Attached files

| file | filename |

|---|---|

| EX-31.1 - EX-31.1 - PBF Holding Co LLC | d499682dex311.htm |

| EX-12.1 - EX-12.1 - PBF Holding Co LLC | d499682dex121.htm |

| EX-21.1 - EX-21.1 - PBF Holding Co LLC | d499682dex211.htm |

| EX-31.2 - EX-31.2 - PBF Holding Co LLC | d499682dex312.htm |

| EX-32.2 - EX-32.2 - PBF Holding Co LLC | d499682dex322.htm |

| EX-32.1 - EX-32.1 - PBF Holding Co LLC | d499682dex321.htm |

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2012

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file Number: 001-35764

PBF Holding Company LLC

PBF Finance Corporation

(Exact name of registrant as specified in its charter)

| Delaware Delaware |

27-2198168 45-2685067 | |

| (State or other jurisdiction of incorporation or organization) |

(I.R.S. Employer Identification No.) | |

| One Sylvan Way, Second Floor Parsippany, New Jersey |

07054 | |

| (Address of principal executive offices) | (Zip Code) | |

Registrants’ telephone number, including area code: (973) 455-7500

Securities registered pursuant to Section 12(b) of the Act: None.

Securities registered pursuant to Section 12(g) of the Act: None.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ¨ No x

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ¨ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer,” and “smaller reporting company” in Rule12b-2 of the Exchange Act.

| Large accelerated filer | ¨ | Accelerated filer | ¨ | |||

| Non-accelerated filer | x | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

Aggregate market value of PBF Holding Company LLC common membership interests held by non-affiliates: None

As of March 15, 2013, 100% of the outstanding membership interests in PBF Holding Company LLC were directly held by PBF Energy Company LLC., its sole member. None of the membership interests are publicly traded. PBF Finance Corporation is a wholly-owned subsidiary of PBF Holding Company LLC. PBF Holding Company LLC has no common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

PBF Energy Inc., the managing member of our direct parent PBF Energy Company LLC, intends to file with the Securities and Exchange Commission a definitive Proxy Statement for its Annual Meeting of Stockholders within 120 days after December 31, 2012. Portions of the Proxy Statement of PBF Energy Inc. are incorporated by reference in Part III of this Form 10-K to the extent stated herein.

Table of Contents

| PAGE | ||||||

| PART I | ||||||

| Item 1. | 1 | |||||

| Item 1A. | 17 | |||||

| Item 1B. | 33 | |||||

| Item 2. | 33 | |||||

| Item 3. | 33 | |||||

| Item 4. | 33 | |||||

| PART II | ||||||

| Item 5. | 34 | |||||

| Item 6. | 36 | |||||

| Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations |

40 | ||||

| Item 7A. | 66 | |||||

| Item 8. | 67 | |||||

| Item 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure |

67 | ||||

| Item 9A. | 68 | |||||

| Item 9B. | 68 | |||||

| PART III | ||||||

| Item 10. | 69 | |||||

| Item 11. | 71 | |||||

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

71 | ||||

| Item 13. | Certain Relationships and Related Transactions, and Director Independence |

71 | ||||

| Item 14. | 71 | |||||

| PART IV | ||||||

| Item 15. |

Exhibits and Financial Statement Schedules | 72 | ||||

Table of Contents

PART I

In this Annual Report on Form 10-K, unless the context otherwise requires, references to the “Company,” “we,” “our” or “us” refer to PBF Holding Company LLC (“PBF Holding”), and, in each case, unless the context otherwise requires, its consolidated subsidiaries. References to “subsidiary guarantors” refer to PBF Services Company LLC, PBF Power Marketing LLC, Paulsboro Natural Gas Pipeline Company LLC, Paulsboro Refining Company LLC (“Paulsboro Refining”), Toledo Refining Company LLC (“Toledo Refining”), Delaware City Refining Company LLC (“Delaware City Refining”), Delaware Pipeline Company LLC and PBF Investments LLC (“PBF Investments”), which are the subsidiaries of PBF Holding that guarantee the PBF Holding Senior Secured Notes (the “notes”) on a joint and several basis. References to “PBF Finance” refer to PBF Finance Corporation. References to “PBF LLC” refer to our direct parent, PBF Energy Company LLC, and to “PBF Energy” refer to our indirect parent, PBF Energy Inc., a Delaware corporation and the managing member of PBF LLC, which trades on the New York Stock Exchange under the symbol “PBF.” In this Annual Report on Form 10-K, we make certain forward-looking statements, including statements regarding our plans, strategies, objectives, expectations, intentions, and resources, under the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. You should read our forward-looking statements together with our disclosures under the heading: “Cautionary Statement for the Purpose of Safe Harbor Provisions of the Private Securities Litigation Reform Act of 1995.” When considering forward-looking statements, you should keep in mind the risk factors and other cautionary statements set forth in this Annual Report on Form 10-K under “Risk Factors” in Item 1A.

| ITEM 1. | BUSINESS |

Overview

We are one of the largest independent petroleum refiners and suppliers of unbranded transportation fuels, heating oil, petrochemical feedstocks, lubricants and other petroleum products in the United States. We sell our products throughout the Northeast and Midwest of the United States, as well as in other regions of the United States and Canada, and are able to ship products to other international destinations. We were formed in 2008 to pursue acquisitions of crude oil refineries and downstream assets in North America. We currently own and operate three domestic oil refineries and related assets, which we acquired in 2010 and 2011. Our refineries have a combined processing capacity, known as throughput, of approximately 540,000 bpd, and a weighted average Nelson Complexity Index of 11.3.

Our three refineries are located in Toledo, Ohio, Delaware City, Delaware and Paulsboro, New Jersey. Our Midcontinent refinery at Toledo processes light, sweet crude, has a throughput capacity of 170,000 bpd and a Nelson Complexity Index of 9.2. The majority of Toledo’s WTI based crude is delivered via pipelines that originate in both Canada and the United States. Since our acquisition of Toledo in 2011, we have added additional truck and rail crude unloading capabilities that provide feedstock sourcing flexibility for the refinery and enables Toledo to run a more cost-advantaged crude slate. Our East Coast refineries at Delaware City and Paulsboro have a combined refining capacity of 370,000 bpd and Nelson Complexity Indices of 11.3 and 13.2, respectively. These high conversion refineries process primarily medium and heavy, sour crudes and have historically received the bulk of their feedstock via ships and barges on the Delaware River. Importantly, in May 2012 we commenced crude shipments via rail into a newly developed crude rail unloading facility at our Delaware City refinery. Currently, crude delivered to this facility is consumed at our Delaware City refinery. In the future we plan to transport some of the crude delivered by rail from Delaware City via barge to our Paulsboro refinery. The Delaware City rail unloading facility allows our East Coast refineries to source WTI based crudes from Western Canada and the Midcontinent, which provides significant cost advantages versus traditional Brent based international crudes.

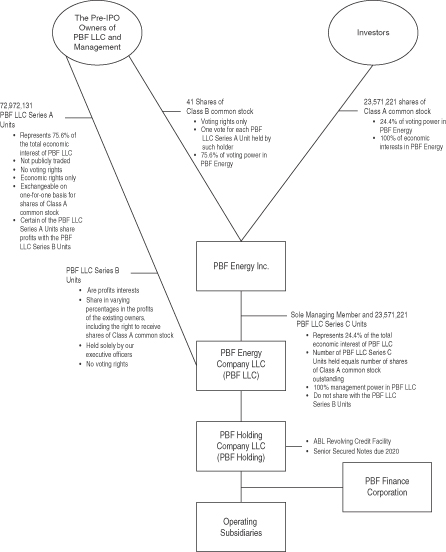

We are a Delaware limited liability company that is a holding company for our operating subsidiaries. We are a wholly-owned subsidiary of PBF LLC, PBF Energy is the sole managing member of, and owner of an equity interest representing approximately 24.4% of the outstanding economic interests in PBF LLC.

1

Table of Contents

Available Information.

Our website address is www.pbfenergy.com. Information contained on our website is not part of this Annual Report on Form 10-K. Our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and any other materials filed with (or furnished to) the Securities and Exchange Commission (SEC) by us are available on our website (under “Investors”) free of charge, soon after we file or furnish such material. In this same location, we also post our corporate governance guidelines, code of business conduct and ethics, and the charters of the committees of our board of directors. These documents are available free of charge in print to any person that makes a written request to the Secretary, PBF Holding Company LLC, One Sylvan Way, Second Floor, Parsippany, New Jersey 07054.

PBF Energy Inc.’s Initial Public Offering

On December 18, 2012 PBF Energy, our indirect parent, completed its initial public offering by issuing 23,567,686 shares of its Class A common stock at a price to the public of $26.00 per share. In connection with the offering, PBF Energy’s shares of Class A common stock began trading on the New York Stock Exchange under the symbol “PBF”. The proceeds to PBF Energy from the offering, before deducting underwriting discounts, were approximately $612.8 million of which PBF Energy used approximately $571.2 million to purchase 21,967,686 PBF LLC Series A Units from funds affiliated with The Blackstone Group L.P. (“Blackstone”) and First Reserve Management L.P. (“First Reserve”), as described in PBF Energy’s Prospectus, dated December 12, 2012, filed pursuant to Rule 424(b) of the Securities Act.

In connection with PBF Energy’s initial public offering, PBF Energy became the sole managing member of PBF LLC and operates and controls all of its business and affairs and consolidates the financial results of PBF LLC and its subsidiaries, including PBF Holding and PBF Finance. PBF LLC is a holding company for the companies that directly or indirectly own and operate our business. As of December 31, 2012, Blackstone and First Reserve, our financial sponsors, and our Executive Chairman, Thomas D. O’Malley, our other executive officers and directors and certain employees beneficially owned 75.6% of the total economic interest of PBF LLC through their ownership of 72,972,131 PBF LLC Series A Units (we refer to all of the holders of the PBF LLC Series A Units as “the pre-IPO owners of PBF LLC”) and PBF Energy owned 24.4% of the total economic interest of PBF LLC through its ownership of 23,571,221 PBF LLC Series C Units. Blackstone and First Reserve continue at the present time to control PBF Energy, which in turn, as the sole managing member of PBF LLC, controls PBF LLC and its subsidiaries, including PBF Holding and its consolidated subsidiaries.

See “Item 13. Certain Relationships and Related Transactions, and Director Independence.”

2

Table of Contents

Corporate Structure and Financial Sponsors

The diagram below depicts our organizational structure as of December 31, 2012:

Recent Developments

In May 2012 we commenced crude shipments via rail into a newly developed crude rail unloading facility at our Delaware City refinery. In February 2013, we completed a second crude unloading facility at the refinery that increased our rail crude unloading capacity at Delaware City from 40,000 barrels per day (“bpd”) to 110,000 bpd, comprised of 40,000 bpd of heavy crude oil and 70,000 bpd of light crude oil. The Delaware City rail unloading facility allows our East Coast refineries to source WTI based crudes from Western Canada and the Midcontinent, which provides significant cost advantages versus traditional Brent based international crudes. Also in February 2013, our board of directors approved a project to add an additional 40,000 bpd of heavy crude rail unloading capability at the refinery. The project is expected to cost approximately $50 million and to be completed in the fourth quarter of 2013. Completion of the project will increase our discharge capacity of heavy crude oil from 40,000 bpd to 80,000 bpd and bring the total rail crude unloading capability up to 150,000 bpd.

3

Table of Contents

During 2012 and January 2013, we entered into agreements to lease or purchase a total of 3,600 coiled and insulated rails cars, which are capable of transporting Canadian heavy crude oils, and 1,300 general purpose cars, which we intend to use to transport lighter crude oils.

In addition, we recently announced that the Toledo refinery experienced a drop in steam pressure on January 30, 2013, which was followed by a brief fire within the FCC complex. Emergency response personnel extinguished the fire and there were no injuries or known offsite impacts. Appropriate government agencies were contacted and a full investigation into the cause of the incident is underway. The FCC was the only unit involved and was temporarily shut down. The refinery resumed running at planned rates on February 18, 2013.

The board of directors of PBF Energy recently authorized the Company to continue its activities into establishing a MLP, including the formation of subsidiaries to hold MLP-qualifying assets. The Company has a number of energy-related logistical assets that qualify for an MLP structure. However, we continue to evaluate our strategic alternatives for these assets.

Refining Operations

We own and operate three refineries, all located in regions with currently favorable market dynamics where finished product demand exceeds operating refining capacity. We produce a variety of products at each of our refineries, including gasoline, ULSD, heating oil, jet fuel, lubricants, petrochemicals and asphalt. We sell our products throughout the Northeast and Midwest of the United States, as well as in other regions of the United States and Canada, and are able to ship products to other international destinations.

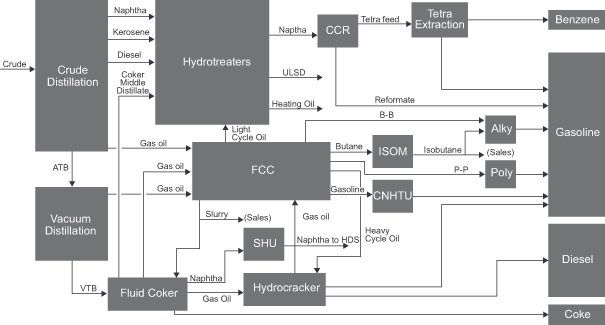

Delaware City Refinery

Acquisition and Re-Start. Through our subsidiaries, Delaware City Refining and Delaware Pipeline Company LLC, we acquired the idle Delaware City refinery and its related assets, including a petroleum product terminal, a petroleum products pipeline and an electric generation facility, on June 1, 2010 from affiliates of Valero for approximately $220.0 million in cash, consisting of approximately $170.0 million for the refinery, terminal and pipeline assets and $50.0 million for the power plant complex located on the property. We also incurred approximately $4.3 million in acquisition costs.

In the fourth quarter of 2009, due to, among other reasons, financial losses caused by one of the worst recessions in recent history, the prior owner shut down the Delaware City refinery. We believe we were therefore able to acquire the refinery at an attractive price. In addition, at the time of acquisition, we reached an agreement with the State of Delaware that provided for a five-year operating permit and up to approximately $45.0 million of economic support to re-start the facility, and negotiated a new long-term contract with the relevant union at the refinery. As of December 31, 2012, we had received $37.4 million in economic support from the State of Delaware under this agreement. We believe that the refinery’s ability to process lower quality crudes allows us to capture a higher margin as these lower quality crudes are typically priced at discounts to benchmark crudes, and to compete effectively in a region where product demand currently significantly exceeds refining capacity.

We restarted the Delaware City Refinery in October 2011. Since our acquisition through December 31, 2012, we have invested more than $500.0 million in turnaround and re-start projects at Delaware City, as well as in the recent strategic development of crude rail unloading facilities. In the first year of operations we have also modified the crude slate and product yield, changed operations of the conversion units, and re-started certain units in order to optimize the refinery. The re-start process included the decommissioning of the gasifier unit located on the property which allowed us to decrease emissions and improve the reliability of the refinery. We have also completed a cogeneration project to convert the electric generation units at the refinery to use natural gas as a fuel and a hydrocracker corrosion control project aimed at increasing the throughput of the hydrocracker. Through these capital investments and by restructuring certain operations, management estimates that we have lowered the annual operating expenses of the Delaware City refinery. In 2012, we commenced a project to

4

Table of Contents

expand and upgrade the existing on-site railroad infrastructure, including the expansion of the crude rail unloading facilities that was completed in February 2013 and is capable of discharging approximately 110,000 bpd. The project cost approximately $57.0 million, $49.7 million of which had been spent as of December 31, 2012. Also in February 2013, our board of directors approved a project to add an additional 40,000 bpd of heavy crude rail unloading capability at the refinery. Additionally, we continue to evaluate the development of a construction project consisting of a mild hydrocracker and hydrogen plant at the refinery. We estimate that the construction of the project, if commenced, could take approximately three years from commencement and if completed could process streams from both Delaware City and Paulsboro.

Overview. The Delaware City refinery is located on a 5,000-acre site, with access to waterborne cargoes and an extensive distribution network of pipelines, barges and tankers, truck and rail. Delaware City is a fully integrated operation that receives crude via rail at the crude unloading facility, or ship or barge at its docks located on the Delaware River. The crude and other feedstocks are transported, via pipes, to an extensive tank farm where they are stored until processing. In addition, there is a 17-bay, 50,000 bpd capacity truck loading rack located adjacent to the refinery and a 23-mile interstate pipeline that are used to distribute clean products.

The Delaware City refinery has a throughput capacity of 190,000 bpd and a Nelson Complexity Index of 11.3. As a result of its configuration and process units, Delaware City has the capability of processing a heavy slate of crudes with a high concentration of high sulfur crudes and is one of the largest and most complex refineries on the East Coast. The Delaware City refinery is one of two heavy coking refineries, in addition to Paulsboro, on the East Coast of the United States with coking capacity equal to approximately 25% of crude capacity.

The Delaware City refinery processes a variety of medium to heavy, sour crude oils. The refinery has large conversion capacity with its 82,000 bpd FCC unit, 47,000 bpd FCU and 18,000 bpd hydrocracking unit with vacuum distillation. Hydrogen is provided via the refinery’s steam methane reformer and continuous catalytic reformer.

Delaware City Process Flow Diagram

5

Table of Contents

The following table approximates the Delaware City refinery’s major process unit capacities. Unit capacities are shown in barrels per stream day.

| Refinery Units |

Nameplate Capacity |

|||

| Crude Distillation Unit |

190,000 | |||

| Vacuum Distillation Unit |

102,000 | |||

| Fluid Catalytic Cracking Unit (FCC) |

82,000 | |||

| Hydrotreating Units |

160,000 | |||

| Hydrocracking Unit |

18,000 | |||

| Catalytic Reforming Unit (CCR) |

43,000 | |||

| Benzene / Toluene Extraction Unit |

15,000 | |||

| Butane Isomerization Unit (ISOM) |

6,000 | |||

| Alkylation Unit (Alky) |

11,000 | |||

| Polymerization Unit (Poly) |

16,000 | |||

| Fluid Coking Unit (Fluid Coker) |

47,000 | |||

Feedstocks and Supply Arrangements. In April 2011, we entered into a crude and feedstock supply agreement with Statoil that expires in December 31, 2015. Pursuant to the agreement as amended in October 2012, we direct Statoil to purchase waterborne crude and other feedstocks for Delaware City and Statoil purchases these products on the spot market or through term agreements. Accordingly, Statoil enters into, on our behalf, hedging arrangements to protect against changes in prices between the time of purchase and the time of processing the feedstocks. In addition to procurement, for these waterborne deliveries Statoil arranges transportation and insurance for the crude and feedstock supply and we pay Statoil a per barrel fee for their procurement and logistics services. Statoil generally holds title to the waterborne crude and feedstocks until we run the crude or feedstocks through our process units. We pay Statoil on a daily basis for the corresponding volume of crude or feedstocks that are consumed in conjunction with the refining process. This crude supply and feedstock arrangement helps us reduce the amount of investment we are required to maintain in crude inventories and, as a result, helps us manage our working capital.

Product Offtake. We sell the bulk of Delaware City’s clean products to MSCG through our offtake agreement, which we have given notice to terminate effective June 30, 2013. Under the offtake agreement, MSCG purchases 100% of our finished clean products at Delaware City, which includes gasoline, heating oil and jet fuel, as well as our intermediates. Subsequent to termination of the offtake agreement, we intend to market and independently sell the products currently purchased by MSCG. The remainder of our products are sold to a variety of customers on the spot market or through term agreements.

Tankage Capacity. The Delaware City refinery has total storage capacity of approximately 10.0 million barrels. Of the total, 18 tanks with approximately 3.6 million barrels of storage capacity are dedicated to crude oil and other feedstock storage with the remaining approximately 6.4 million barrels allocated to finished products, intermediates and other products.

Energy and Other Utilities. Under normal operating conditions, the Delaware City refinery consumes approximately 55,000 MMBTU per day of natural gas. The Delaware City refinery has a 280 MW power plant located on-site that consists of two natural gas-fueled turbines with combined capacity of approximately 140 MW and four turbo-generators with combined nameplate capacity of approximately 140 MW. Collectively, this power plant produces electricity in excess of Delaware City’s refinery load of approximately 90 MW. Excess electricity is sold into the Pennsylvania-New Jersey-Maryland, or PJM, grid. Steam is primarily produced by a combination of three dedicated boilers and supplemented by secondary boilers at the FCC and coker.

6

Table of Contents

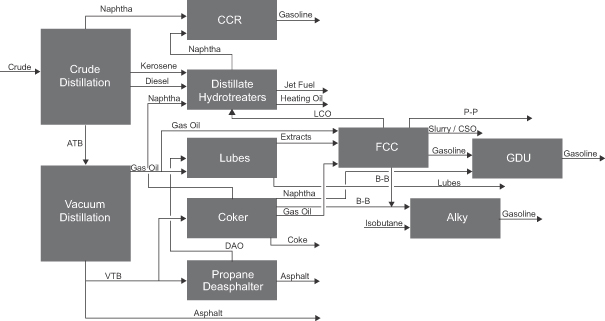

Paulsboro Refinery

Acquisition. We acquired the entities that owned the Paulsboro refinery (including an associated natural gas pipeline) on December 17, 2010, from Valero for approximately $357.7 million, excluding working capital. The purchase price excludes inventory purchased on our behalf by MSCG and Statoil. We invested approximately $60.0 million in capital in early 2011 to complete a scheduled turnaround at the refinery. The refinery was commissioned in 1917 and was purchased by Valero from Mobil Oil Corporation in 1998.

Overview. Paulsboro has a throughput capacity of 180,000 bpd and a Nelson Complexity Index of 13.2. The Paulsboro refinery is located on approximately 950 acres on the Delaware River in Paulsboro, New Jersey, just south of Philadelphia and approximately 30 miles away from Delaware City. Paulsboro receives crude and feedstocks via its marine terminal on the Delaware River. Paulsboro is one of two operating refineries on the East Coast with coking capacity, the other being Delaware City. Major units at the Paulsboro refinery include crude distillation units, vacuum distillation units, an FCC unit, a delayed coking unit, a lube oil processing unit and a propane deasphalting unit.

The Paulsboro refinery processes a variety of medium and heavy, sour crude oils. The Paulsboro refinery predominantly produces gasoline, heating oil and jet fuel and also manufactures Group I base oils or lubricants. In addition to its finished clean products slate, Paulsboro produces asphalt and petroleum coke.

Paulsboro Refinery Process Flow Diagram

7

Table of Contents

The following table approximates the Paulsboro refinery’s major process unit capacities. Unit capacities are shown in barrels per stream day.

| Refinery Units |

Nameplate Capacity |

|||

| Crude Distillation Units |

168,000 | |||

| Vacuum Distillation Units |

83,000 | |||

| Fluid Catalytic Cracking Unit (FCC) |

55,000 | |||

| Hydrotreating Units |

141,000 | |||

| Catalytic Reforming Unit (CCR) |

32,000 | |||

| Alkylation Unit (Alky) |

11,000 | |||

| Lube Oil Processing Unit |

12,000 | |||

| Delayed Coking Unit (Coker) |

27,000 | |||

| Propane Deasphalting Unit |

11,000 | |||

Feedstocks and Supply Arrangements. In December 2010, we entered into a crude and feedstock supply agreement with Statoil that will terminate effective March 31, 2013. Pursuant to the agreement, we direct Statoil to purchase crude and other feedstocks for Paulsboro and Statoil purchases these products on the spot market. Accordingly, Statoil enters into, on our behalf, hedging arrangements to protect against changes in prices between the time of purchase and the time of processing the feedstocks. In addition to procurement, Statoil generally arranges transportation and insurance for the crude and feedstock supply and we pay Statoil a per barrel fee for their procurement and logistics services. Statoil holds title to the crude and feedstocks until we run the crude or feedstocks through our process units. We pay Statoil on a daily basis for the corresponding volume of crude or feedstocks that are consumed in conjunction with the refining process.

In addition, separate from our agreement with Statoil we have a long-term contract with Saudi Aramco. We have been purchasing up to approximately 100,000 bpd of crude oil from Saudi Aramco that is processed at Paulsboro pursuant to this agreement and on a spot basis. The crude purchased is priced off ASCI.

Product Offtake. We sell the bulk of Paulsboro’s clean products to MSCG through our offtake agreement, which we have elected to terminate effective June 30, 2013. With the exception of certain jet fuel and lubricant sales, MSCG purchases 100% of our finished clean products and intermediates under the offtake agreement. Subsequent to termination of the offtake agreement, we intend to market and independently sell the products currently purchased by MSCG including under certain existing agreements with other customers that we will assume upon the MSCG termination. In addition to the finished products offtake agreement with MSCG, we sell the remaining products produced at Paulsboro to third parties under various long-term contracts and on the spot market.

Tankage Capacity. The Paulsboro refinery has total storage capacity of approximately 7.5 million barrels. Of the total, approximately 2.1 million barrels are dedicated to crude oil storage with the remaining 5.4 million barrels allocated to finished products, intermediates and other products.

Energy and Other Utilities. Under normal operating conditions, the Paulsboro refinery consumes approximately 30,000 MMBTU per day of natural gas. The Paulsboro refinery is virtually self-sufficient for its electrical power requirements. The refinery supplies approximately 90% of its 63 MW load through a combination of four generators with a nameplate capacity of 78 MW, in addition to a 30 MW gas turbine generator and two 15 MW steam turbine generators located at the Paulsboro utility plant. In the event that Paulsboro requires additional electricity to operate the refinery, supplemental power is available through a local utility. Paulsboro is connected to the grid via three separate 69 KV aerial feeders and has the ability to run entirely on imported power. Steam is primarily produced by three boilers, each with continuous rated capacity of 300,000-lb/hr at 900-psi. In addition, Paulsboro has a heat recovery steam generator and a number of waste heat boilers throughout the refinery that supplement the steam generation capacity. Paulsboro’s current hydrogen

8

Table of Contents

needs are met by the hydrogen supply from the reformer. In addition, the refinery employs a standalone steam methane reformer that is capable of producing 10 MMSCFD of 99% pure hydrogen. This ancillary hydrogen plant is utilized as a back-up source of hydrogen for the refinery’s process units.

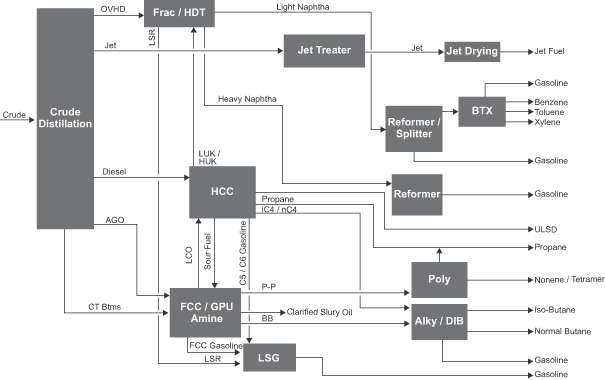

Toledo Refinery

Acquisition. Through our subsidiary, Toledo Refining, we acquired the Toledo refinery on March 1, 2011, from Sunoco for approximately $400.0 million, excluding working capital. We also purchased refined and certain intermediate products in inventory for approximately $299.6 million, and MSCG purchased the refinery’s crude oil inventory on our behalf. Additionally, included in the terms of the sale is a five-year participation payment of up to $125.0 million payable to Sunoco based upon post-acquisition earnings of the refinery, of which $103.6 million was paid in 2012. We currently anticipate paying the balance of the participation payment in April 2013.

Overview. Toledo has a throughput capacity of approximately 170,000 bpd and a Nelson Complexity Index of 9.2. Toledo processes a slate of light, sweet crudes from Canada, the Midcontinent, the Bakken region and the U.S. Gulf Coast. Toledo produces a high percentage of finished products including gasoline and ULSD, in addition to a variety of high-value petrochemicals including nonene, xylene, tetramer and toluene.

The Toledo refinery is located on a 282-acre site near Toledo, Ohio, approximately 60 miles from Detroit. Major units at the Toledo refinery include an FCC unit, a hydrocracker, an alkylation unit and a UDEX unit. Crude is delivered to the Toledo refinery through three primary pipelines: (1) Enbridge from the north, (2) Capline from the south and (3) Mid-Valley from the south. Crude is also delivered to a nearby terminal by rail and from local sources by truck to a truck unloading facility within the refinery.

Toledo Refinery Process Flow Diagram

9

Table of Contents

The following table approximates the Toledo refinery’s major process unit capacities. Unit capacities are shown in barrels per stream day.

| Refinery Units |

Nameplate Capacity |

|||

| Crude Distillation Unit |

170,000 | |||

| Fluid Catalytic Cracking Unit (FCC) |

79,000 | |||

| Hydrotreating Units |

95,000 | |||

| Hydrocracking Unit (HCC) |

45,000 | |||

| Catalytic Reforming Units |

45,000 | |||

| Alkylation Unit (Alky) |

10,000 | |||

| Polymerization Unit (Poly) |

7,000 | |||

| UDEX Unit (BTX) |

16,300 | |||

Feedstocks and Supply Arrangements. We have a short term crude oil acquisition agreement with MSCG pursuant to which we direct MSCG to purchase crude and other feedstocks for Toledo. MSCG purchases these products on the spot market. Accordingly, MSCG enters into, on our behalf, hedging arrangements to protect against changes in prices between the time of purchase and the time of processing the feedstocks. In addition to procurement, MSCG arranges transportation and insurance for the crude and feedstock supply and we pay MSCG a per barrel fee for their procurement and logistics services. We pay MSCG on a daily basis for the corresponding volume of crude or feedstocks two days after they are consumed in conjunction with the refining process. This arrangement helps us reduce the amount of investment we are required to maintain in crude inventories and, as a result, helps us manage our working capital.

Product Offtake. Toledo is connected, via pipelines, to an extensive distribution network throughout Ohio, Illinois, Indiana, Kentucky, Michigan, Pennsylvania and West Virginia. The finished products are transported on pipelines owned by Sunoco Logistics Partners L.P. and Buckeye Partners. In addition, we have proprietary connections to a variety of smaller pipelines and spurs that help us optimize our clean products distribution. A significant portion of Toledo’s gasoline and ULSD are distributed through the approximately 28 terminals in this network.

In March 2011, we entered into an agreement with Sunoco whereby Sunoco purchases gasoline and distillate products representing approximately one-third of the Toledo refinery’s gasoline and distillates production. The agreement has a three year term, subject to certain early termination rights. We sell the bulk of the petrochemicals produced at the Toledo refinery through short-term contracts or on the spot market and the majority of the petrochemical distribution is done via rail.

Tankage Capacity. The Toledo refinery has total storage capacity of approximately 4.0 million barrels. The Toledo refinery receives its crude through pipeline connections and a truck rack. Of the total, approximately 0.4 million barrels are dedicated to crude oil storage with the remaining 3.6 million barrels allocated to intermediates and products.

Energy and Other Utilities. Under normal operating conditions, the Toledo refinery consumes approximately 17,000 MMBTU per day of natural gas. The Toledo refinery purchases its electricity from a local utility and has a long-term contract to purchase hydrogen and steam from a local third party supplier. In addition to the third party steam supplier, Toledo consumes a portion of the steam that is generated by its various process units.

Customers

We sell a variety of refined products to a diverse customer base. We currently have product offtake agreements in place for a large portion of our clean product sales. For the year ended December 31, 2012, MSCG and Sunoco accounted for 57% and 10% of our revenues, respectively. The remainder of our refined products are primarily sold through short-term contracts or on the spot market.

10

Table of Contents

Seasonality

Demand for gasoline is generally higher during the summer months than during the winter months due to seasonal increases in highway traffic and construction work. Decreased demand during the winter months can lower gasoline prices. As a result, our operating results for the first and fourth calendar quarters may be lower than those for the second and third calendar quarters of each year.

Competition

The refining business is very competitive. We compete directly with various other refining companies both on the East and Gulf Coasts and in the Midcontinent, with integrated oil companies, with foreign refiners that import products into the United States and with producers and marketers in other industries supplying alternative forms of energy and fuels to satisfy the requirements of industrial, commercial and individual consumers. Some of our competitors have expanded the capacity of their refineries and internationally new refineries are coming on line which could also affect our competitive position.

Profitability in the refining industry depends largely on refined product margins, which can fluctuate significantly, as well as operating efficiency and reliability, product mix and costs of product distribution and transportation. Certain of our competitors that have larger and more complex refineries may be able to realize lower per-barrel costs or higher margins per barrel of throughput. Several of our principal competitors are integrated national or international oil companies that are larger and have substantially greater resources. Because of their integrated operations and larger capitalization, these companies may be more flexible in responding to volatile industry or market conditions, such as shortages of feedstocks or intense price fluctuations. Refining margins are frequently impacted by sharp changes in crude oil costs, which may not be immediately reflected in product prices.

The refining industry is highly competitive with respect to feedstock supply. Unlike certain of our competitors that have access to proprietary controlled sources of crude oil production available for use at their own refineries, we obtain substantially all of our crude oil and other feedstocks from unaffiliated sources. The availability and cost of crude oil is affected by global supply and demand. We have no crude oil reserves and are not engaged in the exploration or production of crude oil. We believe, however, that we will be able to obtain adequate crude oil and other feedstocks at generally competitive prices for the foreseeable future.

Corporate Offices

We lease approximately 53,000 square feet for our principal corporate offices in Parsippany, New Jersey. The lease for our principal corporate offices expires in 2016. Functions performed in the Parsippany office include overall corporate management, refinery and HSE management, planning and strategy, corporate finance, commercial operations, logistics, contract administration, marketing, investor relations, governmental affairs, accounting, tax, treasury, information technology, legal and human resources support functions.

Employees

As of December 31, 2012, we had approximately 1,612 employees. At Paulsboro, 295 of our 457 employees are covered by a collective bargaining agreement that expires in March 2015. In addition, 652 of our 994 employees at Delaware City and Toledo are covered by a collective bargaining agreement that expires in February of 2015. None of our corporate employees are covered by a collective bargaining agreement. We consider our relations with the represented employees to be satisfactory.

Environmental, Health and Safety Matters

Refinery and pipeline operations are subject to federal, state and local laws regulating the discharge of matter into the environment or otherwise relating to human health and safety or the protection of the

11

Table of Contents

environment. These laws regulate, among other things, the generation, storage, handling, use and transportation of petroleum and other regulated materials, the emission and discharge of materials into the environment, waste management, remediation of contaminated sites, characteristics and composition of gasoline and distillates and other matters otherwise relating to the protection of the environment. Permits are also required under these laws for the operation of our refineries, pipelines and related operations and these permits are subject to revocation, modification and renewal. Compliance with applicable environmental laws, regulations and permits will continue to have an impact on our operations, results of operations and capital requirements. We believe that our current operations are in substantial compliance with existing environmental laws, regulations and permits.

Our operations and many of the products we manufacture are subject to certain specific requirements of the CAA, and related state and local regulations. The CAA contains provisions that require capital expenditures for the installation of certain air pollution control devices at our refineries. Subsequent rule making authorized by the CAA or similar laws or new agency interpretations of existing rules, may necessitate additional expenditures in future years.

Additionally, as of January 1, 2011 we are required to meet an EPA regulation limiting the average sulfur content in gasoline to 30 PPM. The EPA has also announced that it plans to propose new “Tier 3” motor vehicle emission and fuel standards. It has been reported that these new Tier 3 regulations may, among other things, lower the maximum average sulfur content of gasoline from 30 PPM to 10 PPM. If the Tier 3 regulations are eventually implemented and lower the maximum allowable content of sulfur or other constituents in fuels that we produce, we may at some point in the future be required to make significant capital expenditures and/or incur materially increased operating costs to comply with the new standards. As of January 1, 2011, we are required to comply with the EPA’s Control of Hazardous Air Pollutants From Mobile Sources, or MSAT2, regulations on gasoline that impose reductions in the benzene content of our produced gasoline. We purchase benzene credits to meet these requirements. Our planned capital projects will reduce the amount of benzene credits that we need to purchase. In addition, the renewable fuel standards mandate the blending of prescribed percentages of renewable fuels (e.g., ethanol and biofuels) into our produced gasoline and diesel. These new requirements, other requirements of the CAA and other presently existing or future environmental regulations may cause us to make substantial capital expenditures as well as the purchase of credits at significant cost, to enable our refineries to produce products that meet applicable requirements.

Our operations are also subject to the federal Clean Water Act, or the CWA, the federal Safe Drinking Water Act, or the SDWA, and comparable state and local requirements. The CWA, the SDWA and analogous laws prohibit any discharge into surface waters, ground waters, injection wells and publicly-owned treatment works except in strict conformance with permits, such as pre-treatment permits and discharge permits, issued by federal, state and local governmental agencies. Federal waste-water discharge permits and analogous state waste-water discharge permits are valid for a maximum of five years and must be renewed.

We generate wastes that may be subject to the federal Resource Conservation and Recovery Act, or RCRA, and comparable state and local requirements. The EPA and various state agencies have limited the approved methods of disposal for certain hazardous and non-hazardous wastes.

The federal Comprehensive Environmental Response, Compensation and Liability Act of 1980, or CERCLA, also known as “Superfund,” imposes liability, without regard to fault or the legality of the original conduct, on certain classes of persons who are considered to be responsible for the release of a “hazardous substance” into the environment. These persons include the current or former owner or operator of the disposal site or sites where the release occurred and companies that disposed of or arranged for the disposal of the hazardous substances. Under CERCLA, such persons may be subject to joint and several liability for investigation and the costs of cleaning up the hazardous substances that have been released into the environment, for damages to natural resources and for the costs of certain health studies. As discussed more fully below, certain of our sites are subject to these laws and we may be held liable for investigation and remediation costs or claims for natural resource damages. It is not uncommon for neighboring landowners and other third parties to

12

Table of Contents

file claims for personal injury and property damage allegedly caused by hazardous substances or other pollutants released into the environment. Analogous state laws impose similar responsibilities and liabilities on responsible parties. In our current normal operations, we have generated waste, some of which falls within the statutory definition of a “hazardous substance” and some of which may have been disposed of at sites that may require cleanup under Superfund.

As is the case with all companies engaged in industries similar to ours, we face potential exposure to future claims and lawsuits involving environmental matters. These matters include soil and water contamination, air pollution, personal injury and property damage allegedly caused by substances which we manufactured, handled, used, released or disposed of.

Current and future environmental regulations are expected to require additional expenditures, including expenditures for investigation and remediation, which may be significant, at our refineries and at our other facilities. To the extent that future expenditures for these purposes are material and can be reasonably determined, these costs are disclosed and accrued.

Our operations are also subject to various laws and regulations relating to occupational health and safety. We maintain safety, training and maintenance programs as part of our ongoing efforts to ensure compliance with applicable laws and regulations. Compliance with applicable health and safety laws and regulations has required and continues to require substantial expenditures.

In connection with each of our acquisitions, we assumed certain environmental remediation obligations. In the case of Paulsboro, a trust fund established to meet state financial assurance requirements, in the amount of approximately $12.1 million, the estimated cost of the remediation obligations assumed based on investigation undertaken as of the acquisition date, was acquired as part of the acquisition. The short term portion of the trust fund and corresponding liability are recorded as restricted cash and accrued expenses, the long term portion is recorded in other assets and other long-term liabilities. In connection with the acquisition of Delaware City, the prior owners remain responsible subject to certain limitations, for certain environmental obligations including ongoing remediation of soil and groundwater contamination at the site. Further, in connection with the Delaware City and Paulsboro acquisitions, we purchased two individual ten-year, $75.0 million environmental insurance policies to insure against unknown environmental liabilities at each refinery. In connection with the acquisition of Toledo, the seller, subject to certain limitations, initially retains remediation obligations which will transition to us over a 20-year period. However, there can be no assurance that any available indemnity, trust fund or insurance will be sufficient to cover any ultimate environmental liabilities we may incur with respect to our refineries which could be significant.

We cannot predict what additional health, safety and environmental legislation or regulations will be enacted or become effective in the future or how existing or future laws or regulations will be administered or interpreted with respect to our operations. Compliance with more stringent laws or regulations or adverse changes in the interpretation of existing requirements or discovery of new information such as unknown contamination could have an adverse effect on the financial position and the results of our operations and could require substantial expenditures for the installation and operation of systems and equipment that we do not currently possess.

13

Table of Contents

GLOSSARY OF SELECTED TERMS

Unless otherwise noted or indicated by context, the following terms used in this Annual Report on Form 10-K have the following meanings:

“ASCI” refers to the Argus Sour Crude Index, a pricing index used to approximate market prices for sour, heavy crude oil.

“Bakken” refers to both a crude oil production region generally covering North Dakota, Montana and Western Canada, and the crude oil that is produced in that region.

“barrel” refers to a common unit of measure in the oil industry, which equates to 42 gallons.

“blendstocks” refers to various compounds that are combined with gasoline or diesel from the crude oil refining process to make finished gasoline and diesel; these may include natural gasoline, FCC unit gasoline, ethanol, reformate or butane, among others.

“bpd” refers to an abbreviation for barrels per day.

“CAPP” refers to the Canadian Association of Petroleum Producers.

“catalyst” refers to a substance that alters, accelerates, or instigates chemical changes, but is not produced as a product of the refining process.

“coke” refers to a coal-like substance that is produced from heavier crude oil fractions during the refining process.

“complexity” refers to the number, type and capacity of processing units at a refinery, measured by the Nelson Complexity Index, which is often used as a measure of a refinery’s ability to process lower quality crude in an economic manner.

“crack spread” refers to a simplified calculation that measures the difference between the price for light products and crude oil. For example, we reference (a) the 2-1-1 crack spread, which is a general industry standard that approximates the per barrel refining margin resulting from processing two barrels of crude oil to produce one barrel of gasoline and one barrel of heating oil or ULSD, and (b) the 4-3-1 crack spread, which is a benchmark utilized by our Toledo refinery that approximates the per barrel refining margin resulting from processing four barrels of crude oil to produce three barrels of gasoline and one-half barrel of jet fuel and one-half barrel of ULSD.

“Dated Brent” refers to Brent blend oil, a light, sweet North Sea crude oil, characterized by an API gravity of 38° and a sulfur content of approximately 0.4 weight percent that is used as a benchmark for other crude oils.

“distillates” refers primarily to diesel, heating oil, kerosene and jet fuel.

“downstream” refers to the downstream sector of the energy industry generally describing oil refineries, marketing and distribution companies that refine crude oil and sell and distribute refined products. The opposite of the downstream sector is the upstream sector, which refers to exploration and production companies that search for and/or produce crude oil and natural gas underground or through drilling or exploratory wells.

“EPA” refers to the United States Environmental Protection Agency.

“ethanol” refers to a clear, colorless, flammable oxygenated liquid. Ethanol is typically produced chemically from ethylene, or biologically from fermentation of various sugars from carbohydrates found in agricultural crops and cellulosic residues from crops or wood. It is used in the United States as a gasoline octane enhancer and oxygenate.

14

Table of Contents

“feedstocks” refers to crude oil and partially refined petroleum products that are processed and blended into refined products.

“FCC” refers to fluid catalytic cracking.

“FCU” refers to fluid coking unit.

“GHG” refers to greenhouse gas.

“Group I base oils or lubricants” refers to conventionally refined products characterized by a sulfur content less than 0.03% with a viscosity index between 80 and 120. Typically, these products are used in a variety of automotive and industrial applications.

“heavy crude oil” refers to a relatively inexpensive crude oil with a low API gravity characterized by high relative density and viscosity. Heavy crude oils require greater levels of processing to produce high value products such as gasoline and diesel.

“IPO” refers to the initial public offering of PBF Energy’s Class A common stock which closed on December 18, 2012.

“KV” refers to Kilovolts.

“light crude oil” refers to a relatively expensive crude oil with a high API gravity characterized by low relative density and viscosity. Light crude oils require lower levels of processing to produce high value products such as gasoline and diesel.

“light products” refers to the group of refined products with lower boiling temperatures, including gasoline and distillates.

“light-heavy differential” refers to the price difference between light crude oil and heavy crude oil.

“LPG” refers to liquefied petroleum gas.

“Maya” refers to Maya crude oil, a heavy, sour crude oil characterized by an API gravity of approximately 22° and a sulfur content of approximately 3.3 weight percent that is used as a benchmark for other heavy crude oils.

“MLP” refers to master limited partnership.

“MMbbls” refers to an abbreviation for million barrels.

“MMBTU” refers to million British thermal units.

“MMSCFD” refers to million standard cubic feet per day.

“MSCG” refers to Morgan Stanley Capital Group Inc.

“MW” refers to Megawatt.

“Nelson Complexity Index” refers to the complexity of an oil refinery as measured by the Nelson Complexity Index, which is calculated on an annual basis by the Oil and Gas Journal. The Nelson Complexity Index assigns a complexity factor to each major piece of refinery equipment based on its complexity and cost in

15

Table of Contents

comparison to crude distillation, which is assigned a complexity factor of 1.0. The complexity of each piece of refinery equipment is then calculated by multiplying its complexity factor by its throughput ratio as a percentage of crude distillation capacity. Adding up the complexity values assigned to each piece of equipment, including crude distillation, determines a refinery’s complexity on the Nelson Complexity Index. A refinery with a complexity of 10.0 on the Nelson Complexity Index is considered ten times more complex than crude distillation for the same amount of throughput.

“NYH” refers to the New York Harbor market value of petroleum products.

“Platts” refers to Platts, a division of The McGraw-Hill Companies.

“PPM” refers to parts per million.

“refined products” refers to petroleum products, such as gasoline, diesel and jet fuel, that are produced by a refinery.

“sour crude oil” refers to a crude oil that is relatively high in sulfur content, requiring additional processing to remove the sulfur. Sour crude oil is typically less expensive than sweet crude oil.

“Sunoco” refers to Sunoco, Inc. (R&M).

“sweet crude oil” refers to a crude oil that is relatively low in sulfur content, requiring less processing to remove the sulfur than sour crude oil. Sweet crude oil is typically more expensive than sour crude oil.

“Syncrude” refers to a blend of Canadian synthetic oil, a light, sweet crude oil, typically characterized by an API gravity between 30° and 32° and a sulfur content of approximately 0.1-0.2 weight percent.

“throughput” refers to the volume processed through a unit or refinery.

“turnaround” refers to a periodically required shutdown and comprehensive maintenance event to refurbish and maintain a refinery unit or units that involves the inspection of such units and occurs generally on a periodic cycle.

“ULSD” refers to ultra-low-sulfur diesel.

“WCS” refers to Western Canadian Select, a heavy, sour crude oil blend typically characterized by an API gravity between 20° and 22° and a sulfur content of approximately 3.5 weight percent that is used as a benchmark for heavy Western Canadian crude oil.

“WTI” refers to West Texas Intermediate crude oil, a light, sweet crude oil, typically characterized by an API gravity between 38° and 40° and a sulfur content of approximately 0.3 weight percent that is used as a benchmark for other crude oils.

“WTS” refers to West Texas Sour crude oil, a sour crude oil characterized by an API gravity between 30° and 33° and a sulfur content of approximately 1.28 weight percent that is used as a benchmark for other sour crude oils.

“yield” refers to the percentage of refined products that is produced from crude oil and other feedstocks.

16

Table of Contents

| ITEM 1A. RISK | FACTORS |

Risks Relating to Our Business and Industry

You should carefully read the risks and uncertainties described below. The risks and uncertainties described below are not the only ones facing our company. Additional risks and uncertainties may also impair our business operations. If any of the following risks actually occurs, our business, financial condition, results of operations or cash flows would likely suffer.

We have incurred losses in the past and may incur losses in the future. If we incur losses over an extended period of time, our business and operating results will be adversely affected.

We experienced losses during our time as a development company and certain periods thereafter. We may not be profitable in future periods. A lack of profitability could adversely affect our results of operations and financial condition. We may not continue to remain profitable, which could impair our ability to complete future financings and have a material adverse effect on our business.

Our limited operating history makes it difficult to evaluate our current business and future prospects. If we are unsuccessful in executing our business model, our business and operating results will be adversely affected.

We were formed in March 2008, we acquired our first oil refinery in June 2010 in an idle state and we acquired our first operating asset in December 2010. Therefore, we have a limited operating history and track record in executing our business model. Our future success depends on our ability to execute our business strategy effectively. Our limited operating history may make it difficult to evaluate our current business and future prospects. We may not be successful in operating any of our refineries or any other properties we may acquire in the future. In addition, we have encountered and will continue to encounter risks and difficulties frequently experienced by new companies, and specifically companies in the oil refining industry. If we do not manage these risks successfully, our business, results of operations and financial condition will be adversely affected.

The price volatility of crude oil, other feedstocks, blendstocks, refined products and fuel and utility services may have a material adverse effect on our revenues, profitability, cash flows and liquidity.

Our revenues, profitability, cash flows and liquidity from operations depend primarily on the margin above operating expenses (including the cost of refinery feedstocks, such as crude oil, intermediate partially refined petroleum products, and natural gas liquids that are processed and blended into refined products) at which we are able to sell refined products. Refining is primarily a margin-based business and, to increase profitability, it is important to maximize the yields of high value finished products while minimizing the costs of feedstock and operating expenses. When the margin between refined product prices and crude oil and other feedstock costs contracts, our earnings, profitability and cash flows are negatively affected. Refining margins historically have been volatile, and are likely to continue to be volatile, as a result of a variety of factors, including fluctuations in the prices of crude oil, other feedstocks, refined products and fuel and utility services. An increase or decrease in the price of crude oil will likely result in a similar increase or decrease in prices for refined products; however, there may be a time lag in the realization, or no such realization, of the similar increase or decrease in prices for refined products. The effect of changes in crude oil prices on our refining margins therefore depends in part on how quickly and how fully refined product prices adjust to reflect these changes.

In addition, the nature of our business requires us to maintain substantial crude oil, feedstock and refined product inventories. Because crude oil, feedstock and refined products are commodities, we have no control over the changing market value of these inventories. Our crude oil, feedstock and refined product inventories are valued at the lower of cost or market value under the last-in-first-out (“LIFO”) inventory valuation methodology. If the market value of our crude oil, feedstock and refined product inventories were to decline to an amount less than our LIFO cost, we would record a write-down of inventory and a non-cash charge to cost of sales.

17

Table of Contents

Prices of crude oil, other feedstocks, blendstocks, and refined products depend on numerous factors beyond our control, including the supply of and demand for crude oil, other feedstocks, gasoline, diesel, ethanol, asphalt and other refined products. Such supply and demand are affected by a variety of economic, market, environmental and political conditions.

Our direct operating expense structure also impacts our profitability. Our major direct operating expenses include employee and contract labor, maintenance and energy. Our predominant variable direct operating cost is energy, which is comprised primarily of fuel and other utility services. The volatility in costs of fuel, principally natural gas, and other utility services, principally electricity, used by our refineries and other operations affect our operating costs. Fuel and utility prices have been, and will continue to be, affected by factors outside our control, such as supply and demand for fuel and utility services in both local and regional markets. Natural gas prices have historically been volatile and, typically, electricity prices fluctuate with natural gas prices. Future increases in fuel and utility prices may have a negative effect on our revenues, profitability and cash flows.

Our historical financial statements may not be helpful in predicting our future performance.

We have grown rapidly since our inception and have not owned or operated our refineries for a substantial period of time. Accordingly, our historical financial information may not be useful either as a means of understanding our current financial situation or as an indicator of our future results. For the period from March 1, 2008 to December 16, 2010, we were considered to be in the development stage. Our historical financial information for that period reflects our activities principally in connection with identifying acquisition opportunities; acquiring the Delaware City refinery assets and commencing a reconfiguration of the refinery; and acquiring the Paulsboro refinery. As a result of the Paulsboro and Toledo acquisitions, our historical consolidated financial results include the results of operations for Paulsboro and Toledo from December 17, 2010 and March 1, 2011 forward, respectively. Certain information in our financial statements and certain other financial data included in this Annual Report on Form 10-K are based in part on financial data related to, and the operations of, those companies that previously owned and operated our refineries. For example, at the time of its acquisition, Paulsboro represented the major portion of our business and assets. As has been the case in our acquisitions to date, it is likely that, when we acquire refineries, we will not have access to the type of historical financial information that we will report regarding the prior operation of the refineries. As a result, it may be difficult for investors to evaluate the probable impact of major acquisitions on our financial performance until we have operated the acquired refineries for a substantial period of time.

Our profitability is affected by crude oil differentials, which fluctuate substantially.

A significant portion of our profitability is derived from the ability to purchase and process crude oil feedstocks that historically have been cheaper than benchmark crude oils, such as the heavy, sour crude oils processed at our Delaware City and Paulsboro refineries and the WTI based crude oils processed at our Toledo refinery. These crude oil differentials vary significantly from quarter to quarter depending on overall economic conditions and trends and conditions within the markets for crude oil and refined products. Any change in these crude oil differentials may have an impact on our earnings. Our rail investment and strategy to acquire cost advantaged Midcontinent and Canadian crude, which are priced based on WTI, could be adversely affected if the WTI-Brent differential narrows. For example, the WTI/WCS differential, a proxy for the difference between light U.S. and heavy Canadian crudes, has increased from $15.63 per barrel in 2011 to $21.80 per barrel for the year ended December 31, 2012, however, this increase may not be indicative of the differential going forward. Conversely, a narrowing of the light-heavy differential may reduce our refining margins and adversely affect our recent profitability and earnings. In addition, while our Toledo refinery benefits from a widening of the Dated Brent/WTI differential, a narrowing of this differential may result in our Toledo refinery losing a portion of its crude price advantage over certain of our competitors, which negatively impacts our profitability. Divergent views have been expressed as to the expected magnitude of changes to these crude differentials in future periods, including some analysts that expect these crude differentials to contract in upcoming periods. Any narrowing of these differentials could have a material adverse effect on our business and profitability.

18

Table of Contents

Our recent historical earnings have been concentrated and may continue to be concentrated in the future.

Our three refineries have similar throughput capacity, however, favorable market conditions due to, among other things, geographic location, crude and refined product slates, and customer demand, may cause an individual refinery to contribute more significantly to our earnings than others for a period of time. For example, our Toledo, Ohio refinery has produced a substantial portion of our earnings over the past several quarters. As a result, if there were a significant disruption to operations at this refinery, our earnings could be materially adversely affected (to the extent not recoverable through insurance) disproportionally to Toledo’s portion of our consolidated throughput. The Toledo refinery, or one of our other refineries, may continue to disproportionally affect our results of operations in the future. Any prolonged disruption to the operations of such refinery, whether due to labor difficulties, destruction of or damage to such facilities, severe weather conditions, interruption of utilities service or other reasons, could have a material adverse effect on our business, results of operations or financial condition.

A significant interruption or casualty loss at any of our refineries and related assets could reduce our production, particularly if not fully covered by our insurance. Failure by one or more insurers to honor its coverage commitments for an insured event could materially and adversely affect our future cash flows, operating results and financial condition.

Our business currently consists of owning and operating three refineries and related assets. As a result, our operations could be subject to significant interruption if any of our refineries were to experience a major accident, be damaged by severe weather or other natural disaster, or otherwise be forced to shut down or curtail production due to unforeseen events, such as acts of God, nature, orders of governmental authorities, supply chain disruptions impacting our crude rail facilities or other logistical assets, power outages, acts of terrorism, fires, toxic emissions and maritime hazards. Any such shutdown or disruption would reduce the production from that refinery. There is also risk of mechanical failure and equipment shutdowns both general and following unforeseen events. Further, in such situations, undamaged refinery processing units may be dependent on or interact with damaged sections of our refineries and, accordingly, are also subject to being shut down. In the event any of our refineries is forced to shut down for a significant period of time, it would have a material adverse effect on our earnings, our other results of operations and our financial condition as a whole.

As protection against these hazards, we maintain insurance coverage against some, but not all, such potential losses and liabilities. We may not be able to maintain or obtain insurance of the type and amount we desire at reasonable rates. As a result of market conditions, premiums and deductibles for certain of our insurance policies may increase substantially. In some instances, certain insurance could become unavailable or available only for reduced amounts of coverage. For example, coverage for hurricane damage can be limited, and coverage for terrorism risks can include broad exclusions. If we were to incur a significant liability for which we were not fully insured, it could have a material adverse effect on our financial position.

Our insurance program includes a number of insurance carriers. Significant disruptions in financial markets could lead to a deterioration in the financial condition of many financial institutions, including insurance companies and, therefore, we may not be able to obtain the full amount of our insurance coverage for insured events.

Our Toledo refinery is subject to interruptions of supply and distribution as a result of our reliance on pipelines for transportation of crude oil and refined products.

Our Toledo refinery receives a substantial portion of its crude oil and delivers a portion of its refined products through pipelines. The Enbridge system is our primary supply route for crude oil from Canada, the Bakken region and Michigan, and supplies approximately 55% to 60% of the crude oil used at our Toledo refinery. In addition, we source domestic crude oil through our connections to the Capline and Mid-Valley pipelines. We also distribute a portion of our transportation fuels through pipelines owned and operated by Sunoco Logistics Partners L.P. and Buckeye Partners L.P. We could experience an interruption of supply or delivery, or an increased cost of receiving crude oil and delivering refined products to market, if the ability of

19

Table of Contents

these pipelines to transport crude oil or refined products is disrupted because of accidents, weather interruptions, governmental regulation, terrorism, other third party action or any of the types of events described in the preceding risk factor.

In addition, due to the common carrier regulatory obligation applicable to interstate oil pipelines, capacity is prorated among shippers in accordance with the tariff then in effect in the event there are nominations in excess of capacity. Therefore, nominations by new shippers or increased nominations by existing shippers may reduce the capacity available to us. Any prolonged interruption in the operation or curtailment of available capacity of the pipelines that we rely upon for transportation of crude oil and refined products could have a further material adverse effect on our business, financial condition, results of operations and cash flows.

We may have capital needs for which our internally generated cash flows and other sources of liquidity may not be adequate.

If we cannot generate sufficient cash flows or otherwise secure sufficient liquidity to support our short-term and long-term capital requirements, we may not be able to meet our payment obligations (including any earn-outs), or our future debt obligations, comply with certain deadlines related to environmental regulations and standards, or pursue our business strategies, in which case our operations may not perform as we currently expect. We have substantial short-term capital needs and may have substantial long term capital needs. Our short-term working capital needs are primarily related to financing certain of our refined products inventory not covered by our various supply and products offtake agreements. We terminated our agreement with Statoil for our Paulsboro refinery effective March 31, 2013 and our MSCG Offtake Agreements for our Paulsboro and Delaware City refineries effective June 30, 2013. If we cannot adequately handle our crude oil and feedstock requirements without the benefit of the Statoil arrangement at Paulsboro, or if we are required to obtain our crude oil supply at our other refineries without the benefit of the existing supply arrangements or the applicable counterparty defaults in its obligations, our crude oil pricing costs may increase as the number of days between when we pay for the crude oil and when the crude oil is delivered to us increases. Further, if we are not able to market and sell our finished products to credit worthy customers without benefit of the MSCG Offtake Agreements, we may be subject to delays in the collection of our accounts receivable and exposure to additional credit risk. Such increased exposure could negatively impact our liquidity due to our increased working capital needs as a result of the increase in the amount of crude oil inventory and accounts receivable we would have to carry on our balance sheet. Our long-term needs for cash include those to support ongoing capital expenditures for equipment maintenance and upgrades during turnarounds at our refineries and to complete our routine and normally scheduled maintenance, regulatory and security expenditures. In addition, from time to time, we are required to spend significant amounts for repairs when one or more processing units experiences temporary shutdowns. We continue to utilize significant capital to upgrade equipment, improve facilities, and reduce operational, safety and environmental risks. In connection with the Paulsboro acquisition, we assumed certain significant environmental obligations, and may similarly do so in future acquisitions. We will likely incur substantial compliance costs in connection with new or changing environmental, health and safety regulations. See “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations.” Our liquidity will affect our ability to satisfy any of these needs or obligations.

We are a holding company that depends upon cash from our subsidiaries to meet our obligations.

We are a holding company and all of our operations are conducted through our subsidiaries. We have no independent means of generating revenue other than through assets owned by our subsidiaries. Therefore, we depend on the earnings and cash flow of our subsidiaries to meet our obligations, including our indebtedness. If we do not receive such cash distributions, dividends or other payments from our subsidiaries, we may be unable to meet our obligations. To the extent we need funds and any of our subsidiaries is restricted from making such distributions under applicable law or regulation or under the terms of our financing or other contractual arrangements, or is otherwise unable to provide such funds, such restrictions could materially adversely affect our liquidity and financial condition. Our ABL Revolving Credit Facility, the notes and certain of our other outstanding debt arrangements include a restricted payment covenant, which restricts our

20

Table of Contents

ability to make distributions, and we anticipate our future debt will contain a similar restriction. In addition, there may be restrictions on payments by our subsidiaries under applicable laws, including laws that require companies to maintain minimum amounts of capital and to make payments to stockholders only from profits. We are generally prohibited under Delaware law from making a distribution to a member to the extent that, at the time of the distribution, after giving effect to the distribution, liabilities of the limited liability company (with certain exceptions) exceed the fair value of its assets.

We may not be able to obtain funding on acceptable terms or at all because of volatility and uncertainty in the credit and capital markets. This may hinder or prevent us from meeting our future capital needs.