Attached files

| file | filename |

|---|---|

| 8-K - 8-K - TRINITY INDUSTRIES INC | trn8kinvestorpresentationq.htm |

Trinity Industries, Inc. March 2013 Exhibit 99.1

2 Forward Looking Statements This presentation contains “forward looking statements” as defined by the Private Securities Litigation Reform Act of 1995 and includes statements as to expectations, beliefs and future financial performance, or assumptions underlying or concerning matters herein. These statements that are not historical facts are forward looking. Readers are directed to Trinity’s Form 10-K and other SEC filings for a description of certain of the business issues and risks, a change in any of which could cause actual results or outcomes to differ materially from those expressed in the forward looking statements. Any forward looking statement speaks only as of the date on which such statement is made. Trinity undertakes no obligation to update any forward looking statement or statements to reflect events or circumstances after the date on which such statement is made.

3 Agenda I. Overview II. Key Investment Considerations III. Strategy and Vision IV. Financial Highlights V. Appendix

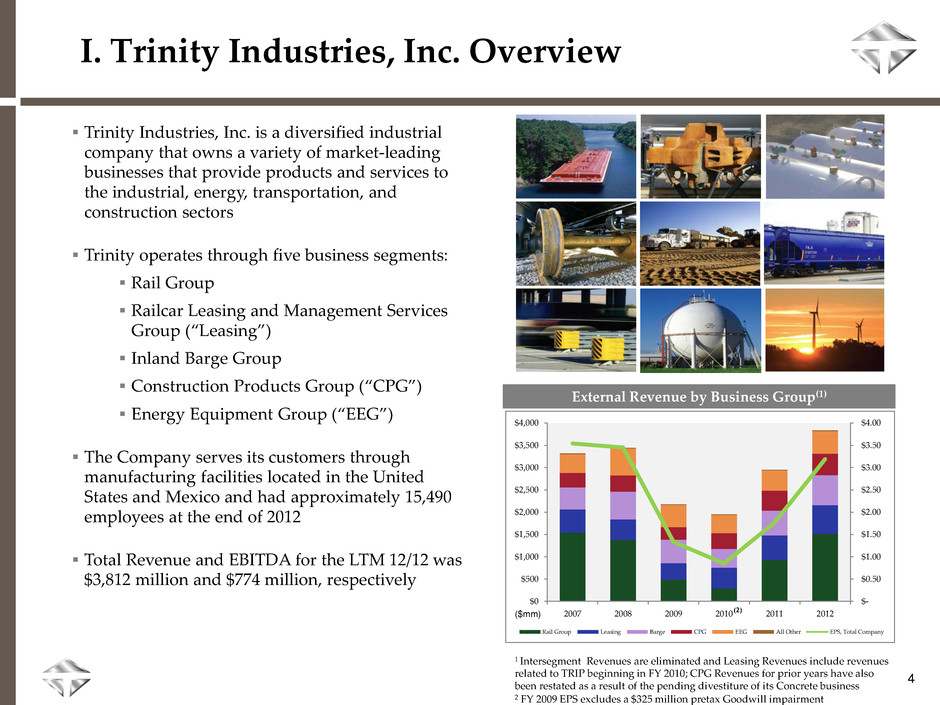

$- $0.50 $1.00 $1.50 $2.00 $2.50 $3.00 $3.50 $4.00 $0 $500 $1,000 $1,500 $2,000 $2,500 $3,000 $3,500 $4,000 2007 2008 2009 2010 2011 2012 Rail Group Leasing Barge CPG EEG All Other EPS, Total Company I. Trinity Industries, Inc. Overview 4 Trinity Industries, Inc. is a diversified industrial company that owns a variety of market-leading businesses that provide products and services to the industrial, energy, transportation, and construction sectors Trinity operates through five business segments: Rail Group Railcar Leasing and Management Services Group (“Leasing”) Inland Barge Group Construction Products Group (“CPG”) Energy Equipment Group (“EEG”) The Company serves its customers through manufacturing facilities located in the United States and Mexico and had approximately 15,490 employees at the end of 2012 Total Revenue and EBITDA for the LTM 12/12 was $3,812 million and $774 million, respectively External Revenue by Business Group(1) 1 Intersegment Revenues are eliminated and Leasing Revenues include revenues related to TRIP beginning in FY 2010; CPG Revenues for prior years have also been restated as a result of the pending divestiture of its Concrete business 2 FY 2009 EPS excludes a $325 million pretax Goodwill impairment ($mm) (2)

II. Key Investment Considerations 5 Leading Market Positions Diversified Portfolio of Businesses Flexible and Cost-Effective Manufacturing Seasoned Performers Enrichment Value Focused

Leading Market Positions 6 Rail Group Leading manufacturer of railcars in North America Leading manufacturer of railcar axles in North America Leading manufacturer of railcar coupling devices in North America Railcar Leasing and Management Services Group Leading provider of railcar leasing and management services Inland Barge Group Leading manufacturer of inland barges in the United States Largest manufacturer of fiberglass covers for barges in the United States Construction Products Group Leading full-line manufacturer of highway guardrail and crash cushions in the United States Leading producer and distributor of aggregates in several regions of Texas with smaller operations in Arkansas and Louisiana Energy Equipment Group Leading manufacturer of structural wind towers in North America Leading producer of containers and tank heads for pressure and non-pressure vessels in North America

Diversified Portfolio of Businesses 7 PRESENT (FY 2012) MEASUREABLE PROGRESS OVER LAST 10 YEARS Total Revenues = $3.8 B Revenues Operating Profit(1) Our diversified portfolio of businesses generated a higher level of EPS on a similar level of deliveries during the last cyclical rail industry downturn (1) Operating Profit Excludes All Other, Corporate and is reduced by Leasing Interest Expense of $174 million in FY 2012 (2) Rail percentage represents Operating Profit less all Intersegment Company Eliminations; Leasing percentage represents Operating Profit less Leasing Interest Expense (3) FY 2009 EPS excludes a $325 million pretax Goodwill impairment 32% 27% 10% 4% 27% Rail Leasing CPG EEG Barge 40% 17% 12% 13% 18% (2) (2) Revenues ( ) 0 5,000 10,000 15,000 20,000 25,000 30,000 -$0.50 $0.00 $0.50 $1.00 $1.50 $2.00 $2.50 $3.00 $3.50 $4.00 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 Calendar Year EPS vs. Railcar Deliveries EPS, Total Company Railcar Deliveries$ (3) Units

Flexible and Cost-Effective Manufacturing 8 Flexibility Cost-Effective Trinity's manufacturing flexibility across product and business segments enhances our ability to opportunistically respond to changes in market demand Trinity’s manufacturing scale, vertical integration, and presence in the Southern U.S. and Mexico provides cost effective benefits across multiple business segments

Enrichment Value Focused 9 E x te rn a l R e p o rti n g G ro u p s O p e ra tio n a l Foc u s A re a s Rail Leasing Construction Energy Inland Barge Customer Sharing Internal Component Sourcing Shared Best Manufacturing Practices Facility Optimization Centralized Cost Savings Trinity focuses on collaboration across business segments… …generating synergies that enrich value and ultimately provide competitive benefits

10 Seasoned Performer Across Economic Cycles Trinity is uniquely positioned to emerge from a severe down cycle with more opportunity for growth to generate significant profits during an up cycle Seasoned management team knows how to assess the market, proactively plan for cycles and address changes in economic conditions Manufacturing flexibility is a core competency, and when combined with our broad product offering allows us to pursue a wide range of orders Cost-effective manufacturing footprint in the Southern United States and Mexico is a competitive advantage for many of our product lines Shared synergies across business lines provide unique opportunities Trinity’s lease fleet of 71,455 railcars (including TRIP) provides a strong strategic connection to our customers, as well as a consistent long-term stream of profit and cash flow Strong liquidity position of more than $1.2 billion and solid balance sheet

III. Strategy and Vision: Operational 11 Strategically Grow the Lease Fleet Maximize Manufacturing Efficiency Selectively Build our Backlogs Diversify Through Organic Growth Acquire Complementary Product Portfolios Be a premier, diversified industrial company that generates superior earnings and returns for shareholders

Liquidity (at 12/31/12): ~ $1,231 mm Strategy and Vision: Financial 12 Maintain a conservative and liquid balance sheet to be attractively positioned to capitalize on opportunities Working Capital Capital Expenditures Acquisitions Shareholder Distributions Corporate Debt(1) - Convertible Subordinated Notes - $450 mm Leasing Debt(2) – Recourse Debt: Capital lease obligations/Term loan - $94 mm Non-recourse Debt: TILC Warehouse borrowings - $174 mm TILC Long-term financings - $1,564 mm TRIP Long-term financings - $859 mm (1) Excludes $87.5mm of unamortized discount related to Company’s convertible debt (2) Total leasing financings of $2.7 billion, including TRIP; Leasing assets have a net book value of $4.3 billion, including TRIP, which leaves a significant amount of unencumbered assets available for financing Cash and Cash Equivalents - $573 mm Corporate Revolver Availability - $356 mm TILC Warehouse Availability - $301 mm Balance Sheet Debt (at 12/31/12): ~ $3,055 mm(1) Equity (at 12/31/12): ~ $2,138 mm

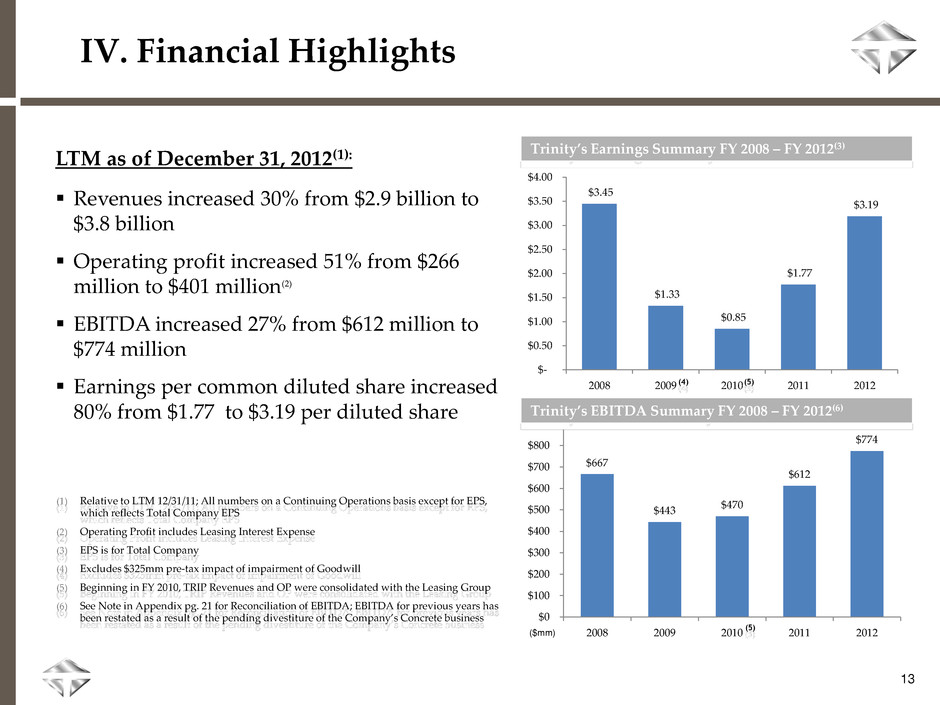

$3.45 $1.33 $0.85 $1.77 $3.19 $- $0.50 $1.00 $1.50 $2.00 $2.50 $3.00 $3.50 $4.00 2008 2009 2010 2011 2012 $667 $443 $470 $612 $774 $0 $100 $200 $300 $400 $500 $60 $700 $800 $900 2008 2009 2010 2011 2012 13 IV. Financial Highlights Trinity’s Earnings Summary FY 2008 – FY 2012(3) LTM as of December 31, 2012(1): Revenues increased 30% from $2.9 billion to $3.8 billion Operating profit increased 51% from $266 million to $401 million(2) EBITDA increased 27% from $612 million to $774 million Earnings per common diluted share increased 80% from $1.77 to $3.19 per diluted share Trinity’s EBITDA Summary FY 2008 – FY 2012(6) ($mm) (1) Relative to LTM 12/31/11; All numbers on a Continuing Operations basis except for EPS, which reflects Total Company EPS (2) Operating Profit includes Leasing Interest Expense (3) EPS is for Total Company (4) Excludes $325mm pre-tax impact of impairment of Goodwill (5) Beginning in FY 2010, TRIP Revenues and OP were consolidated with the Leasing Group (6) See Note in Appendix pg. 21 for Reconciliation of EBITDA; EBITDA for previous years has been restated as a result of the pending divestiture of the Company’s Concrete business (5) (5) (4)

Guidance and Outlook (As of February 21, 2013) 14 Rail Group Revenues ~ $2.4 – 2.6 billion in FY 2013 OP Margin ~ 14 - 16% in FY 2013 Shipments ~ 20,500 – 22,000 in FY 2013 Leasing Group Revenues from Operations ~ $550 – 580mm in FY 2013 OP from Operations ~ $250 - 275mm in FY 2013 Revenue Eliminations ~ $650 - 700mm in FY 2013 EPS Elimination Impact ~ $1.00 - 1.20 in FY 2013 Railcar Sales from Lease Fleet EPS Impact ~ $0.20 - 0.25 in FY 2013 Net Lease Fleet Additions ~ $350 – 400mm in FY 2013 Inland Barge Group Revenues ~ $550 - 580mm in FY 2013 OP Margin ~ 14 - 16% in FY 2013 Construction Products Group Revenues ~ $515 - 550mm in FY 2013 OP Margin ~ 10 - 12% in FY 2013 Energy Equipment Group Revenues ~ $510 - 540mm in FY 2013 OP Margin ~ 8 - 10% in FY 2013 Total Company EPS ~ $0.75 – 0.82 in Q1 2013 EPS ~ $3.45 - 3.75 in FY 2013 Manufacturing and Corporate Capital Expenditures ~ $160 - 195mm in FY 2013 Any forward-looking statements made by the Company speak only as of the date on which they are made. The Company is under no obligation to, and expressly disclaims any obligation to, update or alter its forward-looking statements, whether as a result of new information, subsequent events or otherwise.

Appendix: Operating Business Summaries

0 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 Railcar Deliveries (1958 - 2017P) Projections based on Third Party estimates(1) $2,382 $2,563 $895 $522 $1,275 $2,013 -4.0% 0.0% 4.0% 8.0% 12.0% 16.0% $- $500 $1,000 $1,500 $2,000 $2,500 $3,000 2007 2008 2009 2010 2011 2012 Railcar Revenue Parts & Components Revenue OP Margin 16 Trinity delivered 19,360 railcars representing 33% of industry shipments during FY 2012 Trinity received orders for 22,350 railcars representing 41% of the industry total during FY 2012 Trinity’s order backlog was 31,990 railcars representing 53% of industry backlog as of 12/31/12 The value of Trinity’s order backlog reached an all-time high of approximately $3.7 billion reflecting a more favorable mix of railcars in the backlog and the strength in the pricing environment for certain railcar types Rail Group Leading manufacturer of railcars, railcar axles, and coupling devices in North America Broadest product offering for railcar manufacturing in North America Networking of customers between railcar sales and railcar leasing Focus on new and advanced engineering designs Centralized sourcing provides cost savings Streamlined manufacturing efficiencies Rail Group Highlights Rail Group Revenues and OP Margin(1) (1) Before eliminations for Intersegment Sales to Leasing and Intercompany Profit (2) Excludes $325mm pretax charge for impairment of Goodwill ($mm) (2) (1) Sources: Historical data as reported per the Railway Supply Institute. 2013-2017 projections are an average of estimates provided by Global Insight (11/12) and Economic Planning Associates, Inc. (01/13) and are provided as a point of reference. Rail 40% Total FY 2012 Rev $3.8B

$272 $314 $329 $461 $493 $529 10.0% 20.0% 30.0% 40.0% 50.0% 60.0% $0 $100 $200 $300 $400 $500 $600 2007 2008 2009 2010 2011 2012 TILC Revenue TRIP Revenue Operations Margin PBT Margin 0 10,000 20,000 30,000 40,000 50,000 60,000 70,000 3/00 12/01 12/02 12/03 12/04 12/05 12/06 12/07 12/08 12/09 12/10 12/11 12/12 TILC TRIP Tot al Ra ilc ar s 17 Railcar Leasing & Management Services Group Leading provider of comprehensive railcar leasing and management services Marketed with railcar sales activities as TrinityRail® Single point of contact for equipment and services Strengthens relationship with end-user of railcar Scale of operations facilitates active participation in secondary market activities for portfolio railcar sales as market conditions warrant Secondary market activities generated $58.3 million in Operating Profit during FY 2012 compared to $29.4 million during FY 2011 Trinity Leasing’s capabilities provide the following advantages: Strategic Position Operating Benefits Financial Results Complements product offering (one-stop shopping) Provides Trinity’s rail customers option to purchase or lease Facilitates ideal method for introduction of new products Assists in balancing and extending production lines Minimizes administrative costs Provides an important dashboard of metrics for assessing railcar demand Provides attractive cash return on investment Minimizes the cyclicality of the company Diversifies Trinity’s revenue and cash flow Leasing Operating Revenues and Profit (Excludes Car Sales)(1) ($mm) (1) Operations Margin calculated using only revenues and profit from Leasing Operations and excludes Car Sales; PBT Margin calculated using Operating Profit from Leasing Operations less Leasing Interest Expense (2) Beginning in FY 2010, TRIP Revenues and OP were consolidated with the Leasing Group Trinity’s Lease fleet has grown at a 18% CAGR since 2000 (2) Leasing 17% Total FY 2012 Rev $3.8B

$493 $625 $527 $422 $549 $675 0% 3% 6% 9% 12% 15% 18% 21% 24% $- $100 $200 $300 $400 $500 $600 $700 $800 2007 2008 2009 2010 2011 2012 Revenues OP Margin 18 Revenues up 23% in FY 2012 vs. FY 2011 Profitability continues to be strong compared to historical averages for this business - Operating Profit margin was 18% during FY 2012(3) Backlog remained strong at $564mm at 12/31/12 despite mixed order demand conditions for tank barges and hopper barges. Quickly recovered from 2 significant floods in Tennessee (in 2010) and Missouri (in 2011) that halted production levels for a period of time and impacted financial results in certain periods Inland Barge Group Inland Barge Group Highlights Inland Barge Group Revenues and OP Margin Tank Barges Hopper Barges Transports grain & coal Transports liquids ($mm) Leading manufacturer of barges that transport goods along U.S. inland waterways Largest U.S. manufacturer of fiberglass barge covers Multiple barge manufacturing facilities on inland waterways enable rapid delivery Barge transportation has a cost advantage in high-cost fuel environments Replacement demand driver (as of 12/31/11): 4,250 out of 17,996 hopper barges, or approximately 24%, are 20+ years old 1,152 out of 3,084 tank barges, or approximately 37%, are 20+ years old Over the past 10 years, 22% more barges were scrapped vs. built (9,306 scrapped vs. 7,630 built from 2001 – 2011) (1) (1) OP Margin excludes a $5.1mm net gain due to flood-related insurance settlements (2) OP Margin excludes a $15.5 mm net gain due to flood-related insurance settlements (3) OP Margin excludes a $3.8 mm net gain due to flood-related insurance settlements and the sale of leased barges (2) (3) Barge 18% Total FY 2012 Rev $3.8B

$326 $361 $281 $354 $453 $484 6.0% 7.0% 8.0% 9.0% 10.0% 11.0% 12.0% 13.0% 14.0% $- $100 $200 $300 $400 $500 $600 2007 2008 2009 2010 2011 2012 Highway Products Other OP Margin 19 Revenues increased 6.7%, however Operating Profit decreased 18.0% FY 2012 vs. FY 2011 as a result of competitive pricing pressures in the highway products business Maintained a solid level of profitability during FY 2012 despite a soft highway products market driven by the lack of a long-term Federal Highway Bill heading into the summer construction season Continued portfolio restructuring in 2011 and 2012 through the completion of several acquisitions, including the addition of a custom galvanizing business and a trench shoring company, and increased exposure to Aggregates Construction Products Group Leading U.S. manufacturer of highway guardrail, crash cushions, and other protective barriers; plus a line of proprietary products including guardrail end treatments and cable barrier guardrail systems Leading Texas producer and distributor of aggregates Diversified exposure to commercial, residential, industrial, and highway markets Demand tied to construction projects and federal funding Business has grown both organically and through acquisitions, including the purchase of a galvanizing company in 2011 and a trench shoring equipment company in 2012 Construction Products Group Highlights Construction Products Group Revenues and OP Margin (1) ($mm) (1) Revenues and OP Margin in prior years have been restated as a result of the pending divestiture of the Concrete business (2) OP Margin excludes a $3.8mm net gain as a result of the divestiture of the Asphalt business from within the Concrete and Aggregates business; Acquired Quixote Corporation in February 2010 which increased Highway Products revenue by 31% during 2010. (2) CPG 12% Total FY 2012 Rev $3.8B

$434 $633 $510 $420 $473 $ 559 0% 2% 4% 6% 8% 10% 12% 14% 16% 18% $- $100 $200 $300 $400 $500 $600 $700 2007 2008 2009 2010 2011 2012 Wind Tower Revenues Other Revenues OP Margin 20 Structural Wind Towers: Revenues of $262 million in FY 2012 Backlog of $680 million(1) as of 12/31/12 Plants are strategically located along the central corridor where the majority of wind farms are installed Utilized our flexible manufacturing platform and began shifting excess wind tower capacity in 2012 to support railcar production due to uncertainty in the wind industry as a result of delayed federal legislation Tank Containers: Consistent and mature business Acquired heavy-manufacturing facilities from DMI Industries and quickly and efficiently repositioned a portion of the capacity in support of the tank container business Energy Equipment Group Leading manufacturer of structural wind towers in North America Leading manufacturer of containers and tank heads for pressure and non-pressure vessels in North America Low-cost manufacturer with primary container production in Mexico facilities Synergies among products across multiple Trinity business groups Energy Equipment Group Highlights Energy Equipment Group Revenues & OP Margin ($mm) (1) Approximately $413 million of this backlog is involved in litigation filed by the Company against one of our structural wind tower customers for breach of a long-term supply contract for the manufacture of towers EEG 13% Total FY 2012 Rev $3.8B

2008 2009 2010 2011 2012 Income (loss) from continuing operations $266.8 ($140.8) $69.4 $146.8 $251.9 Add: Interest expense 109.4 123.1 182.1 185.3 194.7 Provision/(Benefit) for income taxes 163.5 (11.5) 37.3 92.2 134.0 Depreciation & amortization expense 126.8 147.1 180.9 187.7 193.7 Goodwill impairment - 325.0 - - - Earnings from continuing before interest expense, income taxes, and depreciation and amortization expense $666.5 $442.9 $469.7 $612.0 $774.3 Reconciliation of EBITDA(1) (in millions) “EBITDA” is defined as income (loss) from continuing operations plus interest expense, income taxes, and depreciation and amortization including goodwill impairment charges. EBITDA is not a calculation based on generally accepted accounting principles. The amounts included in the EBITDA calculation, however, are derived from amounts included in the historical statements of operations data. In addition, EBITDA should not be considered as an alternative to net income or operating income as an indicator of our operating performance, or as an alternative to operating cash flows as a measure of liquidity. We believe EBITDA assists investors in comparing a company’s performance on a consistent basis without regard to depreciation and amortization, which can vary significantly depending upon many factors. However, the EBITDA measure presented in this presentation may not always be comparable to similarly titled measures by other companies due to differences in the components of the calculation. (1) EBITDA for previous years has been restated as a result of the pending divestiture of the Company’s Concrete business (2) Includes results of operations related to TRIP starting January 1, 2010 21 (2) (2) (2)