Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - COOL TECHNOLOGIES, INC. | hpev_8k.htm |

EXHIBIT 99.1

Investor Presentation

March 2014

March 2014

2

Forward Looking Statements

This presentation contains information that is “forward-looking” in that it describes events and conditions HPEV, Inc.

reasonably expects to occur in the future. Expectations for the future performance of HPEV, Inc. are dependent upon

a number of factors, and there can be no assurance that HPEV, Inc. will achieve the results as contemplated herein.

Certain statements contained in this release using the terms “will”, “could”, “may”, “expects to”, “potential”,

“planned”, “expected”, “estimates”, “schedule”, “anticipates”, and other terms denoting future possibilities, are

forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. The accuracy

of these statements cannot be guaranteed as they are subject o a variety of risks, which are beyond HPEV, Inc.’s

ability to predict, or control and which may cause actual results to differ materially from the estimates contained

herein. Among these risks are those set forth in HPEV, Inc.’s Form 10-K and in reports subsequently filed with the

Securities and Exchange Commission, and in addition to the other risks and caveats included in this presentation. It is

important that each person reviewing this presentation understand the significant risks attendant to the operations of

HPEV, Inc.

reasonably expects to occur in the future. Expectations for the future performance of HPEV, Inc. are dependent upon

a number of factors, and there can be no assurance that HPEV, Inc. will achieve the results as contemplated herein.

Certain statements contained in this release using the terms “will”, “could”, “may”, “expects to”, “potential”,

“planned”, “expected”, “estimates”, “schedule”, “anticipates”, and other terms denoting future possibilities, are

forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. The accuracy

of these statements cannot be guaranteed as they are subject o a variety of risks, which are beyond HPEV, Inc.’s

ability to predict, or control and which may cause actual results to differ materially from the estimates contained

herein. Among these risks are those set forth in HPEV, Inc.’s Form 10-K and in reports subsequently filed with the

Securities and Exchange Commission, and in addition to the other risks and caveats included in this presentation. It is

important that each person reviewing this presentation understand the significant risks attendant to the operations of

HPEV, Inc.

Except as required by law, HPEV, Inc. disclaims any obligation to update any forward-looking statement contained

herein.

herein.

3

Company Snapshot

|

Symbol:

|

OTCQB: WARM

|

|

Recent Price:

|

$ 1.85

|

|

52-Week High/Low:

|

$ 2.00 - $ 0.23

|

|

Common Shares

Outstanding(1): |

48.7 million

|

|

Options/Warrants(1)(2):

|

30.1 million

|

|

Market Capitalization:

Enterprise Value:

|

$ 90 million

|

|

$ 90 million

|

Source: Capital IQ, company filings

(1)As of 9/30/2013

(2)Options 5M, Warrants 15.1M, 200 Convertible Preferred Shares that convert to 10M common

|

Sector:

|

Industrial Engineering

|

|

Year Founded / Public:

|

2005 / 2011

|

|

Headquarters:

|

Tampa, FL

|

|

Headcount:

|

8 full time - 45 contract

|

|

Insider Ownership:

|

37.5%

|

|

Auditor:

|

Anton & Chia, LLP

|

|

Fiscal Year End:

|

December 31st

|

March 2014

4

Heat is the waste by-product of mechanical

energy - the ugly evidence of inefficiency

energy - the ugly evidence of inefficiency

• The efficient removal of heat from equipment is a paramount challenge for manufacturers of motors,

generators, and pumps, and many other types of mechanical equipment and products

generators, and pumps, and many other types of mechanical equipment and products

○ Excess heat results in lower power output for equipment such as motors & generators and

others

others

○ Manufacturers must compensate for these thermal losses in their engineering by adding greater

amounts of Active Material (the expensive part of the motor/generator: larger rotor/stator sizes,

heavier gauge wiring and seals, etc.) when manufacturing, thereby increasing product costs

amounts of Active Material (the expensive part of the motor/generator: larger rotor/stator sizes,

heavier gauge wiring and seals, etc.) when manufacturing, thereby increasing product costs

• Less Active Material used in manufacturing results in lower costs (better margins), and the

engineering reality that smaller motors can put out more power (and potentially be sold for

more)

engineering reality that smaller motors can put out more power (and potentially be sold for

more)

• Worldwide environmental and efficiency mandates are being implemented in motors and generators

in three steps: 2013, 2015, 2017(1)

in three steps: 2013, 2015, 2017(1)

(1) International Electrotechnical Commission’s IE3 standards and Minimum Efficiency Performance Standards (MEPS)

March 2014

5

The Solution

HPEV’s patented technology

removes heat better than the

current cooling methods: air

cooling or liquid cooling

removes heat better than the

current cooling methods: air

cooling or liquid cooling

• HPEV’s disruptive thermal dispersion technology transfers heat via

proprietary patented heat pipe arrays with unique capabilities

proprietary patented heat pipe arrays with unique capabilities

• HPEV’s heat pipe arrays and systems allow heat pipes to move heat

in ANY direction (even against gravity) and require little or no

maintenance

in ANY direction (even against gravity) and require little or no

maintenance

○ Heat pipes can be added to almost any electric motor or generator

resulting in a smaller, more efficient, higher output machine that runs

cooler with a longer operating lifespan and lower maintenance costs

resulting in a smaller, more efficient, higher output machine that runs

cooler with a longer operating lifespan and lower maintenance costs

○ Independent third-party & customer testing confirms motors and

generators operating with HPEV’s technology have 25-40% higher

“power density” or horsepower output

generators operating with HPEV’s technology have 25-40% higher

“power density” or horsepower output

○ Higher power density results in up to 30% lower manufacturing costs as smaller motors can put out the

same amount of power and manufacturers can use standard raw materials (wire, insulation, etc.) instead

of costly exotic raw materials

same amount of power and manufacturers can use standard raw materials (wire, insulation, etc.) instead

of costly exotic raw materials

March 2014

6

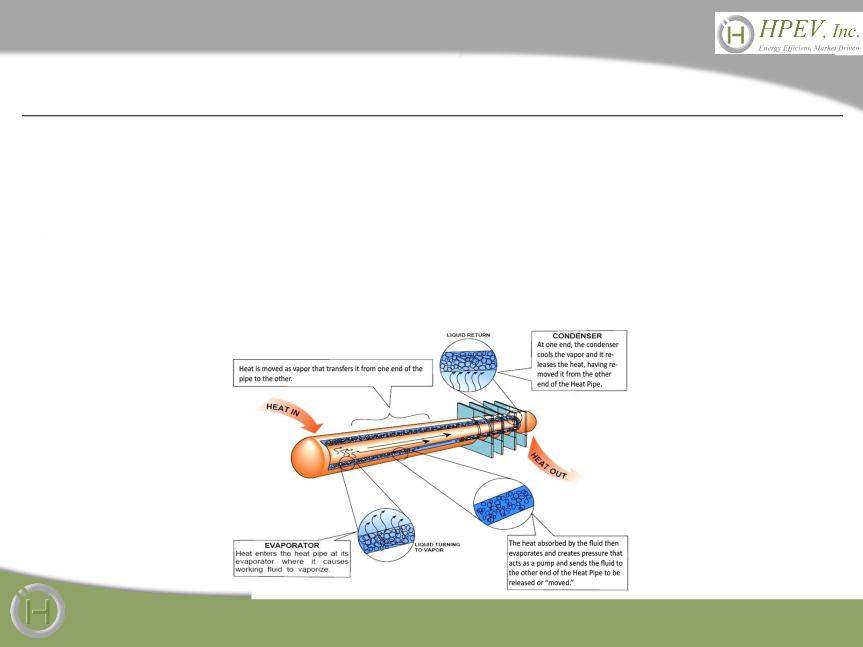

Heat Pipes

• A heat pipe is a heat-transfer device that, at a basic level, consists of a bifurcated hollow metal pipe

filled with water that moves heat from one end to the other via evaporation and condensation within

a closed system

filled with water that moves heat from one end to the other via evaporation and condensation within

a closed system

• Heat pipes have been around since the late 1800’s, and beginning in the late 1970’s and 1980’s

engineers began applying the technology to industrial applications

engineers began applying the technology to industrial applications

• HPEV’s intellectual property consists of application patents and patents-pending that, in conjunction

with unmatched engineering expertise, allows OEMs to implement HPEV’s designs into their

existing manufacturing systems and ensure manufacturability down the production line

with unmatched engineering expertise, allows OEMs to implement HPEV’s designs into their

existing manufacturing systems and ensure manufacturability down the production line

March 2014

7

Intellectual Property

• While heat pipe technology has been around for over 100 years, HPEV controls a patent portfolio

that leverages a unique ability to increase power density and lower manufacturing costs in the motor

and generator industry, among additional markets

that leverages a unique ability to increase power density and lower manufacturing costs in the motor

and generator industry, among additional markets

• Five U.S. utility patents have been issued

• More than 20 Patent Cooperation Treaty (PCT) patents are pending or in the application

process

process

• Patent Attorney: Polster, Lieder, Woodruff & Lucchesi, L.C.

March 2014

8

Technology Applications

Thermal Dispersion

• Electric Motors

• Generators

• Submersible Pumps

• Industrial Pumps

• Compressors

• Bearings

Mobile Generation

• Retrofit any Class 2-8

truck

truck

• “Ultimate Work Truck”

• Eliminates the need for

expensive, tow-behind

mobile generators

expensive, tow-behind

mobile generators

Future Applications

• Hybrid Conversion

• Vehicle Components

• Engines

• Super Chargers

• Industrial

• Power Systems

March 2014

9

Thermal Dispersion

HPEV’s Thermal Dispersion technology is poised to be the most disruptive and ONLY

technology (resulting in more than 5% cost savings) introduced to the industrial

motor/generator industry since the introduction of the frameless DC motor in the 1950s(1)

technology (resulting in more than 5% cost savings) introduced to the industrial

motor/generator industry since the introduction of the frameless DC motor in the 1950s(1)

(1) CEO Tim Hassett’s father, Jack Hassett, invented the frameless DC motor

Benefits to End User

Benefits to Manufacturer

• Easy integration on existing production lines

• More output from the same package or the

same output from a smaller package

same output from a smaller package

• Increased standardization of product line as a

result of a reduction in product modifications

result of a reduction in product modifications

• Scalable application from 1 to 30,000hp

• Better reliability

• Lower maintenance costs

• Increased effective lifespan of motor

• Greater efficiency, therefore lower energy

costs

costs

• Lower purchase cost (provided manufacturer

passes savings along to the end user

passes savings along to the end user

• HPEV’s patented heat pipe arrays provide a unique solution, the best cooling available at the lowest

cost. The technology is unrivaled by air cooling, liquid cooling, and heat exchangers

cost. The technology is unrivaled by air cooling, liquid cooling, and heat exchangers

• The technology can be added to almost any electric motor or generator, or motor driven

pump

pump

• Allows motors to run cooler, have longer operating lifespan, and have lower maintenance costs

March 2014

10

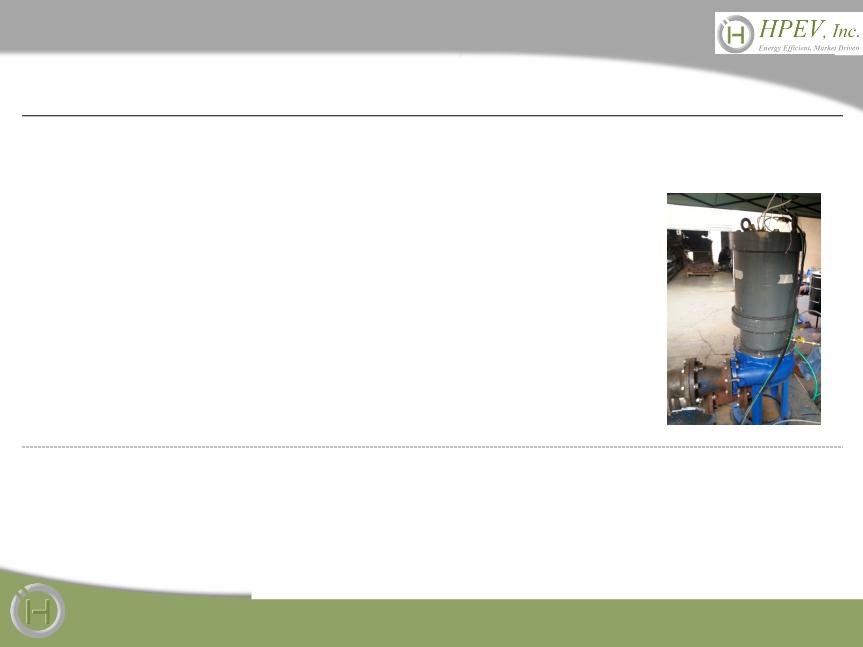

ESSCO Testing - “It’s a Real Game Changer”

ESSCO Pumps and Controls, an industry leader of custom pump solutions since 1955, completed its

final round of testing during November 2013 with stellar results

final round of testing during November 2013 with stellar results

John Ivins, ESSCO President:

• “Honestly, I’m amazed with the results! This is a significant innovation in the pump industry and the biggest

improvement in pumps in more than 50 years.”

improvement in pumps in more than 50 years.”

• “…with HPEV’s technology, we now have a solution for a huge industry problem, solving one of its Achilles’ heels. By

removing heat in this way, we dramatically reduce maintenance costs and time loss while improving pump output and

flow as well. It’s a real game changer.”

removing heat in this way, we dramatically reduce maintenance costs and time loss while improving pump output and

flow as well. It’s a real game changer.”

• Testing Measured the heat tolerance of a Grundfos/Yeomans Chicago motor frame

with Nidec wound stator/rotor (Active Material) inside on a dry-pit submersible

pump

with Nidec wound stator/rotor (Active Material) inside on a dry-pit submersible

pump

○ Current dry-pit submersible pumps are cooled by the effluent (what is being pumped) and

they clog regularly resulting in having to be taken out of service often with extremely

high maintenance costs.

they clog regularly resulting in having to be taken out of service often with extremely

high maintenance costs.

○ Current dry-pit pump motors are rated to run out of water for 15 minutes before heat

causes system shutdown.

causes system shutdown.

○ HPEV’s technology was integrated directly into the Nidec motor and the pump no longer

needs to be cooled by the effluent - no more clogging or maintenance

needs to be cooled by the effluent - no more clogging or maintenance

• Results confirmed an increase of more than 200% horsepower output, and

the pump ran for more than six hours of continuous operation (out of water /

not submersed) at or above full power without reaching critical temperatures

the pump ran for more than six hours of continuous operation (out of water /

not submersed) at or above full power without reaching critical temperatures

March 2014

11

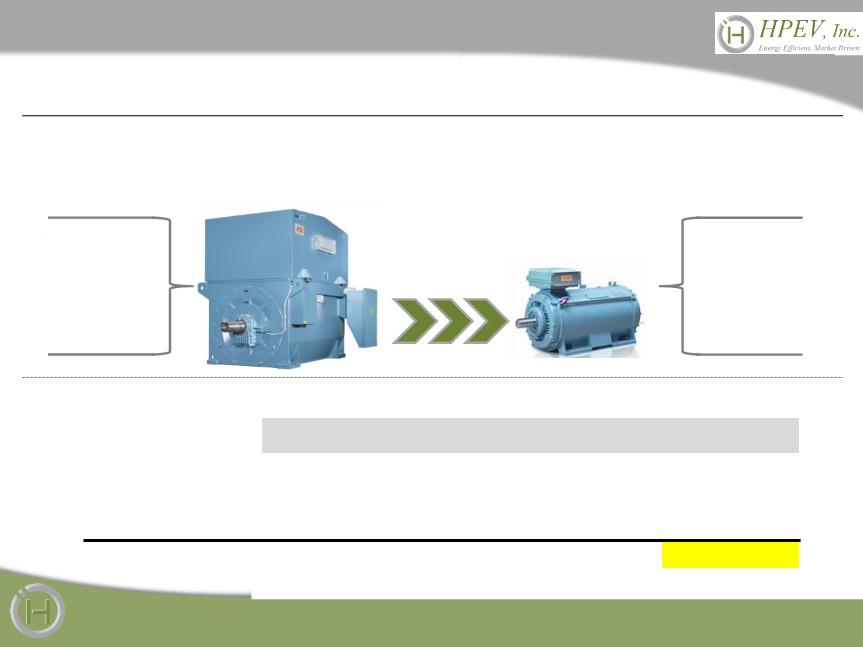

Illustrative Cost Savings Example

Lower manufacturing costs and higher horsepower output favorably move both the

revenue and cost levers for motor manufacturers (HPEV’s customers)

revenue and cost levers for motor manufacturers (HPEV’s customers)

Before: Large

hood on top of the

motor is a heat

exchanger

hood on top of the

motor is a heat

exchanger

After: HPEV’s

technology

eliminates the

need for the heat

exchanger; lower

cost and smaller

footprint

technology

eliminates the

need for the heat

exchanger; lower

cost and smaller

footprint

|

|

Air Cooled Motor

|

HPEV Improved Motor

|

Improvement

|

|

Output (Horsepower)

|

1,000hp

|

1,400hp

|

40%

|

|

Retail Price

|

$100,000

|

$165,000

|

65%

|

|

COGS

|

$50,000

|

$35,000

|

30%

|

|

Gross Profit

|

$50,000

|

$130,000

|

160%

|

Electric Motor - Customer Benefits Model

March 2014

12

Incumbent Cooling Technology

Motor and Generator Cooling Options: HPEV wins in EVERY category and reduces

manufacturing costs by more than 25%

manufacturing costs by more than 25%

|

|

Fan Cooled

|

Liquid Cooled

|

Heat Exchanger

|

HPEV

|

|

Heat Transfer

(W/m2K)(1) |

1x

|

1x

|

4x

|

8-9x

|

|

Required Accessories

|

Blower/Fan and

Piping |

Pump and Piping

|

Pump, Radiator, Fan,

Blower, and Piping |

None

|

|

Construction

|

Complex

|

Medium

|

Complex

|

Simple

|

|

Cost

|

Low

|

Medium-High

|

High

|

Very

Inexpensive |

|

Reliability

|

Low (dust particles

and filters required) |

Medium

|

Low (fouling)

|

High

|

(1) Watts per squared meter kelvin

March 2014

13

Mobile Generation

Mobile Generation (MG) systems transform any Class 2-8 truck into a mobile generator

• Patent-pending gearing system uses the truck’s engine, regardless of type

(natural gas, diesel, gas, fuel cell, etc.), to power an on-board generator

that delivers up to 400kw of electric power

(natural gas, diesel, gas, fuel cell, etc.), to power an on-board generator

that delivers up to 400kw of electric power

• Eliminates the need for a tow-behind generator for a work site, saving

a differential of 1/5th the weight and half the cost versus the tow-

behind alternative

a differential of 1/5th the weight and half the cost versus the tow-

behind alternative

• Used to power any electric equipment including common devices such as

compressors, welders, and even bucket truck arms; also serves as an

emergency power backup and can be plugged right into the Grid

compressors, welders, and even bucket truck arms; also serves as an

emergency power backup and can be plugged right into the Grid

• Adaptable to any type of vehicle/engine and does not affect truck

warranties

warranties

• The secret to making all of this work: HPEV’s patent-pending gearing

system and thermal dispersion technology that provides more power

from a smaller unit and allows it to draw the power from the truck

system and thermal dispersion technology that provides more power

from a smaller unit and allows it to draw the power from the truck

• Technology can be retrofitted into existing work trucks or customers can

purchase the Ultimate Work Truck which is a new design/build model

purchase the Ultimate Work Truck which is a new design/build model

• Massive addressable market beginning with utility fleets and other trades

March 2014

14

Estimated Market Size

Addressable markets estimated at over $90 billion, growing 3-5% annually; management

has relationships with nearly all the major industry players from the executive suite to

engineering to manufacturing

has relationships with nearly all the major industry players from the executive suite to

engineering to manufacturing

• The addressable worldwide motor and generator markets are estimated to be ~$60 billion

Big-8: 80-85%

• We estimate the large industrial pump market in the United States to be ~$30 billion

annually

annually

• HPEV is working with several of the leading pump manufacturers to expeditiously get product to

the market; manufacturers expect swift market adoption

the market; manufacturers expect swift market adoption

○ The “Big-8” control between 80-85% of the market

○ Management has relationships at each of the Big-8

at both the executive and manufacturing levels

at both the executive and manufacturing levels

March 2014

15

Revenue Model

HPEV is an intellectual property and engineering company - not a manufacturer

License Fees

Royalties

• Upfront license fee to use the technology

(1-3 year term)

(1-3 year term)

• Expected motor/generator license fee $1-

10 million depending on factors such as

exclusivity, sales minimums, products

that use the technology and duration

10 million depending on factors such as

exclusivity, sales minimums, products

that use the technology and duration

• Royalties on revenue from sales of

underlying equipment = ~3% of gross

sales

underlying equipment = ~3% of gross

sales

• Royalties from Thermacore on each sale

for the use of HPEV’s IP

for the use of HPEV’s IP

In some cases, HPEV will consider JVs with customers

and share the profit margin with zero cash outlay from

HPEV

and share the profit margin with zero cash outlay from

HPEV

Marketing Strategy

Third-Party Validation

• HPEV has third-party validation reports from

multiple industry leading certification firms

multiple industry leading certification firms

• Three of the Big-8 have done internal validation

• Acceleration of Big-8 implementation schedule

• Existing relationships, strategic alliances, trade

journals, and competitive demand

journals, and competitive demand

• In commercialization phase with 2 and design

phase of discussions with 4 of the Big-8

phase of discussions with 4 of the Big-8

• When one is using the technology in the

marketplace, the others will all need the

technology

marketplace, the others will all need the

technology

March 2014

16

Target Customers

HPEV’s optimal customer is a motor/generator manufacturer producing

units between 1hp and 30,000hp

units between 1hp and 30,000hp

• ESSCO Pumps & Controls

• WI Technologies

• Emerson Corp. (NYSE: EMR)

• Nidec Corp. (NYSE: NJ)

• Flygt (Sub of Xylem - NYSE: XYL)

• WEG Motors (Brazil)

• GE Power Conversion (NYSE: GE)

• Siemens (NYSE: SI)

• Regal Beloit (NYSE: RBC)

• ABB (NYSE: ABB)

• TECO-Westinghouse Motor Company

• Thermacore - Leader in Heat Exchangers

• Fabricate HPEV technology and sell

directly to the OEM

directly to the OEM

• HPEV’s “salesforce” to the 200+

motor/generator OEMs that are not

part of the “Big-8”

motor/generator OEMs that are not

part of the “Big-8”

March 2014

17

Management

|

|

|

|

Tim Hassett

CEO, Chairman & Co-

Founder |

30+ years experience managing and growing mid-sized manufacturing firms: GE, WaveCrest, Hawk Motors,

Rockwell Automation •Turned around two divisions for Jack Welch at GE

•WaveCrest from $0 to $30M in revenues in 18 months (with Mark)

•Lemo from $32 to $75M in revenue and grew net income 22x in 4 years (with Mark)

•Mars Rover drive train co-designer

|

|

Mark Hodowanec

Co-Founder

|

20+ years of engineering & operations expertise: more than 30 publications & numerous patents

•Led new product innovation at Reliance Electric

•Engineering Manager at Siemens Energy and Automation

•Led Emerson to API approval - after Emerson’s efforts had failed for 11 years

•Mars Rover drive train co-designer

|

|

Ted Banzhaf

President

|

20+ years experience in growing public companies in all facets of finance, growth strategies, and management

• Expertise in maximization of shareholder value and maturing small companies into larger organizations

• SpatiaLight Technologies (NASDAQ:HDTV), CE Unterburg Towbin, Raymond James

|

|

Quentin Ponder

Vice Chairman

|

50+ years experience in management: Baldor Electric Motors, Franklin Electric Motors, GE

• Noted in the book “World Class Manufacturing: The Next Decade” as one of the 5 best executives for

manufacturing improvement pathways in the modern industrial era • Coined the term “Flex Flow Manufacturing” based on his revolutionary manufacturing management

techniques |

Experienced management team with a history of bringing technology to market

March 2014

18

Select Recent News

|

|

|

2/20/2014: “Energy Efficiency Innovator HPEV, Inc. Reveals Its Burgeoning Patent Portfolio”

•Announced it has received five U.S. utility patents and has more than 20 global PCT patents either pending or in the application process

|

|

2/20/2014: “Energy Efficiency Innovator HPEV, Inc. Brings Co-Founder Mark Hodowanec on as Chief Technology Officer”

•A significant milestone for the Company as Mark will play a key role in driving customer relationships, shaping technology strategy, and further

developing the Company’s patent portfolio •Mark is an industry veteran having previously served as head of engineering at Curtiss-Wright, Director of Operations at WaveCrest

Laboratories, Engineering Manager at Siemens Energy and Automation, and led new product innovation at Reliance Electric |

|

1/16/2014: “HPEV Announces New Strategic Advisory Board Led by Recently Retired Emerson Electric Heavyweight”

•Dick Schul is a 43 year motor/generator veteran and industry insider who recently retired from Emerson Electric as Group Vice President of

Emerson Climate Technologies •Dick will provide valuable perspective and recommendations in the areas of product guidance, customer development, and sales and territory

expansion |

|

12/17/2013: “Energy Efficiency Innovator HPEV, Inc. Shines in Critical Commercialization Test”

•Mohler Technology, Inc. completed tests for a generator for a yet to be named customer in which power density increased between 25-35%

while all industry certification standards were met |

|

11/25/2013: “Energy Efficiency Innovator HPEV, Inc. Exceeds Expectations in Third-Party Commercialization Tests”

•Announced ESSCO Pumps & Controls completed its final round of commercialization tests for a revolutionary line of dry-pit submersible

pumps for the water and wastewater industry •Current standard is for pumps to run out of water (not submersed) for up to 15 minutes without reaching critical temperatures requiring a

shutdown; the HPEV unit ran continuously for over 2 hours without reaching critical temperatures |

March 2014

19

Investment Considerations

• Patented, disruptive technology is being

commercialized NOW by several of the

Big-8

commercialized NOW by several of the

Big-8

• The immediate addressable market is

approximately $90 billion; a 3% royalty is

an extraordinary earnings opportunity

approximately $90 billion; a 3% royalty is

an extraordinary earnings opportunity

• Improves power output by ~25%, reduces

manufacturing costs by ~25%, and helps

manufacturers meet increasingly stringent

environmental and efficiency mandates

manufacturing costs by ~25%, and helps

manufacturers meet increasingly stringent

environmental and efficiency mandates

• Management team is experienced with

bringing technologies to market and has

extensive relationships with industry

leaders

bringing technologies to market and has

extensive relationships with industry

leaders

• Licensing/royalty revenue model to

provide significant operating leverage

provide significant operating leverage

March 2014

20

Contact Information

OTCQB: WARM

Thank you for your interest

Ted Banzhaf

President

415-971-4873

415-971-4873

tbanzhaf@hpevinc.com

March 2014