Attached files

| file | filename |

|---|---|

| EXCEL - IDEA: XBRL DOCUMENT - Xcerra Corp | Financial_Report.xls |

| EX-32 - EX-32 - Xcerra Corp | d613598dex32.htm |

| EX-31.1 - EX-31.1 - Xcerra Corp | d613598dex311.htm |

| EX-31.2 - EX-31.2 - Xcerra Corp | d613598dex312.htm |

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-Q

(Mark One)

| x | QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the quarterly period ended October 31, 2013

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number: 000-10761

LTX-CREDENCE CORPORATION

(Exact name of registrant as specified in its charter)

| Massachusetts | 04-2594045 | |

| (State or other jurisdiction of incorporation or organization) |

(I.R.S. Employer Identification No.) | |

| 825 University Ave, Norwood, Massachusetts |

02062 | |

| (Address of principal executive offices) | (Zip Code) | |

(781) 461-1000

(Registrant’s telephone number, including area code)

[None]

(Former name, former address and former fiscal year, if changed since last report)

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer | ¨ | Accelerated filer | x | |||

| Non-accelerated filer | ¨ (Do not check if a smaller reporting company) | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

Indicate the number of shares outstanding of each of the issuer’s classes of common stock, as of the latest practicable date.

| Class |

Outstanding at December 5, 2013 | |

| Common Stock, $0.05 par value per share | 48,230,328 shares |

Table of Contents

LTX-CREDENCE CORPORATION

| Page Number |

||||||

| Part I. | ||||||

| Item 1. | ||||||

| Consolidated Balance Sheets as of October 31, 2013 and July 31, 2013 |

3 | |||||

| 4 | ||||||

| 5 | ||||||

| 6-16 | ||||||

| Item 2. | Management’s Discussion and Analysis of Financial Condition and Results of Operations |

17 | ||||

| Item 3. | 26 | |||||

| Item 4. | 26 | |||||

| Part II. | ||||||

| Item 1. | 27 | |||||

| Item 1A. | 27 | |||||

| Item 2. | 36 | |||||

| Item 4. | 36 | |||||

| Item 6. | 36 | |||||

| 37 | ||||||

| 38 | ||||||

2

Table of Contents

CONSOLIDATED BALANCE SHEETS

(In thousands)

| October 31, 2013 |

July 31, 2013 |

|||||||

| (Unaudited) | ||||||||

| ASSETS |

||||||||

| Current assets: |

||||||||

| Cash and cash equivalents |

$ | 30,716 | $ | 28,235 | ||||

| Marketable securities |

87,269 | 96,159 | ||||||

| Accounts receivable—trade, net of allowances of $0 |

28,061 | 28,102 | ||||||

| Accounts receivable—other |

500 | 963 | ||||||

| Inventories |

29,238 | 29,139 | ||||||

| Prepaid expenses and other current assets |

3,031 | 2,497 | ||||||

|

|

|

|

|

|||||

| Total current assets |

178,815 | 185,095 | ||||||

| Property and equipment, net |

16,978 | 16,647 | ||||||

| Intangible assets, net |

1,378 | 1,571 | ||||||

| Goodwill |

43,030 | 43,030 | ||||||

| Other assets |

1,246 | 1,258 | ||||||

|

|

|

|

|

|||||

| Total assets |

$ | 241,447 | $ | 247,601 | ||||

|

|

|

|

|

|||||

| LIABILITIES AND STOCKHOLDERS’ EQUITY |

||||||||

| Current liabilities: |

||||||||

| Accounts payable |

$ | 15,975 | $ | 13,266 | ||||

| Accrued expenses |

19,007 | 19,352 | ||||||

| Deferred revenue |

3,483 | 5,084 | ||||||

|

|

|

|

|

|||||

| Total current liabilities |

38,465 | 37,702 | ||||||

| Other long-term liabilities |

11,288 | 11,402 | ||||||

| Commitments and contingencies (Note 5) |

||||||||

| Stockholders’ equity: |

||||||||

| Common stock |

2,408 | 2,384 | ||||||

| Additional paid-in capital |

745,990 | 746,020 | ||||||

| Accumulated other comprehensive income (loss) |

39 | (64 | ) | |||||

| Accumulated deficit |

(556,743 | ) | (549,843 | ) | ||||

|

|

|

|

|

|||||

| Total stockholders’ equity |

191,694 | 198,497 | ||||||

|

|

|

|

|

|||||

| Total liabilities and stockholders’ equity |

$ | 241,447 | $ | 247,601 | ||||

|

|

|

|

|

|||||

See accompanying Notes to Consolidated Financial Statements.

3

Table of Contents

CONSOLIDATED STATEMENTS OF OPERATIONS AND COMPREHENSIVE INCOME (LOSS)

(Unaudited)

(In thousands, except per share data)

| Three Months Ended October 31, |

||||||||

| 2013 | 2012 | |||||||

| Net product sales |

$ | 24,281 | $ | 34,326 | ||||

| Net service sales |

8,486 | 8,862 | ||||||

|

|

|

|

|

|||||

| Net sales |

32,767 | 43,188 | ||||||

| Cost of sales |

15,636 | 19,684 | ||||||

|

|

|

|

|

|||||

| Gross profit |

17,131 | 23,504 | ||||||

| Engineering and product development expenses |

12,878 | 12,392 | ||||||

| Selling, general and administrative expenses |

10,925 | 10,006 | ||||||

| Amortization of purchased intangible assets |

193 | 396 | ||||||

| Restructuring |

— | 231 | ||||||

|

|

|

|

|

|||||

| (Loss) income from operations |

(6,865 | ) | 479 | |||||

| Other (expense) income: |

||||||||

| Interest expense |

(62 | ) | (50 | ) | ||||

| Interest income |

187 | 261 | ||||||

| Other (expense), net |

(20 | ) | (2 | ) | ||||

|

|

|

|

|

|||||

| (Loss) income before provision for income taxes |

(6,760 | ) | 688 | |||||

| Provision for income taxes |

140 | 139 | ||||||

|

|

|

|

|

|||||

| Net (loss) income |

$ | (6,900 | ) | $ | 549 | |||

|

|

|

|

|

|||||

| Net (loss) income per share: |

||||||||

| Basic and diluted |

$ | (0.14 | ) | $ | 0.01 | |||

| Weighted-average common and common equivalent shares used in computing net (loss) income per share: |

||||||||

| Basic |

47,900 | 48,303 | ||||||

| Diluted |

47,900 | 48,711 | ||||||

| Comprehensive (loss) income: |

||||||||

| Net (loss) income |

$ | (6,900 | ) | $ | 549 | |||

| Unrealized gain (loss) on marketable securities |

103 | (3 | ) | |||||

|

|

|

|

|

|||||

| Comprehensive (loss) income |

$ | (6,797 | ) | $ | 546 | |||

|

|

|

|

|

|||||

See accompanying Notes to Consolidated Financial Statements.

4

Table of Contents

CONSOLIDATED STATEMENTS OF CASH FLOWS

(Unaudited)

(In thousands)

| Three Months Ended October 31, |

||||||||

| 2013 | 2012 | |||||||

| CASH FLOWS FROM OPERATING ACTIVITIES: |

||||||||

| Net (loss) income |

$ | (6,900 | ) | $ | 549 | |||

| Add non-cash items: |

||||||||

| Stock-based compensation |

1,109 | 1,138 | ||||||

| Depreciation and amortization |

1,623 | 2,296 | ||||||

| Other |

565 | 399 | ||||||

| Changes in operating assets and liabilities: |

||||||||

| Accounts receivable |

509 | (2,876 | ) | |||||

| Inventories |

(1,146 | ) | (4,115 | ) | ||||

| Prepaid expenses |

(365 | ) | 1,002 | |||||

| Accounts payable |

2,709 | 4,950 | ||||||

| Accrued expenses |

(839 | ) | (206 | ) | ||||

| Deferred revenue |

(1,600 | ) | (1,089 | ) | ||||

|

|

|

|

|

|||||

| Net cash (used in) provided by operating activities |

(4,335 | ) | 2,048 | |||||

| CASH FLOWS FROM INVESTING ACTIVITIES: |

||||||||

| Proceeds from sales and maturities of available-for-sale securities |

24,031 | 13,300 | ||||||

| Proceeds from sales and maturities of held-to-maturity securities |

2,852 | 2,800 | ||||||

| Purchases of available-for-sale securities |

(18,386 | ) | (9,836 | ) | ||||

| Purchases of held-to-maturity securities |

— | (2,445 | ) | |||||

| Purchases of property and equipment |

(1,045 | ) | (1,038 | ) | ||||

|

|

|

|

|

|||||

| Net cash provided by investing activities |

7,452 | 2,781 | ||||||

| CASH FLOWS FROM FINANCING ACTIVITIES: |

||||||||

| Repurchases of common stock |

— | (8,543 | ) | |||||

| Payments of tax withholdings for vested RSUs, net of proceeds from stock option exercises |

(793 | ) | (599 | ) | ||||

|

|

|

|

|

|||||

| Net cash (used in) financing activities |

(793 | ) | (9,142 | ) | ||||

| Effect of exchange rate changes on cash and cash equivalents |

157 | 157 | ||||||

|

|

|

|

|

|||||

| Net increase (decrease) in cash and cash equivalents |

2,481 | (4,156 | ) | |||||

| Cash and cash equivalents at beginning of period |

28,235 | 29,446 | ||||||

|

|

|

|

|

|||||

| Cash and cash equivalents at end of period |

$ | 30,716 | $ | 25,290 | ||||

|

|

|

|

|

|||||

See accompanying Notes to Consolidated Financial Statements.

5

Table of Contents

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS

(Unaudited)

1. THE COMPANY

LTX-Credence Corporation (“LTX-Credence” or the “Company”) provides market-focused, cost-optimized automated test equipment (ATE) solutions for the semiconductor industry. The Company designs, manufactures, markets and services ATE solutions that address the broad, divergent test requirements of the wireless, computing, automotive and digital consumer market segments of the semiconductor industry. Semiconductor designers and manufacturers worldwide use the Company’s equipment to test their devices during the manufacturing process. After testing, these devices are incorporated in a wide range of products, including personal and tablet computers, mobile internet equipment such as wireless access points and interfaces, broadband access products such as cable modems and set top boxes, personal communication and entertainment products such as mobile phones and personal digital music players, consumer products such as televisions, videogame systems and digital cameras, automobile electronics and power management devices used in portable and automotive electronics. The Company also sells hardware and software support and maintenance services for its test systems.

2. SUMMARY OF SIGNIFICANT ACCOUNTING POLICIES

Basis of Presentation

The accompanying unaudited consolidated financial statements have been prepared pursuant to the Rules of the Securities and Exchange Commission for quarterly reports on Form 10-Q and, accordingly, these footnotes condense or omit information and disclosures which substantially duplicate information provided in our latest audited financial statements. These unaudited consolidated financial statements should be read in conjunction with the financial statements and notes included in the Company’s Annual Report on Form 10-K for the fiscal year ended July 31, 2013. In the opinion of management, these unaudited consolidated financial statements reflect all adjustments, including normal recurring accruals, necessary for a fair presentation of the results for the interim periods presented. The operating results for the three months ended October 31, 2013 are not necessarily indicative of future trends or the Company’s results of operations for the entire fiscal year ending July 31, 2014.

These unaudited consolidated financial statements include the accounts of the Company and its wholly owned subsidiaries. All significant inter-company transactions and balances have been eliminated in consolidation.

Revenue Recognition

The Company recognizes revenue based on guidance provided in Topic 605, Revenue Recognition, to the Financial Accounting Standards Board Codification (“FASB ASC”) and Accounting Standards Update 2009-13, Multiple-Deliverable Revenue Arrangements. The Company recognizes revenue when persuasive evidence of an arrangement exists, delivery has occurred or services have been rendered, the seller’s price is fixed or determinable and collectability is reasonably assured.

Revenue related to equipment sales is recognized when: (a) the Company has a written sales agreement; (b) delivery has occurred or service has been rendered; (c) the price is fixed or determinable; (d) collectability is reasonably assured; (e) the product delivered is a standard product with historically demonstrated acceptance; and (f) there is no unique customer acceptance provision or payment tied to acceptance or an undelivered element significant to the functionality of the system. Generally, payment terms are time based after product shipment. When sales to a customer involve multiple elements, revenue is recognized on the delivered element provided that (1) the undelivered element is a proven technology, (2) there is a history of acceptance on the product with the customer, (3) the undelivered element is not essential to the customer’s application, (4) the delivered item(s) has value to the customer on a stand-alone basis, and (5) if the arrangement included a general right of return relative to the delivered item(s), delivery or performance of the undelivered item(s) is considered probable and substantially in the control of the Company. The arrangement consideration, or the amount of revenue to be recognized on each separate unit of accounting, is allocated at the inception of the arrangement to all deliverables on the basis of their relative selling price.

Revenue related to spare parts is recognized on shipment.

Revenue related to maintenance and service contracts is recognized ratably over the duration of the contracts.

6

Table of Contents

Inventories

Inventories are stated at the lower of cost or market, determined on the first-in, first-out (“FIFO”) method, and include materials, labor and manufacturing overhead. The components of inventories are as follows:

| October 31, 2013 |

July 31, 2013 |

|||||||

| (in thousands) | ||||||||

| Material and purchased components |

$ | 16,265 | $ | 15,379 | ||||

| Work-in-process |

1,851 | 2,887 | ||||||

| Finished testers, including inventory consigned to customers |

11,122 | 10,873 | ||||||

|

|

|

|

|

|||||

| Total inventories |

$ | 29,238 | $ | 29,139 | ||||

|

|

|

|

|

|||||

The Company establishes inventory reserves when conditions exist that indicate inventory may be in excess of anticipated demand or is obsolete based upon assumptions about future demand for the Company’s products or market conditions. The Company regularly evaluates the ability to realize the value of inventory based on a combination of factors including forecasted sales or usage, estimated product end of life dates, estimated current and future market value, and new product introductions.

Purchasing and usage alternatives are also explored to mitigate inventory exposure. When recorded, reserves are intended to reduce the carrying value of inventory to its net realizable value. As of October 31, 2013 and July 31, 2013, inventory is stated net of inventory reserves of $42.8 million and $41.8 million, respectively. If actual demand for products deteriorates or market conditions are less favorable than projected, additional inventory reserves may be required. Such reserves are not reversed until the related inventory is sold or otherwise disposed of.

As of October 31, 2013 and July 31, 2013, the Company’s inventory of $29.2 million and $29.1 million, respectively, was stated net of inventory reserves of $42.8 million and $41.8 million, respectively, and primarily consisted of X-Series, ASL, ASLx, Diamond, and Diamondx products.

Goodwill and Other Intangibles

In accordance with Topic 350, Intangibles—Goodwill and Other, to the FASB ASC, the Company is required to review goodwill by reporting unit for impairment at least annually or more often if there are indicators of impairment present. The Company has determined its entire business represents one reporting unit. Historically, the Company has performed its annual impairment analysis during the fourth quarter of each year. The Company evaluated the implied fair value based on the Company’s market capitalization of its one reporting unit as compared to the carrying value of the net assets assigned to its reporting unit as of July 31, 2013. As of that date, the fair value of the reporting unit exceeded the carrying value of its net assets and therefore no impairment existed.

The Company’s intangible assets as of October 31, 2013 and July 31, 2013, all of which relate to the Credence merger, consisted of the following:

| As of October 31, 2013 | ||||||||||||||||

| Description |

Estimated Useful Life |

Gross Carrying Amount |

Accumulated Amortization |

Net Amount | ||||||||||||

| (in years) | (in thousands) | (in thousands) | (in thousands) | |||||||||||||

| Developed technology—ASL |

6.0 | 16,000 | 15,803 | 197 | ||||||||||||

| Developed technology—Diamond |

9.0 | 9,400 | 8,965 | 435 | ||||||||||||

| Maintenance agreements |

7.0 | 1,900 | 1,154 | 746 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Total intangible assets |

$ | 27,300 | $ | 25,922 | $ | 1,378 | ||||||||||

|

|

|

|

|

|

|

|||||||||||

| As of July 31, 2013 | ||||||||||||||||

| Description |

Estimated Useful Life |

Gross Carrying Amount |

Accumulated Amortization |

Net Amount | ||||||||||||

| (in years) | (in thousands) | (in thousands) | (in thousands) | |||||||||||||

| Developed technology—ASL |

6.0 | 16,000 | 15,737 | 263 | ||||||||||||

| Developed technology—Diamond |

9.0 | 9,400 | 8,906 | 494 | ||||||||||||

| Maintenance agreements |

7.0 | 1,900 | 1,086 | 814 | ||||||||||||

|

|

|

|

|

|

|

|||||||||||

| Total intangible assets |

$ | 27,300 | $ | 25,729 | $ | 1,571 | ||||||||||

|

|

|

|

|

|

|

|||||||||||

7

Table of Contents

Intangible assets are amortized based upon the pattern of estimated economic use over their estimated useful lives. The weighted average estimated remaining useful life over which these intangible assets will be amortized is 1.3 years.

The Company expects amortization for these intangible assets to be:

| Year ending July 31, |

Amount (in thousands) |

|||

| Remainder of 2014 |

$ | 576 | ||

| 2015 |

396 | |||

| 2016 |

321 | |||

| 2017 |

85 | |||

| Thereafter |

— | |||

|

|

|

|||

| Total |

$ | 1,378 | ||

|

|

|

|||

Impairment of Long-Lived Assets Other Than Goodwill

On an ongoing basis, management reviews the value of and period of amortization or depreciation of the Company’s long-lived assets. In accordance with Topic 360, Property, Plant and Equipment, to the FASB ASC, the Company reviews whether impairment losses exist on its long-lived assets other than goodwill when indicators of impairment are present. If this review is needed, the Company assesses future cash flows and re-evaluates the significant assumptions used in determining the original cost of long-lived assets other than goodwill. Although the assumptions may vary, they generally include revenue growth, operating results, cash flows and other indicators of value. Management then determines whether there has been a permanent impairment of the value of long-lived assets based upon events or circumstances that have occurred since acquisition. The extent of the impairment amount recognized is based upon a determination of the impaired asset’s fair value compared to its carrying value. As of October 31, 2013 and July 31, 2013 there were no indicators that required the Company to conduct a recoverability test as of those dates.

Foreign Currency Remeasurement

The financial statements of the Company’s foreign subsidiaries are remeasured in accordance with Topic 830, Foreign Currency Matters, to the FASB ASC. The Company’s functional currency is the U.S. dollar. Accordingly, the Company’s foreign subsidiaries remeasure monetary assets and liabilities at month-end exchange rates while long-term non-monetary items are remeasured at historical rates. Income and expense accounts are remeasured at the average rates in effect during the month. Net gains or losses resulting from foreign currency remeasurement and transaction gains or losses are included in the consolidated results of operations as a component of other expense, net, and were not significant for the three months ended October 31, 2013 and 2012.

Product Warranty Costs

The Company’s products are sold with warranty provisions that require it to remedy deficiencies in quality or performance of products over a specified period of time at no cost to its customers. The Company generally offers a warranty for all of its products, the standard terms and conditions of which are based on the product sold and the customer. For all tester products sold, the Company accrues a liability for the estimated cost of standard warranty at the time of tester shipment. Factors that impact the expected product warranty liability include the number of installed testers, historical and anticipated product failure rates, material usage and service labor costs. The Company periodically assesses the adequacy of its recorded product warranty liability and adjusts it as necessary.

The following table shows the change in the Company’s product warranty liability, as required by Topic 460, Guarantees, to the FASB ASC for the three months ended October 31, 2013 and 2012:

| Three Months Ended October 31, |

||||||||

| Product Warranty Activity |

2013 | 2012 | ||||||

| (in thousands) | ||||||||

| Balance at beginning of period |

$ | 1,217 | $ | 1,672 | ||||

| Warranty expenditures for current period |

(705 | ) | (966 | ) | ||||

| Changes in liability related to pre-existing warranties |

2 | — | ||||||

| Provision for warranty costs in the period |

781 | 1,011 | ||||||

|

|

|

|

|

|||||

| Balance at end of period |

$ | 1,295 | $ | 1,717 | ||||

|

|

|

|

|

|||||

8

Table of Contents

Engineering and Product Development Expenses

The Company expenses all engineering, research and development expenses as incurred. Expenses subject to capitalization in accordance with Topic 985, Software, to the FASB ASC relating to certain software development costs, were insignificant for the three months ended October 31, 2013 and 2012.

Shipping and Handling Costs

Shipping and handling costs are included in cost of sales in the consolidated statements of operations. Shipping and handling costs were insignificant for the three months ended October 31, 2013 and 2012.

Income Taxes

Provision for income taxes relates principally to operating results of foreign entities in jurisdictions primarily in Asia and Europe.

As of October 31, 2013 and July 31, 2013, the Company’s total liability for unrecognized income tax benefits was $6.9 million and $6.8 million, respectively (of which $3.3 million and $3.2 million, if recognized, would impact the Company’s income tax rate). The Company recognizes interest and penalties related to uncertain tax positions as a component of provision for income taxes. As of October 31, 2013 and July 31, 2013, the Company had accrued approximately $0.9 million for potential payment of accrued interest and penalties.

The Company conducts business globally and, as a result, the Company and its subsidiaries or branches file income tax returns in the U.S. federal jurisdiction and various U.S. state and foreign jurisdictions. In the normal course of business the Company is subject to examination by taxing authorities throughout the world, including such major jurisdictions as the United States, Singapore, France and Germany. With few exceptions, the Company is no longer subject to U.S. federal, state and local or non-U.S. income tax examinations for the years prior to 1998.

As a result of completion of the Company’s merger with Credence Systems Corporation (“Credence”) on August 29, 2008, a greater than 50% cumulative ownership change in both entities triggered a significant limitation in net operating loss carryforward utilization. The Company’s ability to use operating and acquired net operating loss and credit carryforwards is subject to annual limitation as defined in sections 382 and 383 of the Internal Revenue Code. The Company currently estimates that the annual limitation on its use of net operating losses generated through August 29, 2008 will be approximately $10.1 million which, based on currently enacted federal carryforward periods, limits the amount of net operating losses able to be used to approximately $202.0 million. The Company will continue to assess the realizability of these carryforwards in subsequent periods.

Accounting for Stock-Based Compensation

The Company has equity awards outstanding under various stock-based compensation plans, including the Company’s 2010 Stock Plan, as amended on November 26, 2010 (“2010 Plan”), the Company’s 2004 Stock Plan, the Company’s 2001 Stock Plan, the Company’s 1999 Stock Plan, and the Company’s 1993 Stock Plan. In addition, the Company assumed and has made awards that remain outstanding under the StepTech, Inc. Stock Option Plan as part of its acquisition of StepTech, Inc. (“StepTech”) in 2003 and the Credence 2005 Stock Incentive Plan in connection with its acquisition of Credence. The Company can only grant new awards under the 2010 Plan.

The Company recognizes stock-based compensation expense for its equity awards in accordance with the provisions of Topic 718, Compensation—Stock Compensation to the FASB ASC (“Topic 718”). Under Topic 718, the Company is required to recognize as expense the estimated fair value as of the grant date of all share-based payments to employees. In accordance with this standard, the Company has elected to recognize the compensation cost of each service based award on a straight-line basis over the vesting period of such award. The Company recorded stock-based compensation expense of approximately $1.1 million for each of the three months ended October 31, 2013 and 2012, respectively, in connection with its share-based payments.

There were no restricted stock unit awards granted during the three months ended October 31, 2013.

The Company granted 793,900 restricted stock unit awards during the three months ended October 31, 2012, all of which are service-based and vest 25% in each of the four years following the grant date.

Net (loss) income per share

Basic net (loss) income per common share is computed by dividing net (loss) income available to common stockholders by the weighted average number of common shares outstanding for the period. Diluted net (loss) income per common share reflects the maximum dilution that would have resulted from the assumed exercise and share repurchase related to dilutive stock options and RSUs, and is computed by dividing net (loss) income by the weighted average number of common shares and the dilutive effect of all securities outstanding.

9

Table of Contents

Reconciliation between the Company’s basic and diluted net (loss) income per share for the three month periods ended October 31, 2013 and October 31, 2012 were as follows:

| Three Months Ended October 31, |

||||||||

| 2013 | 2012 | |||||||

| (in thousands, except per share data) |

||||||||

| Net (loss) income |

$ | (6,900 | ) | $ | 549 | |||

| Basic (loss) earnings per share |

||||||||

| Weighted average shares outstanding- basic |

47,900 | 48,303 | ||||||

| Basic (loss) earnings per share |

$ | (0.14 | ) | $ | 0.01 | |||

| Diluted (loss) earnings per share |

||||||||

| Weighted average shares outstanding- basic |

47,900 | 48,303 | ||||||

| Plus: impact of stock options and unvested restricted stock units |

— | 408 | ||||||

|

|

|

|

|

|||||

| Weighted average common and common equivalent shares outstanding- diluted |

47,900 | 48,711 | ||||||

| Diluted (loss) earnings per share |

$ | (0.14 | ) | $ | 0.01 | |||

For the three months ended October 31, 2013 and 2012, options to purchase approximately 0.7 million shares and 0.9 million shares, respectively, of common stock were not included in the calculation of diluted net (loss) income per share because their inclusion would have been anti-dilutive. These options could be dilutive in the future. The calculation of diluted net (loss) income per share also excludes 1.3 million restricted stock units for the three months ended October 31, 2013, in accordance with the contingently issuable shares guidance of Topic 260, Earnings Per Share, to the FASB ASC.

Cash and Cash Equivalents and Marketable Securities

The Company considers all highly liquid investments that are readily convertible to cash and that have original maturity dates of three months or less to be cash equivalents. Cash and cash equivalents consist primarily of operating cash. Marketable securities consist primarily of debt securities that are classified as available-for-sale and held-to-maturity, in accordance with Topic 320, Investments—Debt and Equity Securities, to the FASB ASC. The Company also holds certain investments in commercial paper or certificates of deposit that it considers to be held-to-maturity, based on their maturity dates. Securities available-for-sale includes corporate, asset-backed, mortgage-backed, and governmental obligations with various contractual maturity dates, some of which are greater than one year. The Company considers the securities to be liquid and convertible to cash within 30 days. The Company has the ability and intent to liquidate any security that the Company holds to fund operations over the next twelve months if necessary and as such has classified these securities as short-term. Governmental obligations include U.S. Government, State, Municipal and Federal Agency securities. The Company has an overnight sweep investment arrangement with its bank for certain accounts to allow the Company to enter into diversified overnight investments via a money market mutual fund which generally provides a higher investment yield than a regular operating account.

Gross unrealized gains and losses on investments held by the Company for the three months ended October 31, 2013 and 2012 were not significant. Unrealized gains and losses on investments held by the Company are reflected as a separate component of comprehensive income (loss) and are included in Stockholders’ Equity. Realized gains, losses and interest on investments held by the Company are included in interest income in the Consolidated Statements of Operations and Comprehensive Income (Loss). The Company analyzes its investments for impairment on a quarterly basis or upon occurrence of indicators of possible impairment. There were no other temporary impairment losses in the three months ended October 31, 2013 or 2012.

10

Table of Contents

Property and Equipment

Property and equipment acquired is recorded at cost. The Company provides for depreciation and amortization on the straight-line method. Charges are made to operating expenses in amounts that are sufficient to amortize the cost of the assets over their estimated useful lives. Equipment spares used for service and internally manufactured test systems used for testing components and engineering projects are recorded at cost and depreciated over three to seven years. Repair and maintenance costs that do not extend the lives of property and equipment are expensed as incurred. The Company’s property and equipment as of October 31, 2013 and July 31, 2013 are summarized as follows:

| October 31, 2013 |

July 31, 2013 |

Estimated Useful Lives | ||||||||

| (in thousands) | (in years) | |||||||||

| Equipment spares |

$ | 58,110 | $ | 58,461 | 5 or 7 | |||||

| Machinery, equipment and internally manufactured systems |

36,068 | 34,587 | 3-7 | |||||||

| Office furniture and equipment |

2,063 | 2,014 | 3-7 | |||||||

| Purchased software |

488 | 488 | 3 | |||||||

| Land |

2,524 | 2,524 | — | |||||||

| Leasehold improvements |

6,952 | 6,983 | Term of lease or useful life, not to exceed 10 years | |||||||

|

|

|

|

|

|||||||

| Property and equipment, gross |

106,205 | 105,057 | ||||||||

| Less: accumulated depreciation and amortization |

(89,227 | ) | (88,410 | ) | ||||||

|

|

|

|

|

|||||||

| Property and equipment, net |

$ | 16,978 | $ | 16,647 | ||||||

|

|

|

|

|

|||||||

3. SEGMENT REPORTING

In accordance with the provisions of Topic 280, Segment Reporting to the FASB ASC, the Company operates as one reporting segment, that is, the design, manufacture and marketing of automated test equipment for the semiconductor industry that is used to test system-on-a-chip, digital, analog and mixed signal integrated circuits.

The Company’s net sales to geographic area for the three months ended October 31, 2013 and 2012, along with its long-lived assets at October 31, 2013 and July 31, 2013, are summarized as follows:

| Three Months Ended October 31, |

||||||||

| 2013 | 2012 | |||||||

| (in thousands) | ||||||||

| Net sales: |

||||||||

| Taiwan |

$ | 12,623 | $ | 12,207 | ||||

| United States |

4,434 | 7,065 | ||||||

| Singapore |

3,379 | 2,726 | ||||||

| Philippines |

3,153 | 7,614 | ||||||

| Malaysia |

1,922 | 4,382 | ||||||

| All other countries |

7,256 | 9,194 | ||||||

|

|

|

|

|

|||||

| Total Net Sales |

$ | 32,767 | $ | 43,188 | ||||

|

|

|

|

|

|||||

Long-lived assets consist of property and equipment:

| October 31, 2013 |

July 31, 2013 |

|||||||

| (in thousands) | ||||||||

| Long-lived assets: |

||||||||

| United States |

$ | 15,248 | $ | 14,844 | ||||

| Japan |

276 | 311 | ||||||

| Singapore |

294 | 311 | ||||||

| Philippines |

494 | 517 | ||||||

| All other countries |

666 | 664 | ||||||

|

|

|

|

|

|||||

| Total long-lived assets |

$ | 16,978 | $ | 16,647 | ||||

|

|

|

|

|

|||||

Transfer prices on products sold to foreign subsidiaries are intended to produce profit margins that correspond to the subsidiary’s sales and support efforts.

11

Table of Contents

4. RESTRUCTURING

In accordance with the provisions of Topic 420, Exit or Disposal Cost Obligation, to the FASB ASC, the Company recognizes certain costs associated with headcount reductions, office vacancies and other costs to move or relocate operations or employees as restructuring costs in the period in which such actions are initiated and approved by management or the obligations are incurred, as applicable. The following table sets forth the Company’s restructuring accrual activity for the three months ended October 31, 2013 and October 31, 2012:

| Severance Costs |

Facility Leases |

Total | ||||||||||

| (in thousands) | ||||||||||||

| Balance July 31, 2013 |

$ | 2 | $ | 2,772 | $ | 2,774 | ||||||

| Additions to expense |

— | — | — | |||||||||

| Accretion |

— | 62 | 62 | |||||||||

| Cash paid |

(2 | ) | (310 | ) | (312 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Balance October 31, 2013 |

$ | — | $ | 2,524 | $ | 2,524 | ||||||

|

|

|

|

|

|

|

|||||||

| Included in the Company’s Consolidated Balance Sheet: |

||||||||||||

| Accrued expenses |

$ | — | $ | 960 | $ | 960 | ||||||

| Other long-term liabilities |

— | 1,564 | 1,564 | |||||||||

|

|

|

|

|

|

|

|||||||

| Balance at October 31, 2013 |

$ | — | $ | 2,524 | $ | 2,524 | ||||||

|

|

|

|

|

|

|

|||||||

| Severance Costs |

Facility Leases |

Total | ||||||||||

| (in thousands) | ||||||||||||

| Balance July 31, 2012 |

$ | 364 | $ | 3,704 | $ | 4,068 | ||||||

| Additions to expense |

231 | — | 231 | |||||||||

| Accretion |

— | 50 | 50 | |||||||||

| Stock based compensation |

(48 | ) | — | (48 | ) | |||||||

| Cash paid |

(195 | ) | (399 | ) | (594 | ) | ||||||

|

|

|

|

|

|

|

|||||||

| Balance October 31, 2012 |

$ | 352 | $ | 3,355 | $ | 3,707 | ||||||

|

|

|

|

|

|

|

|||||||

| Included in the Company’s Consolidated Balance Sheet: |

||||||||||||

| Accrued expenses |

$ | 352 | $ | 982 | $ | 1,334 | ||||||

| Other long-term liabilities |

— | $ | 2,373 | $ | 2,373 | |||||||

|

|

|

|

|

|

|

|||||||

| Balance at October 31, 2012 |

$ | 352 | $ | 3,355 | $ | 3,707 | ||||||

|

|

|

|

|

|

|

|||||||

During the three months ended October 31, 2013, there were no restructuring actions or adjustments to previously recognized liabilities.

As of October 31, 2013, the Company’s restructuring accrual represented obligations related to remaining lease and property tax payments associated with the Company’s decision to vacate a facility during the year ended July 31, 2009, as well as severance obligations payable related to headcount reductions from actions undertaken during the fiscal year ended July 31, 2013.

During the three months ended October 31, 2012 the Company announced changes to its service organization to move certain board repair functions and other roles from North America locations to subsidiary offices in Singapore and the Philippines. As a result of this decision, the Company made certain headcount reductions and recorded the estimated severance and post-employment obligations related to those headcount reductions during the quarter, the impact of which was $0.2 million.

5. COMMITMENTS AND CONTINGENCIES

From time to time, the Company is subject to certain legal proceedings and other contingencies, the outcomes of which are subject to significant uncertainty. The Company accrues for estimated losses if it is probable that an asset has been impaired or a liability has been incurred and the amount of the loss can be reasonably estimated. The Company uses judgment and evaluates, with the assistance of legal counsel, whether a loss contingency arising from litigation should be disclosed or recorded. The outcome of legal proceedings and other contingencies is inherently uncertain and often difficult to estimate. Accordingly, if the outcome of legal proceedings and other contingencies is different than is anticipated by the Company, the Company would record the difference between any previously recorded amount and the full amount at which the matter was resolved, in earnings in the period resolved, which could negatively impact the Company’s results of operations and financial position for the period.

12

Table of Contents

The Company is a defendant in a litigation matter incidental to the business that is related to customer expectations of test system performance for product that was shipped in 2006 by Credence. The Company does not believe the plaintiff’s claims have merit and is vigorously defending its position. An estimate of any potential loss cannot be made; the Company does not believe a loss is probable, and accordingly the Company has not accrued any amounts related to this matter.

In the ordinary course of business, the Company agrees from time to time to indemnify certain customers against certain third party claims for property damage, bodily injury, personal injury or intellectual property infringement arising from the operation or use of the Company’s products. Also, from time to time in agreements with suppliers, licensors and other business partners, the Company agrees to indemnify these partners against certain liabilities arising out of the sale or use of the Company’s products. The maximum potential amount of future payments the Company could be required to make under these indemnification obligations in the aggregate is theoretically unlimited; however, the Company has general and umbrella insurance policies that enable it to recover a portion of any amounts paid and many of its agreements contain a limit on the maximum amount, as well as limits on the types of damages recoverable. Based on the Company’s experience with such indemnification claims, it believes the estimated fair value of these obligations is minimal. Accordingly, the Company has no liabilities recorded for these agreements as of October 31, 2013 or July 31, 2013.

Subject to certain limitations, the Company indemnifies its current and former officers and directors in certain circumstances in connection with their services as directors and officers of the Company. Although the maximum potential amount of future payments the Company could be required to make under these agreements is theoretically unlimited, as there were no known or pending claims, the Company has not accrued a liability for these agreements as of October 31, 2013 or July 31, 2013.

The Company had approximately $14.5 million and $14.8 million of non-cancelable inventory commitments with an outsourced supplier as of October 31, 2013 and July 31, 2013, respectively. The Company expects to consume the inventory through normal operating activity.

The Company has operating lease commitments for certain facilities and equipment that expire at various dates through 2021. Minimum lease payment obligations under non-cancelable leases are as follows:

Lease Commitments:

| For the fiscal year ending July 31, |

Amount | |||

| (in thousands) | ||||

| Remainder of 2014 |

$ | 4,109 | ||

| 2015 |

4,735 | |||

| 2016 |

4,310 | |||

| 2017 |

3,070 | |||

| 2018 |

1,054 | |||

| Thereafter |

2,819 | |||

|

|

|

|||

| Total minimum lease payments |

$ | 20,097 | ||

|

|

|

|||

6. ACCRUED EXPENSES

Accrued expenses consisted of the following at October 31, 2013 and July 31, 2013:

| (in thousands) | ||||||||

| October 31, 2013 |

July 31, 2013 |

|||||||

| Accrued compensation |

$ | 7,907 | $ | 7,538 | ||||

| Accrued vendor liability |

1,907 | 2,153 | ||||||

| Accrued professional fees |

1,068 | 2,043 | ||||||

| Warranty reserve |

1,295 | 1,217 | ||||||

| Accrued income, and other taxes |

1,138 | 1,115 | ||||||

| Accrued restructuring |

960 | 1,037 | ||||||

| Other accrued expenses |

4,732 | 4,249 | ||||||

|

|

|

|

|

|||||

| Total accrued expenses |

$ | 19,007 | $ | 19,352 | ||||

|

|

|

|

|

|||||

13

Table of Contents

7. FAIR VALUE MEASUREMENTS

The Company determines its fair value measurements for assets and liabilities based upon the provisions of Topic 820, Fair Value Measurements and Disclosures to the FASB ASC.

The Company holds short-term money market investments and certain other financial instruments which are carried at fair value. The Company determines fair value based upon quoted prices, when available, or through the use of alternative approaches when market quotes are not readily accessible or available.

Valuation techniques for fair value are based upon observable and unobservable inputs. Observable inputs reflect market data obtained from independent sources, while unobservable inputs reflect the Company’s best estimate, considering all relevant information. These valuation techniques involve some level of management estimation and judgment. The valuation process to determine fair value also includes making appropriate adjustments to the valuation model outputs to consider risk factors.

The fair value hierarchy of the Company’s inputs used in the determination of fair value for assets and liabilities during the current period consists of three levels. Level 1 inputs are composed of unadjusted, quoted prices in active markets for identical assets or liabilities at the measurement date. Level 2 inputs include quoted prices for similar instruments in active markets, quoted prices for identical or similar instruments in markets that are not active, inputs other than quoted prices that are observable for the asset or liability, and inputs that are derived principally from or corroborated by observable market data by correlation or other means. Level 3 inputs incorporate the Company’s own best estimate of what market participants would use in pricing the asset or liability at the measurement date where consideration is given to the risk inherent in the valuation technique and the risk inherent in the inputs to the model. If inputs used to measure an asset or liability fall within different levels of the hierarchy, the categorization is based on the lowest level input that is significant to the fair value measurement of the asset or liability. The Company’s assessment of the significance of a particular input to the fair value measurement in its entirety requires judgment and consideration of factors specific to the asset or liability.

The following table presents financial assets and liabilities measured at fair value and their related valuation inputs as of October 31, 2013 and as of July 31, 2013:

| Fair Value Measurements at Reporting Date Using (in thousands) |

||||||||||||||||

| October 31, 2013 |

Total Fair Value of Asset or Liability |

Quoted Prices in Active Markets for Identical Assets (Level 1) |

Significant Other Observable Inputs (Level 2) |

Significant Unobservable Inputs (Level 3) |

||||||||||||

| Cash and cash equivalents (1) |

$ | 30,716 | $ | 30,716 | $ | — | $ | — | ||||||||

| Marketable securities (2) |

87,269 | 11,824 | 75,445 | — | ||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

| Total assets |

$ | 117,985 | $ | 42,540 | $ | 75,445 | $ | — | ||||||||

|

|

|

|

|

|

|

|

|

|||||||||

| July 31, 2013 |

Total Fair Value of Asset or Liability |

Quoted Prices in Active Markets for Identical Assets (Level 1) |

Significant Other Observable Inputs (Level 2) |

Significant Unobservable Inputs (Level 3) |

||||||||||||

| Cash and cash equivalents (1) |

$ | 28,235 | $ | 28,235 | $ | — | $ | — | ||||||||

| Marketable securities (2) |

93,306 | 8,553 | 84,753 | — | ||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

| Total assets |

$ | 121,541 | $ | 36,788 | $ | 84,753 | $ | — | ||||||||

|

|

|

|

|

|

|

|

|

|||||||||

| (1) | Cash and cash equivalents as of October 31, 2013 and July 31, 2013 included cash held in operating accounts of approximately $25.3 million and $25.9 million, respectively that were not subject to fair value measurements. For purposes of this disclosure they are included as having Level 1 inputs. |

| (2) | Marketable securities as of October 31, 2013 and July 31, 2013 excluded approximately $0 million and $2.8 million, respectively, of commercial paper which was held-to-maturity and not subject to fair value measurements. |

The carrying value of accounts receivable, prepaid expenses and accounts payable approximate fair value due to their short-term nature.

There were no assets or liabilities recorded at fair value on a non-recurring basis requiring valuation disclosures as of October 31, 2013 or as of July 31, 2013.

14

Table of Contents

8. STOCKHOLDERS’ EQUITY

Stock Repurchases

On September 15, 2011, the Company announced that its Board of Directors had authorized a stock repurchase program for up to $25 million of shares of the Company’s common stock. Under this program, the Company is authorized to repurchase shares of its common stock from time to time in open market transactions. The Company will determine the timing and amount of the transactions based on its evaluation of market conditions and other factors. The repurchase program may be suspended or discontinued at any time and has no expiration date. During the three months ended October 31, 2013, the Company did not repurchase any shares under this program. Cumulatively, as of October 31, 2013, the Company has repurchased 3,294,666 shares of common stock for a total purchase price of $18.7 million since the inception of the program.

9. RECENT ACCOUNTING PRONOUNCEMENTS

In July 2013, the FASB issued ASU No. 2013-11, Presentation of an Unrecognized Tax Benefit When a Net Operating Loss Carryforward, a Similar Tax Loss, or a Tax Loss, or a Tax Credit Carryforward Exists. Topic 740, Income Taxes, does not include explicit guidance on the financial statement presented of an unrecognized tax benefit when a net operating loss carryforward, a similar tax loss, or a tax credit carryforward exists. There is diversity in practice in the presentation of unrecognized tax benefits in those instances and the amendments in this update are intended to eliminate that diversity in practice. The amendments are effective for fiscal years, and interim periods within those years, beginning after December 15, 2013. The amendments should be applied prospectively to all unrecognized tax benefits that exist at the effective date. Early adoption is permitted. The Company is currently evaluating the impact of adoption of this amended standard.

10. ACQUISTION OF EVERETT CHARLES TECHNOLOGIES LLC AND MULTITEST

On September 6, 2013, the Company entered into a Master Sale and Purchase Agreement (the “Purchase Agreement”) with Dover Printing & Identification, Inc. (“Dover”) and, solely for the limited purposes set forth in the Purchase Agreement, Dover Corporation (“Dover Parent”). Pursuant to the Purchase Agreement, the Company agreed to purchase from Dover or its specified affiliates (collectively, the “Sellers”) all assets of the Sellers used exclusively or primarily in connection with the research and development, design, manufacture, assembly, production, marketing, distribution, sale and repair of probes, assembled board and bare board test equipment, and fixturing products and the provision of services related thereto (the “ECT Business,” and such assets and intellectual property, the “ECT Assets”) and all assets of the Sellers used exclusively or primarily in connection with the research and development, design, manufacture, assembly, production, marketing, distribution, sale and repair of semiconductor test handlers, semiconductor test contactors and sockets and semiconductor test load boards, and the provision of services related thereto (the “MT Business,” and such assets and intellectual property, the “MT Assets”). The Company also agreed to assume certain specified liabilities of the Sellers related primarily or exclusively to the Acquired Businesses or the Acquired Assets (as defined below) (such transaction, the “Acquisition”). Under the Purchase Agreement, the Company would also acquire all of the issued and outstanding capital stock and other equity interests of specified indirect subsidiaries of Dover Parent and its affiliates that are engaged in the Acquired Businesses, including Everett Charles Technologies LLC (such capital stock and other equity interests, the “Acquired Shares”). The ECT Business and the MT Business are collectively referred to as the “Acquired Businesses” and the ECT Assets, the MT Assets and the Acquired Shares are collectively referred to as the “Acquired Assets.”

At the Closing, the Company agreed to pay the Sellers an aggregate purchase price of $93,500,000, of which $73,500,000 would be paid in cash through a combination of existing cash-on-hand and bank debt and $20,000,000 would be paid by the issuance of a promissory note by the Company to Dover in the original principal amount of $20,000,000.

The foregoing description of the Purchase Agreement is not complete and is qualified in its entirety by reference to the text of the Purchase Agreement, a copy of which was filed as Exhibit 2.1 to the Company’s Current Report on Form 8-K filed with the Securities and Exchange Commission on September 9, 2013.

11. SUBSEQUENT EVENT

On December 1, 2013, the Company completed the purchase from the Sellers of all assets of the Sellers used exclusively or primarily in connection with Acquired Businesses pursuant to the Purchase Agreement. Pursuant to the Purchase Agreement, the Company also assumed the specified liabilities that it agreed to assume and acquired all of the Acquired Shares.

Pursuant to the Purchase Agreement, in connection with the closing of the Acquisition the Company paid the Sellers an aggregate purchase price of $93,500,000, of which $73,500,000 was paid in cash through a combination of existing cash-on-hand and bank debt and $20,000,000 was paid by the issuance of a promissory note by the Company to Dover in the original principal amount of $20,000,000. The cash purchase price is subject to a post-closing working capital adjustment, and will be increased by an amount equal to specified cash balances held by the Sellers as of the closing and decreased by an amount equal to any acquired indebtedness and the amount of certain transaction costs and employee related liabilities of the Sellers as of the closing. Subject to certain conditions, the original principal amount of the promissory note is also subject to reduction upon written certification from the Company to Dover prior to January 1, 2015 of certain specified events related to the Company’s relocation from or refurbishment of certain properties of the Acquired Businesses, or the prepayment of the promissory note in full prior to such date. The promissory note accrues interest on the unpaid balance for each day that it remains outstanding after December 1, 2014 at a per annum rate equal to the London Interbank Offered Rate plus 10%, and may be prepaid by the Company at any time without penalty prior to May 1, 2019. On or prior to December 1, 2013, the Company and Dover, or their affiliates, respectively, also entered into a transition services agreement, an intellectual property termination agreement and a license agreement which govern certain ongoing relationships between the Company and Dover and their respective affiliates following the closing. Pursuant to the Purchase Agreement, the Company has also agreed to assume certain liabilities related to the Acquired Businesses.

On November 27, 2013, in anticipation of the completion of the Acquisition and to fund the purchase price therefore, the Company entered into a credit agreement (the “Credit Agreement”) with Everett Charles Technologies LLC (“ECT” and together with the Company, the “Borrowers”), Silicon Valley Bank, as lender, administrative agent and issuing lender (“SVB”), and the several lenders from time to time party thereto (the “Lenders”). The Credit Agreement provides for a senior secured credit facility in favor of the Borrowers in the aggregate principal amount of up to $55,000,000 (the “Facility”).

15

Table of Contents

The Facility consists of a term loan facility for $50,000,000 that was advanced to the Company on November 27, 2013 (the “Term Loan”) and a revolving credit facility (including a letter of credit facility) for up to $5,000,000 (the “Revolving Loan” and, together with the Term Loan, the “Loans”) that is available from time to time for five years after November 27, 2013 (the “Closing Date”). Under the terms of the Credit Agreement, not more than one time during the period commencing on the Closing Date until the close of business on the date that is one day prior to the 42-month anniversary of the Closing Date, the Facility may be increased by an aggregate amount not to exceed $20,000,000 through an additional facility on a pari passu basis with the Term Loan, subject to specified conditions and the agreement of one or more Lenders to participate therein.

All obligations under the Facility are secured by a first priority security interest in substantially all of the Borrowers’ existing and future assets, including a pledge of the stock or other equity interests of the Borrowers’ domestic subsidiaries and of any first tier foreign subsidiaries, provided that not more than 66% of the voting stock of any such foreign subsidiaries shall be required to be pledged.

The Credit Agreement requires that the Term Loan be repaid in quarterly installments, with 5% of the principal due the first year, 7.5% of principal due the second year, 10% of principal due the third year, 12.5% of principal due the fourth year, 15% of principal due the fifth year, and a final payment of $25 million due on the fifth anniversary of the Closing Date (the “Maturity Date”). All outstanding Loans under the Facility mature on the Maturity Date unless earlier payment is required under the terms of the Credit Agreement. The Term Loan is subject to mandatory prepayment as described in the Credit Agreement. Loans outstanding under the Facilities may, at the Borrowers’ option, be prepaid at any time in whole or in part without premium or penalty, other than customary breakage costs, if any, subject to the terms and conditions of the Credit Agreement.

Borrowings made under the Facility bear interest, at a base rate plus a margin (such margin not to exceed a per annum rate of 2.50%) based on a ratio of consolidated senior debt to consolidated earnings before interest, taxes, depreciation and amortization (EBITDA) (the “Leverage Ratio”), or at a LIBOR rate plus a margin (such margin not to exceed a per annum rate of 3.50%) based on the Leverage Ratio. The interest rate otherwise payable under the Facility will be subject to increase by 2.0% per annum during the continuance of a payment default and may be subject to increase by 2.0% per annum during the continuance of any other event of default. Certain customary fees and expenses are also payable in connection with the Facility.

The proceeds of the Term Loan were primarily used to fund the purchase price with respect to the Acquisition.

The Credit Agreement contains customary affirmative and negative covenants, subject in certain cases to baskets and exceptions, including negative covenants with respect to indebtedness, liens, fundamental changes, dispositions, restricted payments, investments, ERISA matters, matters relating to subordinated debt, affiliate transactions, sale and leaseback transactions, swap agreements, accounting changes, negative pledge clauses, clauses restricting subsidiary distributions, lines of business, amendments to certain documents and use of proceeds. The Credit Agreement also contains customary reporting and other affirmative covenants. The Credit Agreement contains a consolidated fixed charge coverage ratio, consolidated leverage ratio and liquidity requirements.

The obligations of the Company under the Facility may be accelerated upon the occurrence of an event of default under the Credit Agreement, which includes customary events of default, including payment defaults, the inaccuracy of representations or warranties, the failure to comply with covenants, ERISA defaults, judgment defaults, bankruptcy and insolvency defaults and cross defaults to material indebtedness.

The foregoing descriptions of the Acquisition and the Credit Agreement not complete and are qualified in their entirety by reference to the text of the Purchase Agreement, a copy of which was filed as Exhibit 2.1 to the Company’s Current Report on Form 8-K filed with the Securities and Exchange Commission on September 9, 2013, and to the Credit Agreement, a copy of which was filed as Exhibit 10.1 to the Company’s Current Report on Form 8-K filed with the Securities and Exchange Commission on December 2, 2013.

Since the acquisition date occurred subsequent to October 31, 2013, the Acquired Assets and liabilities assumed are not included in the unaudited consolidated balance sheets as of October 31, 2013. Due to the limited time since the acquisition date, the Company has not had sufficient time to prepare the supplemental pro forma revenue and earnings information. In addition, the initial purchase accounting for this business combination was unavailable as of the date of filing of this Quarterly Report, but will be included in Form 8-K/A to be filed within 71 calendar days from the acquisition date. Through October 31, 2013, the Company incurred an aggregate of approximately $3.0 million in expenses in connection with the Acquisition, and the Company expects to incur additional expenses relating to the integration of the Acquired Businesses into the Company’s operations.

16

Table of Contents

Item 2. MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

The following discussion should be read together with the Consolidated Financial Statements and Notes thereto appearing in Part I, Item 1 in this Quarterly Report on Form 10-Q. Certain statements in “Management’s Discussion and Analysis of Financial Condition and Results of Operations” are forward-looking statements that involve risks and uncertainties. Words such as may, will, could, should, would, anticipates, expects, intends, plans, predicts, projects, believes, seeks, estimates and similar expressions identify such forward-looking statements. The forward-looking statements contained herein are based on current expectations and entail various risks and uncertainties that could cause actual results to differ materially and adversely from those expressed in such forward-looking statements. Factors that might cause such a difference include, among other things, those set forth under “Risk Factors” in the Company’s Annual Report for the fiscal year ended July 31, 2013 filed on Form 10-K with the SEC on October 11, 2013 and those appearing elsewhere in this Quarterly Report on Form 10-Q. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date hereof and reflect management’s estimates and analysis only as of the date hereof. We assume no obligations to update these forward-looking statements to reflect actual results or changes in factors or assumptions affecting forward-looking statements.

Overview

We provide market-focused, cost-optimized automated test equipment (ATE) solutions for the semiconductor industry. We design, manufacture, market and service ATE solutions that address the broad, divergent test requirements of the wireless, computing, automotive and digital consumer markets of the semiconductor industry. Semiconductor designers and manufacturers worldwide use our equipment to test their devices during the manufacturing process. After testing, these devices are incorporated in a wide range of products, including personal and tablet computers, mobile internet equipment such as wireless access points and interfaces, broadband access products such as cable modems and set top boxes, personal communication and entertainment products such as mobile phones and personal digital music players, consumer products such as televisions, videogame systems and digital cameras, automobile electronics and power management devices used in portable and automotive electronics. We also sell hardware and software support and maintenance services for our test systems.

We focus our marketing and sales efforts on integrated device manufacturers (IDMs), outsourced semiconductor assembly and test providers, (OSATs), which perform assembly and testing services for the semiconductor industry, and fabless semiconductor companies, which design integrated circuits but have no manufacturing capability. We offer our customers a comprehensive portfolio of semiconductor test systems and provide a global network of strategically deployed applications and support resources.

On September 6, 2013, we entered into a Master Sale and Purchase Agreement (Purchase Agreement) with Dover and, solely for the limited purposes set forth in the Purchase Agreement, Dover Corporation (Dover Parent). Pursuant to the Purchase Agreement, we agreed to purchase from Dover or its specified affiliates (collectively, the Sellers) all assets of the Sellers used exclusively or primarily in connection with the research and development, design, manufacture, assembly, production, marketing, distribution, sale and repair of probes, assembled board and bare board test equipment, and fixturing products and the provision of services related thereto (the ECT Business, and such assets and intellectual property, the ECT Assets) and all assets of the Sellers used exclusively or primarily in connection with the research and development, design, manufacture, assembly, production, marketing, distribution, sale and repair of semiconductor test handlers, semiconductor test contactors and sockets and semiconductor test load boards, and the provision of services related thereto (the MT Business, and such assets and intellectual property, the MT Assets). We also agreed to assume certain specified liabilities of the Sellers related primarily or exclusively to the Acquired Businesses or the Acquired Assets (as defined below) (such transaction, the Acquisition). Under the Purchase Agreement, we would also acquire all of the issued and outstanding capital stock and other equity interests of specified indirect subsidiaries of Dover Parent and its affiliates that are engaged in the Acquired Businesses, including Everett Charles Technologies LLC (such capital stock and other equity interests, the Acquired Shares). The ECT Business and the MT Business are collectively referred to as the Acquired Businesses and the ECT Assets, the MT Assets and the Acquired Shares are collectively referred to as the Acquired Assets.

On November 27, 2013, in anticipation of the completion of the Acquisition and to fund the purchase price therefore, we entered into a credit agreement (Credit Agreement) with Everett Charles Technologies LLC (ECT and together with us, the Borrowers), Silicon Valley Bank, as lender, administrative agent and issuing lender (SVB), and the several lenders from time to time party thereto (the Lenders). The Credit Agreement provides for a senior secured credit facility in favor of the Borrowers in the aggregate principal amount of up to $55.0 million (the Facility). See the Liquidity and Capital Resources section starting on page 24 for more information regarding our obligations and expected impact to our liquidity from the Credit Agreement. See Note 10 and Note 11 to the Consolidated Financial Statements included in this Quarterly Report on Form 10-Q for a more complete description of the Acquisition.

On December 1, 2013, we completed the purchase from the Sellers of all assets of the Sellers used exclusively or primarily in connection with the Acquired Businesses pursuant to the Purchase Agreement. Pursuant to the Purchase Agreement, we also assumed the specified liabilities that we agreed to assume and acquired all of the Acquired Shares.

Pursuant to the Purchase Agreement, in connection with the closing of the Acquisition, we paid the Sellers an aggregate purchase price of $93.5 million of which $73.5 million was paid in cash through a combination of existing cash-on-hand and bank debt and $20.0 million was paid by the issuance of a promissory note by us to Dover in the original principal amount of $20.0 million. The cash purchase price is subject to a post-closing working capital adjustment, and will be increased by an amount equal to specified cash balances held by the Sellers as of the closing and decreased by an amount equal to any acquired indebtedness and the amount of certain transaction costs and employee related liabilities of the Sellers as of the closing. Subject to certain conditions, the original principal amount of the promissory note is also subject to reduction upon written certification from us to Dover prior to January 1, 2015 of certain specified events related our relocation from or refurbishment of certain properties of the Acquired Businesses, or the prepayment of the promissory note in full prior to such date. The promissory note accrues interest on the unpaid balance for each day that it remains outstanding after December 1, 2014 at a per annum rate equal to the London Interbank Offered Rate plus 10%, and may be prepaid by us at any time without penalty prior to May 1, 2019. On or prior to December 1, 2013, we and Dover, or their affiliates, respectively, also entered into a transition services agreement, an intellectual property termination agreement and a license agreement which govern certain ongoing relationships between us and Dover and their respective affiliates following the closing. Pursuant to the Purchase Agreement, we have also agreed to assume certain liabilities related to the Acquired Businesses. See the Liquidity and Capital Resources section starting on page 24 for more information regarding our obligations and expected impact to our liquidity pursuant to the Purchase Agreement.

17

Table of Contents

Since the acquisition date occurred subsequent to October 31, 2013, the Acquired Assets and liabilities assumed are not included in the unaudited consolidated balance sheets as of October 31, 2013. Due to the limited time since the acquisition date, we have not had sufficient time to prepare the supplemental pro forma revenue and earnings information. In addition, the initial purchase accounting for this business combination was unavailable as of the date of filing of this Quarterly Report, but will be included in Form 8-K/A to be filed within 71 calendar days from the acquisition date. Through October 31, 2013, we incurred an aggregate of approximately $3.0 million in expenses in connection with the Acquisition, and we expect to incur additional expenses relating to the integration of the Acquired Businesses into our operations.

Industry Conditions and Outlook

We sell capital equipment and services to companies that design, manufacture, assemble or test semiconductor devices. The semiconductor industry is highly cyclical, causing a cyclical impact on our financial results. As a capital equipment provider, our revenue is driven by the capital expenditure budgets and spending patterns of our customers, who often delay or accelerate purchases in reaction to variations in their business. The level of capital expenditures by these semiconductor companies depends on the current and anticipated market demand for semiconductor devices and the products that incorporate them. Therefore, demand for our semiconductor test equipment is dependent on growth in the semiconductor industry. In particular, three primary characteristics of the semiconductor industry drive the demand for semiconductor test equipment:

| • | increases in unit production of semiconductor devices; |

| • | increases in the complexity of semiconductor devices used in electronic products; and |

| • | the emergence of next generation semiconductor device technologies. |

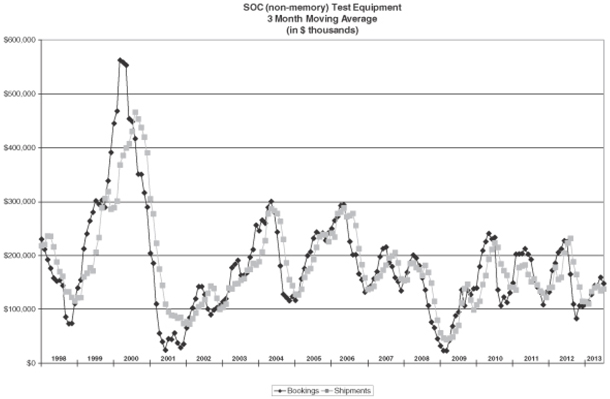

The following graph shows the cyclicality in semiconductor test equipment orders and shipments from fiscal 1998 through fiscal 2013 (using the three month moving average), as calculated by SEMI, an industry trade organization:

18

Table of Contents

Consistent with our business strategy, we have continued to invest significant amounts in engineering and product development to develop and enhance our tester platforms during industry slowdowns. During these slowdown periods, we implement cost reduction measures, such as the strict oversight of expenditures and reduction in discretionary travel and other variable overhead expenses. We believe that these reductions in operating expenses preserve our ability to fund critical product research and development efforts and continue to provide our customers with the levels of responsiveness and service they require. We believe that our competitive advantage in the semiconductor test industry is primarily driven by the ability of our combined tester platforms to meet or exceed the cost and technical specifications required for the testing of advanced semiconductor devices. Our current investment in engineering and product development is focused on enhancements and additions to our product offerings with new options and instruments designed for specific market segments. We believe this will continue to differentiate our tester platforms from the product offerings of our competitors.

In addition, we have transitioned the manufacture of certain components and subassemblies to contract manufacturers, thereby reducing our fixed manufacturing costs associated with direct labor and overhead. We believe that transforming fixed product manufacturing costs into variable costs allows us to improve our performance in the highly cyclical semiconductor industry.

We are also exposed to the risks associated with the volatility of the U.S. and global economies. The lack of visibility regarding whether or when there will be sustained growth periods for the sale of electronic goods and information technology equipment, and uncertainty regarding the amount of sales, underscores the need for caution in predicting growth in the semiconductor test equipment industry in general and in our revenues and profits specifically. Slow or negative growth in the U.S. economy may materially and adversely affect our business, financial condition and results of operations for the foreseeable future. Our results of operations would be further adversely affected if we were to experience lower than anticipated order levels, cancellations of orders in backlog, extended customer delivery requirements or pricing pressure as a result of a slowdown, or other competitive pressures. At lower levels of revenue, there is a higher likelihood that these types of changes in our customers’ requirements would adversely affect our results of operations because in any particular quarter a limited number of transactions accounts for an even greater portion of sales for the quarter.

Critical Accounting Policies and the Use of Estimates

The preparation of financial statements in conformity with generally accepted accounting principles requires management to make estimates and assumptions that affect the reported amount of assets, liabilities, revenues and expenses, and related disclosure of contingent assets and liabilities. We base these estimates and assumptions on historical experience and evaluate them on an on-going basis to ensure they remain reasonable under current conditions. Actual results could differ from those estimates. We believe that our most critical accounting policies upon which our financial reporting depends and which involve the most complex and subjective decisions or assessments are as follows: revenue recognition, inventory reserves, income taxes, warranty, goodwill and other intangibles, impairment of long-lived assets and allowances for doubtful accounts.

19

Table of Contents

A summary of those accounting policies and estimates that we believe to be most critical to fully understand and evaluate our financial results is set forth below. The summary should be read in conjunction with our Consolidated Financial Statements and Notes and related disclosures in Part I, Item 1 in this Quarterly Report on Form 10-Q.

Revenue Recognition