Attached files

| file | filename |

|---|---|

| 8-K - 8-K - DOMINION ENERGY SOUTH CAROLINA, INC. | a13-12112_18k.htm |

Exhibit 99.01

PUBLIC VERSION

V.C. Summer Nuclear Station Units 2 & 3

Quarterly Report to the South Carolina Office of Regulatory Staff

Submitted by South Carolina Electric & Gas Company

Pursuant to Public Service Commission Order No. 2009-104(A)

Quarter Ending March 31, 2013

I. Introduction and Summary

A. Introduction

This quarterly report is submitted by South Carolina Electric & Gas Company (SCE&G or the Company) to the Public Service Commission of South Carolina (the Commission) and the South Carolina Office of Regulatory Staff (ORS). It is submitted in satisfaction of the requirements of S.C. Code Ann. § 58-33-277 (Supp. 2012) and the terms of Commission Order No. 2009-104(A). This report provides updated information concerning the status of the construction of V.C. Summer Nuclear Station (VCSNS) Units 2 & 3 (the Units) and provides the current capital cost forecasts and construction schedules for the Units as of the close of the quarter. In Order No. 2012-884 dated November 15, 2012, the Commission approved updated construction schedules for the Units. This report provides a comparison of the current schedules and forecasts against those approved in Order No. 2012-884.

B. Structure of Report and Appendices

The current reporting period is the quarter ending March 31, 2013. The report is divided into the following sections:

|

Section I: |

|

Introduction and Summary; |

|

|

|

|

|

Section II: |

|

Progress of Construction of the Units; |

|

|

|

|

|

Section III: |

|

Anticipated Construction Schedules; |

|

|

|

|

|

Section IV: |

|

Schedules of the Capital Costs Incurred Including Updates to the Information Required by S.C. Code Ann. § 58-33-270(B) (6) (the Inflation Indices); |

|

|

|

|

|

Section V: |

|

Updated Schedule of Anticipated Capital Costs; and |

|

|

|

|

|

Section VI: |

|

Conclusion. |

Appendices 1, 2, and 4 to this report contain detailed financial, milestone and other information updating the schedules approved by the Commission in Order No. 2012-

PUBLIC VERSION

884. For reference purposes, Appendix 3 provides a copy of the capital cost schedule for the project as approved in Order No. 2012-884. Appendix 5 provides a listing of License Amendment Requests submitted to date.

A confidential and a public version of this report and its attachments are being provided. Unless otherwise specified, all cost information reflects SCE&G’s share of the project’s cost in 2007 dollars. Attached to the end of the report is a glossary of acronyms and defined terms used.

C. Construction Schedule and Milestones

As the report indicates, the Company has met all current construction milestones approved by the Commission in Order No. 2012-884, taking into account the contingencies authorized in Order No. 2009-104(A). There are 146 specific milestones for reporting purposes. As of March 31, 2013, 84 have been completed. Comparing the scheduled milestone completion dates as of the date of this report to the milestone completion dates approved by the Commission in Order No. 2012-884, the completion dates of 49 milestones have changed. Of these, 15 have been accelerated and 34 have been delayed for between one and 11 months.

D. Construction Costs and Cost Forecasts

Spending through December 31, 2013, in current dollars is forecasted to be approximately $173 million below the capital cost schedule approved in Order No. 2012-884. The present cash flow forecast indicates that the Company will be able to complete the Units for $4.548 billion in 2007 dollars, which is the amount approved in Order No. 2012-884. The current cost estimates include no cost changes apart from changes in timing of costs and minor shifts in costs among cost categories that occur in the normal course of managing the project.

In Order No. 2009-104(A), the Commission recognized that forecasts of Allowance for Funds Used During Construction (AFUDC) expense and escalation would vary over the course of the project and required those forecasts to be updated with each quarterly report. The current escalation indices were issued in May of 2013 for the period of July through December of 2012 and have been used in forecasting the construction costs for the project that are presented here.

PUBLIC VERSION

Chart A below compares the current capital cost forecast to the forecast presented in the last quarterly report. This chart shows an increase in Gross Construction Costs of $68.1 million over the life of the project. With each quarterly update, a quarter that had been subject to the five-year escalation rate becomes subject to the one-year rate. The figures reported on Chart A also include the effect of calculating escalation on an updated cash flow projection for the project.

Chart A: Reconciliation of Capital Cost ($000)

|

Forecast Item |

|

Projected @ 3/31/13 |

|

Projected @ 12/31/12 |

|

Change |

| |||

|

Gross Construction |

|

$ |

5,765,835 |

|

$ |

5,697,773 |

|

$ |

68,062 |

|

|

Less: AFUDC |

|

$ |

243,198 |

|

$ |

214,730 |

|

$ |

28,468 |

|

|

Total Project Cash Flow |

|

$ |

5,522,637 |

|

$ |

5,483,043 |

|

$ |

39,594 |

|

|

Less: Escalation |

|

$ |

974,232 |

|

$ |

934,638 |

|

$ |

39,594 |

|

|

Capital Cost, 2007 Dollars |

|

$ |

4,548,405 |

|

$ |

4,548,405 |

|

$ |

0 |

|

Chart B compares the current forecast of gross construction costs, including current escalation, to the forecast on which the Commission relied in adopting Order No. 2012-884. Chart B shows that the forecasted capital cost of the Units in 2007 dollars has not changed. Due to the changes in forecasted escalation and AFUDC, see Section I. F, below, the cost of the plant in future dollars has increased by approximately $11.3 million since Order No. 2012-884 was issued.

Chart B: Reconciliation of Capital Cost ($000)

|

Forecast Item |

|

Projected @ 3/31/13 |

|

As Forecasted |

|

Change |

| |||

|

Gross Construction |

|

$ |

5,765,835 |

|

$ |

5,754,565 |

|

$ |

11,270 |

|

|

Less: AFUDC |

|

$ |

243,198 |

|

$ |

237,715 |

|

$ |

5,483 |

|

|

Total Project Cash Flow |

|

$ |

5,522,637 |

|

$ |

5,516,849 |

|

$ |

5,788 |

|

|

Less: Escalation |

|

$ |

974,232 |

|

$ |

968,444 |

|

$ |

5,788 |

|

|

Capital Cost, 2007 Dollars |

|

$ |

4,548,405 |

|

$ |

4,548,405 |

|

$ |

0 |

|

PUBLIC VERSION

Chart C below shows the current forecasts of the cost of the Units compared to the cost forecasts underlying the initial Base Load Review Act (BLRA) order, which was issued by the Commission in 2009, and the update orders that the Commission issued subsequently. The decline in capital cost forecasts in 2007 dollars between Order No. 2010-12 and 2011-345 reflects the removal of Owner’s contingency amounts from the forecasts as required by the opinion of the Supreme Court of South Carolina in South Carolina Energy Users Comm. v. South Carolina Pub. Serv. Comm’n, 388 S.C. 486, 697 S.E.2d 587 (2010). This chart shows that while the cost of the project in 2007 dollars has increased by $13 million since the initial forecasts, the cost of the project in future dollars is approximately $547 million below the initial forecast.

Chart C: Summary of Nuclear Filings (billions of $)

|

Forecast |

|

Order No. |

|

Order No. |

|

Order No. |

|

Order No. |

|

Projected @ |

| |||||

|

Capital Cost, 2007 Dollars |

|

$ |

4.535 |

|

$ |

4.535 |

|

$ |

4.270 |

|

$ |

4.548 |

|

$ |

4.548 |

|

|

Escalation |

|

$ |

1.514 |

|

$ |

2.025 |

|

$ |

1.261 |

|

$ |

0.968 |

|

$ |

0.974 |

|

|

Total Project Cash Flow |

|

$ |

6.049 |

|

$ |

6.560 |

|

$ |

5.531 |

|

$ |

5.517 |

|

$ |

5.523 |

|

|

AFUDC |

|

$ |

0.264 |

|

$ |

0.316 |

|

$ |

0.256 |

|

$ |

0.238 |

|

$ |

0.243 |

|

|

Gross Construction |

|

$ |

6.313 |

|

$ |

6.875 |

|

$ |

5.787 |

|

$ |

5.755 |

|

$ |

5.766 |

|

E. Escalation Rates

As provided in Order No. 2009-104(A), the most current one-year inflation indices are used to escalate costs occurring in the twelve-month period after the date of each quarterly report. The most current escalation indices are found in the Handy-Whitman January 2013 update which was issued in May 2013 and reports data for the period July through December of 2012. Those rates are reflected in this report. The approved capital cost targets have been adjusted to reflect the currently reported historical escalation rates. The forecasted costs provided here reflect SCE&G’s calculations related to the WEC/CB&I Claims, which change the index applicable to Firm with Indexed Adjustment

PUBLIC VERSION

cost categories going forward from a floating Handy-Whitman adjustment to a fixed rate for the life of the project.

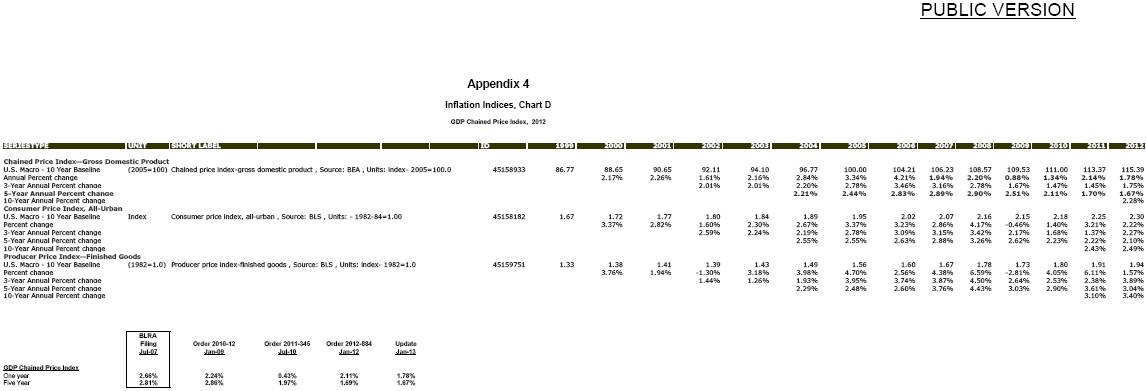

As shown on Appendix 4, utility construction cost escalation rates were at historically high levels during the period 2005-2008, and since then have dropped. Current escalation rates are shown below on Chart D. When compared to the previous Handy-Whitman release, the current update shows an upward trend in one-year average rates and a downward trend in five-year average rates.

Chart D: Handy-Whitman Escalation Rates

Escalation Rate Comparison

|

|

|

Jan-Jun 2012 |

|

Jul-Dec 2012 |

|

|

HW All Steam Index: |

|

|

|

|

|

|

One-Year Rate |

|

1.92 |

% |

4.84 |

% |

|

Five-Year Average |

|

3.60 |

% |

3.25 |

% |

|

Ten-Year Average |

|

4.67 |

% |

4.95 |

% |

|

HW All Steam/Nuclear Index: |

|

|

|

|

|

|

One-Year Rate |

|

2.10 |

% |

5.19 |

% |

|

Five-Year Average |

|

3.64 |

% |

3.32 |

% |

|

Ten-Year Average |

|

4.70 |

% |

4.99 |

% |

|

HW All Transmission Plant Index: |

|

|

|

|

|

|

One-Year Rate |

|

(0.17 |

)% |

3.29 |

% |

|

Five-Year Average |

|

2.56 |

% |

2.10 |

% |

|

Ten-Year Average |

|

4.71 |

% |

4.90 |

% |

F. AFUDC

The AFUDC for the project is currently projected to be approximately $5.5 million higher than the forecast on which Order No. 2012-884 was based. Consistent with Order No. 2009-104(A), SCE&G computes AFUDC based on the Federal Energy Regulatory Commission (FERC) approved methodology as applied to the balance of Construction Work in Progress (CWIP) that is outstanding between rate adjustments. SCE&G’s projected AFUDC rate is currently 6.09%, compared to the rate of 5.28% that applied when Order No. 2012-884 was issued.

PUBLIC VERSION

G. Compliance with the Commission Approved Cumulative Project Cash Flow Target

The current Cumulative Project Cash Flow target for the project was adopted by the Commission in Order No. 2012-884. In Order No. 2009-104(A), the Commission provided that the applicable Cumulative Project Cash Flow target would be adjusted with each quarterly report to reflect updated escalation data.

Appendix 2 provides the Commission-approved Cumulative Project Cash Flow target updated for current escalation data. The cash flow targets through December of 2012 have been updated to reflect actual escalation rates. The cash flow targets for the first quarter of 2013 and beyond have been updated based on the most recently available inflation indices, which for purposes of this report, are the indices provided in May of 2013 that report data for the period July through December of 2012. When final actual indices for 2013 become available, the cash flow data for 2013 will be revised to reflect the actual escalation rates.

Appendix 2 compares the approved Cumulative Project Cash Flow target to the current cumulative cash flow schedules for the project, which include actual costs where available and SCE&G’s working forecasts of annual cash flows for future years. In addition, the project cash flow targets presented on Appendix 2 for 2012 have been adjusted to reflect timing differences between the billing methodology under the Engineering, Procurement and Construction Agreement (EPC Contract) and the calculation of the escalated cash flow targets under Order No. 2009-104(A). Under the EPC Contract, for periods where actual escalation rates are not available, WEC/CB&I bills SCE&G based on a rolling 2-year average of the applicable Handy-Whitman rate and provides adjustments to reflect the actual rate when it is known. An adjustment has been made to Appendix 2 target calculations to offset the timing differences that arise as a result of WEC/CB&I’s approach to estimated billings and credits. This adjustment applies to those EPC Contract cost categories that are subject to indexed escalation.

II. Progress of Construction of the Units

A. Construction

The project continues to maintain an excellent safety record that exceeds industry expectations for projects of comparable size.

1. Unit 2 Nuclear Island (NI) Basemat

On March 11, 2013, the project team successfully completed the placement of the Unit 2 NI basemat which forms the foundation for the NI. The placement required just over 50 hours of continuous production of concrete by the on-site

PUBLIC VERSION

batch plants and the uninterrupted placement of 7,200 cubic yards of concrete. The compliance of the concrete to quality specifications was monitored throughout the placement. Only 1.9% of the concrete delivered was rejected as not within specification as initially delivered.

2. Unit 2 Turbine Building Basement

During the reporting period, the project team began to form and place concrete walls for the Unit 2 Turbine Building Basement. At the close of the period, approximately 50% of the Unit 2 Turbine Building Basement walls were complete.

3. Unit 3 NI Mudmat

During the reporting period, the geological mapping of the Unit 3 excavation was completed and leveling concrete and the lower mudmat were placed for the Unit 3 NI. The waterproof membrane has recently been installed over the lower mudmat in preparation for placing the upper mudmat.

4. Unit 2 Main Condenser Assembly

During the period, substantial progress was made in fabricating the Unit 2 Main Condenser Assembly. By the end of the reporting period, more than 1,800 linear feet or 40% of the welding required to complete the condenser had been performed.

5. Unit 2 CR10 and Containment Vessel Bottom Head

During the reporting period, CB&I completed fabrication of Unit 2 CR10 module, which is the steel framework that will be set on the basemat to support the Containment Vessel Bottom Head (CVBH). The CVBH is the steel bowl that forms the base of the Containment Vessel (CV). In April 2013, CR10 was lifted and set in place on the NI basemat using the Bigge Heavy Lift Derrick.

CB&I has finished fitting together and welding the plates that form the Unit 2 CVBH and is currently placing rebar to support future concrete placement beneath and within the CVBH. Work is progressing on the concrete pedestal at the center of CR10 on which the CVBH will rest. Preparations are being made to place the CVBH on the CR10 in the May/June 2013 period.

The steel plates for the Unit 3 CVBH have been received on site. Pre-assembly work for the Unit 3 CVBH is underway.

PUBLIC VERSION

6. CV Rings

Fabrication of Unit 2 CV Ring 1 is nearing completion. The four courses of plates required to form CV Ring 1 have been fitted and welded together. CB&I is now welding equipment and access hatches, stiffeners, cable penetration fittings, and other fittings to the ring. CB&I has begun Unit 2 CV Ring 2 assembly. During the reporting period, CB&I completed fitting up and welding the first two courses of plates that will form Ring 2.

The individual welds on the Units 2 and 3 CVBH and CV Rings are subject to radiographic testing for quality. Overall acceptance rates are above 99%.

7. Fabrication of Sub-Modules

Fabrication of sub-modules at the CB&I Lake Charles (CB&I-LC) facility continues to be delayed due to issues at the facility. CB&I-LC was formerly known as Shaw Modular Solutions (SMS). The schedule for fabrication and delivery of sub-modules from CB&I-LC remains a focus area for the project. SCE&G continues to devote resources to monitor this area due to its potential to affect the construction schedule. The sub-module delays are discussed further in Section II.B.10.

8. Cooling Towers

By the end of the reporting period, approximately 45% of the precast panels that make up Cooling Tower 2A had been set in place. Fans and fan shrouds were being installed. The setting of precast panels had also begun for Cooling Tower 3A. The backfilling of the Cooling Tower 2B foundation was complete. The initial foundation piles for Cooling Tower 2B had been driven. Driving of piles for the Unit 3 Pump Structure was more than 90% complete. The basin, pads and internal circulating water pipe for Cooling Tower 3B were completed during the reporting period and the Cooling Tower 3B site was ready for turnover to Evaptech for erection of the Cooling Tower structure. Work on the Unit 2 Pump Structure will begin later in the year.

9. Switchyard

The functional tests and walkdowns of the Switchyard as constructed were completed in January. The Switchyard was turned over to SCE&G’s transmission department for operation.

PUBLIC VERSION

10. Workforce

The project continues to recruit and utilize the majority of construction employees from a skilled craft workforce in the state of South Carolina. More than half of these local workers are from Fairfield, Lexington, Richland, and Newberry counties. CB&I plans to employ approximately 3,000 – 3,500 employees throughout the duration of the project, with these numbers fluctuating during the various phases of construction activity.

B. Equipment and Fabrication

1. The Reactor Vessel and Closure Head

The Unit 2 Reactor Vessel and Closure Head have successfully completed hydrostatic testing at the Doosan manufacturing facility in South Korea. They have been packaged and are awaiting shipment to the United States. Their departure will be scheduled pending successful delivery of the Reactor Vessel for the Vogtle Unit 3 by rail to the Vogtle site. Delivery of the Unit 2 Reactor Vessel and Closure Head was rescheduled to allow for modifications to the articulated Schnabel rail car that will be used to transport the reactor vessel to the site. Modifications to the Schnabel car were necessary to address concerns that arose during its first-time use in shipping an AP1000 reactor vessel to the Vogtle site. The VCSNS Unit 2 Reactor Vessel and Closure Head are expected to be delivered to the site in late June or early July 2013.

Machining, cladding and welding of components of the Unit 3 Reactor Vessel are underway at Doosan’s foundry in South Korea.

2. Steam Generators

During the period, the Unit 2 Steam Generator A and Steam Generator B satisfactorily completed primary and secondary hydrostatic tests at the Doosan manufacturing facilities in South Korea. At the close of the period, Steam Generator A was undergoing final inspection and packaging. Post-hydrostatic testing work on Generator B was being completed in preparation for final inspection and packaging for shipment.

PUBLIC VERSION

3. Core Make-Up Tanks

In November of 2012, the two Unit 2 Core Make-Up Tanks completed successful hydrostatic testing at Mangiarotti’s manufacturing facilities in Italy. Final reviews of the Quality Assurance (QA) data packages for the tanks are underway in preparation for shipping them to the site in the second quarter of 2013. The Unit 3 Core Make-Up Tanks are in fabrication at those facilities.

4. Accumulator Tanks

The Unit 2 Accumulator Tanks have undergone successful hydrostatic testing at Mangiarotti’s manufacturing facilities in Italy. Coating activities were begun in March of 2013. The final review of the QA data package for the Unit 2 Accumulator Tanks is underway in preparation for shipment to the site in the second quarter of 2013. The Unit 3 Accumulator Tanks are in fabrication at those facilities.

5. Deaerator and Moisture Separator Reheaters

The Unit 2 Deaerator and Moisture Separator Reheaters have been completed and tested and are in transit to the site. The Unit 3 Deaerator is in fabrication at the manufacturing facilities of Sungjin Geotec Co., Ltd in South Korea. The Unit 3 Moisture Separator Reheaters are in fabrication at the TEi manufacturing facilities in Oklahoma.

6. Reactor Coolant Loop Piping (RCL)

The Unit 2 RCL surge lines have been received on site. The Unit 2 RCL cold and hot legs manufactured by Tioga are currently awaiting installation of fittings and instrumentation access points and other welding activities at the Carolina Energy Solutions (CES) facility in Rock Hill. The technique used at the Tioga manufacturing facility for measuring the bend radius for these pipes is different from the technique used at CES. This difference has required that the work at CES be put on hold pending review of the proper placement of the instrumentation ports. Resolution of this issue is anticipated during the first half of 2013 with no impact foreseen to the as-needed date for these components.

Unit 3 RCL hot legs are undergoing machining at the manufacturing facilities of Tioga’s sub-supplier, IBF, in Italy. Unit 3 RCL cold legs and surge lines were originally manufactured for use in Unit 2 but were rejected due to failure to meet Westinghouse (WEC) piping specifications for grain size. Grain size deviations can affect the ability to inspect the RCL piping ultrasonically. When the Units are in service, periodic ultrasonic inspection of the RCL piping will be required for verification of the condition of piping welds. Further review of the

PUBLIC VERSION

issue has determined that grain size deviations do not impact the form, fit or function of the piping or the ability to perform adequate ultrasonic inspections. The evaluation necessary to authorize the deviation from grain size specification was completed during the review period. Final fabrication work on the Unit 3 RCL cold leg piping and surge lines is now underway.

7. Reactor Coolant Pumps (RCP)

RCP manufacturing is progressing well without significant issues at Curtiss-Wright EMD’s facility in Pennsylvania.

8. Turbine Generator

Fabrication of the Unit 2 Turbine Generator is progressing well without significant issues at Toshiba’s manufacturing facilities in Japan. Turbine generator components such as feedwater heaters were delivered to the site during the reporting period.

9. Squib Valves

The assembly and testing of squib values for both Units have been completed and data packages for the valves are being assembled at SPX’s manufacturing facilities in Pennsylvania. Shipment of the valves is currently on hold to allow SPX with WEC’s assistance to analyze and address anomalies uncovered during the qualification testing required for AP1000 squib valves. SCE&G has monitored WEC’s and SPX’s evaluations and their plans to ensure the valves will perform their design basis functions. Work is progressing to resolve these issues and they are not expected to impact site construction.

10. CB&I-LC Construction Module Fabrication

Challenges related to fabrication of sub-modules at the CB&I-LC facility continue to be a focus area of the project.

Transition to CB&I Ownership of SMS. As a result of its acquisition of the Shaw Group and SMS, the CB&I leadership team has instituted a review of the fabrication schedule and processes at CB&I-LC. CB&I has also begun evaluating alternative vendors for certain scopes of work. As previously reported, the responsibility for manufacturing shield building structural modules has been assigned to Newport News Industries (NNI) which is preparing to fabricate those modules. During the reporting period, mock-ups of certain sub-modules have been received on site from NNI to support testing of concrete placement in constrained areas.

PUBLIC VERSION

CB&I currently requires that CB&I-LC obtain specific review and concurrence from CB&I before it releases structural sub-modules for transportation to the site. This review process involves as-built verification of component installation in the sub-modules and final module walkdown by CB&I personnel. Restrictions on coating and product testing remain in place. SCE&G maintains a presence on site to monitor activities at CB&I-LC and interact with CB&I-LC leadership on a regular basis.

WEC/CB&I is undertaking a review of the design interface between WEC and CB&I-LC to ensure that design requirements are properly communicated and followed.

Notice of Violation. On April 19, 2013, after the close of the reporting period, the Nuclear Regulatory Commission (NRC) issued a notice of violation and proposed a civil penalty of $36,400 against CB&I for discrimination by SMS against an employee who raised a safety concern. The safety concerns did not involve this project. The events underlying the citation occurred before CB&I acquired SMS. In a separate order issued that same day, the NRC requested CB&I take action to improve the nuclear safety culture at CB&I-LC particularly with respect to policies and organizational structure to support the reporting of nuclear safety concerns by CB&I-LC workers.

Shear Stud Spacing. As previously reported, the NRC completed an Inspections, Tests, Analyses, and Acceptance Criteria (ITAAC) inspection at SMS in May 2012. The inspection resulted in the NRC debriefing an Unresolved Item (URI) for deviations from Design Control Document (DCD) provisions primarily related to module shear stud spacing. During the NRC’s 2012 Third Quarter Exit meeting conducted on October 9, 2012, the NRC resolved the previous URI as a NRC-identified Green violation. A “Green” violation is a finding of very low safety significance.

The issue raised by the NRC involved changes to shear stud minimum and maximum spacing allowances where shear studs had to be relocated due to obstructions within the module walls. In response, WEC has developed a revision to the Updated Final Safety Analysis Report (UFSAR) clarifying the licensing commitment concerning shear stud spacing where changes in spacing are indicated as a result of obstructions. A License Amendment Request (LAR) package is being prepared to request NRC authorization to make this change. If the LAR is approved, the specific instances where shear stud spacing must be altered would be addressed on a case by case basis in accordance with the revised UFSAR.

PUBLIC VERSION

Fillet Welds. During the third quarter of 2012, WEC identified an issue related to use of fillet welds in lieu of full penetration welds for several CA20 sub-modules which are now on site. As a result of a WEC design review, WEC determined that the fillet weld process was not reflected in the licensing basis drawings for these components. CB&I contractors on site are preparing to remove the fillet welds to allow rewelding using full penetration welds.

Conclusion. The delays related to fabrication of the sub-modules at CB&I-LC continue to be an important area of focus for the project. At the end of the reporting period, 40 of the 72 required CA20 sub-modules had been delivered to the site. All remaining CA20 sub-modules are in fabrication at CB&I-LC as are the eight sub-modules comprising CA-05. Twenty-one CA-01 modules are in fabrication.

Senior management from both SCE&G and WEC/CB&I continue to monitor the fabrication and delivery process related to sub-modules. WEC personnel provide on-site engineering support for production at CB&I-LC. SCE&G continues to maintain a resident inspector at the CB&I-LC facility who provides additional monitoring.

C. Licensing and Permitting

As licensee for the Units, SCE&G is directly accountable to the NRC for its contractors meeting nuclear safety-related Quality Assurance/Quality Control (QA/QC) requirements both at the project site and at the facilities of its component manufacturers and equipment suppliers worldwide. WEC/CB&I through the EPC Contract is responsible to SCE&G for making sure that these requirements are met.

1. NRC Inspections

The NRC completed the following inspections at the project site:

a) The NRC conducted multiple inspections of the as-built condition of the Unit 2 NI basemat rebar cage prior to the placement of concrete and continued the on-site inspection during the placement of concrete. On March 26, 2013, the NRC exited its Unit 2 Basemat Concrete Placement and Pre-Placement Inspection. Two minor violations were debriefed neither of which had any impact on the actual construction of the basemat rebar cage or the conduct and sampling of the concrete placement.

b) On March 26, 2013, the NRC issued its report related to its 2012 inspection of the concrete reinforcement in the basemat. In that inspection, the NRC had found that the techniques employed in fabricating the steel rebar

PUBLIC VERSION

cages for the basemat did not fully comply with applicable sections of the American Concrete Institute (ACI) Construction Code that were referenced in the UFSAR.

In its March 26, 2013 report, the NRC documented a preliminary finding of White safety significance related to reinforcing steel spacing and development length in some areas of the NI. The NRC rates the safety significance of its findings as Green, White, Yellow, and Red in order of increasing severity. A White finding is considered to be of low to moderate safety significance. Qualitatively, it indicates an acceptable level of performance by the licensee, but is outside the nominal risk range.

SCE&G requested a Regulatory Conference with the NRC to discuss the safety significance of this violation which was held on April 30, 2013. SCE&G presented facts in an attempt to show that the proper safety significance of this event should be Green (i.e., of very low safety significance.) SCE&G anticipates that the NRC will issue a final decision on this matter in June 2013.

c) On January 10, 2013, the NRC completed the CV Ring No. 1 welding inspection with no findings identified.

d) In November of 2012, the NRC conducted its inspection of the Corrective Action Program (CAP) employed by SCE&G and WEC/CB&I. Based on SCE&G’s responses to that report, the NRC approved the CAP presently in place for SCE&G and the Consortium subject to the completion of the NRC end of cycle performance review of VCSNS Units 2 & 3. The NRC staff may now issue non-cited violations in reliance on correction of those issues through the CAP program in lieu of issuing severity level IV or Green violations.

2. LARs

The NRC approves changes from the approved licensing basis for nuclear units through the LAR request and review process. SCE&G envisions that filings for LARs will be a normal part of the construction program for the Units going forward under the Combined Operating License (COL). Additionally, if needed, a licensee can submit a Preliminary Amendment Request (PAR) associated with a LAR. Through the PAR process the licensee can request a notification that the NRC does not object to the licensee installing and testing the proposed changed design feature, at the licensee’s risk, pending NRC’s review of the LAR.

During the first quarter of 2013, SCE&G filed ten LARs with the NRC, two of which (LARs 13-01 and 13-02) were discussed in the Quarterly Report for the Fourth Quarter of 2012. For ease of reference, a report that tabulates all the LARs filed as of March 31, 2013 is attached as Appendix 5. SCE&G has withdrawn LAR

PUBLIC VERSION

13-08 in anticipation of filing a substitute LAR which will specify areas within the design of structural modules where obstructions necessitate alternative spacing for shear studs or trusses and will more clearly define the design requirements for placement of shear studs and internal trusses within these areas.

3. NRC Response to the Japanese Earthquake and Tsunami of March 2011

As previously reported, on October 22, 2012, SCE&G issued its initial status report to the NRC in response to license condition 2.D(13) which relates to restoring core cooling after a beyond design basis accident. In this status report, SCE&G summarized those actions both taken and planned to comply with license condition 2.D(13). At this time, SCE&G is preparing an integrated response plan to submit to the NRC in compliance with license condition 2.D(13) for Units 2 & 3. The plan for Unit 1 was completed in the third quarter of 2012.

NRC Order EA-12-063 relates to spent fuel pool instrumentation issues raised by the Fukushima event. On October 29, 2012, SCE&G issued a technical report to the NRC which provides a complete response to the issues raised in Order EA-12-063. At the close of the reporting period, SCE&G was still awaiting the NRC response to its request to close out Order EA-12-063 on the basis of that technical report.

4. Major Construction Permits

a) Other Major Construction-Related Permits

No other major construction-related permits are outstanding. Other construction-related permits are anticipated to be obtained in the ordinary course of administering the project.

PUBLIC VERSION

5. BLRA Regulatory Proceedings

As reported in the Quarterly Report for the Fourth Quarter of 2012, in May of 2012, SCE&G filed a petition for updates to the capital cost schedules and construction schedules for the Units as approved under the BLRA. On November 15, 2012, the Commission issued Order No. 2012-884 finding that the revisions were prudent under S.C. Code Ann. § 58-33-270(E). The only exception was that the Commission determined that approval of the costs associated with Phase II of the change order addressing Cyber Security upgrades to the Units, in the amount of $4.95 million, was premature since the precise scope of Phase II work will not be determined until the evaluation and work plan created in Phase I is completed. The Commission did not suggest that these costs could not be recovered and indicated that the Company may seek to include them within its approved capital cost schedules when they are more fully known.

Two intervenors filed petitions for re-hearing concerning Order No. 2012-884. The Commission denied those petitions by Order No. 2013-5, dated February 14, 2013. The intervenors have filed notices of appeal to the Supreme Court of South Carolina. The briefing of these appeals is expected to take place over the summer of 2013.

D. Engineering

1. Engineering Completion Status

As of March 31, 2013, the Units 2 & 3 plant design issued to support construction is 76% complete. The ‘issued to support construction’ metric is now the principal metric of design completion for the project.

2. Site Specific Design Activities

Site specific design work is ongoing in support of site specific systems, to include the Circulating Water System (CWS), Yard Fire System (YFS), Potable Water System (PWS), Construction and Offsite Power System (ZRS), Raw Water System (RWS), Sanitary Drain System (SDS), Offsite Water System (OWS) and Waste Water System (WWS).

As discussed in previous reports, the presence of bromides in the Broad River system resulted in redesign of the OWS using reverse osmosis to achieve South Carolina Department of Health and Environmental Control (SCDHEC) potable water requirements. SCE&G is reviewing initial documentation related to this redesign as provided by WEC/CB&I.

PUBLIC VERSION

E. Training

1. The schedule for implementation of the Plant Reference Simulator (PRS) continues to support the schedule for training and licensing reactor operators as required to allow the initial fuel load for Unit 2. WEC has assembled four teams to oversee validation and testing of the PRS. Continuous monitoring and regular status updates are ongoing to ensure that the timetable for the NRC’s certification of the PRS is consistent with the required training schedule for reactor operators. The validation and testing of the PRS will remain an area of continued focus for the project given the importance to the project of meeting the reactor operator training schedule.

2. Twenty-four students continue in the Initial Licensed Operator (ILO) class. The duration is approximately two years and will culminate with an NRC written exam in August 2014 and a simulator demonstrative exam in December 2014. Eighteen students are enrolled in the Non-Licensed Operator (NLO) program and will complete the program in July 2013. A second NLO class will begin in August 2013.

3. The Tri-Party Agreement that is in negotiation between Southern Nuclear Company (SNC), SCE&G and WEC is on hold pending resolution of intellectual property issues. The agreement concerns collaboration related to the development of programs and procedures for operating AP1000 reactors. Work is continuing on these issues, and limited collaboration is occurring based on prior agreements.

F. Change Control/Owners Cost Forecast

1. Change Order 16. Change Order No. 16 will incorporate the agreement entered into between SCE&G and WEC/CB&I resolving the WEC/CB&I claims related to COL Delay, Shield Building Redesign, Module Redesign, and Unit 2 Rock Conditions. The language of Change Order No. 16 is still being negotiated.

PUBLIC VERSION

G. Transmission

1. VCS1-Killian 230 kV Line — By Order No. 2011-978, the Commission approved the siting of the VCS1-Killian 230 kV Line under the South Carolina Utility Facility Siting and Environmental Protection Act. In early January 2012, SCE&G began construction on the VCS1-Killian 230 kV Line. As of March 31, 2013, approximately ninety-five percent (95%) of the VCS1-Killian 230 kV Line is complete.

2. VCS2-Lake Murray 230 kV Line No. 2 and Segment of the VCS2-St. George 230 kV Line No. 1 — Order No. 2011-978 also approved the siting of VCS2-Lake Murray 230 kV Line No. 2, and a segment of the VCS2-St. George 230 kV Line No. 1 which extends from V.C. Summer Switchyard #2 to the Lake Murray 230/115 kV Substation. In May 2012, SCE&G began construction on these lines. As of March 31, 2013, construction of these two lines is approximately sixty percent (60%) complete.

3. The Remaining Segment of VCS2-St. George 230 kV Line No. 1 and the VCS2-St. George 230 kV Line No. 2 — On September 26, 2012, by Order No. 2012-730 the Commission approved the siting of the remaining segment of VCS2-St. George 230 kV Line No. 1 and the VCS2-St. George 230 kV Line No. 2 under the South Carolina Utility Facility Siting and Environmental Protection Act. These lines are being built on existing right of way corridors. Construction of these lines has not yet begun.

4. St. George Switching Station — In Order No. 2012-730, the Commission also issued a Certificate of Environmental Capability and Public Convenience and Necessity authorizing construction of this switching station. The site for it was purchased in 2009. Construction of the switching station has not begun.

5. Saluda River Substation — On December 20, 2012, SCE&G secured the rights to the site for the new Saluda River 230/115 kV Substation. The site is adjacent to the corridor for the St. George lines and one of the St. George 230 kV lines will fold into this new substation when it is built. In Order No. 2012-730, the Commission issued a Certificate of Environmental Capability and Public Convenience and Necessity authorizing construction of the new substation. Lay out of the substation is progressing.

PUBLIC VERSION

III. Anticipated Construction Schedules

As of March 31, 2013, the Company and its contractors remain on schedule to complete all required milestones as adjusted pursuant to the milestone schedule contingencies approved by the Commission in Order No. 2009-104(A). Each of those adjustments is itemized in the BLRA Milestone section that follows. Accordingly, the project is in compliance with the updated construction schedules approved by the Commission in Order No. 2012-884 and with the provisions of S.C. Code Ann. § 58-33-275(A)(1).

A. Construction Schedule

The Project Licensing and Permitting, Engineering, Procurement and Construction work remains on schedule to meet the Units’ Substantial Completion Dates taking into account the schedule contingencies approved in Order 2009-104(A).

B. BLRA Milestones

Appendix 1 to this quarterly report lists and updates each of the specific milestones constituting the anticipated construction schedule for the Units pursuant to S.C. Code Ann. § 58-33-270(B)(1) and Order No. 2012-884. Comparing the current milestone target completion dates to the dates in Order No. 2012-884, 15 milestones have been accelerated and 34 have been delayed.

IV. Schedules of the Capital Costs Incurred Including Updates to the Information Required by S.C. Code Ann. § 58-33-270(B) (6) (the Inflation Indices)

The Capital Costs section of this report (Section IV.A) provides an update of the cumulative capital costs incurred and forecasted to be incurred in completing the project. These costs are compared to the cumulative capital cost targets approved by the Commission in Order No. 2012-884. The approved capital cost targets have been adjusted to reflect the currently reported historical escalation rates. There has not been any use by the Company of the capital cost timing contingencies that were approved by the Commission in Order No. 2009-104(A). The Inflation Indices section (Section IV.B) of this report provides updated information on inflation indices and the changes in them.

A. Capital Costs

Appendix 2 shows the Cumulative Project Cash Flow target as approved in Order No. 2012-884 and as updated for escalation and other Commission approved adjustments under the heading “Per Order 2012-884 Adjusted.”

PUBLIC VERSION

Appendix 2 also shows the cumulative cash flow for the project based on actual expenditures to date and the Company’s current forecast of cost and construction schedule under the heading “Actual through March 2013 plus Projected.”

As shown on Appendix 2, the projected expenditure for the project for the 12 months ended December 31, 2013, is approximately $928 million. As shown on Appendix 2, line 39, the cumulative amount projected to be spent on the project as of December 31, 2013, is approximately $2.701 billion. As shown on Appendix 2, line 18, the Cumulative Project Cash Flow target approved by the Commission for year-end 2013 adjusted for current escalation and WEC/CB&I billing differences is approximately $2.878 billion. As a result, the cumulative cash flow at year-end 2013 is projected to be approximately $176.7 million less than the target.

For comparison purposes, Appendix 3 sets out the cash flow schedule for the project as it was approved in Order No. 2012-884. Appendix 3 does not include any adjustments to the cash flow schedule for changes in inflation indices or adjustments in capital cost schedules made by the Company. The AFUDC forecast presented on Appendix 3 is the AFUDC forecast that was current at the time of Order No. 2012-884.

B. Inflation Indices

Appendix 4 shows the updated inflation indices approved in Order No. 2009-104(A). Included is a history of the annual Handy-Whitman All Steam Index, South Atlantic Region; the Handy-Whitman All Steam and Nuclear Index, South Atlantic Region; the Handy-Whitman All Transmission Plant Index, South Atlantic Region; and the Chained GDP Index for the past 10 years. The changes in these indices and the escalation-related effects of cost rescheduling resulted in a decrease in the projected cost of the Units in future dollars from $6.3 billion as forecast in Order No. 2009-104(A) to a forecast of $5.8 billion using current inflation data.

V. Updated Schedule of Anticipated Capital Costs

The updated schedule of anticipated capital costs for Units 2 & 3 is reflected in Appendix 2.

VI. Conclusion

The Units are currently anticipated to be completed at a cost of approximately $4.5 billion in 2007 dollars. The Company maintains a staff that monitors the work of its contractors and continues to monitor closely areas of concern related to either cost or schedule for the project. The Company will continue to update the Commission and the ORS of progress and concerns as the project proceeds.

PUBLIC VERSION

ATTACHMENT 1

GLOSSARY OF ACRONYMS OR DEFINED TERMS

|

Acronym or |

|

Reference |

|

7Q10 |

|

A standard low-water flow condition used for evaluating the environmental effects of discharges and withdrawals from rivers and streams. The conditions are calculated to reflect the lowest average 7-day flow expected to be encountered during any 10-year period. |

|

ACI |

|

American Concrete Institute. |

|

AFUDC |

|

Allowance for Funds Used During Construction. |

|

AP1000 |

|

The WEC designed Advanced Pressurized water nuclear reactor of approximately 1000 megawatts generating capacity. |

|

APOG |

|

A group of utilities who have submitted applications for AP1000 COLs. |

|

BLRA |

|

The Base Load Review Act, S.C. Code Ann. § 58-33-210 et seq. (Supp. 2009). |

|

CA |

|

The designation for a specific pre-fabricated construction module that forms part of the reactor building, such as Module CA20. |

|

CAP |

|

Corrective Action Program. |

|

CAR |

|

A Corrective Action Report related to design, engineering or construction of the Units, or related processes, that must be corrected. |

|

CB&I |

|

Chicago Bridge & Iron, a sub-contractor on the project which upon acquisition of the Shaw Group became a member of the Consortium and a prime contractor on the project. |

|

CB&I-LC |

|

CB&I Lake Charles - the module fabrication unit formerly known as Shaw Modular Solutions or SMS and located in Lake Charles, Louisiana. |

|

CES |

|

Carolina Energy Solutions, a subcontractor located in Rock Hill, South Carolina. |

|

COLs |

|

Combined Operating Licenses for construction and operation of a nuclear unit issued by the NRC. |

|

COLA |

|

A Combined Operating License Application. |

|

Commission |

|

The Public Service Commission of South Carolina. |

|

Consortium |

|

The joint venture between WEC Electric Company, LLC and CB&I to construct the Units under the terms of the EPC Contract. |

|

CR |

|

A Condition Report communicating and memorializing concerns with the design, engineering or construction of the Units, or related processes, which report in some cases can become the basis for a Corrective Action Report. |

|

CV |

|

The Containment Vessel which provides containment for the reactor vessel and associated equipment. |

|

CVBH |

|

The Containment Vessel Bottom Head that forms the bottom of the Containment Vessel. |

|

CWIP |

|

Construction Work in Progress. |

|

CWS |

|

The Circulating Water System —the system that will transport waste heat from the turbines to the cooling towers. |

|

Cyber Security |

|

Technologies, processes and practices designed to protect networks, computers, programs and data from attack, damage or unauthorized access. |

|

DCD |

|

Design Control Document which is approved by the Nuclear Regulatory Commission and sets forth the approved design of a nuclear reactor. |

|

Departures |

|

Departures are minor deviations from the approved Design Control Document included in the licensing basis for the Units that do not rise to the level requiring a License Amendment Request (LAR). |

PUBLIC VERSION

|

Acronym or |

|

Reference |

|

EMD |

|

Electro-Mechanical Division of Curtiss-Wright Corp., the sub-contractor for the Reactor Coolant Pumps. |

|

EPA |

|

The United States Environmental Protection Agency. |

|

EPC Contract |

|

The Engineering, Procurement and Construction Agreement for construction of the Units entered into by SCE&G and WEC/CB&I. |

|

Exit Debriefing |

|

A meeting held between the NRC and the licensee at the conclusion of an NRC inspection to discuss the results of the inspection. |

|

FEIS |

|

A Final Environmental Impact Statement as required by the National Environmental Policy Act of 1969. |

|

FERC |

|

The Federal Energy Regulatory Commission. |

|

FFD |

|

Fitness For Duty, a program that seeks to provide reasonable assurance that site personnel are trustworthy, will perform their tasks in a reliable manner, and are not under the influence of substances or otherwise impaired in a way that may adversely affect their ability to safely and competently perform their duties. |

|

Fixed/Firm |

|

Prices under the EPC Contract which are either fixed or are firm but subject to defined escalation rates. |

|

FLEX |

|

A diverse, flexible strategy led by NEI for adding more backup systems to cool nuclear reactors and used fuel storage pools and to maintain the integrity of reactor containment structures in response to lessons learned from Fukushima. |

|

FNTP |

|

Full Notice to Proceed authorizing all remaining safety-related work to commence. |

|

FSAR |

|

Final Safety Analysis Report — a report by the applicant providing support to the NRC’s approval and certification of the standard power plant design. |

|

GDP |

|

Gross Domestic Product. |

|

HFE/ISV |

|

Human Factors Engineering/Integrated Systems Validation —part of the development of a training simulator for the Units. |

|

HL or Hot Leg |

|

That part of the Reactor Cooling Loop that transports steam to the steam generators. |

|

HLD |

|

Heavy Lift Derrick - the derrick that was erected on site to move large modules and equipment. |

|

IBF |

|

Subcontractor of Tioga that manufactures the Reactor Coolant Loop piping. |

|

IFC |

|

Issued for Construction — engineering drawings that include information necessary for construction of specific structures, systems and components. |

|

ILO |

|

Initial Licensed Operator. |

|

INPO |

|

Institute of Nuclear Power Operations. |

|

IPS |

|

Integrated Project Schedule for licensing and construction of the Units. |

|

ITAAC |

|

Inspections, Tests, Analyses, and Acceptance Criteria which are the inspections, tests, analyses and acceptance criteria that the NRC has determined to be necessary and sufficient to demonstrate that a nuclear unit has been constructed and will operate in conformity with the COLs, the Atomic Energy Act of 1954, as amended, and the NRC’s regulations. |

|

LAR |

|

License Amendment Request — A formal request made by VCSNS to amend the combined operating license, its appendices, or its associated bases. |

|

LNTP |

|

Limited Notice to Proceed authorizing a vendor to commence specific work. |

|

LSS |

|

Limited Scope Simulator —a training simulator with limited functionality that can be used for the initial stages of operator training. |

PUBLIC VERSION

|

Acronym or |

|

Reference |

|

MAB |

|

Module Assembly Building - a building on site where large modules will be constructed and equipment will be prepared for installation in a space that is protected from the elements. |

|

Near Term Task Force |

|

A senior level task force created by the NRC to address lessons learned from the 2011 earthquake and tsunami in Fukushima, Japan with operating nuclear plants and new reactor applicants. |

|

NEI |

|

Nuclear Energy Institute. |

|

Nelson Studs |

|

Metal studs used in composite construction to secure concrete to steel components. The studs project out of the steel components and are surrounded by the concrete when it is poured. |

|

NI |

|

Nuclear Island, comprising the steel containment vessel, the reactor building, and the auxiliary building. |

|

NLC |

|

Nuclear Learning Center - a training facility operated by SCE&G at the Jenkinsville site. |

|

NLO |

|

Non-Licensed Operator. |

|

NND |

|

The New Nuclear Deployment Team within SCE&G. |

|

NNI |

|

Newport News Industries — a module fabrication subcontractor to WEC/CB&I. |

|

NPDES |

|

National Pollutant Discharge Elimination System. |

|

NRC |

|

The United States Nuclear Regulatory Commission. |

|

ORS |

|

South Carolina Office of Regulatory Staff. |

|

OWS |

|

Off Site Water System — the system that withdraws water from Monticello Reservoir and provides potable and filtered water for the Units. |

|

PAR |

|

Preliminary Amendment Request - A formal request made by VCSNS which allows VCSNS to proceed at its own risk with work consistent with an amendment request contained in an LAR prior to approval. |

|

Pike |

|

Pike Energy Solutions, a contractor for transmission and switchyard related work. |

|

PRA |

|

Probabilistic Risk Assessment. |

|

PRHR |

|

The Passive Residual Heat Removal Exchanger unit —a heat exchanger unit that is part of the passive safety system which provides cooling to the AP1000 reactor during emergency situations. |

|

PRS |

|

Plant Reference Simulator — a training simulator with full functionality that can be used in all stages of operator training. |

|

PWS |

|

The Potable Water System - which provides potable water to the site. |

|

QA |

|

Quality Assurance — The planned and systematic activities implemented in a quality system so that the quality requirements for a product or service will be fulfilled. |

|

QA/QC |

|

Quality Assurance/Quality Control. |

|

QC |

|

Quality Control — The observation techniques and activities used to fulfill requirements for quality. |

|

RAI |

|

Requests for Additional Information issued by the NRC staff to license applicants. |

|

RCA |

|

Root Cause Analysis — identification and evaluation of the reason for non-conformance, an undesirable condition, or a problem which (when solved) restores the status quo. |

|

RCL |

|

The Reactor Coolant Loop — the piping and related equipment that transports heat from the reactor to the steam generator. |

|

RCP |

|

The Reactor Cooling Pump which forms part of the Reactor Coolant System. |

PUBLIC VERSION

|

Acronym or |

|

Reference |

|

RCS |

|

The Reactor Coolant System - the complete system for transferring and transporting heat from the reactor to the steam generator. |

|

RFI |

|

Requests for Information issued by the NRC staff to licensees. |

|

ROW |

|

Right-of-way. |

|

RT |

|

Radiographic Testing - a nondestructive testing method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation (high energy photons) to penetrate various materials. |

|

RWS |

|

Raw Water System — the system for withdrawing and transporting raw water from the Monticello Reservoir. |

|

SAT |

|

Site Acceptance Testing. |

|

SCDHEC |

|

The South Carolina Department of Health and Environmental Control. |

|

SCDNR |

|

The South Carolina Department of Natural Resources. |

|

SCE&G or The Company |

|

South Carolina Electric & Gas Company. |

|

SDS |

|

Sanitary Drain System. |

|

Shaw |

|

The Shaw Group. |

|

SMS |

|

Shaw Module Solutions, LLC. |

|

SNC |

|

Southern Nuclear Company — a subsidiary of Southern Company and licensed operator of the Vogtle Nuclear Units and two other nuclear plants. |

|

SRO |

|

Senior Reactor Operator. |

|

SROC |

|

Senior Reactor Operator Certification. |

|

Target |

|

Costs under the EPC Contract where targets have been established but where SCE&G pays actual costs as incurred. |

|

TEi |

|

Thermal Engineering International — a subsidiary of Babcock Power which manufactures moisture separator reheaters and other power plant equipment. |

|

UFSAR |

|

Updated Final Safety Analysis Report. |

|

Units |

|

V. C. Summer Nuclear Station Units 2 & 3. |

|

Update Docket |

|

A proceeding under the BLRA seeking Commission approval of updated cost and construction schedules for the Units. |

|

URI |

|

Unresolved Items — A term used by the NRC during inspections for items that require further action. |

|

USACOE |

|

The United States Army Corps of Engineers. |

|

VCSNS or VCSN |

|

V. C. Summer Nuclear Station. |

|

WEC |

|

Westinghouse Electric Company, LLC. |

|

WEC/CB&I |

|

The consortium formed by Westinghouse Electric Company, LLC and CB&I. |

|

WEC/CB&I Claims |

|

WEC/CB&I’s claims for additional charges associated with the COLs delay, the Shield Building design changes, the structural modules design changes, and the lower than anticipated rock elevations encountered in certain areas within the Unit 2 Nuclear Island. |

|

WTP |

|

The Off-Site Water Treatment Plant which will take water from Lake Monticello and treat it to potable water standards. |

|

WWS |

|

The Waste Water System — the system for collection, treatment and disposal of domestic waste water generated on site. |

PUBLIC VERSION

|

Acronym or |

|

Reference |

|

YFS |

|

The Yard Fire System — the system that provides fire detection and protection outside of the plant. |

|

ZRS |

|

The Construction and Offsite Power System —the system which provide electrical power to the site. |

PUBLIC VERSION

APPENDIX 1

V. C. Summer Nuclear Station Units 2 & 3

Quarterly Report to the South Carolina Office of Regulatory Staff

Submitted by South Carolina Electric & Gas Company

Pursuant to Public Service Commission Order No. 2009-104(A)

Quarter Ending March 31, 2013

Appendix 1 lists and updates each of the milestones which the Commission adopted as the Approved Construction Schedule for the Units, pursuant to S.C. Code Ann. § 58-33-270(B)(1) in Order No. 2012-884. Appendix 1 provides columns with the following information:

1. Milestone tracking ID number.

2. The description of the milestone as updated in Order No. 2012-884.

3. The BLRA milestone date as approved by the Commission in Order No. 2012-884.

4. The current milestone date.

5. For each actual completed milestone, the date by which it was completed. For milestones completed prior to the current reporting quarter, the milestone entry is shaded in gray. For milestones completed during the current reporting quarter, the milestone entry is shaded in green. For milestones with planned completion dates that vary in days instead of months, the milestone entry is shaded in yellow.

6. Information showing the number of months, if any, by which a milestone has been shifted.

7. Information as to whether any milestone has been shifted outside of the 18/24 Month Contingency approved by the Commission.

8. Information as to whether any current change in this milestone is anticipated to impact the substantial completion date.

9. Notes.

On the final page of the document, there is a chart summarizing milestone completion and movement comparing the current milestone date to the milestone date approved in Order No. 2012-884. This movement is shown for only the milestones that have not been completed.

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 1 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 1 Approve Engineering Procurement and Construction Agreement Complete 5/23/2008 No No 2 Issue P.O.'s to nuclear component fabricators for Units 2 and 3 Containment Vessels Complete 12/3/2008 No No 3 Contractor Issue PO to Passive Residual Heat Removal Heat Exchanger Fabricator - First Payment - Unit 2 Complete 8/18/2008 No No 4 Contractor Issue PO to Accumulator Tank Fabricator - Unit 2 Complete 7/31/2008 No No 5 Contractor Issue PO to Core Makeup Tank Fabricator - Units 2 & 3 Complete 9/30/2008 No No 6 Contractor Issue PO to Squib Valve Fabricator - Units 2 & 3 Complete 3/31/2009 No No 7 Contractor Issue PO to Steam Generator Fabricator - Units 2 & 3 Complete 5/29/2008 No No 8 Contractor Issue Long Lead Material PO to Reactor Coolant Pump Fabricator - Units 2 & 3 Complete 6/30/2008 No No 9 Contractor Issue PO to Pressurizer Fabricator - Units 2 & 3 Complete 8/18/2008 No No 10 Contractor Issue PO to Reactor Coolant Loop Pipe Fabricator - First Payment - Units 2 & 3 Complete 6/20/2008 No No 11 Reactor Vessel Internals - Issue Long Lead Material PO to Fabricator - Units 2 and 3 Complete 11/21/2008 No No 12 Contractor Issue Long Lead Material PO to Reactor Vessel Fabricator - Units 2 & 3 Complete 5/29/2008 No No 13 Contractor Issue PO to Integrated Head Package Fabricator - Units 2 & 3 Complete 7/31/2009 No No 14 Control Rod Drive Mechanism Issue PO for Long Lead Material to Fabricator - Units 2 and 3 - first payment Complete 6/21/2008 No No 15 Issue P.O.'s to nuclear component fabricators for Nuclear Island structural CA20 Modules Complete 8/28/2009 No No 16 Start Site Specific and balance of plant detailed design Complete 9/11/2007 No No PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 2 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 17 Instrumentation & Control Simulator - Contractor Place Notice to Proceed - Units 2 & 3 Complete 10/31/2008 No No 18 Steam Generator - Issue Final PO to Fabricator for Units 2 and 3 Complete 6/30/2008 No No 19 Reactor Vessel Internals - Contractor Issue PO for Long Lead Material (Heavy Plate and Heavy Forgings) to Fabricator - Units 2 & 3 Complete 1/29/2010 No No 20 Contractor Issue Final PO to Reactor Vessel Fabricator - Units 2 & 3 Complete 9/30/2008 No No 21 Variable Frequency Drive Fabricator Issue Transformer PO - Units 2 & 3 Complete 4/30/2009 No No 22 Start clearing, grubbing and grading Complete 1/26/2009 No No 23 Core Makeup Tank Fabricator Issue Long Lead Material PO - Units 2 & 3 Complete 10/31/2008 No No 24 Accumulator Tank Fabricator Issue Long Lead Material PO - Units 2 & 3 Complete 10/31/2008 No No 25 Pressurizer Fabricator Issue Long Lead Material PO - Units 2 & 3 Complete 10/31/2008 No No 26 Reactor Coolant Loop Pipe - Contractor Issue PO to Fabricator - Second Payment - Units 2 & 3 Complete 4/30/2009 No No 27 Integrated Head Package - Issue PO to Fabricator - Units 2 and 3 - second payment Complete 7/31/2009 No No 28 Control Rod Drive Mechanisms - Contractor Issue PO for Long Lead Material to Fabricator - Units 2 & 3 Complete 6/30/2008 No No 29 Contractor Issue PO to Passive Residual Heat Removal Heat Exchanger Fabricator - Second Payment - Units 2 & 3 Complete 10/31/2008 No No 30 Start Parr Road intersection work. Complete 2/13/2009 No No 31 Reactor Coolant Pump - Issue Final PO to Fabricator - Units 2 and 3 Complete 6/30/2008 No No 32 Integrated Heat Packages Fabricator Issue Long Lead Material PO - Units 2 & 3 Complete 10/1/2009 No No 33 Design Finalization Payment 3 Complete 1/30/2009 No No PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 3 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 34 Start site development Complete 6/23/2008 No No 35 Contractor Issue PO to Turbine Generator Fabricator - Units 2 & 3 Complete 2/19/2009 No No 36 Contractor Issue PO to Main Transformers Fabricator - Units 2 & 3 Complete 9/25/2009 No No 37 Core Makeup Tank Fabricator Notice to Contractor Receipt of Long Lead Material - Units 2 & 3 Complete 12/30/2010 No No 38 Design Finalization Payment 4 Complete 4/30/2009 No No 39 Turbine Generator Fabricator Issue PO for Condenser Material - Unit 2 Complete 8/28/2009 No No 40 Reactor Coolant Pump Fabricator Issue Long Lead Material Lot 2 - Units 2 & 3 Complete 4/30/2009 No No 41 Passive Residual Heat Removal Heat Exchanger Fabricator Receipt of Long Lead Material - Units 2 & 3 Complete 5/27/2010 No No 42 Design Finalization Payment 5 Complete 7/31/2009 No No 43 Start erection of construction buildings, to include craft facilities for personnel, tools, equipment; first aid facilities; field offices for site management and support personnel; temporary warehouses; and construction hiring office. Complete 12/18/2009 No No 44 Reactor Vessel Fabricator Notice to Contractor of Receipt of Flange Nozzle Shell Forging - Unit 2 Complete 8/28/2009 No No 45 Design Finalization Payment 6 Complete 10/7/2009 No No 46 Instrumentation and Control Simulator - Contractor Issue PO to Subcontractor for Radiation Monitor System - Units 2 & 3 Complete 12/17/2009 No No 47 Reactor Vessel Internals - Fabricator Start Fit and Welding of Core Shroud Assembly - Unit 2 Complete 7/29/2011 No No 48 Turbine Generator Fabricator Issue PO for Moisture Separator Reheater/Feedwater Heater Material - Unit 2 Complete 4/30/2010 No No 49 Reactor Coolant Loop Pipe Fabricator Acceptance of Raw Material - Unit 2 Complete 2/18/2010 No No PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 4 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 50 Reactor Vessel Internals - Fabricator Start Weld Neutron Shield Spacer Pads to Assembly - Unit 2 Complete 8/28/2012 No No 51 Control Rod Drive Mechanisms - Fabricator to Start Procurement of Long Lead Material - Unit 2 Complete 6/30/2009 No No 52 Contractor Notified that Pressurizer Fabricator Performed Cladding on Bottom Head - Unit 2 Complete 12/23/2010 No No 53 Start excavation and foundation work for the standard plant for Unit 2 Complete 3/15/2010 No No 54 Steam Generator Fabricator Notice to Contractor of Receipt of 2nd Steam Generator Tubesheet Forging - Unit 2 Complete 4/30/2010 No No 55 Reactor Vessel Fabricator Notice to Contractor of Outlet Nozzle Welding to Flange Nozzle Shell Completion - Unit 2 Complete 12/30/2010 No No 56 Turbine Generator Fabricator Notice to Contractor Condenser Fabrication Started - Unit 2 Complete 5/17/2010 No No 57 Complete preparations for receiving the first module on site for Unit 2. Complete 1/22/2010 No No 58 Steam Generator Fabricator Notice to Contractor of Receipt of 1st Steam Generator Transition Cone Forging - Unit 2 Complete 4/21/2010 No No 59 Reactor Coolant Pump Fabricator Notice to Contractor of Manufacturing of Casing Completion - Unit 2 Complete 11/16/2010 No No 60 Reactor Coolant Loop Pipe Fabricator Notice to Contractor of Machining, Heat Treating & Non-Destructive Testing Completion - Unit 2 Complete 3/20/2012 No No 61 Core Makeup Tank Fabricator Notice to Contractor of Satisfactory Completion of Hydrotest - Unit 2 Complete 11/26/2012 No No 62 Polar Crane Fabricator Issue PO for Main Hoist Drum and Wire Rope - Units 2 & 3 Complete 2/1/2011 No No 63 Control Rod Drive Mechanisms - Fabricator to Start Procurement of Long Lead Material - Unit 3 Complete 6/14/2011 No No PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 5 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 64 Turbine Generator Fabricator Notice to Contractor Condenser Ready to Ship - Unit 2 Complete 3/26/2012 No No 65 Start placement of mud mat for Unit 2 Complete 7/20/2012 No No 66 Steam Generator Fabricator Notice to Contractor of Receipt of 1st Steam Generator Tubing - Unit 2 Complete 9/28/2010 No No 67 Pressurizer Fabricator Notice to Contractor of Welding of Upper and Intermediate Shells Completion - Unit 2 Complete 10/28/2011 No No 68 Reactor Vessel Fabricator Notice to Contractor of Closure Head Cladding Completion - Unit 3 Complete 6/28/2012 No No 69 Begin Unit 2 first nuclear concrete placement Complete 3/9/2013 No No 70 Reactor Coolant Pump Fabricator Notice to Contractor of Stator Core Completion - Unit 2 Complete 12/1/2011 No No 71 Fabricator Start Fit and Welding of Core Shroud Assembly - Unit 2 Complete 7/29/2011 No No 72 Steam Generator Fabricator Notice to Contractor of Completion of 1st Steam Generator Tubing Installation - Unit 2 Complete 1/27/2012 No No 73 Reactor Coolant Loop Pipe - Shipment of Equipment to Site - Unit 2 12/31/2012 9/30/2013 +9 Month(s) No No Due to deviation notices related to bend radius. 74 Control Rod Drive Mechanism - Ship Remainder of Equipment (Latch Assembly & Rod Travel Housing) to Head Supplier - Unit 2 Complete 7/16/2012 No No 75 Pressurizer Fabricator Notice to Contractor of Welding of Lower Shell to Bottom Head Completion - Unit 2 Complete 12/22/2011 No No 76 Steam Generator Fabricator Notice to Contractor of Completion of 2nd Steam Generator Tubing Installation - Unit 2 Complete 5/4/2012 No No 77 Design Finalization Payment 14 Complete 10/31/2011 No No 78 Set module CA04 for Unit 2 11/6/2012 8/6/2013 +9 Month(s) No No Due to schedule refinement and review. PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 6 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 79 Passive Residual Heat Removal Heat Exchanger Fabricator Notice to Contractor of Final Post Weld Heat Treatment - Unit 2 Complete 5/24/2011 No No 80 Passive Residual Heat Removal Heat Exchanger Fabricator Notice to Contractor of Completion of Tubing - Unit 2 Complete 5/29/2012 No No 81 Polar Crane Fabricator Notice to Contractor of Girder Fabrication Completion - Unit 2 Complete 10/23/2012 No No 82 Turbine Generator Fabricator Notice to Contractor Condenser Ready to Ship - Unit 3 8/31/2013 8/31/2013 No No 83 Set Containment Vessel ring #1 for Unit 2 1/7/2013 9/4/2013 +8 Month(s) No No Due to schedule refinement and review. 84 Reactor Coolant Pump Fabricator Delivery of Casings to Port of Export - Unit 2 7/31/2012 6/11/2013 +11 Month(s) No No Due to rework of one casing. 85 Reactor Coolant Pump Fabricator Notice to Contractor of Stator Core Completion - Unit 3 8/31/2013 8/31/2013 No No 86 Reactor Vessel Fabricator Notice to Contractor of Receipt of Core Shell Forging - Unit 3 Complete 3/29/2012 No No 87 Contractor Notified that Pressurizer Fabricator Performed Cladding on Bottom Head - Unit 3 Complete 11/9/2011 No No 88 Set Nuclear Island structural module CA03 for Unit 2 6/26/2013 2/3/2014 +8 Month(s) No No Due to schedule refinement and review. 89 Squib Valve Fabricator Notice to Contractor of Completion of Assembly and Test for Squib Valve Hardware - Unit 2 Complete 5/10/2012 No No 90 Accumulator Tank Fabricator Notice to Contractor of Satisfactory Completion of Hydrotest - Unit 3 3/31/2013 7/31/2013 +4 Month(s) No No Due to schedule refinement and review. 91 Polar Crane Fabricator Notice to Contractor of Electric Panel Assembly Completion - Unit 2 Complete 3/6/2013 No No 92 Start containment large bore pipe supports for Unit 2 6/28/2013 1/10/2014 +7 Month(s) No No Due to schedule refinement and review. 93 Integrated Head Package - Shipment of Equipment to Site - Unit 2 3/31/2013 2/28/2014 +11 Month(s) No No Due to design changes. PUBLIC VERSION |

|

|

13-1Q Appendix 1 VC Summer Units 2 and 3 South Carolina Electric & Gas Company 7 o f 1 0 Tracking ID Order No. 2012-884 Description Order No. 2012-884 Date 13-1Q Targeted Milestone Completion Date Actual Completion Date Delta Months from Order No. 2012-884 Date Outside +18/-24 Months Contingency? Substantial Completion Date Impact? Notes 94 Reactor Coolant Pump Fabricator Notice to Contractor of Final Stator Assembly Completion - Unit 2 5/31/2013 9/30/2013 +4 Month(s) No No Due to delay in predecessor schedule activities. 95 Steam Generator Fabricator Notice to Contractor of Completion of 2nd Steam Generator Tubing Installation - Unit 3 6/30/2013 7/31/2013 +1 Month(s) No No Due to schedule refinement and review. 96 Steam Generator Fabricator Notice to Contractor of Satisfactory Completion of 1st Steam Generator Hydrotest - Unit 2 Complete 1/14/2013 No No 97 Start concrete fill of Nuclear Island structural modules CA01 and CA02 for Unit 2 4/3/2014 7/22/2014 +3 Month(s) No No Due to schedule refinement and review. 98 Passive Residual Heat Removal Heat Exchanger - Delivery of Equipment to Port of Entry - Unit 2 12/31/2012 7/31/2013 +7 Month(s) No No Due to schedule refinement and review. 99 Refueling Machine Fabricator Notice to Contractor of Satisfactory Completion of Factory Acceptance Test - Unit 2 11/30/2013 10/31/2013 -1 Month(s) No No Schedule ahead of plan. 100 Deliver Reactor Vessel Internals to Port of Export - Unit 2 1/31/2014 5/31/2014 +4 Month(s) No No Due to schedule refinement and review. 101 Set Unit 2 Containment Vessel #3 4/24/2014 10/20/2014 +6 Month(s) No No Due to schedule refinement and review. 102 Steam Generator - Contractor Acceptance of Equipment at Port of Entry - Unit 2 7/31/2013 9/30/2013 +2 Month(s) No No Due to schedule refinement and review. 103 Turbine Generator Fabricator Notice to Contractor Turbine Generator Ready to Ship - Unit 2 4/30/2013 5/31/2013 +1 Month(s) No No Due to schedule refinement and review. 104 Pressurizer Fabricator Notice to Contractor of Satisfactory Completion of Hydrotest - Unit 3 3/31/2014 12/31/2013 -3 Month(s) No No Schedule ahead of plan. 105 Polar Crane - Shipment of Equipment to Site - Unit 2 1/31/2014 11/30/2013 -2 Month(s) No No Schedule ahead of plan. 106 Receive Unit 2 Reactor Vessel on site from fabricator 5/13/2014 8/31/2013 -9 Month(s) No No Schedule ahead of plan. 107 Set Unit 2 Reactor Vessel 6/23/2014 7/18/2014 +1 Month(s) No No Due to schedule refinement and review. 108 Steam Generator Fabricator Notice to Contractor of Completion of 2nd Channel Head to Tubesheet Assembly Welding - Unit 3 12/31/2013 2/28/2014 +2 Month(s) No No Due to schedule refinement and review. PUBLIC VERSION |

|

|