Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Aleris Corp | a1q13earningsrelease8-k.htm |

| EX-99.1 - PRESS RELEASE - Aleris Corp | a1q13earningsrelease.htm |

1 FIRST QUARTER 2013 EARNINGS PRESENTATION MAY 9, 2013

IMPORTANT INFORMATION This information is current only as of its date and may have changed. We undertake no obligation to update this information in light of new information, future events or otherwise. This information contains certain financial projections and forecasts and other forward looking information concerning our business, prospects, financial condition and results of operations, and we are not making any representation or warranty that this information is accurate or complete. See “Forward-Looking Information” below. FORWARD-LOOKING INFORMATION Certain statements in this presentation are “forward-looking statements” within the meaning of the federal securities laws. Statements about our beliefs and expectations and statements containing the words “may”, “could”, “would”, “should”, “will”, “believe” “expect” “anticipate” “plan” “estimate” “target” “project” “look to” “intend” and similar expressions intended to connote future events and circumstances constitute forward-looking statements. Forward-looking statements include statements about future costs and prices of commodities, production volumes, industry trends, demand for our products and services, anticipated cost savings, anticipated benefits from new products or facilities, and projected results of operations. Forward-looking statements involve known and unknown risks and uncertainties, which could cause actual results to differ materially from those contained in or implied by any forward-looking statement. Important factors that could cause actual results to differ materially from those forward-looking statements include but are not limited to the following: (1) our ability to successfully implement our business strategy; (2) the cyclical nature of the aluminum industry, our end-use segments and our customers’ industries; (3) our ability to fulfill our substantial capital investment requirements; (4) variability in general economic conditions on a global or regional basis; (5) our ability to retain the services of certain members of our management; (6) our ability to enter into effective metal, natural gas and other commodity derivatives or arrangements with customers to manage effectively our exposure to commodity price fluctuations and changes in the pricing of metals; (7) our internal controls over financial reporting and our disclosure controls and procedures may not prevent all possible errors that could occur; (8) increases in the cost of raw materials and energy; (9) the loss of order volumes from any of our largest customers; (10) our ability to retain customers, a substantial number of whom do not have long-term contractual arrangements with us; (11) our ability to generate sufficient cash flows to fund our capital expenditure requirements and to meet our debt service obligations; (12) competitor pricing activity, competition of aluminum with alternative materials and the general impact of competition in the industry segments we serve; (13) risks of investing in and conducting operations on a global basis, including political, social, economic, currency and regulatory factors; (14) current environmental liabilities and the cost of compliance with and liabilities under health and safety laws; (15) labor relations (i.e., disruptions, strikes or work stoppages) and labor costs; (16) our levels of indebtedness and debt service obligations; (17) the possibility that we may incur additional indebtedness in the future; and (18) limitations on operating our business as a result of covenant restrictions under our indebtedness. Investors, potential investors and other readers are urged to consider these factors carefully in evaluating the forward-looking statements and are cautioned not to place undue reliance on such forward-looking statements. We undertake no obligation to publicly update or revise any forward-looking statements, whether in response to new information, future events or otherwise, except as otherwise required by law. NON-GAAP INFORMATION The non-GAAP financial measures contained in this presentation (including, without limitation, EBITDA, Adjusted EBITDA, commercial margin, and variations thereof) are not measures of financial performance calculated in accordance with U.S. GAAP and should not be considered as alternatives to net income (loss) or any other performance measure derived in accordance with GAAP or as alternatives to cash flows from operating activities as a measure of our liquidity. Non-GAAP measures have limitations as analytical tools and should be considered in addition to, not in isolation or as a substitute for, or as superior to, our measures of financial performance prepared in accordance with GAAP. Management believes that certain non-GAAP performance measures may provide investors with additional meaningful comparisons between current results and results in prior periods. Management uses non-GAAP financial measures as performance metrics and believes these measures provide additional information commonly used by the holders of our senior debt securities and parties to the ABL Facility with respect to the ongoing performance of our underlying business activities, as well as our ability to meet our future debt service, capital expenditures and working capital needs. These adjustments are based on currently available information and certain adjustments that we believe are reasonable and are presented as an aid in understanding our operating results. They are not necessarily indicative of future results of operations that may be obtained by the Company. INDUSTRY INFORMATION Information regarding market and industry statistics contained in this presentation is based on information from third party sources as well as estimates prepared by us using certain assumptions and our knowledge of these industries. Our estimates, in particular as they relate to our general expectations concerning the aluminum industry, involve risks and uncertainties and are subject to changes based on various factors, including those discussed under “Risk factors” in our filings with the Securities and Exchange Commission. Disclaimers 2

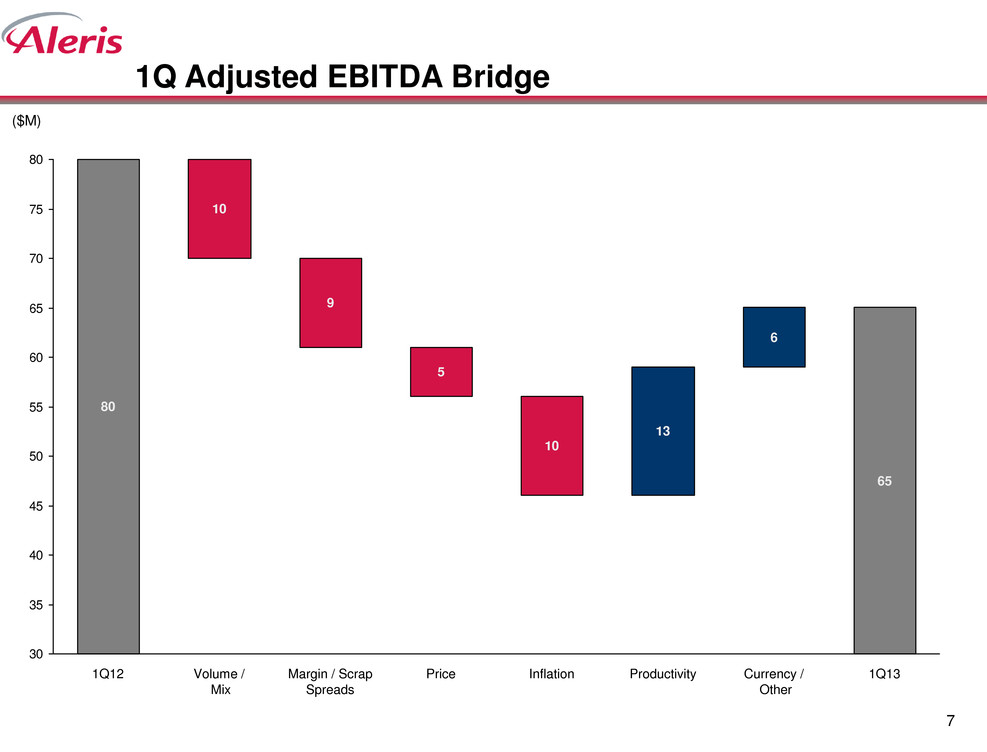

First Quarter Performance Overview 1Q13 Adjusted EBITDA of $65 million; net income of $11 million Lower aerospace and automotive volumes Metal / scrap spread pressure continues Higher Europe regional plate and sheet volumes Duffel wide auto body sheet facility & Zhenjiang plate rolling mill officially unveiled Solid AOS related productivity performance; $13 million saved in 1Q13 3

1Q13 Volume Recap & Highlights Volume Change vs. 1Q12 Drivers RPNA (3%) B&C (5%) Transportation 12% Distribution 4% RPEU / Global Market Segments1 1% Aerospace (3%) Automotive (8%) Heat Exchanger (4%) Plate & Sheet 9% RSAA (4%) Spec / Automotive (2%) Recycling (7%) RSEU (8%) Spec / Automotive (13%) Recycling 1% - Slow start to building season; competitor strike in ‘12 - Trailer builds; share gain - Regaining industry position - Koblenz production issues - Europe inventory destocking - Shedding unprofitable volumes - Rebound from lower demand - NA Auto builds; eliminating unprofitable business - Lower demand - Customer insourcing; EU economy - Slow economic recovery Extrusions (6%) - Slow start to building season; EU economy 4 1RPEU volumes adjusted for Voerde & Zhenjiang

Successful start up; will serve global aerospace & commercial plate customers First shipments in 1Q; 140 tons Achieved ISO 9001 certification in 1Q13 Zhenjiang Plate Rolling Mill Strategic Growth Projects 5 Duffel Wide Cold Mill Expansion Successful start up; widest aluminum heat treated sheet currently in industry Qualification coils produced and approved by key automotive customers Significant volumes contracted

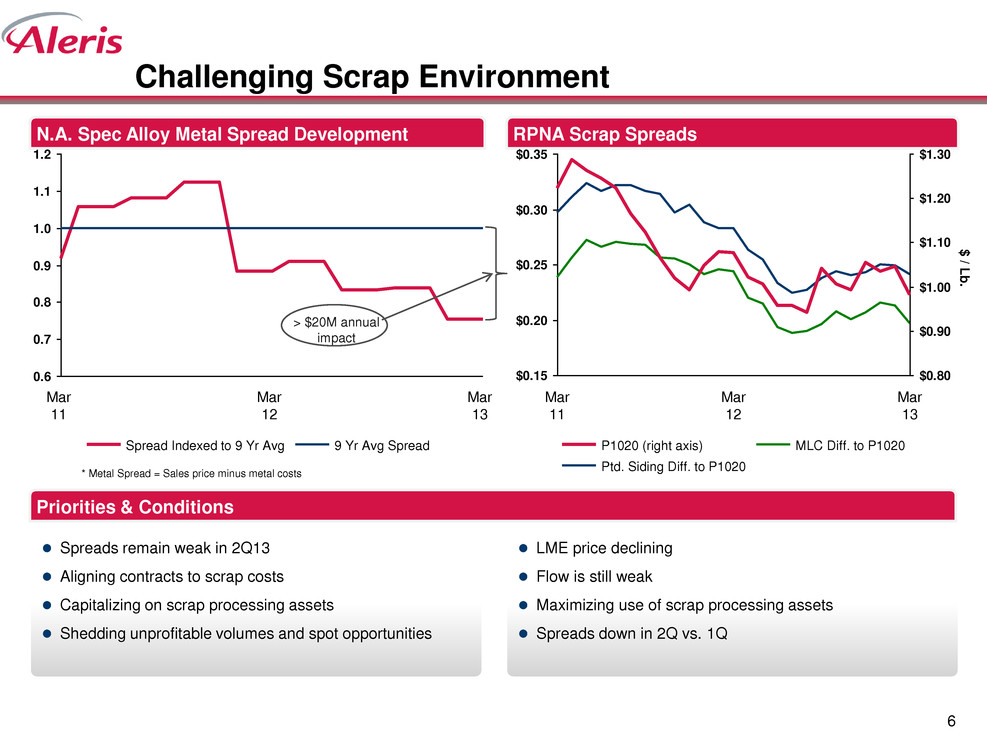

Challenging Scrap Environment 6 Priorities & Conditions Spreads remain weak in 2Q13 Aligning contracts to scrap costs Capitalizing on scrap processing assets Shedding unprofitable volumes and spot opportunities LME price declining Flow is still weak Maximizing use of scrap processing assets Spreads down in 2Q vs. 1Q N.A. Spec Alloy Metal Spread Development RPNA Scrap Spreads 0.6 0.7 0.8 0.9 1.0 1.1 1.2 Mar 11 Mar 13 Mar 12 9 Yr Avg Spread Spread Indexed to 9 Yr Avg $0.15 $0.20 $0.25 $0.30 $0.35 $0.80 $0.90 $1.00 $1.10 $1.20 $1.30 Mar 13 Mar 12 Mar 11 MLC Diff. to P1020 Ptd. Siding Diff. to P1020 P1020 (right axis) $ / L b . * Metal Spread = Sales price minus metal costs > $20M annual impact

($M) 1Q Adjusted EBITDA Bridge 30 35 40 45 50 55 60 65 70 75 80 1Q13 65 Currency / Other 6 Productivity 13 Inflation 10 Price 5 Margin / Scrap Spreads 9 Volume / Mix 10 1Q12 80 7

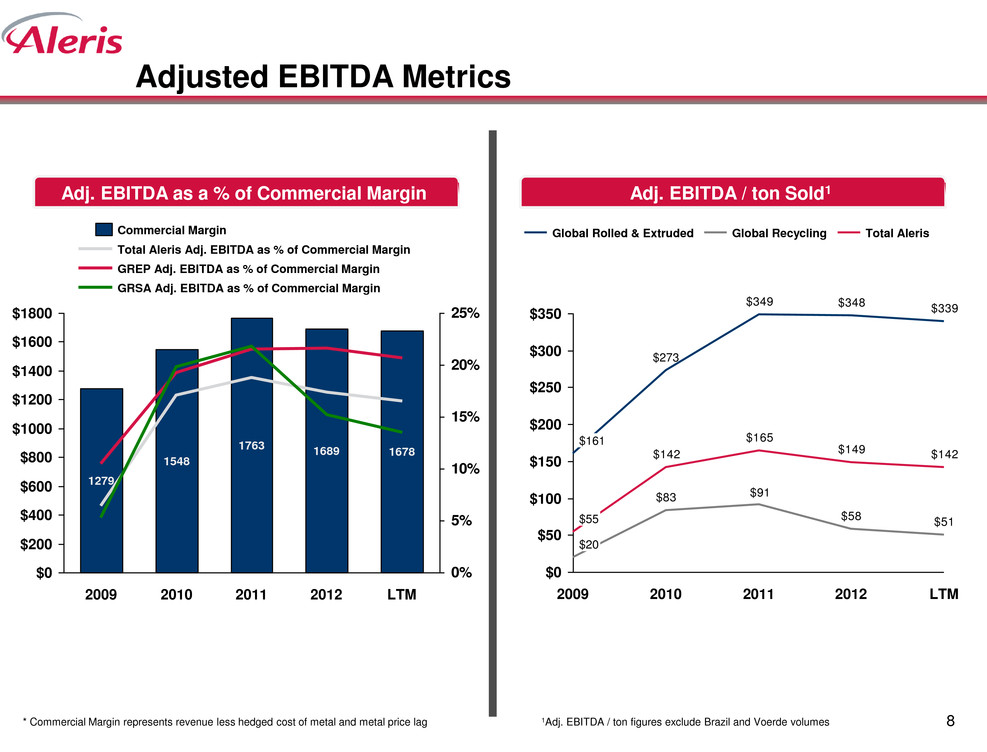

0% 5% 10% 15% 20% 25% $1800 $1600 $1400 $1200 $1000 $800 $600 $400 $200 $0 LTM 1678 2012 1689 2011 1763 2010 1548 2009 1279 Adjusted EBITDA Metrics Adj. EBITDA as a % of Commercial Margin Adj. EBITDA / ton Sold1 8 GRSA Adj. EBITDA as % of Commercial Margin GREP Adj. EBITDA as % of Commercial Margin Total Aleris Adj. EBITDA as % of Commercial Margin Commercial Margin $339 $348$349 $51 $58 $91$83 $142$149 $165 $142 $350 $300 $250 $200 $150 $100 $50 $0 LTM 2012 2011 2010 $273 2009 $55 $20 $161 Total Aleris Global Recycling Global Rolled & Extruded 1Adj. EBITDA / ton figures exclude Brazil and Voerde volumes * Commercial Margin represents revenue less hedged cost of metal and metal price lag

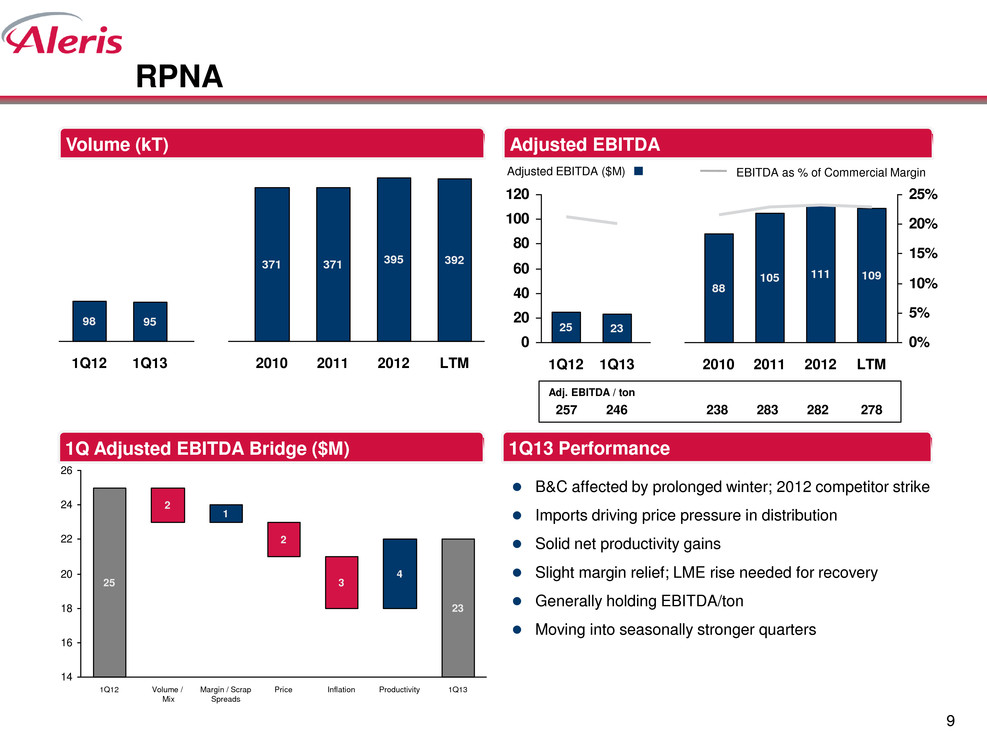

Adjusted EBITDA ($M) Volume (kT) Adjusted EBITDA 1Q13 Performance 14 16 18 20 22 24 26 1Q13 23 Productivity 4 Inflation 3 Price 2 Margin / Scrap Spreads 1 Volume / Mix 2 1Q12 25 1Q Adjusted EBITDA Bridge ($M) LTM 392 2012 395 2011 371 2010 371 1Q13 95 1Q12 98 EBITDA as % of Commercial Margin 0 20 40 60 80 100 120 0% 5% 10% 15% 20% 25% LTM 109 2012 111 2011 105 2010 88 1Q13 23 1Q12 25 RPNA B&C affected by prolonged winter; 2012 competitor strike Imports driving price pressure in distribution Solid net productivity gains Slight margin relief; LME rise needed for recovery Generally holding EBITDA/ton Moving into seasonally stronger quarters 9 Adj. EBITDA / ton 257 246 238 283 282 278

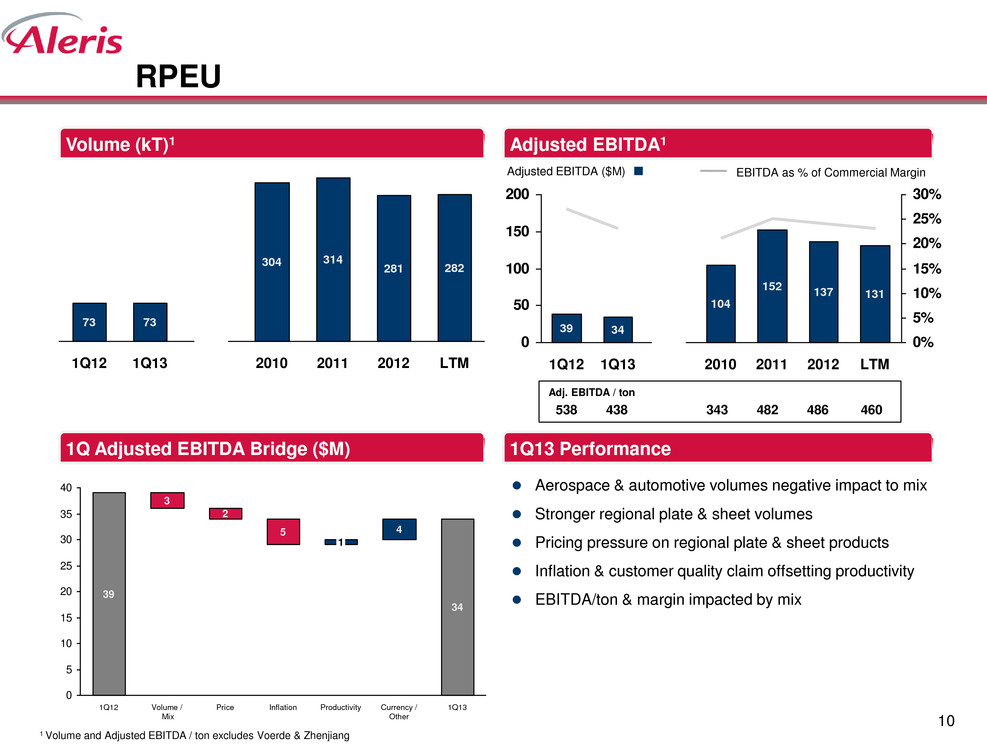

1Q Adjusted EBITDA Bridge ($M) 1 Volume and Adjusted EBITDA / ton excludes Voerde & Zhenjiang LTM 282 2012 281 2011 314 2010 304 1Q13 73 1Q12 73 0 50 100 150 200 0% 5% 10% 15% 20% 25% 30% LTM 131 2012 137 2011 152 2010 104 1Q13 34 1Q12 39 RPEU Adjusted EBITDA ($M) Volume (kT)1 Adjusted EBITDA1 1Q13 Performance Aerospace & automotive volumes negative impact to mix Stronger regional plate & sheet volumes Pricing pressure on regional plate & sheet products Inflation & customer quality claim offsetting productivity EBITDA/ton & margin impacted by mix 0 5 10 15 20 25 30 35 40 1Q13 34 Currency / Other 4 Productivity Volume / Mix 3 1Q12 39 1 Inflation 5 Price 2 10 Adj. EBITDA / ton 538 438 343 482 486 460 EBITDA as % of Commercial Margin

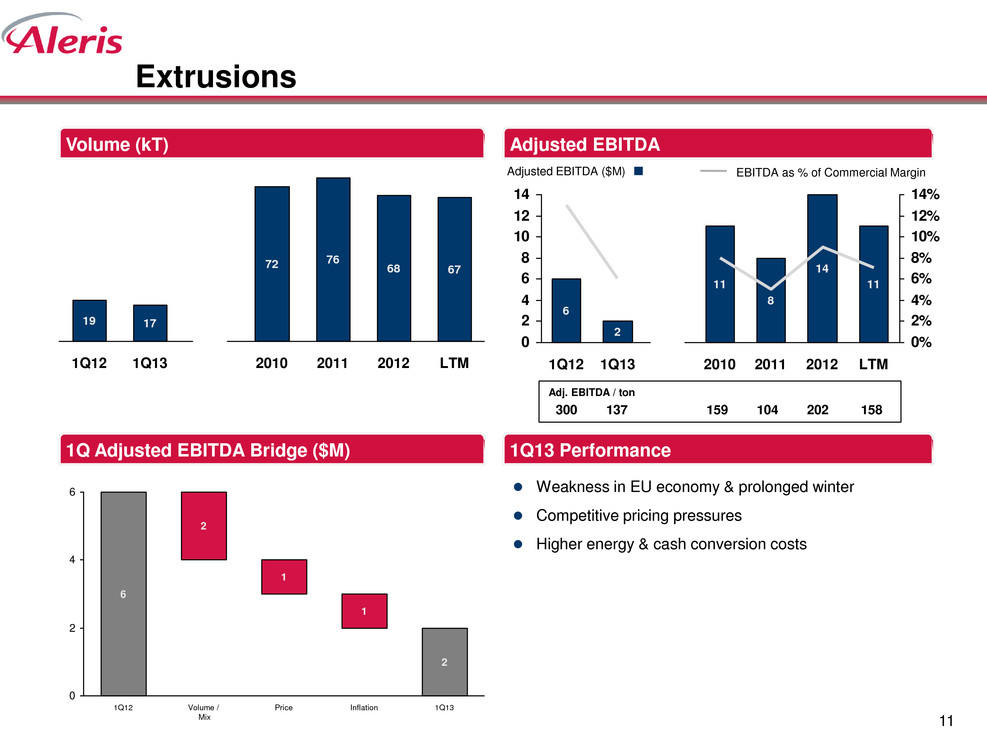

1Q Adjusted EBITDA Bridge ($M) LTM 67 2012 68 2011 76 2010 72 1Q13 17 1Q12 19 0 2 4 6 8 10 12 14 0% 2% 4% 6% 8% 10% 12% 14% LTM 11 2012 14 2011 8 2010 11 1Q13 2 1Q12 6 Extrusions Adjusted EBITDA ($M) Volume (kT) Adjusted EBITDA 1Q13 Performance Weakness in EU economy & prolonged winter Competitive pricing pressures Higher energy & cash conversion costs 0 2 4 6 1Q13 2 Inflation 1 Price 1 Volume / Mix 2 1Q12 6 11 Adj. EBITDA / ton 300 137 159 104 202 158 EBITDA as % of Commercial Margin

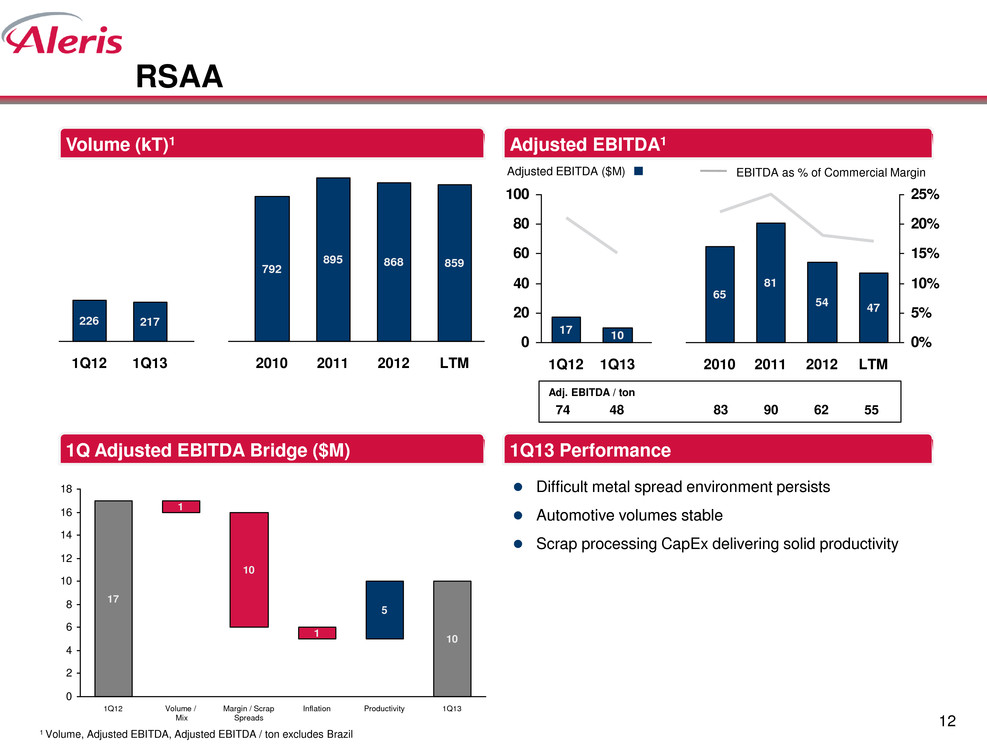

1Q Adjusted EBITDA Bridge ($M) LTM 859 2012 868 2011 895 2010 792 1Q13 217 1Q12 226 0 20 40 60 80 100 0% 5% 10% 15% 20% 25% LTM 47 2012 54 2011 81 2010 65 1Q13 10 1Q12 17 RSAA 12 Adjusted EBITDA ($M) Volume (kT)1 Adjusted EBITDA1 1Q13 Performance Difficult metal spread environment persists Automotive volumes stable Scrap processing CapEx delivering solid productivity 0 2 4 6 8 10 12 14 16 18 1Q13 10 Productivity 5 Inflation 1 Margin / Scrap Spreads 10 Volume / Mix 1 1Q12 17 1 Volume, Adjusted EBITDA, Adjusted EBITDA / ton excludes Brazil Adj. EBITDA / ton 74 48 83 90 62 55 EBITDA as % of Commercial Margin

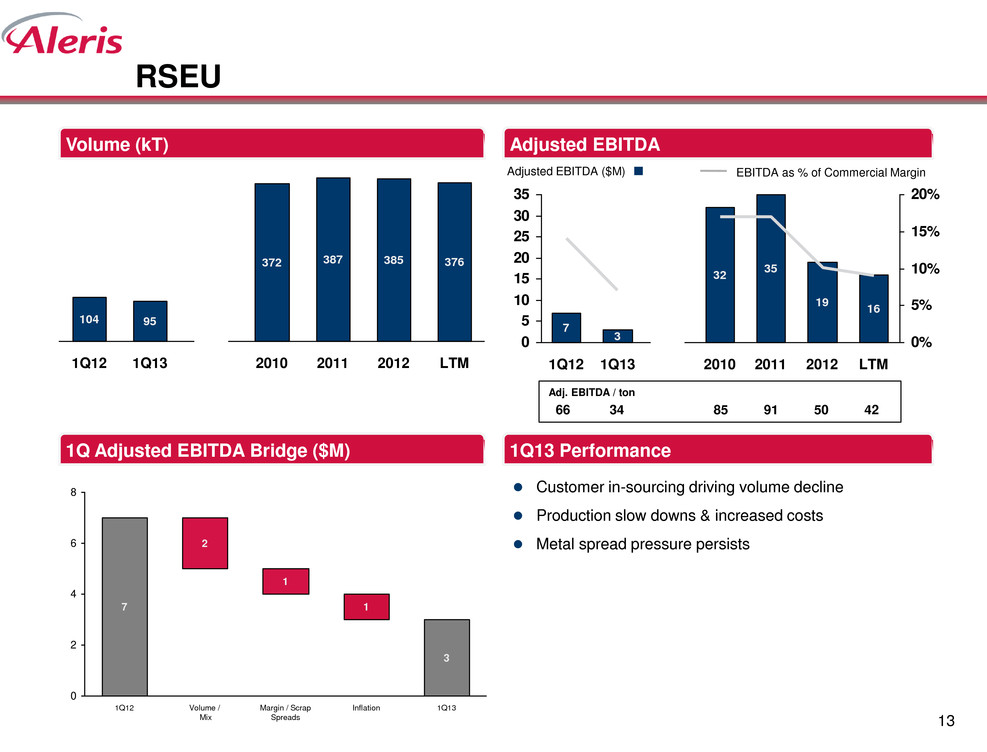

0 2 4 6 8 1Q13 3 Inflation 1 Margin / Scrap Spreads 1 Volume / Mix 2 1Q12 7 1Q Adjusted EBITDA Bridge ($M) LTM 376 2012 385 2011 387 2010 372 1Q13 95 1Q12 104 0 5 10 15 20 25 30 35 0% 5% 10% 15% 20% LTM 16 2012 19 2011 35 2010 32 1Q13 3 1Q12 7 RSEU Adjusted EBITDA ($M) Volume (kT) Adjusted EBITDA 1Q13 Performance Customer in-sourcing driving volume decline Production slow downs & increased costs Metal spread pressure persists 13 EBITDA as % of Commercial Margin Adj. EBITDA / ton 66 34 85 91 50 42

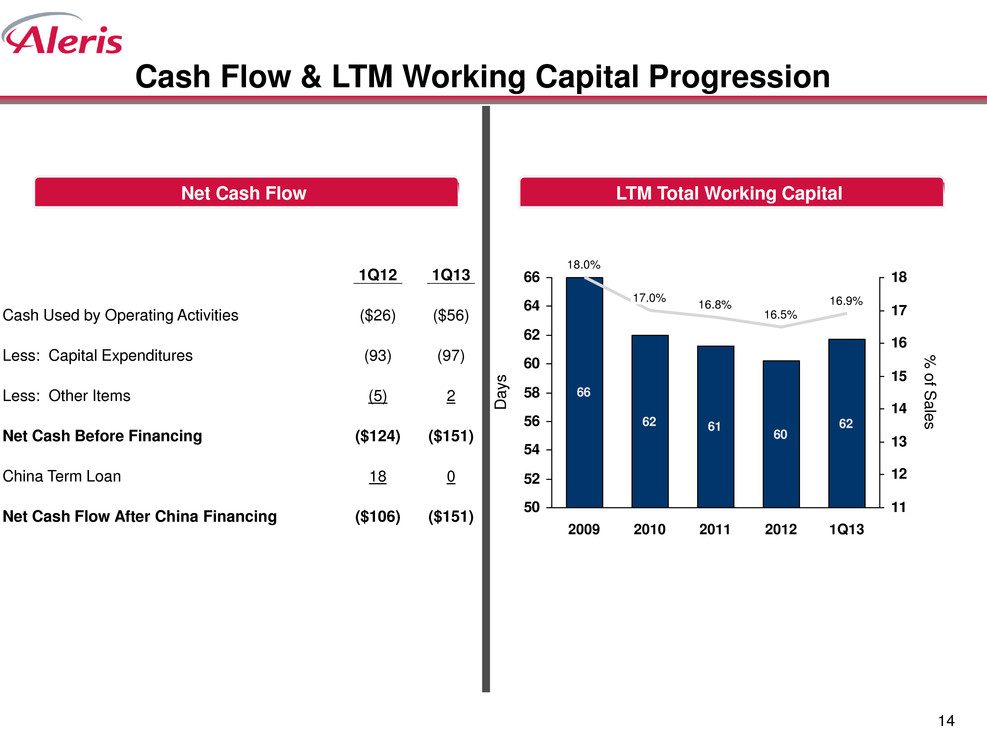

62 61 60 62 66 50 52 54 56 58 60 62 64 66 11 12 13 14 15 16 17 18 16.5% 2012 Da y s 2011 % o f S a le s 16.8% 2010 17.0% 2009 18.0% 16.9% 1Q13 Cash Flow & LTM Working Capital Progression Net Cash Flow LTM Total Working Capital 1Q12 1Q13 Cash Used by Operating Activities ($26) ($56) Less: Capital Expenditures (93) (97) Less: Other Items (5) 2 Net Cash Before Financing ($124) ($151) China Term Loan 18 0 Net Cash Flow After China Financing ($106) ($151) 14

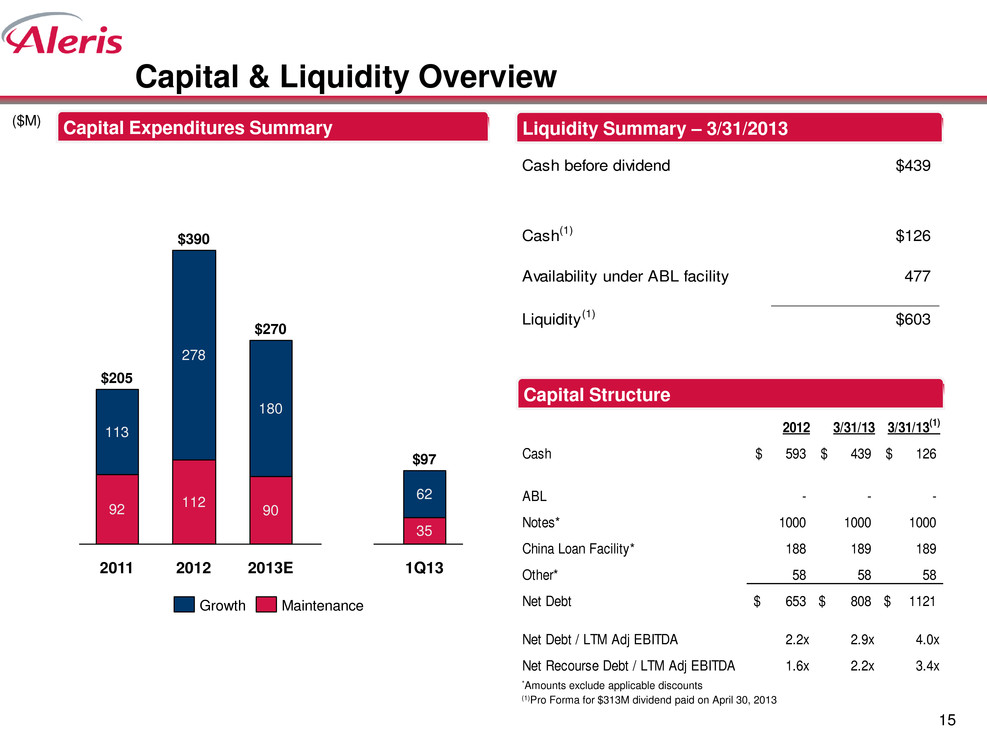

2012 3/31/13 3/31/13(1) Cash 593$ 439$ 126$ ABL - - - Notes* 1000 1000 1000 China Loan Facility* 188 189 189 Other* 58 58 58 Net Debt 653$ 808$ 1121$ Net Debt / LTM Adj EBITDA 2.2x 2.9x 4.0x Net Recourse Debt / LTM Adj EBITDA 1.6x 2.2x 3.4x Cash before dividend $439 Cash(1) $126 Availability under ABL facility 477 Liquidity(1) $603 Capital & Liquidity Overview Capital Structure Capital Expenditures Summary Liquidity Summary – 3/31/2013 ($M) $390 112 278 2011 $205 92 113 2012 180 90 $270 2013E 62 35 $97 1Q13 Growth Maintenance 15 *Amounts exclude applicable discounts (1)Pro Forma for $313M dividend paid on April 30, 2013

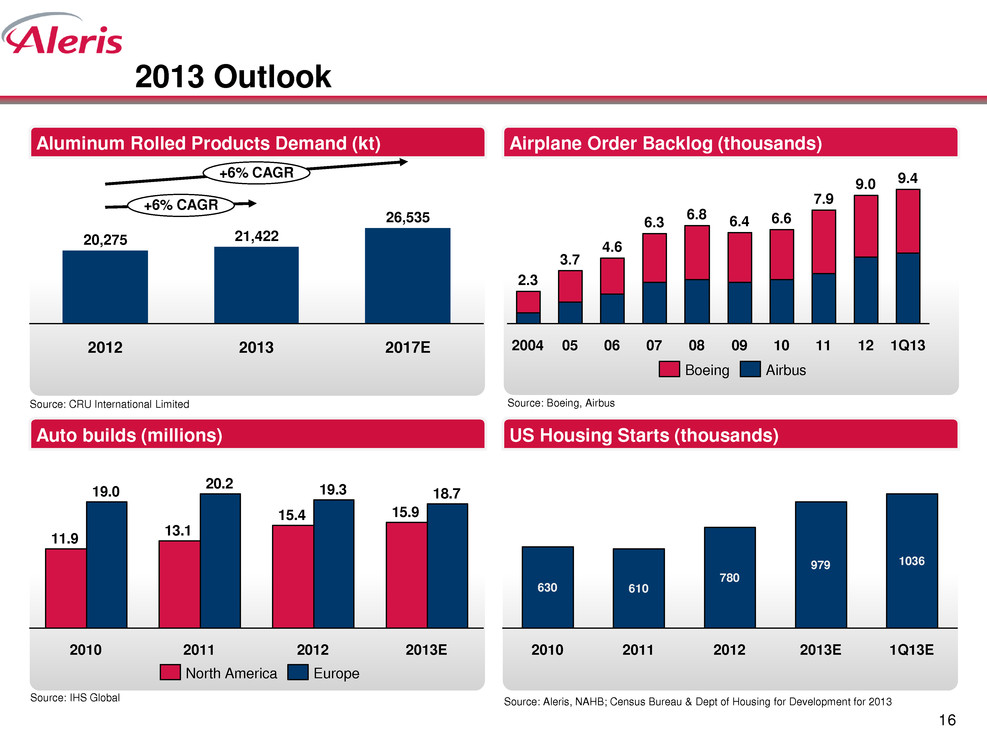

Aluminum Rolled Products Demand (kt) Airplane Order Backlog (thousands) Source: Boeing, Airbus Auto builds (millions) US Housing Starts (thousands) Source: IHS Global 2013 Outlook +6% CAGR +6% CAGR 2017E 26,535 2013 21,422 2012 20,275 1Q13 9.4 12 9.0 11 7.9 10 6.6 09 6.4 08 6.8 07 6.3 06 4.6 05 3.7 2004 2.3 Airbus Boeing Source: CRU International Limited Source: Aleris, NAHB; Census Bureau & Dept of Housing for Development for 2013 1Q13E 1036 2013E 979 2012 780 2011 610 2010 630 16 15.915.4 13.1 11.9 18.719.3 20.2 19.0 2013E 2012 2011 2010 Europe North America

Aerospace and automotive volumes expected to improve from 1Q13 levels Building and construction volumes expected to improve on seasonal ramp up Scrap spread and metal margin compression expected to continue Accelerating productivity and cost reduction Profitability benefits expected to be realized from strategic capital spending Solid sequential improvements, but below 2Q12 Adjusted EBITDA levels 2Q Outlook 17

18 Appendix

1Q 2012 & 2013 Adjusted EBITDA Reconciliation 19 March 31, 2013 March 31, 2012 Adjusted EBITDA 64.5$ 80.5$ Unrealized gains on derivative financial instruments 10.3 10.9 Impact of recording assets at fair value through fresh-start and purchase accounting - 0.3 Restructuring charges (0.9) - Currency exchange (losses) gains on debt (0.5) 1.7 Stock-based compensation expense (2.7) (2.6) Start-up expenses (11.4) (3.7) Favorable metal price lag 5.6 3.1 Other 0.5 (1.6) EBITDA 65.4 88.6 Interest expense, net (21.0) (11.7) Provision for income taxes (6.3) (9.8) Depreciation and amortization (27.2) (19.5) Net income attributable to Aleris Corporation 10.9 47.6 Net income attributable to noncontrolling interest 0.4 - Net income 11.3 47.6 Depreciation and amortization 27.2 19.5 Provision for deferred income taxes 1.0 3.2 Restructuring charges, net of payments (9.8) (1.8) Stock-based compensation expense 2.7 2.6 Unrealized gains on derivative financial instruments (10.3) (10.9) Currency exchange losses (gains) on debt 0.4 (1.7) Amortization of debt issuance costs 1.9 1.6 Other non-cash gains, net (2.1) (0.7) Change in operating assets and liabilities: Change in accounts receivable (105.5) (112.3) Change in inventories (14.1) (37.2) Change in other assets (12.0) 1.2 Change in accounts payable 52.2 100.7 Change in accrued liabilities 1.5 (38.0) Net cash used by operating activities (55.6)$ (26.2)$ (in millions) For the three months ended

1Q 2012 & 2013 Adjusted EBITDA Reconciliation by Segment 20 March 31, 2013 March 31, 2012 RPNA Segment income 23.5$ 26.1$ Favorable metal price lag (0.1) (1.0) Segment Adjusted EBITDA 23.4$ 25.1$ RPEU Segment income 38.5$ 41.1$ Impact of recording amounts at fair value through fresh-start and purchase accounting - (0.3) Favorable metal price lag (4.8) (1.7) Segment Adjusted EBITDA (1) 33.6$ 39.1$ RPAP Segment loss (0.3)$ -$ Segment Adjusted EBITDA (2) (0.3) - Extrusions Segment income 3.0$ 6.0$ Favorable metal price lag (0.6) (0.4) Segment Adjusted EBITDA 2.4$ 5.6$ RSAA Segment income 10.4$ 16.7$ Segment Adjusted EBITDA (2) 10.4 16.7 RSEU Segment income 3.3$ 6.8$ Segment Adjusted EBITDA (2) 3.3 6.8 (1) Amounts may not foot as they represent the calculated totals based on actual amounts and not the rounded amounts presented in this table. (2) There was no difference between segment income (loss) and segment Adjusted EBITDA for this segment. For the three months ended (in millions)

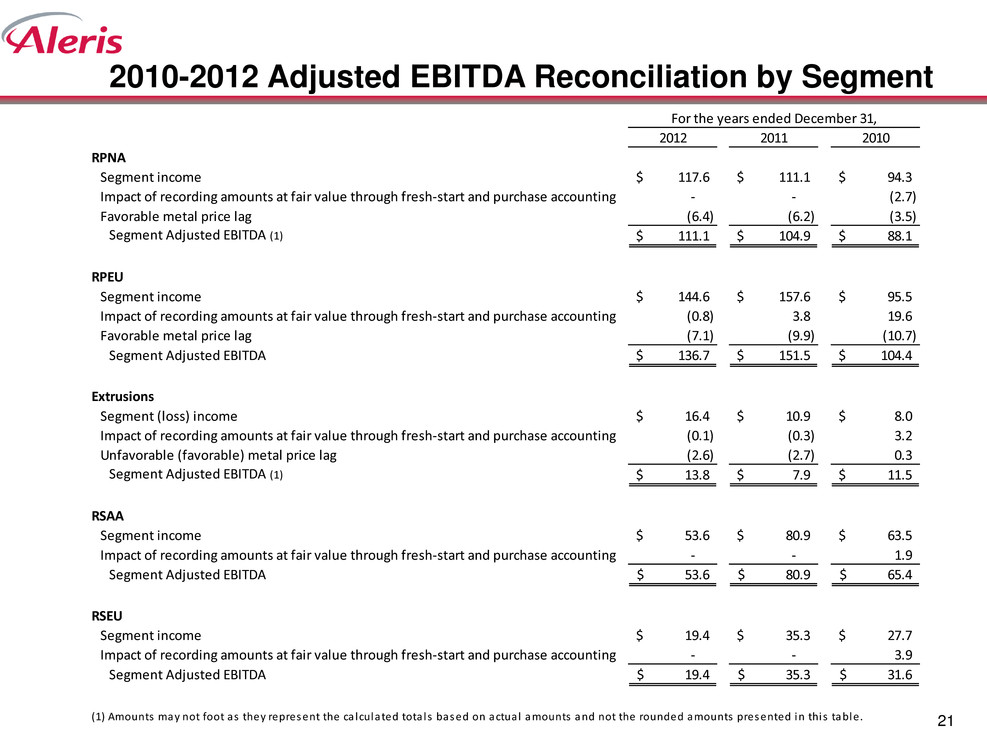

2010-2012 Adjusted EBITDA Reconciliation by Segment 21 2012 2011 2010 RPNA Segment income 117.6$ 111.1$ 94.3$ Impact of recording amounts at fair value through fresh-start and purchase accounting - - (2.7) Favorable metal price lag (6.4) (6.2) (3.5) Segment Adjusted EBITDA (1) 111.1$ 104.9$ 88.1$ RPEU Segment income 144.6$ 157.6$ 95.5$ Impact of recording amounts at fair value through fresh-start and purchase accounting (0.8) 3.8 19.6 Favorable metal price lag (7.1) (9.9) (10.7) Segment Adjusted EBITDA 136.7$ 151.5$ 104.4$ Extrusions Segment (loss) income 16.4$ 10.9$ 8.0$ Impact of recording amounts at fair value through fresh-start and purchase accounting (0.1) (0.3) 3.2 Unfavorable (favorable) metal price lag (2.6) (2.7) 0.3 Segment Adjusted EBITDA (1) 13.8$ 7.9$ 11.5$ RSAA Segment income 53.6$ 80.9$ 63.5$ Impact of recording amounts at fair value through fresh-start and purchase accounting - - 1.9 Segment Adjusted EBITDA 53.6$ 80.9$ 65.4$ RSEU Segment income 19.4$ 35.3$ 27.7$ Impact of recording amounts at fair value through fresh-start and purchase accounting - - 3.9 Segment Adjusted EBITDA 19.4$ 35.3$ 31.6$ (1) Amounts may not foot as they represent the ca lculated totals based on actual amounts and not the rounded amounts presented in this table. For the years ended December 31,