holes Re-logged & Re-assayed by NovaCopper | 10-52 |

| Table 10.4: Core Recovery versus Lithology | 10-53 |

| Table 11.1: Standard Reference Materials Used by Year | 11-57 |

| Table 11.2: Analytical Laboratories Used by Operators of the Bornite Project | 11-58 |

| Table 13.1: Summary of Chemical Analysis of Metallurgical Composites | 13-64 |

| Table 13.2: Summary of Bond Ball Mill Work Index Determinations | 13-65 |

| Table 13.3: Summary of Process Simulation Test Work Results | 13-67 |

| Table 13.4: Summary of Concentrate Analysis – Final Copper Concentrate Results | 13-68 |

| Table 14.1: Summary of Drilling Data for the Bornite Project | 14-72 |

| Table 14.2: Summary of Lithology and Probability Shell Domains | 14-77 |

| Table 14.3: Summary of Copper Estimation Domains | 14-84 |

| Table 14.4: Summary of Treatment of Outlier Copper Sample Data | 14-86 |

| Table 14.5: Variogram Parameters | 14-88 |

| Table 14.6: Block Model Limits | 14-89 |

| Table 14.7: Interpolation Parameters | 14-90 |

| Table 14.8: Parameters Used to Generate a Resource Limiting Pit Shell | 14-97 |

| Table 14.9: Mineral Resource Estimate for the Bornite Project | 14-98 |

| Table 14.10: Sensitivity of Mineral Resources Inside the Pit Shell | 14-99 |

| Table 14.11: Sensitivity of Mineral Resources Below the Pit Shell | 14-100 |

| Table 14.12: Estimate of Mineral Resources for the Bornite Project – February 2013 | 14-100 |

| Table 14.13: Estimate of Mineral Resources for the Bornite Project – March 2014 | 14-101 |

| Table 20.1: Summary of Existing Environmental Baseline Studies Reports | 20-111 |

| Table 20.2: Additional Recommended Environmental Baseline Studies | 20-112 |

| Table 20.3: Permits that May Be Required for the Bornite Project | 20-114 |

| Table 23.1: Mineral Resource Estimate for the Sun Project (November 2012) | 23-122 |

| Table 23.2: Resource Estimate for the Arctic Project (NSR cutoff of $35/tonne) | 24-127 |

| Table 25.1: Estimate of Mineral Resources for the Bornite Project | 25-128 |

| LIST OF FIGURES |

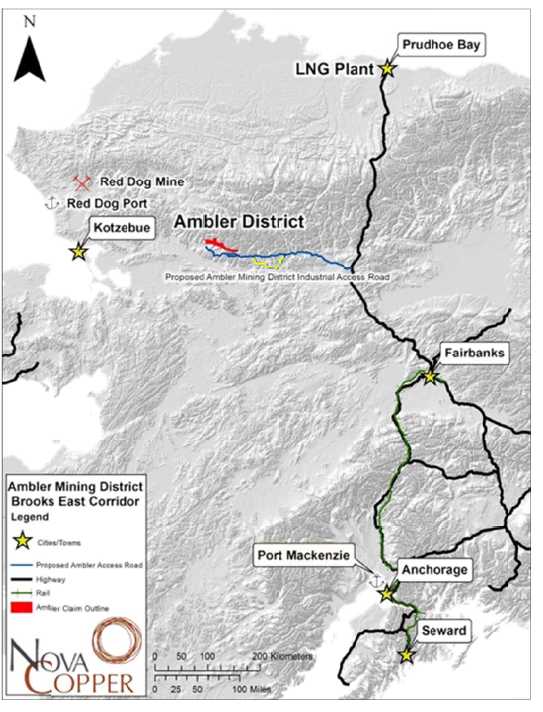

| Figure 1.1: Property Location Map | 1-1 |

| Figure 2.1: Bornite Exploration Shaft and the NovaCopper Exploration Camp | 2-6 |

| Figure 4.1: Upper Kobuk Mineral Projects Lands (NovaCopper, 2014) | 4-9 |

| Figure 4.2: Mineral Tenure Plan (NovaCopper, 2014) | 4-10 |

| Figure 6.1: 1996 Kennecott Residual Gravity | 6-20 |

| NovaCopper Inc. | vi | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| Figure 6.2: Diamond Drilling from the 700 Level of the No. 1 Shaft | 6-21 |

| Figure 6.3: Diamond Drilling from the 975 Level of the No. 1 Shaft | 6-21 |

| Figure 7.1: Generalized Geologic Map of the Cosmos Hills (Modified from Till et al., 2008) | 7-26 |

| Figure 7.2: Typical Limestones and Dolostones of the Bornite Carbonate Sequence | 7-29 |

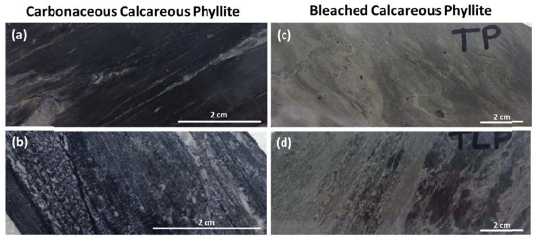

| Figure 7.3: Typical Phyllites of the Bornite Carbonate Sequence | 7-30 |

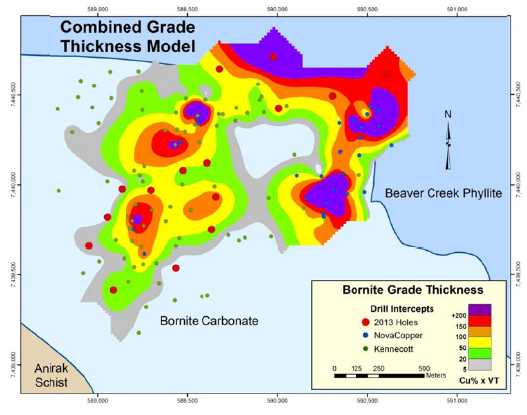

| Figure 7.4: Copper Grade Thickness Plan Map for the Bornite Deposit (NovaCopper, 2014) | 7-32 |

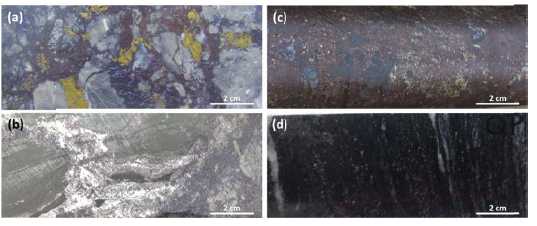

| Figure 7.5: Typical Mineralization of the Bornite Deposit | 7-33 |

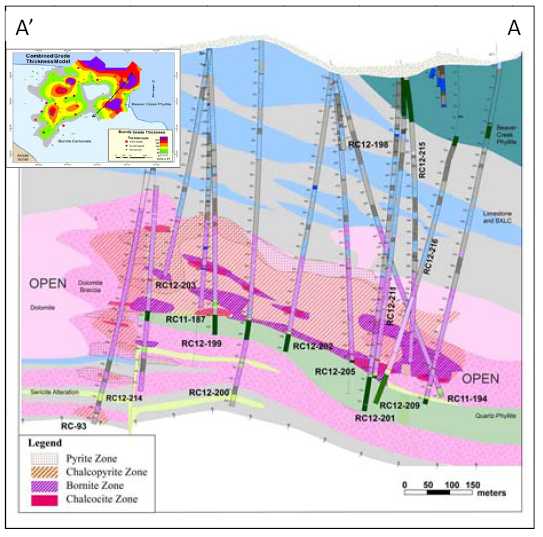

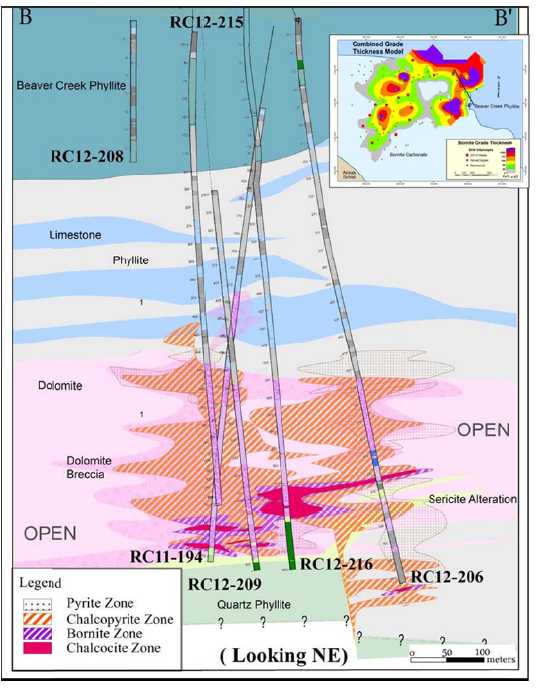

| Figure 7.6: SW-NE Schematic Section through the South Reef Illustrating Geology, Alteration and Sulphide Mineral Zoning | 7-34 |

| Figure 7.7: NW-SE Schematic Section through the South Reef Illustrating Geology, Alteration and Sulphide Mineral Zoning | 7-35 |

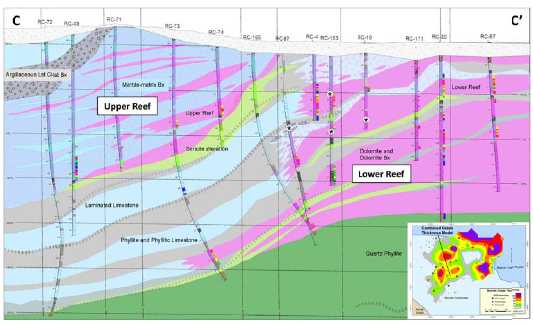

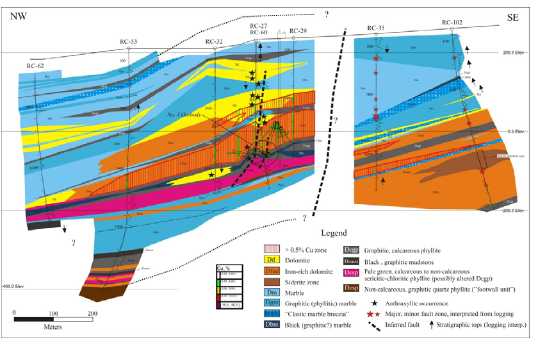

| Figure 7.8: NW-SE Schematic Section through Ruby Creek Upper and Lower Reefs Illustrating Geology, Alteration and Sulphide Mineral Zoning | 7-36 |

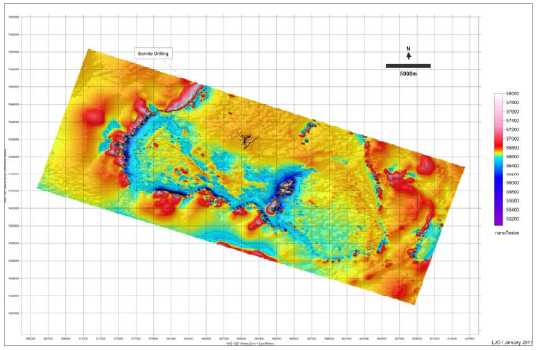

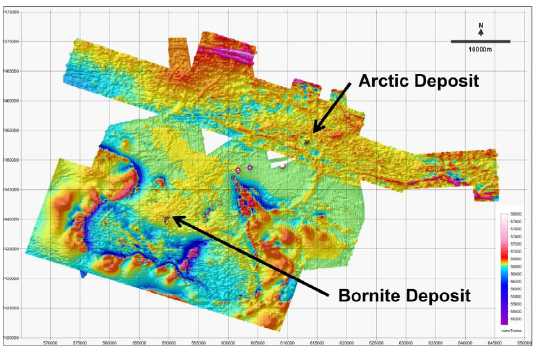

| Figure 9.1: DIGHEM Total Field Magnetics (Fugro, 2007) | 9-39 |

| Figure 9.2: NW-SE Re-interpreted Profile across the Bornite Deposit - 2010 | 9-40 |

| Figure 9.3: District Airborne Magnetics Compiled From Kennecott, AK DNR and NovaGold Surveys (O’Connor, 2010) | 9-41 |

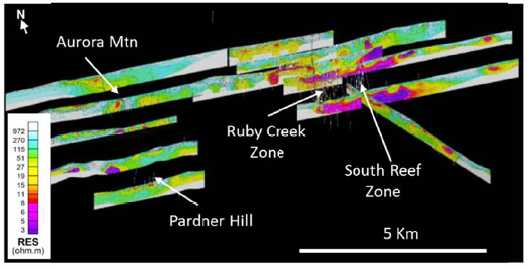

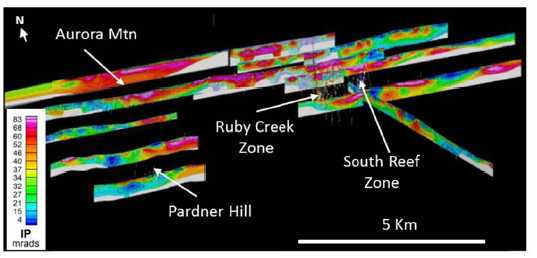

| Figure 9.4: Isometric View of 2011 and 2012 Resistivity Profiles | 9-43 |

| Figure 9.5: Isometric View of 2011 and 2012 Chargeability Profiles | 9-43 |

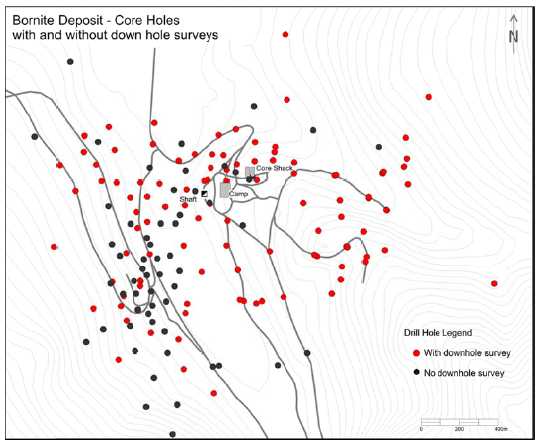

| Figure 10.1: Plan Map Showing Drill Holes Utilized in Resource Estimation (NovaCopper, 2014) | 10-49 |

| Figure 10.2: Surface Drilling with Down-Hole Surveys (NovaCopper, 2014) | 10-55 |

| Figure 13.1: Typical Grain Size Distribution Observed at the Bornite Deposit | 13-66 |

| Figure 13.2: Bornite Flotation Flowsheet | 13-67 |

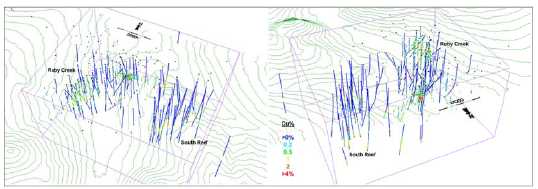

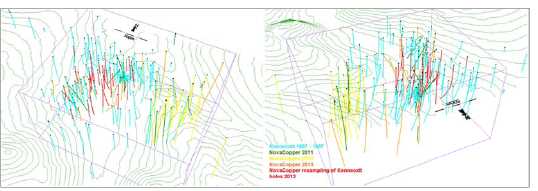

| Figure 14.1: Copper Grades in Drill Holes | 14-72 |

| Figure 14.2: Vintage of Drilling and Sampling | 14-72 |

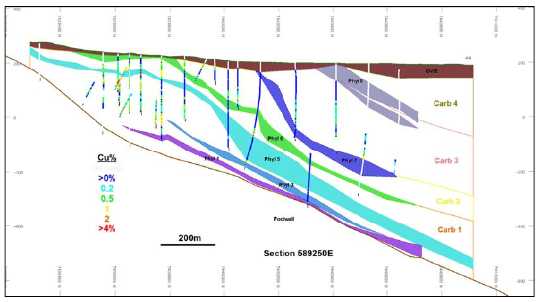

| Figure 14.3: Schematic Section Looking North of Lithology Model Domains | 14-74 |

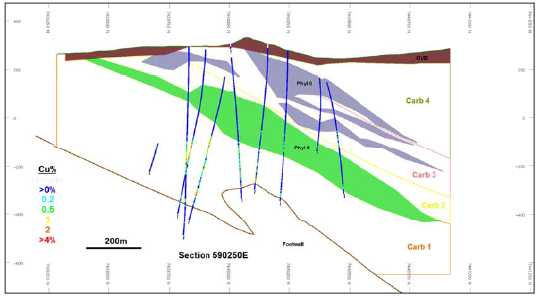

| Figure 14.4: Cross section through Ruby Creek area | 14-74 |

| Figure 14.5: Cross section through the South Reef area | 14-75 |

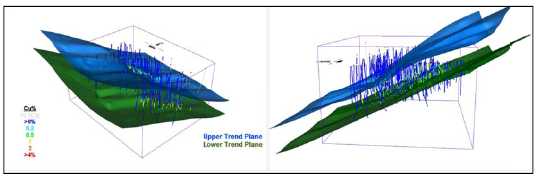

| Figure 14.6: Trend Planes used to control Dynamic Isotropy during block interpolations | 14-76 |

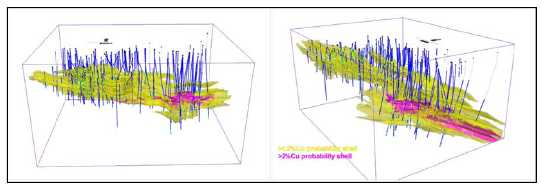

| Figure 14.7: Copper Probability Shells | 14-77 |

| Figure 14.8: Boxplot of Copper by Lithology Domain | 14-79 |

| Figure 14.9: Boxplot of Copper by Probability Shell Domain | 14-79 |

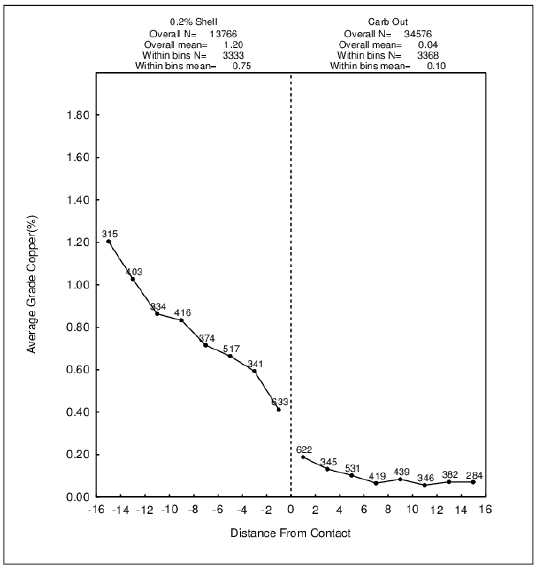

| Figure 14.10: Contact Profile of Copper in Carbonate vs. Phyllite Domains | 14-81 |

| Figure 14.11: Contact Profile of Copper in 2% vs. 0.2% Copper Shells | 14-82 |

| Figure 14.12: Contact Profile of Copper In/Out of the 0.2%Cu Shell in Carbonate Rocks | 14-83 |

| Figure 14.13: Boxplot of Copper in Estimation Domains | 14-85 |

| Figure 14.14: North-South Vertical Section of Copper Estimates in the Block Model in the Ruby Creek Area | 14-91 |

| Figure 14.15: North-South Vertical Section of Copper Estimates in the Block Model in the South Reef Area | 14-91 |

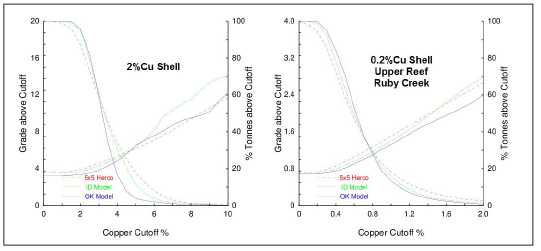

| Figure 14.16: Herco and Model Grade / Tonnage Plots for the 2% Cu Shell and Upper Reef 0.2% Cu Shell Domains | 14-93 |

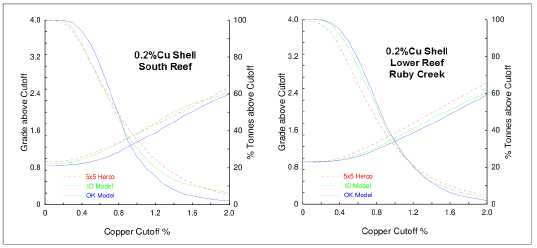

| Figure 14.17: Herco and Model Grade / Tonnage Plots for the 0.2% Cu Shell at South Reef and Ruby Creek Areas | 14-93 |

| Figure 14.18: Comparison of Copper Model Types in Carbonates inside Grade Shell Domains | 14-94 |

| Figure 14.19: Swath plots of Copper in Carbonates Inside Grade Shells | 14-95 |

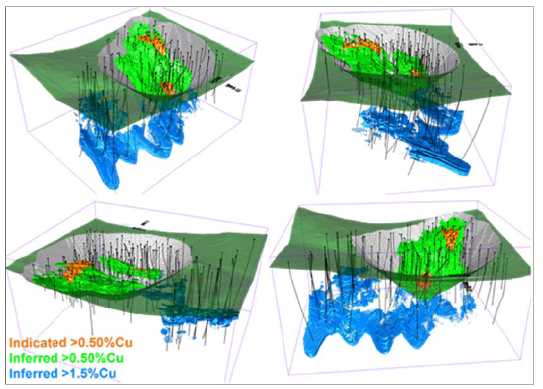

| Figure 14.20: Isometric Views of Bornite Mineral Resource | 14-98 |

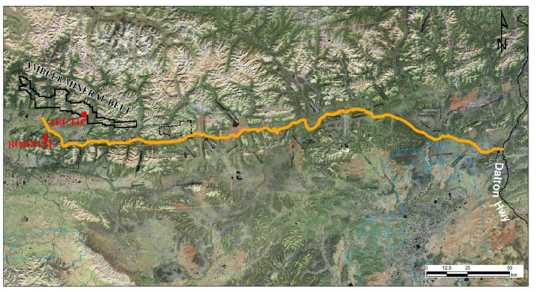

| Figure 18.1: Brooks East Route Access to the UKMP and Location of North Slope LNG (NovaCopper, 2014) | 18-106 |

| Figure 18.2: Brooks East Route Access to the UKMP – Preferred Route (NovaCopper, 2014) | 18-107 |

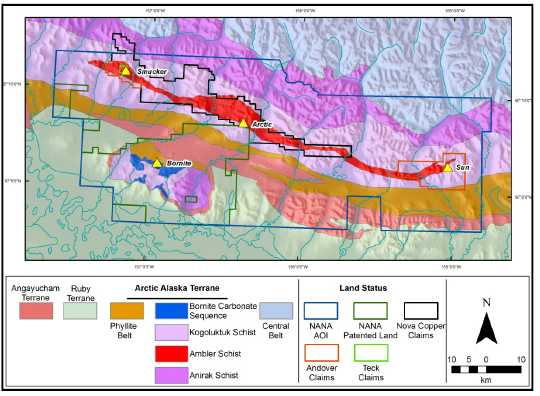

| Figure 23.1: Adjacent Properties and Land Status | 23-121 |

| NovaCopper Inc. | vii | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| GLOSSARY |

| Acme Analytical Laboratories Ltd. | AcmeLabs |

| Alaska Department of Environmental Conservation | ADEC |

| Alaska Department of Fish and Game | ADF&G |

| Alaska Department of Natural Resources | ADNR |

| Alaska Department of Transportation | ADOT |

| Alaska Industrial Development and Export Authority | AIDEA |

| Alaska Native Claims Settlement Act | ANCSA |

| Alaska Native Regional Corporations | ANCSA Corporations |

| Andover Mining Corp. | Andover |

| Annual Hardrock Exploration Activity | AHEA |

| atomic absorption | AA |

| atomic absorption spectroscopy | AAS |

| atomic emission spectroscopy | ICP_AES |

| Audio-Frequency Magneto-Telluric | AMT |

| BD Resource Consulting, Inc. | BDRC |

| Bear Creek Mining Corporation | BCMC |

| Bornite Property | the Property |

| Canadian Institute of Mining, Metallurgy, and Petroleum | CIM |

| complex resistivity induced polarization | CRIP |

| Controlled Source Audio-frequency Magneto-Telluric | CSAMT |

| Dead Creek | Shungnak |

| Electromagnetic | EM |

| Environmental Impact Statement | EIS |

| Environmental Protection Agency | EPA |

| Exploration Agreement and Option to Lease | NANA Agreement |

| Fugro Airborne Surveys | Fugro |

| GeoSpark Consulting Inc | GeoSpark |

| inductively coupled plasma | ICP |

| inductively coupled plasma-mass | ICP-MS |

| International Organization for Standardization | ISO |

| Kennecott Exploration Company and Kennecott Arctic Company | Kennecott |

| Kennecott Research Centre | KRC |

| liquefied natural gas | LNG |

| Mine Development Associates | MDA |

| NANA Regional Corporation, Inc. | NANA |

| National Environmental Policy Act | NEPA |

| National Instrument 43-101 | NI 43-101 |

| natural source audio-magnetotelluric | NSAMT |

| naturally occurring asbestos | NOA |

| net smelter return | NSR |

| North American Datum | NAD |

| NovaCopper Inc. | viii | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| Northern Land Use Research Inc. | NLUR Inc. |

| Northwest Arctic Borough | NWAB |

| Northwest Alaska Native Association | NANA |

| NovaCopper Inc | NovaCopper |

| NovaGold Resources Inc. | NovaGold |

| Polarized Light Microscopy | PLM |

| Quality Assurance/Quality Control | QA/QC |

| SIM Geological Inc. | SGI |

| single point | SP |

| Teck Resources Ltd. | Teck |

| Universal Transverse Mercator | UTM |

| Upper Kobuk Mineral Projects | UKMP |

| US Army Corps of Engineers | USACE |

| US Geological Survey | USGS |

| volcanogenic massive sulphide | VMS |

| WH Pacific, Inc. | WHPacific |

| Zonge International Inc. | Zonge |

| NovaCopper Inc. | ix | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 1.0 |

SUMMARY |

| 1.1 | INTRODUCTION |

|

NovaCopper Inc. (NovaCopper) retained BD Resource Consulting, Inc. (BDRC) and Sim Geological Inc. (SGI), to prepare an updated mineral resource estimate for the Bornite Project and disclose it in a technical report prepared in accordance with National Instrument 43-101 and Form 43-101F1 (collectively “NI 43-101”). The Bornite Property (the Property) is part of the Upper Kobuk Mineral Projects (UKMP) mineral tenure package, which includes the Bornite Deposit, as well as numerous additional mineral showings/deposits. The Property is located in the Ambler mining district of the southern Brooks Range, in the Northwest Arctic Borough (NWAB) of Alaska. The Property is located 248 km east of the town of Kotzebue, 19 km north of the villlage of Kobuk, and 275 km west of the Dalton Highway, an all-weather state maintained highway. Figure 1.1 shows the location of the Property. | |

|

This updated mineral resource estimate and NI 43-101 Technical Report includes assays from an additional 8,142 m of drilling and 10,218 m of previously un-sampled historical drill core completed during the 2013 exploration program. | |

| The effective date of this report is April 1, 2014 and the effective date of the resource model is March 18, 2014. |

Figure 1.1: Property Location Map

| NovaCopper Inc. | 1-1 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 1.2 |

PROPERTY DESCRIPTION AND LOCATION |

|

The Bornite Project is located in the Ambler mining district of the southern Brooks Range, in the NWAB of Alaska. The Property is geographically isolated with no current road access or nearby power infrastructure. The Property is located 248 km east of the town of Kotzebue, 19 km north of the village of Kobuk, and 275 km west of the Dalton Highway, an all-weather state maintained highway. | |

|

The Property is part of the UKMP mineral tenure package, which includes the Bornite Deposit, as well as numerous additional mineral showings/deposits. In October 2011, NovaCopper entered into an exploration agreement with NANA Regional Corporation, Inc. (NANA), the owner of the Property, for the development of the parties’ collective resource interests in the Ambler mining district. The agreement consolidates certain land holdings of the parties into an area of interest of an approximately 143,000 ha land package. | |

| 1.3 |

GEOLOGY AND MINERALIZATION |

|

Mineralization in the UKMP area is characterized by two discrete mineralized belts: the Devonian Ambler Schist Belt and the Devonian Bornite carbonate sequence. The Ambler Schist Belt is host to a series of volcanogenic massive sulphide (VMS) deposits related to metamorphose and strongly deformed bimodal Devonian volcanic and sedimentary rocks. A series of notable VMS deposits, including the Arctic, Dead Creek (Shungnak), Sunshine, Horse Creek, Sun, and Smucker deposits, occur in this belt. At Bornite, the focus of this NI 43-101 technical report, mineralization is hosted in less-strongly deformed Devonian clastic and carbonate sedimentary rocks lying immediately south of the Ambler Schist Belt across the Ambler lowlands. Widespread hydrothermal dolomitization is characteristic of the belt and locally hosts the associated copper mineralization. | |

|

Bornite has characteristics similar to a series of districts and deposits including the Mt Isa district in Australia, the Tynagh deposit in Ireland, the Kipushi deposit in the Congo, and the Tsumeb deposit in Namibia. All of these deposits show: syngenetic to early epigenetic characteristics; emplacement in carbonate stratigraphy; and, early pyrite- dolomite alteration followed by copper dominant sulphide mineralization. All occur in intra-continental to continental margin settings undergoing extensional tectonics and bimodal volcanism. Basin-margin faults seem to play an important role in localizing mineralizing fluids. | |

|

Copper mineralization at Bornite is comprised of chalcopyrite, bornite, and chalcocite as stringers, veinlets, and breccia fillings distributed in stacked, roughly stratiform zones exploiting favourable stratigraphy. Stringer and massive pyrite and locally significant sphalerite occur above and around the copper zones, while locally massive pyrite and sparse pyrrhotite occur in association with siderite alteration below and adjacent to copper mineralization. |

| NovaCopper Inc. | 1-2 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 1.4 | METALLURGICAL TESTING |

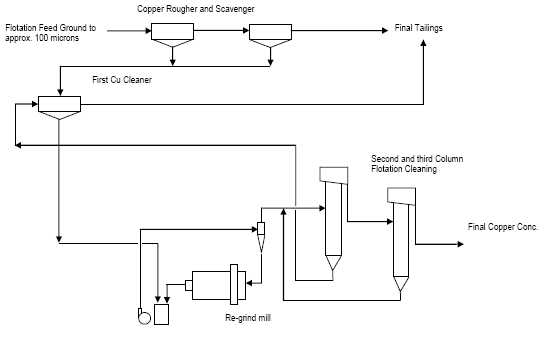

Metallurgical testwork to date indicates that the Bornite Project can be treated using standard grinding and flotation methods to produce copper concentrates. Initial testing indicates copper recoveries of approximately 87% resulting in concentrate grades of approximately 28% copper with very low potential penalty elements. Further metallurgical testwork is warranted to test these assumptions. |

|

| 1.5 | RESOURCE ESTIMATE |

|

An updated mineral resource estimate has been prepared by Bruce M. Davis, FAusIMM, BDRC and Robert Sim P.Geo., SGI, both “Independent Qualified Persons” as defined in section 1.5 of NI 43-101. The mineral resource estimate is listed in Table 1.1. | |

|

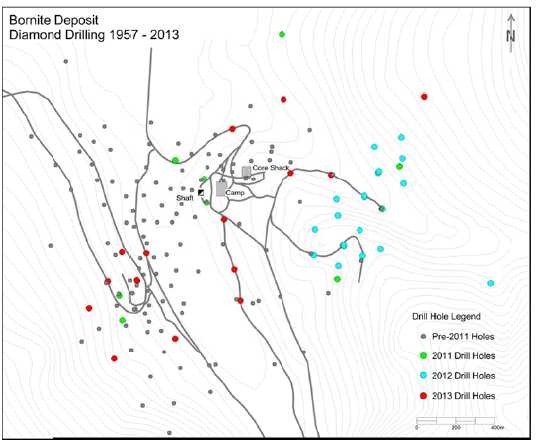

In 2013, NovaCopper drilled an additional 17 holes at Bornite totaling 8,142 m of which 4,684 m was drilled at the Ruby Creek zone and 3,458 m at the South Reef zone. The program expanded the lateral, down-dip, extents in the northern part of the deposit and also provided additional delineation of some internal parts of the western Ruby Creek area. | |

|

In addition to the 2013 drilling, NovaCopper completed an extensive sampling program of 33 historical drill holes located in the Ruby Creek area that were drilled but only selectively sampled by Kennecott. This program has resulted in providing better continuity of mineral resources the Ruby Creek area. | |

|

Tests for reasonable prospects for economic viability suggest that the resource is potentially amenable to a combination of open pit and underground extraction methods. The estimate of mineral resources for the Bornite Project are summarized in Table 1.1. Mineral resources are not mineral reserves, as economic viability has not been demonstrated. |

Table 1.1: Mineral Resource Estimate for the Bornite Project

| Type | Cut-off (Cu %) |

M tonnes | Grade (Cu %) |

Contained Metal (M lbs Cu) |

| Indicated | ||||

| In-Pit(1) | 0.5 | 14.1 | 1.08 | 334 |

| Inferred | ||||

| In-Pit(1) | 0.5 | 109.6 | 0.94 | 2,259 |

| Below-Pit | 1.5 | 55.6 | 2.81 | 3,437 |

| Total Inferred | 165.2 | 1.57 | 5,696 | |

| (1) |

Resources stated as contained within a pit shell developed using a metal price of US$3.00/lb Cu, mining costs of US$2.00/tonne, milling costs of US$11/tonne, G&A cost of US$5.00/tonne, 87% metallurgical recoveries and an average pit slope of 43 degrees. | |

| (2) |

Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resources will be converted into Mineral Reserves. | |

| (3) |

Inferred resources have a great amount of uncertainty as to their existence and whether they can be mined legally or economically. It cannot be assumed that all or any part of the Inferred resources will ever be upgraded to a higher category. |

| NovaCopper Inc. | 1-3 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 1.6 |

INTERPRETATIONS AND CONCLUSIONS |

|

The level of understanding of the geologic controls that influence the distribution of copper mineralization at the Bornite Deposit is relatively good. The drilling, sampling and validation practices utilized by NovaCopper during the various campaigns have been conducted in a professional manner and adhere to accepted industry standards. The confidence in older, historic, drilling conducted by Kennecott has been demonstrated through a series of validation checks and, overall, the underlying database is considered sufficient for the estimation of Indicated and Inferred mineral resources. BDRC and SGI have prepared an updated mineral resource estimate and supporting Technical Report in accordance with NI 43-101. The deposit remains “open” to potential expansion at depth and to the north and east. There are also indications that the mineralization may be continuous between the South Reef zone and the Lower Reef zone at Ruby Creek. Further drilling is warranted to test these assumptions. Metallurgical testwork to date is very limited but suggests that potentially marketable concentrates can be produced using standard grinding and flotation methods. Based on the information to date, the Bornite Project hosts a relatively large copper resource that is potentially amenable to a combination of open pit and underground extraction methods. It is recommended that NovaCopper continue to advance the Project through continued exploration, metallurgical studies, preliminary engineering studies, environmental base line analyses and should consider the generation of a preliminary economic analysis in the near future. | |

| 1.7 |

OPPORTUNITIES AND RECOMMENDATIONS |

|

BDRC and SGI make the following recommendations for the next phase of work on the Bornite Project: |

| • |

Continued integration of lithology, alteration, structural and mineral zoning domains in the interpretation of the geologic model. ($75,000) | |

| • |

Approximately 3,000 m of infill drilling, with holes spaced at 200 m intervals, to test the continuity of mineralization between the Ruby Creek Lower Reef zone and South Reef zone. ($1.5M) | |

| • |

Continued sampling of previously un-sampled Kennecott drill holes. ($200,000) | |

| • |

Update mineral resource estimate and technical report. ($75,000) | |

| • |

Metallurgical studies, including variability and grinding test work, examination of the process parameters needed to optimize the cleaning circuit, and monitoring of concentrate quality. ($170,000) | |

| • |

Implement an initial acid base accounting (ABA) waste characterization study suitable to support a PEA level study. $50,000. | |

| • | Maintain environmental baseline monitoring to support environmental and permitting activities ($30,000) | |

| • | Undertake a hydrogeological and geotechnical program to develop a better understanding of the groundwater regime and pit slope stability to support PEA-level open pit design. ($400,000) |

Total cost of Phase 1 is $2.5M (excludes site costs such as camp support, overhead and other indirect costs. Additional exploration drilling to test for down-dip extensions to known resources north of Ruby Creek and South Reef will require further expenditures.)

Following the successful completion of Phase 1 of the proposed work, it is

recommended that NovaCopper conduct internal engineering and economic

evaluations to support moving forward with a PEA. The estimated cost of a PEA is

$800,000.

| NovaCopper Inc. | 1-4 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 2.0 |

INTRODUCTION |

| 2.1 | TERMS OF REFERENCE |

|

NovaCopper, a company involved in the exploration and development of projects in the UKMP, retained BDRC and SGI to prepare an updated mineral resource estimate for the Bornite Project and disclose it in a technical report prepared in accordance with National Instrument 43-101 and Form 43-101F1 (collectively “NI 43-101”). | |

|

This report replaces the previous Technical Report for the Bornite Deposit, South Reef and Ruby Creek Zones, prepared for NovaCopper by BDRC and SGI dated February 8, 2013. | |

|

BDRC and SGI Qualified Persons (QPs) are responsible for sections 1 – 12 and 14 - 26 of the current technical report. NovaCopper engaged AGP Mining Consultants Inc. of Vancouver, BC to evaluate the general economic viability of the resource and to prepare a resource limiting pit shell as described in Section 14 of this report. International Metallurgical and Environmental Inc., of Kamloops, BC provided a summary of Bornite metallurgical test work (Section 13.0), and is the responsible QP for this section. BDRC and SGI used the information completed by these contributors to support information in this current technical report. | |

| 2.2 |

UNITS OF MEASUREMENT |

|

All units of measurement in this technical report are metric, unless otherwise stated. Specifically, in the section describing historic resource estimates, and when reporting contained copper, imperial units are used. | |

|

The monetary units are in US dollars, unless otherwise stated. | |

| 2.3 |

QUALIFIED PERSONS |

|

Bruce Davis, FAusIMM, the president of BDRC, is the principle author of this Technical Report. Robert Sim, P.Geo., the president of SGI, and Jeff Austin, P.Eng., the president of International Metallurgical & Environmental Inc., are co-authors of this Technical Report. Bruce Davis, Robert Sim and Jeff Austin are QPs as defined in NI 43-101, Standards of Disclosure for Mineral Projects, and in compliance with Form 43-101F1. | |

|

Neither Bruce Davis of BDRC, Robert Sim of SGI, nor Jeff Austin of International Metallurgical & Environmental Inc., nor any associates employed in the preparation of this report (Consultants), has any beneficial interest in NovaCopper. These Consultants are not insiders, associates, or affiliates of NovaCopper. The results of this Technical Report are not dependent on any prior agreements concerning the conclusions of this report, and there are no undisclosed understandings concerning future business dealings between NovaCopper and the Consultants. The Consultants are paid a fee for their work in accordance with normal professional consulting practices. |

| NovaCopper Inc. | 2-5 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 2.4 |

SITE VISIT |

|

Bruce Davis conducted a site visit to the Bornite Project on July 26-27, 2011, and again on September 25, 2012. Figure 2.1 shows the Bornite exploration shaft and the NovaCopper exploration camp. The site visits included a review of: drilling procedures, site facilities, historic and recent drill core, logging procedures, data capture, and sample handling. During the 2012 Bornite site visit, Mr. Davis undertook a helicopter traverse along proposed access corridors and within the UKMP. |

Figure 2.1: Bornite Exploration Shaft and the NovaCopper Exploration Camp

| 2.5 |

INFORMATION SOURCES |

|

Reports and documents listed in Section 27.0 were used to support the preparation of the technical report. Additional information was sought from NovaCopper personnel where required. |

| NovaCopper Inc. | 2-6 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 3.0 |

RELIANCE ON OTHER EXPERTS |

BDRC and SGI have fully relied on NovaCopper’s management team for matters relating to mineral tenure and mining rights permits, surface rights, royalties, agreements and encumbrances relevant to this report, which are documented in the NovaCopper and NANA Exploration Agreement and Option to Lease dated October 19, 2011 (the “NANA Agreement”). BDRC and SGI have not researched the property title or mineral rights for the Bornite Project and express no legal opinion as to the ownership status of the property.

BDRC and SGI believe the data and information provided by NovaCopper is essentially complete and correct to the best of their knowledge and that no information was intentionally withheld that would affect the conclusions made herein.

| NovaCopper Inc. | 3-7 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 4.0 |

PROPERTY DESCRIPTION AND LOCATION |

| 4.1 |

LOCATION |

|

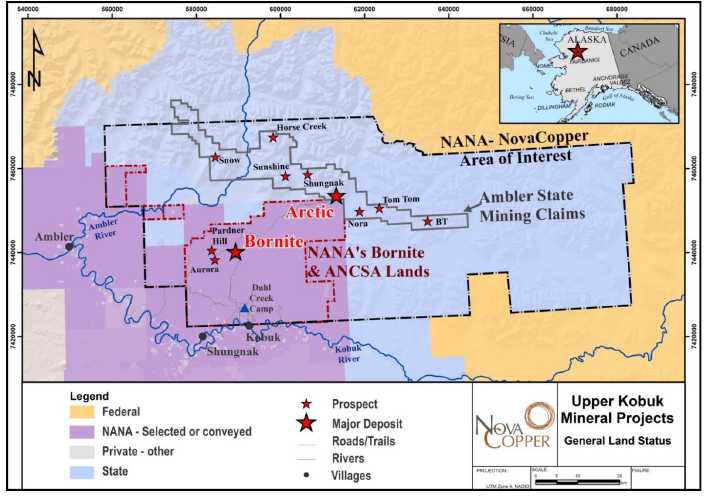

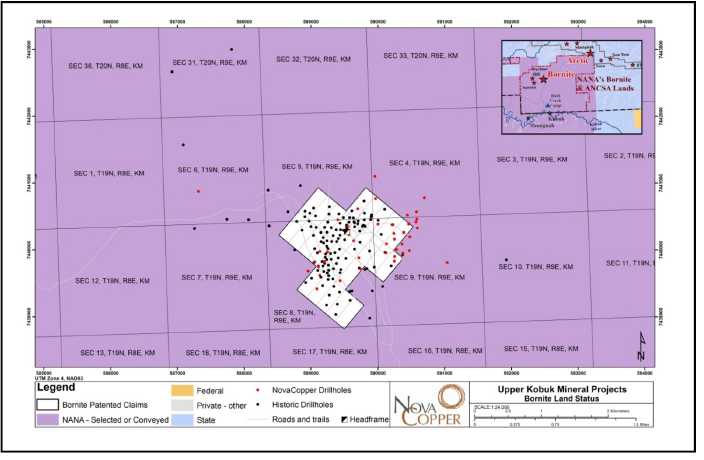

The Property is part of the UKMP mineral tenure package, which includes the Bornite Deposit, as well as numerous additional mineral showings/deposits (Figure 4.1 and Figure 4.2). The Property is located in the Ambler mining district of the southern Brooks Range, in the NWAB of Alaska. The Property is located in Ambler River A-2 quadrangle, Kateel River Meridian T 19N, R 9E, sections 4, 5, 8 and 9. | |

|

The Bornite Project is located 248 km east of the town of Kotzebue, 19 km north of the village of Kobuk, 275 km west of the Dalton Highway, an all-weather state maintained public road, at geographic coordinates N67.07° latitude and W156.94° longitude (Universal Transverse Mercator (UTM) North American Datum (NAD) 83, Zone 4W coordinates 7440449N, 589811E). | |

| 4.2 |

MINERAL TENURE |

|

The UKMP lands consist of NANA owned patented lands, NANA selected ANCSA lands, State of Alaska mining claims, and patented land owned by NovaCopper. The total land tenure package consists of 142,831 ha, 140,500 ha of which are within the NANA/NovaCopper “Area of Interest” covered by the NANA/NovaCopper Agreement. Twenty contiguous State of Alaska mining claims totaling 2,331 ha are outside of the NANA/NovaCopper Area of Interest. A breakdown of the UKMP lands is provided in Table 4.1. |

Table 4.1: Summary of UKMP Lands Status

| Owner | Number | Type | Acres | Hectares |

| NovaCopper | 1336 | State Claims (inside AOI) | 106,026 | 42,907 |

| NovaCopper | 20 | State Claims (outside AOI) | 5,760 | 2,331 |

| NovaCopper | 2 | Patented | 272 | 110 |

| NovaCopper Total | 112,058 | 45,348 | ||

| NANA (ANCSA) | N/A | Selected/Patented | 240,369 | 97,274 |

| NANA (Bornite) | 25 (2 USMS Patents) |

Patented | 517 | 209 |

| NANA Total | 240,885 | 97,483 | ||

| Grand Total | 352,943 | 142,831 |

| NovaCopper Inc. | 4-8 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Figure 4.1: Upper Kobuk Mineral ProjectsLands (NovaCopper, 2014)

| NovaCopper Inc. | 4-9 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Figure 4.2: Mineral Tenure Plan (NovaCopper,2014)

| NovaCopper Inc. | 4-10 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 4.3 | ROYALTIES, AGREEMENTS AND ENCUMBRANCES |

| 4.3.1 | KENNECOTT AGREEMENTS |

|

On March 22, 2004, Alaska Gold Company, a wholly-owned subsidiary of NovaGold Resources Inc. (NovaGold) completed an Exploration and Option to Earn an Interest Agreement with Kennecott Exploration Company and Kennecott Arctic Company (collectively, Kennecott) on the Ambler land holdings. | |

|

On December 18, 2009, a Purchase and Termination Agreement was entered into between Alaska Gold Company and Kennecott whereby NovaGold agreed to pay Kennecott a total purchase price of $29 million for a 100% interest in the Ambler land holdings, which included the Arctic Project, to be paid as: $5 million by issuing 931,098 NovaGold shares, and two installments of $12 million each, due 12 months and 24 months from the closing date of January 7, 2010. The NovaGold shares were issued in January 2010, the first $12 million payment was made on January 7, 2011, and the second $12 million payment was made in advance on August 5, 2011; this terminated the March 22, 2004 exploration agreement between NovaGold and Kennecott. Under the Purchase and Termination Agreement, the seller retained a 1% net smelter return (NSR) royalty that is purchasable at any time by the land owner for a one-time payment of $10 million. | |

|

During 2011, NovaGold incorporated the NovaCopper entities and transferred its Ambler land holdings, including the Arctic Project from Alaska Gold Company to NovaCopper US Inc. In April 2012, NovaGold completed a spin-out of NovaCopper, with the Ambler lands, to the NovaGold shareholders and made NovaCopper an independent publically listed company, listed on the TSX and NYSE-MKT exchanges. | |

| 4.3.2 |

NANA AGREEMENT |

|

In 1971, the US Congress passed the Alaska Native Claims Settlement Act (ANCSA) which settled land and financial claims made by the Alaska Natives and provided for the establishment of 13 regional corporations to administer those claims. These 13 corporations are known as the Alaska Native Regional Corporations (ANCSA Corporations). One of these 13 regional corporations is the Northwest Alaska Native Association (NANA) Regional Corporation, Inc. ANCSA Lands controlled by NANA bound the southern border of the Property claim block. National Park lands are within 25 km of the northern property border. The Bornite Deposit is located entirely on lands owned by NANA. | |

|

On October 19, 2011, NovaCopper and NANA Regional Corporation, Inc. entered into the “NANA Agreement” for the cooperative development of their respective resource interests in the Ambler mining district. The NANA Agreement consolidates NovaCopper’s and NANA’s land holdings into an approximately 142,831 ha land package and provides a framework for the exploration and development of the area. The NANA Agreement provides that NANA will grant NovaCopper the nonexclusive right to enter on, and the exclusive right to explore, the Bornite Lands and the ANCSA Lands (each as defined in the NANA Agreement) and in connection therewith, to construct and utilize temporary access roads, camps, airstrips and other incidental works. The NANA Agreement has a term of 20 years, with an option in favour of NovaCopper to extend the term for an additional 10 years. The NANA Agreement may be terminated by mutual agreement of the parties or by NANA if NovaCopper does not meet certain expenditure requirements on NANA’s lands. |

| NovaCopper Inc. | 4-11 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

If, following receipt of a feasibility study and the release for public comment of a related draft environmental impact statement, NovaCopper decides to proceed with construction of a mine on the lands subject to the NANA Agreement, NovaCopper will notify NANA in writing and NANA will have 120 days to elect to either (a) exercise a non-transferrable back-in-right to acquire between 16% and 25% (as specified by NANA) of that specific project; or (b) not exercise its back-in-right, and instead receive a net proceeds royalty equal to 15% of the net proceeds realized by NovaCopper from such project. The cost to exercise such back-in-right is equal to the percentage interest in the Project multiplied by the difference between (i) all costs incurred by NovaCopper or its affiliates on the project, including historical costs incurred prior to the date of the NANA Agreement together with interest on the historical costs; and (ii) $40 million (subject to exceptions). This amount will be payable by NANA to NovaCopper in cash at the time the parties enter into a joint venture agreement and in no event will the amount be less than zero.

In the event that NANA elects to exercise its back-in-right, the parties will, as soon as reasonably practicable, form a joint venture with NANA electing to participate between 16% to 25%, and NovaCopper owning the balance of the interest in the joint venture. Upon formation of the joint venture, the joint venture will assume all of the obligations of NovaCopper and be entitled to all the benefits of NovaCopper under the NANA Agreement in connection with the mine to be developed and the related lands. A party’s failure to pay its proportionate share of costs in connection with the joint venture will result in dilution of its interest. Each party will have a right of first refusal over any proposed transfer of the other party’s interest in the joint venture other than to an affiliate or for the purposes of granting security. A transfer by either party of a net smelter royalty return on the project or any net proceeds royalty interest in a project other than for financing purposes will also be subject to a first right of refusal.

In connection with possible development on the Bornite Lands or ANCSA Lands, NovaCopper and NANA will execute a mining lease to allow NovaCopper or the joint venture to construct and operate a mine on the Bornite Lands or ANCSA Lands (the “Mining Lease”). These leases will provide NANA a 2% net smelter royalty as to production from the Bornite Lands and a 2.5% net smelter royalty as to production from the ANCSA Lands.

If NovaCopper decides to proceed with construction of a mine on its own lands subject to the NANA Agreement, NANA will enter into a surface use agreement with NovaCopper which will afford NovaCopper access to the project along routes approved by NANA (the “Surface Use Agreement”). In consideration for the grant of such surface use rights, NovaCopper will grant NANA a 1% net smelter royalty on production and an annual payment of $755 per acre (as adjusted for inflation each year beginning with the second anniversary of the effective date of the NANA Agreement and for each of the first 400 acres (and $100 for each additional acre) of the lands owned by NANA and used for access which are disturbed and not reclaimed.

| NovaCopper Inc. | 4-12 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 4.4 |

ENVIRONMENTALLIABILITIES |

|

Under the NANA Agreement, NANA is required to complete a baseline environmental report following the cleanup of the former mining camp on the Bornite Lands; this work must be completed to Alaska Department of Environmental Conservation standards. Cleanup includes the removal and disposal, as required by law, of all hazardous substances present on the Bornite Lands. NANA has indemnified and will hold NovaCopper harmless for any loss, cost, expense, or damage suffered or incurred attributable to the environmental condition of the Bornite Lands at the date of the baseline report which relate to any activities prior to the date of the agreement. | |

|

In addition, there are no indications of any known environmental impairment or enforcement actions associated with NovaGold’s activities to date. As a result, NovaGold, now NovaCopper has not incurred outstanding environmental liabilities in conjunction with its entry into the NANA Agreement. | |

| 4.5 |

PERMITS |

|

Multiple permits are required during the exploration phase of the Property. Permits are issued from Federal, State, and Regional agencies, including: the Environmental Protection Agency (EPA), the US Army Corps of Engineers (USACE), the Alaska Department of Environmental Conservation (ADEC), the Alaska Department of Fish and Game (ADF&G), the Alaska Department of Natural Resources (ADNR), and the NWAB. The State of Alaska permit for exploration on the Property, the Annual Hardrock Exploration Activity (AHEA) Permit, is obtained and renewed every five years through the ADNR – Division of Mining, Land and Water. NovaCopper holds an AHEA exploration permit in good standing with the Alaska DNR, and has done so each year since 2004 under Alaska Gold Company, a wholly owned subsidiary of NovaGold and now NovaCopper. The Property is within the NWAB thus requiring a Title 9 Miscellaneous Land Use permit for mineral exploration, fuel storage, gravel extraction, and the operation of a landfill. NovaGold held these permits in good standing during the 2004 to 2008 seasons and renewed the permits for the 2010 exploration season to 2015. The Bornite Camp, Bornite Landfill, Dahl Creek Camp, and the to-be-constructed Arctic Camp are permitted by the ADEC. | |

|

A number of statutory reports and payments are required to maintain the claims in good standing on an annual basis. As the Bornite Project progresses, additional permits for environmental baseline and detailed engineering studies will be necessary at federal, state, and local levels. A detailed outline of permitting requirements is discussed in Section 20.0. |

| NovaCopper Inc. | 4-13 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 5.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, |

| 5.1 |

ACCESSIBILITY |

| 5.1.1 |

AIR |

|

Primary access to the Property is by air, using both fixed wing aircraft and helicopters. | |

|

There are four well maintained, approximately 1,500 m-long gravel airstrips located near the Property, capable of accommodating charter fixed wing aircraft. These airstrips are located 40 km west at Ambler, 23 km southwest at Shungnak, 19 km south at Kobuk, and 15 km south at Dahl Creek. There is daily commercial air service from Kotzebue to the village of Kobuk, the closest community to the Property. During the summer months, the Dahl Creek Camp airstrip is suitable for larger aircraft, such as C-130 and DC-6. | |

|

In addition to the four 1,500 m airstrips, there is a 700 m airstrip located at the Bornite Camp. The airstrip at Bornite is suited to smaller aircraft, which support the Bornite Camp with personnel and supplies. | |

| 5.1.2 |

WATER |

|

There is no direct water access to the Property. During spring runoff, river access is possible by barge from Kotzebue Sound to Ambler, Shungnak, and Kobuk via the Kobuk River. | |

| 5.1.3 |

ROAD |

|

A one-lane dirt track suitable for high-clearance vehicles or construction equipment links the Bornite Project’s main camp to the 400 m Dahl Creek airstrip and village of Kobuk. | |

| 5.2 |

CLIMATE |

|

The climate in the region is typical of a sub-arctic environment. Exploration is generally conducted from late May until late September. Weather conditions on the Property can vary significantly from year to year and can change suddenly. During the summer exploration season, average maximum temperatures range from 10°C to 20°C, while average lows range from -2°C to 7°C (Alaska Climate Summaries: Kobuk 1971 to 2000). By early October, unpredictable weather limits safe helicopter travel to the Property. During winter months, the Property can be accessed by snow machine, track vehicle, or fixed wing aircraft. Winter temperatures are routinely below -25°C and can exceed - 50°C. Annual precipitation in the region averages at 395 mm with the most rainfall occurring from June through September, and the most snowfall occurring from November through January. |

| NovaCopper Inc. | 5-14 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 5.3 |

LOCAL RESOURCES |

|

The Property is approximately 248 km east of the town of Kotzebue, on the edge of Kotzebue Sound, 19 km north of the village of Kobuk, 275 km west of the Dalton Highway, and 485 km northwest of Fairbanks. Kobuk (population 151; 2010 US Census) is a potential workforce source for the Bornite Project, and is the location of one of the airstrips near the Property. Several other villages are also near the Property, including Shungnak located 23 km to the southwest with a population of 262 (2010 US Census) and Ambler, 40 km to the west with a population of 258 (2010 US Census). Kotzebue has a population of 3,201 (2010 US Census) and is the largest population centre in the Northwest Arctic Borough. Kotzebue is a potential source of limited mining-related supplies and labourers, and is the nearest centre serviced by regularly scheduled, large commercial aircraft (via Nome or Anchorage). In addition, there are seven other villages in the region that will be a potential source of some of the workforce for the Property. Fairbanks (population 32,036; 2011 US Census) has a long mining history and can provide most mining-related supplies and support that cannot be sourced closer to the Property. | |

|

Drilling and mapping programs are seasonal and have been supported out of the Main Bornite Camp and Dahl Creek Camp. The main Bornite Camp facilities are located on Ruby Creek on the northern edge of the Cosmos Hills. The camp provides office space and accommodations for the geologists, drillers, pilots, and support staff. There are four 2-person cabins installed by NANA prior to NovaCopper’s tenure. | |

|

In 2011, the main Bornite Camp was expanded to 20 sleeping tents, 3 administrative tents, 2 shower/bathroom tents, 1 medical tent, and 1 dining/cooking tent. With these additions, the camp capacity was increased to 49 beds. A 30 m by 9 m core logging facility was also built in summer of 2011. An incinerator was installed near the Bornite airstrip to manage waste created by the Bornite Project. Power for the Bornite Project is supplied by a 175 kW Caterpillar diesel generator. Water is provided by a permitted artesian well located 250 m from the Bornite Camp. | |

|

In 2012, the camp was further expanded with the addition of a laundry tent, a women's shower/washroom tent, a recreation tent, several additional sleeping tents, and a 2 x enlargement of the kitchen tent. Camp capacity increased to 76 beds. The septic field was upgraded to accommodate the increase in camp population. One of the two-person cabins was winterized for use by the winter caretaker. A permitted landfill was established to allow for the continued cleanup and rehabilitation of the historic shop facilities and surroundings. | |

|

The Dahl Creek camp is an overflow or alternative facility to the main Bornite Camp. The Dahl Creek camp has a main cabin for dining and administrative duties, and a shower facility. Sleeping facilities include two hard-sided sleeping cabins with seven beds (primarily used for staff), two 4-person sleeping tents, and three 2-person sleeping tents for a total of 21 beds. There are support structures, including a shop and storage facilities. |

| NovaCopper Inc. | 5-15 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 5.4 |

INFRASTRUCTURE |

|

Proposed infrastructure is discussed in more detail in Section 18.0. Currently, the Bornite Project does not have access to Alaska power and transportation infrastructure. | |

|

Beginning in 2009, the Property has been the focus of an access corridor study. The State of Alaska has spent approximately $10 million to identify proposed access routes to the Ambler mining district, and to initiate environmental baseline studies. The working group for this study consists of the Alaska Department of Transportation (ADOT), the ADNR, the Governor’s Office, the Alaska Industrial Development and Export Authority (AIDEA), NANA, and NovaCopper. | |

|

Based on this work the Brooks East route has been selected as the preferred alternative. It is a 322 km road running east from the Property to the Dalton Highway and is now referred to as the Ambler Mining District Industrial Access Road or AMDIAR. The environmental baseline study for the route is expected to be completed in 2013, with the environmental impact study to follow in early 2014. A budget of $8.5M has been committed for 2013/2014 to support pre-design and environmental permitting. A budget of $10M has been proposed for 2014/2015 to support environmental studies, legal and permitting the preferred access route. | |

| 5.5 |

PHYSIOGRAPHY |

|

The Bornite Project is located on Ruby Creek on the northern edge of the Cosmos Hills. The Cosmos Hills are part of the southern flank of the Brooks Range in Northwest Alaska. Topography in the area is moderately rugged. Maximum relief in the Cosmos Hills is approximately 1,000 masl with an average of 600 masl. Talus covers the upper portions of the hills; glacial and fluvial sediments occupy valleys. | |

|

The Kobuk Valley is located at the transition between boreal forest and Arctic tundra. Spruce, birch, and poplar are found in portions of the valley, with a ground cover of lichens (reindeer moss). Willow and alder thickets and isolated cottonwoods follow drainages, and alpine tundra is found at higher elevations. Tussock tundra and low, heath-type vegetation covers most of the valley floor. Patches of permafrost exist on the Property. | |

|

Permafrost is a layer of soil at variable depths beneath the surface where the temperature has been below freezing continuously from a few to several thousands of years (Climate of Alaska 2007). Permafrost exists where summer heating fails to penetrate to the base of the layer of frozen ground and occurs in most of the northern third of Alaska as well as in discontinuous or isolated patches in the central portion of the state. |

| NovaCopper Inc. | 5-16 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

|

Wildlife in the Property area is typical of Arctic and Subarctic fauna (Kobuk Valley National Park 2007). Larger animals include caribou, moose, Dall sheep, bears (grizzly and black), wolves, wolverines, coyotes, and foxes. Fish species include salmon, sheefish, arctic char, and arctic grayling. The Kobuk River, which briefly enters the UKMP on its southwest corner, is a significant salmon spawning river. The Caribou on the Property belong to the Western Arctic herd that migrates twice a year – south in August, from their summer range north of the Brooks Range, and north in March from their winter range along the Buckland River. | |

| 5.6 |

SUFFICIENCY OF SURFACE RIGHTS |

|

The Company has sufficient surface rights for its planned mining operations including sufficient land to construct various facilities such as tailings storage areas, potential waste disposal areas, potential stockpile areas and potential processing plants. |

| NovaCopper Inc. | 5-17 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 6.0 |

HISTORY |

|

Regional exploration began in the early 1900s when gold prospectors noted copper occurrences in the hills north of Kobuk, Alaska. In 1947, local prospector Rhinehart “Rhiny” Berg along with various partners traversing in the area located outcropping mineralization along Ruby Creek (Bornite) on the north side of the Cosmos Hills. They subsequently staked claims over the Ruby Creek showings and constructed an airstrip for access. In 1957, BCMC, Kennecott's exploration subsidiary, optioned the property from Berg. | |

|

Exploration drilling in 1961 and 1962 culminated in the discovery of the “No.1 Ore Body” where drill hole RC-34 cut 20 m of 24% copper (the “No.1 Ore Body” is a historic term used by BCMC that does not connote economic viability in the present context; it is convenient to continue to use the term to describe exploration work and historic resource estimation in a specific area of what is now generally known as Ruby Creek Upper Reef). The discovery of the “No.1 Ore Body” led to the development of an exploration shaft in 1966. The shaft, which reached a depth of 328 m, encountered a significant watercourse and was flooded near completion depth. The shaft was subsequently dewatered and an exploration drift was developed to provide access for sampling and mapping, and to accommodate underground drilling to further delineate mineralization. A total of 59 underground holes were drilled and, after the program, the shaft was allowed to re-flood. | |

|

The discovery of the Arctic Project in 1965 prompted a hiatus in exploration at Bornite, and only limited drilling occurred up until 1976. | |

| 6.1 |

GEOCHEMISTRY |

|

In the late 1990s, Kennecott resumed its evaluation of the Bornite deposit and the mineralization in the Cosmos Hills with an intensive soil, stream, and rock chip geochemical sampling program using 32 element ICP analyses. Grid soil sampling yielded 765 samples. Ridge and spur sampling resulted in an additional 850 soil samples in the following year. Skeletonized core samples (85 samples) from key historic drill holes were also analyzed using 32 element ICP analytical methods. Geochemical sampling identified multiple areas of elevated copper and zinc in the Bornite region (Kennecott Annual Ambler Project Reports, 1995-1997). | |

| 6.2 |

GEOPHYSICS |

|

Kennecott completed numerous geophysical surveys as an integral part of exploration throughout their tenure on the property. Various reports, notes, figures, and data files stored in Kennecott’s Salt Lake City exploration office indicated that geophysical work included, but was not limited to, the following: |

| NovaCopper Inc. | 6-18 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| • |

Airborne magnetic and electromagnetic (EM) surveys (fixed-wing INPUT) (1950s) | |

| • |

Gravity, single point (SP), Audio-Frequency Magneto-Telluric (AMT), EM, borehole and surface IP/resistivity surveys (1960s) | |

| • |

Gravity, airborne magnetic, and Controlled Source Audio-frequency Magneto- Telluric (CSAMT) surveys (1990s) |

NovaCopper has little information or documentation associated with these geophysical surveys conducted prior to the 1990s. Where data are available in these earlier surveys, the lack of details in data acquisition, coordinate systems, and data reduction procedures limit their usefulness. The only complete geophysical report available concerns down-hole IP/resistivity results (Merkel, 1967).

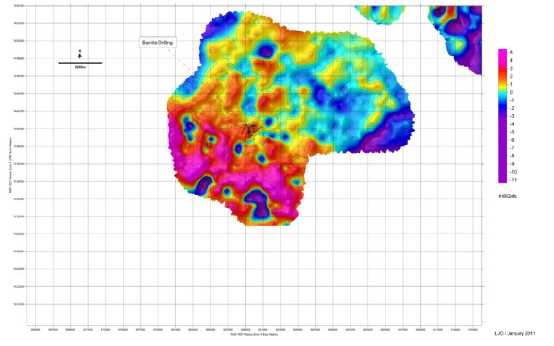

Most notable is the 1996 Bouger gravity survey from the Bornite deposit into the Ambler lowlands. Figure 6.1 shows the terrain-corrected Bouger residual gravity survey anomalies. The Bornite deposit itself is seen as a significant 3 milligal anomaly. Numerous 2 milligal to > 6 milligal anomalies occur under cover in the Ambler lowlands and near the Aurora Mountain and Pardner Hill occurrences.

The wide range of geophysical techniques used in and around the deposit over a span of 40 years indicates the level of difficulty experienced by Kennecott/BCMC while trying to detect mineralization. When applying EM and IP/resistivity methods, the problem appears to be that deeper mineralization is often masked by the response of near-surface conductive rocks.

In addition to the geophysical surveys conducted by Kennecott, the Alaska Department of Natural Resources and Geometries completed an aeromagnetic survey of portions of the Ambler mining district in 1974-1975. Part of this survey is reproduced in Figure 9.3 (Gilbert et al., 1977).

| NovaCopper Inc. | 6-19 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Figure 6.1: 1996 Kennecott Residual Gravity

| 6.3 | DRILLING AND UNDERGROUND WORKINGS |

Between 1957 and 1976, Kennecott

(BCMC) completed 178 holes (including 51 underground holes) totaling

47,801 m. In 1997, Kennecott drilled an additional 3 core holes totaling

928 m. | |

Drilling for all BCMC/Kennecott

campaigns in the Bornite Deposit area (1957 to 1997) totals 181 core holes

for a combined 48,729 m. A complete and comprehensive discussion of all

the drilling undertaken at the Bornite Deposit is contained in Section

10.0 of this report. | |

In October 1965, Kennecott began

a shaft to further investigate the Ruby Creek Upper Reef “No.1 Ore Body”

mineralization. In 1966, the shaft reached the 297 m (975 ft) level. At

this level, a 91 m crosscut was driven due north to the mineralized zone.

The shaft was continued to 328 m (1,075 ft) deep to prepare a sump and

loading pocket. On October 27, 1966, a small blast to excavate a bay at

the bottom of the shaft opened a watercourse. The in-flood of water

quickly exceeded the pump capacity and within 12 hours the 328 m shaft was

flooded to within 13 m from the surface (Hawke, 1966). | |

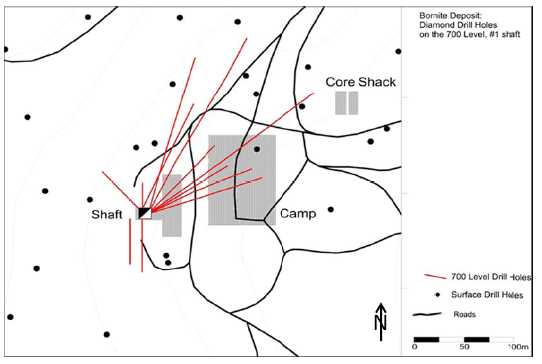

Prior to the shaft flooding, six

diamond drill holes were completed from the 700 level shaft station and 22

drill holes from the 975 shaft station and crosscut. In 1967, the shaft

bottom was partially sealed and then pumped out, and an additional 24

holes were drilled from the 700 level and the 975 level shaft stations.

Figure 6.2 and Figure 6.3 show underground diamond drilling from the 700

and 975 levels. |

| NovaCopper Inc. | 6-20 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Figure 6.2: Diamond Drilling from the 700 Level of the No. 1 Shaft

Figure 6.3: Diamond Drilling from the 975 Level of the No. 1 Shaft

| NovaCopper Inc. | 6-21 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 6.4 |

PETROLOGY, MINERALOGY, AND RESEARCH STUDIES |

|

Several studies have been undertaken reviewing the geology and geochemistry of the Bornite deposit. Most notable is Murray Hitzman’s PhD dissertation at Stanford University (Hitzman, 1983) and Don Runnel’s PhD dissertation at Harvard University (Runnels, 1963). Bernstein and Cox reported on mineralization of the “No. 1 Ore Body” in a 1986 paper in Economic Geology (Bernstein et al, 1986). | |

|

In addition to the historical work, Ty Connor at the Colorado School of Mines is currently undertaking an MSc thesis study on the breccias and mineralization at Bornite. | |

| 6.5 |

GEOTECHNICAL AND HYDROLOGICAL STUDIES |

|

Kennecott conducted two technical reviews of the groundwater conditions (Vance, 1962) and a summary of the findings related to the flooding of the exploration shaft (Erskine, 1970). | |

| 6.6 |

METALLURGICAL STUDIES |

|

In 1961, Kennecott collected 32 coarse reject samples from five drill holes to support preliminary metallurgical test work at Bornite. Samples targeted high-grade (> 10%) copper mineralization from the Upper Reef at Ruby Creek (Lutz, 1961). An extensive discussion of the historic and current metallurgical studies is presented in Section 13.0 of this report. | |

| 6.7 |

HISTORICAL MINERAL RESOURCE ESTIMATES |

|

All of the historical mineral resource estimates presented below were made prior to the implementation of NI 43-101. They do not conform to NI 43-101 reporting standards and should not be relied upon or interpreted as such. A QP has not done sufficient work to classify the historical estimates as current mineral resources and NovaCopper is not treating the historical estimates as current mineral resources. They are presented here for information purposes only. | |

|

LUND (1961) | |

|

The earliest and most widely repeated resource number reported 91 million tons at 1.2% Cu in an unconstrained polygonal resource estimate. At a constrained 1% Cu cut-off grade, 21.2 million tons of 3.04% Cu and at a 2.5% Cu cut-off, 5.2 million tons of 5.83% Cu were reported. The estimation is based on an 11.0 ft3/ton tonnage factor for the Lower Reef or lower grade mineralization and a 10.0 ft3/ton tonnage factor for the higher grade Upper Reef mineralization. It is not known if the tonnage factors were based on any direct specific gravity measurements of the Bornite drill core. Metals such as silver and cobalt were not considered in any of the historical estimations. |

| NovaCopper Inc. | 6-22 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

C.T.PENNEY (1968)

This estimate is restricted to the “No.1 Ore Body” in the Ruby Creek Upper Reef. The reported resource is 180,000 - 200,000 tons at 8.4% Cu.

REED (1971)

This estimate is (apparently) tabulated using an unknown grade times thickness (copper x thickness) cut-off criterion. It includes both Ruby Creek Upper Reef and Lower Reef mineralization with a reported total of 35.7 M tons at 2.15% Cu.

SICHERMANN (1974)

This estimate utilized a polygonal methodology and is not considered entirely accurate as down-hole surveys were not available for all drill holes and mineralization lenses were observed to be erratic. A 10.5 ft3/ton tonnage factor for >1% Cu mineralization and an 8.0 ft3/ton tonnage factor for >4% Cu mineralization was applied. Two different resource estimates are reported: 5 million tons (4.56 million tonnes) at 4% Cu and 40 million tons (36.2 million tonnes) at 2% Cu, respectively, without reporting cut-off grades.

KENNECOTT (1997)

In 1997, Macfarlane conducted a more rigorous resource estimation of the Ruby Creek (Bornite) deposit. This estimation used VulcanTM 3D modeling and resource estimation software. A series of grade shells at 0.2%, 0.5% and 1.0% copper were manually constructed on sections and imported into Vulcan. Within each shell, separate resource calculations at 0.5%, 1.0%, 2%, and 4.0% copper cut-off grades were made. The grade shells were constructed irrespective of various lithology or mineralization styles. Attempts to create meaningful semi-variograms for copper mineralization were reportedly unsuccessful. An inverse distance squared weighting methodology was used to estimate the resource. Results are shown in Table 6.1.

Table 6.1: Bornite (Ruby Creek) Historica lResource (Kennecott, 1997)

| Cut-off | 0.2% Grade shell | 0.5% Grade shell | 1% Grade shell | |||

| (% Cu) | Tonnage (M tonnes) |

Grade (Cu %) |

Tonnage (M tonnes) |

Grade (Cu %) |

Tonnage (M tonnes) |

Grade (Cu %) |

| 0.5 | 71.6 | 1.24 | 40.5 | 1.41 | 17.1 | 2.02 |

| 1.0 | 27.0 | 2.09 | 22.3 | 1.92 | 14.2 | 2.26 |

| 2.0 | 6.6 | 4.48 | 4.7 | 4.02 | 4.0 | 4.39 |

| 4.0 | 2.2 | 8.06 | 1.5 | 7.15 | 1.1 | 9.54 |

| NovaCopper Inc. | 6-23 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

In an absence of actual measured densities, an approximation of the specific gravity, based on the relationship of copper grade to specific gravity, was used by Kennecott. No support for this approach was presented. Macfarlane noted, using the method, tonnages for massive pyrite areas with low grade copper were significantly underestimated.

| NovaCopper Inc. | 6-24 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 7.0 |

GEOLOGICAL SETTING AND MINERALIZATION |

| 7.1 | REGIONAL GEOLOGY |

|

The Bornite Project is located within the Arctic Alaska Terrane, a sequence of mostly Paleozoic continental margin rocks that make up the Brooks Range and North Slope of Alaska (Moore, 1992). It is within the Phyllite Belt geologic subdivision, which together with the higher-grade Schist Belt, stretches almost the entire length of the Brooks Range and is considered to represent the hinterland of the Jurassic Brooks Range orogeny. The southern margin of the Phyllite Belt is marked by mélange and low angle faults associated with the Kobuk River fault zone, while the northern boundary is thought to be gradational with the higher-grade metamorphic rocks of the Schist Belt (Till et al., 2008). | |

| 7.2 |

TECTONIC AND METAMORPHIC HISTORY |

|

The tectonic setting of the project area during mineralization (early Devonian) has been masked by subsequent deformation and remains poorly understood. Dillon et al. (1980) interpret the existence of Devonian granites throughout the Brooks Range as supporting a volcanic arc environment, while Hitzman et al. (1986) point to bimodal volcanic rocks and abrupt sedimentary facies transitions as supporting an extensional tectonic setting. Based on igneous geochemistry, Ratterman et al. (2006) suggest that the Ambler sequence volcanic rocks were emplaced in an extensional back-arc spreading environment; however, the original pre-deformation spatial relationship between the Bornite Project area and the Ambler sequence is still poorly understood. | |

|

The project area underwent regional deformation and metamorphism during the Middle Jurassic to Early Cretaceous Brooks Range orogeny. The collision of the Koyukuk Arc Terrane from present-day south caused north-directed imbrication and partial subduction of the Arctic Alaska passive margin sedimentary sequence. Rocks in the Schist Belt were metamorphosed to blueschist facies but were partially exhumed by north-directed faulting prior to full thermal equilibration. Both the Schist Belt and the Phyllite Belt cooled from greenschist conditions during a period of rapid extension and erosion beginning around 103 Ma (Moore et al., 1994, Vogl et al., 2003). | |

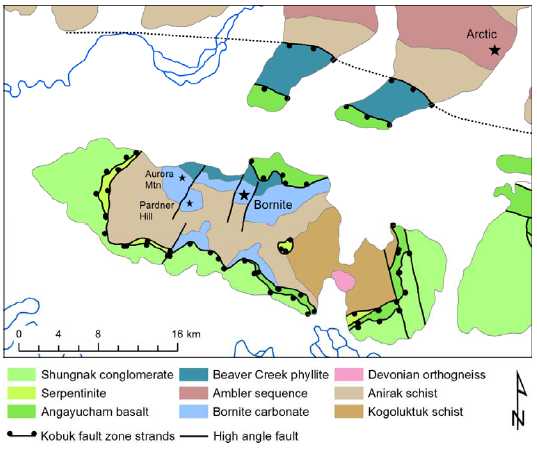

|

In the project area, a strand of the Kobuk fault zone separates the Cosmos Hills stratigraphy (Schist Belt and Phyllite Belt) from the overlying Angayucham Terrane, and another strand may separate Cosmos Hills from the Ambler sequence to the north (Figure 7.1). |

| NovaCopper Inc. | 7-25 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Figure 7.1: Generalized Geologic Map of the Cosmos Hills (Modified from Till etal., 2008)

| 7.2.1 |

REGIONAL STRATIGRAPHY |

|

The autochthonous stratigraphy of the district is characterized by lower greenschist to epidote-amphibolite facies, pelitic, carbonate, and local metavolcanic rocks as shown in Figure 7.1 and summarized in Table 7.1. |

| NovaCopper Inc. | 7-26 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

Table 7.1: Stratigraphic Units of the Cosmos Hills Area (modified from Hitzman etal., 1986 )

| Unit (age) | Lithology | Metamorphic grade | Approximate thickness |

| Shungnak conglomerate (Cretaceous) | Pebble conglomerate, sandstone, siltstone, minor intermediate volcanics | Unmetamorphosed | 1000m |

| Angayucham terrane (Devonian- Mississippian) (allochthonous) | Pillow basalt, pillow breccia | Prehnite-Pumpellyite | >500m |

| Beaver Creek phyllite (Devonian*) | Phyllite, quartzite, marble | Lower Greenschist | >2000m |

| Ambler sequence (Devonian*) | Metarhyolite, metabasite, tuffaceous metasediments, calcareous metasediments, pelitic schist | Blueschist to Greenschist | 700-1850m |

| Bornite carbonate sequence (Lower Devonian to Upper Silurian*) | Marble, argillaceous marble, dolostone, phyllite, phyllitic marble | Lower Greenschist | 200-1000m |

| Anirak schist (Devonian*) | Pelitic schist, quartzite, marble, minor metabasite | Greenschist | 3000m |

| Kogoluktuk schist (Precambrian to Devonian*) | Pelitic schist, quartzite, metagabbro, minor marble | Epidote-Amphibolite | 4000m |

*Ages from Till et al., 2008

| 7.2.2 |

IGNEOUS ROCKS |

|

The intersection of the Cosmos Arch and the Kogoluktuk River drainage 14 km southeast of Bornite exposes a cataclastic orthogneiss of granitic composition which intrudes the Kogoluktuk Schist. Zircons return a syn-mineral uranium-lead age of 386 ± 3 Ma (Till et al., 2008, citing W.C. McClelland). | |

|

Higher in the section, the Kogoluktuk Schist is also intruded by sill-form metagabbro bodies of unknown age. Other metamafic ‘greenstones’ are interpreted to have originated as flows and/or tuffaceous sediments (Hitzman, 1986). | |

|

Although none occur in the Bornite resource area, discontinuous stratabound greenstone bodies occur in the Anirak Schist and at the base of the Bornite carbonate sequence, particularly west and southwest of Bornite (Hitzman et al., 1982). A gabbroic outcrop approximately 200 m in width outcrops 2 km east of Bornite and is interpreted to be Cretaceous to Tertiary in age. | |

|

The most significant igneous rocks in the district are the bimodal volcanic rocks of the Ambler sequence—host of the Ambler VMS district—which outcrop 20 km north of Bornite, but are not observed in the Cosmos Hills (Table 7.1). These include sub-alkaline basaltic flows and sills with an un-depleted mantle geochemical signature. Sub-alkaline rhyolitic to andesitic tuffs and flows have geochemistry consistent with formation from a source that includes melting continental crust. Geochemistry collectively implies origin in an extensional, back-arc basin setting (Ratterman et al., 2006). Uranium-lead zircon dating from Ambler sequence metarhyolites returns ages of 376-387 Ma (McClelland et al., 2006), which are syn- to early post-mineral with respect to the Bornite (Ruby Creek) deposit. |

| NovaCopper Inc. | 7-27 | |

| NI 43-101 Technical Report on the Bornite Project, | ||

| Northwest Alaska |

| 7.2.3 |

TIMING OF MINERALIZATION IN THE DISTRICT |

|

Sulphide mineralization (chalcopyrite, pyrite, and bornite) from Bornite (Ruby Creek) was dated by Re-Os techniques (Selby et al., 2009), producing an age of 384 ± 4.2 Ma for main stage copper mineralization. | |

|

The syngenetic VMS deposits in the Ambler sequence are constrained by dating of related felsic volcanic rocks. Early post-mineral metarhyolite at the Arctic deposit yielded a mean uranium-lead zircon age of 378 ± 2Ma. Uranium-lead zircon ages for metarhyolite at the Tom-Tom prospect, 11 km east of Arctic, and the Sun prospect, 60 km east of Arctic, are 381 ± 2 Ma and 386 ± 2 Ma, respectively (McClelland et al., 2006). Since the VMS deposits and Bornite deposit may have a common fluid source, the potential scale of Bornite type mineralization may be much larger than the reefs delineated by current drilling. | |

| 7.3 |

DEPOSIT GEOLOGY |

|

The geology of the Bornite resource area is composed of alternating beds of carbonate rocks (limestone and dolostone) and calcareous phyllite. Limestone transitions laterally into dolostone, which hosts the majority of the mineralization and is considered to be hydrothermal in origin. Spatial relationships and petrographic work establish dolomitization as genetically related to early stages of the copper mineralizing system (Hitzman, 1986). | |

|

NovaCopper geologists have been unable to identify any meta-igneous rocks in the resource area; all lithologies described are interpreted as meta-sedimentary in origin. | |

| 7.3.1 |

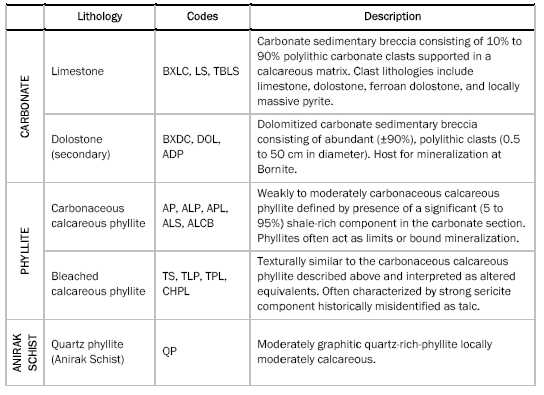

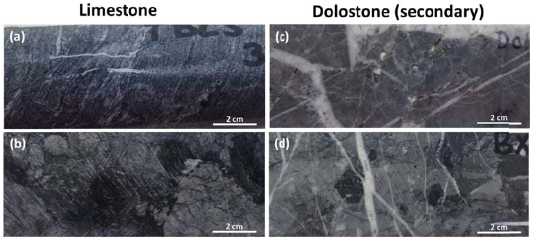

LITHOLOGY UNITS |

|

The current lithology system derives from early BCMC core logs (1960). Original unit descriptions have not been found; however, the units were re-described during re-logging by NovaGold geologists in the summer of 2010. The scheme encompasses not only primary lithology, but also alteration, and compositional and textural variations. Resource-scale geologic interpretation and modeling is based on the hierarchical generalization shown in Table 7.2. Figure 7.2 shows typical dolomitized sedimentary breccias of the Bornite carbonate sequence, which are the principal host of mineralization at Bornite. |

| NovaCopper Inc. | 7-28 | |